Voltronic Power +Power 30U-90, +Power 42U-120, +Power 42U-200, +Power 42U-210, +Power 30U-120 User Manual

...

Modular Online UPS

Uninterruptible Power Supply System

Version: 1.2

User Manual

Table Of Contents

1. Safety ............................................................................................................................... 1

1.1 Important Safety Instructions ..................................................................................... 1

1.2 EMC .......................................................................................................................... 1

1.3 Installation information .............................................................................................. 1

1.4 Maintenance ............................................................................................................. 2

1.5 Recycling the used battery ......................................................................................... 2

2 Operation & structure .......................................................................................................... 3

3. Installation .................................................................................................................... 4

3.1 Mechanism and Exterior ......................................................................................... 4

3.1.1 Mechanical Data ............................................................................................ 5

3.1.2 Other Views .................................................................................................. 6

3.2 Internal Mechanisms ............................................................................................ 8

3.2.1 Input and Output Breakers ............................................................................. 8

3.2.2 Wiring Terminal Block .................................................................................... 9

3.2.3 Modules ...................................................................................................... 10

3.3 Control Panel & interface .................................................................................... 11

3.3.1 LED indications ............................................................................................ 11

3.3.2 LCD Display ................................................................................................. 11

3.3.3 Function Keys .............................................................................................. 12

3.4 Installation and Wiring ......................................................................................... 12

3.4.1 Before Installation ....................................................................................... 12

3.4.2 Installation Environment .............................................................................. 12

3.4.3 Transportation ............................................................................................. 13

3.4.4 Unpacking ................................................................................................... 14

3.4.5 Positioning .................................................................................................. 15

3.5 Modules ............................................................................................................ 15

3.5.1 Power Module .............................................................................................. 15

3.5.2 Install a Power Module ................................................................................. 16

3.5.3 Remove a Power Module .............................................................................. 17

3.5.4 STS Module ................................................................................................. 17

3.5.5 Remove the STS Module .............................................................................. 18

3.5.6 Install Battery .............................................................................................. 18

3.6 Power Cable ...................................................................................................... 19

3.6.1 AC input and output maximum current and power cable configuration. ........... 20

3.6.2 DC input maximum current and power cable configuration. ............................ 20

4. Control Panel and Display Description ............................................................................... 21

4.1 Introduction ............................................................................................................ 21

4.2 Screen Description ................................................................................................... 23

4.2.1 Start Screen .................................................................................................. 23

4.2.2 Main Screen ................................................................................................... 23

4.2.3 Menu Screen ................................................................................................. 24

4.2.4 Control Screen ............................................................................................... 24

4.2.5 Measurement Screen ...................................................................................... 25

4.2.6 Setup Screen ................................................................................................. 27

4.2.7 Information Screen ........................................................................................ 37

4.2.8 Events Screen ................................................................................................ 38

4.3 Alarm List ............................................................................................................... 41

5. Interface and Communication ........................................................................................... 44

5.1 Remote EPO Input Port ............................................................................................ 44

5.2 BCB Port ................................................................................................................. 45

5.3 Maintenance Bypass Switch State Port ...................................................................... 45

5.4 Internal Output Switch State Port ............................................................................. 46

5.5 Battery Cabinet Temperature Detection Port .............................................................. 46

5.6 Bypass back feed Control Port .................................................................................. 47

5.7 Battery breaker Control Port ..................................................................................... 47

5.8 Other Communication Interface ................................................................................ 48

6. Service ......................................................................................................................... 49

6.1

Replacement Procedures Of Power Module, STS & Control Module And Battery Module 49

6.1.1 Notes ........................................................................................................ 49

6.1.2 Power Module Replacement Procedures ....................................................... 49

6.1.3 STS & Control Module Service Procedures.................................................... 50

6.1.4 Battery Module replacement Procedures ...................................................... 50

6.2 Replacement Procedures Of Air Filter ......................................................................... 51

7. Specifications ................................................................................................................ 52

7.1 Conformity And Standards ........................................................................................ 52

7.2 Environmental Characteristics ................................................................................... 52

7.3 Mechanical Characteristics ........................................................................................ 53

7.4 Electrical Characteristics (Input Rectifier) ................................................................ 53

7.5 Electrical Characteristics (Intermediate DC Circuit) ..................................................... 54

7.6 Electrical Characteristics (Inverter Output) ................................................................. 54

7.7 Electrical Characteristics (Bypass Mains Input) ........................................................... 55

1

1. Safety

1.1 Important Safety Instructions

This UPS contains LETHAL VOLTAGES. All repairs and service must be performed by AUTHORIZED

SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS inside the UPS.

WARNING:

The UPS designed for commercial and industrial purpose, it is forbidden to apply for any life

sustainment and support.

The UPS system contains its own energy source. The output terminals may carry live voltage

even when UPS is disconnected from an AC source.

To reduce the risk of fire or electrical shock, UPS installation has to be in a temperature and

humidity controlled, indoor environment. Ambient temperature must not exceed 40°C. The

system is not intended for outdoor use.

Ensure all power is disconnected before performing installation or service.

Service and maintenance should be performed by qualified service personnel only.

1.2 EMC

WARNING:

This is a product for commercial and industrial application in the second environment - installation

restrictions or additional measures may be needed to prevent disturbances.

1.3 Installation information

WARNING:

Installation must be performed by qualified personnel only.

The cabinets must be installed on a level floor suitable for computer or electronic equipment.

The UPS cabinet is heavy. If unloading instructions are not closely followed, cabinet may

cause serious injury.

Do not tilt the cabinets more than 10∘.

Ground conductor is properly installed.

Installation and Wiring must be performed in accordance with the local electrical laws and

regulations.

The disconnection device should break line and neutral conductors- four poles for three

phases.

Before working on this circuit

- Isolate Uninterruptible Power System (UPS)

- Then check for Hazardous Voltage between all terminals including

the protective earth.

Risk of Voltage Backfeed

The isolation device must be able to carry the UPS input current.

2

1.4 Maintenance

UPS is designed to supply power even when disconnected from the utility power. After

disconnect the utility and DC power, authorized service personnel should attempt internal

access to the UPS.

Only qualified service personnel should perform the battery installation.

Do not disconnect the batteries while the UPS is in Battery mode.

Disconnect the charging source prior to connecting or disconnecting terminals.

Batteries can present a risk of electrical shock or burn from high short circuit current.

The following PRECAUTIONS should be observed

1. Remove watches, rings, or other metal objects.

2. Use tools with insulated handles.

3. Wear rubber gloves and boots.

4. Do not lay tools or metal parts on top of batteries or battery cabinets.

5. Disconnect the charging source prior to connecting or disconnecting terminal.

6. Determine if the battery is inadvertently grounded. If it is, remove the source of the

ground. Contact with any part of a grounded battery can result in electrical shock. The

likelihood of such shock is reduced if such grounds are removed during installation and

maintenance.

When replacing batteries, use the same number of sealed, lead-acid batteries.

Do not dispose of battery in a fire. The battery may explode.

Do not open or mutilate the battery. Release electrolyte is harmful to the skin and eyes, and

may be toxic.

1.5 Recycling the used battery

Do not dispose of the battery in a fire. Battery may explode. Proper disposal of battery is

required. Refer to your local codes for disposal requirements.

Do not open or mutilate the battery. Released electrolyte is harmful to the skin and eyes. It

may be toxic.

Do not discard the UPS or the UPS batteries in the trash. This product contains sealed,

lead-acid batteries and must be disposed of properly. For more information, contact your local

recycling/reuse or hazardous waste center.

Do not discard waste electrical or electronic equipment (WEEE) in the trash. For proper

disposal, contact your local recycling/reuse or hazardous waste center.

3

2 Operation & structure

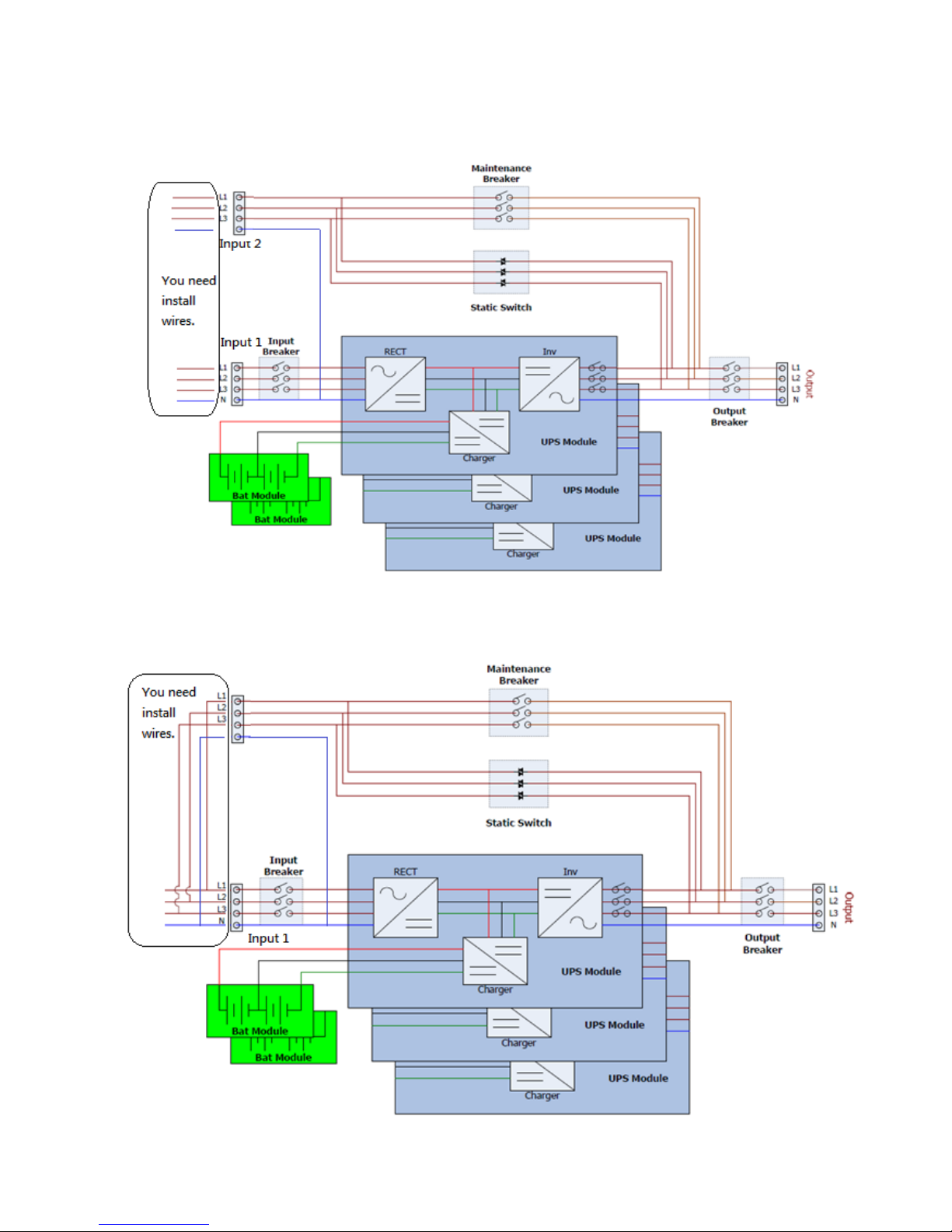

Figure 2-1: Wiring diagram for dual inputs

Figure 2-2: Wiring diagram for single input

4

3. Installation

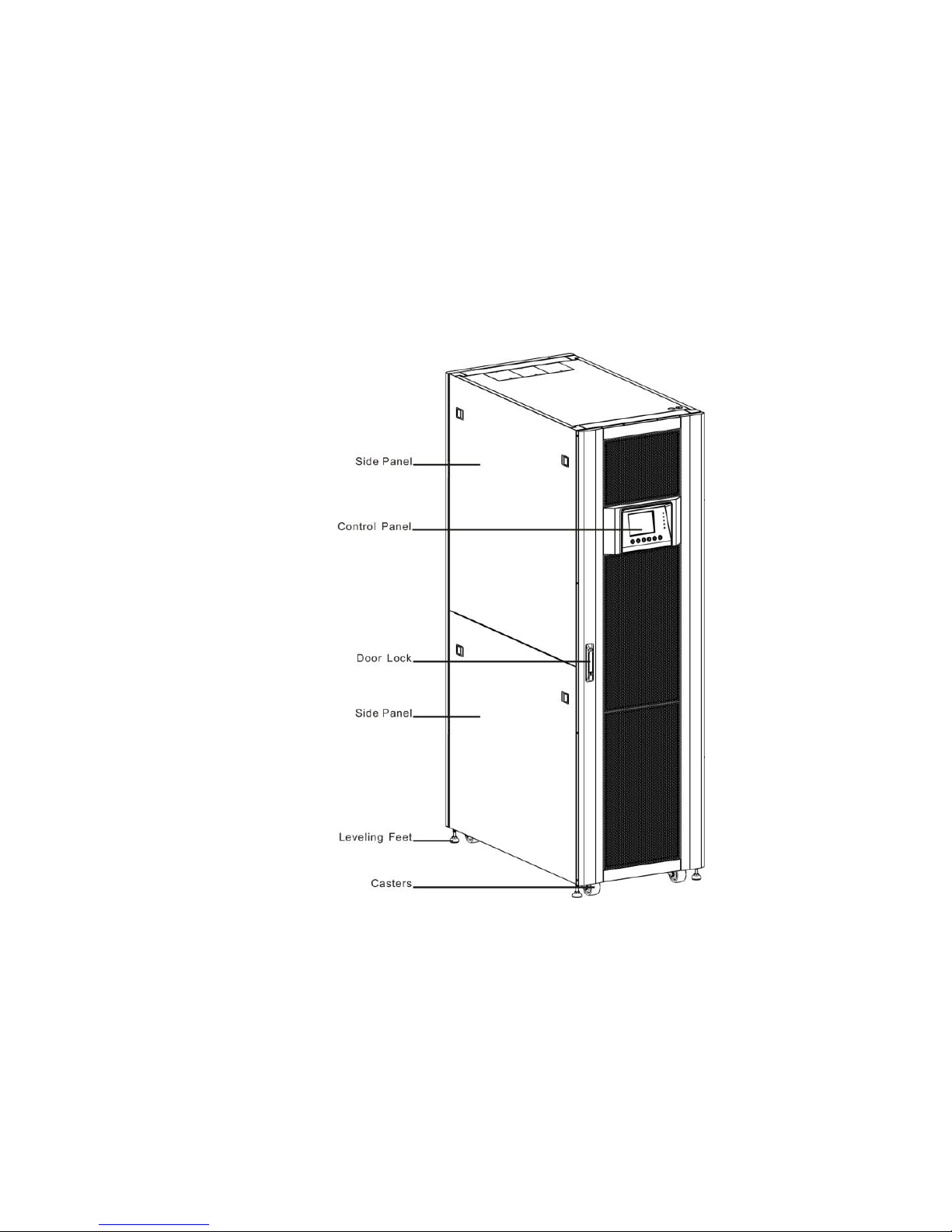

3.1 Mechanism and Exterior

In the front of the UPS, there are control interface (LCD Panel) and door lock. Inside the cabinet,

there are an STS Module, 1~8 Power Module slots and Battery modules.

All wiring terminal blocks are allocated in the back of system. The side panels are lockable. The

casters at the bottom of the UPS cabinet can be used to move over short distances. There are four

leveling feet to fix and stabilize the UPS cabinet on the ground.

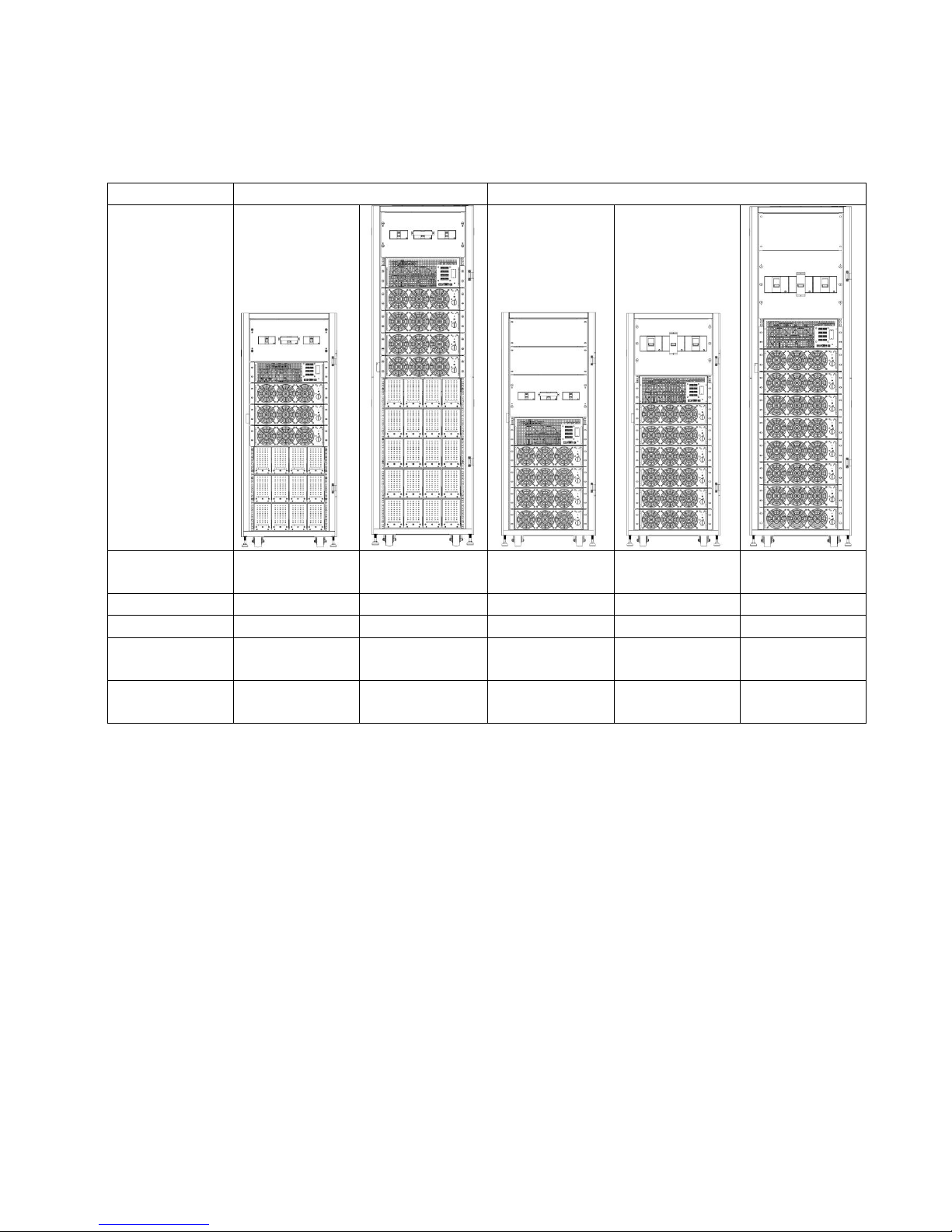

Figure 3-1:UPS Exterior

5

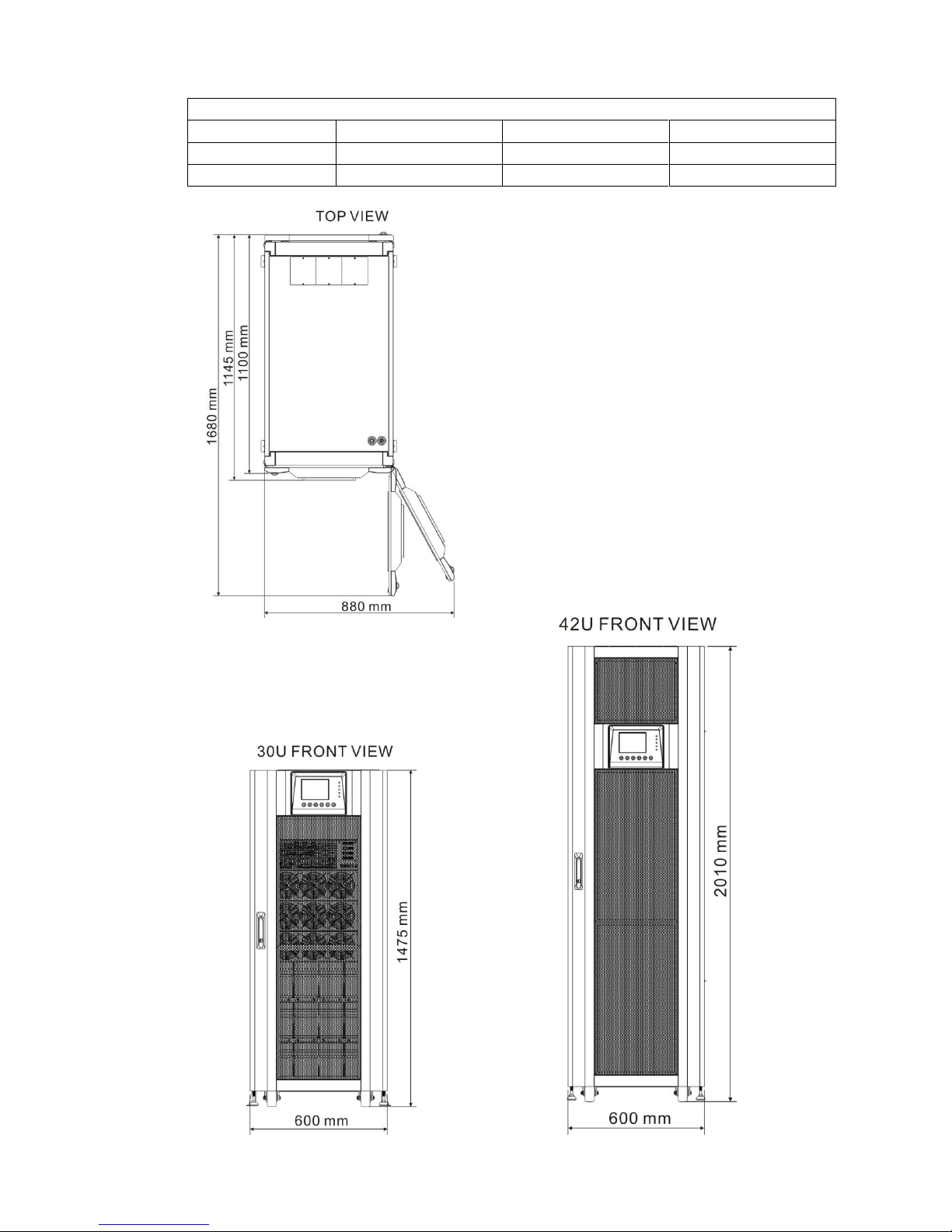

3.1.1 Mechanical Data

Dimensions

UPS cabinet

Width

Depth

Height

30~90Kw(30U)

600mm

1100m

1475mm

30~210Kw(42U)

600mm

1100m

2010mm

Figure 3-2: Dimensions

6

3.1.2 Other Views

‧Front View : Unlock and open the front door to see STS Module, Switch unit, Power Module and

Battery Module.

‧Rear View : Unlock and open the rear door to see Battery Breaker.

(Rear View) (Front View)

1. Switch unit

2. Bypass module

3. Power module

4. Battery module

5. Battery breaker

Figure 3-3: Front and Rear View

7

Configurations:

There are two basic configurations for different applications.

It’s required to have battery module for Standard Series.

Please consider the external battery space and wiring gauge for Extended Series.

Standard Series

Extended Series

Photo

Cabinet

Height

30U

42U

30U

30U

42U

Switch Unit

1 1 1 1 1

STS 1 1 1 1

1

Max. Power

Module

3 4 4 6 8

Battery

Module

12

20

N/A

N/A

N/A

8

3.2 Internal Mechanisms

After opening the front door, you can see the Switch unit, Bypass module, Power module and

Battery module. After opening the back door, you can see the Battery Breaker and input/ output

wiring terminal block. Please refer to the following sections.

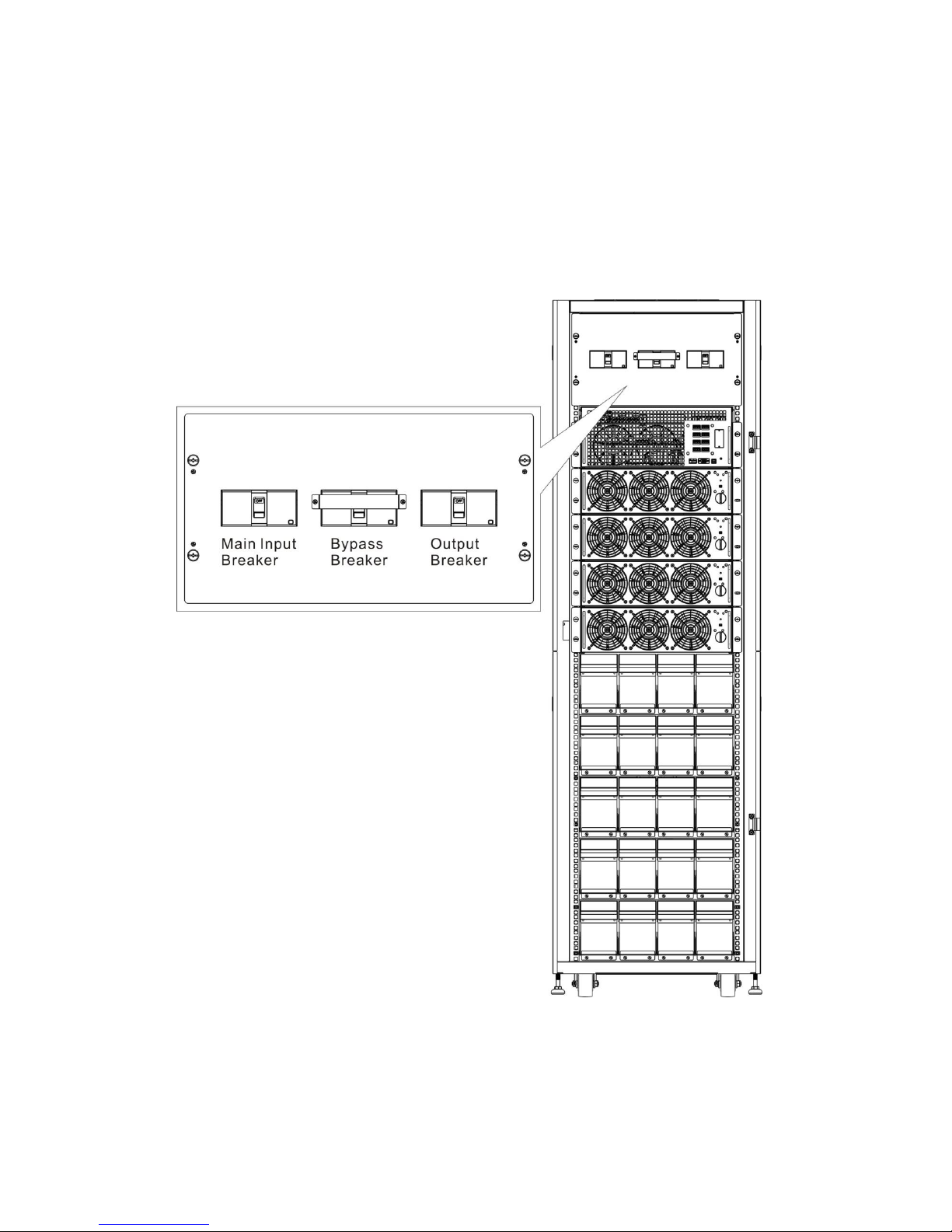

3.2.1 Input and Output Breakers

Open front and back door. The Input Breaker, Bypass Breaker and Output Breaker are located on

the front of the UPS. The Battery Breaker and input/ output wiring terminal block are at the back of

the UPS. See Figure 3-4.

Figure 3-4: Front View/Output, Bypass, and Main Input Breakers

9

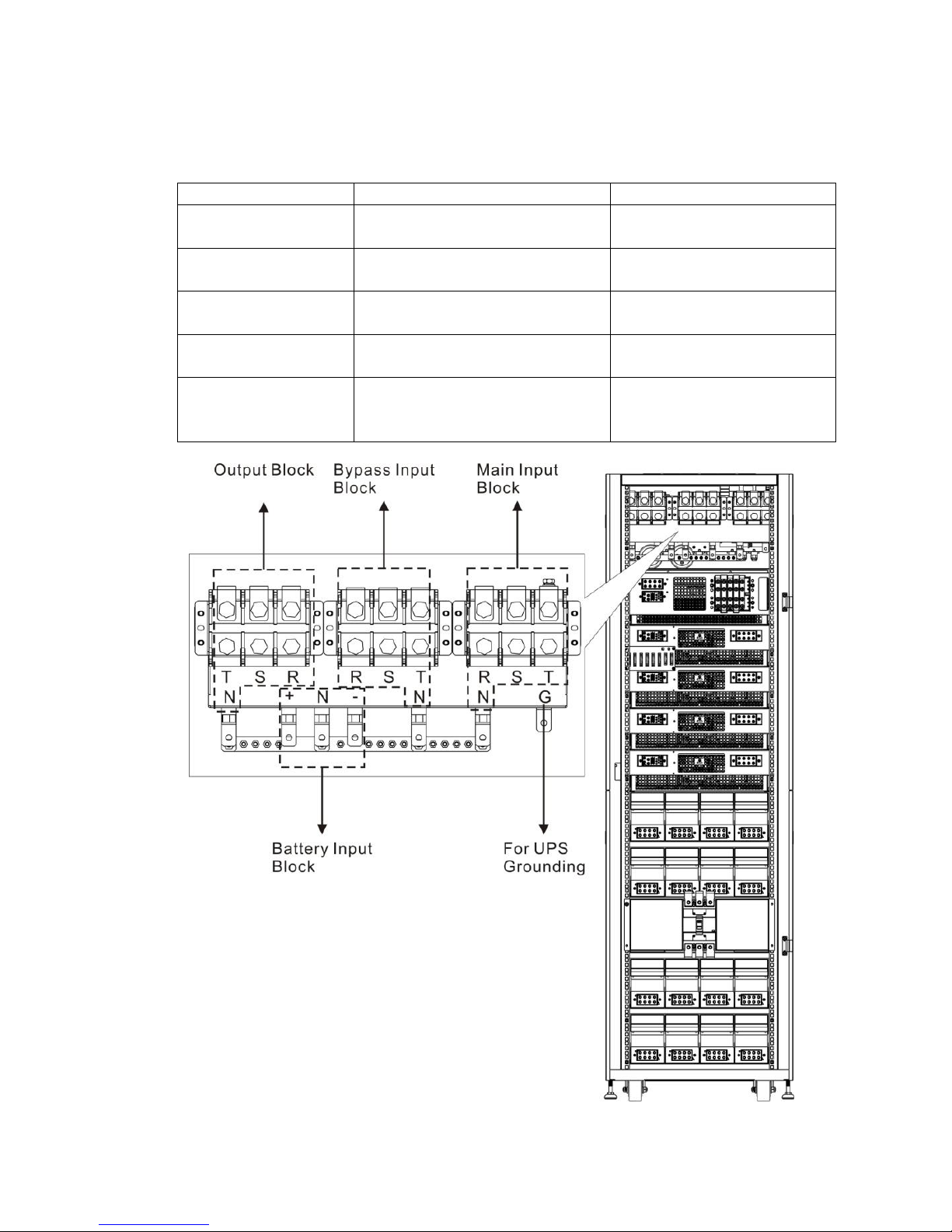

3.2.2 Wiring Terminal Block

Open the UPS’s back doors and you will see the wiring terminal block. For connection instructions,

please refer to Figure 3-5.

Item

Function

Description

Output Block

Connects the critical loads

Includes R, S, T and

Neutral terminals.

Bypass Input Block

Connects bypass AC source

Includes R, S, T and

Neutral terminals.

Main Input Block

Connects main AC source

Includes R, S, T and

Neutral terminals.

For UPS Grounding

For UPS grounding

Includes one grounding

terminal.

Battery Input Block

Connects an external battery

cabinet

Includes

Positive (+), Negative (-)

and Neutral (N) terminals.

Figure 3-5: Rear View & Wiring Terminal Block

10

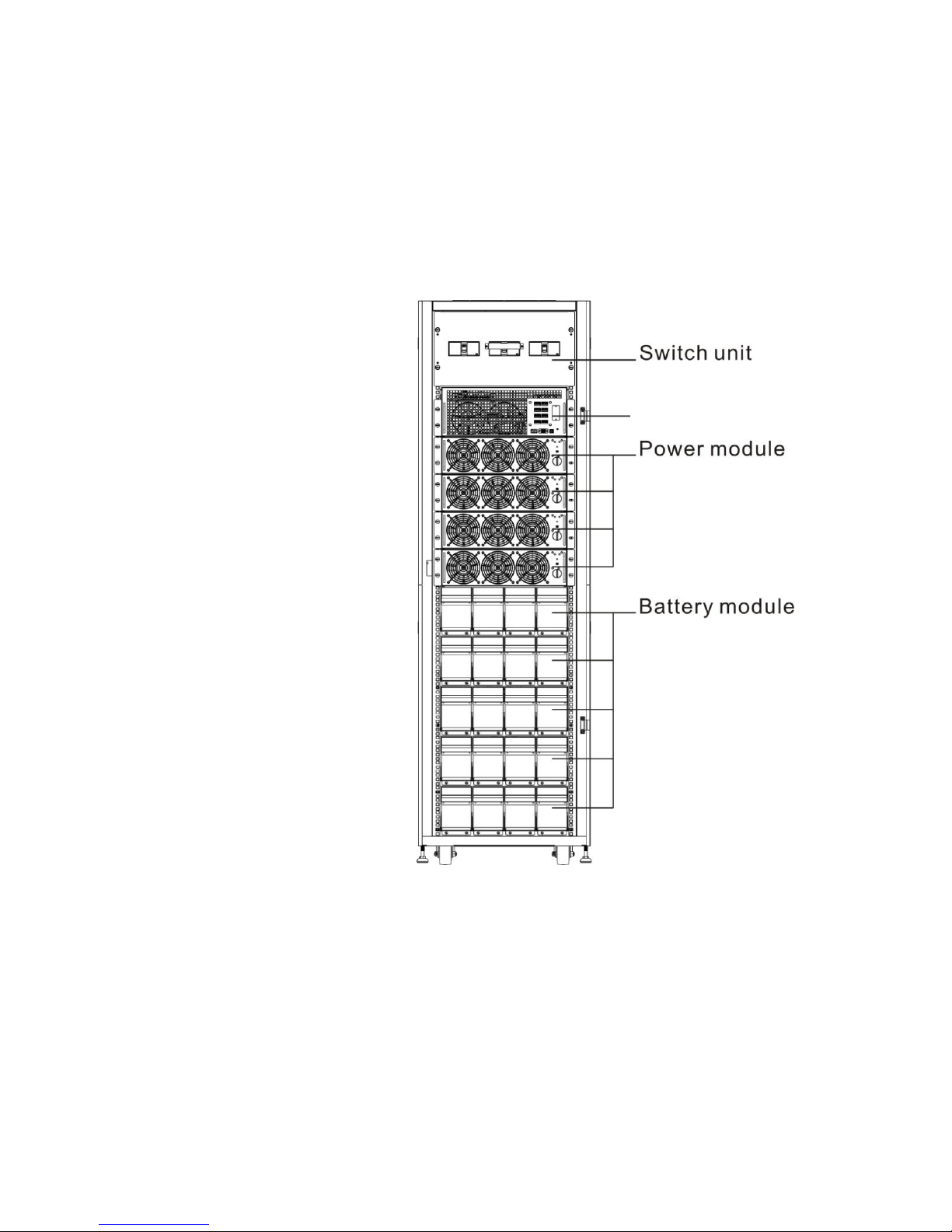

3.2.3 Modules

The STS & Control module and Power Module allow quick maintenance, replacement and

expansion. The module latches secure the modules in place.

‧STS & Control Module: It includes control, power, communication circuits, an internal Static

Transfer Switch and a fuse.

‧Power Module: Each power module capacity is 30kVA/ 30kW. It includes a power factor

correction rectifier, a battery charger, an inverter and control circuits.

‧Battery Module: It contains 4 sets of 10 pieces 12V/9Ah batteries inside of one battery

compartment.

Figure 3-6: Front View with Modules

STS & control module

11

3.3 Control Panel & interface

The front access Graphic Display & Control interface brings all measured parameter, UPS & Battery

current states and Alarms. Through the interface, users can easily monitor status and configure

settings. For detailed information, please refer to the charter 4.

Figure 3-7: Control Panel

3.3.1 LED indications

LED

Color

Status

Definition

INPUT

Green

On

Input source is normal.

Flashing

Input source is abnormal.

Off

No input source

BYPASS

Green

On

Load on Bypass.

Flashing

Input source is abnormal.

Off

Bypass not operating.

INVERTER

Green

On

Load on inverters.

Off

Inverters not operating.

BATTERY

Yellow

On

Load on Battery.

Flashing

Low battery

Off

Battery converter is normal and battery is charging.

ALARM

Red

On

UPS fault.

Flashing

UPS alarm.

Off

Normal.

3.3.2 LCD Display

Graphic display and all measured parameters.

12

3.3.3 Function Keys

Control Key

Description

Esc

Return to previous screen or cursor displacement. When screen is in

Main screen, it will enter setting menu by pressing ESC key.

Up(Left)

Key for menu page navigation or digit modification.

Down(Right)

Key for menu page navigation or digit modification.

Enter

Confirmation of commands, or cursor displacement.

Home

Return to Main screen.

Power

On/Off

Turn on UPS or Turn off UPS.

3.4 Installation and Wiring

3.4.1 Before Installation

Due to different installation environments, please read this user manual thoroughly before

installation and wiring. Only authorized engineers or service personnel can perform installation and

maintenance. If you want to install the UPS by yourself, installation must be under the supervision

of authorized engineers or service personnel.

If you use a forklift or other equipment to move the UPS, please make sure its load bearing is

sufficient.

3.4.2 Installation Environment

The UPS is designed for indoor use only. Do not install or place it in an outdoor area.

Make sure that transportation routes (e.g. corridor, door gate, elevator, etc) and installation

area can accommodate and bear the weight of the UPS, the external battery cabinet and

handling equipment.

Ensure that the installation area is big enough for maintenance and ventilation.

Keep the installation area’s temperature around 30°C and humidity within 90%. The highest

operating altitude is 2000 meters above sea level.

The UPS is intended for indoor installation and should be located in an environment with clean

air and with adequate ventilation to keep the ambient temperature within the specified

operating range. The UPS is air-cooled with the aid of internal fans. Cold air enters the UPS

through.

If necessary, install a system of room extractor fans to avoid room temperature build-up. Air

filters are necessary if the UPS is operated in a dusty environment.

Note: The UPS is suitable for mounting on concrete or other non-combustible surface only.

The UPS is air-cooled with the aid of internal fans. Cold air enters the UPS through the

ventilation grilles at the front of the cabinet and hot air is released through the grilles at the

back. Do not cover the ventilation openings.

Do not allow unauthorized personnel to enter the installation area. Assign specific personnel to

keep the UPS key.

13

For safety concerns, we suggest that you shall:

1. Surroundings of the installation area with CO2 or dry powder fire extinguishers.

2. Install the UPS in an area where the walls, floors and ceilings were constructed by fireproof

materials.

It is recommended that you parallel the external battery cabinets to the UPS. The following

clearances are suggested:

1. Keep a clearance of 100cm from the top of the UPS for maintenance, wiring and ventilation.

2. Keep a clearance of 100cm from the back of the UPS and the external battery cabinets for

ventilation.

3. Keep a clearance of a 150cm from the front of the UPS and the external battery cabinets for

maintenance and ventilation.

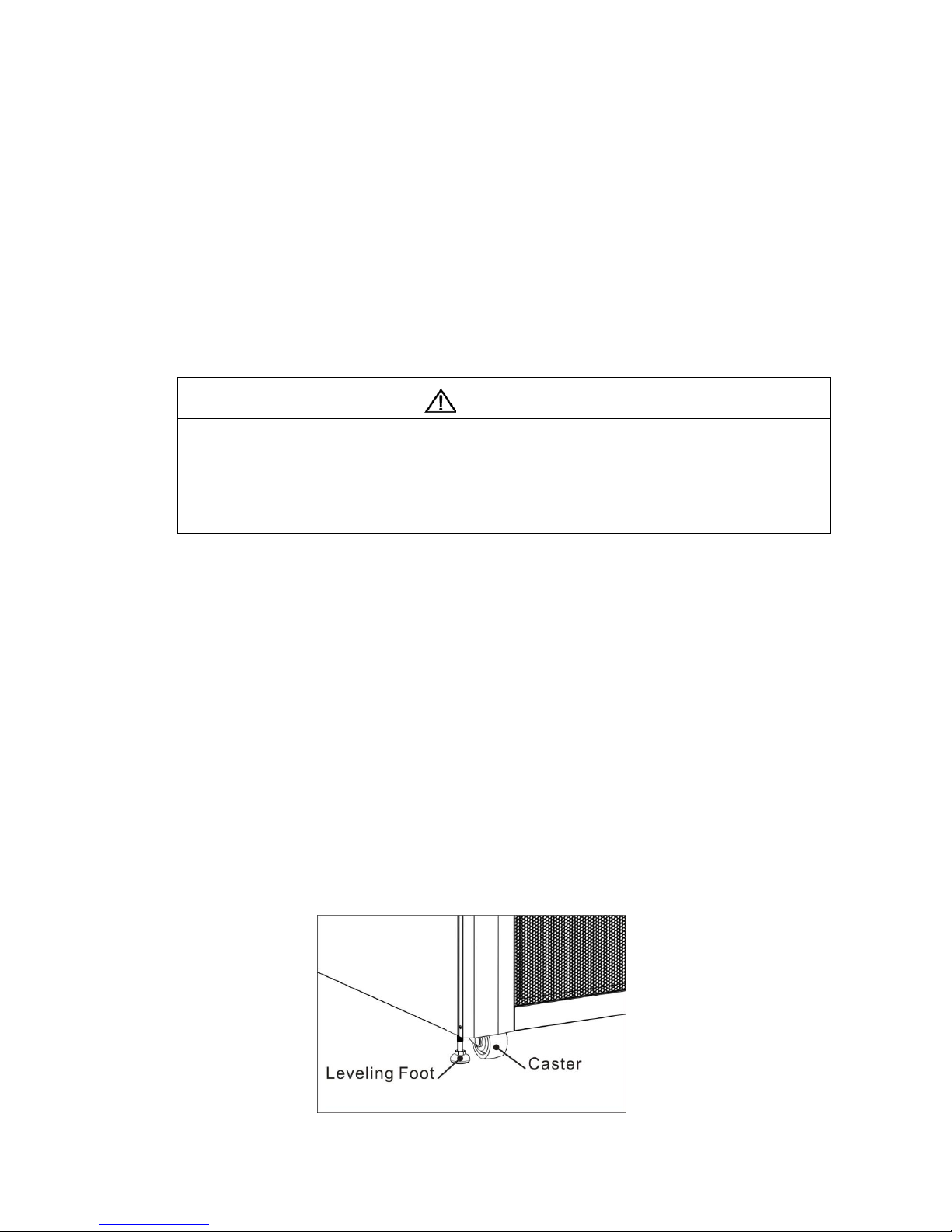

3.4.3 Transportation

Warning

The UPS is fixed on the pallet with four balance supports. When removing them,

pay attention to the movement of the casters to avoid accidents.

The cabinet can be pushed forward or backward only. Pushing it sideward is not

allowed. When pushing the cabinet, take care

not to overturn it as the gravity center is high.

If you need to move the UPS over a long distance, please use appropriate equipment like a

forklift. Do not use the UPS casters to move the over a long distance.

After the UPS has been removed from the pallet to ground, we suggest that at least three

people move the UPS to the installation area. One person use hands to hold a lateral side of

the UPS, one person hold the other lateral side of the UPS with hands, and one person use

hands to push the UPS either from the front side or from the backside to move the unit to the

installation area and avoid tipping the UPS.

The casters are designed to move on level ground. Do not move the UPS on an uneven

surface. This might cause damage to the casters or tip the UPS which could damage the unit.

Ensure that the UPS weight is within the designated surface weight loading of any handling

equipment.

At the bottom of the UPS, there are four casters to help you to move the UPS to a designated

area. Before you move the UPS, please turn the four leveling feet counterclockwise to raise

them off the ground. This protects the leveling feet from damage when moving the UPS.

Please use sufficient manpower(at least six people) and equipment (e.g. forklift) to carefully

move the UPS from its pallet to ground. Please pay attention to the movement of the casters to

avoid accidents.

Figure 3-8: Leveling foot and caster

14

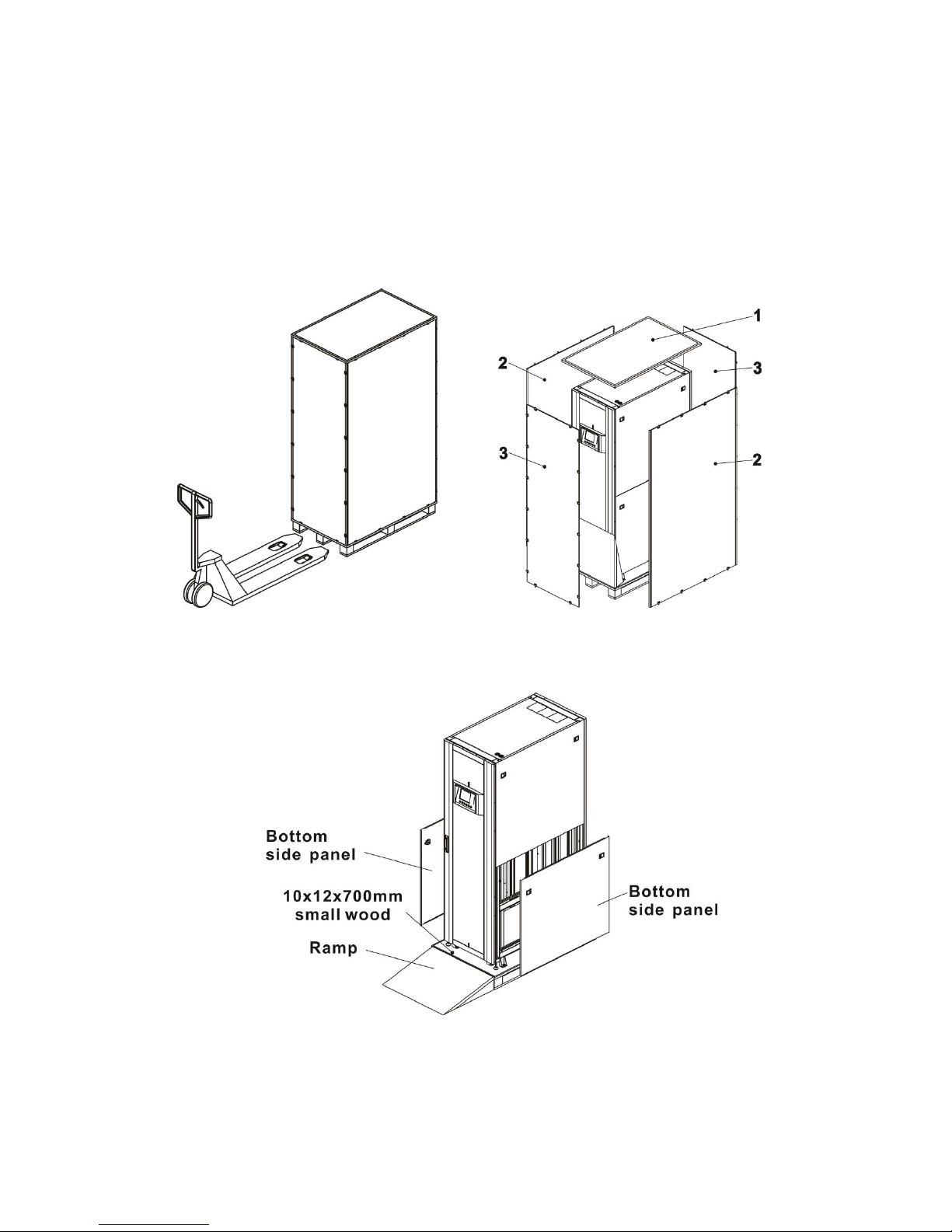

3.4.4 Unpacking

After shipping the product to the user first check the packaging to determine intact, and then

open the package, check the equipment in good condition. If damaged, please immediately

notify the carrier.

3.4.4.1 System Packaging

1. Use a forklift to move the product to installed area. Refer to Figure 3-9.

2. Please remove 5 boards in order (from 1 to 5) as shown in Figure 3-10.

Figure 3-9 Figure 3-10

3. Put a ramp in the front of the cabinet and insert small wood into groove. Then, remove two

side panels. Refer to Figure 3-11.

Figure 3-11

15

4. Remove 4 fixing cabinet plates and loosen leveling feet by rotating in counterclockwise.

Then, move the cabinet from the pallet.

5. To fix the cabinet in position, simply rotate leveling feet in clockwise.

Figure 3-12 Figure 3-13

3.4.5 Positioning

Leveling feet are provided at the bottom of the UPS cabinet to prevent the UPS from moving once

it has been placed to its final position. For optimal design life, the installed place must be:

easy connection

enough space to easily work on the UPS

sufficient air exchange to dispel heat produced by UPS

protection against atmospheric agents

protection against excessive humidity and high heat sources

protection against dust

compliance with the current fire prevention requirements

For VRLA (Valve Regulated Lead Acid) batteries the operating environment

temperature is kept between 20°C and 25°C. VRLA batteries are at maximum

efficiency in this temperature range

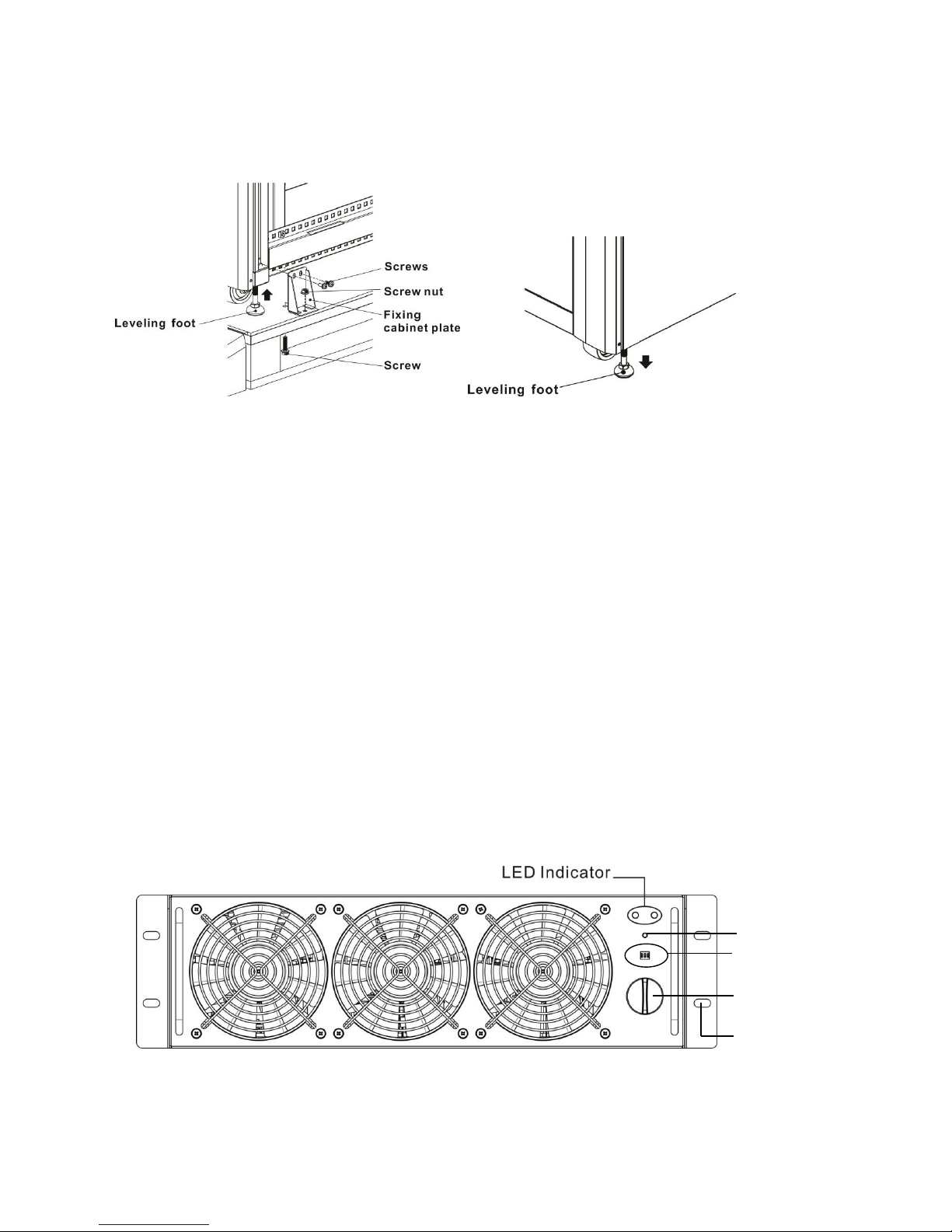

3.5 Modules

The hot-swappable Power Modules allow quick maintenance and expansion. A latch located on the

front of each module fixes and locks the module in its assigned slot. Each Power Module has an

LED indicator to show its operation status.

3.5.1 Power Module

Figure 3-14: Power module

Cold start button

DIP switch

Ready switch

Fixing hole

16

The Power Module’s LED indicator shows its operation status. Please refer to the following table:

No.

LED indicator

Description

1

FAULT

Steady red LED indicates that the system is abnormal.

2

FAULT

Flashing red LED indicates that the system is in parallel

abnormal.

3

RUN

Flashing green LED indicates normal operation of the

host UPS.

4

RUN

Steady green LED indicates normal operation of the

slave UPS.

3.5.2 Install a Power Module

Follow below procedures to install the power module.

1. Use the DIP switch on the front panel of each Power module to set the module address.

The setting range is from 1 to 3. The module address should be exclusive. The setting

method is shown in Table 3-1.

Module address

MODULE

DIP SWITCH

Parallel board

0

POWER

SW1 and SW2 DIP

Parallel board is

located at the back of

UPS cabinet. The

appearance is shown

in figure 3-15.

1

POWER

2

POWER

3

POWER

4

POWER

5

POWER

6

POWER

7

POWER

Table 3-1 DIP switch setting method

17

Figure 3-15 Parallel board

2. Place the ready switch on the front panel of the module to the “ ” position (i.e., in

unready state).

3. Insert one power module in the installation position and push it into the cabinet.

4. Secure the module to the cabinet through the fixing holes on both sides of the front

panel of the module.

5. Place the ready switch to the “ ” position (i.e., in ready state).

3.5.3 Remove a Power Module

Warning

Before removing any Power Module, make sure the remaining Power Modules can

support the critical loads.

1. Turn the ready switch to the “ ” position.

2. The Power Module LED indicator is off to indicate the Power Module discharged and

shut down completely.

3. Use a screwdriver to remove the four screws from fixing holes.

4. Two people pull out together and remove the Power Module from its slot.

3.5.4 STS Module

For detail settings, please refer to character 4.

Figure 3-16: STS module

18

3.5.5 Remove the STS Module

Warning

1. Only qualified service personnel can perform the following procedures.

2. The STS Module has been pre-installed in the factory. Only remove the STS Module

when maintenance or replacement is necessary.

3. When the UPS is in Bypass Mode and its critical loads are connected, removing the

STS Module without turning off the Bypass Breaker could generate high voltage,

which may melt its connectors.

4. If the UPS is in Bypass Mode, cutting off the bypass AC source will terminate power

supply to the critical loads.

5. The STS Module is heavy (>30 kg). At least two people are required for handling.

Please follow the steps below to remove the STS Module.

1. Turn OFF the Bypass Breaker.

2. Use a Screwdriver to remove the four screws from the two sides of the STS Module.

3. Two people together pull out and remove the STS Module.

NOTE: Reverse the steps above to insert the STS module.

3.5.6 Battery Installation

Please follow below charts to install and connect wires to internal battery modules and external

battery cabinet.

Internal Battery Module Connection

19

External Battery Cabinet Connection

After battery is completely installed, be sure to set up nominal battery voltage, battery capacity

and maximum charging current in LCD setting. Otherwise, if battery setting is different from real

installation, the UPS will keep warning. Please refer to section 4.2.6.3 and Table 5-17 for the

details.

3.6 Power Cable

Warning

Please follow the local wiring regulations. Follow environmental conditions and

refer to IEC60950-1.

20

3.6.1 AC input and output maximum current and power cable configuration.

For standard model in 30U cabinet (battery inside)

Model

30KVA

60KVA

90KVA

Current (A)

57

114

171

Power cable (mm2)

10

35

70

Fixation torque force (lb-in)

20

20

20

For standard model in 42U cabinet (battery inside)

Model

30KVA

60KVA

90KVA

120KVA

Current (A)

57

114

171

228

Power cable (mm2)

10

35

70

95

Fixation torque force (lb-in)

20

20

20

20

For extended series in 30U & 42U cabinet

Model

30KVA

60KVA

90KVA

120KVA

150KVA

180KVA

210KVA

Current (A)

57

114

171

228

285

342

399

Power cable

(mm2)

10

35

70

95

150

240

300

Fixation torque

force (lb-in)

20

20

20

20

20

20

20

Notice: Installer has to consider the max. current and wiring gauge as possible for future

extension.

3.6.2 DC input maximum current and power cable configuration.

For standard series in 30U cabinet (battery inside)

Model

30KVA

60KVA

90KVA

Current (A)

100

200

300

Power cable (mm2)

25

95

150

Fixation torque force (lb-in)

20

20

20

Notice: 90KVA is required to set up external battery cabinet for standard model.

For standard series in 42U cabinet (battery inside)

Model

30KVA

60KVA

90KVA

120KVA

Current (A)

100

200

300

400

Power cable (mm2)

25

95

150

240

Fixation torque force (lb-in)

20

20

20

20

Notice: 120KVA is required to set up external battery cabinet for standard model.

For extended series in 42U cabinet

Model

30KVA

60KVA

90KVA

120KVA

150KVA

180KVA

210KVA

Current (A)

100

200

300

400

500

600

700

Power cable

(mm2)

25

95

150

240

120 x 2

150 x 2

240 x 2

Fixation torque

force (lb-in)

20

20

20

20

20

20

20

21

4. Control Panel and Display Description

4.1 Introduction

This control panel and display description is located on the front door of the UPS. It is the USER

control and monitoring of all measured parameters, UPS and battery status and alarms. The

control panel and display description is divided into three functional areas: (1) LCD display, (2)

LED indications, (3) Control keys, (4) Audio Alarm, as shown in Figure 4-1.

Figure 4-1 Control panel parts

(1) LCD display: Graphic display and all measured parameters.

(2) LED indications. Refer to table 4-1.

(3) Control keys. Refer to table 4-2.

22

Table 4-1: LED indications

LED

Color

Status

Definition

INPUT

Green

On

Input source is normal.

Flashing

Input source is abnormal.

Off

No input source

BYPASS

Green

On

Load on Bypass.

Flashing

Input source is abnormal.

Off

Bypass not operating.

INVERTER

Green

On

Load on inverters.

Off

Inverters not operating.

BATTERY

Yellow

On

Load on Battery.

Flashing

Low battery

Off

Battery converter is normal and battery

is charging.

ALARM

Red

On

UPS fault.

Flashing

UPS alarm.

Off

Normal.

Table 4-2: Function key table

Control Key

Description

Esc

Return to previous screen or cursor displacement. When

screen is in Main screen, it will enter setting menu by

pressing ESC key.

Up(Left)

Key for menu page navigation, or digit modification.

Down(Right)

Key for menu page navigation, or digit modification.

Enter

Confirmation of commands, or cursor displacement.

Home

Return to Main screen.

Power On/Off

Turn on UPS or Turn off UPS. (hold 2-Sec)

(4) Audible Alarm: Table 4-3

Audio Type

Description

Power on/off

Buzzer sounds two seconds.

Battery mode

Buzzer sounds every 2 seconds.

Low battery

Buzzer sounds every half seconds.

UPS alarm

Buzzer sounds every 1 second.

UPS fault

Buzzer continuously sounding.

23

4.2 Screen Description

4.2.1 Start Screen

Upon UPS start, the UPS executes self-test. The initial screen displays and remains approximately

5 seconds as shown in Figure 4-2.

Figure 4-2 Initial screen

4.2.2 Main Screen

After initialization, the main screen will display as Figure 4-3. Main screen is divided into five parts.

(1) UPS Mode: Current Operation Mode.

(2) UPS Flow Chart: Current flow chart and measurement data.

(3) Menu: Press ESC button to enter Menu screen.

(4) UPS model name with power rating.

(5) Date and Time.

Figure 4-3 Main screen

24

4.2.3 Menu Screen

Use UP and DOWN buttons to choose between different menus, and Press ENTER to enter into the

sub screen, as shown in Figure 4-4 and 4-5.

Figure 4-4 Menu tree

Figure 4-5 Menu screen

4.2.4 Control Screen

Use UP and DOWN buttons to choose CONTROL option, and press ENTER button to enter into the

submenu, as shown in Figure 4-6 and 4-7.

Figure 4-6 Control menu

25

Figure 4-7 Control screen

Use LEFT and RIGHT buttons to choose YES or NO. Choose YES and press ENTER button to

confirm command or choose NO to cancel command, as shown in Figure 4-8.

Figure 4-8 Yes or No screen

4.2.5 Measurement Screen

Use UP and DOWN buttons to choose MEASUREMENT option. Choose module ID number to

measure Input, Output, Bypass, Load, and Battery of every module, as shown in Figure 4-9, 4-10

and Table 4-4.

Figure 4-9 Measurement menu

26

Figure 4-10 Measurement screen

Table 4-4

Menu

Item

Explanation

Input

L-N Voltage (V)

Input phase voltage (L1, L2, L3). Units 0.1V.

Frequency (Hz)

Input Frequency (L1, L2, L3). Units 0.1Hz.

Output

L-N Voltage (V)

Output phase voltage (L1, L2, L3). Units 0.1V.

L-N Current (A)

Output phase current (L1, L2, L3). Units 0.1A.

Frequency (Hz)

Output Frequency (L1, L2, L3). Units 0.1Hz.

Power Factor

Output Power Factor (L1, L2, L3).

Bypass

L-N Voltage (V)

Bypass phase voltage (L1, L2, L3). Units 0.1V.

Frequency (Hz)

Bypass Frequency (L1, L2, L3). Units 0.1Hz.

Power Factor

Bypass Power Factor (L1, L2, L3).

Load

Sout (KVA)

Apparent power. Units 0.1KVA.

Pout (KW)

Active power. Units 0.1KW.

Load Level (%)

The percentage of the UPS rating load. Units 1%.

Battery

Positive Voltage (V)

Battery Positive Voltage. Units 0.1V.

Negative Voltage

(V)

Battery Negative Voltage. Units 0.1V.

Positive Current (A)

Battery Positive Current. Units 0.1A.

Negative Current

(A)

Battery Negative Current. Units 0.1A.

Remain Time (Sec)

Battery run time remaining. Units 1sec.

Capacity (%)

The percentage of the capacity of the battery.

Units 1%.

Test Result

Battery test result

Charging Status

Battery charging status

27

4.2.6 Setup Screen

Use UP and DOWN buttons to choose SETUP options. It’s required to enter password to access

General, SYSTEM and BATTERY sub-menus, as shown in Figure 4-11, 4-12 and 4-13.

Figure 4-11 Setup menu

It’s required to enter 4-digit password to enter SETUP menu. If incorrect password is entered, the

LCD screen will ask for retry.

Figure 4-12 Enter password screen

Figure 4-13 Setup screen

28

Table 4-5 All setting items in Setup Menu

UPS operation

mode

Setting item

Standby

Mode

Bypass

Mode

Line

Mode

Battery

Mode

Battery

Test Mode

Fault

Mode

Converter

Mode

ECO

Mode

Model Name

Y Y Y Y Y Y Y Y Language

Y Y Y Y Y Y Y Y TIME

Y Y Y Y Y Y Y

Y

Change Password

Y Y Y Y Y Y Y Y Baud Rate

Y Y Y Y Y Y Y

Y

Audible Alarm

Y Y Y Y Y Y Y Y Factory Reset

Y

EEPROM Reset

Y

EPO Function

Y Save Setting

Y Y

Output Voltage

Y Y

Bypass Voltage

Range

Y Y Y Y Y Y Y

Y

Bypass Frequency

Range

Y Y

Converter Mode

Y ECO Mode

Y Y Y Y Bypass Mode

Y Y Auto-Restart

Y Y Y Y Y Y Y Y Cold Start

Y Y Y Y Y Y Y

Y

Battery Mode

Delay Time

Y Y Y Y Y

Y

System Shutdown

Time

Y Y Y Y Y Y Y

Y

System Restore

Time

Y Y Y Y Y Y Y

Y

Redundancy

Y Y Y Y Y Y Y

Y

Nominal Battery

Voltage

Y Y

Battery Capacity

in Ah

Y Y Y Y Y

Y

Maximum

Charging Current

Y Y

Battery

Low/Shutdown

Setting

Y Y Y Y Y

Y

29

Periodic Battery

Test

Y Y Y Y Y Y Y

Y

Battery Test

Interval

Y Y Y Y Y Y Y

Y

Stop by Time

Y Y Y Y Y Y

Y

Stop by Battery

Voltage

Y Y Y Y Y Y

Y

Stop by Battery

Capacity

Y Y Y Y Y Y

Y

Battery Age Alert

Y Y Y Y Y Y Y Y Pre-Alarm

Y Y Y Y Y Y Y Y UPS Parallel

Y Y

Independent

Battery

Y Y

Y means that this setting item can be set in this operation mode.

4.2.6.1 Setup-General Screen

Use UP and DOWN buttons to choose between different sub-menus, and press ENTER button to

enter into the GENERAL setting screen, as shown in Figure 4-14. General setting can be set in any

operating mode and Setup-General setting list is shown in table 4-6.

Figure 4-14 Setup-General screen

Use LEFT and RIGHT buttons to choose YES or NO. Choose YES and press ENTER button to

confirm the setting change or choose NO to cancel the setting, as shown in Figure 4-15.

30

Figure 4-15 SETUP YES or NO screen

Table 4-6

Setting Item

Sub Item

Explanation

Model Name

Set UPS Name(xxxxxxxxxx)

Language

--

Provides 3 optional LCD languages (English,

Traditional Chinese and Simplified Chinese )

TIME

Adjust Time

Set current date and time (yyyy / mm / dd

hour : min : sec)

System Installed Date

Set system installed date (yyyy / mm / dd)

System Last Maintain

Date

Set system latest maintenance date (yyyy /

mm / dd)

Battery Installed Date

Set battery installed date (yyyy / mm / dd)

Battery Last Maintain

Date

Set battery latest maintenance date (yyyy /

mm / dd)

Change Password

--

Set New Password.

Baud Rate

--

Set COM Port0 Baud Rate(2400, 4800,

9600)

Set COM Port1 Baud Rate(2400, 4800,

9600)

Audible Alarm

--

Set Audible Alarm “Disable” or “Enable”

Factory Reset

--

Restore to factory default setting

EEPROM Reset

--

Set EEPROM default

EPO Function

--

Set EPO “Normal Close Active” or “Normal

Open Active”

Save Setting

--

Save EEPROM

31

4.2.6.2 Setup-System Screen

Use UP and DOWN buttons to browse different menus and press ENTER button to enter into the

SYSTEM setting screen, as shown in Figure 4-16. System setting can be set only when UPS is

operated in certain mode. Please check setting item availability table 4-5 for the details. If it’s not

set up under specific mode, the warning screen will appear. Refer to figure 4-17 and Setup-System

setting list is shown in table 4-7.

Figure 4-16 Setup-System screen

Figure 4-17 Warning screen

32

Table 4-7

Setting Item

Sub Item

Explanation

Output Voltage

--

Set output voltage (220Vac, 230Vac,

240Vac)

BYPASS SETTING

Bypass Voltage

Range

Set bypass voltage range: upper limit

(+10%, +15%, +20%) and lower limit

(-10%, -20%, -30%)

Bypass Frequency

Range

Set bypass Frequency range: upper limit

(+1Hz, +2Hz, +4Hz) and lower limit

(-1Hz, -2Hz, -4Hz)

Converter Mode

--

Set converter mode “Disable” or ”Enable”

ECO Mode

--

Set ECO mode “Disable” or ”Enable”

Bypass Mode

--

Set bypass mode “Disable” or ”Enable”

Auto-Restart

--

Set auto-restart “Disable” or ”Enable”.

After “Enable” is set up, once UPS

shutdown occurs due to low battery and

then utility restores, the UPS will return to

line mode.

Cold Start

--

Set cold start “Disable” or ”Enable”.

After “Enable” is set, the UPS can be

turned on without utility connection by

pressing Battery Start Button. Refer to

cold start operation for the details.

Battery Mode Delay

Time

--

Set system shutdown delay time in

battery mode (0~9990sec)

System Shutdown

Time

--

Set system shutdown time (0.2~99min)

System Restore

Time

--

Set system restore time (0~9999min)

Redundancy

--

Set total power and redundancy

33

Cold Start Operation

Step 1: Press “Cold Start” button as shown in below chart.

Cold Start Button

Step 2: After pressing Cold Start Button, UPS will enter Standby mode. Refer to below chart for

LCD display.

Step 3: Before UPS enters shutdown mode, please press “Power On/Off” button for 2 second

immediately as shown in below chart.

34

Step 4: Then, UPS will enter Battery Mode as shown below chart. Cold start procedure is

complete.

4.2.6.3 Setup-Battery Screen

Use UP and DOWN buttons to switch different sub-menus. Press ENTER button to enter into the

BATTERY setting screen, as shown in Figure 4-18. Battery setting can be set only when UPS is

operated in standby mode. If it’s not in standby mode, the warning screen will appear as shown in

Figure 4-17. See Battery-System setting list in table 4-8.

Figure 4-18 Setup-Battery Screen

35

Table 4-8

Setting Item

Sub Item

Explanation

Nominal Battery Voltage

--

Set battery nominal voltage(16x12V,

18x12V, 20x12V)

Battery Capacity in Ah

--

Set battery capacity. (0~999)

Maximum Charging

Current

--

Set battery maximum charging current

(1~128A)

BATTERY

LOW/SHUTDOWN

SETTING

Battery Low

Voltage

Set battery low voltage

(10.5~11.5V)x(battery Number)

Battery Low

Capacity

Set battery low capacity (20~50%)

Battery Shutdown

Voltage

Set battery voltage point for system

shutdown in battery mode

(10.0~11V) x (battery Number)

Battery Shutdown

Capacity

Set battery level for system shutdown in

battery mode (10~50%)

BATTERY TEST

Periodic Battery

Test

Set periodic battery test “Disable”

or ”Enable”

Battery Test

Interval

Set battery test interval (7~99 Days)

Stop by Time

Set testing time for battery test

(10~1000sec)

Stop by Battery

Voltage

Set stop battery voltage in battery test

(11~12V) x (battery Number)

Stop by Battery

Capacity

Set battery capacity to stop

battery-testing. (20~50%)

Battery Age Alert

Battery Age Alert

(Months)

Set battery age for replacement.

(12~60Months)

4.2.6.4 Pre-Alarm Screen

Use UP and DOWN buttons to switch different sub-menus. Press ENTER button to enter into the

Pre-Alarm setting screen, as shown in Figure 4-19. Pre-Alarm setting can be set in any operation

mode. See Setup-Pre-Alarm setting list in table 4-9.

Figure 4-19 Setup-Pre-Alarm screen

36

Table 4-9

Setting Item

Sub Item

Explanation

Line Voltage Range

--

Set line voltage range: upper limit (+5%,

+10%, +15%, +20%) and lower limit

(-5%, -10%, -15%, -20%)

Line Frequency Range

--

Set line frequency range: upper limit

(+1Hz, +2Hz, +3Hz, +4Hz) and lower

limit (-1Hz, -2Hz, -3Hz, -4Hz)

Load

Overload

Set UPS Overload percentage

(40~100%)

Load Unbalance

Set UPS output load unbalance

percentage (20~100%)

4.2.6.5 Parallel Screen

Use UP and DOWN buttons to switch different sub-menus. Press ENTER button to enter into the

Parallel setting screen, as shown in Figure 4-20. Parallel setting can be set only when UPS is

operated in standby or bypass mode. If it’s not in standby or bypass mode to set up, the warning

screen will appear as shown in Figure 4-17. See Setup-Parallel setting list in table 4-10.

Figure 4-20 Setup-Parallel screen

Table 4-10

Setting Item

Sub Item

Explanation

UPS Parallel

--

Set UPS parallel “Disable” or ”Enable”

Independent Battery

--

Set Independent Battery “Disable”

or ”Enable”

37

4.2.7 Information Screen

In this Screen you can check the UPS configuration of the unit, and INFORMATION divided into

Identification, System and Battery, as shown in Figure 4-21, 4-22, 4-23, 4-24 and 4-25.

Figure 4-21 Information menu

Figure 4-22 Information screen

Figure 4-23 Information-Identification screen

38

Figure 4-24 Information-System screen

Figure 4-25 Information-Battery screen

4.2.8 Events Screen

When event occurs, you will see flashed warning text in the Main Screen as shown in Figure 4-26.

Besides, you also can enter the EVENTS Menu to check the latest event lists and history events as

shown in Figure 4-27 and 4-28.

Figure 4-26 Alarm warning screen

Figure 4-27 Events menu

39

Figure 4-28 Events screen

4.2.8.1 Current Events

When event occurs, it displays Module ID and alarm code in Current Events screen. It can save up

to 50 events in current events. Only 4 events can list in one page. Therefore, if it exceeds more

than four, you have to press UP or DOWN button to read other event as shown in Figure 4-29.

Figure 4-29 Current Events screen

4.2.8.2 History Events

It saved detailed information in history events. When warning occurs, it will display alarm code,

alarm time and Module ID. When fault event occurs, it will display alarm code, alarm time, Module

ID and data 1~2. Refer to Figure 4-30 for display screen.

40

Figure 4-30 History Events screen

4.2.8.3 Reset All Events

It’s required to enter 4-digit password to enter Reset All Events screen as shown in Figure 4-31.

Then, use LEFT and RIGHT buttons to choose YES or NO. Choose YES and press ENTER button to

reset all events or choose NO to cancel this action as shown in Figure 4-32.

Figure 4-31 Reset All Events screen

41

Figure 4-32 Reset All Events screen

4.3 Alarm List

In Table 4-11, it provides the complete list of UPS alarm messages.

Table 4-11

Representation in display LCD

Explanation

Fault! Bus Over Voltage

DC bus voltage is too high

Fault! Bus Under Voltage

DC bus voltage is too low

Fault! Bus Voltage Unbalance

DC bus voltage is not balanced

Fault! Bus Short

DC bus is short

Fault! Bus Soft Start Time Out

The rectifiers could not start due to low

DC bus voltage within specified duration

Fault! Inverter Soft Start Time Out

Inverter bus voltage cannot reach desired

voltage within specified duration

Fault! Inverter Voltage Over

Inverter Voltage over (Peak Value)

Fault! Inverter Voltage High

Inverter Voltage is too high

Fault! Inverter Voltage Low

Inverter Voltage is too Low

Fault! R Inverter Voltage Short

R phase inverter Output is shorted

Fault! S Inverter Voltage Short

S phase inverter Output is shorted

Fault! T Inverter Voltage Short

T phase inverter Output is shorted

Fault! RS Inverter Voltage Short

R-S inverter Output is shorted

Fault! ST Inverter Voltage Short

S-T inverter Output is shorted

Fault! TR Inverter Voltage Short

T-R inverter Output is shorted

Fault! Inverter R Negative Power

R phase inverter Output Negative Power

over range

Fault! Inverter S Negative Power

S phase inverter Output Negative Power

over range

42

Fault! Inverter T Negative Power

T phase inverter Output Negative Power

over range

Fault! Over Load Fault

Heavy overload causes UPS fault.

Fault! Battery Fault

Battery reverse

Fault! Over Temperature

Make sure adequate space is allowed for

air vents and the fan is working

Fault! CAN Fault

CAN communication fault

Fault! TRIG0 Fault

Synchronized trigger signal fault

Fault! Relay Fault

Inverter relay fault

Fault! Line SCR Fail

Line SCR short circuit fault

Fault! EEPROM Fault

EEPROM operation error

Fault! Parallel Cable Loosen Fault

As stated.

Fault! DSP MCU Stop Communicate

As stated.

Fault! Bypass Temperature Fault

As stated

Fault! Bypass SCR Fault

As stated.

Line Fail

Utility lost or abnormal

Line Restore

Utility recovered to normal

Warning! EPO Active

Check the EPO connector

Warning! Over Load Fail

The load devices are demanding more

power than the UPS can supply. Line

mode will transfer to Bypass mode.

Warning! Communicate CAN Fail

CAN communication error

Warning! Over Load

In Line mode, the load devices are

demanding more power than the UPS can

supply.

Warning! Battery Open

Battery not connected

Warning! Battery voltage High

Battery voltage is too High

Warning! Module Un-Lock

As stated.

Warning! Turn On Abnormal

As stated.

Warning! Charge Fail

As stated.

Warning! EEPROM Fail

EEPROM operation error

Warning! Fan Lock

As stated.

Warning! Line Phase Error

As stated.

Warning! Bypass Phase Error

As stated.

Warning! N Loss

Neutral loss

Warning! Internal Initial Fail

As stated.

Warning! Comm Syn Signal Fail

Communicate Synchronization Signal Fail

Warning! Comm TRIG0 Fail

Communicate Trigger signal fault

Warning! Redundancy Set Fail

As stated.

Warning! Parallel Sys Config Wrong

Parallel System Configure error

43

Warning! Maintenance Bypass

Enter maintenance

Warning! Battery Age Alert

Battery Life expiration

Warning! Parallel Rack Cable Loosen

As stated.

Warning! Parallel Rack Config Wrong

Parallel Rack Configure error

Pre-Alarm! Line Voltage Fail

Line voltage over range

Pre-Alarm! Line Voltage Normal

Line voltage recovered to normal

Pre-Alarm! Line Frequency Unstable

Line frequency over range

Pre-Alarm! Line Frequency Normal

Line frequency recovered to normal

Pre-Alarm! Over Load

Output Load over range

Pre-Alarm! Load Normal

Output Load recovered to normal

Pre-Alarm! Load Unbalance

Output Load unbalance

44

5. Interface and Communication

As shown in figure 5-1, the Static Transfer Switch (STS) Module includes dry contact Port (X1~X8),

and communication port (RS232 Port, USB port, SNMP Card Port) on the front panel.

Figure 5-1 Dry contact ports and communication ports

Dry Contact

No.

Function

X1

Remote EPO input port

X2

Reserve for system use

X3

BCB Port (Battery Circuit Breaker) – reserved

function

X4

Maintenance Bypass Switch State Port

X5

Internal Output Switch State Port – reserved

function – reserved function

X6

Battery Cabinet Temperature Detection

Port – reserved function

X7

Bypass back feed Control Port – reserved

function

X8

Battery breaker Control Port – reserved

function

5.1 Remote EPO Input Port

The UPS has an Emergency Power off (EPO) Function that can be operated by a remote contact

provide by user. Users can set the logic (N.C or N.O) of this EPO Function through LCD panel.

X1 is the remote EPO input port. The port is shown in Figure 5-2 and described in Table 5-1.

Figure 5-2 Remote EPO input port

45

Table 5-1 Description of remote EPO port

EPO Logic Setting

Position

Description

N.C

X1.1 & X1.2

EPO activated when Opened X1.1 & X1.2

N.O

X1.1 & X1.2

EPO activated when Shorted X1.1 & X1.2

If EPO Logic setting is Normal Closed (N.C), EPO is triggered when pins 1 and 2 of X1 are opened.

Otherwise, EPO Logic setting is Normal Opened (N.O). EPO is triggered when pins 1 and 2 of X1

are opened.

Note:

1. EPO action shuts down the rectifiers, inverters and static transfer switch. But it does not

internally disconnect the input power supply.

2. The default setting of the EPO function logic is Normal Opened (N.O).

5.2 BCB Port

This function is reserved.

Figure 5-3 BCB port

Table 5-2 Description of BCB port

Name

Position

Description

BCB CONNECTED Pin1

X3.1

Reserved

BCB CONNECTED Pin 2

X3.2

Reserved

BCB STATUS Pin 3

X3.3

Reserved

BCB STATUS Pin 4

X3.4

Reserved

5.3 Maintenance Bypass Switch State Port

X4 is the maintenance bypass switch and External maintenance bypass switch state port. The port

is shown in Figure 5-4 and described in Table 5-3. (This function is reserved)

46

Figure 5-4 Maintenance Bypass Switch State port

Table 5-3 Description of Maintenance Bypass Switch State port

Name

Position

Description

Maintain Bypass Pin1

X4.1

Maintenance bypass switch state

Maintain Bypass Pin 2

X4.2

Maintenance bypass switch state

Ext.Maintain Bypass Pin 3

X4.3

Ext.Maintenance bypass switch state

Ext.Maintain Bypass Pin 4

X4.4

Ext.Maintenance bypass switch state

5.4 Internal Output Switch State Port

X5 is the internal output switch state port. The port is shown in Figure 5-5 and described in Table

5-4. (This function is reserved)

Figure 5-5 Internal Output Switch State Port

Table 5-4 Description of Internal Output Switch State Port

Name

Position

Description

Internal Output Pin1

X5.1

Internal Output switch state (Reserved)

Internal Output Pin 2

X5.2

Internal Output switch state (Reserved)

5.5 Battery Cabinet Temperature Detection Port

The UPS has battery cabinet temperature detection function. UPS can through the external battery

cabinet temperature detection board to receive battery cabinet temperature. Communication

between the Ups and Battery temperature detection board was by I2C communication protocol. X6

is the battery cabinet temperature detection port. The port is shown in Figure 5-6 and described in

Table 5-5.

47

Figure 5-6 Battery Cabinet Temperature Detection Port

Table 5-5 Description of Battery Cabinet Temperature Detection Port

Name

Position

Description

SCL

X6.1

I²C communication SCL Signal

SDA

X6.2

I²C communication SDA Signal

+3.0V

X6.3

3V

Power GND

X6.4

GND

5.6 Bypass back feed Control Port

This function is reserved.

Figure 5-7 Bypass back feed Control Port

Table 5-6 Description of Bypass back feed Control Port

Name

Position

Description

Pin1

X7.1

Reserved

Pin 2

X7.2

Reserved

5.7 Battery breaker Control Port

This function is reserved.

48

Figure 5-8 Battery breaker Control Port

Table 5-7 Description of Battery breaker Control Port

Name

Position

Description

Pin1

X8.1

Reserved

Pin 2

X8.2

Reserved

5.8 Other Communication Interface

The RS232 port and USB Port can use in UPS commissioning and service or monitor the Ups

information by Monitoring Software .

This UPS has facility of internally fitted SNMP Card options.

49

6. Service

This chapter introduces the UPS service, including the service procedures of the power module,

STS & control module, battery module and the replacement of air filter.

6.1

Replacement Procedures Of Power Module, STS & Control Module And

Battery Module

6.1.1 Notes

1. Only the customer service engineers shall service the power modules, bypass module and

battery modules.

2. Remove the power modules, bypass module and battery modules from top to bottom, so as to

prevent cabinet toppling due to high centre of gravity.

3. To ensure safety, before servicing the power modules and bypass module, be sure to use a

multimeter to verify that the DC bus capacitor voltage is lower than 60Vdc, and that the

voltages between the earth and the components you are going to work on are under dangerous

voltage values, that is, lower than 60Vdc or 42.4Vac peak value.

4. The static transfer switch module is NOT hot pluggable. It should be replaced only when

the UPS is in maintenance bypass mode or completely powered off.

5. The power modules and bypass module should be serviced five minutes and installed in the

cabinet again 10 minutes after they are removed.

6.1.2 Power Module Replacement Procedures

Confirm UPS is in normal mode and bypass function/source is available.

1. Enter to “menu” control Turn To Bypass YES on the operator control and display panel

for manually turn off the inverters. Then, the UPS transfers to bypass mode.

2. Turn ready switch to “ ” position on replaceable power module.

3. Two minutes later, remove the fixing screws on both sides of the front panel of the module and

pull the module out from the cabinet.

Note: The module will be blocked by a metal safe locker on the left side of the module when the

module is pulled out halfway from the cabinet. At this point, you must press the metal safe locker

before you continue to pulling the module out.

4. After servicing the module, confirm that the DIP switch of the module is set correctly and the

ready switch is in unready state “ ”.

5. Push the module into the cabinet and tighten the screws on both sides. If it’s more than one

power module to re-install, please wait 10-second duration before installing another module.

6. Wait for two seconds before turning ready switch of the module to “ ” position, it will be added

into the system automatically and begin to work few seconds later.

7. Press manual control system turn on YES on the operator control and display panel for

50

two seconds to manually turn on the inverter mode.

6.1.3 STS & Control Module Service Procedures

The static transfer switch module is NOT hot pluggable.

Confirm the UPS is in normal mode and bypass function is available.

1. Press menu control Turn To Bypass YES on the operator control and display panel for

manually turn off the inverters, and the UPS transfers to bypass mode.

2. Turn on main switch and off maintenance bypass switch.

3. Two minutes later, remove the fixing screws on both sides of the front panel of the module and

pull the module out from the cabinet.

Note: The module will be blocked by a metal safe locker on the left side of the module when the

module is pulled out of the cabinet halfway. At this point, you must press the metal safe locker

before you continue to pulling the module out. Please refer to below illustration.

4. After servicing the module, push the module into the cabinet and tighten the screws on both

sides.

5. Turn on maintenance bypass switch and off main switch.

6. Wait for two seconds. Press menu control system turn on YES on the operator control

and display panel for two seconds to manually turn on the inverter mode.

6.1.4 Battery Module replacement Procedures

1. Disconnect each input connector of the battery module.

2. Remove the fixing screws on both sides of the front panel of the module, and pull out the

battery module.

3. Push the new battery module into cabinet and fixing screws on both sides of the front panel.

4. Re-connect each input connector of the battery module.

51

6.2 Replacement Procedures Of Air Filter

As shown below figure, the UPS provides four air filters on the back of the front door. Each filter is

fixed by a fixing bar on both sides.

The air filter replacement procedures are as follows:

1. Open the front door of the UPS to reveal the air filters on the back of the door.

2. Remove a fixing bar on either side of the air filter.

3. Remove the air filter, and insert a clean one.

4. Replace the fixing bar.

52

7. Specifications

The chapter provides the UPS specifications.

7.1 Conformity And Standards

The UPS has been designed to conform to the European and international standards listed in Table

7-1.

Table 7-1 European and international standards

Item

Normative reference

Uninterruptible power systems (UPS) –Part 1:

General and safety requirements for UPS

IEC/EN62040-1

Electromagnetic compatibility (EMC) requirements

for UPS

IEC/EN62040-2

Method of specifying the performance and test

requirements of UPS

IEC/EN62040-3

Notes:

ESD

IEC/EN 61000-4-2 Level 3

RS

IEC/EN 61000-4-3 Level 3

EFT

IEC/EN 61000-4-4 Level 3

Surge

IEC/EN 61000-4-5 Level 3

CS

IEC/EN 61000-4-6 Level 3

Power-Frequency Magnetic field

IEC/EN 61000-4-8 Level 3

Low Frequency Signals

IEC/EN 61000-2-2 Level 10V

Conduction

IEC/EN62040-2 Category C3

Radiation

IEC/EN62040-2 Category C3

7.2 Environmental Characteristics

Table 7-2 Environmental characteristics

Item

Unit

Specifications

Noise within 1 m

dB

Max. 75

Altitude

m

≤1000, derate power by 1% per 100m between

1000m and 2000m

Relative humidity

% RH

0 ~ 95, non condensing

Operating temperature

°C

0 ~ 40°C

(Output capacity will be derated when

temperature is over 30°C. It will be derated to

90% at 35°C and 80% at 40°C.

Storage and transport

temperature for UPS

°C

-15 ~ 60

53

7.3 Mechanical Characteristics

Table 7-3 Mechanical characteristics

30U

Model

30U-90

30U-120

30U-180

Rated power (kVA)

Unit

90

120

180

Dimensions, W x D x H

mm

600 x 1100 x 1475

Weight

kg

675.5

335

453.5

Color

N/A

Black

Protection degree, IEC (60529)

N/A

IP20 (front door and back door is

open or closed)

42U

Model 42U-120

42U-210

Rated power (kVA)

Unit

120

210

Dimensions, W x D x H

mm

600 x 1100 x 2010

Weight

kg

932

549

Color

N/A

Black

Protection degree, IEC

(60529)

N/A

IP20 (front door and back door is open or closed)

7.4 Electrical Characteristics (Input Rectifier)

Table 7-4 Rectifier AC input (mains)

Rated power (kVA)

Unit

30~210

Rated AC input voltage

Vac

380/400/415 (3-phase and

sharing neutral with the bypass

input)

Input voltage tolerance

Vac

305 ~ 477; 304 ~ 208 (output

derated below 70%)

Frequency

Hz

50/60 (tolerance: 40Hz ~ 70Hz)

Power factor

kW/kVA,

full load (half load)

0.99 (0.98)

Harmonic current distortion

THDI% FL

<3

54

7.5 Electrical Characteristics (Intermediate DC Circuit)

Table 7-5 Battery

Intermediate DC circuit

Model

30U-90

42U-120

30U-120

30U-180

42U-210

Rated power (kVA)

Unit

90

120

120

180

210

Number of lead-acid

cells

Nominal

216 (6cells x 36 12V battery block)

Maximum

240 (6cells x 40 12V battery block)

Minimum

192 (6cells x 32 12V battery block)

Float voltage

V/cell

2.3V/cell

Constant current and constant voltage charge mode

Temperature

compensation

mV/ /cl

-3.0 (Option)

Ripple voltage

% V float

≤1

Ripple current

% C10

≤5

Boost voltage

VRLA

2.35V/cell

Constant current and constant voltage charge mode

EOD voltage

V/cell

1.67V/cell

Battery charge

V/cell

Limit current and constant voltage charge mode

Floating Voltage 2.3V/cell

Boost charging 2.35V/cell

Battery charging

power

1

max current

A

8 / per power module (adjustable)

Note:

1. At low input voltage the UPS recharge capability increases with load decrease (up to the

maximum capacity indicated).

7.6 Electrical Characteristics (Inverter Output)

Table 7-6 Inverter output (to critical load)

Rated power (kVA)

Unit

30 ~ 210

Rated AC voltage1

Vac

380/400/415 (three-phase four-wire, with neutral

reference to the bypass neutral)

Frequency

Hz

50/60 Auto Selectable

Overload

%

105%~110% for 60min

110%~120% for 10min

121%~150% for 1min

>150% for 200ms

Neutral current capability

%

170%

Steady state voltage stability

%

± 1 (balanced load), ± 2 (100% unbalanced load)

Total harmonic voltage

%

<1 (linear load), <4 (non-linear load3)

Synchronization window

+/- 1Hz, +/- 2Hz, +/- 4Hz (default: 4Hz)

Note:

1. Factory setting is 400V. 380 or 415V is selectable by commissioning engineer.

55

7.7 Electrical Characteristics (Bypass Mains Input)

Table 7-7 Bypass mains input

Rated power (kVA)

Unit

30 ~ 210

Rated AC voltage1

Vac

380/400/415 (Three-phase four-wire, sharing neutral with

the rectifier input and providing neutral reference to the

output)

Rated current

A

30U for 90KW 171, 380V / 164, 400V / 157, 415V

42U for 120KW 228, 380V / 218, 400V / 209, 415V

42U for 210KW 397, 380V / 380, 365V / 329, 415V

Overload

%

105%~110% for 60min

110%~120% for 10min

121%~150% for 1min

>150% for 200ms

Upstream protection,

bypass line

N/A

Circuit breaker, rated up to 100% of nominal output

current.

Current rating of neutral

cable

A

1.7 × In

Frequency

Hz

50/60 Auto Selectable

Transfer time (between

bypass and inverter)

ms

Synchronous transfer: ≤20ms

Bypass voltage

tolerance

%Va

c

Upper limit: +10, +15 or +20, default: +15

Lower limit: -10, -20, -30 default: -20

(delay time to accept steady bypass voltage: 10s)

Frequency Range

Hz

+/- 1Hz, +/- 2Hz, +/- 4Hz (default: 4Hz)

Note:

1. Factory setting is 400V. 380V or 415V is selectable by commissioning engineer.

Loading...

Loading...