Voltea DiUse Installation, Operation And Service Manual

1

The installation, service and maintenance of this equipment should be rendered by a qualified and trained

technician. This manual is written specifically for these individuals and is intended for their use. Untrained

individuals who use this manual assume the risk of any resulting property damage or personal injury.

The DiUse system meets the essential safety and health requirements of the European Union. This means that

DiUse can be operated and maintained safely if all safety precautions are considered. However, dangerous

situations can occur due to injudicious or negligent use of the system.

NOTE: The DiUse system is not intended for use with water of unknown quality.

NOTE: The DiUse system is to be supplied with cold water.

WARNING!

Electrical shock hazard! Prior to servicing equipment,

disconnect power supply to prevent electrical shock.

WARNING!

Electrical shock hazard: Located on the electrical cabinet

door and inside the electrical cabinet. The electrical

cabinet may never be opened when the system is

producing water.

WARNING!

If incorrectly installed, operated or maintained, this

product can cause severe injury. Those who install,

operate or maintain this product should be trained in its

proper use, warned of its dangers, and should read the

entire manual before attempting to install, operate or

maintain this product.

CAUTION!

This product is not to be used by children or persons with

reduced physical, sensory or mental capabilities, or lack

of experience or knowledge, unless they have been given

supervision or instruction.

CAUTION!

If the power cord of the unit looks or becomes damaged,

the cord should be replaced by a Voltea service engineer

or similarly qualified person to avoid hazard.

All rights reserved. No part of this publication may be reproduced, stored in a database or retrieval system, published in any form or in any way, electronically,

mechanically, by print, photo print, microfilm or any other means without prior written permission from the manufacturer. All Voltea trademarks and logos

are owned by Voltea B.V. All other brand or product names are trademarks or registered marks of their respective owners. Because we are continuously

improving our products and services, Voltea reserves the right to change specifications without prior notice. Voltea is an equal opportunity employer. DiUse

Owner’s Guide: Copyright © 2018

EUROPEAN OFFICE

Wasbeekerlaan 24

2171 AE Sassenheim, Netherlands

+31(0)252.200.100

US OFFICE

1920 Hutton Court #200

Farmers Branch, TX 75234

+1(469)620.0133

2

CONTENTS

1 DiUse Manual .................................................................................................................................. 4

1.1 General safety precautions ..................................................................................................... 5

2 Liability and Warranty ..................................................................................................................... 5

2.1 Liability .................................................................................................................................... 5

2.2 Warranty ................................................................................................................................. 5

3 Voltea CapDI - Membrane Capacitive Deionization ........................................................................ 5

4 DiUse ............................................................................................................................................... 7

4.1 Features .................................................................................................................................. 7

4.2 Specifications .......................................................................................................................... 7

4.3 Feed water quality .................................................................................................................. 8

5 System Overview............................................................................................................................. 9

6 System Installation ........................................................................................................................ 10

6.1 Packing .................................................................................................................................. 10

6.2 Tools and materials ............................................................................................................... 10

6.3 Module installation ............................................................................................................... 10

6.4 Placing leak sensor ................................................................................................................ 12

6.5 Placing the covers. ................................................................................................................ 12

6.6 Water connections ................................................................................................................ 13

6.7 Powering the system up/down ............................................................................................. 13

6.8 replacement of CIP solution .................................................................................................. 13

6.9 Flushing the module.............................................................................................................. 14

7 System Start Up - Operation ......................................................................................................... 15

7.1 Operation with pressurized tank .......................................................................................... 15

7.2 Operation with atmospheric tank ......................................................................................... 15

7.3 System pump ........................................................................................................................ 16

8 System Control Through LCD ........................................................................................................ 16

8.1 DiUse Screen Navigation Chart ............................................................................................. 17

8.2 Voltea DiUse .......................................................................................................................... 17

8.2.1 Process steps ................................................................................................................. 18

8.2.2 Alarms ........................................................................................................................... 19

8.3 Device info ............................................................................................................................ 20

8.4 System ................................................................................................................................... 20

8.4.1 Setpoints ....................................................................................................................... 21

8.5 User functions ....................................................................................................................... 23

3

9 Advance System Functions ........................................................................................................... 23

9.1 Receive data and alarms remotely ....................................................................................... 23

9.2 Connecting to laptop and utilizing docklight ........................................................................ 24

9.2.1 Laptop connection ........................................................................................................ 24

9.2.2 Docklight ....................................................................................................................... 26

9.2.3 Downloading operational data from the system .......................................................... 28

9.2.4 Adding e-mail and telephone users. ............................................................................. 29

9.2.5 Daily summary report ................................................................................................... 29

9.2.6 Remote control through SMS ....................................................................................... 30

10 Changing Flow Restrictors ......................................................................................................... 31

11 Electrical Conductivity Probe Calibration ................................................................................. 32

12 Flushing, Bleaching, Storing and Module Disposal ................................................................... 36

12.1 Flushing the module.............................................................................................................. 36

12.2 Bleaching the module ........................................................................................................... 36

12.3 Storage .................................................................................................................................. 36

12.4 Disposal ................................................................................................................................. 37

13 System maintenance ................................................................................................................. 37

14 System Components ................................................................................................................. 38

14.1 Electric cabinet ...................................................................................................................... 38

14.2 Valves, switches and pumps ................................................................................................. 38

Appendix ............................................................................................................................................... 39

Flow restrictor color and flow ........................................................................................................... 39

Spare parts list .................................................................................................................................. 39

50% w/w citric acid solution preparation ......................................................................................... 40

P&ID .................................................................................................................................................. 41

Process flow diagram ........................................................................................................................ 42

DiUse installation PFD ....................................................................................................................... 43

Weekly checklist sheet ...................................................................................................................... 44

4

1 DIUSE MANUAL

This manual:

• Familiarizes the user with the equipment.

• Explains installation and setup procedures.

• Provides basic programming information.

• Explains the various steps of operation.

• Gives specification information.

Read this manual first: Before you operate DiUse, read this manual to become familiar with the device.

Through this manual, special symbols will appear:

NOTE

Is used to emphasize information related with installation,

operation and maintenance without highlighting any

hazard.

WARNING!

Warning is used to indicate a hazard which could cause

injury or death if ignored.

CAUTION!

Caution is used when failure to follow directions could

result in damage to equipment or property.

The WARNING and CAUTION signs are not meant to cover all possible conditions and situations that may occur

during installation, maintenance and operation. Understand that common sense, caution and careful attention

is always needed.

Before installing be sure to check all applicable plumbing codes and ordinances. Local codes and legislation may

prohibit the discharge of sanitizing or descaling solution to drain. The system and installation shall comply with

applicable state and local regulations.

Always use protective clothing and proper face or eye protection when handling chemicals and tools.

The CapDI system meets the essential safety and health

requirements of the European Union. This means that the

system can be operated and maintained safely if all safety

precautions are observed. However, dangerous situations can

occur due to injudicious or negligent use of the CapDI system.

If a UL mark is attached to the system, then it has performed

to UL standards and is certified.

The DiUse system conforms to NSF/ANSI 42, for specific performance claims as verified and substantiated by

test data.

5

1.1 GENERAL SAFETY PRECAUTIONS

Observe the following general safety precautions:

• Check the proper functioning of the system daily.

• Always replace damaged or defective parts before putting the system into use again.

• Do not make modifications to the system without prior approval of the manufacturer.

• Do not open the electrical cabinet when the system is powered on.

• If chemicals are supplied, the attached safety procedures should be observed.

2 LIABILITY AND WARRANTY

2.1 LIABILITY

Voltea will, under no circumstances be held liable for any consequential damages. The recipient hereby disclaims

all representations and warranties, whether expressed or implied with respect to materials and/or prototypes.

Including without limitation any warranties of non-infringement, merchantability or fitness for merchantability

or fitness for any particular purpose save that such shall have been prepared with reasonable skill and care. The

recipient accepts all risks which may be inherent in its use of materials and/or DiUse system and shall hold

harmless and indemnify each of Voltea and its affiliates officers, director, shareholders, employees and agents

from and against any and all claims, damage, losses or other liabilities that may arise directly and solely from

recipient’s use, storage, handling or disposal of the materials and/or systems.

2.2 WARRANTY

CapDI modules supplied with DiUse have been tested and have a guaranteed performance as they have passed

Voltea’s quality control test (a certificate of analysis will be supplied with each module upon request). Voltea

does warrant workmanship (leakage, connections) of the CapDI module for a period of 1 year from shipment

provided that the CapDI module is operated within the recommended operational limits as provided in the

section 4.2 and 4.3. Voltea does not warrant desalination and other performance aspects of the CapDI modules

within the customer application. Voltea warrants the DiUse for a period of 1 year from shipment provided that

the system is operated in accordance with this manual.

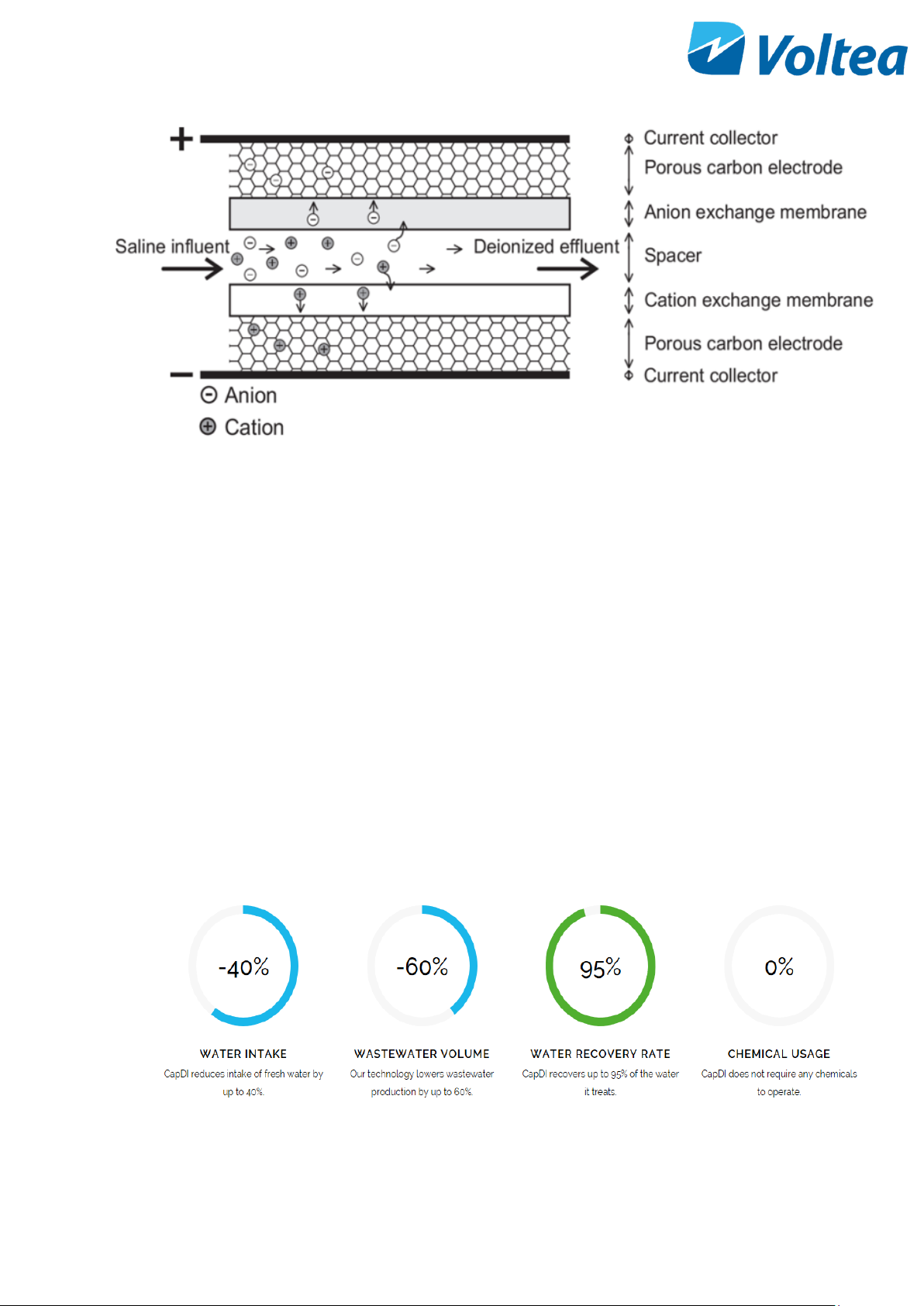

3 VOLTEA CAPDI - MEMBRANE CAPACITIVE DEIONIZATION

The CapDI system uses Capacitive Deionization technology and its function is the removal of ions from the water.

NOTE: The CapDI system does not disinfect water.

CapDI: A tunable water deionization technology that is designed to remove dissolved salts from a variety of

water sources ranging from tap water and brackish groundwater to industrial process water. CapDI achieves this

at a lower economic cost and reduced environmental impact than any other available technology.

6

A CapDI module consists of a housing which contains multiple stacks of parallel unit cells. Each unit cell consists

of two porous carbon electrodes separated from each other by a spacer. On top of the electrodes, ion exchange

membranes are placed. The spacer between the membranes acts as a flow channel to transport the water to be

desalinated.

The water flows through a small electrical field of approximately 1.5 volts that is created over a pair of

electrodes. Dissolved ions are pulled out of the water stream, toward the electrodes. The electrodes are

separated from the water by the membranes that selectively allow only positive or negative ions to pass. CapDI

is effective at removing all type of ions from water (e.g. calcium, sodium, chloride, carbonate).

Uniquely: Our technology is environmentally friendly by its low energy consumption and minimal to no chemical

usage. Thus, allowing any unrecovered water to flow back into the ecosystem safely.

Scalable: Voltea’s technology treats water types ranging from residential consumer appliances to large-scale

industrial plants. Our systems are modular, allowing easy expansion to meet any increased water demands.

Tunable: CapDI is tunable, allowing adjustable TDS reduction between 25% - 95% depending on customer needs.

Eliminating the requirements for blending to achieve a specific water quality. The customer sets their desired

reduction rate and the CapDI maintains this level, continually adjusting itself to account for any fluctuations in

feed water characteristics.

7

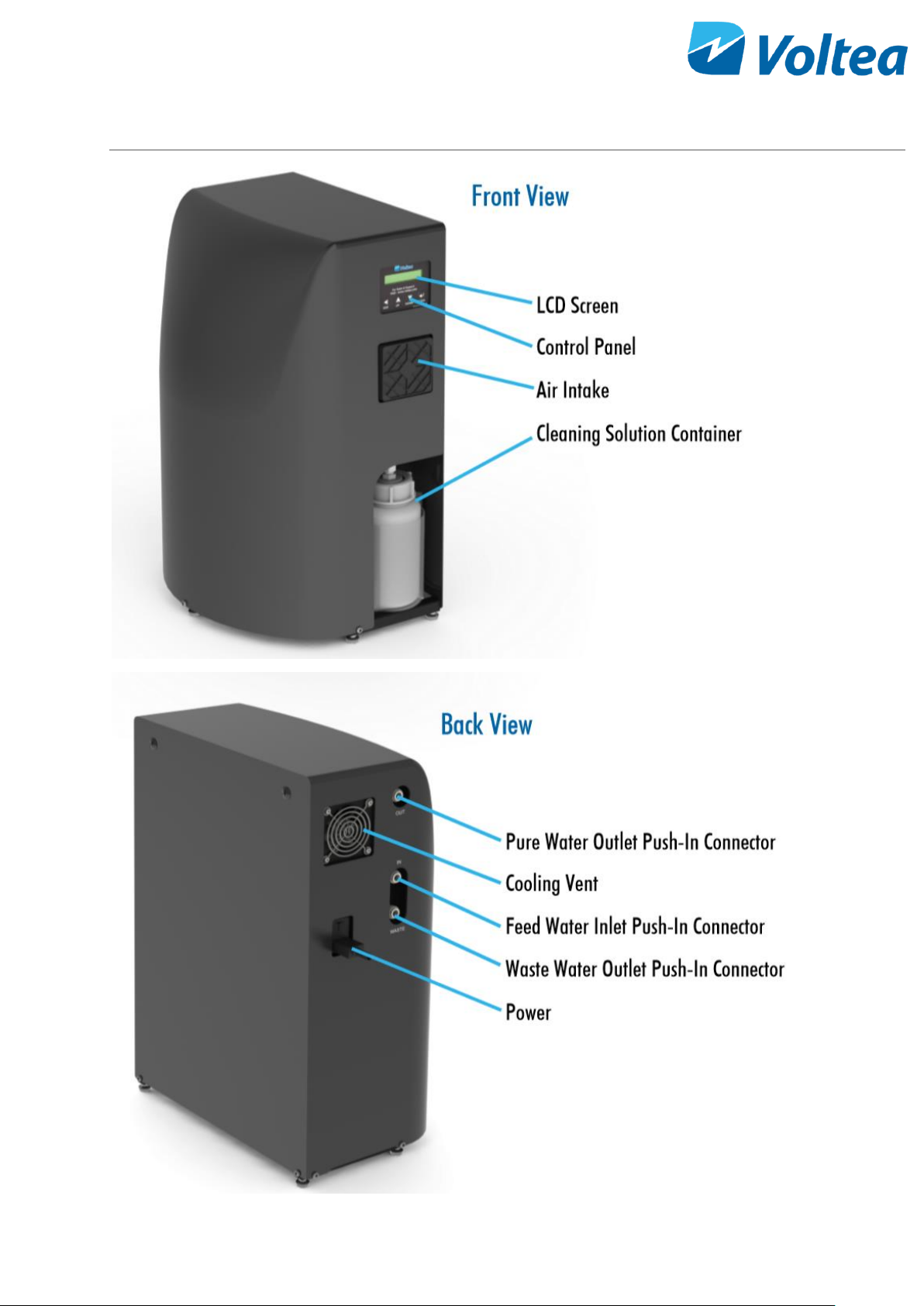

4 DIUSE

Voltea’s miniaturized version of the CapDI systems, specifically made for the point-of-use applications. DiUse

softens and desalinates brackish water for homes and businesses at an advantage to traditional desalination

technologies due to it being a salt-free, chemical-free alternative. DiUse is ideal for the HoReCa industry

alongside small households.

4.1 FEATURES

• Automated system CIP (Clean-In-Place)

• Voltea’s remote monitoring and control (option)

• Pure outlet conductivity meter (0 – 10 mS/cm)

• Total flow meter (0 – 10 L/min or 0 – 2.6 gpm)

• Built in display

4.2 SPECIFICATIONS

Performance

Produced flow rate*

0.6 – 2.9 L/min (0.2 - 0.8 gpm )

Instant flow rate*

1 - 5 L/min (0.3 - 1.3 gpm)

Salt removal

25 - 95 %

Water recovery

40 - 95 %

System Specifications

Average power requirements

0.13 kW, Single Phase (110 - 240 V AC / 50 - 60 Hz)

System dimensions (L x W x H)

0.32 x 0.43 x 0. 64 m (1’10’’ x 1’5’’ x 2’1’’)

Power output to modules

0 - 65 A / 0 - 2 V DC

Weight**

17kg (37.5 lbs.)

Feed inlet coupling

3/8’’ push fit

Product outlet coupling

3/8’’ push fit

Concentrate/Waste outlet

coupling

3/8’’ push fit

Operational

Requirements

Water feed pressure

3 - 10 bar (44 - 145 psi) System is equipped with a

pressure reducer

Water pressure produced***

≤6,5 bar (95psi)

Operating ambient air

temperature

< 35 ﮿C (95 ﮿F)

8

In/Outputs

Start/Stop

Pressure switch (standard) or external signal (24 V DC)

Cleaning

Procedure

Automated cleaning with citric acid

Control (auto/manual)

Automatic: on cycles of operation

Storage

1L chemical container

Controls

Remote control / Data

monitoring

Total flow, average conductivity, average voltage, (2G

SIM card with data or locally via laptop)

Parameter change

Locally

*Depends on TDS reduction and water recovery

**Weight without module

***Depends on flow target

4.3 FEED WATER QUALITY

Parameter

UNIT

RANGE

INTERMITTENT

Removal limit

Δppm

0 - 1300

Total dissolved solids

(TDS)

ppm

0 - 2000

Total organic carbon

ppm

< 10

Chemical oxygen

demand

ppm

< 20

< 100

Turbidity

NTU

< 4

< 100

Fats, Oils, Greases

ppm

< 0.5

Total suspended solids

(TSS)

ppm

< 4

< 20

Free Chlorine

ppm

< 2

< 25

pH

2 – 10

1 – 12

Iron total

ppm

< 0.5

Total hardness (CaCO3)*

ppm

< 1000

M Alkalinity (CaCO3)

ppm

< 1000

Pre – filtration

µm

5

Temperature

﮿C / ﮿F

1 - 35 / 34 - 95

Chemicals

Contact Voltea

*Limit depends on set TDS reduction and water recovery

CAUTION!

5-micron filter is the minimum required pretreatment

for the feed water.

9

5 SYSTEM OVERVIEW

10

6 SYSTEM INSTALLATION

NOTE: Read this section entirely before starting the installation. Follow all applicable plumbing and electrical

instructions.

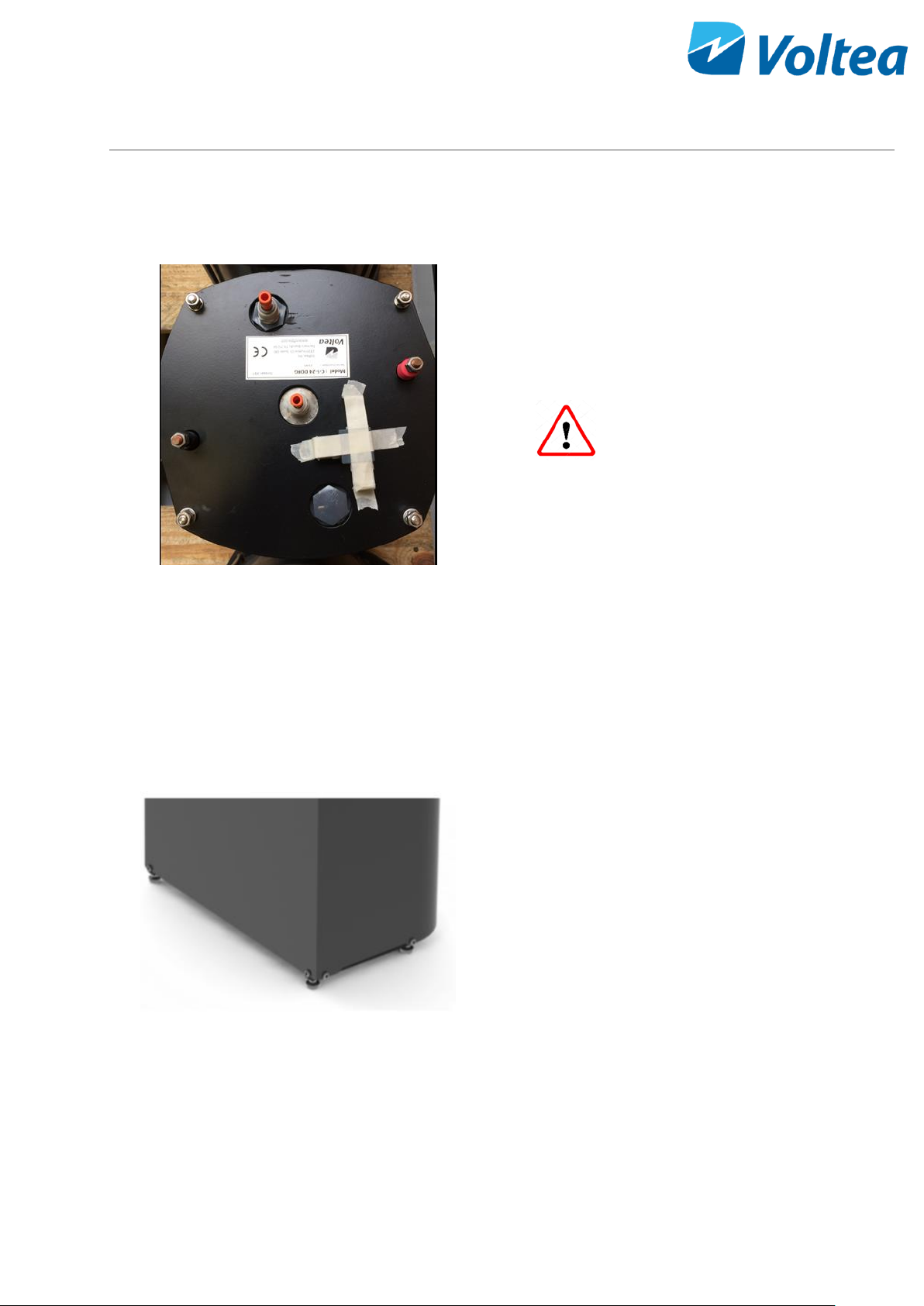

6.1 PACKING

• The DiUse system is shipped in two boxes.

• One box contains the module and module T-

junction, the other the DiUse frame, power

cable and spare flow restrictors.

Modules weigh 23 kg (50.7 lbs.)

6.2 TOOLS AND MATERIALS

• Safety shoes

• 2x size 13 wrenches

• Hex key number 4

• Flathead screwdriver

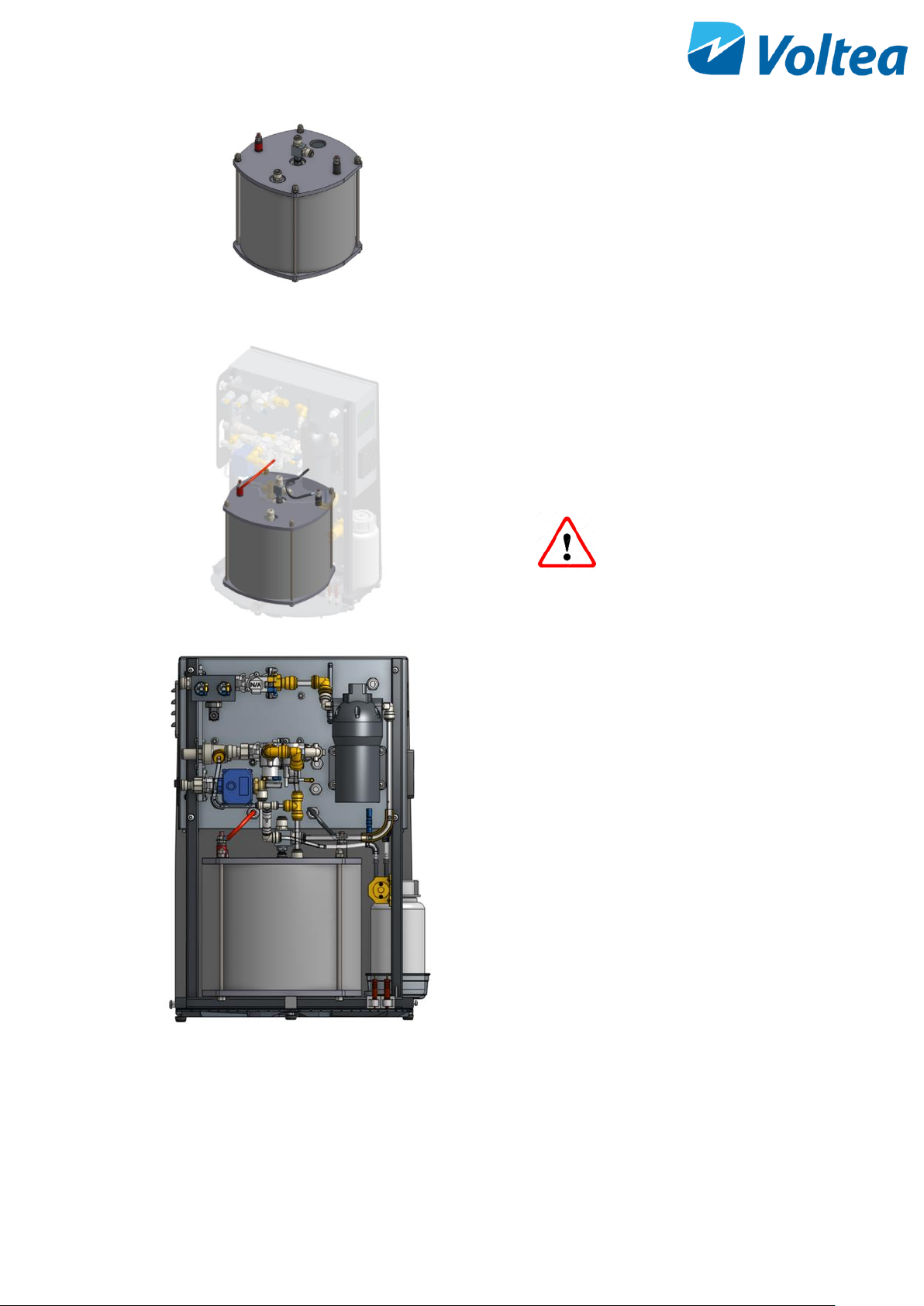

6.3 MODULE INSTALLATION

• Loosen the connections holding the curved

cover in place.

• Lift off the curved cover being careful of

protruding parts (e.g. air filter).

11

• Remove orange stoppers from module. Add

manifold to center of module using stem

adapter. The module manifold has check valves

pre-installed before each 3/8’’ push in fitting.

• Rotate the module so the red terminal is on the

left and the black terminal is on the right, when

facing the water side of the electrical cabinet.

• Push the module on the frame up against the

stoppers.

Modules weigh 23 kg (50.7 lbs.) and

the system 17 kg (37.5 lbs.). It is recommended to

wear safety shoes during installation.

• If done correctly, the module inlet (the

connection that is NOT in the middle of the

module top) will be facing outward from the

system, and the edge of the module will be in

line with the edge of the frame.

• The vertical tube that is attached to a T-junction

should be pushed into the module outlet. If

placed correctly, pulling on the tube firmly

should not disconnect it from the module.

• The tubing that comes from the waste line

(above the center of the module) should be

pushed into the vertical connection coming

from this point.

12

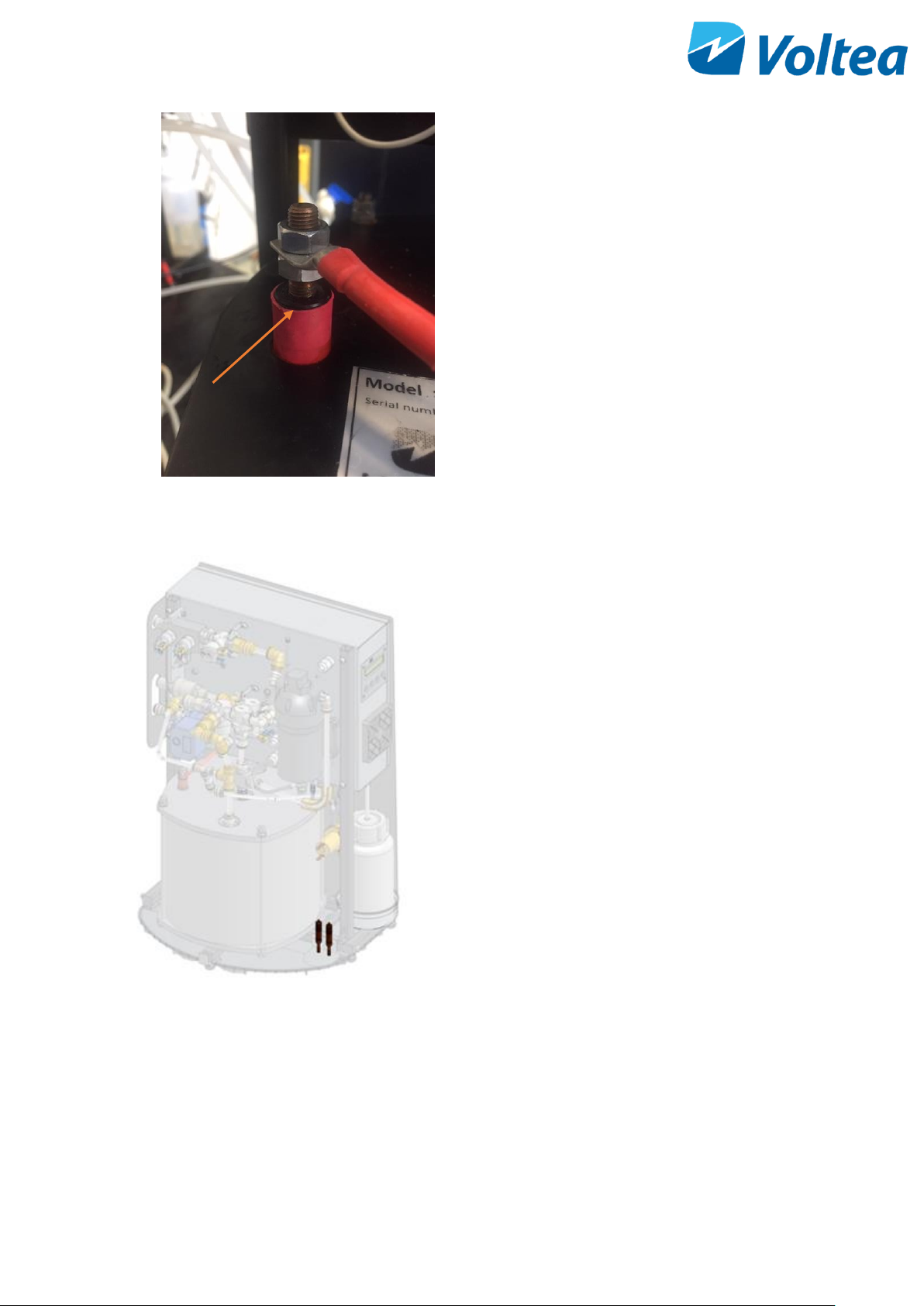

• Each module has one red and one black

electrical terminal, with each terminal having

two M8 nuts. Unscrew one of the nuts from the

red terminal. Place the red cable from the

system on the red electrical terminal, then

screw the nut back on. Tighten using two size 13

wrenches, one on the top nut and one on

bottom nut. Repeat the process with the black

terminal and black cable. Be sure the bottom

nut is isn’t sitting on the plastic bushing.

6.4 PLACING LEAK SENSOR

• Take the two sensors and place them in the

clamps as shown in the image. The tip of the

sensor should be in contact with the leak

tray.

NOTE: Leak tray should always be dry to avoid

triggering the leakage alarm and stopping the

system.

6.5 PLACING THE COVERS.

Place the covers back and tighten the connections holding the covers in place.

NOTE: Every connection has a spacer attached to it. Spacers should be between the covers and frame before

tightening.

Plastic bushing

13

6.6 WATER CONNECTIONS

Size 3/8” tubing should be used to connect the inlet to the middle connection on the side of the unit. The purified

(Out) water is discharged through the top 3/8’’ connection. Concentrate (Waste) is discharged through the

bottom 3/8’’ connection. Connections are indicated by stickers.

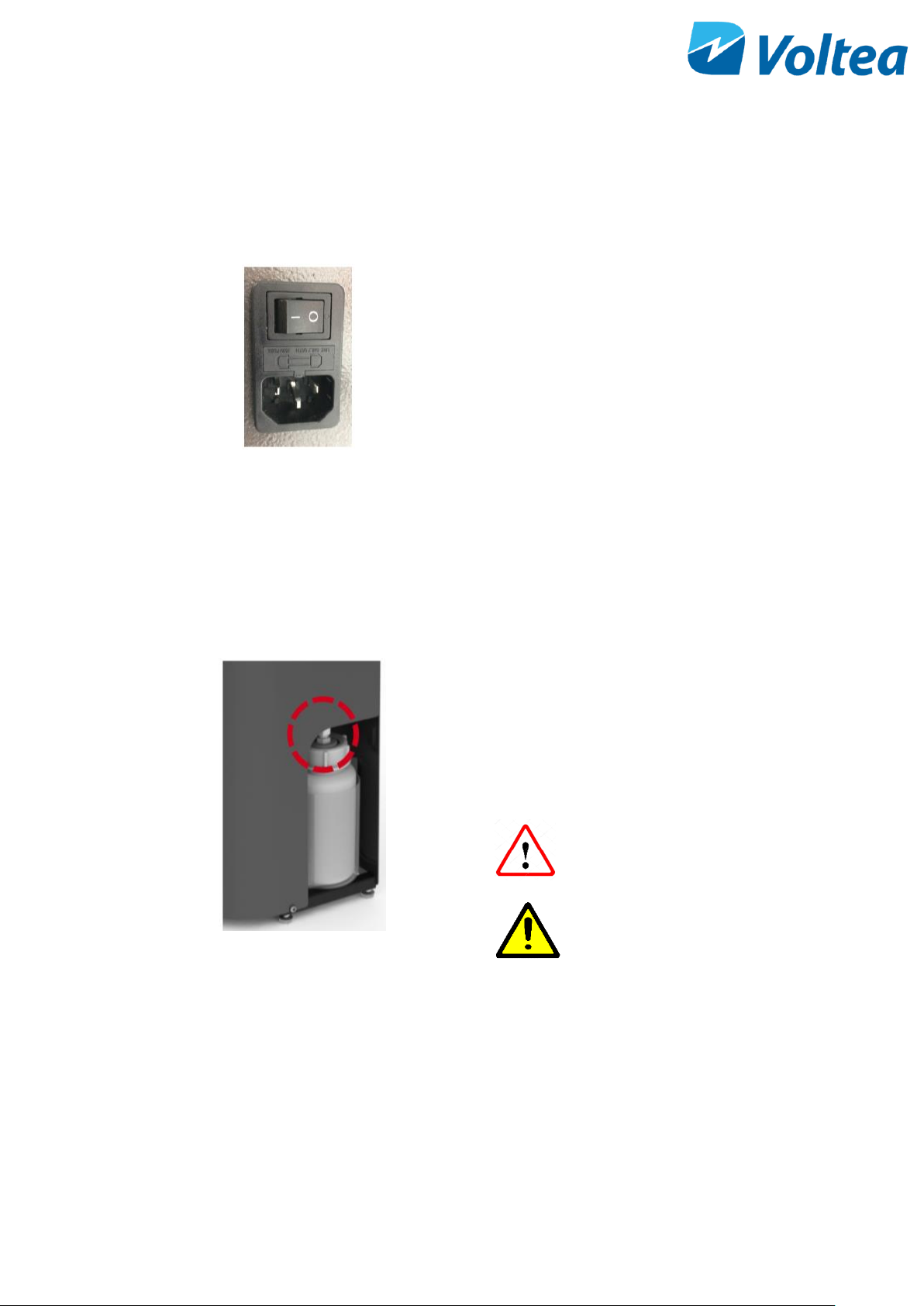

6.7 POWERING THE SYSTEM UP/DOWN

• A power cable is provided with the system.

• Connect the cable to the power connection on

side of unit.

• Turn the switch on to power the system.

NOTE: DiUse systems are specific to either 110 V or 240

V. If in doubt about system specifications, please contact

Voltea.

6.8 REPLACEMENT OF CIP SOLUTION

• Loosen the white tube gland by rotating the

gland nut (topmost piece, circled in red), whilst

holding the bottle steady.

• After the gland nut is loose, unscrew the lid of

the CIP container.

Acid may splash. Avoid

contact with eyes.

CAUTION!

If using citric acid powder

always use distilled or

sterile water for CIP

solution preparation.

Loading...

Loading...