Model VI770

Digital Inverter Generator

User’s Manual

January 2015

PREFACE

Thank you for purchasing a Voltmaster® inverter generator.

This manual covers operation and maintenance of the VI770 generator.

All information in this publication is based on the latest product information

available at the time of approval for printing.

We reserve the right to make changes at any time without notice and without

incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered a permanent part of the generator and should

remain with it if it is resold.

Pay special attention to statements preceded by the following words;

WARNING

WARNING

CAUTION

WARNING

Failed to properly follow these precautions can result in

property damage, serious injury or DEATH

Read all labels and the owner's manual before operating

this generator.

Operate only in well ventilated areas. Exhaust gas

contains poisonous carbon monoxide, and can be

deadly. Always stop engine before refueling. Wait 5

minutes before restarting.

Check for spilled fuel or leaks. Clean and/or repair

before use.

Keep any sources of ignition away from fuel tank, at all

times.

Indicates a strong possibility of severe personal injury or

death if instructions are not followed.

Indicates a possibility of personal injury or equipment

damage if instructions are not followed. If a problem

should arise, or if you have any questions about the

generator, consult an authorized dealer.

Our generators are designed to give safe and

dependable service if operated according to instructions.

Read and understand the Owner's Manual before

operating the generator. Failure to do so could result in

personal injury or equipment damage.

CONTENTS

1. Safety Instructions

2. Safety Label Locations

3. Component Indentificaction

1

3

4

11. SPECIFICATIONS

Rated frequency (Hz)

Rated voltage (V)

Rated current (A)

Rated rotation speed [r/min]

Rated output (kVA)

Max. output (kVA)

4. Pre-operation Check

5. Starting the Engine

6. Generator Use

7. Stopping the Engine

8. Maintenance

9. Transporting/Storage

10. Troubleshooting

11. Specifications

12. Electric diagram

5

9

12

16

18

25

27

29

30

Engine

Type

Displacement (BorexStroke)

Compression ratio

Rated power [kW(Hp)/(r/min)]

Rated rotation speed [rpm]

Ignition system

Spark plug

Starting system

Fuel

Fuel consumption (g/kW.h)

Lube oil

Fuel tank capacity (L)

Continuous running time (hr) (at rated output)

Noise level (zero load-full load) [dB(A)/7m]

Overall dimension (LxWxH) [mm(in)]

Dry weight [kg(lbs)]

*The declared values shall consider uncertainties due to production variation and

measurement procedures.

1. SAFETY INSTRUCTIONS

WARNING

Operate carefully to ensure safety.

WARNING

Our generators are designed to give safe and

depend-able service if operated according to

instructions.

Read and understand the Owner's Manual before

operating the generator. Failure to do so could result

in personal injury or equipment damage.

WARNING

Exhaust gas contains poisonous carbon monoxide.

Never run the generator in an enclosed area.

Be sure to provide adequate ventilation.

WARNING

The muffler becomes very hot during operation and

remains hot for a while after stopping the engine.

Be careful not to touch the muffler while it is hot.

The engine exhaust system will be heated during

operation and remain hot immediately after stopping

the engine.

To prevent scalding, pay attention to the warning

marks attached to the generator.

Gasoline is extremely flammable and explosive under certain conditions.

Refuel in a well ventilated area with the engine stopped.

Keep away from cigarette, smoke and sparks when re-fueling the

generator. Always refuel in a well-ventilated location.

Wipe up spilled gasoline at once.

Usage of generator should be limited in ambient where the risk of fire may

be high.

WARNING

--

WARNING

Connections for standby power to a building's electrical system must be

made by a qualified electrician and must comply with all applicable laws and

electrical codes. Improper connections can allow electrical current from the

generator to back feed into the utility lines. Such back feed may electrocute

utility company workers or others who contact the lines during a power

outage, and when utility power is restored, the generator may explode, burn,

or cause fires in the building's electrical system.

WARNING

Always make a pre-operation inspection before you start the engine. You

may prevent an accident or equipment damage.

Place the generator at least 1m(3ft) away from buildings or other

equipment during operation.

Operate the generator on a level surface.

If the generator is tiled, fuel spillage may result.

Know how to stop the generator quickly and understand operation of all

the controls. Never permit anyone to operate the generator without proper

instructions.

Keep children and pets away from the generator when it is in operation.

Keep away from rotating parts while the generator is running.

The generator is a potential source of electrical shocks when misused; do

not operate with wet hands.

Do not operate the generator in rain or snow and do not let it get wet.

--

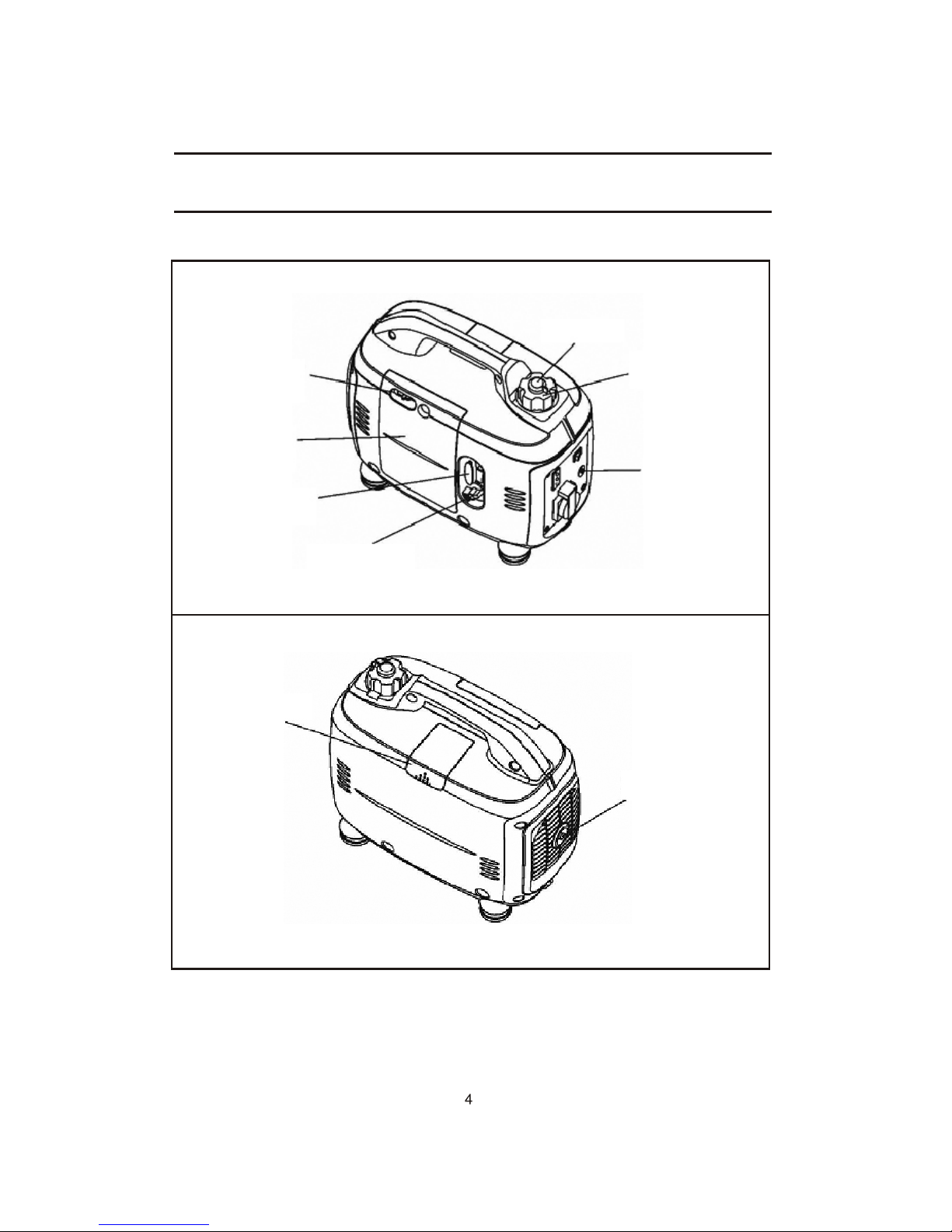

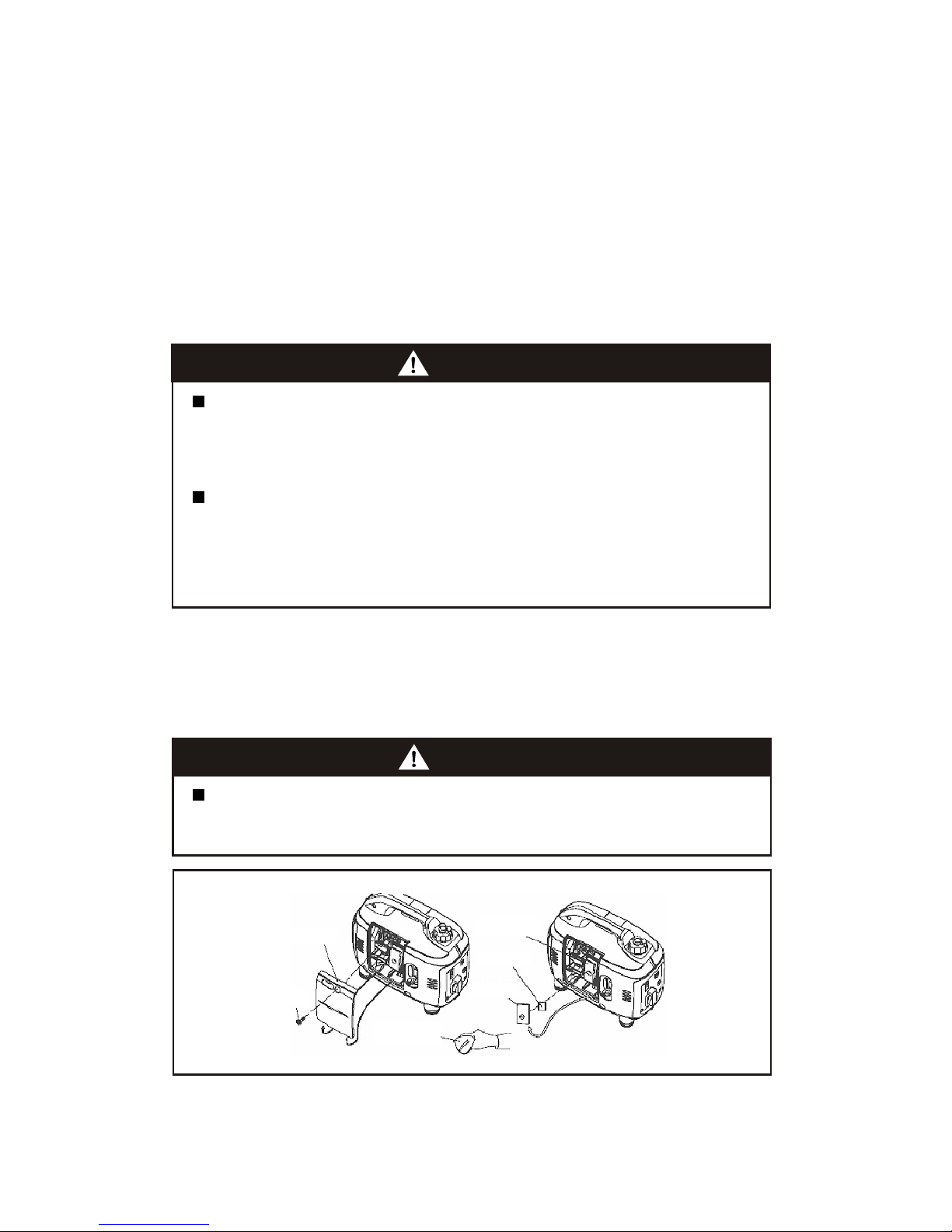

2. SAFETY LABEL LOCATIONS

These labels warn you of potential hazards that can cause serious injury. Read

the labels and safety notes and precautions described in this manual carefully.

If a label comes off or becomes hard to read, contact your dealer for a

replacement.

Chock handle

Oil level

Model

Safety caution

Engine switch

Air inlet

Hot caution

--

3. COMPONENT IDENTIFICATION

Fuel cap lever

Chock lever

Maintenance cover

Starter grip

Engine switch

Spark plug

maintenance

cover

Oil filler cap

Control panel

Muffler

--

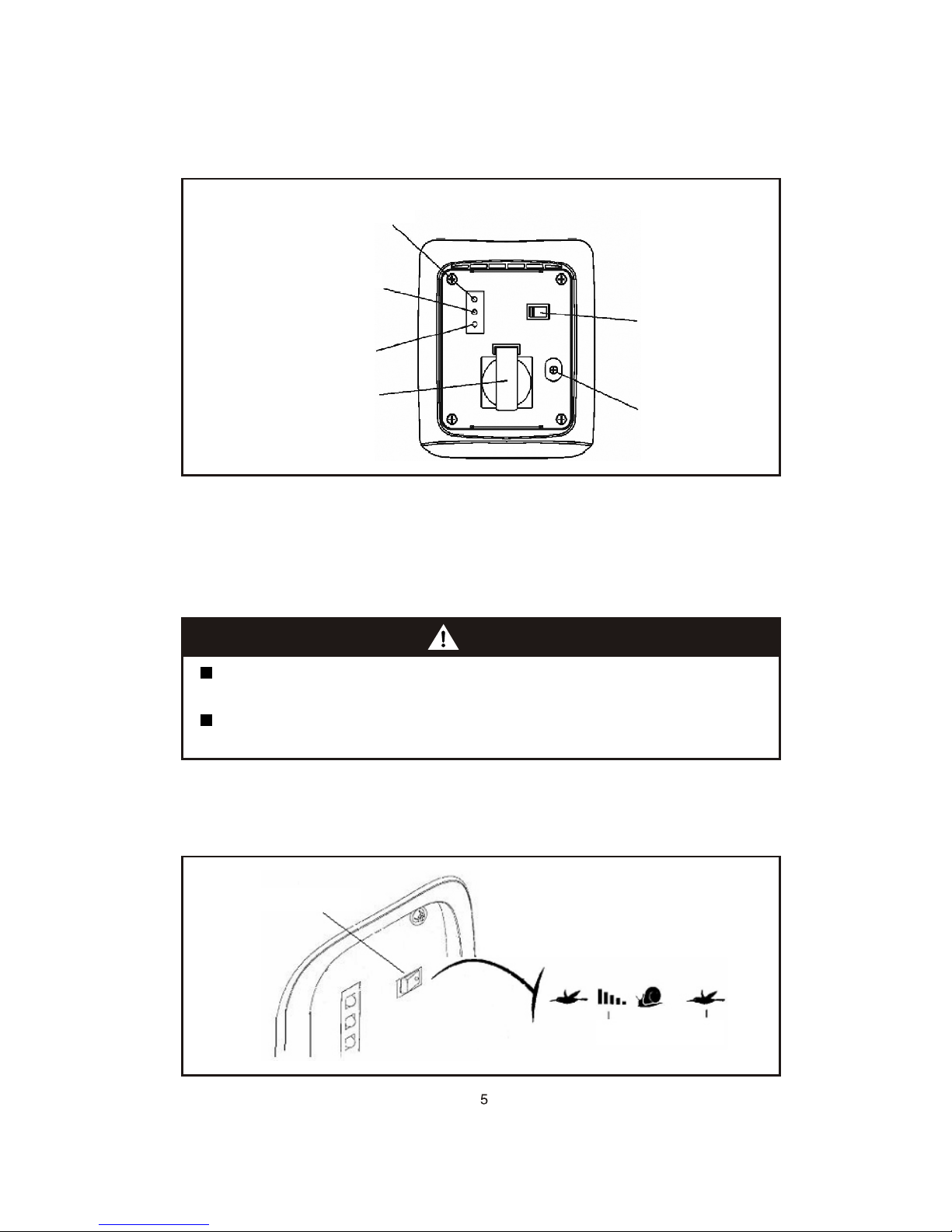

Control panel

Overload indicator light

Output indicator light

Low oil alarm indicator light

Smart switch

AC receptacle

Ground terminal

SMART throttle:

Engine speed is kept at idle automatically when the electrical appliance is

disconnected and it returns to the proper speed to power of the electrical load

when electrical appliance is connected. This position is recommended to

minimize the fuel consumption while in operation.

NOTE

Smart throttle system does not operate effectively if the electrical

appliance requires the big electric power.

When high electrical loads are connected simultaneously turn the smart

throttle switch to the OFF position to re-duce voltage changes.

OFF:

Note: Smart throttle system does not operate. Engine speed is kept at thighspeed lever.

Smart throttle

switch

ON OFF

--

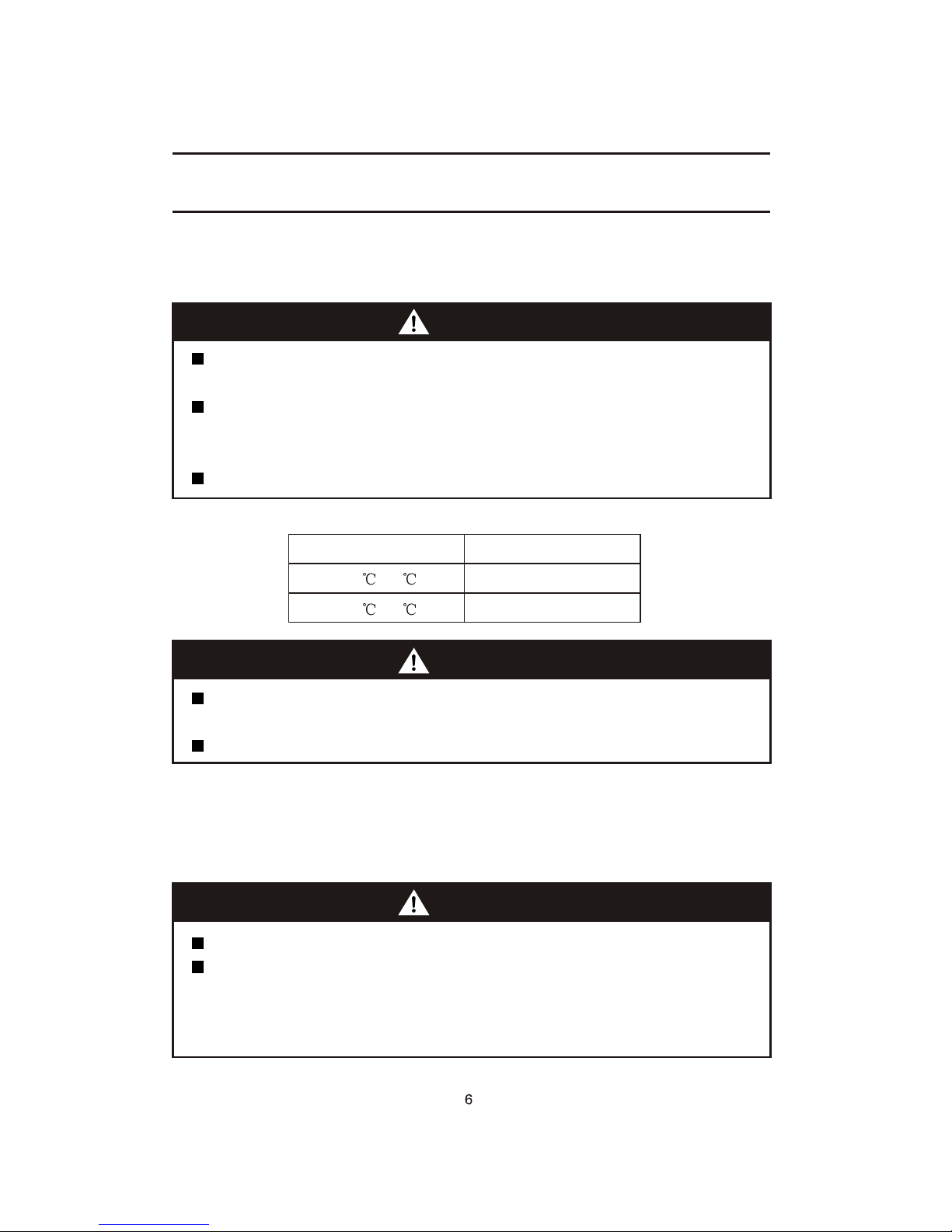

4. PRE-OPERATION CHECK

Be sure to check the generator on a level surface with the engine stopped.

1. Check the engine oil level.

CAUTION

Using nondetergent oil or 2-stroke engine oil could shorten the engine's

service life.

Use a high-detergent, premium quality 4-stroke engine oil, certified to

meet or exceed U.S. automobile manufacturer's requirements for API

Service Classification SG/SF.

Select the appropriate viscosity for the average temperature in your area.

SAE Viscosity Grades

Ambient temperature Engine oil type

-25 -30

-15 -40

10W-30

15W-40

CAUTION

Store and use the oil carefully in order to prevent dust or dirty flowing into

the oil. If oil is overfilled, wipe it up at once.

Never mix different kinds of oil.

Remove and wipe the dipstick with a clean rag. Check the oil level by inserting

the dipstick in the filler hole without screwing it in.

If the oil level is below the end of the dipstick, refill the recommended oil up to the

top of the oil filler neck.

CAUTION

Running the engine with insufficient oil can cause serious engine damage.

The Low Oil Alarm System will automatically stop the engine before the oil

level falls below the safe limit. However, to avoid the inconvenience of an

unexpected shutdown, it is still advisable to visually inspect the oil level

regularly.

--

Upper lever

Oil rule

Oil filler hole

Upper limit

Lower limit

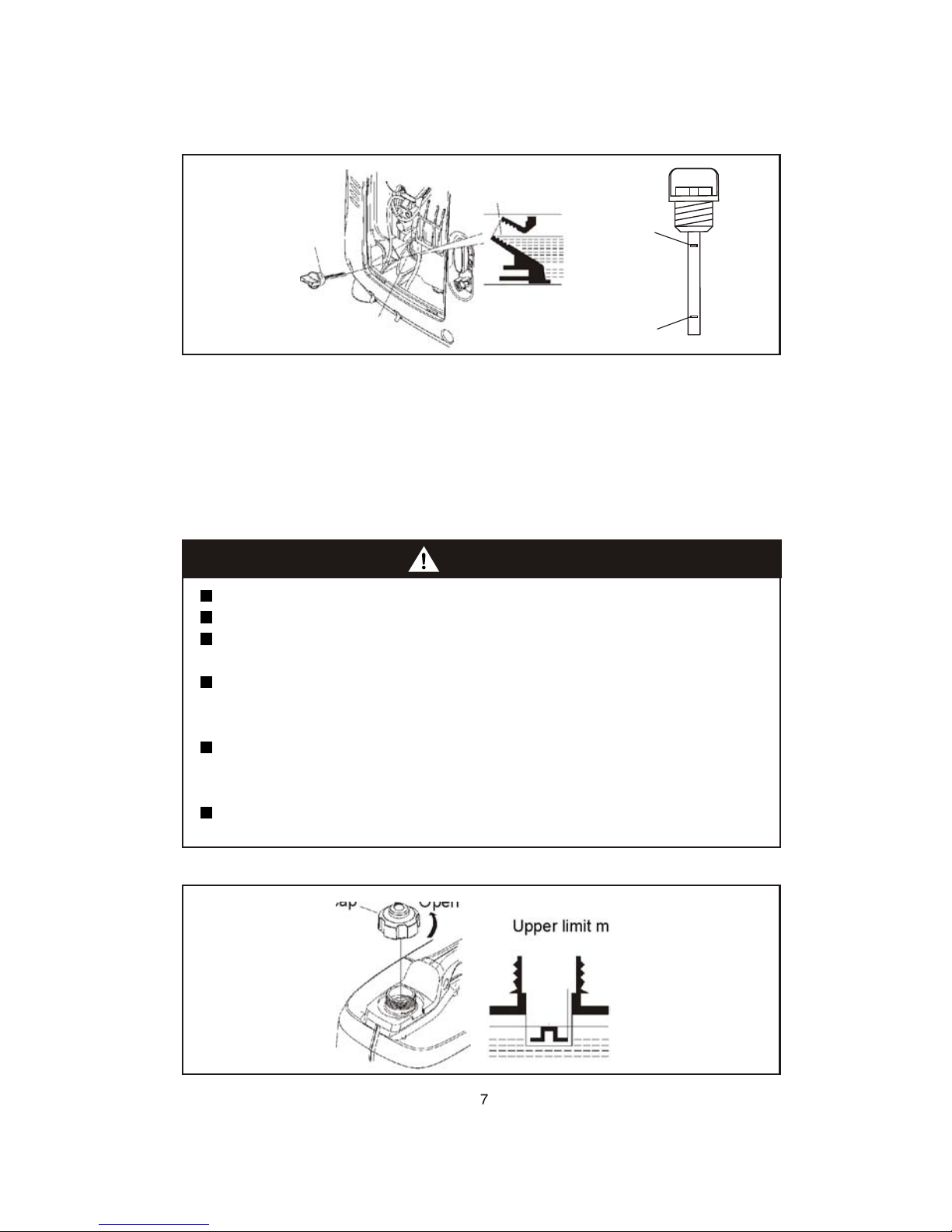

2. Check the fuel level.

Use automotive gasoline (Unleaded or low-leaded is preferred to minimize

combustion chamber deposits).

If the fuel level is low, refuel the fuel tank until the level as specified.

Never use an oil/gasoline mixture or dirty gasoline.

Avoid getting dirt, dust or water in the fuel tank.

After refueling, tighten the oil rule seurely.

WARNING

Gasoline is extremely flammable and is explosive under certain conditions.

Refuel in a well-ventilated area with the engine stopped.

Do not smoke or alow flames or sparks in the area where the engine is

refueled or where gasoline is stored.

Do not overfill the fuel tank (there should be no fuel above the upper limit

mark). After refueling, make sure the tank cap is closed properly and

securely.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may

ignite, if any fuel is spilled, make sure the area is dry before starting the

engine.

Avoid repeated or prolonged contact with skin or breath-ing of vapor,

KEEP OUT OF REACH OF CHILDREN.

Fuel tank capacity: 1.55L

Fuel filler cap

Open

Upper limit mark

--

Gasoline containing alcohol

If you decide to use a generator containing alcohol (gasohol), be sure it's octane

rating is at least as high as that recommended by us. There are two types of

gasohol: one containing ethanol, and the other containing methanol. Do not use

gasohol that contains more than 10% ethanol. Do not use gasoline containing

methanol (methyl or wood alcohol) that does not also contain cosolvents and

corrosion inhibitors for methanol. Never use gasoline containing more than 5%

methanol, even if it has cosolvents and corrosion inhibitors.

CAUTION

Fuel system damage or engine performance problems resulting from the

use of fuel that contain alcohol is not covered under the warranty. We cannot

endorse the use of fuels containing methanol since evidence of their

suitability is as yet incomplete.

Before buying fuel from an unfamiliar station, try to find out if the fuel

contains alcohol. If it does, confirm the type and percentage of alcohol used.

If you notice any undesirable operating symptoms while using a gasoline

that contains alcohol, or one that you think contains alcohol, replace it by a

gasoline that you know does not contain alcohol.

3.Check the air cleaner.

Check the air cleaner element to be sure it is clean and in good condition.

Loosen the cover screw and remove the left side maintenance cover. Press the

latch tab on the top of the air cleaner body, remove the air cleaner cover, check

the element. Clean or replace the element if necessary.

CAUTION

Never run the engine without the air cleaner. Rapid engine wear will result

from contaminants, such as dust and dirt, being drawn through the

carburetor, into the engine.

Maintenance cover

Screw

Foam filter

element

Air filter

Air filter element

Air filter cover

-8-

5. STARTING THE ENGINE

CAUTION

Before starting the engine, disconnect the load from the DC terminals.

When starting the generator after adding fuel for the first time or after long

term storage, or after running out of fuel, turn the fuel valve lever to the ''

ON'' position, then wait for 10 to 20 seconds before starting the engine.

1. Turn the fuel cap lever fully clockwise to the ON position.

Note: Turn the fuel cap vent lever to the OFF position when transporting generator.

Fuel cap lever

ON

2. Turn the engine switch to the On position.

ON

OFF

ON

Engine switch

--

3.Move the choke lever to the START position.

Note: Do not use the choke when the engine is warm or the air temperature is high.

Choke lever

Run

Run

4. Pull the starter grip until resistance is felt, then pull the starter grip briskly toward

the arrow as shown below.

CAUTION

Do not allow the starter grip to snap back, return it slowly by hand.

Starter grip

--

5. Move the choke lever to the RUN position after the engine warms up.

Choke lever

Run

Run

CAUTION

If the engine stops and will not restart, check the engine oil level before

troubleshooting in other areas.

High altitude operation

At high altitude, the standard carburetor air-fuel mixture will be excessively rich.

Performance will decrease, and fuel consumption will increase.

High altitude performance can be improved by installing a smaller diameter main

fuel jet in the carburetor and readjusting the pilot screws. If you always operate

the generator at altitudes higher than 1,500m (5,000 feet) above sea level, have

your authorized dealer perform these carburetor modifications.

Even with suitable carburetor jetting, engine horsepower will decrease

approximately 3.5% for each 305m (1,000 feet) increase in altitude. The affect of

altitude on the horsepower will be greater than this if no carburetor modification is

made.

Operation of the generator at an altitude lower than the carburetor is jetted

for may result in reduced performance, overheating, and serious engine

damage caused by an excessively lean air/fuel.

CAUTION

--

6. GENERATOR USE

WARNING

To prevent electrical shock from faulty appliances, the generator should

be grounded. Connect a length of heavy wire between the generator's

ground terminal and an external ground source.

Connections for standby power to a building's electrical system must be

made by a qualified electrician and must comply with all applicable laws and

electrical codes. Improper connections can allow electrical current from the

generator to backfeed into the utility lines. Such backfeed may electrocute

utility company workers or others who contact the lines during a power

outage, and when utility power is restored, the generator may explode, burn,

or cause fires in the building's electrical system.

CAUTION

Maximum power would be available for the first 30 minutes.

For continuous operation, do not exceed the rated power.

Do not exceed the current limit specified for any one receptacle.

Do not connect the generator to a household circuit. This could cause the

damage to the generator or to electrical appliances in the house.

Do not modify or use the generator for other purposes than it is intended

for. Also observe the following when using the generator.

A. Do not connect generators in parallel.

B. Do not connect an extension to the exhaust pipe.

When an extension cable is required, be sure to use a tough rubber

sheathed flexible cable.( IEC245

Limit length of extension cables: less than 60 m for cables if 1.5 mm and

less than100m for cables of 2.5 mm .

Keep the generator away from other electric cables or wires such as

commercial power supply lines.

2

2

Electrical equipment (including electrical lines and plugs connection)

could not be defective.

CAUTION

--

AC applications

1.Start the engine and make sure the output indicator light (green) comes on.

2.Confirm that the appliance to be used is switched off, and plug in the appliance.

Output indicator light(green)

Overload indicator

Smart switch

Plug

light(red)

CAUTION

Be sure that all appliances are in good working order before connecting

them to the generator. If an appliance begins to operate abnormally,

becomes sluggish, or stops suddenly, turn off the generator engine switch

immediately. Then disconnect the appliance, and examine it for signs of

malfunction.

3. In order to acquire both the best effect and the maximum service life of the

generator. Usually, the new generator should run 20 hours under 50% load, the

generator may reach the best performance.

Output and Overload Indicators

The output indicator light(green)will remain ON during normal operating

conditions.

If the generator is overloaded(in excess of 1.0kVA), or if there is a short in the

connected appliance, the output indicator light(green) will go OFF, the overload

indicator light(red) will go ON and current to the connected appliance will be shut

off.

Stop the engine if the overload indicator light (red) comes ON and investigate the

overload source.

--

CAUTION

Before connecting an appliance to the generator, check that it is in good

order, and that its electrical rating does not exceed that of the generator.

Then connect the power cord of the appliance, and start the engine.

CAUTION

Indicator lights (both red and green) may come ON during generator

starting. It is normal if the red indicator light goes off after 4 seconds, if not,

please contact your dealer.

1. Connect the ground terminal.

Grounding terminal

2. Start each engine according to "STARTING THE ENGINE".

When the output indicator light(green)does not light and the overload indicator

light (red) lights instead, set the engine switch to STOP, stop the engine at once

and then start the engine again.

3. Confirm that the equipment to be used is switched off, and insert the plug

of the equipment to be used into the AC receptacle

Confirm that the use equipment to be connected is switched off. When the

equipment to be used is switched on, it will operate suddenly, and injuries or

accidents may be caused.

CAUTION

--

4. Switch on the equipment to be used.

In case of overload operation or when trouble occurs for the equipment being

used, the output indicator light(green) will go out, the overload indicator light(red)

will light continuously, and no power will be put out.

At this time, the engine will not stop, so that the engine must be stopped by

setting the respective engine switch to STOP.

CAUTION

When equipment requiring a large starting power, like a motor etc., is used,

the overload indicator light (red) and the output indicator light(green)may

light together for a short time (about 4 sec), but this is no abnormality. After

start of the equipment, the overload indicator light (red) will go out and the

output indicator light(green) will stay lit.

Low oil alarm system

The Low oil alarm system is designed to prevent engine damage caused by an

insufficient amount of oil in the crankcase. Before the oil level in the crankcase

falls below a safe limit, the Low oil alarm system will automatically shut down the

engine (the engine switch will remain in the ON position).

If the low oil alarm system shuts down the engine, the low oil alarm indicator

light(red) will come on when you operate the starter, and the engine will not run. If

this occurs, add engine oil.

Low oil alarm

indicator (red)

Overload indicator

light (red)

Output indicator light (green)

--

7. STOPPING THE ENGINE

To stop the engine in an emergency, turn the engine switch to the OFF position.

IN NORMAL USE:

1. Switch off the connected equipment and pull the inserted plug.

Plug

2 .Turn the engine switch to the OFF position.

Engine switch

--

OFF~

3.Turn the cap lever fully counterclockwise to the "OFF"position

Fuel cap lever

CAUTION

OFF

Be sure the fuel cap lever, choke and the engine switch are "OFF" when

stopping, transporting and/or storing the generator.

--

8. MAINTENANCE

The purpose of the maintenance and adjustment schedule is to keep the generator

in the best operating condition.

WARNING

Shut off the engine before performing any maintena-nce. If the engine

must be run, make sure the area is well ventilated. The exhaust contains

poisonous carbon monoxide gas.

CAUTION

Use genuine our parts or their equivalent. The use of replacement parts

which are not of equivalent qual-ity may damage the generator.

7.1 Maintenance Schedule

REGULAR SERVICE PERIOD(1) Perform at every

indicated month or operating

hour interval,whichever occurs first.

ITEM

EACH

USE

FIRST

MONTH

OR

20HRS

EVERY 3

MONTHS

OR

50HRS

EVERY 6

MONTHS

OR

100 HRS

EVERY

YEAR

OR

300 HRS

Engine oil

Air cleaner

Spark plug

Spark arrester

Fuel sediment cup

Valve clearance

Fuel tank and strainer

Fuel line

NOTE:

(1) Log hours of operation to determine proper maintenance.

(2) Service more frequently when used in dusty areas.

(3)These items should be serviced by an authorized dealer, unless the owner has

the proper tools and is mechanically proficient.

Check

Change

Check

Clean

Clean-adjust

Clean

Clean

Check-adjust

Clean

Check

(2)

(3)

(3)

Every 2 years (Replace if necessary)(3)

1.CHANGING OIL

Drain the oil while the engine is still warm to assure rapid and complete draining.

CAUTION

Confirm if engine lever and ventilation lever of oiling port are turned to the

Off side before the oil drainage.

1. Loosen the cover screw and remove the left side maintenance cover.

2. Remove the oil filler cap.

3. Drain dirty oil into a container thoroughly.

4. Refill with the recommended oil, and check the oil level.

5. Reinstall the left side maintenance cover and tighten the cover screw securely.

Engine oil capacity: 0.15L

Maintenance cover

Screw

Upper level

Dipstick

Oil filler cap

Wash your hands with soap and water after handing used oil.

CAUTION

Please dispose of used motor oil in a manner that is compatible with the

environment. We suggest you take it in a sealed container to your local

service station for reclamation. Do not throw it in the trash or pour it on the

ground.

2. AIR CLEANER SERVICE

A dirty air cleaner will restrict air flow to the carburetor. To prevent carburetor

malfunction, service the air cleaner regularly. Service more frequently when

operating the generator in extremely dusty areas.

WARNING

Do not use gasoline or low flash point solvents for cleaning. They are

flammable and explosive under certain conditions.

CAUTION

Do not run generator without air cleaner for causing engine accelerated

wear.

a. Loosen the cover screw and remove the left side maintenance cover.

b. Press the latch tab on the top of the air cleaner body, and remove the air

cleaner cover.

c. Wash the element in a non-flammable or high flash point solvent and dry it

thoroughly.

d. Soak the element in clean engine oil and squeeze out the excess oil.

e. Reinstall the air cleaner element and the cover.

f. Reinstall the left side maintenance cover and tighten the cover screw securely.

Maintenance

cover

Screw

Air filter

Air filter element

Air filter cove

Foam filter

element

--

3. SPARK PLUG SERVICE

RECOMMENTED SPARK PLUG: UR5

To ensure proper engine operation, the spark plug must be properly gapped and

free of deposits.

(1). Remove the spark plug maintenance cover.

Spark plug

maintenance cover

(2). Remove the spark plug cap.

(3). Clean any dirt from around the spark plug base.

(4). Use the wrench to remove the spark plug.

Handle bar

Spark plug cap

Plug wrench

--

(5). Visually inspect the spark plug. Discard it if the insulator is cracked or

chipped. Clean the spark plug with a wire brush if it is to be reused.

(6). Measure the plug gap with a feeler gauge.

The gap should be 0.6-0.7mm(0.024-0.028in). Correct as necessary by carefully

bending the side electrode.

Clearance

CAUTION

The spark plug must be securely tightened. An improperly tightened plug

can become very hot and possibly damage the generator. Never use a spark

plug with an improper heat range.

(7). Install the spark plug carefully, by hand, to avoid cross-threading.

(8). After a new spark plug has been seated by hand, it should be tightened 1/2

turn with a wrench to compress its washer.

If a used plug is being reinstalled, it should only require 1/8 to 1/4 turn after being

seated.

(9). Reinstall the spark plug cap on the spark plug securely.

(10). Close the left maintenance cover.

--

4. SPARK ARRESTER MAINTENANCE

WARNING

If the generator has been running, the muffler will be very hot. Allow it to

cool before proceeding.

The spark arrester must be serviced every 100 hours to maintain its

efficiency.

(1). Remove the four M5 screws, and remove the muffler protector.

Muffler protector

M5 screw

(2). Remove the there M6 bolts, and remove the muffler, the spark arrester and

the muffler gasket

Muffler gasket

M6 screw

--

(3). 3.Use a brush to remove carbon deposits from the spark arrester screen.

(4). Check the muffler gasket; replace if damaged. Reinstall the muffler gasket, the

spark arrester, the muffler and the muffler protector in the reverse order of removal.

--

9. TRANSPORTINT/STORAGE

To prevent fuel spillage when transporting or during temporary storage, the

genera-tor should be secured upright in its normal operating position, with the

engine switch OFF. Turn the cap lever fully counterclockwise to the "OFF"

position.

WARNING

When transporting the generator:

Do not overfill the tank (there should be no fuel in the filler neck)

Do not operate the generator while it is on a vehicle.

Take the generator off the vehicle and use it in a well ventilated place.

Avoid a place exposed to direct sunlight when putting the generator on a

vehicle. If the generator is left in an enclosed vehicle for many hours, high

temperature in-side the vehicle could cause fuel to vaporize resulting in a

possible explosion.

Do not drive on a rough road for an extended period with the generator on

board, if you must transport the generator on a rough road, drain the fuel

from the generator beforehand.

Before storing the unit for an extended period:

1. Be sure the storage area is free of excessive humidity and dust.

2. Drain out the fuel completely.

CAUTION

Gasoline is extremely flammable and explosive under certain conditions.

Do not smoke or allow flames or sparks in the area.

Drain screw

--

A. Drain all gasoline from the fuel tank into an approved gasoline container.

B. Turn the engine switch ON, and loosen the carburetor drain screw and drain

the gasoline from the carburetor into a suitable container.

C. With the drain screw loosened remove the spark plug cap, and pull the starter

grip 3 to 4 times to drain the gasoline from the fuel pump.

D. Turn the engine switch to the OFF position, and tighten the drain screw

securely.

E. Reinstall the spark plug cap on the spark plug

3. Change the engine oil.

4. Remove the spark plug and pour about a tablespoon of clean engine oil into

the cylinder.

Crank the engine several revolutions to distribute the oil, then reinstall the spark

plug.

5.Slowly pull the starter grip until resistance is felt. At this point, the piston is

coming up on its compression stroke and both the intake and exhaust valves are

closed. Storing the engine in this position wil help to protect it from internal

corrosion.

Starter grip

--

10. TROUBLESHOOTING

When the engine will not start:

Is there fuel in the tank?

YES

NO

Refill the fuel tank.

Is the engine switch on?

YES

Is there enough oil in the engine?

YES

Is there a spark from

the spark plug?

NO Still no

WARNING

Be sure there is no spilled

fuel around the spark pulg.

Spilled fuel may ignite.

If the engine still does not

start, take the generator to

an authorized dealer.

NO

NO

Replace the

spark plug.

To check:

1)Remove the spark plug cap and clean

any dirt from around the spark plug.

2)Remove the spark plug and install the

spark plug in the plug cap.

3)Set the plug side electrode on the

cylinder head to ground.

4)Pull the recoil starter, sparks should jump

across the gap.

Turn the engine switch on.

Add the recommended oil.

Take the generator to

spark

an authorized dealer.

--

Appliance does not operate:

Is the output indicator light ON?

YES

Is the overload

indicator light ON?

Check the electrical appli-

ance or equipment for any

defects.

YES

NO

YES

NO

NO

Take the generator to an

authorized dealer.

Take the generator to an

authorized dealer.

Replace the electrical

appliance or equipment

Take the electrical appli-

ance or equipment to an

electrical shop for repair

--

11. SPECIFICATIONS

1

3

4

5

9

12

16

18

25

27

Model

Rated frequency (Hz)

Rated voltage (V)

Rated current (A)

Rated rotation speed [r/min]

Rated output (kVA)

Max. output (kVA)

Engine

Model Type

Type

Displacement (BorexStroke)

Compression ratio

Rated power [kW(Hp)/(r/min)]

Rated rotation speed [rpm]

Ignition system

Spark plug

Starting system

Fuel

Fuel consumption (g/kW.h)

Lube oil

VI770

50

230

3.04

Single cylinder, 4 stroke, air-cooled, vertical, OHV

37.68ml (40 30mm)

Automotive unleaded gasoline

CD grade or SAE 10W/30

60

120

5.82

6000

0.70

0.77

KG140

8.5:1

1.00/6000

6000

T.C.I

UR5

Recoil starter

450

60

240

2.92

29

Fuel tank capacity (L)

30

Continuous running time (hr) (at rated output)

Noise level (zero load-full load) [dB(A)/7m]

Overall dimension (LxWxH) [mm(in)]

Dry weight [kg(lbs)]

*The declared values shall consider uncertainties due to production variation and

measurement procedures.

1.55

3

60-65 *

410 220 360

10.5

--

12. ELECTRIC DIAGRAM

-30--30-

WANCO INC.

5870 Tennyson Street

Arvada, Colorado 80003

800-730-3927

303-427-5700

303-427-5725 fax

www.voltmaster.com

©2015 Wanco Inc. All rights reserved.

Voltmaster is a Wanco brand. Voltmaster, Wanco, and the Voltmaster

and Wanco logos are registered trademarks of Wanco Inc. All other

trademarks are property of their respective owners.

Loading...

Loading...