Page 1

User Manual

EnerSolar 3K PV Inverter

Page 2

Table Of Contents

1. Introduction ............................................................. 3

2. Important Safety Warning ......................................... 4

3. Unpacking & Overview .............................................. 6

4. Installation ............................................................... 6

5. Grid (AC) Connection ................................................ 8

6. PV Module (DC) Connection ...................................... 9

7. Commissioning ....................................................... 11

8. Operation ............................................................... 12

9. Maintenance & Cleaning .......................................... 17

10. Trouble Shooting .................................................... 18

11. Specifications ......................................................... 19

Page 3

Distribution Box

Electric grids

PV module 2

EnerSolar PV inverter

PV module 1

1. Introduction

1-1. Overview

The EnerSolar inverter is designed to convert solar electric (photovoltaic or PV) power into

utility-grade electricity that can be sold to the local power company. This inverter is allowed for

2 arrays of PV modules. Embedded with two smart independent MPPTs, the EnerSolar PV

inverter can operate at optimum power output voltage.

Figure 1 Basic PV System Overview

This inverter is only compatible with PV module types of single crystalline and poly crystalline.

Do not connect any sources of energy other than these two types of PV modules to the

EnerSolar inverter. When designing the PV system, ensure that the values comply with the

permitted operating range of all components at all times. See Figure 1 for a simple diagram of

a typical PV system with EnerSolar Inverter.

1-2. Affecting Factors for Performance of the Inverter

There are a lot of factors to influence the performance of this inverter.

Rating for PV Modules

PV modules are rated at ideal factory conditions, such as specified illumination (1000 W/m2),

spectrum of the light and temperature (25 °C / 77 °F). This is called the STC (Standard Test

Condition) rating and is the figure that appears on the spec label of PV module. Generally

speaking, only around 60% to 70% of its peak STC-rated output will be produced from your

PV modules due to unpredicted environmental factors.

Temperature and Power Reduction

Environment temperature affects the power output of PV modules. Higher the temperature,

lower the power output of PV module. Comparing with pole-mounted PV module array,

roof-mounted PV module array generates less power due to less air circulation and excess

heat from roof top.

Page 4

Conventions used:

WARNING! Warnings identify conditions or practices that could result in personal injury;

CAUTION! Caution identify conditions or practices that could result in damaged to the

unit or other equipment connected.

Important: The inverter will reduce its output generation to protect its electronic circuits

from overheating and any damage under high temperature environment. For maximum power

output in high temperature, it’s recommended to mount the inverter in a shaded location with

good ventilation.

Angle of the Sun

The angle of the sun in relation to the PV array surface—the array orientation can dramatically

affect the PV array output. The array energy output will vary depending on the time of day and

time of year as the sun’s angle in relation to the array changes. Sunlight output decreases as

the sun approaches the horizons (such as in winter in Europe) due to the greater atmospheric

air mass it must penetrate, reducing both the light intensity that strikes the array’s surface and

spectrum of the light. In general, you can expect only four to six hours of direct sunlight per

day depending on what part of Europe the inverter is installed.

Partial Shade

Shading on a single PV module of the array will reduce the output power of the entire system.

Such shading can be caused by something as simple as the shadow of a utility wire or tree

branch on part of the array’s surface. This condition, in effect, acts like a weak battery in a

flashlight, reducing the total output, even though the other batteries are good. However, the

output loss is not proportionate to shading even a tiny bit of shading will reduce the PV power

to the inverter. The inverter is designed to maximize its power production in all of the above

situations using its proprietary MPPT algorithm.

Other Factors

Other factors to reduce power generation of a solar system are:

Dust or dirt on the modules

Fog or smog

Mismatched PV array modules, with slight inconsistencies in performance from one

module to another.

Inverter efficiency

Wire losses

Utility grid voltage

2. Important Safety Warning

Before using the inverter, please read all instructions and cautionary markings on

the unit and this manual. Store the manual where it can be accessed easily.

This manual is for qualified personnel. The tasks described in this manual may be performed

by qualified personnel only.

General Precaution-

Page 5

WARNING! Before installing and using this inverter, read all instructions and cautionary

markings on the inverter and all appropriate sections of this guide.

WARNING! Normally grounded conductors may be ungrounded and energized when a

ground fault is indicated.

WARNING! This inverter is heavy. It should be lifted by at least two persons.

CAUTION! Authorized service personnel should reduce the risk of electrical shock by

disconnecting both the AC and DC power from the inverter before attempting any

maintenance or cleaning or working on any circuits connected to the inverter. Turning off

controls will not reduce this risk. Internal capacitors can remain charged for 5 minutes after

disconnecting all sources of power.

CAUTION! Do not disassemble this inverter yourself. It contains no user-serviceable parts.

Attempt to service this inverter yourself may cause a risk of electrical shock or fire and will

void the warranty from the manufacturer.

CAUTION! To avoid a risk of fire and electric shock, make sure that existing wiring is in good

condition and that the wire is not undersized. Do not operate the Inverter with damaged or

substandard wiring.

CAUTION! Under high temperature environment, heat sink of this inverter could be hot

enough to cause skin burns if accidentally touched. Ensure that this inverter is away from

normal traffic areas.

CAUTION! Use only recommended accessories from installer . Otherwise, not-qualified tools

may cause a risk of fire, electric shock, or injury to persons.

CAUTION! To reduce risk of fire hazard, do not cover or obstruct the heat sink.

CAUTION! Do not operate the Inverter if it has received a sharp blow, been dropped, or

otherwise damaged in any way. If the Inverter is damaged, called for an RMA (Return Material

Authorization).

Page 6

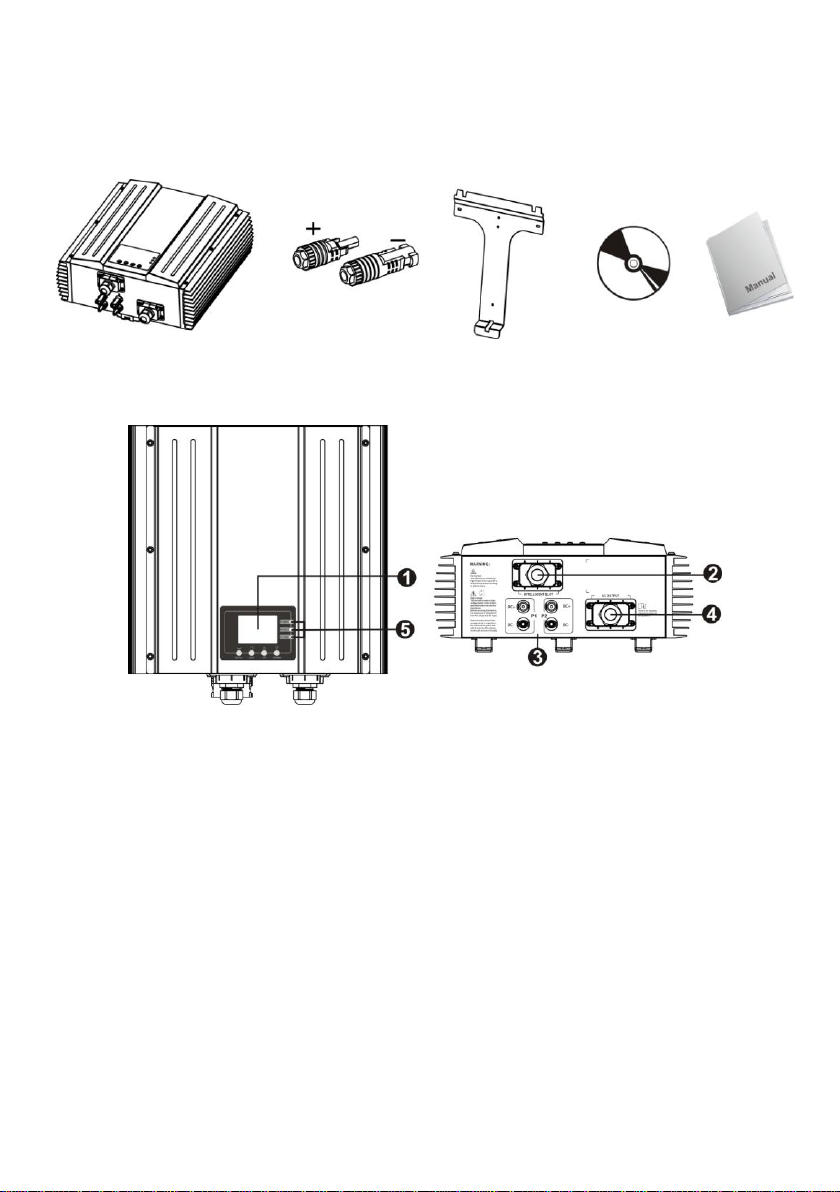

3. Unpacking & Overview

3-1. Packing List

Before installation, please inspect the unit. Be sure that nothing inside the package is

damaged. You should have received the following items inside of package:

Inverter unit PV connectors x 2 sets Mounting plate Software CD Manual

3-2. Product Overview

1) LCD display panel (Please check section 8 for detailed LCD operation)

2) Interface connection RS485 (Modbus card)

3) Connectors for solar modules

4) Grid connection

5) LED indicators

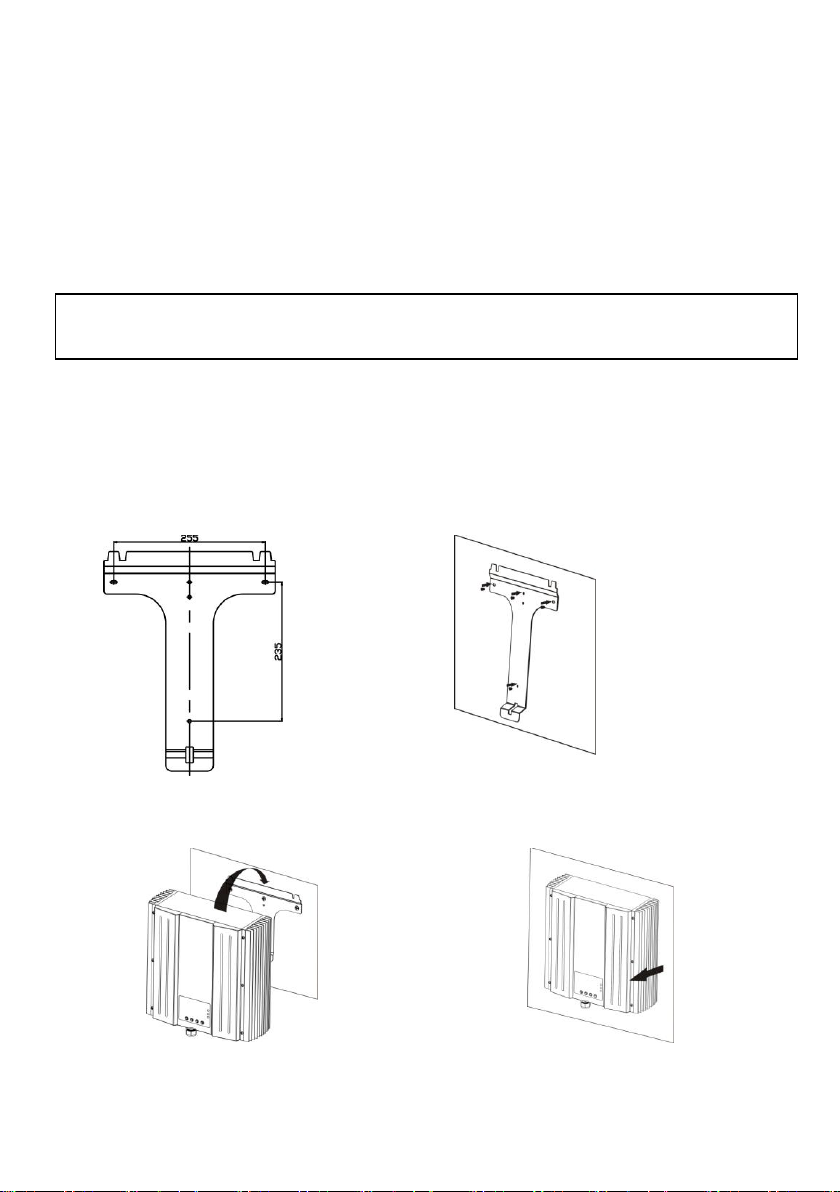

4. Installation

4-1. Selecting Mounting Location

Consider the following points before selecting where to install:

Do not mount the inverter on flammable construction materials.

Mount on a solid surface

Although the unit is fitted with UV resistant components, direct exposure to sunlight

may cause a power reduction due to excessive heating.

This inverter can make noises during operation which may be perceived as a nuisance in

a living area.

Install this inverter at eye level in order to allow the LCD display to be read at all times.

For proper air circulation to dissipate heat, allow a clearance of approx. 20 cm to the

Page 7

WARNING!! Remember that this inverter is heavy! Please be carefully when lifting out

from the package.

side and approx. 50 cm above and below the unit.

1. Employ the mounting plate as a

template for marking the positions of

the boreholes

2. Mount the mounting plate with

appropriate screws (M5,SUS304) into

four holes to fix the plate in place

3. Follow the below figure to place the

solar inverter onto the mounting

plate.

4. Check if the solar inverter is firmly

secured.

Dusty conditions on the unit may impair the performance of this inverter.

The ambient temperature should be between -25°C and 60°C to ensure optimal

operation.

The recommended installation position is to be adhered to (vertical).

Unused DC connectors and interfaces must be sealed with sealing plugs to ensure

protection class IP65 for the whole system (inverter & cables).

This inverter is designed with IP65 for outdoor applications with high humidity.

4-2. Mounting Unit with Wall Mounting Bracket

Please utilize the delivered mounting plate for problem-free installation of the solar inverter.

Installation to the wall should be implemented with the proper screws. Mount the wall bracket

so that the solar inverter can be easily attached to the wall. After that, the device should be

bolted on securely.

Page 8

5. To avoid theft, you may add a lock

between mounting plate and inverter.

NOTE: Please follow below requirements to

choose suitable lock.

Model

Diameter(mm)

Conductor cross-section

(mm2)

AWG no.

Temperature

EnerSolar

3kW

6± 0.2

≥3

≤12

125°C

5. Grid (AC) Connection

5-1. Preparation

Before connecting to AC utility, please install a separate circuit breaker between inverter and

AC utility. This will ensure the inverter can be securely disconnected under load.

NOTE1: Although this inverter is equipped with a fuse (F1 point on PCB, 250VAC/20A), it’s

still necessary to install a separate circuit breaker for safety consideration. Please use

250VAC/20A circuit breaker.

NOTE2: If you want to add a manual RCMU, it shall be type B.

WARNING! It's very important for system safety and efficient operation to use appropriate

cable for grid connection. To reduce risk of injury, please use the proper recommended cable

size as below.

Suggested cable requirement for AC wire

5-2. Connecting to the AC Utility

Step 1: Check the grid voltage and frequency with an AC voltmeter. It should be the same to

“VAC” value on the product label.

Step 2: Turn off the circuit breaker.

Step 3: Insert utility cable through cable gland. Connect wires according to polarities

indicated on terminal block.

L→LINE (brown or black)

Step 4: Fasten the gland plate with attached screws.

Step 5: Twist the gland so that the cable is firmly

connected.

G→Ground (yellow-green)

N→Neutral (blue)

Page 9

CAUTION: To prevent risk of electric shock, ensure the ground wire is properly earthed

before operating the solar inverter.

WARNING: This inverter is only compatible to two types of PV modules: single crystalline

and poly crystalline. To avoid any malfunction, do not connect any sources of energy other

than these two types of PV modules to the EnerSolar inverter.

NOTE: To optimize the inverter performance, the two PV arrays should be the same.

6. PV Module (DC) Connection

CAUTION: Before connecting to PV modules, please install a separate circuit breaker

between inverter and PV modules.

NOTE: Please use 500VDC/12A circuit breaker.

Please follow below steps to implement PV module connection:

Step 1: Assemble provided PV connectors into PV modules by following below steps.

Negative terminal connection

Page 10

Positive terminal connection

Model

Diameter(mm)

Conductor cross-section

(mm2)

AWG no.

Temperature

EnerSolar

3kW

6± 0.2

≥3

≤12

125°C

CAUTION: Exceeding the maximum input voltage can destroy the unit!! Check the system

before wire connection.

Step 2: Remove the cover of PV modules. Check the input voltage of PV modules. The

acceptable input voltage of the solar inverter is 125VDC - 500VDC. The maximum current load

of each PV input connector is 10A.

Step 3: Disconnect the circuit breaker.

Step 4: Check correct polarity of connection cable from PV modules and PV input connectors.

Then, connect positive pole (+) of connection cable to positive pole (+) of PV input connector.

Connect negative pole (-) of connection cable to negative pole (-) of PV input connector.

WARNING! It's very important for system safety and efficient operation to use appropriate

cable for grid connection. To reduce risk of injury, please use the proper recommended cable

size as below.

Suggested cable requirement for AC wire

Page 11

CAUTION: Never disconnect running inverter from AC Grid. If it’s necessary to turn off the

inverter, disconnect the AC breaker first and then DC breaker next.

CAUTION: Never directly touch terminals of the inverter. It will cause lethal electric shock.

Step 5: Insert the sealing caps provided into unused DC connectors on the inverter.

7. Commissioning

Step 1: Check the following requirements before commissioning:

Ensure the inverter is firmed secured

Check if the open circuit DC voltage of PV module meets requirement (Refer to Section

6)

Check if the open circuit utility voltage of the utility is at approximately same to the

nominal expected value from local utility company.

Correct connection to grid

Full connection to PV modules

Unused DC input connectors are sealed with supplied sealing plugs.

AC circuit breaker and DC circuit breaker are installed correctly.

Step 2: Switch on the AC & DC circuit breakers. All three LEDs will light up. Then:

If green LED lights up, commissioning has been successfully.

Or, if yellow LED lights up, there is insufficient radiation and the inverter is in standby

mode. Wait for sufficient radiation.

Page 12

Or, if red LED lights up, there has been an error. Please inform your installer.

Display

Function

Indicates input voltage of PV module 1 or PV module 2.

P1: PV1, P2: PV2, V: voltage

Indicates AC output voltage or frequency.

V: voltage, Hz: frequency

Indicates current feeding power.

Indicates energy generated today.

Indicates total energy generated so far.

Indicates that the warning occurs.

Indicates that the fault occurs.

Indicates fault code in fault mode or WR for warning

situation.

Indicates PV module status.

8. Operation

8-1. Interface

This LCD panel with 3 indicators shows current status and

value of your system. This display is operated by four

buttons.

NOTICE: To accurately monitor and calculate the energy generation, please calibrate the

timer of this unit via software every one month. For the detailed calibration, please check the

user manual of bundled software.

NOTEC: There is a battery inside of control board. It’s recommended to replace the battery

every 5 years. Check the replacement procedure in Maintenance section.

8-2. LCD Information Define

Page 13

Each indicates 150VDC. When input voltage is

below 100VDC, icon will flash.

When both of PV modules are not connected,

icon will flash.

Indicates the Inverter circuit is working.

Indicates grid.

Indicates energy generated in graphic bar.

8-3. Button Definition

Button

Function

Up Button

Press this button to select last selection or increase value.

Down Button

If it’s in query menu, press this button to select next selection

or decrease value.

Press this button to mute alarm in standby mode.

ENTER Button

Press to enter query menu.

If it’s in query menu, press this button to confirm selection or

entry.

ESC Button

Press to return to last menu.

Procedure

LCD Display

Default setting is P1.

NOTE: If backlight shuts off, you may activate it by pressing any button. When an error

occurs, the buzzer will continuously sound. You may press any button to mute it.

8-4 Query Menu Operation

This display shows current values of your system. This displayed values can be changed in

query menu via button operation. Press “Enter” button to enter query menu. There are three

query selections:

Input voltage of PV modules

Frequency or voltage of AC output

Graphic bar display of power generation in yearly, monthly, or daily basis.

Setting Display Procedure

Input voltage of PV module

Page 14

Frequency or voltage of AC output

Procedure

LCD Display

Energy generation

Energy generation display of selected year in monthly basis

Procedure:

LCD Display:

Energy generation display of selected month in daily basis

Procedure:

LCD Display:

Press “up” button to display info from 17th to 30th.

Page 15

Energy generation display of selected date in hourly basis

Mode

LCD Display

Indicator

Alarm

Description

Power on

mode

All three

LEDs light

up.

Off

The inverter is

initializing.

Grid

mode

Green LED

lights up

Off

The inverter is feeding

power to the grid.

Standby

mode

Yellow LED

lights up

Sounding

every 5 sec.

The inverter is waiting

for the DC voltage to

reach a certain level so

that it can start

feeding the grid.

Fault

mode

and

icons will flash.

Red LED

lights up

Continuously

sounding

An error occurs inside

of the inverter. Please

inform your installer.

Procedure:

LCD Display:

Press “down” button to display info in AM

8-5. Operation Mode & Display

Page 16

8-6. Self test

Please follow below steps to complete the self-test:

Step 1: Connect the inverter to your computer, and start up the SolarPower that installed in

your computer.

Step 2: Click the menu into self-test.

Step 3: Click “start” and then “yes”.

Step 4: Wait for a moment and then popup a interface, it displays the result of the self-test. So

far the self-test is completed.

Page 17

WARNING: There are no user-replaceable parts inside of the inverter. Do not attempt to

service the unit yourself.

9. Maintenance & Cleaning

Check the following points to ensure proper operation of whole solar system at regular

intervals.

Heat sink of the inverter should be cleaned from dust.

WARNING: Although the inverter is designed in sealed IP65 enclosure, it is not

recommended to use a pressure washer to clean the inverter, or use other high pressure

cleaning methods that could allow water or moisture to enter the unit.

Clean the PV modules, during the cool time of the day, whenever it is visibly dirty.

Periodically inspect the system to make sure that all wires and supports are securely

fastened in place.

Record the output power of the system and compare with the record on the same day in

last year to realize the performance of the solar system. Do maintain the log of system

performance for records.

Page 18

10. Trouble Shooting

No PV module is connected

flash failure

Inverter initial failure

Line loss

Islanding is detected

Fault event

Fault code

Icon(flashing)

Over voltage on Bus

1 Under voltage on Bus

2 Time out for Bus soft start

3 Time out for Inverter soft start

4

Inverter over current

5 Over temperature

6 Relay fault

7 Output current sensor failure

8 High voltage on PV module

9 Power down

10 DC input over current

11 GFCI failure

12 PV insulation failure

13 Inverter DC current over

14 Line value consistent fail between MCU & DSP

15 GFCI sensor failure

16 Connection failure between MCU & DSP

17 Communication failure between MCU & DSP

18 Ground loss

19

When errors or fault conditions occur, it will display icon in LCD. Please contact your

installer to solve the problem.

10-1. Warning Situation

There are 5 situations defined as warnings. When a warning situation occurs, icon will

flash and the fault code area will display “WR” wordings.

10-2. Fault Reference Codes

When a fault occurs, the icon will flash as a reminder. See below for fault codes for

reference.

Page 19

11. Specifications

MODEL

EnerSolar 3KW

INPUT (DC)

Max. DC Power

3200W

Maximum DC Voltage

500 VDC

MPP Voltage Range

150 VDC ~ 450 VDC

DC Nominal Voltage

370 VDC

Start-up Voltage / Initial Feeding Voltage

116VDC / 150VDC

Maximum Input Current / Per String

2 x 10A / 10 A

Number of MPP Trackers / Strings per MPP

Tracker

2 / A:1;B:1

OUTPUT (AC)

AC Nominal Power

3000 W

Maximum AC Apparent Power

3000 VA

Nominal AC Voltage / Range

230 VAC / 184 VAC ~ 253 VAC

AC Grid Frequency

50 Hz

AC Grid Frequency Range

47.5~ 50.2 Hz

Nominal Output Current

13A

Power Factor @ > 50% load

> 0.99

EFFICIENCY

Maximum Efficiency @ Nominal Voltage

96.5%

European Efficiency @ Nominal Voltage

95.5%

PROTECTION

DC Reverse-Polarity Protection

Yes

Ground Fault Monitoring

Yes

Grid Monitoring

Yes

AC Short Circuit Protection

Yes

PHYSICAL

Dimension, D X W X H (mm)

420 x 415 x 170

Net Weight (kgs)

20.5

INTERACE

Intelligent Slot

Modbus card / Optional SNMP card

ENVIRONMENT

Protection Degree

IP65/Pollution Degree Ⅲ

Humidity

0 ~ 100%

Operating Temperature

-25°C to 60°C*

Altitude

0 ~ 1000 m

* When temperature is above 50°C, the unit will de-rate the capacity 10 % per centigrade.

Page 20

Page 21

Voltronic Power Technology (Shenzhen) Corporation

ADD: 1-4F, Building 5, YuSheng lndustrial Park, No.467, Section Xixiang, National

Highway 107,

Xixiang, Bao An District, Shenzhen, China

TEL: +886-2-27918296

FAX: +886-2-87918216

Loading...

Loading...