Page 1

Page 2

FOREWORD

wor kshop

Thi s

The

i nst r uct i ons

t he

headi ng

Bot h t he

when

or der i ng

r eser ve

We

bi ndi ng

.

UNI T

SI

Uni t s

accor di ng

Power

Tor que

i s

ear l i er uni thp( hor se- power )

ear l i er uni t

ear l i er uni t

Pressur e

ear l i er

ear l i er

manual

" Speci al

engi ne

i s

desi gnat i on

par t s

t he

r i ght

gi ven

i nkW( ki l owat t )

gi ven

kpm

l bf

i s

gi ven

uni t

kp/ cm

uni t

I bf / i n2( pounds

cont ai ns

concer ni ng over haul i ng

t ool s"

.

t o

car r y

SYSTEM

i nt er nat i onalSIsyst em

t o

t he

i n

Nm

( newt on

( ki l opond

f t ( poundf oot )ear l i er uni t

( Pascal )

i n

Pa

2

( ki l oponds

.

and

out

met r e)

per

r epai r

i t s

ser i al

desi gn

met r e)

per

squar e

i nst r uct i ons

descr i be

number

modi f i cat i ons

squar e

cent i met r e)

i nch)

f or

t he 2001,

t he

most

sui t abl e

mustbecl ear l y

and,

f or

t hi s

have been

I mp

used

i n

Speed

Vol ume

. gal ( I mper i al gal l on)

2002

wor ki ng

st at ed

r eason,

t hi s

ear l i er

ear l i er

ear l i er

and

2003

met hod

i n

al l

cor r espondence

t he

cont ent soft hi s

book.The

i s

gi ven

uni t

r ev/ mi n

i s

gi ven

uni tl( l i t r e)

uni t

US

ear l i er

i n

r ev/ s

i ndm3

gal

engi nes

usi ng

Techni cal

uni t s

( r evol ut i ons

( r evol ut i ons

( cubi c

( Uni t ed

.

t he

speci al

concer ni ng

manual cannotber egar ded

Publ i cat i ons

ar e

deci met r e)

St at es

gi ven

per

t ool s

AB

af t er

per

second)

mi nut e)

gal l on)

l i st ed

t he

VOLVO

Depar t ment

t he

engi ne

PENTA

SI

under

and

uni t s

as

.

Page 3

I NDEX

Component s

DI SASSEMBLY

Cyl i nder

Tr ansmi ssi on

Pi st on,

Fl ywheel

Cr ankshaf t

Camshaf t

OVERHAUL

Di sassembl i ng

Val ve

Val ve

Val ves......

Val ve

Rocker

I nj ect or

I nj ect or s....

Assembl i ng

Feed- pump.. . ... . . . . . ... . . . . . ... . . . . . ... . . . . . .....

Pi st ons...... . ....... . ... . . . . . ... . . . . . ..... . . . .....

Cr ankshaf t..

Camshaf t.... . ....... . ....... . ....... . ....... . .....

Connect i ng

Ther most at.. . ....... . ... . . . . . ... . . . . . ... . . . . . ... . .

Sea- wat er

gui de..

head

. ... . ... . .....

. ... . ... . ....... . ..... . . . ....... . ... . . .

pi st on

. . ... . .

. . . . ... . ... . ....... . ... . . . . . ... . ... . ... . . .

. ... . ... . ... . ....... . .....

..... . ........... . ..... . . . ... . . . . . ... . . .

gui des

seat s.. . ....... . ....... . ... . . . . . ... . . . . . . . . . . .

. . ....... . ... . ... . ....... . .....

spr i ngs

. ....... . ....... . ....... . ... . ... . ... . . .

ar m

mechani sm...... . ... . . . . . ....... . ..... .

sl eeve..

. . ....... . ....... . ..... . . . ....... . ... . ..8

t he

...

r ods

pump....

. . ....... . ... . . . . . ... . . . . . ... . .

.

. . ....... . ....... . ... . . .

r ods..

. . ... . ... . ... . . . . . ....... . ... . . .

... . ....... . ....... . ... . ... . ... . . .

...

. . .

...

.

.

.

t he

cyl i nder

. . ... . ....... . ..... . . . ....... . .....

cyl i nder

.

...

.

. . . . . . . . . . . ....... . ... . ... . . ... . . .

head.... . . . ..... . . . ... . . .

... .

head

. . ..... . . . ... . . . . . ... . ..9

.

.

. . . . . . ... . . . . . ... . ... . .....

. .

. . ... . . . . . ... . . . . . ..... . . . .....

. . ... . . .

.

. .

. .

. 12

.

2

3

4

5

5

5

5

7

7

7

7

8

8

8

.

10

11

11

11

13

13

ASSEMBLY

Cr ankshaf t..

Pi st ons...... . ..... . . . ... . . . . . ....... . ... . ... . ... . .

Fl ywheel

Tr ansmi ssi on

Adj ust i ng t he

Checki ng

2003

Tur bo..

Fr esh

El ect r i cal

Faul t t r aci ng

Speci al

Techni cal

. . ... . ... . ... . ... . ... . . . . . ....... . ... . .

. . . . . . ... . ... . ... . ... . ..:........ . ... . ... . .

. ... . ... . ... . ... . ........... . ... . ... . .

val ve

cl ear ance

t he

i nj ect i on

. . ... . . . . . . . . . . . . . . . .

wat er

cool i ng

syst em

scheme

t ool s.. . . . . . . . . . . . ... . . . . . . . . ... . . . . . . . . . . . .

Dat a.. . . . . . . . ..... . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . ... . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . ... . . . . . . . . . . . .

. . . . ... . . . ... . . ....... .

angl e

. . . . . ... . . . ... . . ... . ... .

. . . . . . . . . ..... . . .

14

14

15

15

17

17

21

25

26

28

29

30

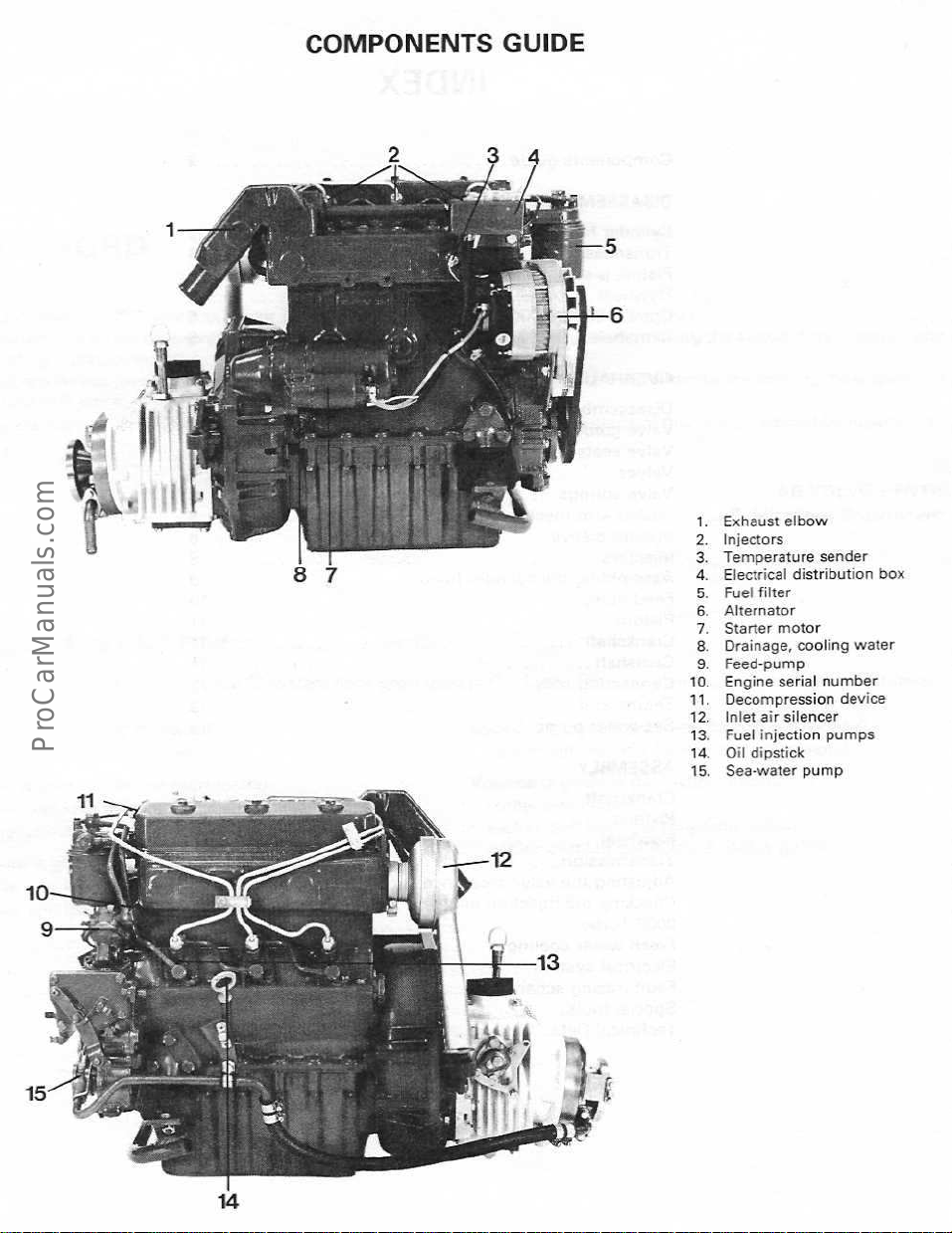

Page 4

COMPONENTS

8

GUI DE

1

.Exhaust

2.I nj ect or s

3.Temper at ur e

4

.El ect r i cal

5

.Fuel

6.Al t er nat or

7

8

9.Feed- pump

10

11

12

13

14.Oi l

15

f i l t er

Engi ne

di pst i ck

mot or

ser i al

ai r

si l encer

i nj ect i on

.St ar t er

.Dr ai nage,

.

.Decompr essi on

.I nl et

.Fuel

.Sea- wat er

el bow

sender

di st r i but i on

cool i ng

number

devi ce

pumps

pump

box

wat er

Halpert@Optonline.net

Page 5

Dr ai n

on

engi ne

engi ne

of f

t he

i s

cool i ng

cr adl e

f r esh

p/ n

wat er

wat er

9992520

cool ed,

and

t he

and

see

l ubr i cat i ng

f i xt ur e

p/ n

page21.

DI SASSEMBLY

oi l

f r om

t he

.

I f

884837

t he

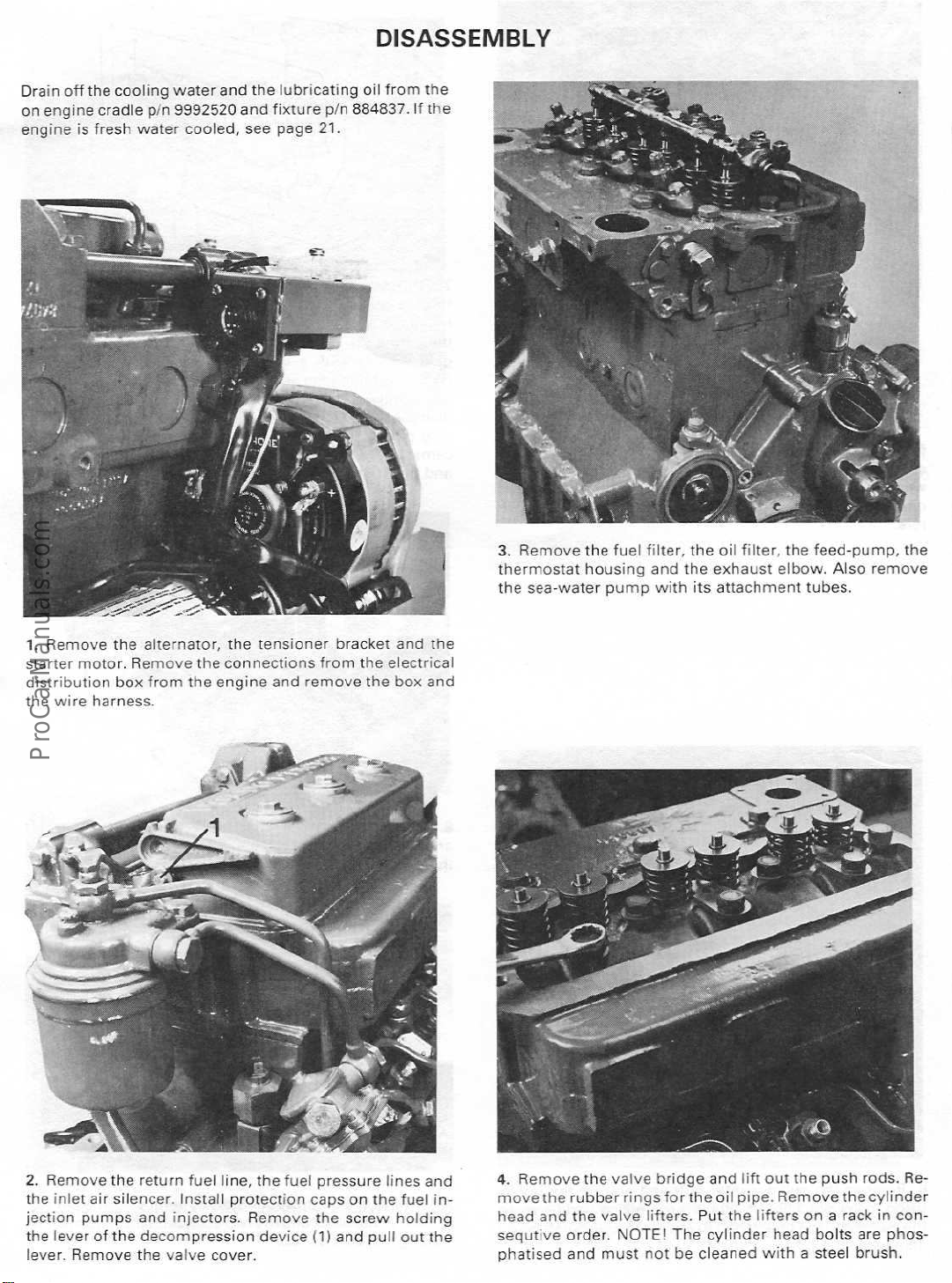

1.Remove

st ar t er

di st r i but i on

wi r e

t he

t he

al t er nat or ,

mot or.Remove

box

f r om

har ness

.

t he

t he

engi ne

connect i ons

t he

t ensi oner

and

r emove

br acket

f r om

t he

t he

and

t he

el ect r i cal

box

and

3.Remove

t her most at

t he

sea- wat er

t he

f uel

housi ng

pump

f i l t er ,

and

wi t h

t he

t he

exhaust

i t s

oi l

f i l t er ,

el bow.Al so

at t achment

t he

f eed- pump,

t ubes

t he

r emove

.

2

.

Remove

t he

i nl et

t he l everoft he

l ever.Remove

t he

ai r

si l encer.I nst al l

pumps

r et ur n

f uel

l i ne,

and

i nj ect or s

decompr essi on

t he

val ve cover

t he

f uel

pr ot ect i on

.

Remove

devi ce

.

pr essur e

caps on

t he

scr ew

and

( 1)

t he

pul l

l i nes

f uel

hol di ng

out

and

t he

and

l i f t

out

t he

push

r ods

t he

r ack

.

cyl i nder

Remove

i n

consecut i ve

or der , NOTE!Thecyl i nder

head

bol t sar e

phosphat i sed

andmustnot becl eanedwi t ha

st eel

br ush.

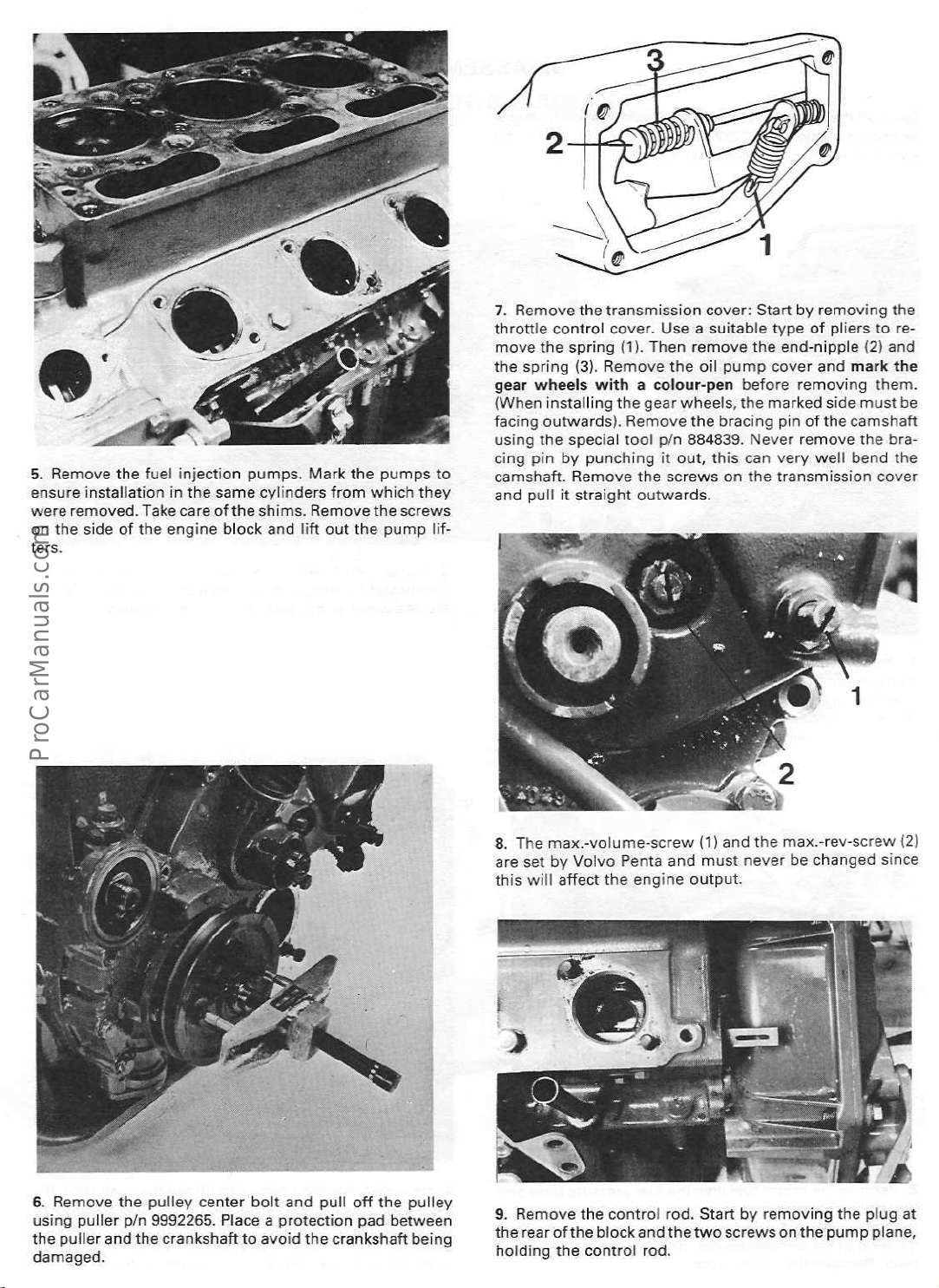

4.Remove

i nj ect i on

head

t he

and

t he

r ubber

t he

val ve

r i ngs

val ve

br i dge

f or t heoi l

l i f t er s.Put t he

pi pe.Remove

l i f t er sona

Page 6

5.Remove

ensur e

wer e

on

t he

.

t he

f uel

i nst al l at i on

r emoved.Take

si de of

t he

i nj ect i on

i n

t he

car eoft he

engi ne

same

bl ock

pumps.Mar k

cyl i nder s

shi ms.Remove

and

f r omwhi ch

l i f t

out t he

t he

pumps

t he

pump

t hey

scr ews

l i f t er s

7.Remove

t hr ot t l e

t he spr i ng

gear

( When

f aci ng

usi ng

t o

camshaf t.Remove

and

t he

t r ansmi ssi on

cont r ol

t he

wheel s

i nst al l i ng

out war ds).Remove

t he

pi nbypunchi ng

pul l

cover.Use a

spr i ng

( 1).Then

( 3).Remove

wi t hacol our - pen

t he

speci al

i t

st r ai ght

t ool

t he

out war ds

cover:St ar tbyr emovi ng

sui t abl e

r emove

t he

oi l

gear

wheel s,

t he

884839.Never

p/ n

i t

out ,

scr ewsont he

.

pump

t he

br aci ng

t hi s

t ypeofpl i er s

t he

end- ni ppl e

cover

bef or e

mar ked

pi noft he

can

ver y

t r ansmi ssi on

and

r emovi ng

si de

r emove

wel l

t he

t o

r emove

( 2)

and

mar k

t he

t hem

must

camshaf t

t he

br aci ng

bend

t he

cover

.

be

6.

Remove

usi ng

pul l er

t he

pul l er

damaged

and

.

t he

p/ n

t he

pul l ey

cent er

9992265.Pl ace

cr ankshaf t

t o

bol t

avoi d

and

a

pr ot ect i on

t he

pul l

of f

pad bet ween

cr ankshaf t

t he

pul l ey

bei ng

8.The

ar e

t hi s

9.Remove

t he

set

wi l l

r ear of

hol di ng

max

by

t he

. - vol ume- scr ew

Vol vo

Pent a

af f ect

t he

engi ne out put

t he

cont r ol

t he

bl ock

cont r ol

( 1)

and

t he

and

must

never

.

r od.St ar tbyr emovi ng

and

r od

t het wo

.

scr ewsont he

max

. - r ev- scr ew

changed

be

t he

pump

si nce

pl ug

pl ane,

( 2)

at

Page 7

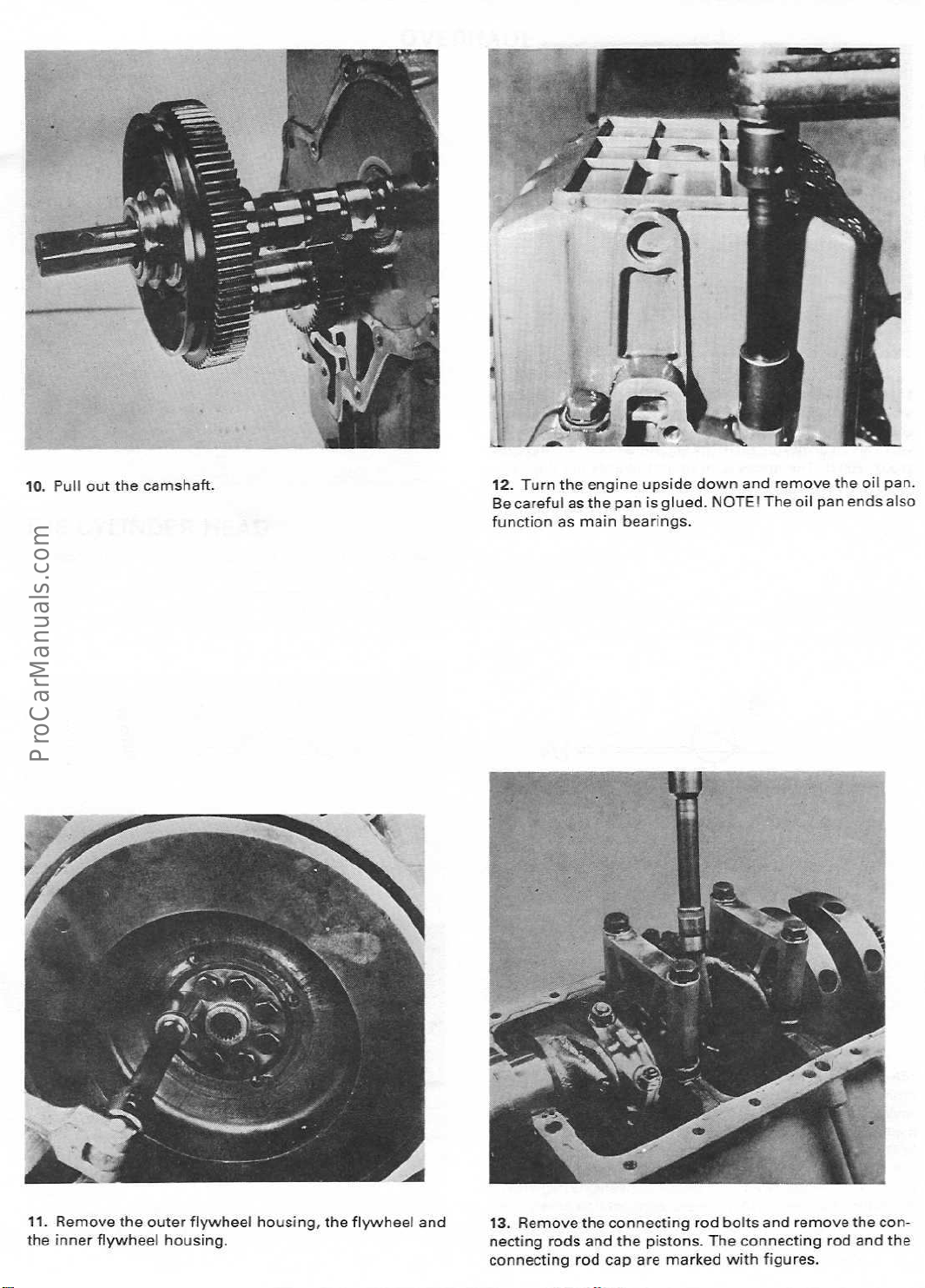

10.Pul l

out t he

camshaf t

.

12.Tur n

Be

f unct i onasmai n

t he

engi ne

car ef ulast he

upsi de

pan

i s

bear i ngs

gl ued

down

.

NOTE!

.

and

r emove

The

oi l

pan

t he

oi l

ends

pan

al so

.

11

.

Remove

t he i nner

t he

f l ywheel

out er

f l ywheel housi ng,

housi ng

t he

f l ywheel

.

and

13.Remove

r ods

connect i ng

t he

r od

and

cap

connect i ng

t he

pi st ons

ar e

mar ked

r od

.

The

bol t s

and

connect i ng

wi t h

f i gur es

r emove

r od

.

t he

and

t he

connect i ng

Page 8

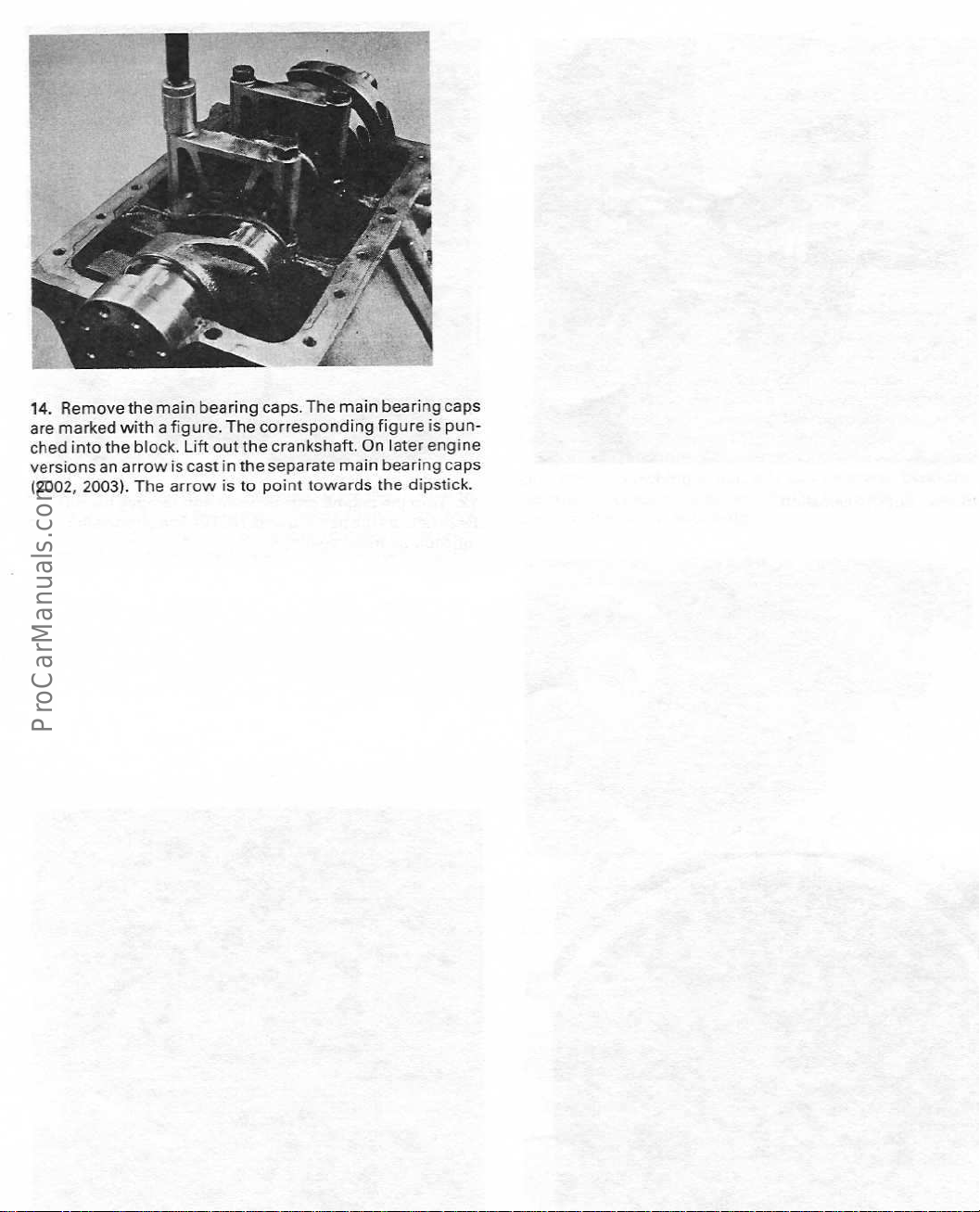

t he

mai n

14.Remove

ar e

mar ked

i nt o

t he

ver si ons

( 2002,

an

2003).The ar r ow

wi t h

bl ock.Li f t

ar r ow

bear i ng

a f i gur e.The

out

i s

cast

i n

i s

t he

t he

t o

caps.The

cor r espondi ng

cr ankshaf t.On

separ at e

poi nt

mai n

mai n

t owards

bear i ng

f i gur e

l at er

bear i ng

t he

di pst i ck

caps

i s

engi ne

punched

caps

.

Page 9

3.Use

t he

new

884559

down

mandr el

val ve

i nst al l

t o

t o

t he

.

p/ n

gui des

t hem.Press

cyl i nder

5218

t o

pr ess

ext er nal l y

head.Ream

down

out t he

and

t he

mandr el

t he

val ve

use

val ve

gui des.Oi l

mandr el

al l

t he

gui des

p/ n

way

i f

necessar y

THE CYLI NDER

1 .

Remove

bow.Remove

Pl ace

st and

.

t he

t he

" col l et s"

t he val ves.Removethe

val ves

i n

HEAD

and

t he

val ve

pr oper

spr i ngs

val ve

sequence

usi ng

a

st em

i naval ve

val ve

seal s

.

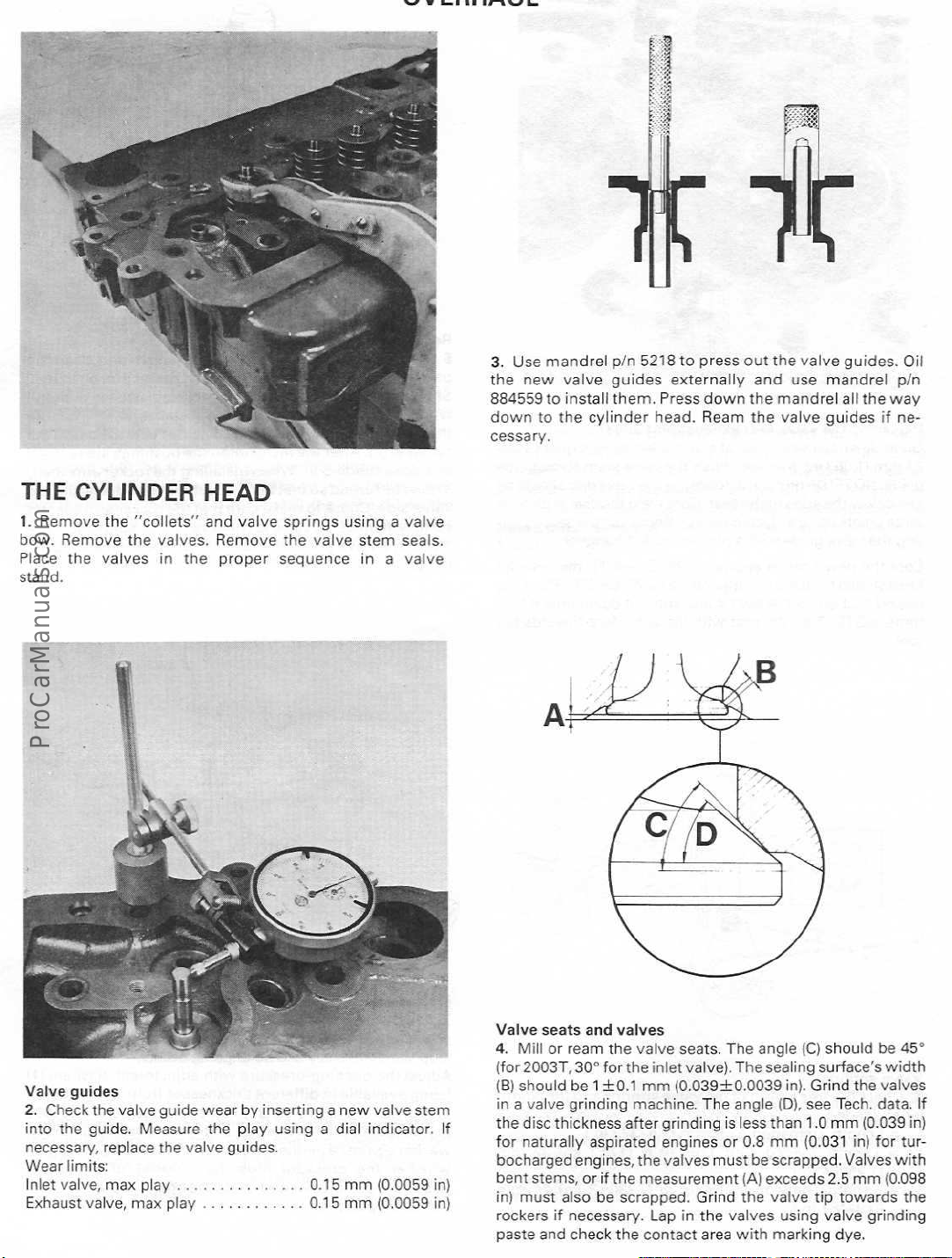

Val ve

gui des

2.Check

i nt o

t he

necessar y,

Wear

l i mi t s

I nl et

val ve,

Exhaust

t he val ve

gui de.Measur e

r epl ace t he

val ve,

:

max

pl ay

max

gui de

pl ay

wearbyi nser t i ng

gui des

usi ng

.

t he pl ay

val ve

. ...

. . . . . . ... . .0. 15

. . . . . . . . . . . .0. 15

anew

a

di al

val ve

i ndi cat or.I f

mm

( 0

mm

( 0

. 0059

. 0059

st em

i n)

i n)

Val ve

seat s

and

4.Mi l lorr eam

( f or

2003T,

30°

( B)

shoul dbe1±0. 1

i n

a val ve

t he

f or

bent

i n)

r ocker s

past e

gr i ndi ng

di sc

t hi ckness

nat ur al l y

engi nes,

st ems,ori f

must

al sobescr apped.Gr i nd

i f

necessar y.Lap

and

check

val ves

t he

val ve

f or

t he

machi ne.The

af t er

aspi r at ed

t he

t he

t he

seat s.The

i nl et

val ve).The

mm

( 0

. 039±0

gr i ndi ng

engi nes

val ves

must

measur ement

i n

t he

cont act

ar ea

angl e

( C)

seal i ng

sur f ace' s

. 0039

i n).Gr i nd

angl e

( D) ,

see

t han

i s

l ess

or 0

. 8

be scr apped.Val ves

( A)

t he

val ves

wi t h

1

. 0

mm

( 0. 031

exceeds2. 5

val ve

t i p

usi ng

mar ki ng

shoul dbe45°

wi dt h

t he

val ves

Tech.dat a.I f

mm

( 0

. 039

i n)

f or

wi t h

t ur bochar ged

mm

( 0

. 098

t owards

val ve

gr i ndi ng

dye

.

i n)

t he

Page 10

Repl aci ng

Gr i nd

27

mm

gui de.NOTE! Do

j ust

t hr ee poi nt s usi ngael ect r i c

Cool

head

cool ed

t ool

down

( 1

bel ow

t he

t he

shoul d

seat on

NOTE!

.

t he

. 063

t he

val ve

new

t he

beat

Tur n

val ve

seat

exhaust

val ve

di scofa

i n)

di amet er

not

edge

gui de

seat

t ool

r oom

.

push

i n t oo

of t he

seat.Spot

wi t hapl ast i c- headed

t o

appr ox.- 20°C

t emper at ur e

884961- 4

t he seat

di scar ded

Push

wel der.Knockout

and

wi t h

por t

2003T

t he

val ve

f ar -

t he

wel d

( - 4°F);t he

( +

20° 0168° F).Pl ace

knock

i t

t he

val ve

val ve

st em

val ve

t he

hammer

down

f ace

t o j ust

t hr ough

di sc

di sc

i n

t he seat

unt i l

t owards

bel ow

shoul d

pl ace

by

.

cyl i nder

i t

bot t oms.

t he

be

hi t t i ng

t he

t he

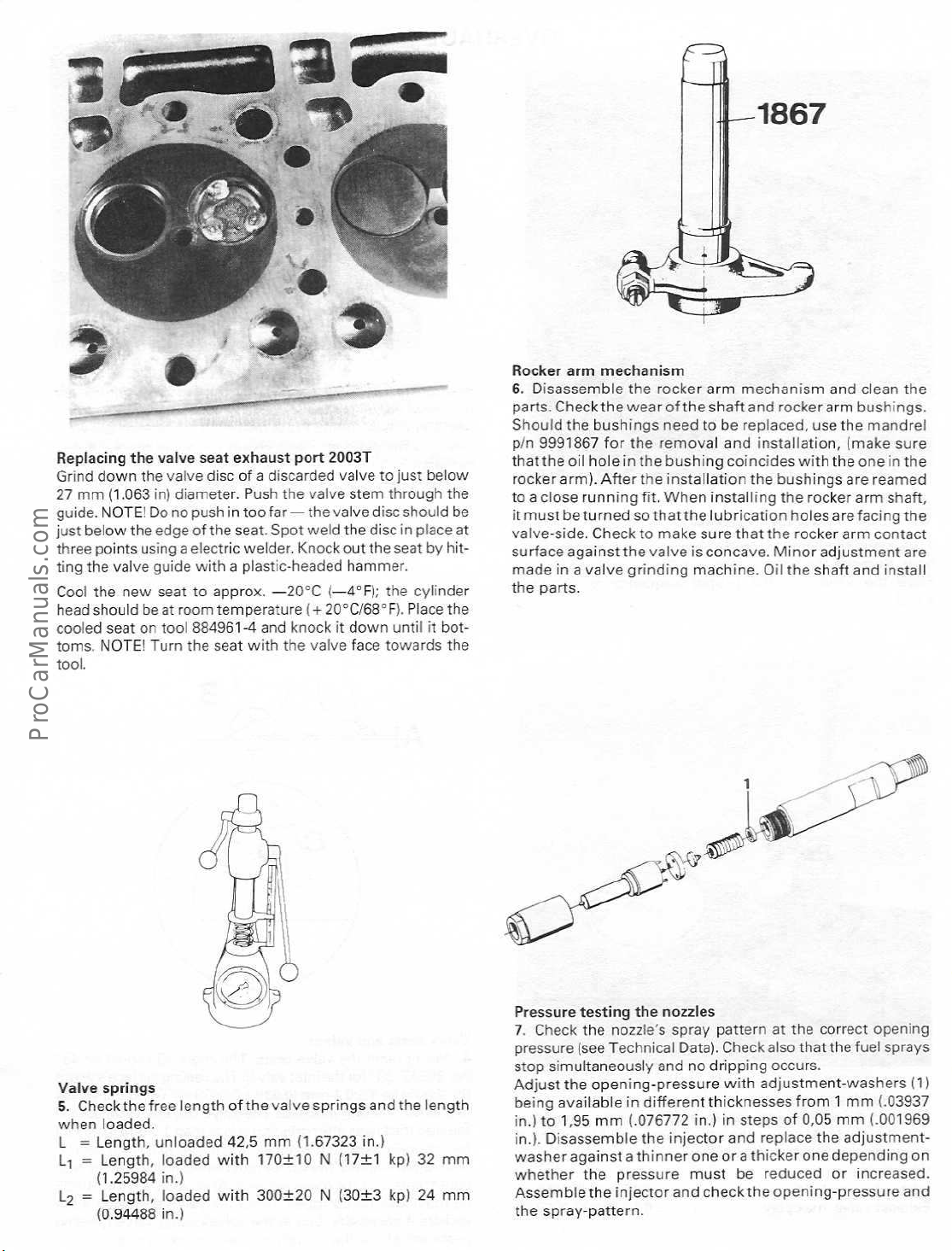

Rocker

6

par t s.Check

Shoul d

p/ n

t hat

r ocker

t oacl ose

at

i t

val ve- si de

sur f ace

made

t he

ar m

.

Di sassembl e

t he

9991867

t he

oi l

ar m)

must

be t ur nedsot hat

agai nst t he

i naval ve

par t s

.

mechani sm

t he

t he

wearoft he

bushi ngs

f or t he

hol e

i n

.

Af t er

r unni ng

.

Check

gr i ndi ng

r ocker

need

r emoval

t he

bushi ng

i nst al l at i on

t he

f i t

. When

t o

make

val ve

ar mmechani sm

shaf t

and

t ober epl aced,

and

i nst al l at i on,

coi nci des

t he

i nst al l i ng

t he

l ubr i cat i on

sur e

t hat t he

i s

concave.Mi nor

machi ne.Oi l

and

cl ean

r ocker ar m

wi t h

bushi ngs

t he r ocker ar m shaf t ,

hol es

r ocker

t he

bushings

uset he

shaf t

mandr el

( make

t he

one

ar e

ar e

f aci ng

ar m

adj ust ment s

and

r eamed

cont act

i nst al l

sur e

i n

t he

.

t he

t he

ar e

Val ve

spr i ngs

5.Checkt he

when

l oaded

L =

Lengt h,

L

1 =

Lengt h,

( 1

. 25984

L2=

Lengt h,

( 0

. 94488

f r ee

l engt h

.

unl oaded

l oaded

i n

. )

l oaded

i n

. )

t he

val ve

of

42, 5

mm

wi t h

170±10 N

wi t h

300±20N( 30±3

spr i ngs

( 1

. 67323

i n

( 17±1

and

. )

kp)

kp)

t he

l engt h

32

24

mm

mm

Pressur e

7.Check

pr essur e

st op

Adj ust

bei ng

i n

i n

whet her

Assembl e

t he

t est i ng

t he

( see

si mul t aneousl y

t he

avai l abl e

. )

t o 1, 95

. ).Di sassembl e

t he

t he

spr ay- pat t er n

t he

nozzl es

nozzl e' s

Techni cal

openi ng- pr essur e

mm(. 076772

pr essur e

i nj ect or

spr ay

Dat a)

andnodr i ppi ng

i n

di f f er ent

t he

i nj ect or

and

.

i n

must

pat t er natt he

Check

al so t hat t he

.

wi t h

adj ust ment - washer s

t hi cknesses

. )

i n

st eps

and

r epl ace

be

r educed

check

t he

cor r ect

occur s

.

f r om1mm

of

0, 05

t he

openi ng- pr essur e

openi ng

f uel

U3937

mm(. 001969

adj ust ment - washer

or

i ncr eased

spr ays

( 1)

agai nstat hi nneroneorat hi ckeronedependi ngon

.

and

Page 11

I nj ect or - sl eeve

8.I nser t

884811

t he

i nt o

st ud

cyl i nder

nut

scr ew

t he

bol t of

( 2)

and

t he

expandi ng

i nt o

t he

har d

copper

t he

headasa

t i ght en

scr ew

copper

t o

mat er i al.Then

i nj ect or.Putacyl i nder

sl eeve

al l ow

t he

suppor t f or t he

unt i l

i t

t he

on

and

t hr eads

i nst al l

l egoft he

sl eeve

t he

t ur n

t o

t he

i s

wor k

head

r emoved

speci al

t he

t ool

scr ew

t hemsel ves

( 1)

yoke

scr ew

yoke.I nst al l

.

on

i n

p/ n

ant i - cl ockwi se

t he

t he

t he

10.Oi l

t hef l ar e- t ool

( make

sur e

unt i l

t he

scr ew

has

st uck

i n

t he

sl eeve. Ti ght en

t ool

as

t he

sl eeve

1

mm

wi t h

t hat

t he

i nj ect or

shoul der

t he

sl eeve.Remove

out si de

(

. 03937

t he

dowel

i n

t he

t he

pl aneoft he

i n

. )

.

p/ n

884283 and

i s

pr oper l y

yoke.Scr ew

i nj ect or

t he

t ool.Adj ust

i nser t

r et r act ed).Brace

down

sl eeve

cyl i nder

i t

i nt ot he

t he

f l ar e- t oolasf ar

al l ows,

t he

head

t her eby

l engt h

t o

sl eeve

t he

f l ar i ng

of t he

maxi mum

9.Repl ace

t he

cyl i nder

t o

f aci l i t at e

and

i nst al l

sl eeve

unt i l

t he

O- r i ng,

head.Di p t he

t he

i nst al l at i on.Oi l

i t ,

usi ng

speci al

i t

bot t oms

seal i ng

new

t ool

.

of f

bet ween

O- r i ng

i n

t he

p/ n

884557.Knock

t he

soap- wat er

new

i nj ect or

sl eeve

down

and

i n

or der

sl eeve

t he

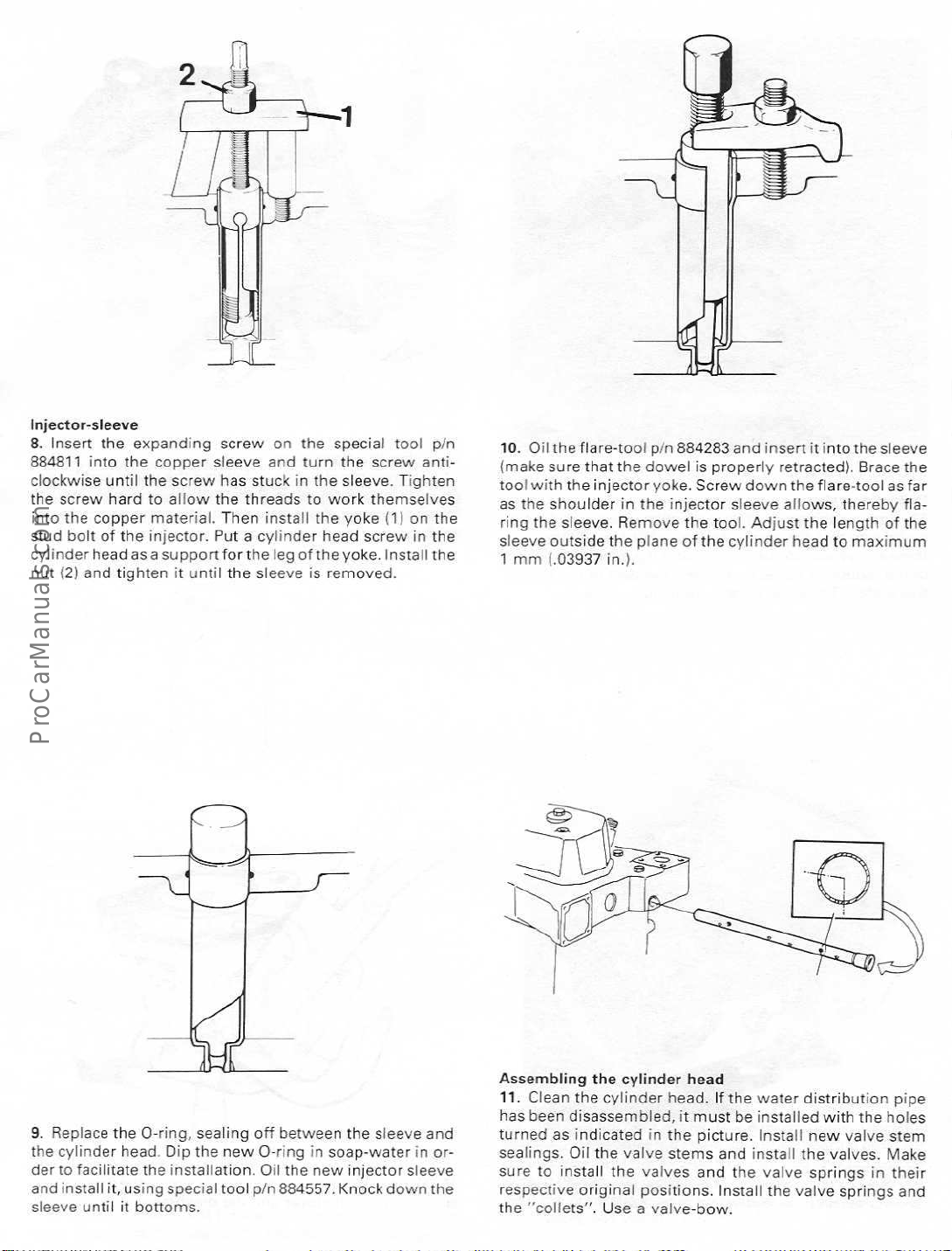

Assembl i ng

11.Cl ean

has

been

t ur nedasi ndi cat ed

seal i ngs.Oi l

sur e

t o

r espect i ve

t he

" col l et s".Useaval ve- bow

t he

cyl i nder

t he

cyl i nder

di sassembl ed,

t he

val ve

i nst al l

t he

or i gi nal

i n

val ves

posi t i ons.I nst al l

head

head.I f

t he

st ems

t he

i t

mustbei nst al l ed

pi ct ur e.I nst al l

and

and

t he

.

wat er

di st r i but i on

new

i nst al l

t he val ves.Make

val ve

spr i ngs

t he

val ve

wi t h

spr i ngs

t he

val ve

i n

pi pe

hol es

st em

t hei r

and

Page 12

Reduct i on

12.Remove

make

t her e ar e

of t he

See

sur e t hat

r easons

r educt i on

under

val ve

t he

coveroft he r educt i on

spr i ng

t he

t o

suspectaf aul t

val ve,

t hen

" Techni cal

Dat a"-r educt i on val ve

and

t he

check

val ve

and

pi st on

ar e

i n

t he

openi ng

t he

dat aoft he spr i ng

check

f aul t l ess.I f

pr essur e

.

Changi ng

14.Remove

pump

t o

( 1)

shaf t

.

housi ngs

and

.

t he

t he

r emove

di aphr agm

si x

scr ews, hol di ng

t oget her.Remove

t he

scr ew

( 2)

t he

t he

hol di ng

upper

pump

t he

and

l ever

pump

l ower

spr i ng

l ever

Feed- pump

13

.

Depr ess

sounds

squeaky,

t he

pump

t he

l ever.i f

di aphr agm

t he

di aphr agm

i s

f aul t l ess

of t he

.

pump

15.Useasui t abl e

shaf t.Pul l

out

t he

pai rofpl i er s

l ever

and

and

di aphr agm

t he

r emovet he

.

pump

l ever

Page 13

16.Cl ean

par t s.I nst al l

scr ew.Assembl e

at t achment

t he

shaf t

pump

t he

Then

.

pl at e

housi ng

di aphr agm

i nser t

t he

t wo

( 1).Then

t he

housi ng

i nst al l

Val ve

l i f t er s

17.Check

sar y

t he

val ve

l i f t er s

f or

.

car ef ul l y

and

shaf t

wear.Repl ace

t he

t he

and

hal ves

spr i ng

and

l ever

t i ght en

r epl ace

on

and

( 2)

t he

i t

wi t h

i nst al l

and

t hem

wor n

di aphr agm

t he

t he

t heO-r i ng

i f

neces

19.Pl ace a

hydr aul i c pr ess

( 3)

.

suppor t

t o

under

r emove

t he

t he

camshaf t

gear

.

gear

and

use

a

Camshaf t

18.Check

ces.Al so

pr essed

t he

i nst al l at i on

t he

check

i nt o

camshaf t

t he

t hei r

.

f or

wearoft he

l ocat i ons

wearoncams

bear i ngs.The

and must

be

and

l i ne

bear i ng

bear i ngs

bor ed

r a

ar e

af t er

Cr ankshaf t

20.Remove

cr ankshaf t.Measur e

eccent r i ci t y

t aper

t he

0. 05

mm(. 001969

cr ankshaf t

t he

must

gear

not

wheel

.

Use

a

t he

cr ank- and

exceed0. 06

i n

. ).Shoul d

must be gr ound

mm(. 002362

pr ong

mai n

t hese

t o

pul l er.Cl ean

bear i ng

val uesbeexceeded,

a

i n

sui t abl e

pi ns.The

. )

and

under - di mensi on,

t he

t he

seeunder" Techni calDat a".

Page 14

Pi st ons,

21.Check

pi ns.Repl ace

gauge

t he

t he

sur ementoft he

cent er.As

Useami cr omet er

see

t o

bi ggest

upper

under

cyl i nder s

t he

wearonpi st ons, pi st on ri ngs

t hese

i f

necessar y

measur e

dead

t o

" Techni cal

wear

t he

t he

i s

made

cent er

smal l est

cyl i nder

t o

cyl i nder

i mmedi at el y

and

cr osswi se

wear

di amet er , see

measur e

Dat a"

.

Use

bor es.The

i s

madeatt he

t he

pi st ons.Pi st on

.

cyl i nder

a

measur ement

beneat h

t he

engi ne.The

" Techni cal

and

t he

l ower

gudgeon

i ndi cat or

edge

mea

dead

Dat a"

di amet er ,

of

of

24

.

.

Use

mar ki ngoft he

must

be

pr essi on

compr essi on

r i ngssot hat

pi st on

r i ngs

t ur ned

r i ng:1, 75

r i ng

pl i er s

( TOPort he

upwards.The

mm(. 068898

r i ng

;

2, 00

t he

gaps

t o

i nst al l

mar koft he

hei ghtoft he

i n

. )

mm(. 07874

ar e

t ur ned

t he

The

pi st on

manuf act ur er )

hei ght

i n

. ).Tur n

120

°

f r om

r i ngs.The

upper

of

t he

t he

each

com

l ower

pi st on

ot her.

22.I nser t a

t he

pi st on ri ng

" Techni cal

speci al

23.Measur e

r i ng

" Techni cal

new

Dat a".I f

f i l e

.

gr ooves.Regar di ng

Dat a"

pi st on

gap.As

necessar y

t he

cl ear anceoft he

.

r i ng i nt o

t o

t he

t he

t he

cyl i nder and

measur ement ,

i ncr ease

pi st on r i ngs

measur ement ,

t he

gap,

i n

measur e

see

usi ng

t he

see

under

pi st on

under

a

Connect i ng

25.Check

.

r ods

t he

connect i ng

r ods

f or

st r ai ght ness

and

t wi st i ng

Page 15

26

.

Check

t he

pi n asagauge.Ther e

must

be

r epl aced,

and

i nst al l at i on.Make

oi l

hol e

coi nci di ng

t he

new

bushi ngs.The

pi n

by

i t s

own

connect i ng

useasui t abl e

wei ght

wi t h

sur e

t hat of

f i t

can

r od

i s

mustbeno

t o

cor r ect

sl owl y

bushi ngs

mandr el

i nst al l

t he

t he

connect i ng

whenanoi l ed

sl i de

by

pl ay.I f

f or

bushi ng

t hr ough

usi ng

t he

t he

r od.Ream

t he

gudgeon

bushi ngs

r emoval

wi t h

t he

gudgeon

t he

bushi ng.

Sea- wat er

27.The

When

housi ng

f ol l owi ng.Useasui t abl e

f r om

Repl ace

and

t he

di st ance

bal l - bear i ng.Coat

t hr ough

damage

bear i ngs

Checki ng

28.I mmer se

Techni cal

f aul t y,

pump

pump

i s

equi pped

di sassembl i ng,

and

push

out t he

t he shaf t.NOTE!

seal i ngs

t he

make

sur e

pump- housi ng.Repl ace

of

39, 5

t he

seal i ngs

t hem.Push

t o

bot t om

t he

t her most at s

check

Dat a

i t

mustber epl aced

( 4).NOTE!

t hat

t heydonot

mm

( 1

t he

and

i n

and

t he

t her most at

i f

i t

opens

f or openi ng t emper at ur es.I f

r emove

shaf t ,

mandr el

Do

not

. 55512

shaf t

t he

t he

t hen

at

.

wi t h

t he

wher eby

f or get t he

Tur n

bl ock

t he

O- r i ng

i n

. )

f r om

wi t h

O- r i ng

shaf t

i nst al l

i n

wat er

t he

cor r ect

t wo

bal l - bear i ngs

l ocki ng- r i ng

t he

t o

r emove

spacer

t he

seal i ngs

t he

dr ai nage

( 5).I nst al l

t he shaf t

gr ease

and

t ake

as

f ar

as t o

t he

l ocki ng- r i ng

and,

t emper at ur e.See

t he

bear i ngs

t he

sl eeve

end

and

" scr ew"

car e

usi ng

t her most at

( 2)

i n

bear i ngs

cor r ect l y

hol e

t he

bal l - bear i ngs

t o

not

al l ow

( 2)

a

t her momet er ,

( 1)

t he

ar e

( 3)

t he

t he

.

.

i n

and t hespacersl eeve

ont o

t heshaf tand

l eave

a

i t

t o

.

i s

Page 16

ASSEMBLY

Al ways

and

t hem

I f

1.Heat

pr i or

cr ankshaf t

bear i ng

Put

f l ywheel

use

l ock- washer s.Coat

and

al so

engi ne

t he

t he

cr ankshaf t

t he

i nst al l at i on.Pl ace

t o

and

hal ves

t he

cr ankshaf t.NOTE!

i n

al so

new

gasket s,

al l

oi l

i s

f r esh- wat er

pr ess

( wi t h

f unct i ons

seal i ng

t he

movi ng

gear wheel

on

t he

oi l

hol e)

as a

r i ngs,

seal i ngs wi t h

par t s

pr i or t o

cool ed,

gear

The

see

t o

appr ox

key

wheel

i nst al l

mai n

i n

bear i ng

t he

and

t hr ust - bear i ng

seal i ng

gr ease

i nst al l i ng

21

page

150° C

.

t he

key- wayoft he

Oi l

.

t he

t hem

i n

shel latt he

.

washer s

or

t hem

.

( 302°F)

new

t he

bl ock

mai n

oi l

.

3

t o

poi nt s

Fi t

.

mar ki ng.The

t owards

Ti ght eni ng

St ep

St ep2:70Nm

.

each

Tur n

t he

1

t he

ot her.The

t owards

caps

t he pi st on

:25Nm

pi st on

t he

wi t h

cr ankshaf t

t or ques

( 2

( 7

r i ngs

pi st on

t he

. 5

. 0

bel t

mar ki ng

.

:

kpm)

kpm)

so t hat

t he

cr own

pul l ey.Use

al i gned

can

( 18

f t / l b)

( 53

f t / l b)

gaps

i s

mar ked

i nst al l at i on

be

t ur ned

ar e

of f set

wi t h an

r i ng

wi t h

t he cr ankshaf t ' s

i n

any

i n

r el at i on

ar r ow

t hat

884813- 7

di r ect i on

.

2.Oi l

t he

cap

bear i ng

caps

i n

accor dance

no

i nt er medi at e

t owards

bear i ngs

t i ght eni ng60Nm

t he

oi l

: 1st

t i ght eni ng20Nm( 2

hal ves

t he

wi t h

bear i ng).I fanar r ow

di pst i ck

Ti ght eni ng t or que

.

kpm)

( 44

( 6

and

mar ki ng

. 2

f t

i nst al l

t hem.I nst al l

i n

t he

i s

cast ,

kpm)

( 14

. l bs).Tur n

bl ock

i t

f or

. 7

t he

( 2001

shal l

t he

f t

. l b) ,

engi ne

t he

has

poi nt

mai n

2nd

i n

oi l

4.I nst al l

t he

scr ews

( 2, 0

60

.

t he

edgeoft he

p/ n

840879

and

t he

kpm)

( 14

( 6, 0

kpm)

Nm

mai n

mai n

. 7

f t

. l bs

bear i ng

oi l

pan

I nst al l

.

bear i ng

. )

( 44

. 2

and

f t

wi t h

t he

t hen

. l bs

hal ves

oi l

scr ews

. )

t hi n l ayer of

pan and

al t er nat i ngl y

t he

mai n

.

t he

t i ght en

pan

seal i ng

bear i ng

and

t he

oi l

t o20Nm

scr ews

coat

compound

pan

t o

Page 17

5.Repl ace

compound

housi ng

spr i ng

shal l

t he

seal i ng

t he

( p/ n

and

be t ur ned

i s

f l ywheel

t he

i nst al l ed

840879)ont he

housi ng

seal i ng.NOTE!

t owards

i n

accor dance

r

seal i ng

edge

bet ween

The

t he

engi ne.Make

( 1).Smear

seal i ng

wi t h

t he pi ct ur e

t he

seal i ng

f l ywheel

l i p

wi t h

sur e

t hat

.

7A.Heat

appr ox.150° C

a

Check

camshaf t.I nst al l

mar ki ngsont he

t he

t he

camshaf t

( 302° F)

t o

make

sur e

gear

wheel

camshaf t gear

i nsot hat

t he

gear

wheel

and use

t hat

t he

camshaf t

camshaf t

coi nci de.Put t he

wheel

t abs

t he

( 2)

gear

.

Check

ar e

a

gear

t oat emper at ur e

sui t abl e

and

wheel

t hat

i nsi de

sl eeve

wheel

make

and

washer

al l

t he

t o

i nst al l

" bot t oms"ont he

sur e

t hat

t he

t he

on

cr ankshaf t

( 1)ont he

wei ght s

washer

ar e

.

hub

pr essed

of

i t

.

of

6.Repl ace

Ti ght eni ng

I nst al l

t he

( 48

. 0

f t

. l bs) .

t he

O- r i ngs

t or que25Nm

f l ywheel.Ti ght eni ng t or que 65

and

( 2, 5

i nst al l

kpm)

t he

( 18

f l ywheel

. 4

f t

. l bs)

Nm

housi ng

.

( 6, 5

kpm)

.

7B.I nst al l

l i p

wi t h

t he spr i ng

i n

t he

seal i ng

" bot t oms"

oi l

channel

Useanew

t he

pr essur e

washer )

by

pr essi ng

sl eeve

i s

camshaf t ,

equal l y

ar e

you

pi n

i nt o

i t s

wi l l

t henbebent

anew

seal i ng

housi ng,

r i ng

agai nst

i n

t he

gasket

sl eeve

i n

t he

cont r ol

t he

l ever

pr essed

t o

agai nst

usi ng

speci al

muchonbot h

useahammerorsome

l ocat i on

.

r i ng

usi ng

mandr el

i s

t o

bet ur ned t owar ds

f r om

t he

housi ng.I nst al lanew

bl ock

( 3

and

i nst al l

( wi t h

t he

ar m

t o

t he

t ool

wi t h

t he

f or

t he

camshaf t

p/ n

884838.The

t he

out si de

f i g.7A)

i t s

.

t he t i mi ng

bear i ng

l ever.Hol d

bot t om

t owards

posi t i on

housi ng.I nst al l

884839.The

p/ n

si des.Under no

such

ai d of a

mandr el.The

i n

t he

engi ne.Press

unt i l

t he

O- r i ng

gear

cover.Pl ace

t he

t he

sl eeve

t he

pi n

ci r cumst ances

t ool

t o

t he

t r ansmi ssi on

seal i ng

mandr el

i n

pr essur e

i n

pl ace

wher e

pi n of t he

must

punch

camshaf t

t he

t he

pr ot r ude

t he

Page 18

8

.I nser t

gear

casi ng.I nst al l

push

t he

Fi t

t he

( wi t h

Then,

i n

t he engi ne

seal i ng

t he

cont r ol

t he

cont r ol

spr i ng

( Not e!

copper

scr ew

washer s

cont r ol

r od

t hr ough

t he bear i ng

r od

t hr ough

( 3)

and

scr ewont he

Do

seal i ng

t he

not use

l ower

any

washer s)

bol t s

bl ock.NOTE! The

Appl y

r od

.

moves

Permat ex

f r eel y

t he

bl ack

bal l

i nt o

( 1)

t he

hol e

i n

end

t ool s).Scr ew

t hat

gui de

t hat

hol d

t he

l ower

bol t s

t o

t he

.

and

i nt o

t he

t he

cont r ol

t he

cont r ol

ni ppl e

( 4)

unt i l

i n

t he

upper

t he

cont r ol r od

cont r ol

r od

shoul d

t hr eads.Check

r od

l ever

i n

not

t i mi ng

and

( 2)

i t

bot t oms

bol t s

pl ace

have

t hat

.

.

10

.I nser t

t he

f t.I bs)

t he key

f or

t he

pul l ey

i n

pul l ey.Ti ght eni ng t or que 40

.

t he

cr ankshaf t

Nm

( 4, 0

and

kpm)

i nst al l

( 29

. 5

I nst al l

9

.

( f r om

gear

seal i ng

pump' s

t he

oi l

di sassembl y).I nser t

t he

cover.Oi l

r i ng

t he

.

gear

gear wheel

wheel and

a

new

f i t

accor di ng

O- r i ng

The

cover

mar ks

t o

t he

i n

t he t i mi ng

usi nganew

11.Cl ean

sur f

ace

agai nst

Oi l

t he

.

Cl ean

t he

t hen

t hr ough

t he

ar e

t he

t he

t hr eads).Check

cor r ect l y

gr oove

2001

Regar di ng

page

t he

val ve

l i f t er s

t he

camshaf t

val ve

gui des

r ol l er

l i f t er soft he

i n

t he

bl ock.Lock

bl ock

af t er

car ef ul l y

i nst al l ed

.

t he

i nst al l at i onoft he

.

t he

and

i n

t he

car ef ul l y

wi t h

mol ybdenum

bl ock

f uel

i nj ect i on

t he

r ol l er

i nst al l at i on

t o

make

t hat

t hey

cyl i nder

and

and

ar e

coatt he

i nst al l

l i f t er s

( appl y

sur e

r unni ng

head,

pumps

wi t h

Permat ex

t hat

seet he

di sul phi de

t he

t he

cont act

l i f t er s

and

scr ews

l i f t er s

easi l y

.

i nst al l

t o

i n

f ol l owi ng

Page 19

2003

14.Val ve

i n

. ).Tur n

val ves

one

t ur n

t he

cl ear ance

t he

i n

one

mor e

pr ocedur e

engi ne

cyl i nder

and

col d/ war m

i n

t he

ar e

" rocki ng".Then

t he val ves

adj ust

f or

t he

engi ne0. 30

di r ect i on of rot at i on

t ur n

f or

t hi s

r emai ni ng

cyl i nder s

mm

(

unt i l

t he

cyl i nder

.

. 01181

t he

engi ne

.

Repeat

12.Ti ght en

and

" Top"

Make

bol t s

bol t s,

r esul t.NOTE!

cl ean

Coat

and

t i ght en

20

Nm

f t . l bs) .

13.I nst al l

new

on

same

t he

i nst al l

t he

f aci ng

upwards

sur e

t hat

ar e

f r ee

t her e

i s

al ways

f or ce

i n

t hem

wi t hast eel - br ush

t he

cyl i nder

t hem

( 2

. 0

kpm/ 14. 7

t he

push

r ubber

t i me as

t he r ocker

t wo

gui de

cyl i nder

t he

cont act sur f ace

f r om

pai nt.Shoul d

t he

t he

bol t

The

bol t s

head

i n

accor dance

f t

. l bs)

r ods

r i ngs

t o

scr ews

head

.

I nst al l

r i skofhavi ng an

j oi nt

ar e

bol t s

and

and

t he

ar m

gasket wi t h

t he

wi t h

subsequent

phospat ed,

.

wi t h

mol ybdenum

wi t h

t hen

t he

r ocker

oi l

pi pe

br i dge

p/ n

884840

cyl i nder

f or

t he

t her e

be

i nsuf f i ci er t

t her ef or edonot

t he

di agr am,

t o70Nm

ar m

whi ch

.

i n

t he

head

cyl i nder

pai nt

l eakages

di sul phi de

( 7

. 0

br i dge,

i s

f i t t ed at

t he

bl ock

mar ki ng

.

on

f i r st

kpm/ 51

push

head

t he

t i ght eni ng

as a

t he

. 6

t o

Adj ust i ng

15.i f

ar e

be

shi m

bei ng

new

bl ock

t hi ckness

t hatont he

Exampl e:The

I n

t hi s

i n

. ).Pl ace

i nst al l

wi t h

0

. 6

Sof t

(

. 007874

t he

f uel

i nj ect i on

t he

same

bl ock

camshaf t

used

when

assembl i ng,

i nst al l ed

ones.Car ef ul l y

anot her

and0. 9

shi ms

i n

t hei r

or i gi nal

t hi cknessasear l i er.The

i nst al l ed

and

case

t he

pump

agai nst

t he

f uel

equal

f uel

bl ock

(

. 015748

The

pump

(

. 015748

Tot al

sel ect

t he

har d

pump.NOTE!

har d

.

Har d

mm(. 011811, . 02362,

ar e

and

. 011811

t he

cl ean

i nj ect i on

t o t he

sumoft he

i nj ect i on

mar ki ng

i n

. )

mar ki ng4( =4t ent hs

i n

. )

amountofshi ms=0

t wo

sof t

shi m bet ween

shi moragai nst

shi ms

avai l abl e

i n

pump

and

t he

f uel

posi t i ons

so

bl ock,

t he

cont act

pumps

pump,

4 ( =4t ent hs

shi ms0. 2

Never

i nst al lahar d

ar e

avai l abl e

i n

t hi cknesses0. 2

. )

.

l ocat i on

cal l ed

mustber epl aced

and

mar ki ng

( 4)

ear l i er

t he

t he

. 035433

wi t h

f uel

I nj ect i on

i nj ect i on

and

wi t h

sof t

shi ms,

sur f aces

i nst al l

on

t he

mar ki ng

ofami l l i met er )

of a

. 8

mm(. 031496

and0. 3

mm(. 011811

t wo

sof t

shi m

bl ock

or

i n

t hi cknesses0. 3,

i n

.

r espect i vel y)

pump

bet ween

shi ms

mi l l i met er )

t he

and0. 3

shi ms

pumps

must

t he

same

al ways

agai nst

wi t h

bl ock

.

ones

t oget her

f uel

t he

and

i n

and

mm

. )

i nj ect i on

.

Page 20

On

l at er

seal

har d

Har d

0

. 3

ver si on

bet ween

shi ms

shi ms

mm

( 0

engi nesanO- r i ng

t he

i nj ect i on

may

be

ar e

avai l abl e

. 0118

i n) ,

pump

usedont hese

i n

t hi cknesses

0

. 6

mm

. 0024

( 0

and

i n)

has

been

t he

bl ock.Onl y

engi nes

of 0

and0. 9

i nt r oduced

when

. 2

mm

mm

as a

so- cal l ed

shi mmi ng

( 0

. 0079

( 0

. 0354

i n) ,

i n)

.

.

16.New

I f

t he

measur ed and

andasl i di ng

A.The

out er.The

each

The

a

pi n

B.Mount

not t i ght en t he bol t s.Tur n

bl ock

or

camshaf t

bl ockort he

set t i ng- di sc

r espect i ve

i nj ect i on

( 1)

.

t he set t i ng- di scort he

cal i per

i nner

angl e

camshaf t

mar ked,

r i ng

engi ne

usi ng

.

consi st soft wo

det er mi nes

t ype,

i s

st amped

t he

set t i ng- di sc

ar e

r epl aced

t he

see

Techni cal

i n

degr ees

pul l ey

t he

bl ock

set t i ng- di sc

r i ngs,ani nner

t he

i nj ect i on

Dat a

and

wi t h

t wo

so

t hat t he

p/ n

i s

must be

884787

and

angl e

( page

f i xed

bol t s,

an

f or

25)

wi t h

do

gui de

pi n

( 2)

comes

Press

i n

t i ght en

The

set t i ng- di sc

Mar ki ng

.

Cyl i nder

Cyl i nder

Cyl i nder

Cyl i nder

i n

t he l ar gest of

t he

gui de

pi n

( 2)sot hat

t he

bol t s

.

i s

mar ked

Denot es

1

Cyl i nder1( 1,2,3

2/ 2Cyl i nder2( 2

2/ 3Cyl i nder2( 3

3/ 3Cyl i nder3( 3

t he

f or

each

cyl i nder

cyl i nder

cyl i nder

f our

t he

di sc

r espect i ve

cyl i nder

engi ne)

engi ne)

engi ne)

hol es

i n

t he

i s

cent er ed

engi nes

pul l ey

cyl i nder

;

.

and

:

Page 21

Tur n

C

gui de

t he

set t i ng- di sc' s

Measur e

bl ock

r ol l er )

The

2001:55

2002,

2003T:55

Exampl e

2001

means

be pl aced

2002,

i n)

i n)

The measur ed shi ms

t o

The

measur ement s

Exampl e

The

The pump' s

No

cyl i nderno.1t o

.

pi n

( 2)

i n

cr ankshaf tal i t t l e

and

t her eaf t er

gui de

usi ngacal i per

and

t he

.

di st ance

2003:55, 6

.

I f

2003.I f

t hi s

i s

t obepl aced

be

t ot al

bl ock' s

of

.

mm

. 8

mm

. 9

:

t he

measur ed

t hat a

bet ween

means

st amped

shi m

measur ement s

shi ms

shoul d be

shi m

t he

mar ki ng

t he

r ol l er

( 2

. 1

mm

( 2

t hatashi m

i nt o

t hi ckness

and

i t ' s

set t i ng- di sc' s

agai nst

i n

t he

nor mal

pi n

( 2)

goes

t he

l i f t er ' s

:

i n)

9685

( 2

. 18504

. 2007

i n)

di st ance

wi t h

t hi ckness

t he

cal i per

measur ed

wi t h

bet ween

t hi ckness

t he

bl ockasi n

i s

t he

pump' s

i nj ect i on.posi t i on

hol e

mar ked

t he

nor mal

r ot at i on di r ect i on

i n

di st ance

edge

( do

i n)

i s55. 2

0 . 6

and

di st ance

t hi ckness0. 6

cal i per

t he

( i n

f oun

d

mar ki ng

6 ( =0. 6

2(=0. 2

di r ect i on of

t he t i mi ng

bet ween

not

mm

mm

bl ock

t he

i s55. 0

and

t hi s

exampl e0. 6

f i g.15

by

addi ng

.

0

. 8

.

Pl ace

t he

. 1 .

Tur n

cyl

unt i l

t he

r ot at i on

cover ' s

measur eont he

. 17323

( 2

( 0

. 02362

.

mm

mm

t he

.

mm/ 0

mm/ 0. 007874

mm

t he

( 2

( 0

bl ock.

t he

. 02362

hol e

cyl i nder

i n)

t hi s

i n)

i s

. 16535

. 02362

mm)

bl ock' s

i n)

i n)

wi t h

t he

17.Fi t

t he

i nj ect i on

shi m

t hi ckness

pump

i s

not

i n

pi n l ocat es

and

f i t t i ng

.

Ti ght eni ng t or que

f t

. l bs).Connect

pi pe

hol e

channel

' Out " )

t o

i s

i n

t he l ocks

each

f r om

t he

bol t f or

t han

.

t he

pump

Tur n

.

t he

l i f t i ng

cont r ol r od' s

mar ki ngs

t hat

f or

t he

f uel

f uel

f i l t er

t he

r et ur n

t he

ot her s

pump( s)

t he

engi nesot hat

posi t i on.Check

coi nci de

t he

t he

nut s

pi pe

t o

t he

hose

( on

t oget her

gr oove

cont r ol

bet ween

hasasmal l er

( see

20

i s

i nj ect i on

l at er

ver si ons

and

f i gur e).Check

r od

Nm

t he

pump.NOTE!

cal cul at ed

t he

cam

t hat

t he

t hat

oper at es

pump( s)

t he

( 2, 0

kpm)

pumps

t hr ough- f l ow

i t

i s

f or

t he

pump' s

af t er

easi l y

( 14. 7

and

t he

The

mar ked

.

t hi s

I n

( 0

( 0

ones

f i t t ed

t he

Har d

( 0

Sof t

( 0, 007874

D.Repeat

i n

The

case

. 007874

. 011811

. 011811,0. 02362

t he

and

i n).Pl ace

and

r ef i t

t oget her wi t h

bl ockorpump

shi ms

shi ms

and0. 011811

t he

same

set t i ng- di sc' s

choose t wo

. 011811

0

t he

ar e

avai l abl e

ar e

avai l abl e

pr ocedur e

way

i n)and one

t he

pump.NOTE!Ahar d

anot her

.

and0. 035433

as f or

cyl i nder1.

mar ki ng

sof t

shi ms0. 2

har d

shi m bet ween

har d

shi m

har d

shi mordi r ect l y

i n

t hi cknesses0. 3,0. 6

i n)

.

i n

t hi cknesses0. 2

i n)

.

f or

t he

ot her

pumps

expl ai ned

i s

and0. 3

shi mof0 . 3

t he

must

and

and0. 3

( 2002,

under

poi nt B

t wo

never

agai nst

0 . 9

2003)

mm

mm

sof t

mm

mm

.

be

18.I nst al l

t her most at

f or get

t he

housi ng

t hef eed

housi ng

l i f t i ng

.

pump

eyel et

wi t h

bet ween

and

t hef uel

t he

t her most at.NOTE!

t he

f i l t er.Al so

f i l t er

f uel

and

i nst al l

Do

t he

t he

not

t her most at

Page 22

21.Fi t

t he

t he

r ound

posi t i on.Fi t

pi pes

Al so

r ef i t

val ve

cover usi nganew

hol e

f or

t he

decompr essi on

bet ween

t he

i nl et

t he

t he

ai r

si l encer

cr ankcase

i nj ect or s

gasket.Make

vent i l at i on

devi ce

and

.

l ever.Fi t

t he

i s i n

i nj ect i on

sur e

t he

t he

pumps

t hat

r i ght

pr essur e

.

19.I nst al l

t he

sea- wat er

.

pump

and

t he

cool i ng

wat er

pi pes

20.I nst al l

t or que

f or

i nst al l

t he

t her most at

t he

i nj ect or s

t he

i nj ect or s

exhaust

housi ng

el bow

and

and

20

and

t he

t he

Nm

r et ur n

( 2, 0

t he

wat er

exhaust

f uel

pi pe.Ti ght eni ng

kpm)

( 14

pi pe

el bow

. 7

f t

. l bs

bet ween

.

. ) .

Al so

t he

22.I nst al l

hook- up

t he

st ar t er

V-bel t.Al so

t he

cabl e

mot or ,

i nst al l

har ness

t he

t he

el ect r i cal

.

al t er nat or

di st r i but i on

and

t he

box

al t er nat or

and

Page 23

2003T

Tur bo- Compr essor

Wher e

be

t hat

t he

boat ' s

t he

cl eaned

become

t her e

i sanexcessi ve

t he

t ur bo- compr essor

speed

t hr ough

boat ' s

wher e

cl ogged,

bot t om

necessar y.Check

and

shoul d

cl ean

t he

amount

i s

wat er

t he

of

not

f unct i oni ng pr oper l y

i s

gr adual l y

al so

be

t hat

t he

i nt ake

si l ender

smoke

ai r

i n

decr easi ng,

i nspect ed,

i nt ake

.

t he

has

exhaust

and

not

f umesor

t he

engi neout puti s par t i cul ar l yl owi t may

.

I f

Fi l lupwi t h

23

.

quant i t y

l ubr i cat i ng

and

qual i t y,

see

I nspect i ng

Check

t he

bear i ng

j oi nt s

bear i ng

housi ng

t he

bet ween

housi ng,

and

Seal s

t he

t he

t ur bi ne

and bet ween

compr essor

housi ng

t he

housi ng

and

t he

compr essor

compr essor

.

Checks

Check

t he

pr e- i nj ect i on

and

t he

spr ay

shoul d

oi l

t o

t he

under

cor r ect

" Techni cal

l evel.Regar di ng

Dat a"

.

Checki ng

Di smount

measur e

Maxi mum

axi al

t he

t ur bo- compr essor

t he

r ot or

per mi ssi bl e

angl e,

t he

and

axi al

axi al

The

.

r adi al

cl ear ance

pat t er n

al sobechecked

uni t ' s

i nj ect or ' s

val ve

.

cl ear ance

f r om

and

r adi al

openi ng

cl ear ance

t he

engi ne,

cl ear ance

and

0

. 09

pr essur e

compr essi on

and

.

mm

24.Vent i ng

A.Open

Wat ch

B.Use

bubbl es

C.Ease

t ur n t he

of t he

nut s

t he

out

t he

i s

of f

t he

engi ne

f uel

.

t he

f uel

vent i ng

f or

f uel - spl ashes

hand- pump

comi ng

t he

f uel

t hr ot t l e

cont r ol

wi t h

pr essur e

syst em

scr ewon

out.Cl ose

pr essur e

t he

pi pes.Ti ght en

t he

.

t o

pump

pi pe nut satt he

i n

t he

st ar t er

f uel

f uel

t he

vent i ng

posi t i on

mot or

unt i l

t he

f i l t er

unt i l

f uel

appr ox.4

f uel

f r ee

scr ew

i nj ect or s

f or

f ul l

f uel

pr essur e

t ur ns

f r om

ai r

.

.

Posi t i on

speed and

comes

out

pi pe

.

Maxi mum

I f

wear

t ur bo- compr essor

per mi ssi bl e

and

t ear

r adi al

cl ear ance

has

r eached

shoul dber econdi t i onedorr epl aced

t he

maxi mum

per mi ssi bl e

0

. 17

mm

t he

.

Page 24

RECONDI TI ONI NG

l i ne- up

Make

bear i ng

t he

t hr eaded

dol l i esont he

( 2)

housi ng

compr essor

nut

and

di smant l e

mar ks bet ween

and

t he

housi ng

whi ch

hol ds

t ur bi ne

shaf t.Remove

t he

t ur bi ne

t he

compr essor

( 1).Unscr ew

t he

compr essor

housi ng

t ur bi ne

t he

housi ng,

housi ng.Di smant l e

t he

l ef t - hand

wheel ,

compr essor

( 3)

.

t he

usi ng

wheel

Di smant l e

t ur bi ne

.

Unf ast en

and

scr ew

Take

t he

shaf t

oi l

t he

t ur bi ne

st i cks,

t wo

def l ect or

t he

M5

shaf t

t ap t he

t hr ee

scr ews

( 7)

( 4)

and

end

gent l y

scr ews

outoft he

i nt o

whi ch

t he

t he

heat

shi el d.I f

wi t hawooden

hol d

t he

cover.Then

cover

.

t he

hammer

cover

l i f t i tup.

( 3)

Page 25

Compr essor

Check

t hat

t he

causedbyexcessi ve

shoul d

Heat

Check

wear

be

Shi el d

t hat

and

.

r epl aced

t he

t ear ,

Housi ng,

housi ngs

heat

heatorcor r osi on,

.

shi el d

ar e

f r ee

wear

i s

f r ee

Tur bi ne

f r om

cr acksorot her

and

t ear.Damaged

f r om

and

Housi ng

damage

r epl ace

caused

i t

i f

necessar y

damage

par t s

by

Unf ast en

bear i ng

compr essi on

t he

t wo

Remove

t wo

car ef ul l y

Measur i ng

Tur bi ne

Check

shape.Do

shoul d

t he

f our

scr ews

( 8).Usi ngasmal l

bear i ng

ci r cl i ps

bear i ngs

t he

packi ng

.

( 10)

( 11)

packi ng

r i ngs

and

Wheel

t hat

be

t ur bi ne

t he

damage.The

not

r epl aced

i nsi de

.

r i ng

( 13)

I nspect i on

and

Shaf t

t r y

t o

.

and

t he

bear i ng

( 12)ont he

t he

on

wheel

vanes

r eal i gn

whi ch

copper

t he

bushi ng

housi ng

oi l

def l ect or.Cl ean

and

shaf t

must

t he

vanes.Damaged

hol d

mandr el ,

t ur bi ne

not

t he

compr essi on

( 9)

.

Then

and

shaf t

ar e

f r ee

be

wor norout

out

t ap

r emove

r emove

and

t he

f r om

t he

t he

t he

par t s

mechani cal

par t s

Bushi ng,

Oi l

Def l ect or ,

Compr essor

Bear i ng

Check

t hat

amount

.

of

t he

.

wear

of

Damaged

par t s ar e f r ee

and

f r om

par t s

shoul dber epl aced

t ear

i s

wi t hi n

wear

and

t he per mi t t ed

t ear

and

even

i f

t he

di scol our at i on

t ol er ances

Bushi ng

Check

4

. 07

measur ement

mm

.

( A) ,

whi ch

shoul d

not

be

l ess

t han

Pl ace

t he

bear i ng

shaf t.The

Check

t he

per mi ssi bl e

t he

shaf t

i s1. 29

mm

shaf tont wo

r ecesses,

maxi mum

di amet eroft he

pi st on

and

di amet er

r i ng

.

suppor t s,

check

per mi ssi bl e

shaf t

i s7. 98

gr oove

Maxi mum

.

whi ch

t he

bear i ng

shoul dbeunder

t hr ow

at t he

t hr ow

i s0. 011

r ecesses.The

mm.Check

per mi ssi bl e

endoft he

mm

t he

wi dt h

wi dt h

Def l ect or

Oi l

( B)

and

t he

Check

measur ement s

t han1. 31

mm,

Compr essor

Check

of

wear

Mi ni mum

wi dt hoft he

t he

and

per mi ssi bl e

t ear

( C)

shoul d notbemor e

Bear i ng

bear i ng,

i s

i n

excess

wi dt h

( C).( B)

of

i s3. 98

and

r epl ace

t he

shoul d

t han1. 11

i t i f

per mi t t ed

mm

.

notbemor e

mm

.

t he

amount

t ol er ance

.

Bear i ngs

.

mi ni mum

of

Check

i nt er nal

di amet er

di amet er

t he

and

bear i ngs

ext er nal

shoul d

shoul d

f or

abnor mal

di amet er sofal l

notbel ess

not

be

mor e

t han

t han

and

wear

bear i ngs.The

12

. 31

8. 04

mm

mm,

t ear or

t he

.

di scol our at i on,

ext er nal

i nt er nal

and

r epl acet hem

wher e

necessar y.Check

t he

Page 26

Bear i ng

Check

measur ement

Housi ng

t he

housi ng

( D)

and

Measur ement

.

( E) ,

( E)

f or

cor r osi on

and

( D)

shoul d

r epl ace

shoul d

not

cr acks.Check

or

t he

be

not

be

mor e

housi ng

mor e t han

t han 15

wher e

12

. 05

measur ement s

. 42

necessar y

mm

mm,

.

Reassembl y

Gr ease

Mount

Posi t i on

pl ace

Mount

bear i ng

The

Ti ght en

quar t er

t or que

Posi t i on

The

Posi t i on

t he

The

Ti ght en

t or que

al l

r emovabl e

t he

ci r cl i ps

i n

t hem

t he

packi ng

i n

r i ngsot hat

t he

t he

t he

t ur bi ne

t he

bushi ngont he

bear i ng

casi ng,

t or que

t he

t ur n

agai n

t he t wo

openi ng

t hat

i n

t he

bear i ng

usi ng

Permat ex

t hi cknessoft he

Fi t t he

coveront he

scr ews

quar t er

Posi t i on

f ast en

be

t he

Smear

t ouch

t he

0

posi t i on.The

Check

agai n

i t

2 . 0

Nm±0

Mount

t he

t o

t he

maki ng

compr essor

Nm±0

. 5

t he

wi t h

pur pose.The

. 1- 0

. 2

t o

t he

t he

axi al

cl ear ance

and

t he

t ur n

t he

wi t h

( M6) ,

mm.Then

l i ne- up

cl ear ance

ar e

heat

shoul dbe1

scr ews

.

i n

t he

oi l

housi ng

washer s.The

scr ews

.

compr essor wheel

t ur bi ne

l i ne- up

edgesoft he

t he

axi al

par t s

i n

t he

f aci ng

r i ng

shi el dont he

axl e

i n

wi t h

engi ne

usi ng

new

t o t he

bef or e

bef or e

t he

. 1

t i ght eni ng

packi ng

t he

i nner

out er

r i ng

def l ect or

whi ch

f or t he

seal ant

bear i ng

t he

t o

t i ght eni ng

l ef t - hand

.

housi ngont he

mar ks.Scr ew

sur e

t hat

housi ng

26. 0±1, 0

compr essor

t hi cknessoft he

mount

mar ks,

i s

and

0

shoul dbe4

r adi al

i s

0. 09

. 17

mm

t or que

when

r eassembl i ng

bear i ng

t owards

on

i t

. 3

pur pose

bear i ng

housi ngsot hat

t he

oi l

shaf t.Tur n

t he

t ur bi ne

i s

f aci ng

t owards

bear i ng

t he

bear i ng

t ur bi ne

scr ews

Nm±0

above

r i ngsont he

r i ng

shoul dbef aci ng

shoul d

i n

t he

come

shoul dbeabout0. 1- 0

housi ng,

t or que shoul dbe1 . 3

above

t hr ead

t he

scr ews

.

The

( M8)

.

housi ng,

t he

compr essor

and

scr ew

cl ear ance.Maxi mum

mm,

.

housi ng

shaf t.Gr ease

oi l ,

and

and washer s

. 1

.

t or que,

cover.Smear

t or que,

t hen l oosen

t hem

oi l

f aci ng

be

i n

t ouch

.

and

t hen l oosen

t hem

on

t he

nut.The

bear i ng

t he

l ocki ng

used

t or que shoul d

housi ng

usi ng

seal ant

t he

. 5

Nm±0

maxi mum

t hem

t he

out l et

.

t he

t he

oi l

i nt ake

casi ng,

mount

up

def l ect or.NOTE

f ast en

up

t ur bi ne

wher e

l ocki ng

and

.

i n

t he

i t

on

f ast en

t o

t hem

t o

t he

cor r ect

t he

oi l

t he

oi l

i nt ake

t he

edges

wi t h

t he

. 2

i t wi t h

Nm±0

t hem

t o

t he

cor r ect

shaf t

t or que shoul d

housi ng

ar e not

shoul dbeabout

housi ng

. 5

per mi ssi bl e

cover

i nt o

t hose

be11. 0

i t

comes

Permat ex

accor di ng

cover

.

per mi ssi bl e

accor di ng

.

Posi t i on

openi ngs

openi ng

t hen

compr essor

t he

out l et ,

cover ,

mm

new

. 1

and

i nt o

f or

posi t i on,

f or

r adi al

.

i t

.

a

:

.

of

.

.

a

i n

Cover

Check

measur ement s

wher e

necessar y

t han12. 45

10

. 05

mm

Packi ng

Check

t he

r y

and

.

shape,

mm,

measur ement

.

Ri ngs

packi ng

r epl ace

( F)

and

Measur ement

.

r i ngs

t o

t hem

see

wi t h

( G)

( G)

.

( F)

shoul d

i f

t hey

new

and

shoul d

ar e

ones

r epl ace

t he

not

notbemor e

wor norout

wher e

be

cover

mor e

t han

necessa

Fi t t i ng

Bef or e

cl ean

shaf tsot hat

cor r ect

of

changes

Cl ean

t he

Tur bo- Compr essor

f i t t i ng

t he

engi ne

t he

oi l

t he

qual i t yofoi l

shoul d be

i n

t he

ai r

f i l t er

t ur bo- compr essor

i nt o

t he

oi l

i nt ake,

evenl y

( see

i n

di st r i but ed.Cl ean

under

out

or der

oi l i s

car r i ed

Manual ,

.

on

and

" Techni cal

i n

accor dance

t o

keep

t he

t ur n

t he

engi ne,

t he

t he

Dat a" ).Oi l

wi t h

engi ne

spr ay

t ur bi ne

t ur bo- compr essor ' s

t he

cl ean

i nst r uct i ons

del i ver yandr et ur noi ll i nes.Changet heengi neoi landt hef i l t erf ort hel ubr i cant.Besur et ouset he

.

Page 27

FRESHWATER

1

.Fi t

t he

20

Nm

2

.Suspend

doubl e

b)

Fi t

Fi t

c)

3

.Locat e t he

washer s) ,

4

.Fi t

t he

11)

and

Fi t

t he

5

.

6

.Fi t

t he

7

.Fi t

t he

8

.Fi t

t he

Fi t

t he

9

.

i n)

( onl y si ngl e

10

.Fi t

t he

Fi t t he

11

.

i n) ,

posi t i on18.

12.Fi t

13

.Fi l l

2003=5

t he

t he

COOLI NG

ci r cul at i on

( 2, 0

kpm)

t he

heat

a)

hose cl amps

t he

pi pe

bet ween

t he

pi pe

bet ween

pi pes

posi t i ons

pi pe

bet ween

t he

l ock (posi t i on11a)

pi pe

bet ween

pi pe

bet ween

al t er nat or ,

expansi on

hose

bet ween

ni ppl e,

hose

pl ugs

syst em

addi t i ve

posi t i on17.

bet ween

i n

t o

. 5dm3

pump

( 14

. 7

exchanger

Fi t

t he

i n

t he

5 and9.

t he

pl ace

t ank

hose

t he

exhaust

t he

( VP