Volvo 240 1975, 260 1975 Service Manual

Service

Manual

Repairs

and maintenance

Section 8

(87)

Climate unit

(Heater

unit)

240,260

1975-

Heater

unit

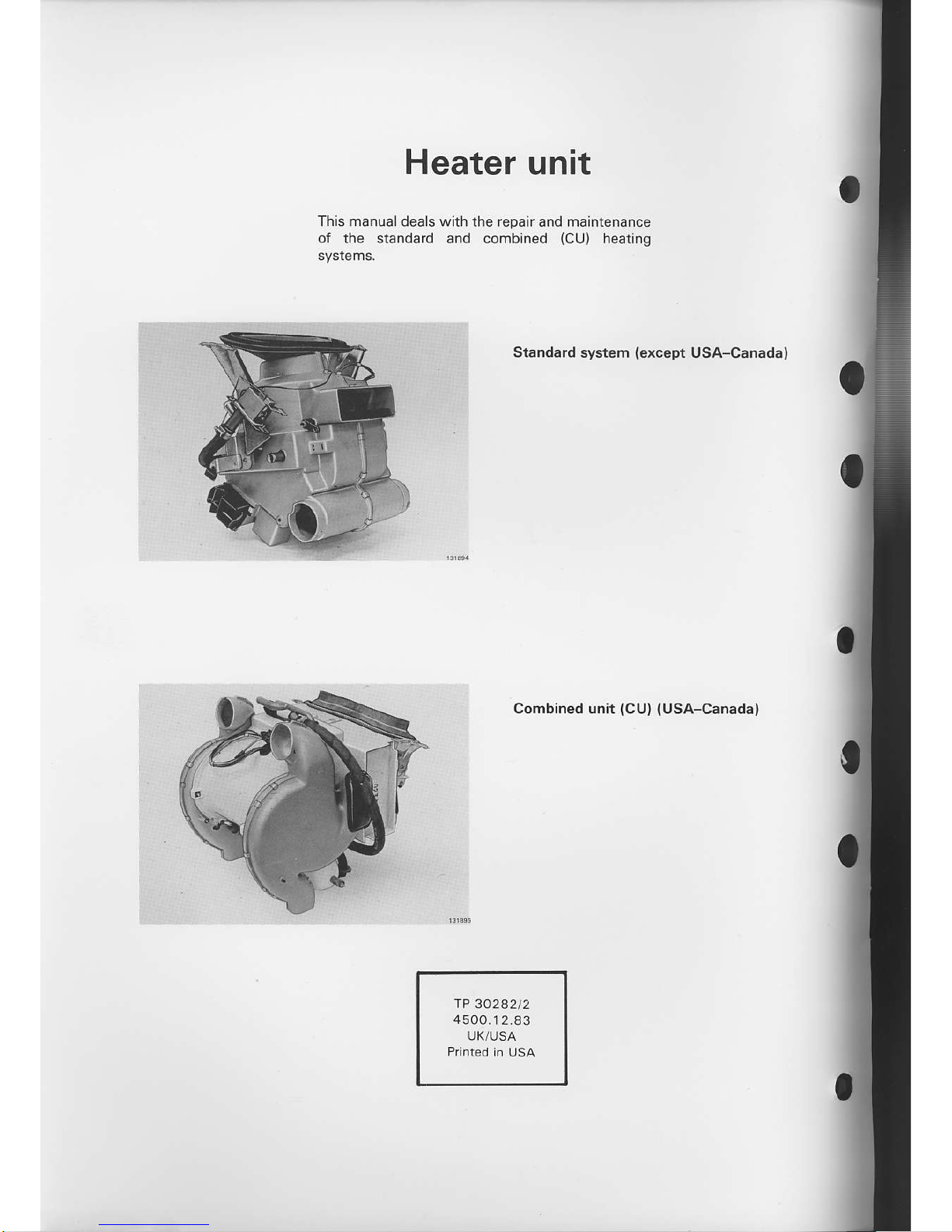

This manualdeals with

the repair and maintenance

of the standard and combined

(CU)

heating

Standard system

{except

USA-Canadal

Combined unit

(CU) (USA-Canada)

IP 30282t2

4500.1

2.83

UK/USA

Group 87

Climate

Contents

unit

(Heater

unit)

Standard

unit

Control

panel

and,/or cable, replacement

Operation

A1-A10

B 1_82

cl c24

D1-D23

E1_E9

F1-F20

Page

14

Fan motor

switch, replacement

Heat

exchanger and,/or fan motol

Heater control

valve, replacement

Air distribution

1 975-1980

1981-

replacement

(removed

heater)

2

3

4

I

Combined

unit

(CU)

USA-Canada

Heater contrcl

and,/or conrol cable, repla

cemeni

c 1

-G

7

Contrcl

panel

and,/or fan motor

switch, replacement

.. .... . . . .

Shutter actuator for

rcar

floor

vent, replacemenr

REC

shLtte'. replacement

Hedler,.emoval

...

Insrallarron

..

Hedl

erchanger. repldLement

rremov€d

h.ater)

t.n motor

replacemenr

Heatercontro

valve. replacement .......

H1-H7

t1-t6

J]

J2

K] K26

L1 t21

M] Ml6

N1-N36

o 1-06

P1-P13

R1-R17

21

22

23

24

25

30

35

38

45

46

49

Charts

A. Heater controls,

standad lnit

B. Healer

convols, CIJ

C. Standard

heater unit

D. Heater

housing, standard

unit

E. Combined heater

unit, CU

F. Heater

housing,

CU

G. Hole template,

standard

unit

H. Conversion

table

metric,/IJSA

standard

Index

page

53

fhis

manual deals with heater units

only. Air conditioning

is

dealt wlth in another nran!al.

Volvos

are sold

in

versions adapted for different markets.

These adaptions depend on many factors

including legal,

laxation

and

market

requirements,

This

manual may lherefore show illustrations

and text

which do not apply to cars in

you.

country.

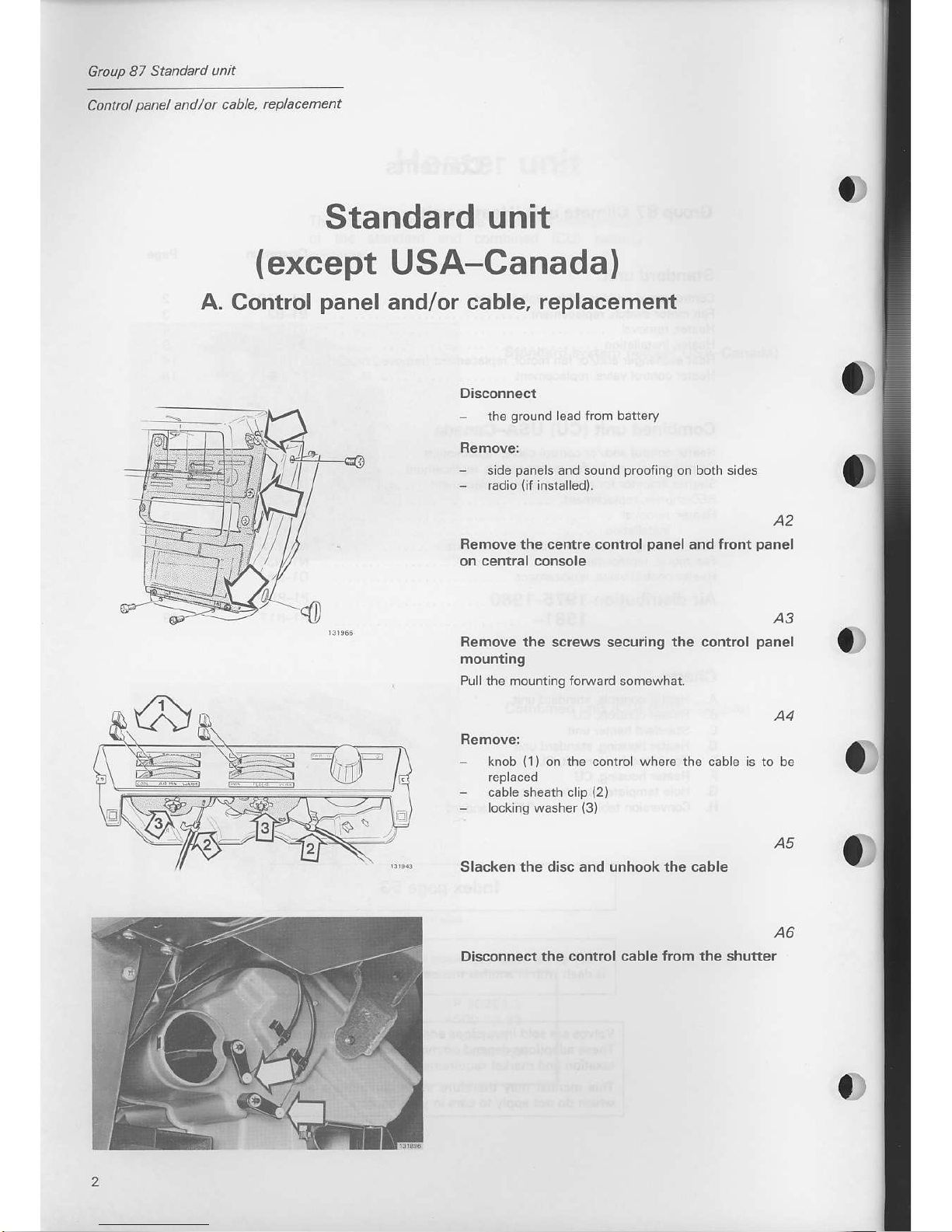

Group

87 Standa.d

unit

Control

panel

and/or cable,

replacement

Standard

unit

(except

USA-Canada)

A.

Control

panel

and/or

cable, replacement

Disconnect

the

ground

lead fiom

battery

Remove:

-

slde

pane

s and sound

proofing

on both sides

-

ladio

{if

installed).

A2

Remove

the cefire control

panel

and tront

panel

on central console

a)

A3

Remove the screws securing the control

panel

moufirng

Pull the mounting forwad somewhat.

knob

(1)on

the control where the

cable

-

cable sheath clip

(2)

-

locking washer

(3)

Slacken the disc and unhook the cable

O)

O)

Disconnect

the control cable from the shutter

Adjust

the control

cable

Install:

control

mounting

-

front

panelfor

cenrral

console

and controt

panel

-

radio

(if

installed)

-

side

panels

and

soundproofing

on borh sides.

Group

B7 Standard

unit

Fan

motor switch,

replacement

Ato

A7

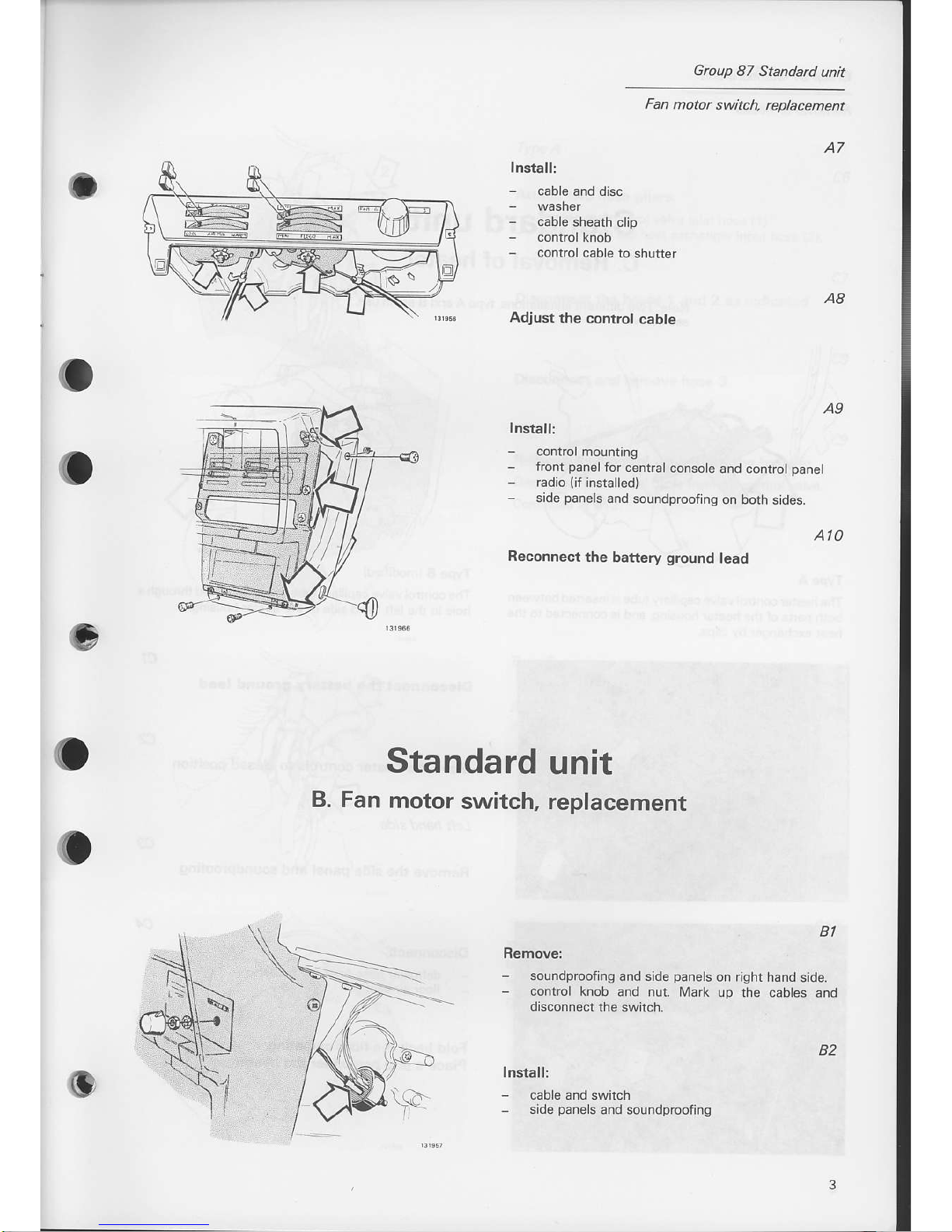

Install:

-

cable

sheath clip

-

contro

cable to

shutter

Reconnect

the battery

ground

lead

Standard

unit

B. Fan

motor

switch, replacement

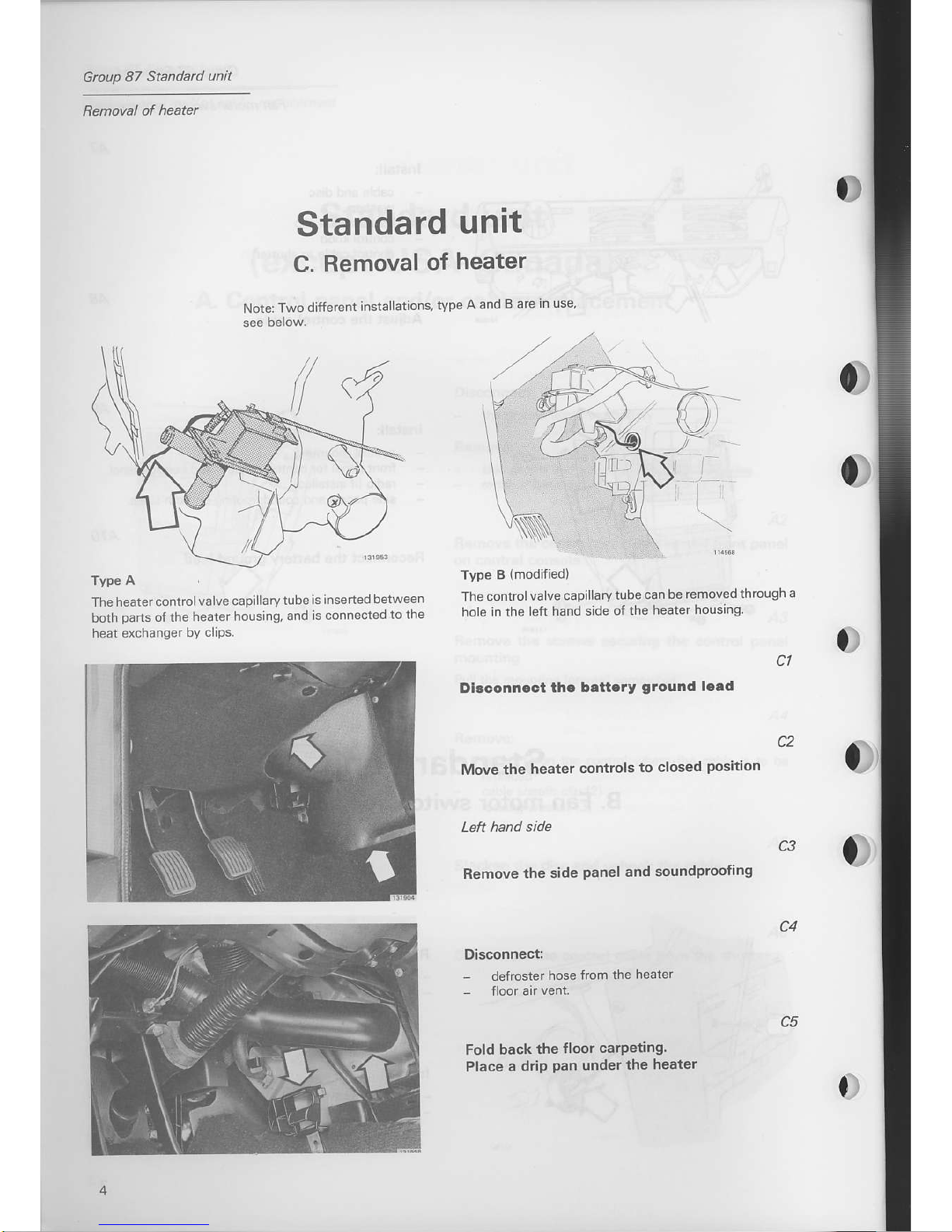

BI

Remove:

-

soundprcofing

and side

panels

on right hand

side.

-

control knob

and nut. Mark

up rhe cabes

and

disconnect

the switch.

Install:

-

cable and switch

-

side

panels

and soundproof ng

o

B2

Gtoup

87

Standad

unit

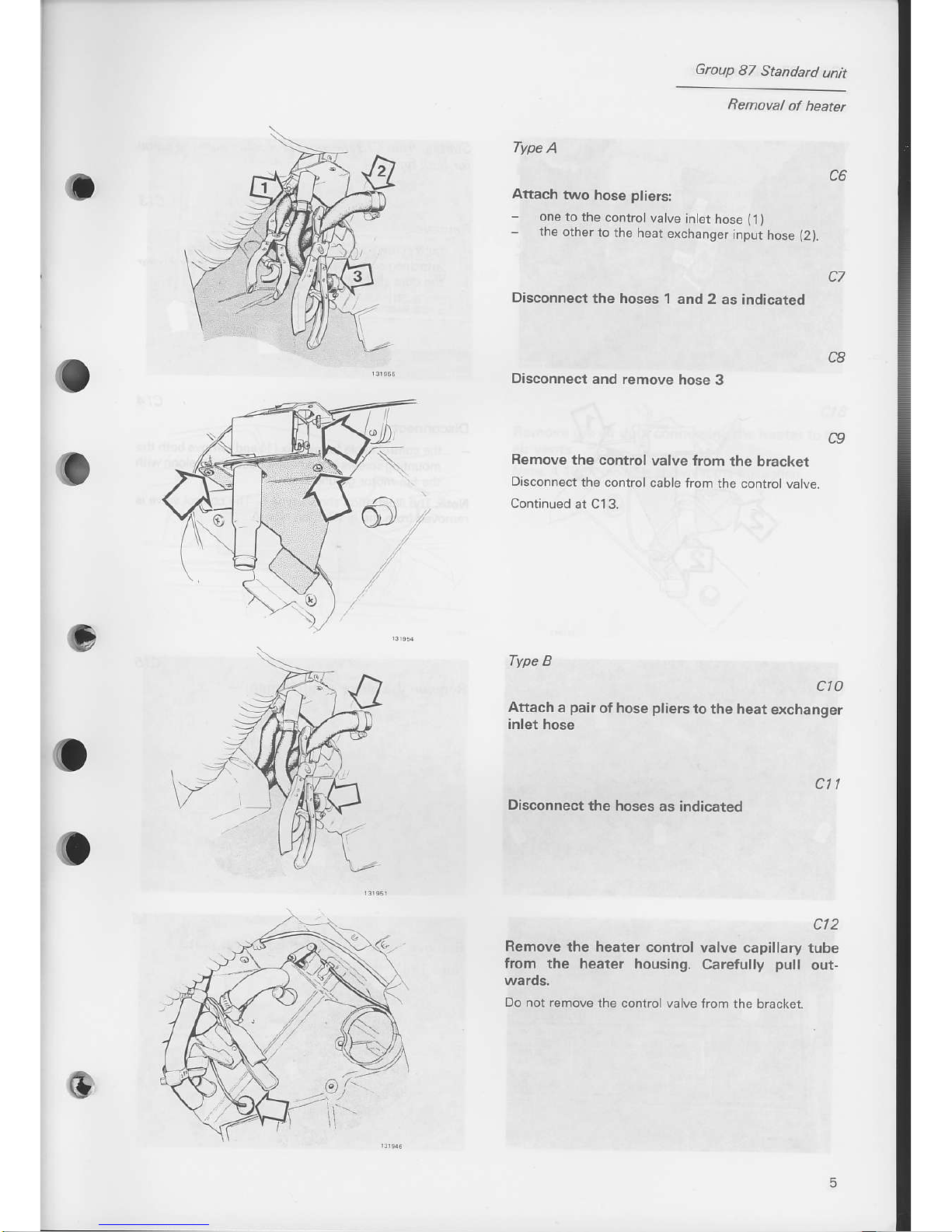

The

heater control

va lve capiLlarv

tube

is insened

between

both

paris

of the

healer housing,

and

rs connectcn

to the

heat exchanger

by

clLps.

Standard

unit

C.

Removal

of

heatel

Note:

Two

differcnt

installations,

tvpe

A and

B are

in 'rse'

0)

Type A

(modifled)

The

control valve

capilla

ry

tube can be

removedthrough

a

hole in the

left

hand side of

the heater

housing

Dlsconn.ct

thc

bettery

ground

lcad

Move

the heater

controls

to closed

Remove

the side

panel

and soundproofing

Disconnectl

-

defroster

hose

ircm the

heater

Fold back

the

floor carpetin9.

Place

a

drip

pan

under

the heater

I

Gtoup

87

Standatd

unit

Removal

of healer

Type

A

Attach

two

hose

pliers:

-

one to

the convolvatve

inter

hose

(t

)

-

the

other

to the heat

erchanger

input hose

(2).

Disconnect

the hoses

1 and 2

as indicated

C7

c6

CB

c9

o

Disconnect

and remove

hose 3

Remove

the control

Disconnect

rhe conrrol

Continued

at Cl3.

valve {rom

the bracket

cable from

the control va ve.

Type

B

cto

Attach a

pair

of hose

pliers

tothe heat

exchanger

inlet hose

cll

Disconnect

the hoses

as indicared

ct2

Remove the heater

control valve

capillary tube

from the

heater housing.

Carefully

pull

out-

Do not remove

the controlvalve

frcm the bracket

)'

Group

87 Standard unit

Removal ol heater

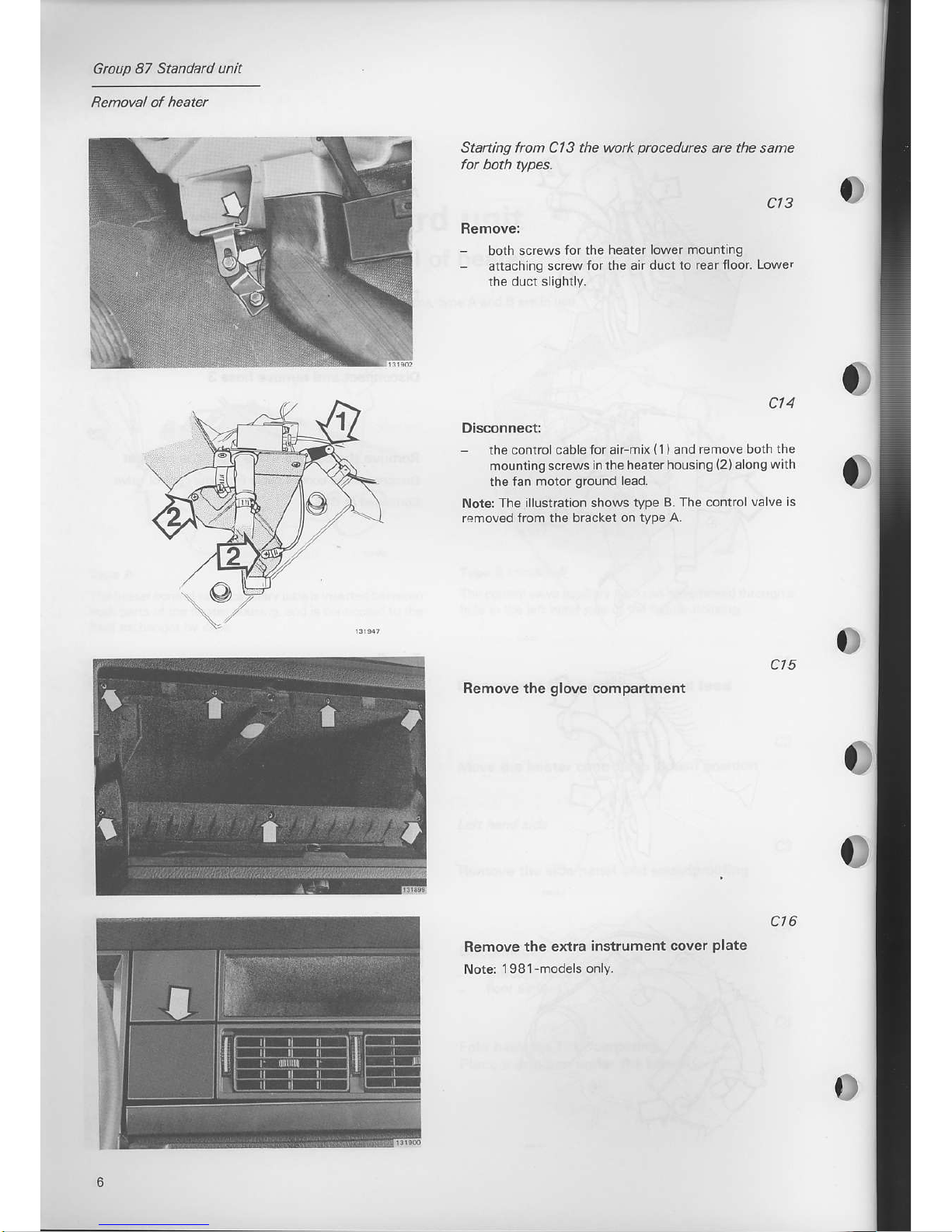

Starting

frcm

Cl 3 the work

procedures

are the same

cl4

Disconnectr

the controlcablefor aiFmix

{1)and

remove both

the

mounting screws

in the heaterhousing

(2)alongwith

the

fan motor

ground

l€ad.

Note: The illustlation shows

type B. The control

valve is

Irmoved from the bracket on

type A.

ct5

Remove the

glove

compartment

ct3

Remove:

-

both

screws for the heater

lower mounting

-

attaching

screw for the ah

duct to rear floor.

Lower

the

duct slightly.

ct6

Remove

the extra

instrument cover

plate

Nots

1981-models only.

Grcup

87 Standa.d

unit

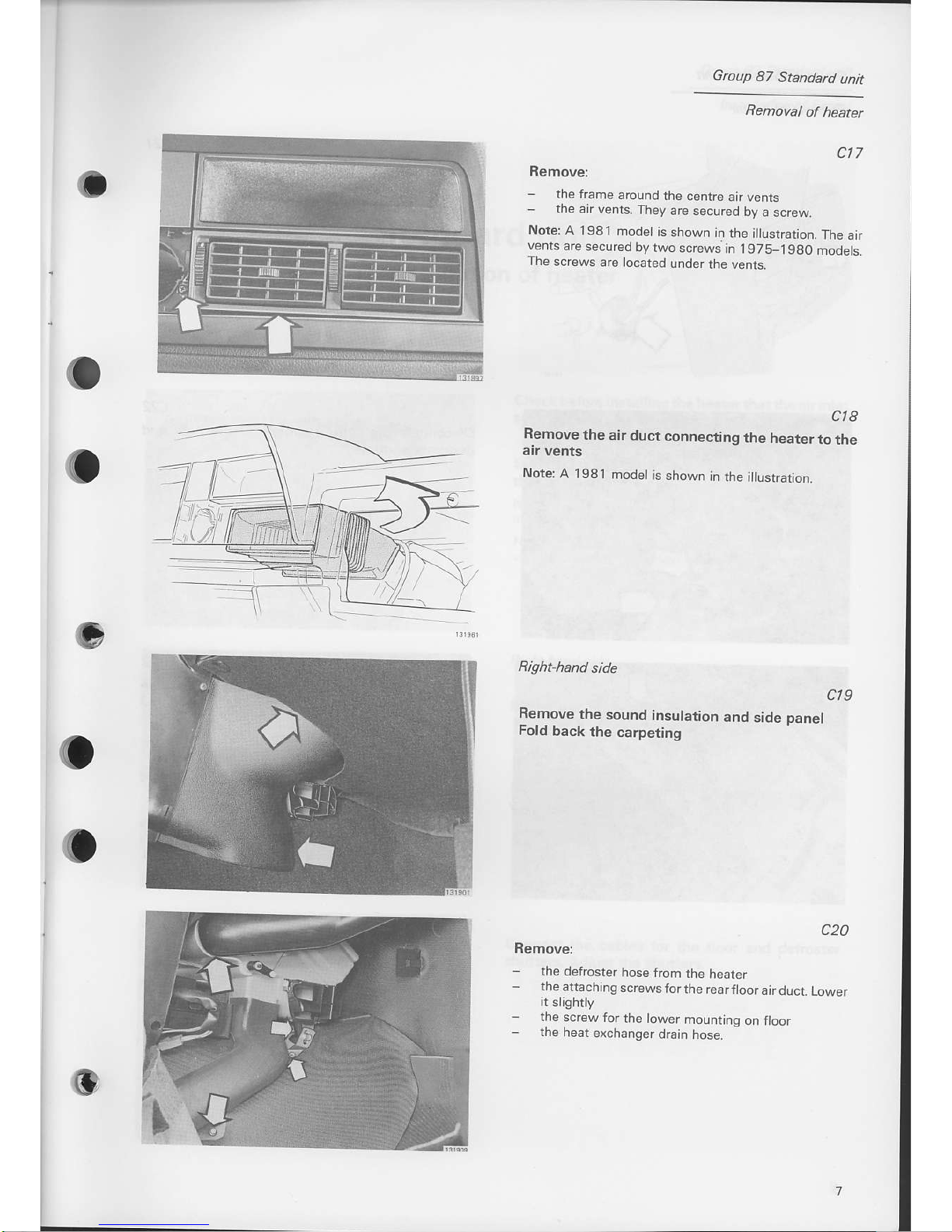

ct7

Remove:

-

the frame

around

the

centre

air vents

-

the ar vents.

They

arc

secured

by

a screw.

Note:

A 1981

modet

is shown

in

the i

ustration.

The

air

vents

are

secured

by two

screws

in 1975_198o

modets.

The

screws

are located

under

the vents.

cl8

Remove

the

air duct

connecting

the heater

to

the

Note

A 1981

modet

is

shown

in the

i usrrarion.

Remove

the

sound insulation

Fold

back

the

carpeting

ct9

and

side

panel

c20

Remove:

-

the

defroster

hose from

the

heater

-

the

attaching

screws

forthe rearftoorairducr

Lower

it

sljghtly

-

lhe screw

for

the tower

mounring

on ftoor

-

the

heat

exchanqer

drain

hose.

..---

Group 87 Standatd unit

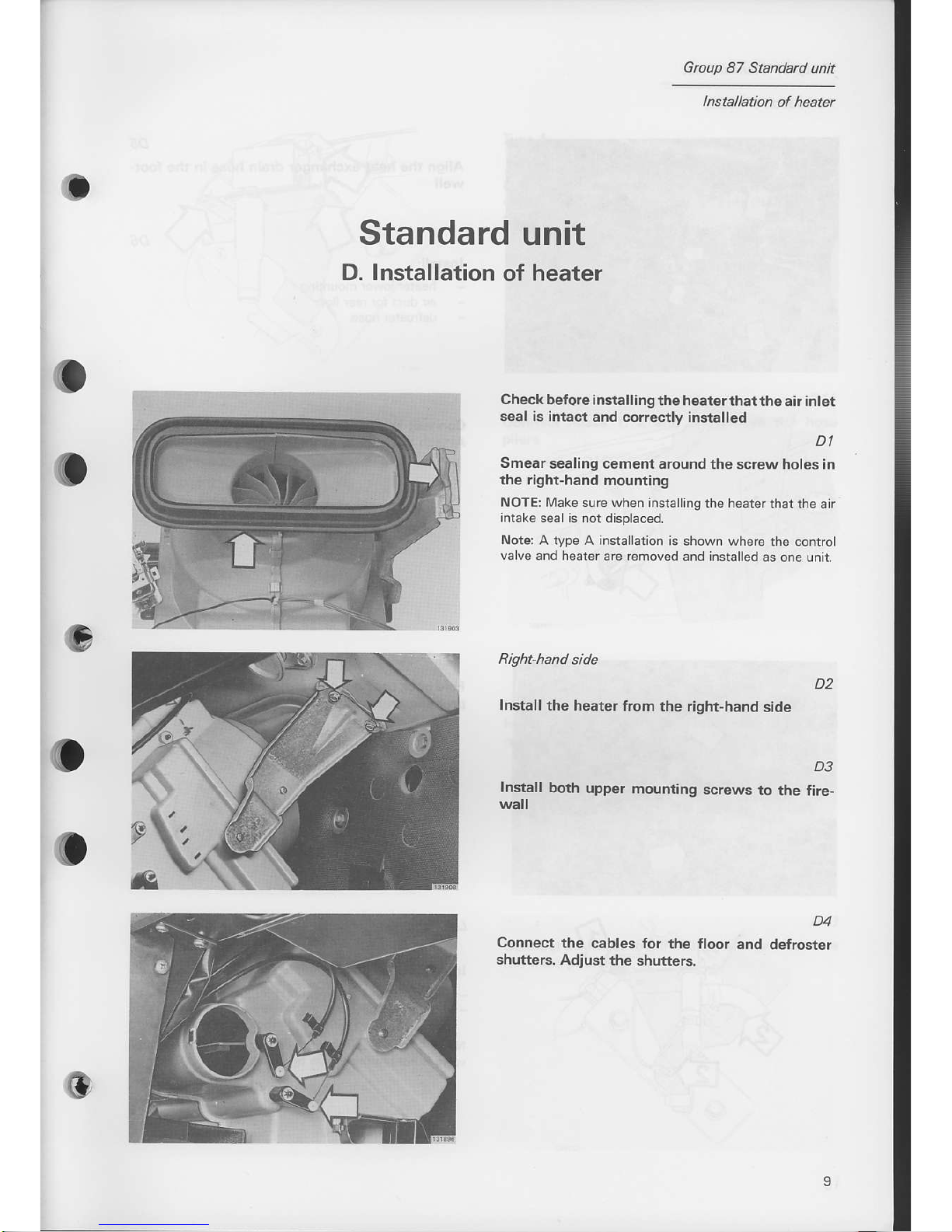

Disconnectl

-

fan motor switch from

panel

-

pos

tive

lead from

the swilch

Disconnect

the control

de{roster

shutters

c22

cables for

the

floor

and

c23

Remove both the screws in the firewall for the

upper mounling. Then remove the heater

and

mounting

as one unit,

c24

Remove

the

heater

via right-hand side

For

type Ar the control valve and capillary tube are

attached to the heater

For type B: the controlvalve is mounted on the bracket.

Gtoup 87 Standard

unit

lnstallation

of

heatel

Standard

unit

D. Installation

of

heater

o

o

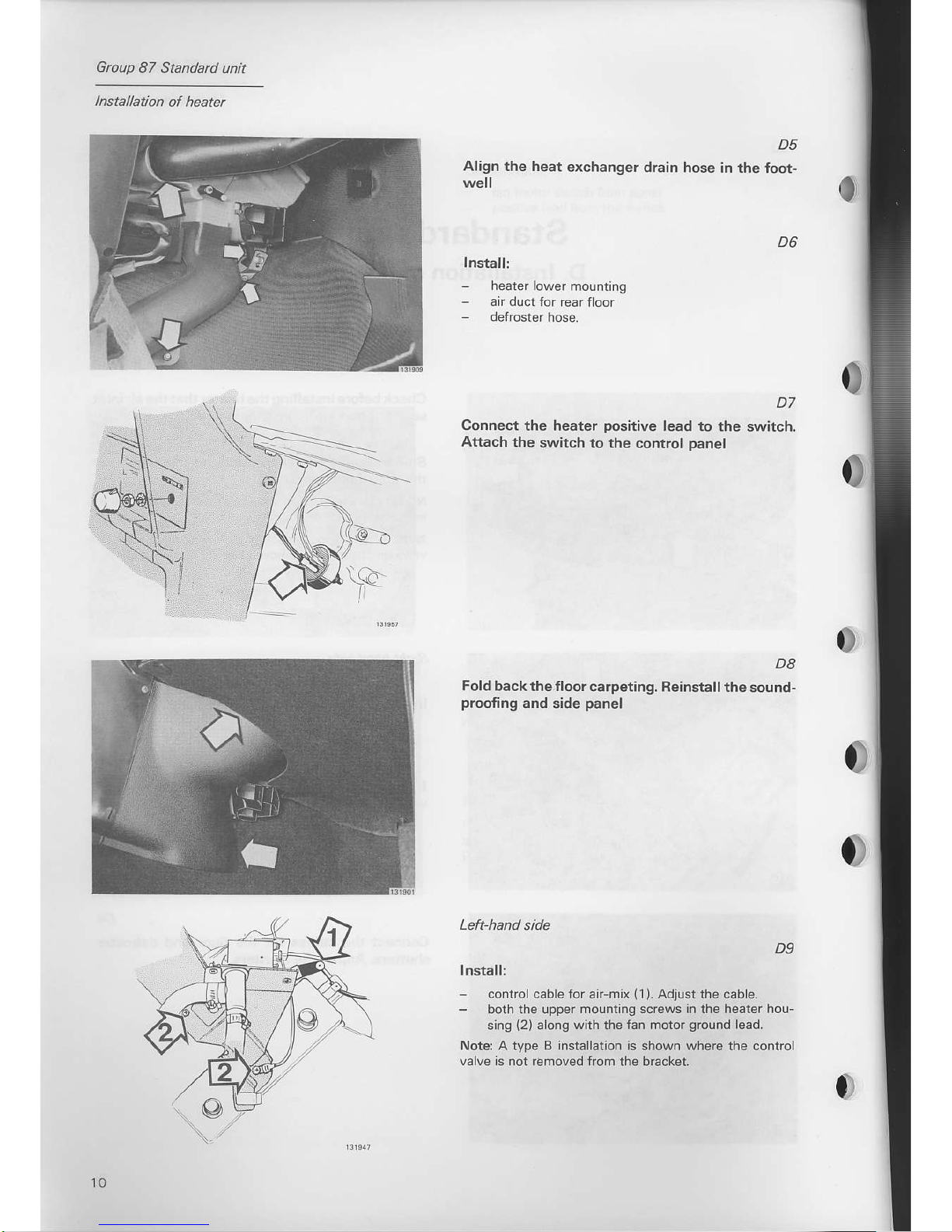

Check bef

ore

installing

the heaterthatthe

air

inlet

seal is intact

and correcllv installed

DI

Smear

sealing cement around

the screw holes in

the right-hand

mounting

NOTE: lvlake surc when installing

rhe hearer

that the air

intake seal is not displaced.

Nots

A tvpe A installatio.

is shown where the

control

valve

and heater are removed

and installed

as one unit.

Install lhe

heater trom

the right-hand

side

D2

Install both

upper

mounting

wall

D3

screws

to the

fire-

D4

Connect the

cables lor the

floor and

defroster

shutters.

Adjust the

shutters.

Group

87 Standatd

unit

lnstallation

of heatel

Align the heat

exchanger

drain

well

D5

hose in

the foot'

D6

D7

Connect

the heater

positive

lead to the switch.

Aftach the

switch

to the control

panel

lhstall:

-

heater lower

rnountrng

-

air duct for rear

floor

D8

Fold

back the floor carpeting.

Reinsta ll the

sou nd-

proofing

and side

panel

D9

Install:

-

contrcl cable for air-mix

{1).

Adjust the cable.

-

both the upper mounting screws

in

the

h€ater hou-

sins

(2)

along

with

the

fan motor

ground

lead.

Nots A type B installation is shown where the control

valve is not removed from the bracket.

10

Group

87 Standard

unit

lnstallation

of heatel

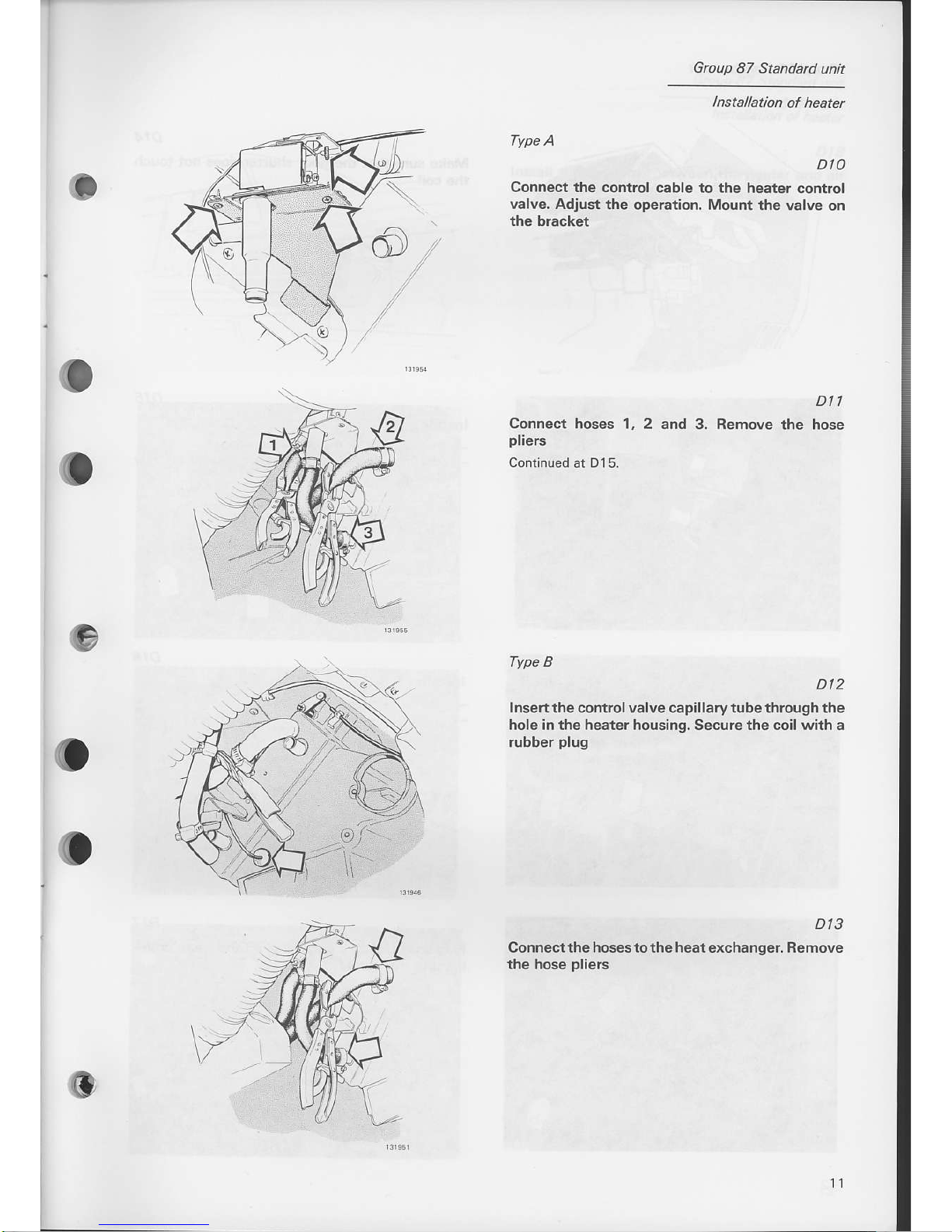

Type

A

Connect the

valve. Adjust

the bracket

Dl0

control

cable to the heater

control

the

operation, Mount the valve

on

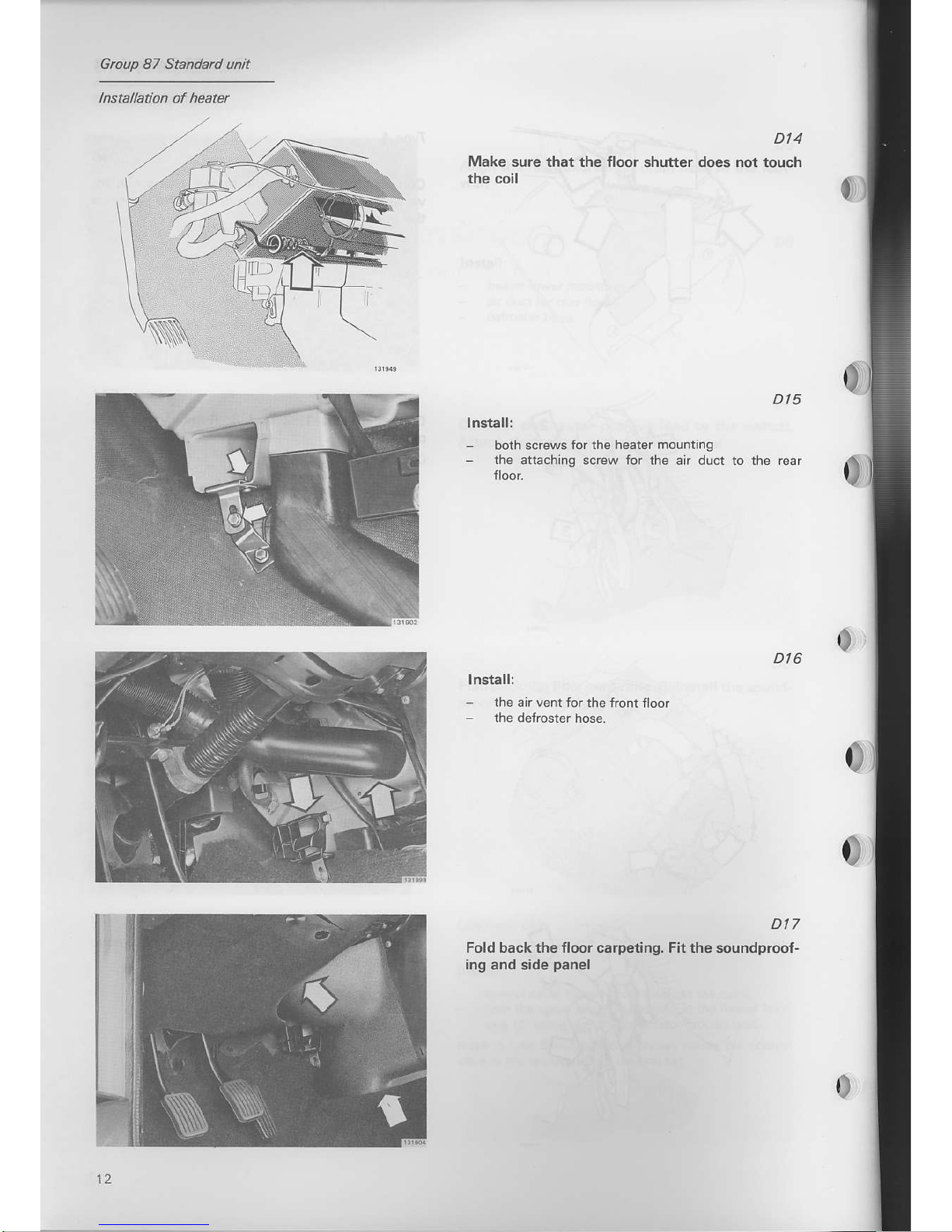

Dl

.l

2 and 3. Remove

the hose

o

i

Connect hoses

1,

pliers

Continued

at

D15.

Type B

Dt2

Insert the controlvalve capillarytube through the

hole in the heater housing. Secure the coil with a

rubber

plug

Dt3

Connectthe

hosestothe heatexchanger,

Remove

the hose

pliers

Group 87 Standard unit

lnstallation of heater

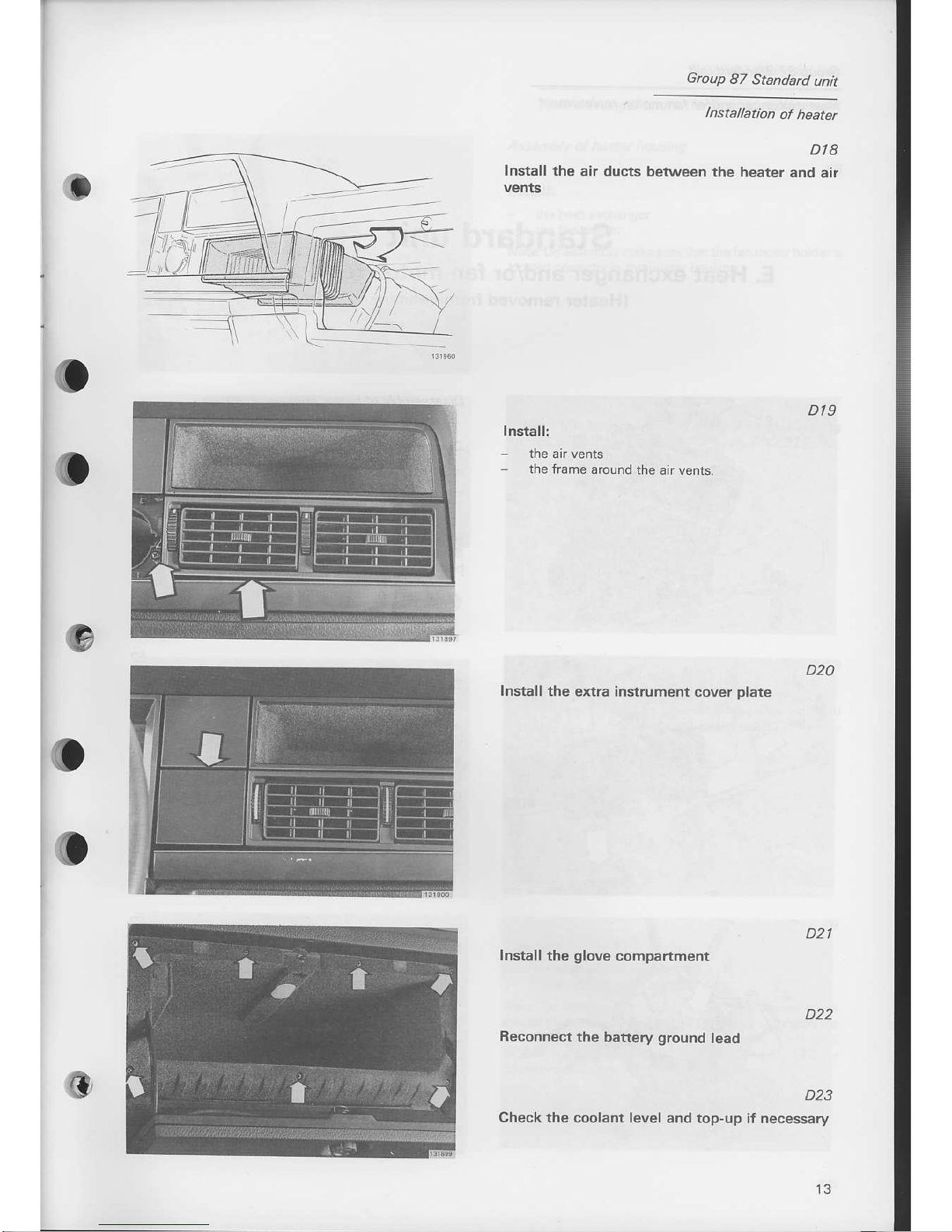

D|4

Make

sure that the Jloor shutter does not touch

the coil

Dt5

lnstall:

-

both screws

for the heater

mounting

-

the attaching

screw for the air duct to the rear

0

Dt6

lnstallr

-

the air vent

for the front floor

-

the defrcster

hose.

Dt7

Fold back the floor carpeiing. Fitthe soundprcofing and

side

panel

0

12

Group

87

Standad

unit

lnstallation

of

heater

D18

Install

the air ducts

betwo€n the

heater and

air

Dt9

Install:

-

the

fram€ around

the air vents.

D20

Install

th€ 6xtra instrument

cover

Dlate

Install

the

glove

compartment

D22

R€connect

tho

battery

ground

lead

D23

Check the coolant level

and top-up if necessary

D2l

Group

87 Standard

untt

Heat exchanger

and/or

fan motoL

rcplacement

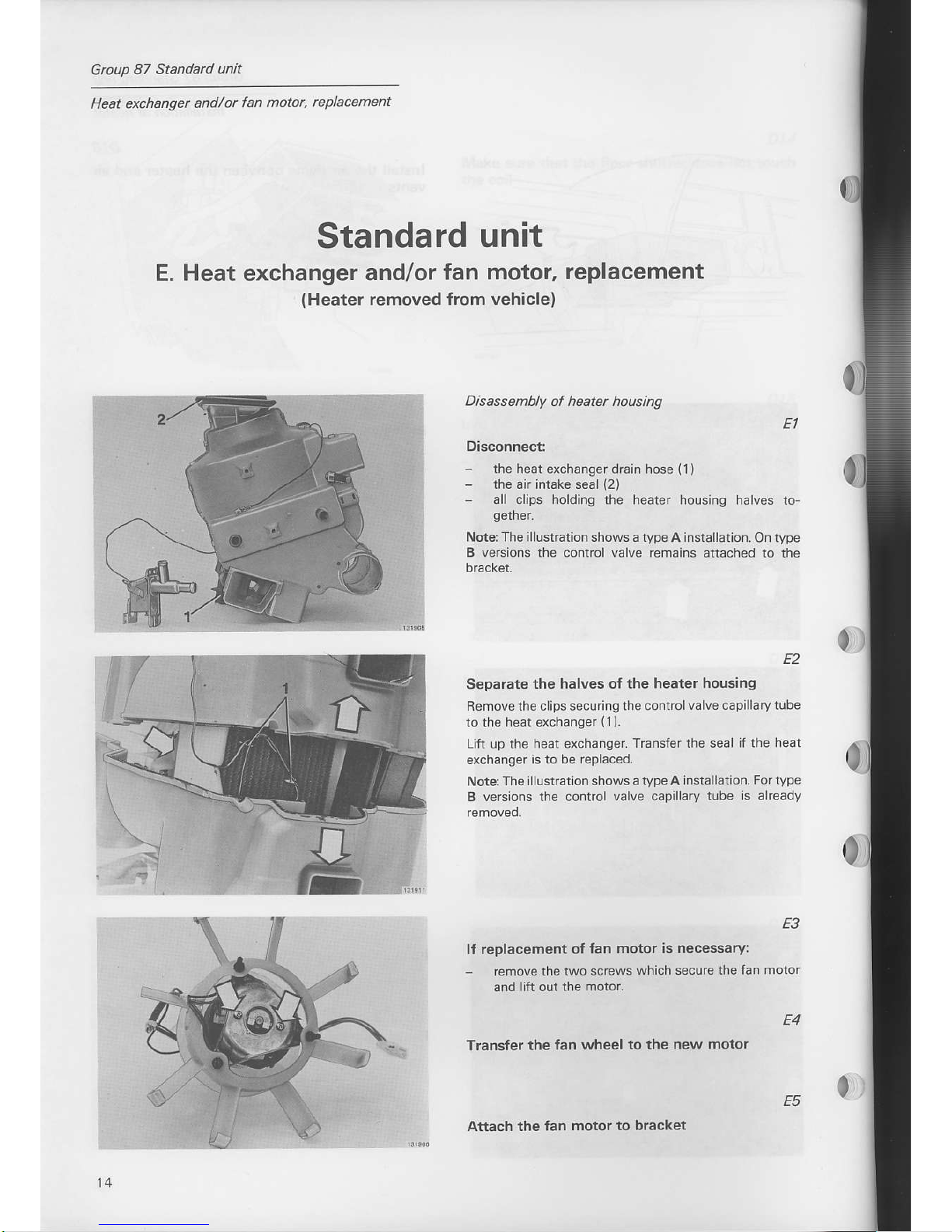

Disassembly of heatet housing

Disconnect:

-

the heat exchanger drain hose

-

the air intake seal

(2)

-

all cips

holding

the heater

(t)

housing halves to

Note The

i llstration

shows a type A nsta latlon.

On type

B versions the control valve remains

attached to the

replacement of

fan motor

is necessary:

remove the

two screws which

secure the fan

motor

and

lift out the

motor.

Separate

the halves of the

heater housing

Removethe

clips securing the controlvalve

capilary tube

to the

heal exchanger

(1).

Lrft up the heat exchanger.

Transfer the seal

if

the

hest

exchanger

is to be replaced.

Note:The

illustraton shows a

type A instalat on.

For

type

B

versons the controi valve caplary

tlbe is already

ff

Transter the

{an wheel to the

new motor

14

Standard

unit

E. Heat exchanger

and/or fan

lHeater removed

from

motor, replacement

vehicle)

Attach the fan

motor to bracket

E4

Gtoup

87 Standatd unit

Heat exchanger and/or

fan motor, rcplacement

Assembly of heatet housing

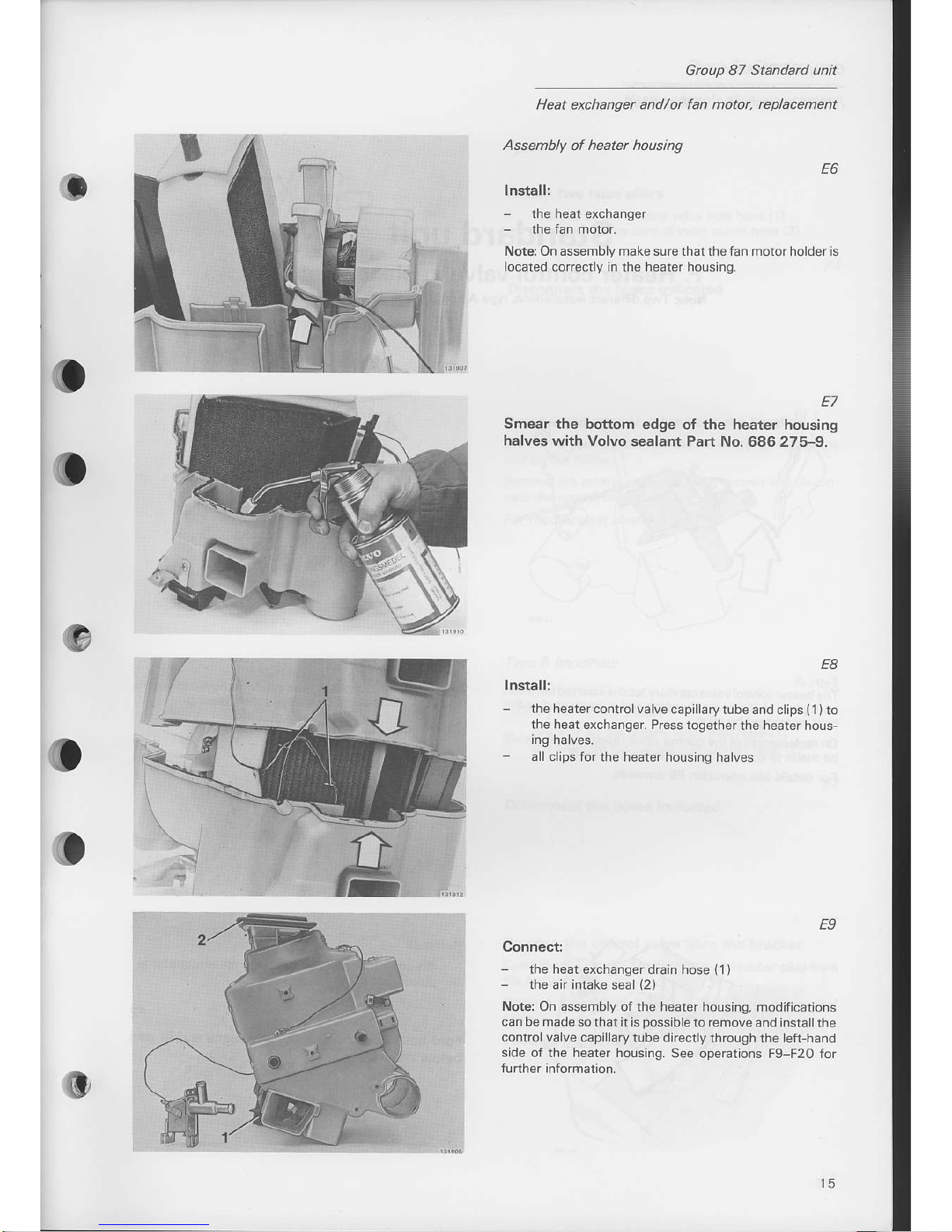

E6

lnstall:

-

the heat exchanger

Nota On assembly makesure thaithefan motorhold€ris

ocated corectly in

the

heater hor.rsing

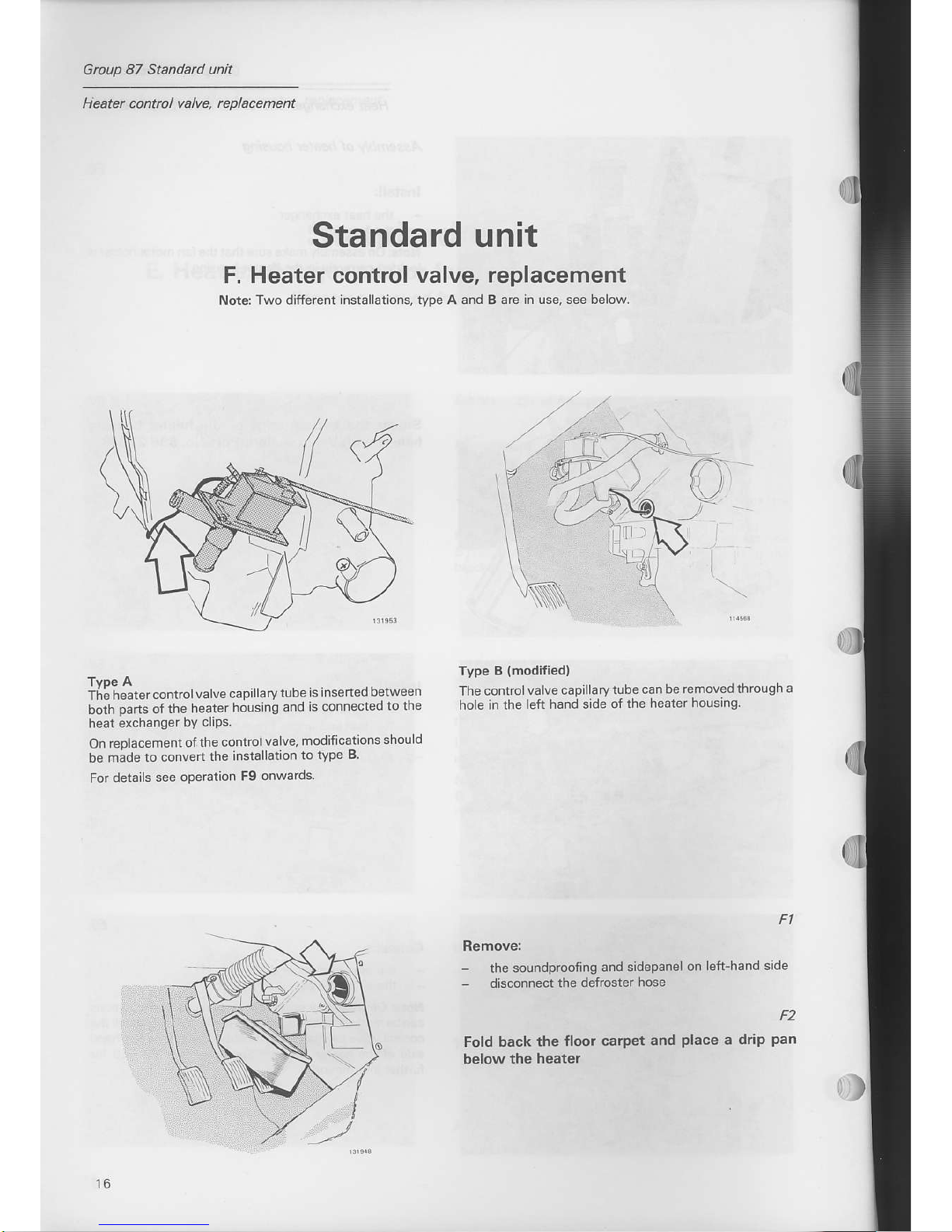

Smear

the bottom edge

halves

with Volvo sealant

E7

oI

the heater

housing

Pan

No. 686 275-9.

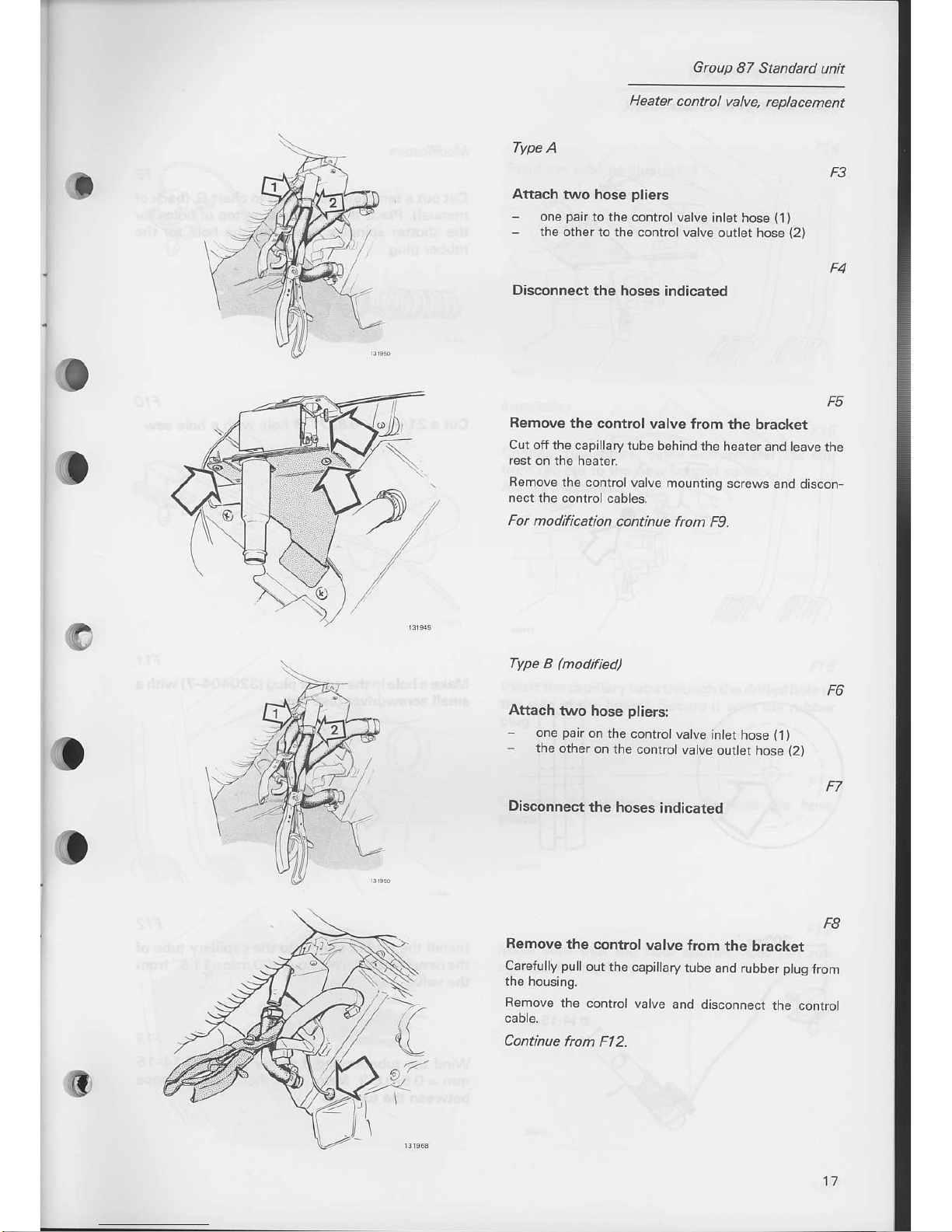

E8

Install:

-

the heater control

valve cap llaryrubeand

clips

(1)to

ihe heat

exchanger. Press iogether

the heater ho!s

ing halves.

3ll c ips forthe

heater housing halves

E9

Connectl

the heat exchanger drain hose

(1)

the

air intake seal

(2)

Noter

On assembly of the he.ter housing,

modifications

can be made so that it is

possib

e to

remove

and inst.llthe

controlva ve capillarytube directly

through the left-hand

side of lhe heater housing.

See operations F9-F20 ior

0,

l5

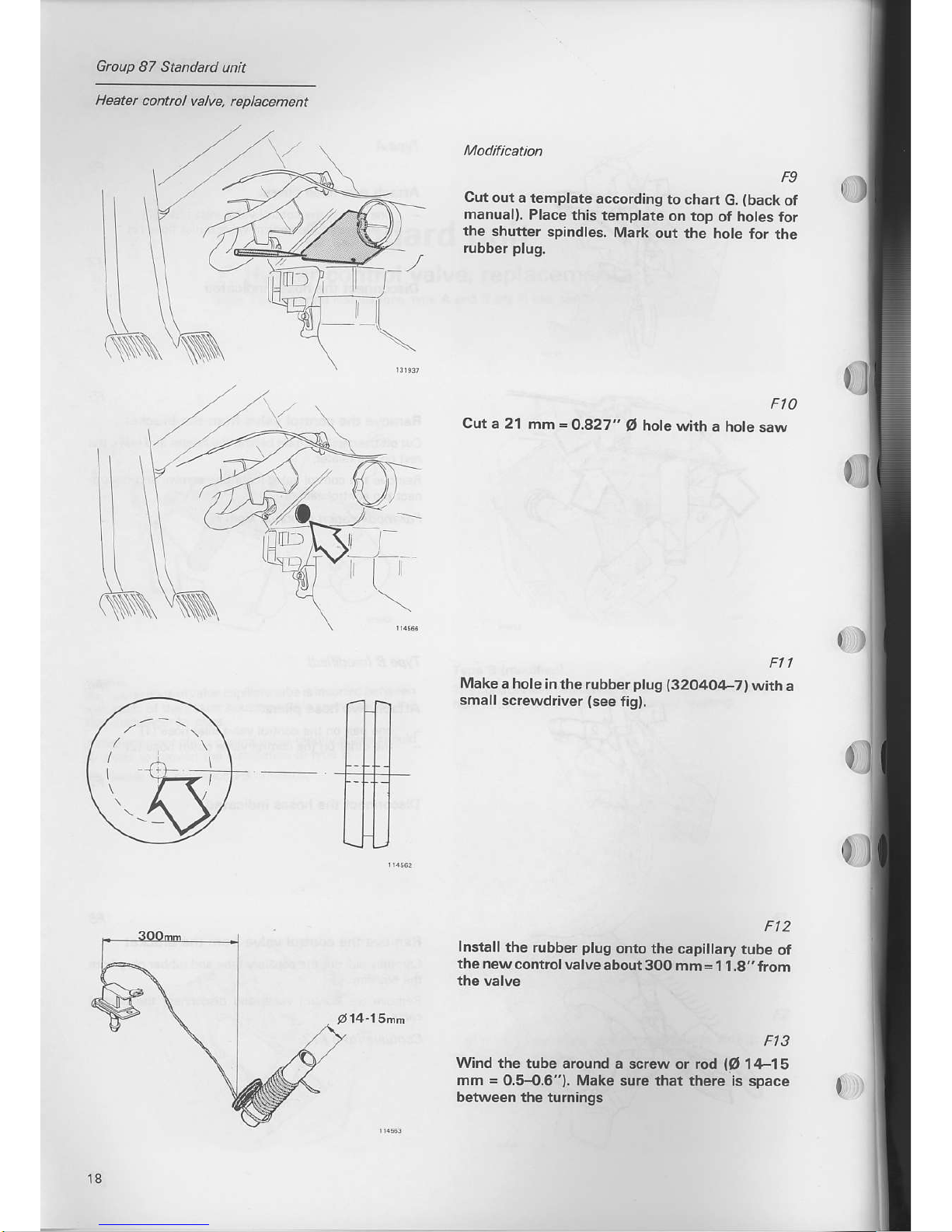

Group 87

Standad unit

heater contrcl valve. replacement

Standard

unit

F. Heater control valve,

Notq Two different instalations.

tvDe A and

replacement

B are in use, see below.

The heare'

con trol

va lve capillarvlube

is nserlpd

betweFn

both

parts

of the

heater

housing

and

is connected

to the

heat exchanger

by clrps.

On replacement

ofthe

controlvalve,

modifications

shou ld

be made to convert

the

installation

to tvpe

B

For

details see

operation

F9 onwards

Type

B

{modified}

Thecontrolvalve

capillarytube

can

be removed thlough

a

ho e in the

left hand side

of the

he.ter housing

Remove:

-

the soundproofing

and sidepanel

on

left-hand side

-

disconnect

the defroster

hose

F2

Fold back

the floor carpet

and

place

a drip

pan

below

the healer

Type

A

Attach two hose

pliers

-

one

pair

to the control valve

inlet hose

(1)

-

the orher to rhe controlvalve

ouder hose

(2)

Disconnect

the hoses

indicated

F5

Remove

the control valve

Jrom the bracket

Cut off the

capillary tube behind

the heaterand teave

the

Remove

the control

valve mounring

screws and

discon

nect the

control cables.

Fot modiflcation

continue

frcm K).

Type

B

(modif

ied)

Attach

two hose

pliers:

-

one

pair

on

the controtvalve

jntet

hose

(1/

-

the

other on

rhe controtvatve

outtet

hose

(2)

Disconnect

the hoses

indicated

Group

87 Standard

unit

Heater control

vafue,

rcplacement

F8

Remove

the control

valve

trom

the bracket

Carefully

pulloutthe

capillary

tube and

rubber

plug

from

Remove

the

control valve

and disconnect

the

control

Continue

from

Fl2.

Group

87 Standard unit

Heater

contrcl valve.

rcplacement

F9

Cut out

a template

according

to chan

G.

(back

of

manuall.

Place this

template

on top

o{ holes for

the

shutter spindles.

Mark

out the

hole {or

the

rubber

plug.

Fto

Cut a

21 mm

=

0.827"

O

hote

with a hote

saw

Make

a hole

inthe rubber

plug

{32040,1-7)wirh

a

small screwdriver

(see

tig).

Ft2

Install

the

rubber

plug

onto the

capillary tube

of

the new

controlvalve

abour300

mm=1 1.8,,

from

the valve

Ft3

Wind the lube

a.ound a screw or rod

lO

14-15

mm

=

0.5-O.6r'). Make surc that

there is space

beNveen the turnings

l8

14-15hn

Group 87

Standad

unit

Heater

contrcl valvq

replacement

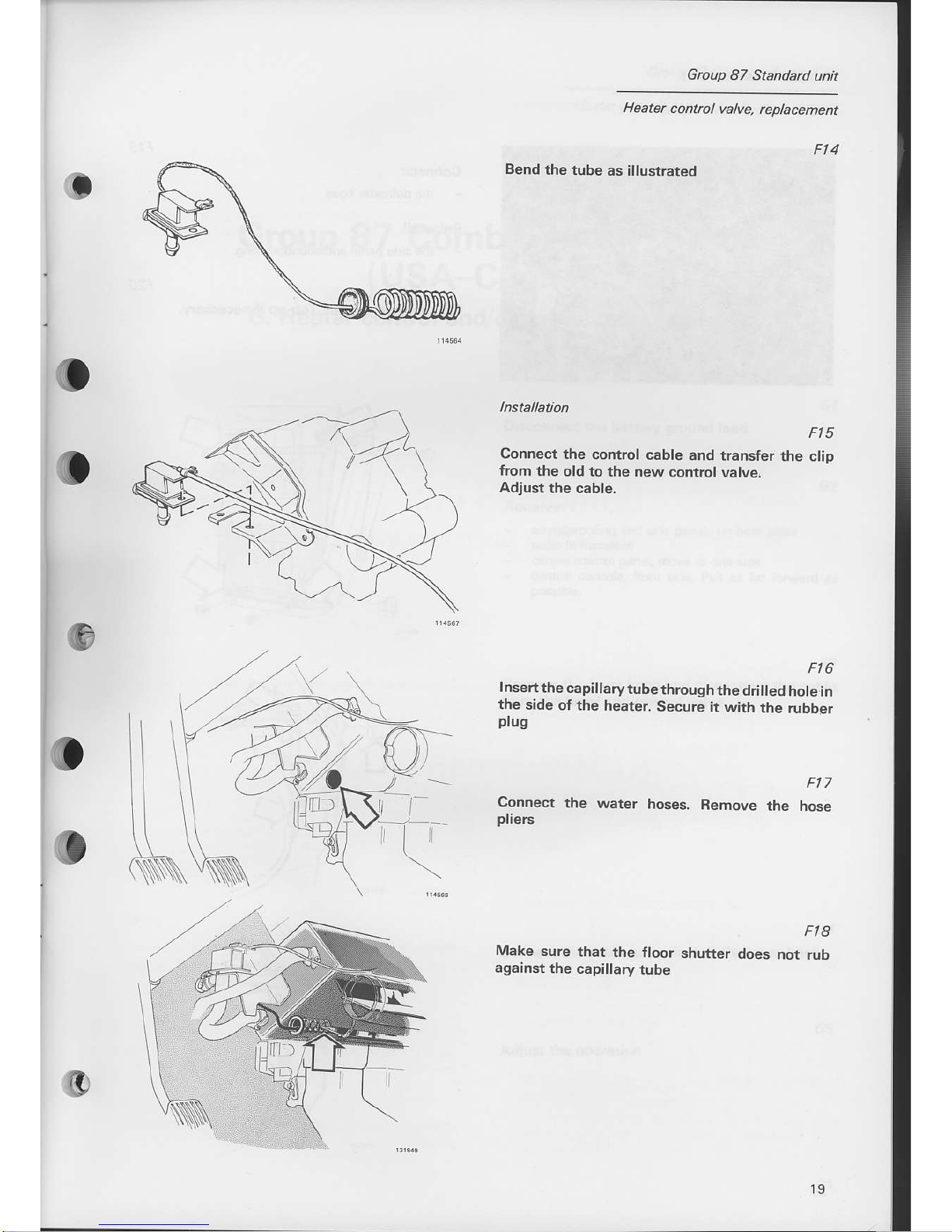

Bend

the tube

as illustrated

Ft5

Connect

the control

cable and

transter the

clip

lrom the

old to the

new control

valve.

Adiust

the cable.

Ft6

Insertthe

capillarytubethrough

the drilled

hole in

the

side

oI the heater.

Secure

it with

the rubber

ptug

Connect

the

water

hoses.

Bemove

the nose

pliers

o

G

Make

sure

that the

floor

against

the

capillary

tube

Fta

shufter

does not

rub

o

-l-

I

i

Group 87 Standad unit

Heater

control vafue. replacement

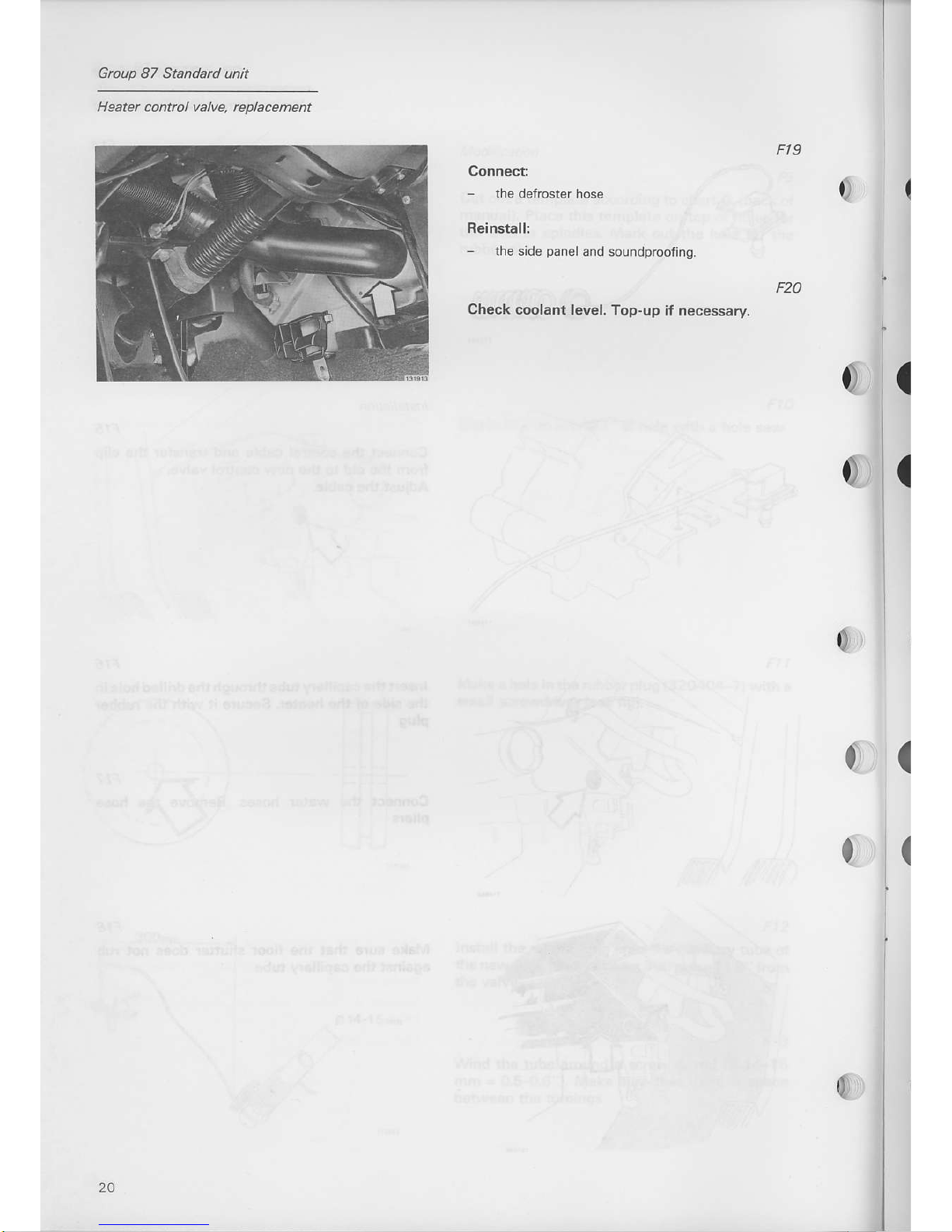

Ft9

Connect:

-

the defroster

hose

Reinstall:

-

the side

paneland

soundproofing.

Check coolant level,

Top-up if necessary.

(

0,

0)

{

l

Loading...

Loading...