PM3000ACE

User Manual

Version 6

Applies to:

PM3000ACE

(Standard)

PM3000ACE-001

(with torque and speed inputs)

PM3000ACE-002

(for full compliance IEC harmonics)

VPN 98-051/6

PM3000A U

SER MANUAL

H

EALTH AND SAFETY

H

EALTH AND SAFETY AT WORK

Electrical devices can constitute a safety hazard. It is the responsibility of the user to ensure the

compliance of the installation with any local acts or bylaws in force. Only qualified personnel should

install this equipment, after reading and understanding this users guide. These operating instructions

should be adhered to. If in any doubt, consult your supplier.

DANGER

ELECTRIC SHOCK RISK

Please note:

This equipment is supplied under warranty conditions, in force at the time of purchase from

your supplier. Contact your supplier for details. Any attempt to disassemble or modify the

unit will render any warranty agreement invalid.

The contents of this guide are believed to be accurate at the time of printing. The

manufacturers, however, reserve the right to change the content, product specification, and

performance criteria, without notice. No liability is accepted for the inappropriate, negligent,

or incorrect set-up of the instrument by the user, either by manual or automated means.

EALTH AND SAFETY

H

PM3000A U

SER MANUAL

S

AFETY PRECAUTIONS

1.

The PM3000A is constructed in compliance with the requirements of EN61010-1, Pollution

Degree 2, Installation Category II, and as such ensures the safety of the meter and the user

when normal precautions are followed.

2. The power source should be inserted in a socket with a protective ground contact.

3. The power source should be inserted before connections are made to measuring or control

circuits.

4. Do not attempt to remove outer cover without first disconnecting auxiliary and test power

supply.

5. This instrument must only be serviced by qualified personnel who understand the danger of

shock hazards.

6. When the instrument is removed from its case hazardous voltages are present.

7. The electronic circuitry of this instrument is fully floating with respect to ground. If the

instrument is opened and dangerous voltages (above 50V peak) applied to the input terminals

then all the circuitry must be considered 'Live'.

8. The signal leads must be in good condition with no damage.

PM3000A USER MANUAL TABLE OF CONTENTS

ABLE OF

T

ONTENTS

C

TABLE OF CONTENTS PM3000A USER MANUAL

PM3000A USER MANUAL TABLE OF CONTENTS

TABLE OF CONTENTS

CHAPTER 1 GENERAL DESCRIPTION PAGE

1.1 Equipment Checklist 1-1

1.2 Accessories 1-2

1.3 System Overview 1-3

CHAPTER 2 GETTING STARTED PAGE

2.1 Power On 2-1

2.2 Using the Control Keys 2-1

2.3 Connection Diagrams 2-4

CHAPTER 3 BASIC FUNCTIONS PAGE

3.1 Basic Measurement Function Keys 3-1

3.2 Set-Up Keys 3-4

3.3 Harmonic Analysis 3-9

CHAPTER 4 PROGRAM SET-UP PAGE

4.1 Programming 4-1

CHAPTER 5 THE FUNCTION MENUS PAGE

5.1 F[1] Power On Default 5-1

5.2 F[2] Bandwidth 5-1

5.3 F[3] Wiring 5-1

5.4 F[4] Efficiency 5-3

5.5 F[5] Program Switch 5-4

5.6 F[6] IEC555 Testing Mode 5-4

5.7 F[7] PWM Drives Mode 5-10

5.8 F[8] Ballast/Ultrasonic Mode 5-14

5.9 F[9] Transformer Test Mode 5-14

5.10 F[10] Calibration 5-16

TABLE OF CONTENTS PM3000A USER MANUAL

CHAPTER 6 ADVANCED CONFIGURATION

6.1 [F][P] Configuration 6-1

P

AGE

CHAPTER 7 INTEGRATOR PAGE

7.1 Integrator Measurements 7-1

7.2 Integrator Menu 7-2

CHAPTER 8 INTERFACES PAGE

8.0 Interface Menu 8-1

8.1 Printer Interface 8-1

8.2 IEEE Interface 8-3

8.3 RS232 Interface 8-3

8.4 Chart Recorder Interface 8-5

8.5 Analogue Output Interface 8-6

8.6 Auxiliary Inputs 8-8

CHAPTER 9 DATALOG PAGE

9.1 Datalog Overview 9-1

9.2 Cycle by Cycle Analysis 9-1

9.3 Datalog 9-3

CHAPTER 10 IEEE COMMUNICATION PAGE

10.1 IEEE488 Overview 10-1

10.2 Addressing 10-2

10.3 Data Sources 10-2

10.4 IEEE 488.1 Operation 10-3

10.5 Example IEEE 488.1 Program 10-14

10.6 IEEE 488.2 Operation 10-17

10.7 Program Timing 10-49

10.8 VPAS Demonstration Software 10-50

PM3000A USER MANUAL TABLE OF CONTENTS

CHAPTER 11 SPECIFICATION

11.1 Voltage 11-1

11.2 Current 11-1

11.3 Power 11-2

11.4 Apparent Power 11-2

11.5 Reactive Power 11-3

11.6 Power Factor 11-3

11.7 Crest Factor 11-3

11.8 Inrush Current 11-4

11.9 Impedance 11-4

11.10 Frequency 11-4

11.11 Harmonic Analysis 11-4

11.12 Integrator 11-4

11.13 Bandwidth 11-5

11.14 Chart Recorder Outputs 11-5

11.15 External Frequency Source 11-5

11.16 External Trigger Input 11-5

11.17 Operating Temperature and Humidity 11-5

11.18 Dielectric Strength 11-5

11.19 Power Source 11-6

11.20 Dimensions and Weight 11-6

11.21 Auxiliary Inputs 11-6

11.22 Warranty 11-7

CHAPTER 12 COMPLIANCE WITH EC DIRECTIVES

12.1 Declaration of Conformity 12-1

12.2 EMC Precautions 12-2

P

P

AGE

AGE

APPENDIX 1 INDEX TO FUNCTION KEYS

APPENDIX 2 ALPHABETICAL INDEX

APPENDIX 3 FORMULAE

TABLE OF CONTENTS PM3000A USER MANUAL

PM3000A USER MANUAL GENERAL DESCRIPTION

CHAPTER 1

ENERAL DESCRIPTION

G

GENERAL DESCRIPTION PM3000A USER MANUAL

PM3000A USER MANUAL GENERAL DESCRIPTION

1.1 EQUIPMENT CHECK LIST

The following items comprise a complete instrument:

1 off PM3000A Unit

6 off Yellow Test Leads

6 off Black Test Leads

6 off Yellow Crocodile Clips

6 off Black Crocodile Clips

1 off AC Power Lead

1 off User Manual

1 off RS232 Lead

1 off VPAS Demonstration Disk

1 off IEC1000-3 Demonstration Disk

PAGE 1-1

GENERAL DESCRIPTION PM3000A USER MANUAL

1.2 ACCESSORIES

Current Transformer 1000/100:1 (CT1000)

1000:1 Current Clamp Transformer (CL1000)

100:1 Current Clamp Transformer (CL100)

Ballast Current Transformer (Ballast CT)

Parallel Printer Cable (VPN 77-001)

VPAS (Visual Power Analysis Software) (VPAS)

IEC1000-3 Software for Windows (IEC1000-3)

PS1000 Power Switch for Inrush Current Measurements (PS1000)

1.2.1 APPLICATION NOTES

Power Measurements in Lighting Applications (APP Note 101)

IEC1000-3 Application Note (APP Note 104)

PWM Drives (APP Note 105)

PAGE 1-2

PM3000A USER MANUAL GENERAL DESCRIPTION

1.3. SYSTEM OVERVIEW

The user is referred to the block diagram on the next page.

The PM3000A has 6 isolated input channels (3 voltage - 3 current) with 12 ranges per

channel. Each channel has its own A/D converter, which samples the input and sends the

digital data back to a microprocessor using an isolation link. This technique allows the

PM3000A to have an extremely high common mode rejection, minimizing the effects

caused by high dv/dt waveforms such as those existing in motor drives etc.

The sampling is under the direct control of the processor and the analogue to digital

conversion for all channels is simultaneous (no phasing errors). The normal measurement

procedure is as follows. (Note that many of the measurements have separate routines).

All channels are sampled at a sample rate set by the microprocessor. The data is stored

in memory until 400 samples for each channel have been made. The data is then

checked for over-range or under range. If the range is correct, the frequency of the input

is calculated. If the sample rate is not right for the input frequency, the sample rate is

adjusted and 400 new samples are taken.

The digital signal processor then calculates the volts, amps and watts etc. for each

channel and then performs a Fourier analysis of the data to compute the fundamental

components of the volts and amps and any other harmonics required.

This data is then transferred to the interface processor and another set of samples is

taken. The interface processor averages and displays the results required for the front

panel display. Further to this all the results for every phase are computed, averaged, and

stored in memory. These background results are available to the IEEE, RS232 and printer

interfaces.

The user can select over 400 different measurements from this store making the

PM3000A an extremely versatile instrument.

P

AGE 1-3

GENERAL DESCRIPTION PM3000A USER MANUAL

PM3000A BLOCK SCHEMATIC

PAGE 1-4

PM3000A USER MANUAL GETTING STARTED

CHAPTER 2

ETTING STARTED

G

GETTING STARTED PM3000A MANUAL

PM3000A USER MANUAL GETTING STARTED

2.1 POWER ON

The instrument is supplied with a power lead to suit the local electricity supply. In some

cases a power plug will need to be fitted: connect brown wire to phase or live pin; blue

wire to neutral pin and green/yellow wire to ground or earth pin. On no account should

the instrument be used without the safety ground being made.

Turn the power on at the front of the instrument.

The display will briefly show 'VOLTECH INSTRUMENTS’ and the firmware version

number, followed by the default display:

0.000 V 0.000 A

Watts = +0.000 W

All the LED indicators will be lit for a short time before the default display is shown and it

is assumed at this stage that no voltage and current inputs are present.

The factory set default display is for a single-phase 2-wire connection (see section 2.3).

Watts, Volts and Amps are displayed for channel 1 (confirmed by the LED indicator below

the [CH1] key. In this display mode the keys for phases 2 and 3, [CH2] and [CH3], as well

as the calculated sum key [∑] and neutral current key [N] are invalid.

(The power on display may have been changed by a previous user. It is possible to

restore the default display by loading the standard program - see section 4.1.1)

Important Note. The PM3000A is a high bandwidth (500kHz) instrument. The standard

and 001 versions of the instrument are fitted with a low bandpass (25 kHz) filter that is

enabled as default.

Version PM3000A-002 has a 5kHz filter to meet requirements of the EN60555-2 and

EN61000-3-2 standards. For high frequency measurements disable the filter as described

in section 5.2.

2.2 USING THE CONTROL KEYS

Although a sophisticated instrument, the PM3000A is extremely easy to configure and

operate. The control keys are all front panel mounted, and are arranged in a manner to

aid intuitive operation of the equipment.

To enable the user to get ‘up and running’ as quickly as possible several of the basic

measuring functions are described below. Greater detail of their operation plus a

description of the remainder of the control keys is covered in the following chapters.

PAGE 2-1

GETTING STARTED PM3000A MANUAL

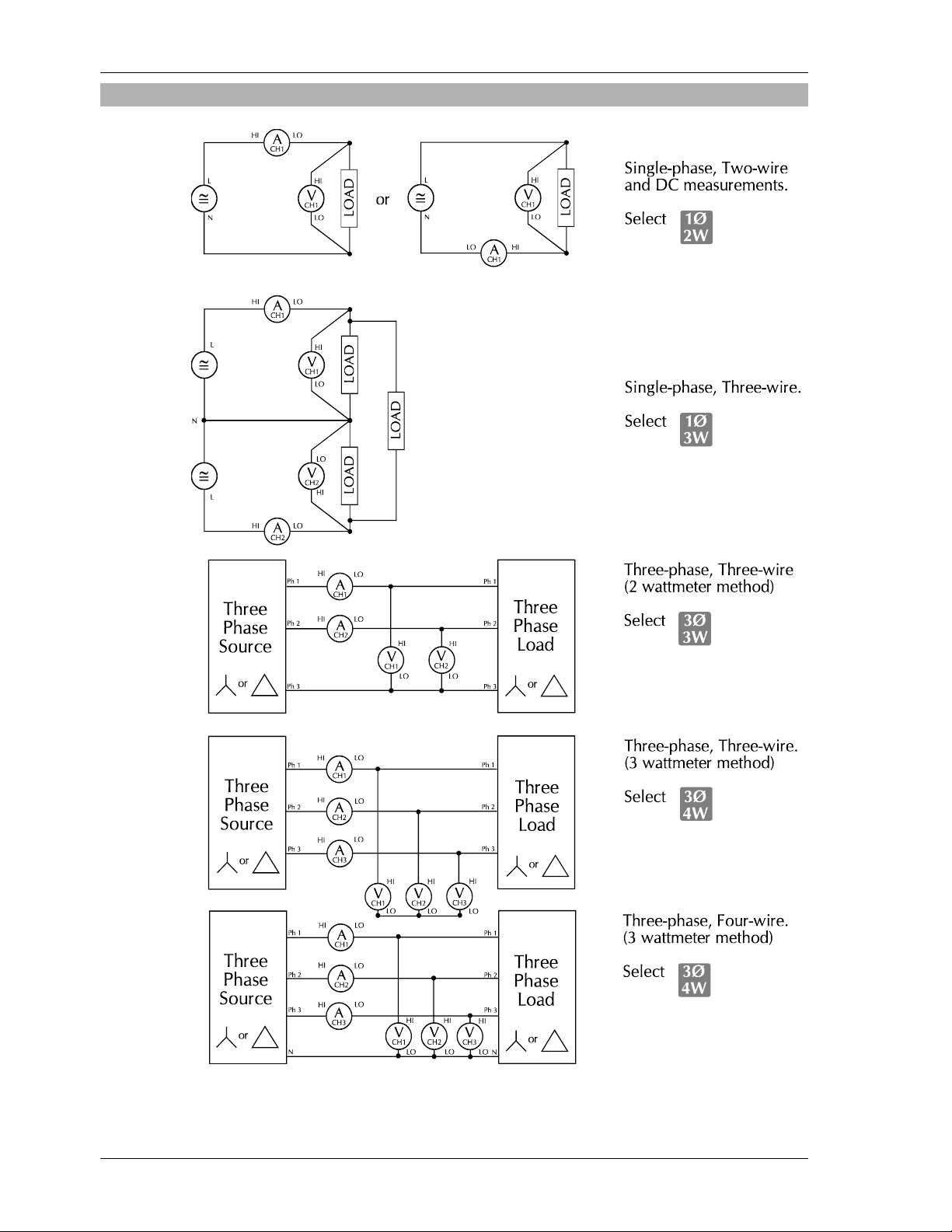

2.2.1 WIRING KEYS

Before meaningful measurements can be made the wiring mode must be selected and

appropriate connections made to the rear panel. The PM3000A is highly versatile and can

be configured to analyze almost any electrical system. This versatility is achieved

because all power inputs are ac + dc coupled and isolated from each other and ground.

The four main wiring modes are:

[1Ø2W] SINGLE PHASE, TWO WIRE.

Select for single phase loads with two-wire distribution system.

[1Ø3W] SINGLE PHASE, THREE WIRE.

Select for single phase loads with three-wire distribution system.

[3Ø3W] THREE PHASE, THREE WIRE.

Select for single-phase loads without neutral connection (two-wattmeter method).

[3Ø2W] THREE PHASE, FOUR WIRE.

Select for single-phase loads with or without neutral connection (three-wattmeter

method).

Refer to section 2.3 for the rear panel connections to be used for each wiring mode.

2.2.2 CHANNEL SELECT KEYS

These keys are used in conjunction with the wiring keys to display the measure values for

the selected phase or channel.

The function of each is as follows:

[CH1] Displays the measured values for the phase connected to channel 1

[CH2] Displays the measured values for the phase connected to channel 2

[CH3] Displays the measured values for the phase connected to channel 3

[∑] Displays the summation (total) value for multiphase systems

[N] Displays neutral currents in multiphase systems. These waveforms are

computed by summation of the instantaneous values of the individual phase

currents.

Information is only displayed if relevant to the wiring mode selected. For example, if

[1Ø2W] has been selected only the [CH1] key will display the measured parameters.

Selecting any of the other four keys will result in the message FUNCTION INVALID being

displayed.

The user is encouraged to assess the effect of selecting combinations of the Channel

Select and Wiring keys.

PAGE 2-2

PM3000A USER MANUAL GETTING STARTED

2.2.3 AUTO KEYS

The PM3000A is a fully auto-ranging instrument, and in most measurement modes the

green LED under the [AUTO] keys for volts and amps should be illuminated. Specific

ranges for voltage or current may be chosen if desired. Use the up and down arrow keys

beneath the appropriate display to select a measurement range. The green LED beneath

the [AUTO] key will be extinguished and the range chosen (volts or amps) indicated by

the red LED panel. If the voltage or current range is set too low an OVERLOAD message

will be displayed.

2.2.4 MEASUREMENT KEYS

The use of the six keys at the top left of the front panel is described below – these are

used for the most common measurements of power systems. Further details of these and

other measurement keys are covered in the following chapters.

2.2.4.1 [W] TRUE POWER

Measures the power absorbed by a load or delivered from an ac source even with

distorted waveforms. The instrument is ac + dc coupled and therefore measures the total

real power.

2.2.4.2 [VA] APPARENT POWER

Determines the apparent power absorbed by a load or delivered from a source.

2.2.4.3 [VAR] REACTIVE POWER

Computes and displays the reactive power flow due to the phase difference between the

current and voltage waveforms and due to waveform distortion.

2.2.4.4 [V] VOLTAGE

Displays the true RMS or mean values of the input voltage(s) even with distorted

waveforms.

2.2.4.5 [A] C

2.2.4.6 [PF] POWER FACTOR

URRENT

Displays the true RMS or mean values of the load current(s) even with distorted

waveforms.

Displays the true power factor of an ac load.

PAGE 2-3

GETTING STARTED PM3000A MANUAL

2.3 CONNECTION DIAGRAMS

PAGE 2-4

PM3000A USER MANUAL BASIC FUNCTIONS

CHAPTER 3

ASIC FUNCTIONS

B

BASIC FUNCTIONS PM3000A USER MANUAL

PM3000A USER MANUAL BASIC FUNCTIONS

=

×

3.1 BASIC MEASUREMENT FUNCTION KEYS

3.1.1 [W] TRUE POWER

Measures accurately the power absorbed by a load or delivered from an AC source, even

with distorted waveforms. The instrument is (AC + DC) coupled (see section 3.2.4), and

therefore measures the total real power.

Connect the PM3000A as shown in the appropriate connection diagram (see section 2.3)

and select [W]. The instrument is fully autoranging and the display will show the actual

power in watts. The polarity indicates the direction of power flow.

Real power is computed as:

T

=

1

vidt

ii

∫

0

T

rms rms

2

()

2

W

v and i represent instantaneous volts and amps

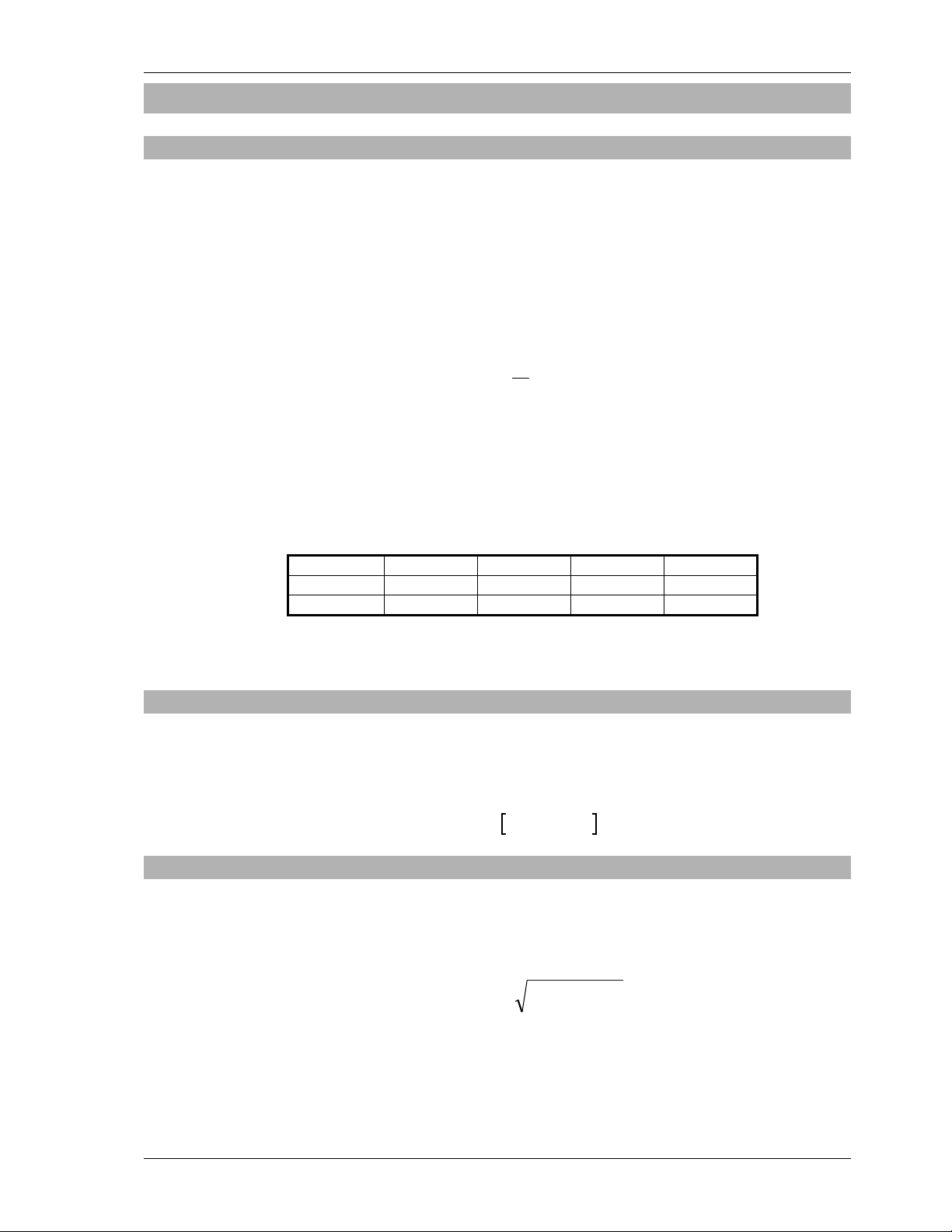

The polarity of Watts, VArs (fundamental) and PF (fundamental) are given in the table

below. The displacement angle is the angle of the current fundamental with reference to

the voltage fundamental.

0º -90º -180º -270º -360º

W + - - +

PF.f - - + +

VArs.f + + - -

For Watts: + indicates positive power flow.

- indicates negative power flow.

3.1.2 [VA] A

Determines the apparent power absorbed by a load or delivered from a source. Connect

the instrument as for power measurements and select [VA]

VA is computed as:

PPARENT POWER

3.1.3 [VAR]-REACTIVE POWER (VOLT-AMPERES)

The PM3000A computes and displays the reactive power flow due to the phase difference

between the current and voltage waveforms and due to waveform distortion.

VAr is computed as:

The polarity of the (fundamental) VArs is shown in the table in section 3.1.1. for various

angles between current and voltage.

For VArs: + indicates an inductive load

- indicates a capacitive load

VA V A

VAr VA W=−

PAGE 3-1

BASIC FUNCTIONS PM3000A USER MANUAL

3.1.4 [V] VOLTA GE

The input is (AC + DC) coupled, (see section 3.2.4) and the instrument will record the

RMS or MEAN (see section 3.2.2) value of the combined AC and DC components. Only

the voltage input leads need be connected for Vrms measurements. Vrms is computed

as:

T

and Vmean is computed as:

V

RMS i

=

T

1

1

MEAN

=

∫

T

∫

T

0

2

vdt

0

dtvV

3.1.5 [A] CURRENT

Only the current input need be connected when taking Arms measurements. Arms is

computed as:

T

and Amean is computed as:

3.1.6 [PF] P

Displays the true power factor of an AC load. Power factor is only cos

waveforms; cos

shift between the voltage and current waveforms). Power factor is computed as:

If the current waveform is distorted, the fundamental components of the voltage and

current may well be in phase, with cos

unity. The PM3000A computes the ratio W/VA, which is the true power factor even for

distorted waveforms. The polarity of the (fundamental) power factor is given in the table of

section 3.1.1 for various angles between current and voltage.

For PF: + indicates a leading current

- indicates a lagging current

NB. The polarity of the power factor can be reversed if desired (see section 6.1).

OWER FACTOR

ø is merely the displacement factor of the load (a measure of the phase

A

RMS i

=

T

1

1

A

MEAN

=

T

PF

ø = 1, but the true power factor will be less than

Watt

=

VA

×

rms rms

∫

0

T

∫

0

2

idt

idt

ø for undistorted

PAGE 3-2

PM3000A USER MANUAL BASIC FUNCTIONS

3.1.7 [VPK], [APK] PEAK VOLTAGE O R CURRENT

These keys display the repetitive peak current or voltage. The peak voltage measurement

is used to determine the working voltage of insulation or the voltage available for

rectification.

The peak current measurement can be used to set current limit or trip levels in UPS or

similar equipment.

3.1.8 [VCF], [ACF] V

Crest factor is the ratio of the magnitude of the peak value to the RMS value of a

waveform.

OLTAGE OR CURRENT CREST FACTOR

CF =

ValuePeak

ValueRMS

The crest factor of a sinewave is √2 or 1.41.

Many loads, such as rectifiers with capacitor filters, produce a distorted current waveform

where the Amps crest factor will be much larger than √2.

3.1.9 [INRUSH A] PEAK INRUSH CURRENT

The [INRUSH A] key allows the user to capture and hold the peak current of all three

current channels. This feature is typically used to display the peak inrush current as

power supplies, motors, etc., are switched-on.

The measurement is made by sampling continuously on all three current channels and

holding the highest value. The sample rate varies according to the wiring configuration.

WIRING SELECTION SAMPLE RATE

Single phase two wire 3.6µS

Single phase three wire 6.8µS

Three phase three wire 6.8µS

Three phase four wire 10.0µS

Inrush current can also be measured using the data log function (see section 9.1). This

has the advantage of allowing the user to view the captured inrush waveforms and of

making other measurements on the same data.

To measure inrush current press the [INRUSH A] key- the display will then be similar to

that shown below.

SET MANUAL RANGE

Inrush = 0.000 A

Using the up and down arrow keys beneath the red LED panel select an amps range that

is able to accommodate the expected peak inrush current. Switch on the load and the

display will show the highest current captured.

PAGE 3-3

BASIC FUNCTIONS PM3000A USER MANUAL

If the load is multi-phase, the inrush current on each phase will have been captured and

can be viewed with the [CH1], [CH2] and [CH3] CHANNEL SELECT keys.

The highest value captured will be held until the [INRUSH] key is pressed again to reset

the display or a higher value is measured. If an overload occurs the display will not clear

until the [INRUSH] key is pressed even if the overload is no longer present. Press another

Function key to return to the previous displays.

3.1.10 [IMPEDANCE]

The impedance of a load can be measured by pressing the [IMPEDANCE] key. The total

impedance will be displayed in ohms, calculated as:

VoltsRMSTotal

Z =

AmpsRMSTotal

If fundamentals have been selected, i.e. the FUND LED is on, the complex impedance

due to the fundamental volts, amps and power factor is displayed.

Z = R + jX Ohms

Only the resistive part, R, of the impedance is displayed on the single function and

multiple channel displays.

+R Indicates power flow into load

-R Indicates power flow from load

+X Indicates inductive reactance

-X Indicates capacitive reactance

3.1.11 [ENTER] TO HOLD THE DISPLAY

When not in a configuration, programming or data entry mode, the [ENTER] key may be

used to hold the value of the parameter in the lower line of the display. The values of

other parameters are also held when [ENTER] is pressed and these may be displayed by

pressing the appropriate control key.

To return to real-time display press [ENTER] again.

3.2 SET-UP KEYS

The SET UP keys control the configuration of the input circuits of the PM3000A. Since

each channel is entirely separate and isolated from each other, the set-up can be different

for each channel when independent channel wiring modes are selected. In normal 3

phase 3 wire or 3 phase 4 wire connection modes, the set-up parameters are linked

together for simplicity.

3.2.1 [FREQ SOURCE]

As part of the operation of the PM3000A the measurement functions are synchronized to

the ac supply frequency. The source of this frequency is selected by means of the [FREQ

SOURCE] key.

[INT] mode synchronizes measurement to input voltage or current over the frequency

range 5Hz to 1MHz. The user can choose between voltage or current frequency

measurement. This feature is useful in applications such as motor drives where one input

may be ‘chopped’.

PAGE 3-4

PM3000A USER MANUAL BASIC FUNCTIONS

[EXT] mode synchronizes measurement to a signal applied to a rear panel connector. It is

typically used when both voltage and current are ‘chopped’, or when frequencies as low

as 0.1Hz are required to be measured.

Options

There are four options. Use the [SELECT] key to display the required option and then

press [ENTER]:

i. >voltage<: CH1 Volts with a frequency range of DC and (5Hz -1MHz)

ii. >current<: CH1 Amps with a frequency range of DC and (5Hz -1MHz)

iii. >external<: Frequency source applied to EXTERNAL FREQUENCY input, with a

iv. >slow external<: Frequency source applied to EXTERNAL FREQUENCY input,

The maximum voltage to be applied to the EXTERNAL input is limited to 10Vrms.

Phase Reference

If voltage is selected, the phase reference source is automatically set as the Voltage

Waveform of CH1.

If current, external or slow external have been selected, the display then shows:

range of DC and 5Hz -1MHz.

with a range 0.1Hz-100Hz. Selecting this mode will give measurement times in

excess of 10 seconds for frequencies under 5Hz

PHASE REFERENCE

By pressing [SELECT] the user can switch between voltage and current as the phase

reference source for harmonic analysis. Press [ENTER] to confirm the selection. Either

the red or green LED beneath the [FREQ SOURCE] key will illuminate to indicate the

status.

3.2.2 [VOLTS AMPS] RMS OR MEAN

The PM3000A can display voltage and current in either true RMS or rectified mean

values.

RMS mode is the default and this is indicated by the corresponding LED beneath the key.

In the mean mode voltage, current and amp hours only are displayed as rectified mean

values. All other parameters are displayed as RMS. However when printing results all

values are printed as RMS.

3.2.3 [AVG] AVERAGING

The PM3000A will average a number of measurements to display a steady reading

despite fluctuations at the inputs. The results to be averaged are placed in an averaging

store of user-defined length. When a new result is added to the store the oldest result in

the store is discarded.

>Voltage<

PAGE 3-5

BASIC FUNCTIONS PM3000A USER MANUAL

In AUTO mode the instrument will average the last 16 results. If a large change occurs at

the input the averaging store is reset (all values are made zero) and only new data is

averaged. This gives a fast response to large input changes. The number of results

averaged (the ‘averaging depth’) in AUTO mode can be changed by using the

configuration keys [F],[P] 38 (see section 6.1). (For independent wiring modes, [F],[P] 58

and [F],[P] 78 set the AUTO averaging depth for CH2 and CH3 respectively.)

In FIXED mode the instrument performs averaging as before, but large changes at the

input will not reset the averaging store. This can be useful when measuring an input,

which contains large voltage spikes for example.

To make a selection, press the [AVG] key. Choose >fixed< or >auto reset< with the

[SELECT] key and press [ENTER]. If fixed averaging has been chosen the green LED

next to ‘N’ beneath the [AVG] key will illuminate. Next enter an averaging depth using the

digit keys and press [ENTER].

The averaging store can be reset by pressing the channel key for the measurement

currently selected. For example, if Watts is currently selected, pressing the [W] key resets

the averaging store. Zeros are temporarily displayed for all measurements before new

averaged values are displayed.

3.2.4 [COUPLING] INPUT COUPLING

AC + DC coupling is normally selected. The PM3000A computes results due to all

components in the input voltage and current including DC and low frequency components

in this mode.

AC coupling the instrument means that DC and low frequency components are ignored.

This is useful measuring the ripple voltage on rectifier outputs, and for calibration of

instruments that are only AC coupled.

Press the [COUPLING] key to toggle between AC + DC coupling and AC coupling only.

3.2.5 [SHUNT] SHUNT SELECTION

This key switches between internal (INT) and external (EXT) shunt selection.

INT mode is selected for direct measurement of ac and dc currents up to 30A rms and

uses signals from precision internal shunts in the PM3000A. This mode is also used with

ac current transformers.

EXT mode is used when taking current measurements with external high current shunts,

dc current transformers or other devices providing a voltage signal that is proportional to

current.

3.2.6 [SCALING]

Scale factors for the voltage and current input on all three channels can be entered. If

1000:1 current transformers are being used, for example, use a current scale factor of

1000 UP to make the PM3000A display the actual currents, watts, etc.

If a wiring configuration other than 1Ø2W is used scaling can be locked (the same scaling

on all channels) or independent. Press the [SCALING] key. Choose >locked< or

>independent< voltage scaling using the [SELECT] key and press [ENTER] to confirm the

setting. Enter a voltage scale factor (if required) using the numeric keys and press

[ENTER] to confirm the setting.

PAGE 3-6

PM3000A USER MANUAL BASIC FUNCTIONS

If you have chosen independent scale factors you are then prompted for the CH1, CH2,

and CH3 scale factors.

Next choose >locked< or >independent< current scaling, and then enter a scale factor in

the same manner if required. If a current scale factor other than 1.0 is entered, the display

then shows:

CURRENT SCALING

>up<

Pressing [SELECT] switches between >up< and >down<. Choose >up< to multiply the

measured current by the scale factor or >down< to divide the measured current by the

scale factor. Press [ENTER] to confirm the setting.

A scale factor of 100 down is equivalent to 0.01 up. If you return to this menu, the scale

factor is always displayed as the equivalent >up< scale factor.

3.2.6.1 SCALING THE EXTERNAL SHUNT

The external shunt input has a range of 0 to 2.5V peak. This corresponds to 12.5mV per

amp (2500mV = 200A). If for example a 0.1Ω external shunt is used, this will generate

100mV per Amp. The current scale factor must be set to 8.0 'down' to obtain the correct

display.

AmpmV

/100

AmpmV

/5.12

The formulae for UP and DOWN scaling are as follows:

SF

=

UP DOWN

If you return to this menu, the scale factor is always displayed as the equivalent 'up' scale

factor. If 8.0 'down' were entered, the display will show a SF of 0.125 the next time this

menu is accessed.

5.12

AmpmVActual

/

down

8

=

SF =

/ AmpmVActual

5.12

3.2.7. [DISPLAY] DISPLAY FORMAT

Using this key allows the user to specify the measurements to be shown in each part of

the display. If multi-channel measurements are being made it is possible to display

simultaneously the results for all channels plus the sum. Examples of use are provided

below.

3.2.7.1. S

INGLE FUNCTION DISPLAY

Press the [DISPLAY] key and use the [SELECT] key to show the following display:

DISPLAY FORMAT

>single<

PAGE 3-7

BASIC FUNCTIONS PM3000A USER MANUAL

Press [ENTER] to select this display mode. The display will be similar to the following:

UPPER RIGHT DISPLAY

>Arms<

Press the required function key (at the top left of the front panel) to choose the required

parameter for display. The allowed keys are [V], [A], [W], [VA], [FREQ], [PF], [Vpk] and

[Apk]. The lower line of the display will change to show the selected parameter. Press

[ENTER] to confirm, and then repeat this procedure for the upper left display.

The display will reconfigure to show the selected measured parameters on the upper line.

(The lower line may be changed simply by pressing the required function key).

3.2.7.2 MULTIPLE FUNCTION DISPLAY.

To display measure parameters for all channels first select the [3Ø4W] key, the Channel

Select key [∑] and the required function key, for example [W]. Press the [DISPLAY] key

and use the [SELECT] key until the display is as shown below:

DISPLAY FORMAT

>multiple<

Press [ENTER] to select this option and the display will be similar to:

+0.000 +0.000 +0.000

Watts = +0.000 W

The three numbers on the top row correspond to CH1, CH2 and CH3 respectively and the

bottom row shows the sum of the Watts. Other function keys may be pressed to indicate

their values but note that not all are valid for a multiple display.

3.2.7.3 FOUR FUNCTION DISPLAY.

Press the [DISPLAY] key and use the [SELECT] key until the display is as shown below:

DISPLAY FORMAT

Press [ENTER] to select this option and then choose the parameters to be displayed in a

manner similar to that for single function display. Note that not all are valid for the four

function display.

3.2.8 [CLOCK SET] DATE AND TIME

The date and time may be changed by the user. To do this, press the [CLOCK SET] key.

Use [SELECT] to switch between >accept< and >change< and then press [ENTER]. If

changing the current date and time use the digit keys to enter new values in the format

shown. Press [ENTER] after each entry and again to >accept< the revised date and time.

PAGE 3-8

>four function<

PM3000A USER MANUAL BASIC FUNCTIONS

3.3 HARMONIC ANALYSIS

The PM3000A will measure the harmonic content of the voltage and current waveforms

for all components up to the 99th harmonic. It will also analyze the current flowing in the

neutral wire of a 3 phase 4-wire system and calculate any DC components.

A specially designed mode is incorporated for testing to EN60555 and EN61000-3. Flicker

and fluctuating harmonics as well as steady state harmonics can be measured in the

IEC555 mode. (See section 5.6).

The VPAS Demo software supplied can be used to display and print harmonic barcharts

(see section 10.8).

Harmonic measurements can be made at any frequency within the bandwidth of the

instrument.

3.3.1 [V HARM] VOLTAGE HARMONIC

Press the [V HARM] key. Enter the required harmonic using the number keys followed by

[ENTER]. Use [SELECT] if you make a mistake during number entry. The chosen

harmonic amplitude is displayed.

For harmonic 0 (DC component) and harmonic 1 (fundamental) the absolute value of the

amplitude is displayed, for other harmonics (up to 99) the harmonic amplitude is displayed

as a percentage of the fundamental. To display harmonics 2 to 99 as absolute values use

[F],[P]18 (see section 6.1).

To view another harmonic press [V HARM] again and repeat the above procedure, or

press [ENTER] for the next highest order harmonic. Harmonic phase information is not

displayed in the multiple channel display.

To get a printout of all harmonics up to a pre-set limit, use the printer selection menu (see

section 8.1.). Watts harmonics can also be selected for print if both volts and current

harmonics are selected.

3.3.2 [A HARM] CURRENT HARMONIC

Press the [A HARM] key. Enter the required harmonic using the number keys followed by

[ENTER]. Use [SELECT] if you make a mistake during number entry. The chosen

harmonic amplitude is displayed.

For harmonic 0 (DC component) and harmonic 1 (fundamental) the absolute value of the

amplitude is displayed, for other harmonics (up to 99) the harmonic amplitude is displayed

as a percentage of the fundamental. To display harmonics 2 to 99 as absolute values use

[F],[P]18 (see section 6.1).

To view another harmonic press [A HARM] again and repeat the above procedure, or

press [ENTER] for the next highest order harmonic. Harmonic phase information is not

displayed in the multiple channel display.

To get a printout of all harmonics up to a pre-set limit, use the printer selection menu (see

section 8.1). Watts harmonics can also be selected for print if both volts and current

harmonics are selected.

PAGE 3-9

BASIC FUNCTIONS PM3000A USER MANUAL

(

3.3.3 [V THD] VOLTA GE HARMONIC DISTORTION MEASUREMENTS

The distortion factor of the voltage waveform can be measured by pressing the [V THD]

key. The result is obtained by the calculation:

22

−

df

RMS H

=

1

)

×

100%

REF

where REF is normally the fundamental component. It can be set to RMS (see [F],[P] 17,

section 6.1). This method is known as the ‘difference formula’.

This measurement takes into account all distortion including noise and DC offsets. This

will give very good results with waveforms having greater than 2% distortion.

An alternative method which works well with any distortion level, is to measure individual

harmonics and calculate the total harmonic distortion with the formula:

thd H H H H=++++2345

where H2 is the 2nd harmonic percentage of reference and H3 is the third harmonic

percentage of the chosen REF value.

The default for the front panel display values is the difference formula. This can be

changed to ‘harmonic series’ (THD) value by using [F],[P] 16 (see section 6.1).

2222

....

3.3.4 [A THD] CURRENT HARMONIC DISTORTION MEASUREMENTS

The distortion factor of the current waveform can be measured by pressing the [A THD]

key. The calculation method is similar to that described in section 3.3.3 above.

3.3.5 [FREQ] F

Press the [FREQ] key to display the fundamental frequency of the AC input.

This frequency is used as the basis for harmonic analysis. Frequency is derived from the

volts, amps or external source - see [FREQ SOURCE] (section 3.2.1). In 1Ø2W, 1Ø3W,

3Ø3W, and 3Ø4W wiring modes, the frequency source is channel 1. In independent CH3

wiring, the frequency source for channels 1 and 2 is CH1, and for channel 3 it is CH3. For

all other wiring modes, the frequency source is its respective channel.

REQUENCY

3.3.4 [FUND] FUNDAMENTAL VALUES

The PM3000A normally displays measurements as true RMS values. This takes into

account all harmonics, noise, offsets, etc. that can be measured within the bandwidth of

the instrument.

When the [FUND] key is pressed, results are displayed which are calculated from the

fundamental components of voltage and current only. For example, the fundamental

power factor displayed cos Ø, is the phase shift between the voltage and current

fundamentals.

PAGE 3-10

PM3000A USER MANUAL PROGRAM SET-UP

CHAPTER 4

ROGRAM SET-UP

P

PROGRAM SET-UP PM3000A USER MANUAL

PM3000A USER MANUAL PROGRAM SET-UP

4.1 PROGRAMMING

Up to five set-ups can be stored in the PM3000A's non-volatile memory. Any of the five

programs may be loaded on power up to configure the instrument automatically to a

particular set-up. All settings are stored when a set-up is saved.

The [P] button can also switch the instrument from the P[1] set-up to the P[2] set-up if the

PROGRAM SWITCH function is enabled. (See section 5.5).

To save a set-up, press the [P] key. Use the [SELECT] key to choose >save program<

and press [ENTER]. The next display shows >Program 1-5<. Press [ENTER] to continue

(or [SELECT] to quit). Then select the required program number with the digit keys and

press [ENTER]. The current configuration will be stored as the program selected in nonvolatile memory. This is powered by a lithium battery with a life of at least five years.

4.1.1 TO LOAD A STORED SETUP

Press the [P] key. Use the [SELECT] key to choose >load program< and press [ENTER].

The next display offers the choice of >standard<, >program 1 to 5< or >Quit<. Using the

[SELECT] key, choose >standard< for power-up configuration, or >program 1 to 5< for a

programmed configuration. Press the [ENTER] key to confirm the setting.

If >program 1 to 5< is selected, the next display allows choice of the program number.

Enter the number using the digit keys and press [ENTER]. The set-up will be loaded. If no

program has ever been loaded into that store or the data has been corrupted, the load will

be cancelled and the program will exit the menu.

4.1.2 TO SET THE POWER ON DEFAULT

The contents of any of the five program stores P1 - P5, or the power down setting, can be

made the power on default set-up. To do this, press the [F] key. Use the [SELECT] key to

display the following:

F[1] P. ON DEFAULT

Press [ENTER] and then use [SELECT] to display >standard<, >program 1-5< or >power

down<. Press [ENTER] to confirm the choice. If >program 1-5< is selected, then enter the

program number using the digit keys and press [ENTER] again. Until the default is

changed back to 'standard', the PM3000A will power up with the set-up stored in the

program number selected.

4.1.3 TO PRINT A PROGRAM SET-UP

The program configuration currently in use can be printed at any time. To print any other

program set-up it must first be loaded.

To print, press [P], then use the [SELECT] key to display >print program<. Press [ENTER]

and select >yes<. The configuration will then be printed.

<select> or <enter>

PAGE 4-1

PROGRAM SET-UP PM3000A USER MANUAL

************************************************************

PM3000 configuration data

operating mode 1

program switch off

1 phase 2 wire

wiring lock on

phase lock on

function selection 00000001 10000001 11110000 11111111

target power factor +1.000

pre-averaging time 5

fixed frequency 60.00

channel control 10001000 00110001 00000000

voltage range auto

current range auto

averaging 16 auto

voltage scale +1.000

current scale +1.000

harmonic control 00000100

maximum harmonic 7

printer control 00000000 10100001

integrator control 00000001

datalog control 00000001

datalog window 0

IEEE address 10

RS232 baud rate 9600

1

****************************************

There are 6 items of information marked on the printout that require further explanation.

They are:

1. Function Selection

2. Channel Control

3. Harmonic Control

4. Printer Control

5. Integrator Control

6. Datalog Control

PAGE 4-2

PM3000A USER MANUAL PROGRAM SET-UP

1. Function Selection

xxxxxxxx xxxxxxxx xxxxxxxx xxxxxxxx

bit 31 bit 0

bit 0 Watts selected

bit 1 VA selected

bit 2 VAr selected

bit 3 Vrms selected

bit 4 Arms selected

bit 5 Power factor selected

bit 6 V peak selected

bit 7 A peak selected

bit 8 V crest factor selected

bit 9 A crest factor selected

bit 10 Not used

bit 11 impedance selected

bit 12 W hours selected

bit 13 VA hours selected

bit 14 VAr hours selected

bit 15 A hours selected

bit 16 Average PF selected

bit 17 Correction VArs selected

bit 18 Efficiency selected

bit 19 Voltage harmonics selected

bit 20 Current harmonics selected

bit 21 Voltage THD selected

bit 22 Current THD selected

bit 23 Frequency selected

bit 24 Channel 1 selected

bit 25 Channel 2 selected

bit 26 Channel 3 selected

bit 27 Sum channel selected

bit 28 Neutral channel selected

bit 29 Fundamentals selected

bit 30 Watt harmonics selected

bit 31 Not used

2. Channel Control

xxxxxxxx xxxxxxxx xxxxxxxx

bit 23 bit 0

bit 0&1 Freq source: 0 = voltage

1 = current

10 = external

11 = slow external

bit 2 Slow sampling enabled

bit 3 Fast mode

bit 4 Jitter fixed

bit 5 Frequency fixed

bit 6 Voltage range fixed

bit 7 Current range fixed

bit 8 Filter on

bit 9 Not used

bit 10 Rectified mean enabled

bit 11 Fundamentals enabled

bit 12 Jitter enabled

bit 13 AC coupled

bit 14 External shunt selected

bit 15 Current phase reference

bit 16 Ballast/ultrasonic mode

bit 17 Ballast/ultrasonic mode

bit 18 Fixed sample rate

bit 19 Autozero enabled

bit 20 PWM mode

bit 21 PWM mode

bit 22 Not used

bit 23 Channel enabled

3. Harmonic Control

xxxxxxxx

bit 7 bit 0

bit 0 Harmonic reference = rms

bit 1 Harmonic display = absolute

bit 2 Even harmonics in series

bit 3 not used

bit 4 Series thd formula

bit 5 DC included in thd

bit 6 not used

bit 7 not used

PAGE 4-3

PROGRAM SET-UP PM3000A USER MANUAL

3. Printer Control

xxxxxxxx xxxxxxxx

bit 15 bit 0

bit 0 manual trigger

bit 1 external trigger

bit 2 timed trigger

bit 3 not used

bit 4 not used

bit 5 printer port = RS232

bit 6 print selection

bit 7 printer enabled

4. Integrator Control

xxxxxxxx

bit 7 bit 0

bit 0 manual trigger

bit 1 external trigger

bit 2 timed trigger

bit 3 cyclic interval

5. Datalog Control

xxxxxxxx

bit 7 bit 0

bit 0 manual trigger

bit 1 external trigger

bit 2 timed trigger

bit 3 cycle by cycle

bit 8 logic output 1

bit 9 logic output 2

bit 10 logic output 3

bit 11 logic output 4

bit 12 logic output 5

bit 13 not used

bit 14 not used

bit 15 not used

bit 4 averaged integration display

bit 5 reset accumulators after print

bit 6 not used

bit 7 integrator enabled

bit 4 not used

bit 5 not used

bit 6 not used

bit 7 not used

PAGE 4-4

PM3000A USER MANUAL THE FUNCTION MENUS

CHAPTER 5

HE FUNCTION MENUS

T

THE FUNCTION MENUS PM3000A USER MANUAL

PM3000A USER MANUAL THE FUNCTION MENUS

5.0 THE FUNCTION MENUS

The Func [F] key can be used to configure the PM3000A into special operating modes for

a wide number of application areas including:

PWM motor drives

High-frequency electronic ballasts

Testing to EN60555 parts 2 and 3 and EN61000-3

Transformer testing to IEC76-1

The function system also accesses other PM3000A configuration menus including the

calibration menu.

The function structure and operation are described below in the same numerical order in

which they appear on the PM3000A.

5.1. F[1] POWER ON DEFAULT

The contents of any of the five program stores P1 - P5, or the power down setting, can be

made the power on default set-up. To do this, press the [F] key. Use the [SELECT] key to

display the following:

F[1] P. ON DEFAULT

<select> or <enter>

Press [ENTER] and then use [SELECT] to display >standard<, >program 1-5< or >power

down<. Press [ENTER] to confirm the choice. If >program 1-5< is selected, then enter the

program number using the digit keys and press [ENTER] again. Until the default is

changed back to 'standard', the PM3000A will power up with the set-up stored in the

program number selected.

5.2. F[2] BANDWIDTH

The power-up default is >low< i.e. filter enabled:

25 kHz for 001 and standard models

5 kHz for 002 models

This option allows the user to select the full 1MHz bandwidth by selected >high<.

5.3. F[3] WIRING

Various wiring modes are available to suit the various input connections that can be made

by the user (see Connection Diagrams - Section 2.3). All the voltage and current inputs

are isolated from each other and from ground.

PAGE 5-1

THE FUNCTION MENUS PM3000A USER MANUAL

Connection to the PM3000A voltage channel inputs is via 4mm sockets on the rear panel

of the instrument. Currents up to 30A RMS may be connected directly to similar rear panel

sockets. For higher current measurement, use either a current transformer to reduce the

current presented to the PM3000A, or an external shunt to derive a voltage input suitable

for the external shunt input. Four wiring keys are provided on the front panel to allow

convenient access to these modes of operation. These and other modes may also be

accessed via the menu system as follows:

Press the [F] key and then use [SELECT] until the display is as shown below:

F[3] WIRING

<select> or <enter>

Press [ENTER] to display the Wiring Configuration options. Use the [SELECT] key to cycle

through the options and press [ENTER] to confirm the required setting. The options are

covered in more detail below.

5.3.1. 1 PHASE 2 WIRE

Select for single-phase loads on a 2-wire distribution system. Also use to measure the

output of a rectifier stage. Connect to channel 1.

5.3.2. 1 P

Select for three-wire, single-phase distribution systems. Connect to channels 1 and 2.

HASE

3 W

IRE

5.3.3. 3 PHASE 3 WIRE

Select for three phase measurements where there is no neutral connection (two wattmeter

method). The current in the [N] channel is computed by summation of the instantaneous

phase currents. In this way Arms, Amean, Apk, Acf and Amps harmonics can be displayed

for the 3rd wire. They are displayed as neutral current measurements. Total watts, volts,

etc. for CH1 and CH2 are displayed as ∑ values. Connect to channels 1 and 2.

5.3.4. 3 PHASE 4 WIRE

Select for three phase measurements with or without a neutral connection (three wattmeter

method). The current in the neutral wire is computed by summation of the instantaneous

phase currents. In this way Arms, Amean, Apk, Acf and Amps harmonics can be displayed

for the neutral wire. Total watts, volts, etc. are displayed as ∑ values.

5.3.5. CHANNEL 3 ONLY

Select for single-phase measurements on channel 3.

5.3.6. C

Select for single-phase measurements on channel 2.

HANNEL 2 ONLY

PAGE 5-2

PM3000A USER MANUAL THE FUNCTION MENUS

5.3.7. INDEPENDENT CH3

Channel 3 will operate completely independently of the other channels. For example, use

in conjunction with 3-phase, 3-wire mode for taking simultaneous input and output

measurements on 3-phase rectifier assemblies.

5.3.8. ALL INDEPENDENT

All three channels operate completely independently of each other. Each channel

operates as a completely independent power analyzer, sourcing its own frequency, and

selecting ranges and set-up functions.

5.3.9. P

When voltage measurements are made by the PM3000A, the value displayed is normally

the voltage across the Vhi and Vlo inputs. In the case of three-phase, four-wire, multiphase measurements (three watt meter), this voltage is normally the phase to neutral

volts. In other cases, the required voltage is the phase-to-phase voltage.

When wiring is set to 3∅ 4W mode, an additional menu allows the PM3000A voltage

display to be configured to display phase to phase measurement. Select 3∅4W in the

wiring menu to achieve this.

The voltage readings will be from phase to phase, computed vectorially from the phase to

neutral data.

HASE TO PHASE VOLTAGE

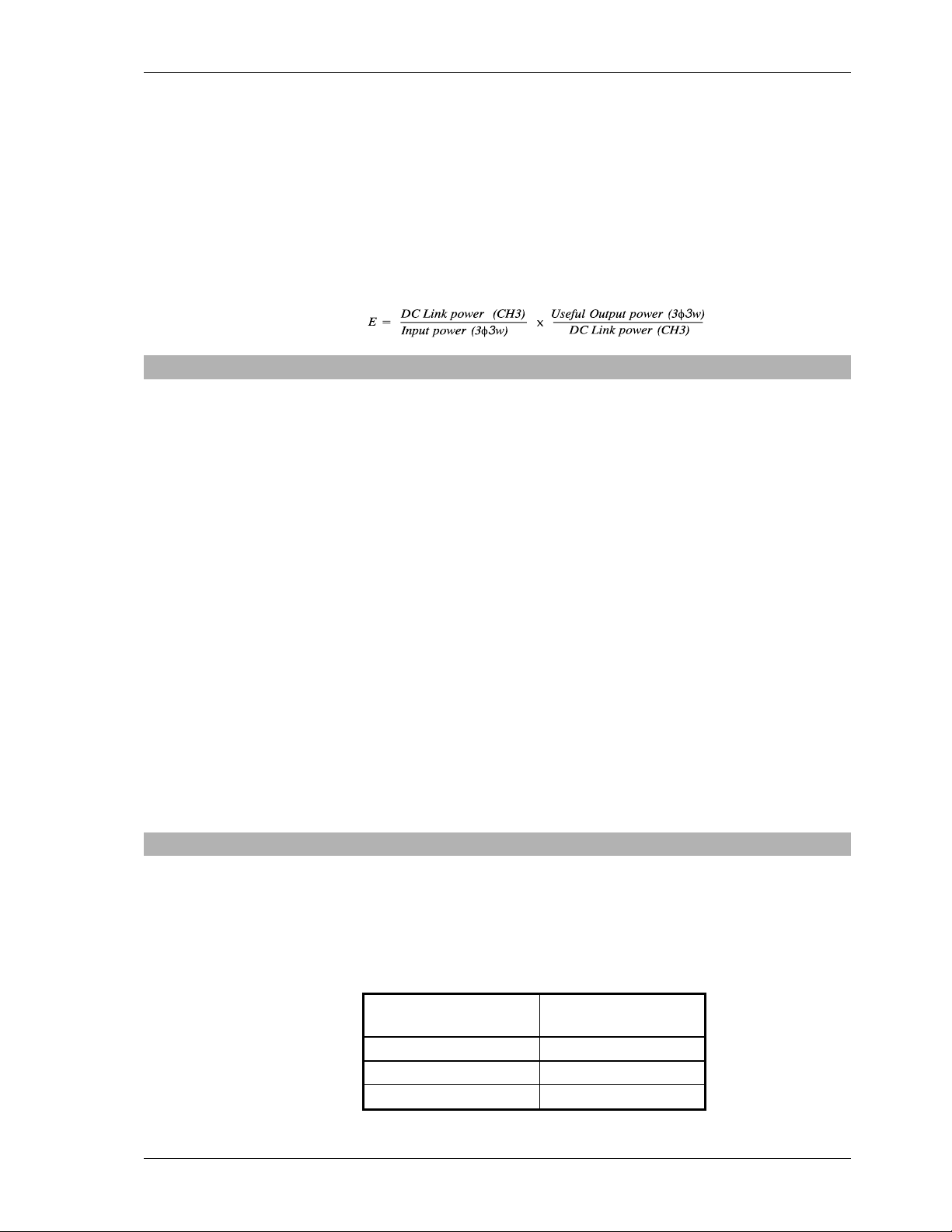

5.4 F[4] EFFICIENCY

The PM3000A can be configured to calculate efficiency, using a combination of power or

apparent power between any two channels, or between a 3-phase 3-wire measurement

and CH3. Press the [F] key and use [SELECT] and [ENTER] to choose F[4]

‘EFFICIENCY’ mode. The display is as follows:

Select >enabled< to give the following display:

Use [SELECT] and [ENTER] to choose the channels to calculate the efficiency from:

EFFICIENCY

>disabled<

EFFICIENCY FORMULA

>ch3/sum<

>ch3/sum<

>sum/ch3<

>ch1/ch3<

>ch2/ch3<

>ch1/ch2<

PAGE 5-3

THE FUNCTION MENUS PM3000A USER MANUAL

Then use [SELECT] and [ENTER] to choose the units for calculation from:

>Watts/Watts<

>VA/VA<

>Watts/VA<

>VA/Watts<

If required, the efficiency can then be scaled to suit the application using the digit keys

followed by [ENTER]. When the [FUND] key is pressed, the efficiency is calculated from

the fundamental values of WATTS and/or VA.

When efficiency is enabled, independent CH3 is set-up, irrespective of the previously

selected wiring mode. The efficiency units, formula, and scaling are printed when Watts

and VA are selected for printout.

5.5 F[5] PROGRAM SWITCH

The program switch facility enables two stored set-ups to be alternatively loaded with a

single key press. To use, save the first set-up in P[1] and reconfigure the instrument for

the second set-up; save this in P[2]. Press the [F] key and use [SELECT] and [ENTER] to

choose F[5] ‘PROGRAM SWITCH’ mode. Use [SELECT] and [ENTER] to switch the

option >on<.

Pressing the [P] key now switches the configuration between set-up P[1] and set-up P[2].

To restore the [P] function to normal operation, repeat the above procedure, selecting

PROGRAM SWITCH >off<.

N.B. The Program Switch does not change integrator, chart recorder or datalog functions.

5.6. F[6] IEC555 TESTING MODE

The EN60555 and EN61000-3 standards provide limits for the magnitude of harmonics

that can be generated by equipment connected to the public low voltage system. It

defines these limits for steady state harmonics and fluctuating harmonics. Voltage

fluctuations that cause flicker in lighting equipment are also limited by the standard. It

further defines the requirements of the measuring instrument and the method by which

the measurements are made.

To simplify measurements to EN60555 and EN61000-3, Voltech recommends the use of

the ‘Windows’ based PC software that is available for the PM3000A power analyzer as

listed in the accessories section of this manual (page 1-2). This software is available from

your supplier, and comes complete with its own user manual.

For steady state (fixed) harmonics, the PM3000A harmonic measurement mode normally

meets these criteria. Special operating modes are included to meet the requirements of

fluctuating harmonics and voltage fluctuation measurement. See Voltech Application Note

104 for more details.

To select this mode, press the [F] key and use [SELECT] and [ENTER] to choose F[6]

‘IEC555 TESTING’.

PAGE 5-4

PM3000A USER MANUAL THE FUNCTION MENUS

The options available are:

>Disable<

>Fixed Harmonics<

>Fluctuating Harmonics<

>Changing Voltage<

>Flickermeter<

Use the [SELECT] and [ENTER] keys to choose the desired measurement mode.

5.6.1 FIXED HARMONICS

There are various classes of EN60555 and EN61000-3-2 Limits. Each of these limits is

applicable to certain types of equipment, such as, balanced 3 phase, portable tools,

lighting, motor driven or other.

The equipment under test has met the IEC555 specification of fixed harmonics, if the

appropriate limits are not exceeded.

Selecting this mode automatically sets up the printer output for 40 current harmonics

(AH1-AH40), Watts and Power Factor. Press [DATADUMP] to print the selection to the

printer. Refer also to our EN60555/61000-3 Test Software Disk, which provides bargraphs

with IEC limits, and captured waveform display.

5.6.2 F

Fluctuating harmonics mode continuously measures the current harmonics of the

equipment under test over a set period of time.

The harmonic levels are tested against the appropriate class limits and against a second

set of limits, which are 1.5 × class limits for the set period of time.

If any harmonic exceeds the second set of limits at any time during the test period, the

unit under test has failed the test. If any harmonics exceed the first set of limits for more

than 15 seconds (10%) over any 2.5-minute interval, it has failed the test and does not

meet the IEC specifications for fluctuating harmonics.

To choose this mode of analysis, select >fluctuating harmonics< and then press [ENTER].

The display then shows:

LUCTUATING HARMONICS

IEC555 MODE

Freq = xx.xx

Select the appropriate display harmonic by pressing [A HARM], the digit keys and

[ENTER]. The harmonics can be stepped through using [SELECT].

Refer also to our EN60555/61000-3 Test Software Disk which provides a real time

bargraph of fluctuating harmonics with IEC limits, and graphs of single harmonic levels

over time.

PAGE 5-5

THE FUNCTION MENUS PM3000A USER MANUAL

5.6.3 CHANGING VOLTA G E

Flicker is defined as the fluctuating luminance of lighting equipment caused by voltage

fluctuations on the supply system to which it is connected.

Changing Voltage is a method of measuring ‘flicker’ to EN60555-3 and is suited to

measurements where the load is changing regularly.

The EN60555 Standard 555-3 stipulates limits for voltage disturbances in the supply

system that can be caused by household (and similar) electrical equipment. The limits are

defined in the graph below. This shows the magnitude of the maximum permissible

percentage voltage changes (∆U/U), with respect to the allowed number of voltage

changes per minute (R).

In addition, the total ‘accumulated memory time’ should not exceed the duration of the

observation period. Memory time is a concept defined by the standard.

The "power measurement" technique is used, in which the in-phase and quadrature

components of current are measured to define the size of the voltage disturbance.

Connect and power-up the load under test to the CH1 inputs. Selecting this option causes

the display to report the MEMORY TIME. This will accumulate in value over the

observation period, for the voltage fluctuations detected. At the end of the test period,

pressing the [DATADUMP] key will automatically cause a print-out of the total memory

time, elapsed time, and the number of occurrences for each size of voltage fluctuation

(∆U/U), from 0.1% to >3% (40 bins in all). These can then be checked according to the

graph for IEC555-3 to assess compliance. For more guidance, refer to our Application

Note 104.

5.6.4 FLICKERMETER

Flickermeter is the preferred method of measuring flicker to EN60555/61000-3-3, and is

suited to measuring flicker where the load is either changing regularly or varying

irregularly.

The IEC 868 Flickermeter simulates the Lamp-Eye-Brain Chain; the basis upon which an

acceptable level of disturbance to the supply caused by a piece of equipment was

decided.

PAGE 5-6

PM3000A USER MANUAL THE FUNCTION MENUS

The Flicker Meter produces flicker values of Pst or Pst and Plt where:-

Pst is the short term flicker severity evaluated over a short period (in minutes) and:

is the long-term flicker severity evaluated over a long period (a few hours), using

Plt

successive Pst values.

IEC set limits for Pst=1 and Plt=0.65 where a Pst > 1, or Plt > 0.65 indicates that the

equipment under test causes flicker that exceeds the acceptable level.

The PM3000A can measure flicker by the Voltage Method, which provides full compliance

testing, and by the Current Method, which is not part of the IEC 868 Flickermeter

Standard, but provides very effective pre compliance testing.

5.6.5 FULL-COMPLIANCE TESTING

Equipment Required:

AC Power Source.

Source Impedance.

PM3000A

PC

Printer.

Note 1: The AC power source must meet stability and distortion requirements of the

EN60555/61000-3-3 standards.

Note 2: Source Impedance of R=0.4Ω, X=0.25Ω must meet specification of the

standards.

The PM3000A monitors the voltage fluctuations and performs a series of filter functions

(digitally), to produce an instantaneous flicker level. This flicker level is classified into

1024 logarithmically scaled ‘Bins’ to provide a 1024 level classifier.

At the end of the observation period, the PC reads the values in the ‘Bins’ and creates a

‘Cumulative Probability Function’, representing the probability of exceeding a particular

flicker level for a given percentage of the observation time.

The PC will then calculate values of Pst and Plt from equations defined in this standard.

5.6.6 PRE-COMPLIANCE TESTING

Pre Compliance testing does not require a Source Impedance as the measurement is

made by the fluctuating current taken by the load.

Operation is the same, except that the PM3000A determines the fluctuating voltage by

calculating the instantaneous voltage drop across a Standard Source Impedance (as set

in flickermeter menu), and subtracting this calculated voltage drop from the voltage seen

by the PM3000A.

PAGE 5-7

THE FUNCTION MENUS PM3000A USER MANUAL

5.6.7 VOLTAGE DEVIATION TESTS

The Flickermeter technique provides an excellent assessment of continuous voltage

changes. However, a load that causes a single or very occasional large voltage change

will have only a small effect on the Pst/Plt measurement, yet this large voltage change will

have a disturbing effect on lamps.

Because of this, measurements of voltage deviations are made throughout the

observation period by the PM3000A, and the percentage value displayed is the largest

change in voltage seen during observation.

A steady state voltage that undergoes a voltage change (dmax), exceeding the limit dc%

for a time dt seconds (but staying within the limit dmax%), before returning to a second

steady state dc voltage level (which is less than dc%, with dt being less than 200ms), will

pass the dc, dmax, and dt voltage deviations test.

5.6.8 IEC1000-3 SOFTWARE FOR WINDOWS

This versatile software package greatly simplifies the task of making the measurements

that qualify a product under test to the specification EN61000.

The software runs on a PC and works with your Voltech PM3000A Power Analyzer and

the programmable ac source of your choice. The test equipment may be connected to the

PC using either an RS232 or IEEE488 interface.

The software allows you to quickly set up the tests to be done, and controls the ac source

and Power Analyzer to make the measurements. It then reads back the measurement

data, and presents the results in easy-to-read tables and graphs, including comparisons

with the specification limits and highlighting the Passes and Fails.

When the test is finished, all results can be archived to disk, printed or passed on to

another application, for example to be included in a document produced by a word

processor.

5.6.8.1 INSTALLATION

To enable this software to install and run correctly, please ensure that your PC and

relevant hardware conforms to the specifications outlined as follows.

PAGE 5-8

PM3000A USER MANUAL THE FUNCTION MENUS

5.6.8.2 PC REQUIREMENTS

PC: 486 DX. or higher

At least 4Mb

RAM:

Disk: 1Mb of hard disk space for program installation, plus at least 1Mb for

recording test data

(The requirements for each type of test are as follows:

Waveform capture: 1.5kb per waveform

Steady State Harmonics: 1kb per measurement

Fluctuating Harmonics: 7Mb per hour

Flicker: 5kb per 10 minutes)

Windows: Version 3.1 or higher

5.6.8.3 IEEE 488 INTERFACE CARDS SUPPORTED

All current National Instruments cards supporting 488.2 protocols

5.6.8.4 INSTALLING THE SOFTWARE TO YOUR PC

1) Insert the 3½ inch disk into drive A on your PC.

2) From the Windows Program Manager, using the mouse

- Pull down the File menu

- Click on Run

3) In the Run dialogue box, on the Command Line type

a:\setup, and click on the OK button.

4) Follow the on-screen prompts.

The default directory for the IEC1000 for Windows software is C:\IEC1000. You may

choose an alternative drive / directory, when prompted, during the installation process.

(For more information on installation, please refer to the IEC1000-3 User Manual.)

5.6.8.5 S

ETTING UP YOUR

IEEE488

INTERFACE CARD

.

Initially, refer to the user manual supplied with your IEEE488 interface card for the

recommended procedures for installation and set-up of the card in your PC. If there is any

difficulty, please refer to the IEC1000 software on-line help.

PAGE 5-9

THE FUNCTION MENUS PM3000A USER MANUAL

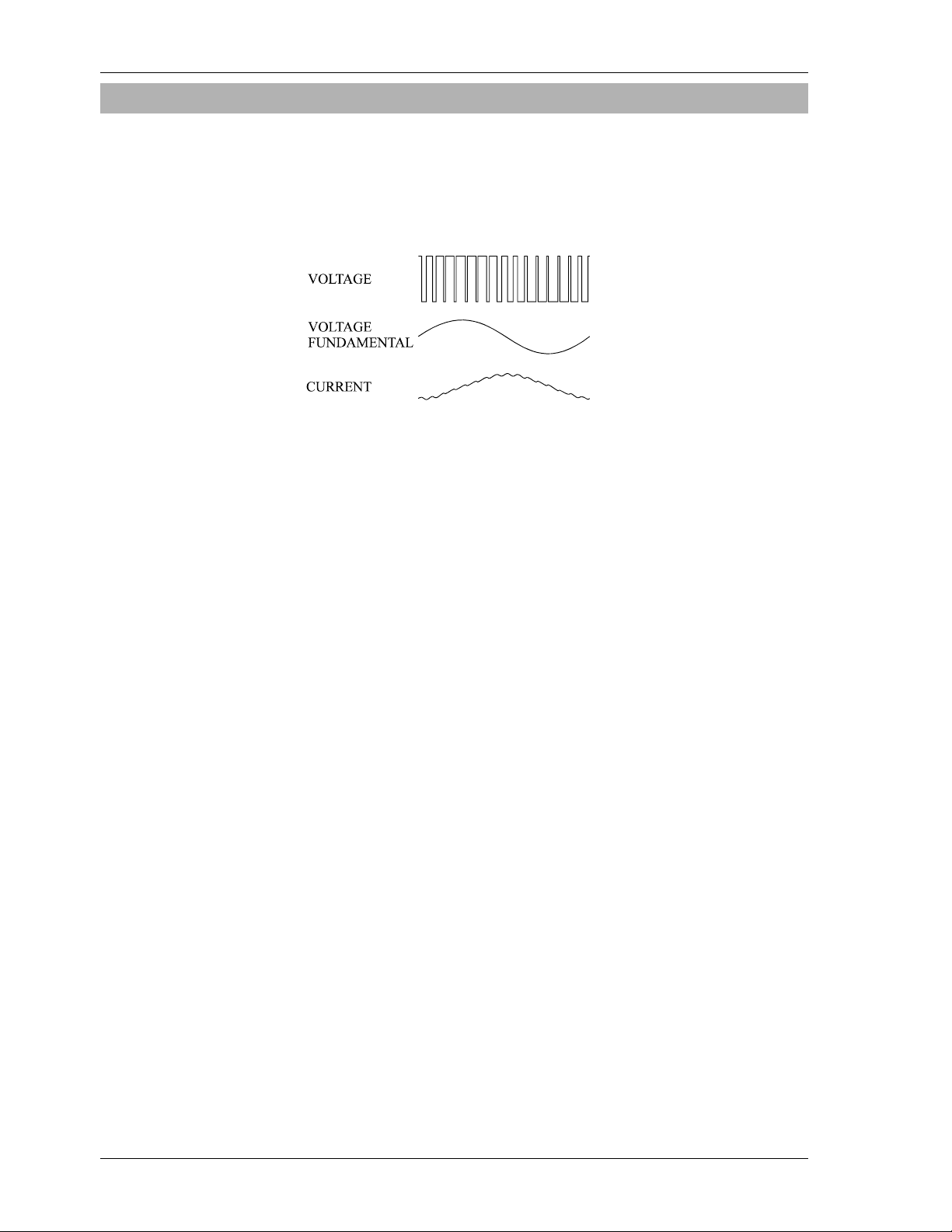

5.7 F[7] PWM DRIVE MODE

The difficulties associated with making measurements on the complex waveforms of

PWM drives are overcome with this special operating mode. It is described fully in Voltech

Application Note 105. High frequency sampling and digital filtering reject the carrier

frequency, and extract the motor frequency and harmonic components. True power and

other rms parameters are computed from the PREFILTERED data.

There is a choice of 3 filters, selected according to the frequency range of the motor:

5Hz to 1kHz (400ms display update)

0.5Hz to 50Hz (4sec update time)

0.1Hz to 40Hz (16sec update time)

Notes:

1. The low bandpass filter is normally applied to prevent anti-aliasing. This will affect the

PWM pre-filtered data values. PWM filtered values will be unaffected.

2. Output mode harmonics are blanked to give zero values above the maximum

frequency of the filter selected. For example,

Filter = 5Hz to 1kHz

Motor frequency = 30 Hz

Max. harmonic computed = 33rd (990Hz)

3. Input mode harmonics are blanked at frequencies above the limit (400/input window)

Hz.

4. For low loaded motors, it is advisable to remove the display blanking as the

fundamental can be very small compared to the total rms value. In such a case, the

display value may be forced to zero. Select [F],[P] 26 (Low value blanking).

5 It is important to check that the correct frequency has been obtained when the mode

is selected. If not, then select [FREQ SOURCE] to >current<.

6. The wiring for PWM mode is either 3Ø3W or 3Ø4W. The [N] channel provides

computed values of neutral current (Arms, AFund, Acf, Apk, Aharm and Athd).

PAGE 5-10

PM3000A USER MANUAL THE FUNCTION MENUS

−

=

To use this operating mode, select F[7] PWM DRIVES by pressing the [F] key and then

using [SELECT and [ENTER]. Four options are then available:

>disable<

>input<

>output<

>real time output<

All wiring configurations for the PWM mode that are 3Ø 3W will enable the third channel

(CH3) as independent. This allows the DC link of the drive to be measured simultaneously.

Using the DC link, efficiency (E) measurements for the drive can be derived:

5.7.1 OUTPUT MODE

1. Connect the output of the drive to the PM3000A and motor in either 3Ø3W or 3Ø4W

mode (see diagram in section 2.3).

2. Select PWM DRIVES >output< mode.

3. Select the chosen frequency band depending on the motor operating speed range,

e.g. >5Hz to 1kHz< using the [SELECT] and [ENTER] keys.

4. Select >3Ø3W< or >3Ø4W< as required.

5. Select High Bandwidth mode (see section 5.2)

Check that the frequency is being monitored correctly. Measurement of the RMS values,

fundamentals and harmonics (up to the limit frequency of the filter) can now be analyzed. It

is normal for there to be a large difference between the Vrms & Vfund values, but only small

differences between Arms & Afund and Wrms & Wfund, as the inductive motor filters the

current.

Note that if a printer output is selected, then Watts Harmonics can be selected for printout (if

Aharm and Vharm have previously been selected in the menu). For measurement of

harmonics above the upper filter limit, see the later section on harmonics.

5.7.2 INPUT MODE

If the output of the drive is unbalanced, the input waveforms are modulated by the output

motor frequency. Accurate measurements are obtained by synchronizing the sampling of

data to the line frequency, and sampling over an interval (

follows:

Output frequency f

10 < f 1

1 < f < 10 10/f

f < 1 1/f

PowerlFundamentaPowerTotalLossesHarmonic

τ) between 1 and 10 seconds as

τ input time

window

PAGE 5-11

THE FUNCTION MENUS PM3000A USER MANUAL

For example, if f = 7.2Hz, then set τ to 10/7.2 = 1.39 (or a multiple of this value).

1. Connect the input of the drive to the PM3000A in 3Ø3W or 3Ø4W mode (see

diagram in section 2.3).

2. Select PWM DRIVES >input< mode and the display will be as follows:

PWM INPUT WINDOW

>1.000<

3. Use the digit keys to set the calculated value for

you make a mistake, press [SELECT] to re-enter the value and then press [ENTER].

4. Select >3Ø3W< or >3Ø4W< as required.

The PM3000A will now measure input power over an integral number of input cycles

within the selected time window of measurement, 1.39 seconds.

τ (e.g. 1.39) and press [ENTER]. If

5.7.3 REAL TIME OUTPUT MODE

Real time output of the FILTERED values of Vrms, Arms, Wrms, and PF, can be output

as analogue outputs for chart recorders.

1. Connect the output of the drive to the PM3000A in 3Ø3W or 3Ø4W mode (see

diagram in section 2.3).

2. Select PWM DRIVES >real time output< mode and the display shows as follows:

PWM OUTPUT RANGE

>5 Hz to 1kHz<

3. Use the [SELECT] and [ENTER] keys to choose the frequency band depending on

the motor operating speed range, e.g. ‘5Hz to 1kHz’.

4. Use the digit keys to enter the maximum PWM OUTPUT VOLTS for recorder

scaling, e.g. 250. Press [ENTER].

5. Use the digit keys to enter the maximum PWM OUTPUT AMPS for recorder scaling,

e.g. 20. Press [ENTER].

6. Use the digit keys to enter the maximum PWM OUTPUT WATTS for recorder

scaling, e.g. 5000. Press [ENTER].

PAGE 5-12

PM3000A USER MANUAL THE FUNCTION MENUS

The computed results appear on outputs 1 to 4 of the analogue output connector. For

example:

Output 1 total Vrms 0 to 5V = 0 to 250 V

Output 2 total Arms 0 to 5V = 0 to 20 A

total Watts 0 to 5V = -5000W

5.7.4 HARMONICS

To extend the measurement of harmonics that exceed the filter cut-off frequency

(provided the frequency is not fluctuating), the following procedure can be followed.

First measure and store the frequency with the PWM filter on. Switch to a configuration

that uses the stored frequency and disables the filter. Harmonics to the 99th may now be

analyzed. By using the PROGRAM SWITCH, these two configurations can be toggled to

update the stored frequency.

1. Select PWM >output< mode and the appropriate filter, as described in the

earlier sections.

2. Select [F],[P] 36 LOAD FIXED FREQUENCY and set >enable<. Press

[ENTER]. This will store the frequency.

3. Save as Program 1 (see section 4.1). Note that this overwrites any program

previously stored in P1.

4. Set PWM mode F[7] to >disabled<.

5. Select [F],[P] 21 FIXED FREQUENCY and set >enabled<.

6. Save as in Program 2.

7. Load Program 1 (see section 4.1.1).

8. Enable the PROGRAM SWITCH (see section 5.5).

9. The [P] key now toggles the configuration between Program 1 and Program 2,

each time it is pressed. Full harmonics can be measured when Program 2 is

set.

Output 3

to +5000W

Output 4 total PF 0 to 5V = 0 to 1

PAGE 5-13

THE FUNCTION MENUS PM3000A USER MANUAL

VavV

5.8. F[8] BALLAST/ULTRASONIC MODE

In situations where high-frequency voltage and current waveforms are heavily modulated

by mains borne frequencies, it is difficult to make accurate measurements, as the

sampling is not synchronized to the 50/60 Hz modulation. This occurs frequently with

lighting ballast power measurements.

The ballast/ultrasonic mode F[8] solves this problem. Voltech Application Note 101 covers

its use in detail. To use the function:

1. Press the [F] key and use [SELECT] and [ENTER] to choose F[8] ‘BALLAST’ mode.

2. Select ‘off’ or ‘50Hz’ or ‘60Hz’ and press [ENTER].

2. The PM3000A will now capture and analyze the relevant number of samples that

correspond to one complete cycle of 50Hz or 60Hz at the fastest sampling rate.

Once captured, the subsequent processing is carried out as normal, including

autoranging. The display automatically sets to a four-function display.

The frequency displayed is the carrier frequency.

4. If three-phase, three-wire mode has previously been selected as the wiring

configuration, then after selecting 50/60Hz (step 2), you can select INDEPENDENT

CH3. This allows you to measure ballast power output using CH1, CH2, and ∑,

whilst measuring input power on CH3.

5.9 F[9] TRANSFORMER MODE

The Transformer Test Mode has an application in the measurement of ‘no-load’ losses

when testing large (e.g. 10 to 20 kVa) power transformers. The ‘no-load’ losses include

core loss, dielectric loss, conductor loss in the winding due to excitation current, and

conductor loss due to circulating current in parallel windings. The core loss is usually the

most important; it is a function of the magnitude, frequency and waveform of the input

voltage, and it also varies significantly with temperature.

The method of testing is specified in the Standards: IEC76 - 1 and IEEE C57. An example

single-phase test circuit as specified in IEEE C57 is as follows:

Source

Arms

where:

Arms = Ammeter (rms)

W = Wattmeter

Vrms = Voltmeter (rms)

Vav = Voltmeter (mean sensing - rms scaled for sinewave).

rmsW

PAGE 5-14

PM3000A USER MANUAL THE FUNCTION MENUS

Other test circuits are shown in the Standards, involving both current and voltage

(instrumentation) transformers, and three phases.

IEEE C57 also quotes the formula:

P

PT

cm

()=

mr

PkP

+

12

Where:

T

m

P

c(Tm

P

m

P

1

P

2

E

= the test voltage measured by the rms voltmeter (≡ Vrms)

r

E

a

= temperature

) = the no load losses corrected for waveform at temperature Tm

= the measured no load losses at temperature Tm

= the ratio of hysteresis loss to total iron losses

= the ratio of eddy-current loss to total iron losses

= the test voltage measured by the mean-sensing voltmeter (≡ Vav)

In the Transformer Test Mode, the PM3000A will measure the Vav, and will calculate the

factor ‘k’ and the corrected power P

(using a value of 0.5 for both P1 and P2).

c

5.9.1 SETTING UP TRANSFORMER TEST MODE

Press the [F] key and use [SELECT] and [ENTER] to choose F[9] ‘TRANSFORMER’

mode. The display is as follows:

TRANSFORMER MODE

>off<

2

E

k

=

E

a

Use [SELECT] and [ENTER] to choose from the following options:

Vav

k-fctr

P-corr.

The measured results are typically displayed as:

0.000 V 0.000%

+0.000 W 0.000 V*

for Vav,

0.000 V 0.000 A

+0.000 W 0.000

for k-fctr,

0.000 V 100.00%

+0.000 W 0.000 W*

for P-corr,

although use of the function keys and other display changes will alter the parameters

displayed.

PAGE 5-15

THE FUNCTION MENUS PM3000A USER MANUAL

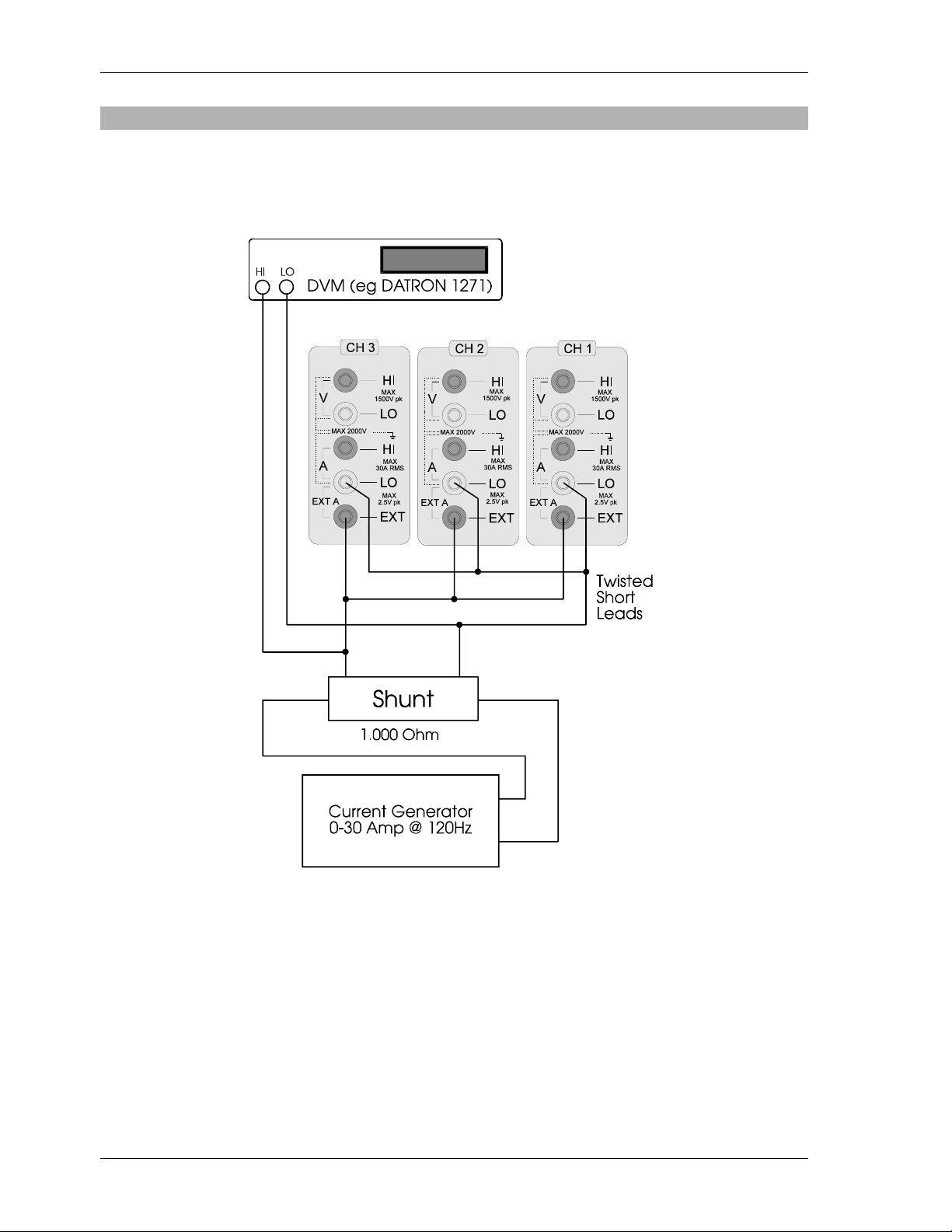

5.10 F[10] CALIBRATION

5.10.1 CALIBRATION OVERVIEW

All calibration constants are stored in EEPROM, allowing the PM3000A to be calibrated

without having to remove the cover. The calibration sequence is passcode protected. All

three voltage or current inputs are calibrated simultaneously for maximum efficiency,

although it is possible to calibrate each channel separately if required. The integrity of the

EEPROM contents is verified at power-on, and the message ‘UNCALIBRATED’ is

displayed if the contents are invalid.

5.10.2 PASSCODE

The passcode is a 4-digit number that allows entry to the calibration routines. It comes

factory set at 3000 but may be changed by the user for extra security. (If the new code is

lost or forgotten then a master code is held at Voltech to allow access. Contact Voltech or

your dealer if this is needed.)

To change the passcode press the [F] key and use [SELECT] and [ENTER] to choose

F[10] ‘CALIBRATION’ mode. Press [ENTER] to proceed. The display is as follows:

Enter the current 4-digit passcode – if this is incorrect you will be returned to the default

display. The display then shows:

Press [ENTER] to change the passcode and then enter the new code. (If the instrument

does not require calibration it may be switched off at this point.) To skip entering a new

passcode press [SELECT] to display >no< and then [ENTER]. The system will now enter

the main calibration menu. Refer to section 5.10.8 for the equipment needed.

5.10.3 MANUAL CALIBRATION