Voltronic VCC 1212-25 IUoU-Li, 3306, 3308, VCC 2412-25 IUoU-Li, VCC 1212-45 IUoU-Li Operating Manual

...Page 1

Installation and Operating Manual

Charging Converter, B2B Battery to Battery, Battery Charging During Driving:

VCC 1212-25 IUoU-Li Input Voltage 12 V Charging Capacity 12 V / 25 A No. 3306

VCC 1212-45 IUoU-Li Input Voltage 12 V Charging Capacity 12 V / 45 A No. 3308

VCC 2412-25 IUoU-Li Input Voltage 24 V Charging Capacity 12 V / 25 A No. 3314

VCC 2412-45 IUoU-Li Input Voltage 24 V Charging Capacity 12 V / 45 A No. 3315

Please read the mounting instructions and the operating manual including the safety

instructions attentively. Particularly observe page 2 "Safety Regulations and Appropriate

Application", prior to starting connection and start-up.

Fully automatic Battery Charging Converter for special purpose vehicles, campers, boats.

The charging converters (boosters) had been developed according to the latest regulations for supply battery charging in

lead-acid, lead-gel, lead-AGM or LiFePO4 technology from the generator during driving.

In case of long supply lines or insufficient cross-sections of the cables, the charging voltage will be increased according to

the default charging values and losses will be compensated. Charging converters with 24 V input voltage allow charging of

the 12 V supply battery without installation of a second generator.

Thus, the charging converter ensures the known high-quality battery charging of the VOTRONIC chargers also during

driving. Due to the intelligent microprocessor charging control with charging characteristic lines "IU1oU2" and dynamic

charging time calculation an automatic, quick and gentle full charging is ensured, as well as subsequent 100 % trickle charge

of the connected batteries from any charging state. At the same time, simultaneous supply of 12 V consumers, which are

connected in parallel, is ensured. Overcharging or excessive gassing of the batteries is avoided, even in case of extremely

long driving times. Any consumed energy will be compensated immediately.

The charging converters excel by their compact design, low weight (high-frequency switch mode technology), powerfully

dimensioned power components and consequently full charging capacity, even with long charging cables or strong voltage

fluctuations at the generator / starter battery (EURO standard 6, 6 + plus vehicles).

Information see page 9, table 2, switch position "D".

Battery Output OUT "I", Charging Programs:

Depending on the battery type, select one of the 4 charging programs, see table 1:

a) "Lead Acid/AGM1": Closed and open acid/lead-acid-lead batteries, as well as AGM 14.4 V (factory adjustment)

b) "AGM 2": Closed, gas-tight AGM batteries (absorbed glass mat, lead-fleece technology)

c) "Gel": Closed, gas-tight Gel batteries, (dryfit, determined electrolyte)

d) "LiFePO4": Charging voltage 14.4 V for lithium LiFePO4 batteries with completely integrated electronic system

and safety circuit (BMS).

Further Characteristics of the Unit:

The charging voltage is free from peaks and is controlled in such a way, that overcharging of the batteries is excluded.

Fully automatic operation by means of control input (ignition, running engine), as well as voltage control.

No intervention into the electric system of the vehicle. The charging converter acts like a consumer at the generator.

Automatic, adjustable power control giving priority to charging of the starter battery by the generator in case of

overloaded vehicle mains to ensure that the vehicle can be started at any time.

No discharge (current 0.000 A) of the batteries during stand-by or with switched-off charging converter.

Parallel and Floating Operation: In case of simultaneous consumption, the battery will either continue to be charged

or maintained via trickle charging. Calculation and control of the adaptation of the charging time is effected

automatically by the charging converter.

Unattended Charging: Multiple protection against overload, overheating, overvoltage, short circuit, reverse battery at

the output, incorrect behaviour and back discharge of the battery by electronically controlled gradual reduction down

to complete separation of charging converter and battery by integrated safety relays.

Galvanic isolation between input and output: Complete separation of the battery circuits, even in case of failure

(particularly important for 24 V/12 V mixed systems) and neat ground ratio, also in case of long supply lines.

Charging aid for deeply discharged lead batteries or switched-off LiFePO4 batteries: Gentle preliminary charging of

the (lead-acid, gel, AGM) battery or automatic reactivation of the Li battery in case of possibly switched-on consumers.

Page 2

- 2 -

Lead Temperature Equalization: The delivered battery temperature sensor effects an automatic adaptation of the

charging voltage to the battery temperature. In case of low outside temperatures, full charging of the weaker battery is

improved, and in case of summery temperatures unnecessary battery gassing will be avoided.

LiFePO4 temperature control and adaptation of the charging by the delivered battery temperature sensor, which allows

also charging beyond the recommended LiFePO4 battery temperatures below 5 °C and above 35 °C.

Integrated On-board Mains Suppression Filter: Unproblematic parallel operation of solar systems, wind and petrol-

driven generators, mains supply chargers etc. at a single battery.

Charging Cable Compensation: Automatic compensation of voltage losses on the charging cables.

Battery Lifetime and Efficiency:

Keep the batteries cool, LiFePO4 preferably above 0 °C. Choose an appropriate location

for installation.

Store only fully charged batteries and recharge them periodically.

Open lead-acid batteries and batteries being "maintenance-free according to EN / DIN":

Check the acid level periodically!

Recharge deeply discharged lead batteries immediately!

LiFePO4: Only use complete batteries with BMS and safety circuit.

! Deep discharge is to be absolutely avoided !

Safety Regulations and Appropriate Application:

The charging converter has been designed according to the valid safety regulations.

Appropriate application is restricted to:

1. Charging of lead-gel, lead-AGM, lead-acid or LiFePO4 complete batteries (with integrated BMS,

balancing, safety circuit and approval!) Charging of batteries of the indicated nominal voltage and

simultaneous supply of the consumers being connected to these batteries in fixed installed systems with

the indicated battery capacities and charging programs.

2. Connection in consideration of the indicated cable cross-sections at the inputs and outputs of the

charging converter.

3. With the indicated minimum battery capacity at the input of the charging converter.

4. Fuses of the indicated capacity are to be provided near the battery to protect the cabling between

battery and connections of the charging converter.

5. Technically faultless condition.

6. Installation in a well-ventilated room, protected from rain, humidity, dust, aggressive battery gases, as

well as in an environment being free from condensation water.

Never use the unit in locations where the risk of gas or dust explosion exists!

Open-air operation of the unit is not allowed.

Lay the cables in a way, that damage is avoided and observe to fasten them tightly.

Never lay 12 V (24 V) cables and 230 V mains supply cables into the same cable conduit (empty conduit).

Check live cables or leads periodically for insulation faults, points of break or loosened connections. Occurring

defects must be remedied immediately.

The unit is to be disconnected from any connection prior to execution of electrically welding or work on the

electric system.

If the user is not able to draw from the manual, which characteristic values are valid for a unit or which

regulations are to be observed, a specialist is to be consulted.

The user / buyer is responsible for the observation of construction and safety regulations of any kind.

The unit does not contain any parts, which can be replaced by the user. Even after having been switched-off,

the unit may be live for an extended period (particularly in case of failure).

Keep children away from the charging converter and the batteries.

Observe the safety regulations of the battery manufacturer; deaerate the battery room.

Non-observance may result in injury or material damage.

The warranty period is 36 months from the purchase date (against presentation of the sales slip or invoice).

The warranty will be void in case of any inappropriate utilisation of the unit, if it is used beyond the technical

specification, in case of improper operation or external intervention. We do not assume any liability for any

damage resulting hereof. The liability exclusion is extended to any service being executed by third, which has

not been ordered by us in writing. Service is to be effected exclusively by VOTRONIC Lauterbach.

Page 3

- 3 -

Installation of the Unit:

The charging converter can be installed at any location, which is clean and which is protected from humidity and dust.

Choose an installation location ensuring that the length of the connection cable between starter battery (IN) and board

battery (OUT) is as short as possible. By this, unnecessary losses over the cables are avoided.

Despite the charging converter’s high efficiency, heat is produced, which is brought out of the casing by means of the builtin fans.

Ensure sufficient ventilation in the environment of the unit, so that the heat can be removed. Protect the unit from

aggressive battery gas.

The unit can be installed in any position. However, the vent holes of the casing (front panel and rear panel) should never be

covered to ensure the full charging capacity (minimum distance: 10 cm).

Ensure a solid and vibration reducing installation using rubber bushings on an even and hard mounting surface.

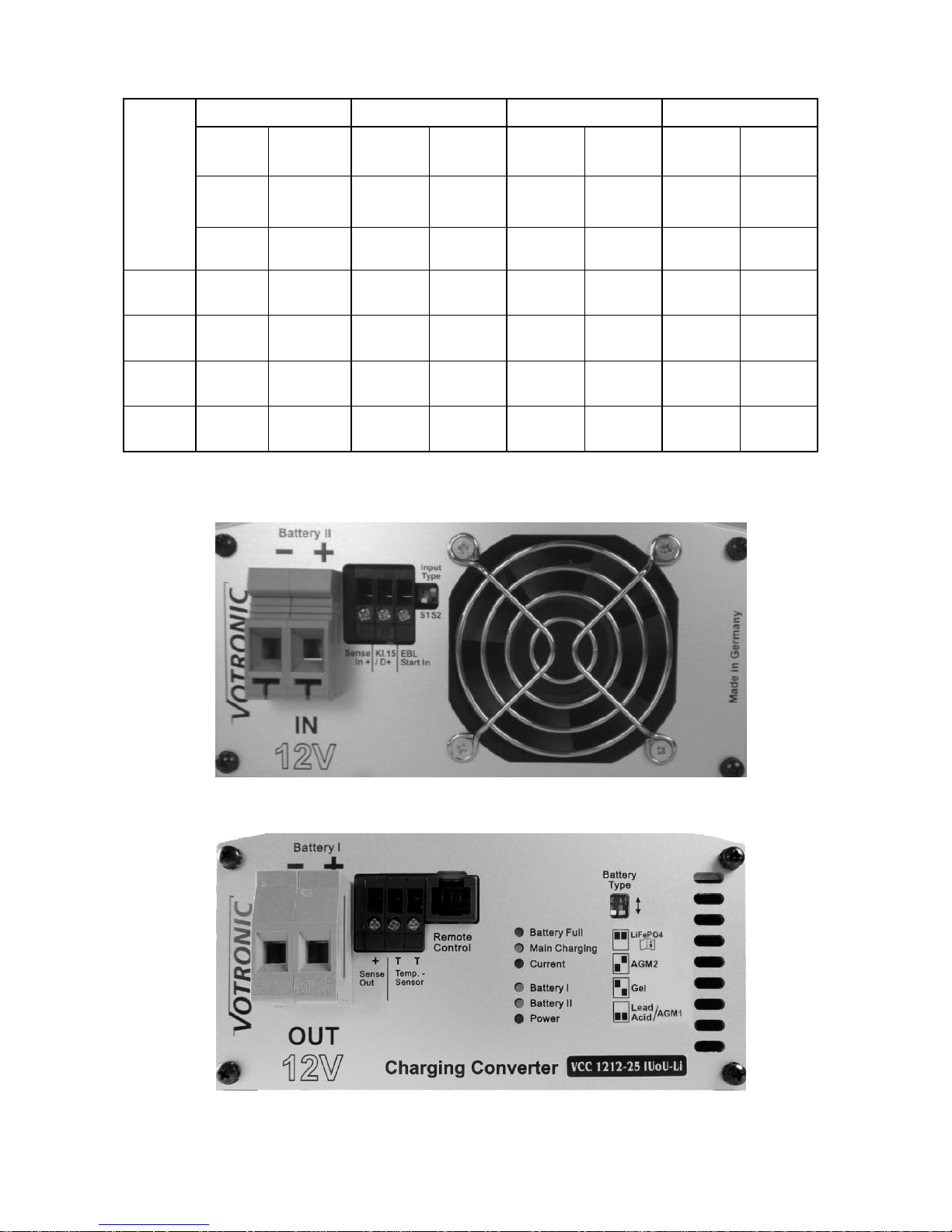

Connection and Settings:

Choose the suitable connection plan according to your application. Observe the indications, fuses, polarity

+/-!

Table Page 5: Observe the "Recommended Cable Cross-sections and Lengths of the Power Connection

Cable"!

First connect the charging converter, after that the batteries.

Output Side:

1. Connect the board/supply battery to the large terminals "Battery I OUT" "-" and "+" observing the correct

polarity. Recommended in case of a cable length exceeding 2 m:

Lead a voltage sensor line with fuse directly from the positive pole of the board battery to the terminal

"+ Sense Out". Recommended in case of a cable length of less than 2 m: The terminal "+ Sense Out" can be

left free.

2. Terminals "T T Temp. Sensor": Connect the temperature sensor (included in the delivery scope) for

battery temperature equalization and control. See "Option Temperature Sensor", page 7.

Input Side:

3. Connect the vehicle's starter battery to the large terminals "Battery II IN" "-" and "+" observing the

correct polarity! Reverse battery (mixing up) +/- at this place will result in serious damage of the unit!

4. Terminal "Sense In+": Lead a voltage sensor line with fuse directly from the positive pole of the starter

battery. Without connection, the unit does not work!

For further details (such as operation without separate sensor line) please refer to table 2, page 9.

5. Terminal "Kl.15/D+", control input for activation of the unit:

Connection preferably to the signal D+ "Generator active" of the vehicle.

If this signal does not exist, the signal "Ignition ON" (vehicle terminal 15) can be used for automatic unit

control.

6. Terminal "EBL Start In": Refer to connection plan "EBL" and "EVS", otherwise leave it free.

Settings for Start-up:

7. Output Side of the Charging Converter:

Set the type, design (lead-acid, AGM, gel or Lithium-LiFePO4) of the board battery "I" to be charged using

the switches "Battery Type". See table 1, page 8.

8. Input Side of the Charging Converter:

Set the installation operating mode IN at the starter battery "II" to be supplied by means of the switches

"Input Type". See table 2, page 9.

9. Start-up and function test, see page 10. Further details, see page 11.

Further operation of the unit is not required during normal automatic mode.

Page 4

- 4 -

General Connection Plan Charging Converter, All Types:

If possible, the unit should always be installed as close as possible to the board battery I.

Observe the cable cross-sections, lengths and fuses according to the table on page 5!

Possibly existing cables, which do not have the required cross-sections must be adapted to the

minimum requirements in any case!

Reverse battery (+/-) at the IN II (Start) side will result in serious damage of the unit!

Input and output side of the charging converter are separated by galvanic isolation, i. e. there is no conductive

connection between the input II side (START) and the output I side (BOARD).

Thus, the two battery circuits are completely independent of each other, and a mutual influence or disturbance

is avoided.

Therefore, the minus (-) terminals I and II must imperatively be connected observing the indicated cable crosssections. Refer to connection plan.

If required, the two sensor lines "Sense In +" and "+ Sense Out" (see table2) must be led separately and as

separate line to the + poles of the battery!

This is the only way to achieve a correct voltage measurement at the batteries.

The sensor lines near the battery must be protected with a fuse (cable protection)!

Page 5

- 5 -

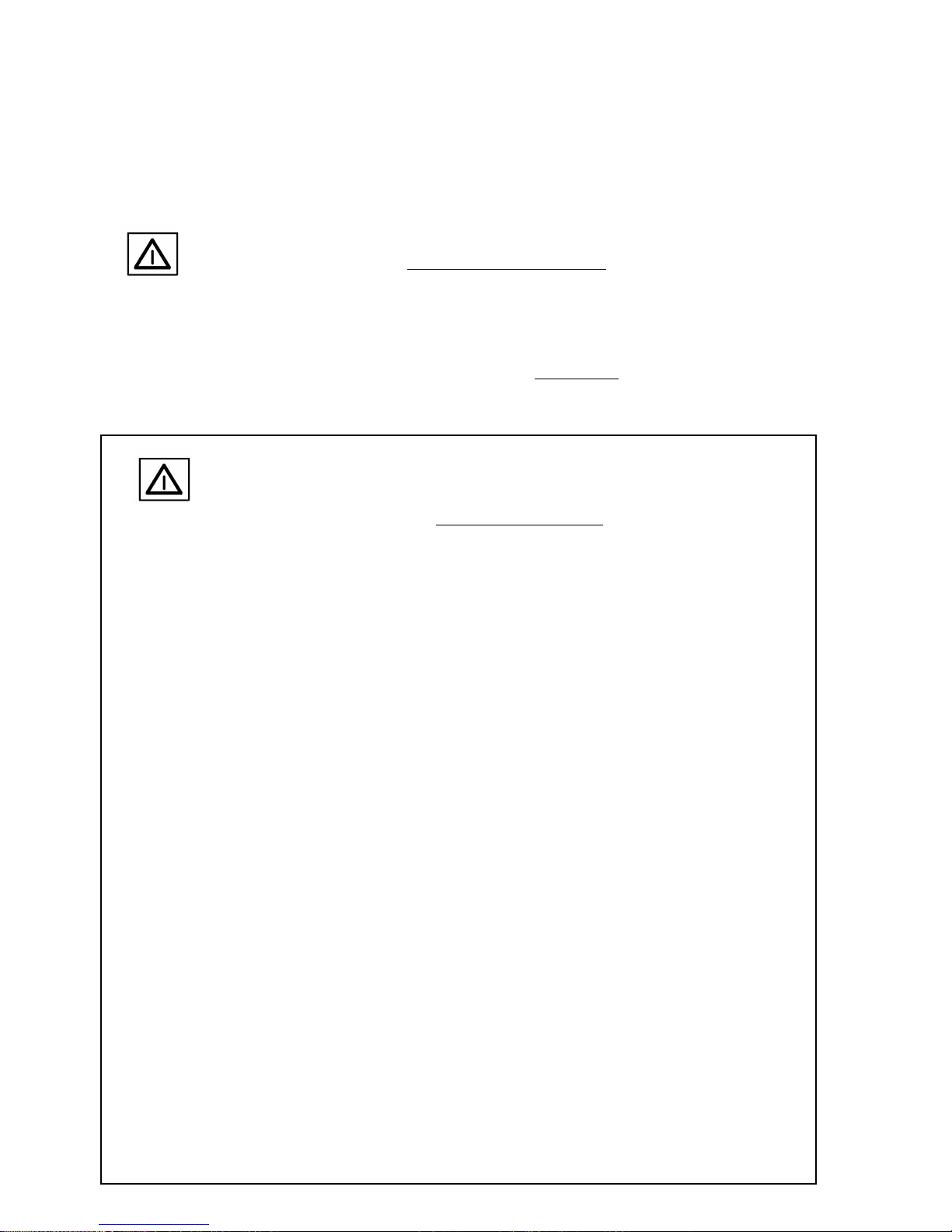

Recommended Cross-sections and Lengths of the Power Connection Cables:

Cable

Cross-

sections,

each

+ / - Pole

VCC 1212-25

VCC 1212-45

VCC 2412-25

VCC 2412-45

START

Batt.

BOARD

Batt.

START

Batt.

BOARD

Batt.

START

Batt.

BOARD

Batt.

START

Batt.

BOARD

Batt.

Fuse II:

40 A

Fuse I:

30 A

Fuse II:

80 A

Fuse I:

50 A

Fuse II:

30 A

Fuse I:

30 A

Fuse II:

40 A

Fuse I:

50 A

Cable

Length:

Cable

Length:

Cable

Length:

Cable

Length:

Cable

Length:

Cable

Length:

Cable

Length:

Cable

Length:

4 mm²

-

0.5 - 2.0 m

-

-

up to

6.0 m

0.5 - 2.0 m

-

-

6 mm2

up to

5.5 m

1.5 - 3.5 m

-

0.5 - 2.0 m

up to

11.0 m

1.5 - 3.5 m

up to

6.0 m

0.5 - 2.0 m

10 mm2

up to

9.0 m

3.0 - 6.5 m

up to

5.0 m

1.5 - 3.5 m

up to

18.0 m

3.0 - 6.5 m

up to

10.0 m

1.5 - 3.5 m

16 mm2 - -

up to

8.0 m

3.0 - 5.0 m

-

-

up to

16.0 m

3.0 - 5.0 m

* * Insert the cable into the terminal without wire-end ferrule

View Front Panel Input

View Front Panel Output

Page 6

- 6 -

Connection Plan VCC 1212-25, VCC 1212-45 including:

VOTRONIC charger with separate charging port for starter battery

VOTRONIC solar charging controller with separate charging port for starter battery

If possible, the unit should always be installed as close as possible to the board battery I.

Observe the cable cross-sections, lengths and fuses according to the table on page 5!

Possibly existing cables, which do not have the required cross-sections must be adapted to the

minimum requirements in any case!

Reverse battery (+/-) at the IN II (Start) side will result in serious damage of the unit!

Page 7

- 7 -

Option: Temperature Sensor (Connect the delivered temperature sensor):

Connect the temperature sensor to the terminals "T T Temp. Sensor" (any polarity).

It serves for control of the temperature of the BOARD supply battery. Also refer to page 15

"Charging Voltage Rates and Temperature Equalization/Control of the Battery Board I".

Ensure that the installation place of the sensor is not influenced by any source of heat (engine heat, exhaust, heater

etc.)!

Lead-Acid, Gel, AGM Batteries:

Installation: The thermal contact of sensor and battery inside temperature should be well. Thus, it should be screwed

down to the negative pole or positive pole of the battery. It is also possible to fasten it at the sidewall centre of the bat tery

casing.

Function: The temperature-dependent charging voltage of the BOARD battery will be adapted automatically to the battery

temperature (automatic temperature equalization). For this purpose, the temperature sensor measures the battery

temperature. In case of low temperatures (winter operation), the charging voltage will be increased, in order to improve

and accelerate full charging of the weak battery. Sensitive consumers are protected by a voltage limitation in case of very

low outside temperatures.

In case of summery temperatures, the charging voltage is reduced to minimize the load (gassing) of the battery and to

extend the lifetime of gas-tight batteries.

Battery Protection: In case of excessive battery temperatures (from +50 °C), the charging voltage will be reduced strongly

to the safety charging voltage, approx. 12.80 V, for battery protection, and the maximum charging current rate will be

halved (safety mode, LED "Battery I" is flashing. Any charging data being recorded hitherto will be kept in memory. Battery

charging is then interrupted, but the supply of possibly connected consumers will be continued by the unit, and the battery

is allowed to cool down. After that, automatic charging is resumed.

The unit recognizes automatically a missing sensor, cable break or short circuit of the sensor cables, as well as unreasonable

measuring values. In that case, it will switch automatically to the usual charging voltage rates of 20 °C / 25 °C being

recommended by the battery manufacturers.

LiFePO4 Batteries:

Installation: The thermal contact of sensor and inside temperature of the battery should be well. Thus, it should be

screwed down to the negative pole of the battery, because in most of the cases, this is the cooler side (the positive pole is

often biased by the exhaust heat of internal fuses of the battery, electronic systems for cell equalization, balancers etc.)

Function: In case of abnormal battery temperatures, such as < -20 °C, > 50 °C, the charging voltage will be reduced strongly

to the safety charging voltage, approx. 12.80 V, for battery protection, and the maximum charging current rate will be

halved (safety mode, LED "Battery I" is flashing). Any charging data being recorded hitherto will be kept in memory.

Battery charging is then interrupted, but the supply of consumers being possibly connected will be continued by the

charger until the battery temperature is again within the acceptable range. After that, automatic charging will be resumed.

Below 0 °C, the charging current will be reduced more strongly for battery protection, LED "Battery I" turns off shortly

every 2 seconds and longer charging times can be expected.

Warning: If the charging characteristic line had been set for a LiFePO4 battery, the temperature sensor

must be connected for reasons of battery safety. Otherwise, the unit will not operate, and the LED "Main

Charge" will be flashing!

Option: Remote Control (Tip Jack "Remote Control")

If the charging converter has been installed in a difficult to access location, the Remote Control S

for Automatic Charger, order No. 2075, can be used for remote control of the charging process

(plug-and-go connection cable of 5 m length is included in the delivery scope).

Connection:

Connect the remote control to the tip jack "Remote Control".

Function:

The remote control is equipped with the same pilot lamps (light-emitting diodes) as the charging

converter.

Switch Function:

Position "ON": Charging converter works with full charging capacity. LED display is active.

Position "OFF": Charging converter is switched-off (stand-by).

Page 8

- 8 -

Table 1: Setting of the Charging Program OUT for Type (Design) Board Battery I:

Move the 2 slide switches "Battery Type" OUT 12 V (24 V) at the front panel to the desired position for

board battery "I" using a small screw-driver. (Factory-adjusted position "Lead Acid"=Lead Acid Battery).

The control levers are shown in white.

Battery

Type

Selector

Switch

Output Side of the Converter:

If not being specified divergently by the battery manufacturer, the suitable charging program

for the battery type (design, technology) can be determined by means of the following

description and the technical data (voltage rates U1 and U2).

Note: The possible parallel/floating operation with consumers being

connected to the battery is also automatically considered by all charging programs.

"LiFePO4": 14.4 V Lithium charging program, adapted to

types, such as Super B SB12Vxx - M (Epsilon) **, RELION types RB **, Büttner types "MT-Li XX",

all with integrated battery management system and integrated safety circuit!

** also to be used with indication "Charging Voltage: 14.6 V", because of the lower battery load.

Check Super B SB12VxxE, GNB/Exide SL12 xxxHC with BMS and other batteries for their suitability

for 14.4 V charging voltage and only use them with completely own BMS and prescribed safety circuit!

LiFePO4 Charging Program IU1oU2:

U1 Main/Full Charging: 14.40 V 20 °C 0.3-1 h

U2 Full/Trickle/Storage Charging: 13.80 V 20 °C Continuous

"AGM 2": Charging program for lead, AGM/fleece batteries:

Adapted to closed, gas-tight AGM (absorbed glass mat) batteries and batteries in lead-fleece

technology requiring a particularly high level U1 for full charging.

voltage U1 14.7 V.

Unsuitable batteries might age prematurely due to loss of electrolyte!

Some manufacturers of AGM/fleece batteries are also prescribing a "gel" or "acid"

charging program with a charging voltage of 14.4 V for charging! In these cases, set

"Lead Acid / AGM 1" (14.4 V/13.50 V).

Charging program AGM/Fleece IU1oU2:

U1 Main/Full Charging: 14.70 V ! 20 °C 0.5-4 h

U2 Full/Trickle/Storage Charging: 13.60 V 20 °C Continuous

"Gel": Charging program for lead gel/dryfit batteries:

Adapted to closed, gas-tight Gel batteries with determined electrolytes, which are generally requiring a

higher charging voltage level and longer dwell times U1 to achieve short charging times with

particularly high capacity storage and to avoid deep discharge, e. g. EXIDE, Sonnenschein dryfit- Start,

Dryfit-Sport-Line, DETA Gel Battery Funline, Bosch AS Gel Batteries Va/Z, AS Gel Drive Batteries, AS Gel

Lighting Batteries.

If not being specified divergently by the battery manufacturer, also recommended for batteries in

round cell technology, such as EXIDE MAXXIMA (DC).

EXIDE, DETA, VARTA Characteristic Line Gel IU1oU2:

U1 Main/Full Charging: 14.40 V 20 °C 4-10 h

U2 Full/Trickle/Storage Charging: 13.80 V 20 °C Continuous

"Lead Acid/AGM 1": Universal charging program for acid/lead-acid batteries:

For charging and trickle charging of supply (board) batteries. Ensures short charging times, high

charging factor and acid mixing for open standard batteries and closed, low-maintenance,

maintenance-free "non-solid electrolyte", "lead-acid", drive, lighting, solar and heavy-duty batteries.

Also suitable for recently developed batteries (low-antimonous, batteries with silver alloy,

calcium/calcium or similar) with low and very low water consumption, as well as AGM batteries with

the designation 14.4 V.

Universal charging program IU1oU2:

U1 Main/Full Charging: 14.40 V 20 °C 0.5-4 h

U2 Full/Trickle/Storage Charging: 13.50 V 20 °C Continuous

Page 9

- 9 -

Table 2: Setting the Input, Installation Operating Mode IN II at the Starter Battery:

Power Control for Starter Battery and Generator

Move the 2 slide switches "Input Type S1, S2" IN II 12 V (24 V) at the front panel to the desired position

for Starter Battery "II" using a small screw-driver.

The control levers are shown in white.

Input

Type

Selector

Switch

Input side of the converter (at the starter battery for protection against LiMa peaks):

The operating range of charging converter must be set for the operating mode (control

connection, switching thresholds) and the mode of installation (cable lengths to the starter

battery). Also refer to: "Function of the Power Control for Starter Battery and Generator",

page 10.

A. Pure voltage control of the charging converter, without separate control signal "Kl.15 / D+":

Because of the high voltage thresholds, only to be used with separately laid "Sense In +" line,

sufficiently dimensioned cable cross-sections and powerful generator. The starter battery will not be

discharged under any circumstances.

Control connection "Kl.15 / D+" must be connected to "Sense In" via a wire jumper !

Increase of the charging capacity: > 13.60 V (27.2 V)

Reduction of the charging capacity: < 13.20 V (26.4 V)

Switching off threshold charging converter: < 12.60 V (25.2 V) 30 sec.

B. Slight load on the starter battery:

Only use these voltage thresholds with separately laid "Sense In +" line, sufficiently dimensioned cable

cross-sections and powerful generator.

Note: A continuous signal at "Kl.15 / D+" without running motor might discharge the STARTER battery!

Increase of the charging capacity: > 13.20 V (26.4 V)

Reduction of the charging capacity: < 12.80 V (25.6 V)

Switching off threshold charging converter: < 12.20 V (24.4 V) 30 sec.

C. Without sense line "Sense In +" of the starter battery:

If the cross-sections of the cables to the starter battery are sufficiently dimensioned, a separately laid

line "Sense In+" is not required. A wire jumper must be laid from "IN +" to "Sense In +"!

Note: A continuous signal at "Kl.15 / D+" without running motor might discharge the STARTER battery!

Increase of the charging capacity: > 13.40 V (26.8 V)

Reduction of the charging capacity: < 12.80 V (25.6 V)

Switching off threshold charging converter: < 12.20 V (24.4 V) 30 sec.

D. Vehicles according to EURO Standard 6, 6+ and for parallel operation of 2 charging converters:

If the cable to the starter battery is short (<2 m) and the cable cross-section is sufficiently

dimensioned, a separately laid voltage sensor line "Sense In+" is not required.

However, in this case a wire jumper is required for connection of "Sense In+" to "IN+".

This switch position is also provided for EURO standard 6, 6+ vehicles with energy management,

start/stop automatics, strongly varying voltage of generator/starter battery during energy recovery

etc.). If the cables are very long (losses), a separate voltage sensor line from the + starter battery to

"Sense In+" might be advantageous.

Always use the control input "Kl.15 / D+", and either connect it to KL.15 (ignition ON) or more safely to

D+ of the vehicle (generator is "active"), since in case of a continuous signal without running motor the

starter battery can be strongly discharged!

Increase of the charging capacity: > 11.70 V (26.0 V)

Reduction of the charging capacity: > 11.40 V (24.8 V)

Switching off threshold charging converter: < 11.20 V (23.6 V) 30 sec.

Option: Parallel Connection of 2 Charging Converters:

An increase of the charging capacity for large battery systems or high loads (such as operation of an air-conditioning

system) can be realized by parallel connection of two identical units. Couple the connections and set both units to switch

position "D" according to table 2.

A separately laid voltage sensor line from starter battery + (plus) is then to be distributed to the "Sense In +"

inputs of the units, particularly for Euro Standard 6 vehicles.

Due to the occurring high current rates, the required cable cross-sections of the power supply connections must

be multiplied by two, or they must be observed absolutely in case of separate laying.

Page 10

- 10 -

Start-up and Function Test:

After connection and setting of the charging converter the function can be tested:

1. Start the vehicle or switch on ignition (Kl.15).

- The charging converter will be activated and starts with 10 % of the maximum charging capacity.

- The LEDs "Power”, "Battery I”, "Main Charging” will be lighting, LED "Current” is lighting dimly.

2. Increase the speed of the vehicle to increase the voltage at the starter battery until it exceeds the adjusted value for

the "increase of the charging capacity".

- The charging capacity will be increased and is raised to the maximum value or to the required value of the charging

characteristic line, if the board battery is already full.

- The lighting intensity of the LED "Current" will be reduced or increased depending on the charging current.

Function of the Power Control for Starter Battery and Generator:

The charging converter is activated by the control input "Kl.15 / D+" and will be deactivated automatically if the motor is

switched-off. It starts with 10 % of its achievable charging capacity.

The setting of the two slide switches "Input Type" on the unit's rear (see table 2) now affects the further load of the starter

battery circuit supplying current to the charging converter.

After the engine start, also the starter battery shall be charged immediately and its starting capacity shall be maintained.

Therefore, the gradual increase of the charging capacity for the board battery will not be effected before the voltage value

"increase of the charging capacity" of the starter battery is reached.

In case of strong load on the starter circuit due to many large consumer loads and the starter battery’s voltage drops below

the value "reduction of the charging capacity", such as during motor idling, there will be a gradual reduction of the chargin g

capacity for the battery Board I, to relieve the starter circuit. But the minimum charging capacity will always be at least

10 % of the achievable charging capacity.

If the voltage drops below the "Switching off threshold charging converter" for 30 sec., the charging converter will be

switched-off automatically. As soon as the voltage exceeds the threshold "increase of the charging capacity", the converter

will be switched-on, and the capacity will be increased gradually until the required (maximum) charging capacity is reached.

A reduction of the charging capacity by more than 30 % due to insufficient input voltage of the dynamo will be indicated by

a flashing LED "Battery II". The LED will turn off, as soon as the input voltage is sufficient or when the power requirement

had dropped anyway due to a charged board battery "I".

Pilot Lamps:

"Battery Full" (Board battery fully charged, green):

If it is on: Battery has been charged to 100 %, trickle charge U2, finished.

If it is flashing: Main charging process is effected in the charging phase U1,

indication of charging state of approx. 80 % (short flashing, 90 % LiFePO4), gradual increase

to 100 % (long flashing).

Off: Main charging process is still being executed in the phase I.

"Main Charging" (Main charging board battery, yellow):

If it is on: Main charging process is effected in the charging phase I or U1.

Off: Trickle charge U2.

If it is flashing: 1. Battery temperature sensor is not connected with charging characteristic lines LiFePO4!

2. External battery overvoltage > 15.5 V delay 20 s,

Automatic reset < 13.2 V (depending on type), delay 30 s.

"Current" (Charging Current, red):

If it is on: The lighting intensity will be reduced or increased depending on the supplied charging

current.

Off: The instantaneous charging current is less than approx. 0.2 A.

"Battery I" (Board battery, yellow):

If it is on: Control and charging of board battery "I".

If it is flashing: Battery protection: Battery overtemperature > 50 °C, switching to

low safety charging voltage and half of the max. charging current,

automatic return, in case of slight cooling down to 48 °C,

with LiFePO4 also at low temperature of the battery < -20°C.

If it turns off shortly Only LiFePO4: Battery temperature below 0 °C. The charging current can be reduced for battery

every 2 s: protection for all modes of charging. If the battery is discharged, longer charging times.

Off: Board battery "I" is separated from the charging converter (safety switch).

Page 11

- 11 -

"Battery II" (Starter Battery, yellow):

If it is flashing: The power control of the charging converter has reduced the output capacity by more than

30 % (starter battery discharge protection, starting capacity is maintained), since the voltage of

the starter battery dropped below the adjusted value for "Reduction of the charging capacity"

(table 2). The charging capacity will be increased again, as soon as the voltage exceeds the

value "increase of the charging capacity".

"Power" (red):

If it is on: The charging converter had been activated and is ready for operation.

If it is flashing: 1. Disconnection by safety timer. Duration of the charging phase I was too long (15 hours) due to

too many consumers or defective battery (short circuit of the cells).

Reset only by removal of the signal at "D+ / Kl.15" (engine, ignition off).

2. Internal unit failure (overheating), automatic reset after cooling down.

3. Reverse battery of the battery board I by mistake (+ and - are mixed up).

Operating Instructions:

Interruption of the charging process:

If the control signal D+ or Kl.15 fails or the starter battery is drawn below the adjusted switching off threshold during

the charging process, the charging process will be interrupted. The connected batteries will not be discharged by the

charging converter. In this way, the charging process can be interrupted at any time. In case of frequent interruptions,

particularly before reaching full charge (LED "Battery Full" is lighting permanently), the battery should be subject to an

occasional full charging cycle of 24 hours for equalization of the charge.

Lifetime lead battery: Partially discharged lead batteries:

In contrast to other battery types, batteries on lead basis do not have any harmful memory effect. Consequently: In

case of doubt, partially discharged batteries have to be charged fully as soon as possible.

Store only fully charged batteries and recharge them periodically, particularly in case of used (older) batteries and

higher temperatures.

Lifetime lead battery: Recharge deeply discharged batteries immediately:

Sulphation of the battery plates due to deep discharge is to be prevented by immediate charging, particularly in case

of low and high ambient temperatures. If the grade of sulphation is not too intensive, the battery can recover part of

the battery capacity after several charging/discharging cycles.

Output overvoltage limitation at the board battery I (OUT):

Sensitive consumers are protected by means of a limitation of the charging voltage to max. 15.0 V during all modes of

charging, independently of the input voltage, charging programs etc.

Output overvoltage limitation at the board battery I (OUT):

Charging converters protect themselves against connection of excessive battery voltage rates, or they are switched-off

in case of defective additional charging systems (solar systems, generators etc.) switching threshold 15.5 V, delay 20 s.

Reset by battery <12.8 V (<13.4 V LiFePO4) or by disconnection of the control signal D+ or Kl.15.

Input overvoltage protection at the starter battery II (IN):

According to the EURO standards, the units supply uniform output voltage rates and output current rates in case of

varying input voltage rates. Extreme overvoltage of > 16.5 V (32.2 V) in the starter circuit causes a disconnection.

Overload/Overheating Protection Charging Converter:

The charging converter is equipped with a double electronic protection against overload and with an automatic

protection against adverse installation conditions (e. g. insufficient ventilation, excessive ambient temperatures) by

gradual reduction of the charging capacity.

Tips:

The unit is not activated with running motor:

Check the voltage rates, directly between terminal "Battery II –" and: Measure "+", "Sense In+" and "Kl. 15/D+",

fuses, wiring "+" and "–", stripped cable ends / at the clamping screws.

Full charging current is not reached:

Full charging is not effected, since the voltage is too low between terminal "Battery II –" and: "+", "Sense In+":

Observe the cable cross-sections and cable lengths, check the fuses, check the switch position S1, S2 according to table 2.

Insufficient voltage supply to "Sense In+" from a distributor or the like: Put the line to plus starter battery.

Concealed cutoff relay (such as EBL, EVS) bridges the charging converter: Check connection plan.

Battery Board I had been already charged: Turn on devices with high current draw.

Charging cable to board I: Check the cross-section and the length, check the fuses, if required, lay sensor line "Sense

Out+".

Downstream current distribution equipment or control units are not working correctly:

For instance, the signal D+ is not supplied: Ground (minus) connection between starter and board battery is missing.

Operation with EBL:

The charging converter changes permanently between active and stand-by: "Kl. 15/D+" must be connected directly to

the input EBL-D+ coming from the generator/electronic system of the vehicle.

Page 12

- 12 -

Special case: Connection Plan for Existing Electroblock "EBL",

Only for Types VCC 1212-25 Li and VCC 1212-45:

Option: Voltage display at an EBL of older design (EBL START In):

After installation of the charging converter in connection with an EBL of older design, it might happen, that the voltage for

the starter battery will not be displayed, if the charging converter had been switched-off.

In this case, the terminal "EBL START In" is to be connected to the voltage of the starter battery.

If possible, the unit should always be installed as close as possible to the board battery I.

Observe the cable cross-sections, lengths and fuses according to the table on page 5!

Possibly existing cables, which do not have the required cross-sections must be adapted to the

minimum requirements in any case!

Reverse battery (+/-) at the IN II (Start) side will result in serious damage of the unit!

Page 13

- 13 -

Special case: Connection Plan for Existing Electroblock "EVS",

Only for Types VCC 1212-25 and VCC 1212-45:

A special feature of the "EVS" systems is only a single connection to the starter battery, which means, that

separate connections for charging and voltage measurement for the starter battery do not exist.

For this reason, the connections "Sense In +" and "EBL Start In" must be bridged to ensure, that the

starter battery will also be charged during mains charging mode.

Determined by the system, the voltage of the starter battery will not be displayed correctly at the EVS during

driving.

If possible, the unit should always be installed as close as possible to the board battery I.

Observe the cable cross-sections, lengths and fuses according to the table on page 5!

Possibly existing cables, which do not have the required cross-sections must be adapted to the

minimum requirements in any case!

Reverse battery (+/-) at the IN II (Start) side will result in serious damage of the unit!

Page 14

- 14 -

Charging Process of the Board Battery I, Out, Output Side of the Charging Converter:

A new, complete main charging cycle will be executed:

After a standstill of the generator or removal of the control signal D+ or Kl.15.

If the voltage of the starter battery has dropped below the adjusted switching off threshold for more than 30 seconds.

If the battery voltage drops below the reset voltage of approx. 12.8 V (13.4 V with LiFePO4) for 30 seconds due to high

load beyond the maximum charging current.

If the charging converter had been switched-off by means of the remote control and on subsequent restart.

1. Charging aid for deeply discharged lead batteries. From 0 V, they will be subject to gentle preliminary charging for

recovery with a small current rate up to approx. 8 V or a switched-off LiFePO4 battery will be reactivated.

2. Main charging with maximum charging current (phase I) in the mean voltage range up to close to the phase U1 for

short charging times, LED "Main Charging" is lighting, and approx.75 % (lead), approx. 90 % (LiFePO4) of the

capacity will be charged. The duration of phase I depends on the battery conditions, the load by additional

consumers and the charging state. The charging converter records the charging process. For reasons of safety, the

phase I will be terminated by the safety timer after 15 hours, at the latest (cell defects etc.).

3. In case of high battery voltage rates, the charging current will be slightly reduced for battery protection (orientation

phase). After that, automatic switching to the following phase U1.

4. During the phase U1 (full charging, cell equalization charging, LED "Main Charging" is lighting), the battery voltage

will be kept constant on a high level. The green LED "Battery Full" is flashing (at first, short flashing, with rising

charge increasingly longer flashing), and gentle charging of the additional high battery capacity. The charging

converter controls the charging time as well as the charging current. From these values and from the course of

charging being recorded during the phase I, the charging converter determines the 100 % full charge point of the

battery for automatic switching to U2. In case of only slightly discharged batteries, the duration of phase U1 will be

kept short for relief of the battery and low maintenance expenditure. In case of major discharge, the phase U1 must

be extended for full charging of the battery and cell equalization charging. During this process, any influence by

consumer loads is avoided reliably.

The LED "Main Charging" turns off at the end of the phase U1.

5. Phase U2 (LED "Battery Full" is lighting permanently): The charging converter has now switched to the lower

voltage for trickle charge maintaining and buffering 100 % charge of the battery. Only the low compensating

recharging current is flowing, which is determined by the battery, and which is required for constant conservation of

the full charge.

Note: During the phases U1, U2 (battery full) almost the total charger current is available for the additional supply of

consumers, without any discharge of the battery.

Any consumed energy will be recharged immediately.

Charging Process of the Board Battery:

Page 15

- 15 -

Charging Voltage Rates and Temperature Equalization/Control of the Battery Board I:

TS = Temperature Sensor

Charging Program "Gel", IU1oU2 Charging Program "AGM 2", IU1oU2

Charging Program Acid "Lead Acid/AGM 1", IU1oU2 Charging Program "LiFePO4" 14.4 V, IU1oU2

Option: Several Batteries at the Charging Port OUT I:

Parallel charging of two or several batteries of the same voltage (12 V) is admissible. For this purpose, the batteries are

connected "in parallel". The capacity values (Ah) are summed up. The total capacity (total Ah) should not exceed the

indicated maximum battery capacity !

According to the battery manufacturers, permanent parallel operation is admissible in case of two or several batteries of

the same voltage, same type, same capacity, and of about the same age (history).

Example: Connection in parallel of 2 batteries (cross connection):

Both positive poles must be connected with a powerful cable. Also, both negative poles must be connected with a powerful

cable.

Now, the supply cables are connected advantageously "in cross connection", which means

Minus supply cable at negative pole of battery "1".

Plus supply cable at positive pole of battery "2".

This ensures that both batteries "1" and "2" of the system will receive/supply the same voltage.

Page 16

- 16 -

Technical Data VCC 1212-25 VCC 1212-45 VCC 2412-25 VCC 2412-45

IUoU-Li IUoU-Li IUoU-Li IUoU-Li

Input IN Starter Battery "II":

Nominal Voltage Battery: 12 V 12 V 24 V 24 V

Recomm. Battery Capacity min.: 60 Ah 80 Ah 50 Ah 60 Ah

Power Consumption max.: 480 W 720 W 450 W 740 W

Current Draw (at lowest input voltage) max.: 37 A 63 A 18 A 30 A

Current Consumption during Stand-by: 0.07 A 0.08 A 0.09 A 0.11 A

Current Consumption OFF (K1.15/D+ without Signal): 0.0004 A 0.0004 A 0.0004 A 0.0005 A

Overvoltage Disconnection EURO 6+: 16.50 V 16.50 V 32.20 V 32.20 V

Output OUT Board Battery "I":

Nominal Voltage Battery: 12 V - 13.3 V 12 V - 13.3 V 12 V - 13.3 V 12 V - 13.3 V

Battery Capacity, recommended/up to: 50-170/220 Ah 90-300/400 Ah 50-170/220 Ah 90-300/400 Ah

Charging Current Main Charging, Phase I, 8 V up to U1, 0-15 h: 25 A 45 A 25 A 45 A

Charging/Floating/Load Current, controlled, Phase U1-U2: 0 - 25 A 0 - 45 A 0 - 25 A 0 - 45 A

Selectable Charging Programs AGM/Gel/Lead Acid, LiFePO4: 4 4 4 4

Minimum Battery Voltage for Charging Start: 0 V 0 V 0 V 0 V

Prelim. Charg. Current (deeply discharged battery): 12.5 A (0-8 V) 22.5 A (0-8 V) 12.5 A (0-8 V) 22.5 A (0-8 V)

Reverse Current from Battery, OFF (K1.15/D+ without Signal): 0.000 A 0.000 A 0.000 A 0.000 A

Reset Voltage AGM-Gel-Lead Acid/LiFePO4 (30 sec): 12.8 V/13.4 V 12.8 V/13.4 V 12.8 V/13.4 V 12.8 V/13.4 V

Limit of Charging Voltage (Consumer Protection): 15.00 V 15.00 V 15.00 V 15.00 V

External Overvoltage Disconnection (20 sec.): 15.50 V 15.50 V 15.50 V 15.50 V

Ripple Factor Voltage: < 30 mV rms < 30 mV rms < 30 mV rms < 30 mV rms

Input for Battery I Temperature Sensor: Yes Yes Yes Yes

Charging Timer: 3-fold 3-fold 3-fold 3-fold

Safety Protect. ag. Reverse Batt./Short Circuit/Back Discharge: Yes Yes Yes Yes

Safety Timer per Charging Phase I /U1: Yes Yes Yes Yes

EBL START In, Measuring Input/Charging Port: Yes Yes -- -Charging/Trickle Charging for Starter Battery 12V: 0...3 A 0...3 A -- -Overcharge Protection: Yes Yes -- -Safety Protect. ag. Reverse Batt./Short Circuit/Back Discharge: Yes Yes -- --

Fitting Position of Unit: any any any any

Temperature Range: -20/+45 °C -20/+45 °C -20/+45 °C -20/+45 °C

Speed-controlled, Temperature-controlled Fan: Yes Yes Yes Yes

Gradual Reduction of Charging Capacity at Overtemperature: Yes Yes Yes Yes

Safety Disconnection in Case of Overheating: Yes Yes Yes Yes

System of Protection: IP21 IP21 IP21 IP21

Weight: 1350 g 1700 g 1350 g 1700 g

Dimensions (mm): 245 x 160 x 71

Declaration of Conformity:

In accordance with the provisions of Directives 2014/35/EU, 2014/30/EU, 2009/19/EC, this

product complies with the following standards or normative documents:

EN55014-1; EN55022 B; EN61000-6-1; EN61000-4-2; EN61000-4-3; EN61000-4-4;

EN62368-1; EN50498.

The product

must not be

disposed of in

the household

waste.

The product is RoHS compliant.

It complies with the directive

2011/65/EU for Reduction of

Hazardous Substances in electrical

and electronic equipment.

Delivery Scope:

Charging Converter

Temperature Sensor 825

Operating Manual

Available Accessories:

Remote Control S for Automatic Charger Order No. 2075

Subject to misprints, errors and technical modification without notice.

All rights reserved, particularly the right of reproduction. Copyright VOTRONIC 07/18.

Made in Germany by VOTRONIC Electronic-Systeme GmbH & Co. KG, Johann-Friedrich-Diehm-Str. 10, 36341 Lauterbach/GERMANY

Phone: +49 (0)6641/91173-0 Fax: +49 (0)6641/91173-20 E-mail: info@votronic.de Internet: www.votronic.de

Loading...

Loading...