Welding & Fabrication Tools

FBW-Flat Butt Welding

System - Model II

Instruction Manual

The Next Step in Belting

Table of Contents

Page

How to use this manual

Symbols used in this manual

1. Introduction

2. Technical Specifications

2.1. FBW (Flat Butt Welding System Model II) Layout

2.2. The Storage Case

2.3. The Electrical System

2.4. Care and Maintenance

2.5. Safety Precautions

2.6. Warning Notice for Welding Tools

3. Welding Instruction

3.1. Preparing the Temperature Controller

3.2. Preparing the Pliers

3.3. Preparing the Belt

3

3

3

4

5

6

7

7

7

8

8

9

9

9

10

3.4. Welding the Belt

3.5. Trimming and Checking the Weld

4.

Welding Texture Top Belts

4.1.

Saw Tooth (IST) & Nub Top (NT)

4.2.

MiniCleat (MC)

4.3.

Spikes (SP)

4.4. Cresent top (CT)

5. Instructions for Splicing Reinforced Flat Belts

6. Instructions for Welding Narrow Belts

7. Instructions for Welding H Material Belts

8. Welding Positive Drive Belts

8.1. Instructions for Welding SuperDrive™ H/M Material Belts

8.2. Instructions for Welding SuperDrive™ Belts Using FBW Adapter

8.3. Positioner for Welder

8.4. Welding DualDrive

8.5. Welding Mini SuperDrive™ and Mini DualDrive™ Belts

TM

Belts

11

12

13

13

14

15

17

18

19

19

20

20

22

22

23

25

8.6. Welding Mini SuperDrive™ MiniCleat Belt

8.7. Welding DualDrive™ SP (DDSP) Belts and DDSP Lace

8.8. Welding Volta Hinge Lace

9. General Tips

10. Troubleshooting Guide

11. FBW System Model II Shinko Controller and Welder Electrical Diagram

12. Calibrating the FBW Welder System Model II Shinko Controller

13. Pitch Gauge Measuring Tool for the Positive Drive Belts

27

29

31

33

33

34

35

37

Thank you for buying the Volta FBW Welding Kit. If you have any questions about the use of this

tool please contact our Technical Service Department at email: sales@voltabelting.com or visit our

website www.voltabelting.com.

How to Use this Manual

This manual has been designed to provide the operator with all the necessary information on how to use the above tool

correctly. Warnings in the manual should be carefully followed for your personal safety. Be sure you carefully read the

instructions in this manual before using the tool. This will ensure use in compliance with safety standards.

Symbols Used in the Manual

This symbol is used for important Notes & Tips

This symbol is used to warn you of actions that are dangerous for the operator.

Read the associated warnings and instructions carefully.

Identification Data

The identification plate is on the front of the clamp. You should include the model and serial number in all inquiries to

Volta Belting about this tool.

VOLTA

FBW 301

S/No. PL. 067/09

Example

Important: the identification plate should never be removed.

The data on the plate should not be modified.

www.voltabelting.com

3

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

1. Introduction

The FBW Welding Kit is designed to splice Volta

flat conveyor belts of up to 2300mm/ 90" wide.

FBW Welding Kit

The FBW Welding Kit is available in a variety of sizes and voltage/power ratings. The model number indicates

the width of belt that may be welded on a 90° joint. For example, the Model FBW 301 welds a 300mm (12”) wide belt

and the model FBW 1301 welds a belt that is 1300mm (51”) wide.

Qty. Description FBW Standard Welding Kit Components

No.

1 Case for FBW

1

2

1 Pliers

3

1 Welding Accessories (Welder, Control Box - Shinko)

4

1 SD Cutting Bar

5

1 Locator Bar

6

1 V Trim knife

1 Temperature Controller Instructions

1 FBW Welding Instructions Manual

3

4

5

2

3

6

FBW Case see picture at the top of the page

Models 301, 721, 1061 and 1301 may be operated by one person. The FBW 1701, 2101 and 2301require two

operators for correct and safe operation because of the length and weight of the Welder. The FBW Welding Kit is

supplied in a storage case to store the system components. Store only the FBW Welding components in this box to

avoid damage of the items.

Qty. Description FBW Positive Drive (PD &Mini) Welding Kit Components

No.

1 1

2 1

3 1

4 1

5 1

6 1

7 2

8

9102 Stopper for the DD /DDSP

Welding Accessories (Welder, Control Box - Shinko)

2 PD1” Adapter Set

1 Temperature Controller Instructions

1

2

FBW Welding Instructions Manual

Case for FBW

Pliers

SD Cutting Bar

Locator Bar

V Trim knife

DD Adapter

Positioner for welder*

10

2

3

4

5

7

8

3

9

6

Note: Positioner for welder* available in the FBW-1301 and FBW-1701 PD & Mini welding kits only.

FBW Case see picture at the top of the page

4

Volta Belting Technology Ltd.

2. Technical Specifications

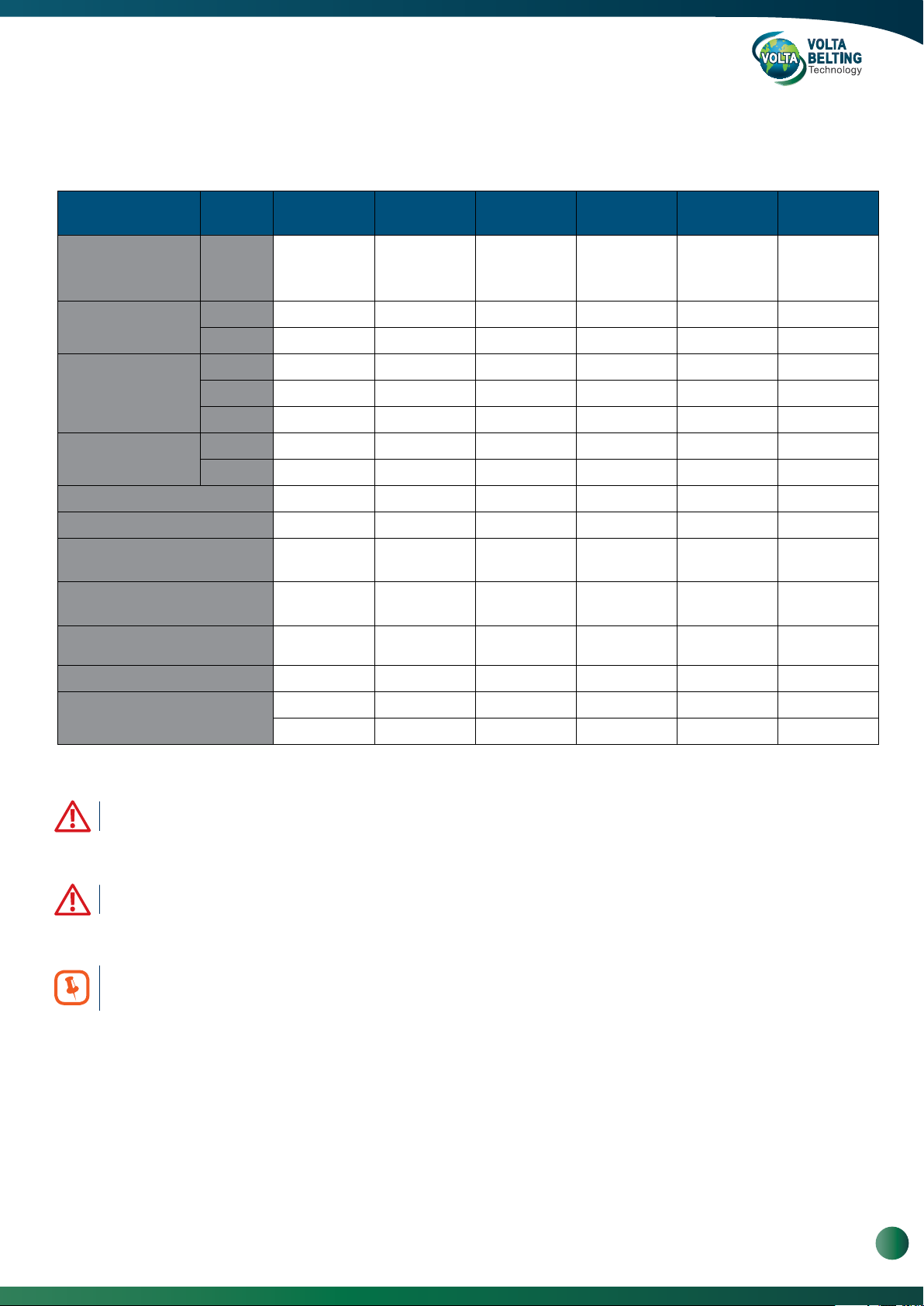

Table 1: FBW Welder System Specifications

FBW

301

110 / 230 V

Electricity

Maximum Current

Fuse

AC plug

Pliers Weight lb/ kg 13 / 6 35 /16 48 / 22 82 / 37 106 / 48* 121 / 55*

Total Weight lb/ kg 22 / 10 70 / 32* 92 / 42* 181 / 82** 225 / 102** 255 / 116**

Max. Belt Width at 90° in/ mm 24 / 300 28 / 720 41.7 / 1060 51 / 1300 66.9 / 1700 82.5 / 2100

Max. Belt Width at 45° in/ mm 6 / 150 15.7 / 400 24.4 / 620 33 / 845 45.7 / 1160 56 / 1420

Belt Thickness: in/ mm

Preheating in minutes 15 15 15 15 15 15

110 VAC 3.7 amps 7.3 amps 10 amps 12 amps N/A N/A

230 VAC 1.8 amps 3.6 amps 5 amps 5.9 amps 7.4 amps 8.7 amps

Type slow-blow slow-blow slow-blow slow-blow slow-blow slow-blow

110 VAC 10 amp 10 amps 15 amps 15 amps N/A N/A

230 VAC 10 amp 10 amps 10 amps 10 amps 10 amps 15 amps

110 VAC yes yes yes yes N/A N/A

230 VAC yes yes yes yes yes yes

Single phase

400 W

0.06-0.2 /

1.5-5

FBW

721

110 / 230 V

Single phase

800 W

0.06-0.2 /

1.5-5

FBW

1061

110 / 230 V

Single phase

1100 W

0.06-0.2 /

1.5-5

FBW

1301

110/ 230 VAC

Single phase

1300 W

0.06-0.2 /

1.5-5

FBW

1701

230 VAC

Single phase

1700 W

0.06-0.2 /

1.5-5

FBW

2101

230 VAC

Single phase

2000 W

0.06-0.2 /

1.5-5

Working Temperature

428 - 518°F 428 - 518°F 428 - 518°F 428 - 518°F 428 - 518°F 428 - 518°F

220 - 250°C 220 - 250°C 220 - 250°C 220 - 250°C 220 - 250°C 220 - 250°C

* This equipment is heavy and must be carried by two persons.

** This equipment is heavy and must be carried by a forklift.

In the USA, units are supplied with a 110 VAC North American Standard plug. In Europe, units are supplied

with a 230V German standard plug. Users must adapt the plug to the local electrical standards. This must be done

by a certified electrician and in compliance with local electrical codes and standards.

www.voltabelting.com

5

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

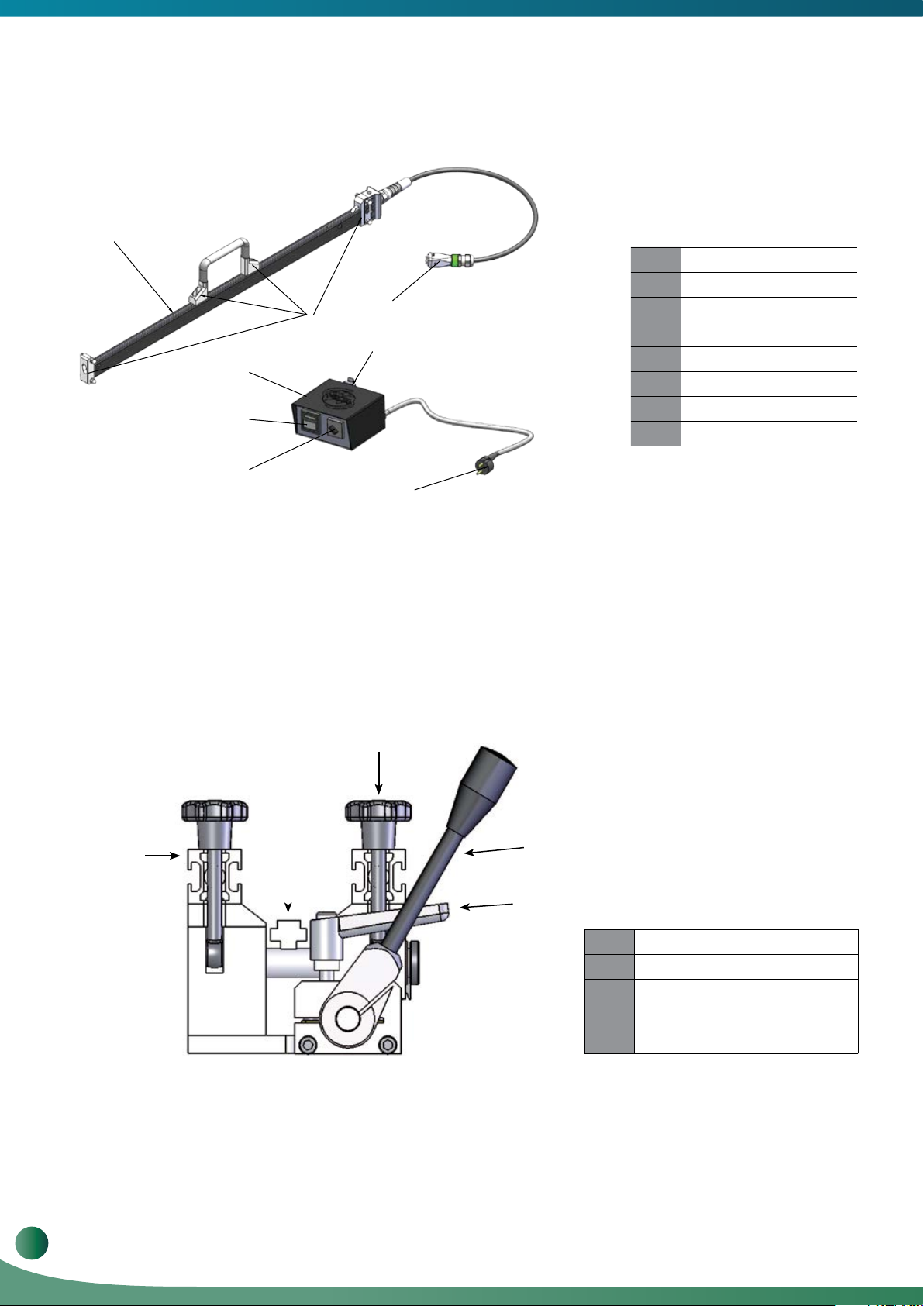

2.1. FBW Layout

1

8

2

7

3

4

5

6

1

Welder

2

Isolation Pad

3

Control Box (Shinko)

4

Temperature Control

5

Main Switch

6

Main Power

7

Output

8

Welder Input Plug

Figure 3: FBW Welder and Temperature Controller - Shinko

3

1

2

5

4

1

Crossbar

2

Locator Bar

3

Knob

4

Adjustable Lever

5

Operating Handle

6

Volta Belting Technology Ltd.

Figure 4: FBW Pliers

2.2. The Storage Case

The storage case is meant to protect the tools against dirt and damage during transportation. The case is designed to

store the entire FBW system. Tools and other items that do not belong to the FBW Welding System should not be

placed in the storage case. Loose, unsecured items may move around and damage the Teflon coating of the Welder.

Do not store chemicals in the FBW storage case - chemical fumes and possible spills may damage the wiring and

internal components

of the Controller.

2.3. The Electrical System

All metal parts of the FBW Welding System are grounded. Ensure that the electrical plug is connected to a power

source with an earth ground and a Residual-current device (RCD). The thermo-couple wires must not be disconnected

as this will cause uncontrolled heating and damage the Welder.

Electrical Shock Hazard - Never remove the ground from the power cord or

internal wiring.

2.4. Care and Maintenance

Keep the system dry and clean.

Occasionally apply a light coating of oil to sliding metal parts.

The quality of the finished weld is affected by the condition of the Welder. To obtain the highest quality results from your

Welder, always wipe the Welder’s flat surfaces with a clean cotton cloth to remove material and dirt immediately after welding.

When welding is completed, return the tools to their storage box. There is no need to wait for the Welder to fully cool

down. The partitions inside the box will ensure that the system does not move during transportation and guarantee the

tool’s long lasting functioning.

The Welder must be cleaned while hot. Because the temperature of the welder

is high, extra care must be taken to avoid burns. It is recommended that you

wear protective gloves.

www.voltabelting.com

7

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

2.5. Safety Precautions

Volta Belting accepts no liability for use of this tool in a manner other than that specified in this manual.

Volta Belting accepts no responsibility for unauthorized modifications performed on this tool.

This Instruction Manual and the warnings contained herein must be read carefully and kept clearly visible

in the vicinity of the FBW Welding Tool.

Failure to pay attention to these warnings can lead to accidents, injuries or damage to health.

2.6. Warning Notice for Welding Tools

1. Always use the original storage box to keep the welding tool when not in use. Always store tools in a

dry and secure environment.

2. Select and use the most appropriate welding tool for your application. The selection is based on

material dimensions.

3. Use the welding tool only at its rated voltage (See Table 1 - FBW Welder System Specifications).

4. Ensure that the unit is connected to an earth grounded power source. Failure to comply with this

requirement can cause electrical shock.

5. Do not use the welding tool in a damp or wet environment.

6. Do not carry the welder by its power cord or use it for unsuitable purposes.

7. Protect the cord from heat and sharp objects.

8. Do not pull on the power cord to remove the plug from its socket.

9. Always work in a well ventilated area when welding. Some materials can generate toxic fumes when

overheated.

10. Always weld on a non-combustible surface and be aware of surrounding materials. Heat may cause

fire or damage other materials.

11. Ensure that the surface of the welding bar is clean and in good condition.

12. Hold the Welder by the handles only. The Welder surface can be very hot and will cause burns.

13. If the unit requires repair, return it to Volta Belting or to your local Volta distributor.

8

Volta Belting Technology Ltd.

3. Welding Instructions

3.1. Preparing the Temperature Controller

a.

Connect the Welder to the Controller, and then connect the main power to the

power supply. Turn the Power Switch to “ON” and allow 15 minutes for the

Welder to warm up and the temperature to stabilize. The Welder is supplied

after factory adjustment and should not be altered unless there is a problem.

The Temperature Controller should be adjusted to 220°C (428°F) for all belt

types. If you need to readjust the temperature, please refer to Page 32.

3.2. Preparing the Pliers

Operating Handle

2

Cross Bar

3

1

Power Switch

Knobs (4 each)

a. Position the Pliers with the Operating Handle closest to

you.

b.

Loosen the 4 knobs securing the Crossbars. The two

knobs closest to the Operating Handle are hinged

and can be swung out and down to remove the

Crossbars.

c.

Remove the Crossbars and set them aside. FBW

models 1301, 1701 & 2101 are equipped with magnetic

crossbars. To remove these crossbars, slide or roll

them off the Pliers.

Apply strips of good quality double-sided tape on the

d.

upper surfaces of the Pliers’ jaws.

54

e.

Position the Locator Bar between the jaws of the

Pliers. Place the Locator Bar in the center of the

Pliers and over the Pliers Shafts. The belt locator has

reference marks for belt alignment, Each side of the

Belt Locator Bar has notes for different belt

thicknesses. One side is marked for 1.5 to 2.5 mm

belts and the opposite side for 3 to 5 mm belts.

Ensure that you have the correct side facing up.

f.

Move the Operating Handle to close the Pliers jaws

and lock in place using the Locking Lever. (By pulling

the lever up you can adjust the handle position).

www.voltabelting.com

9

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

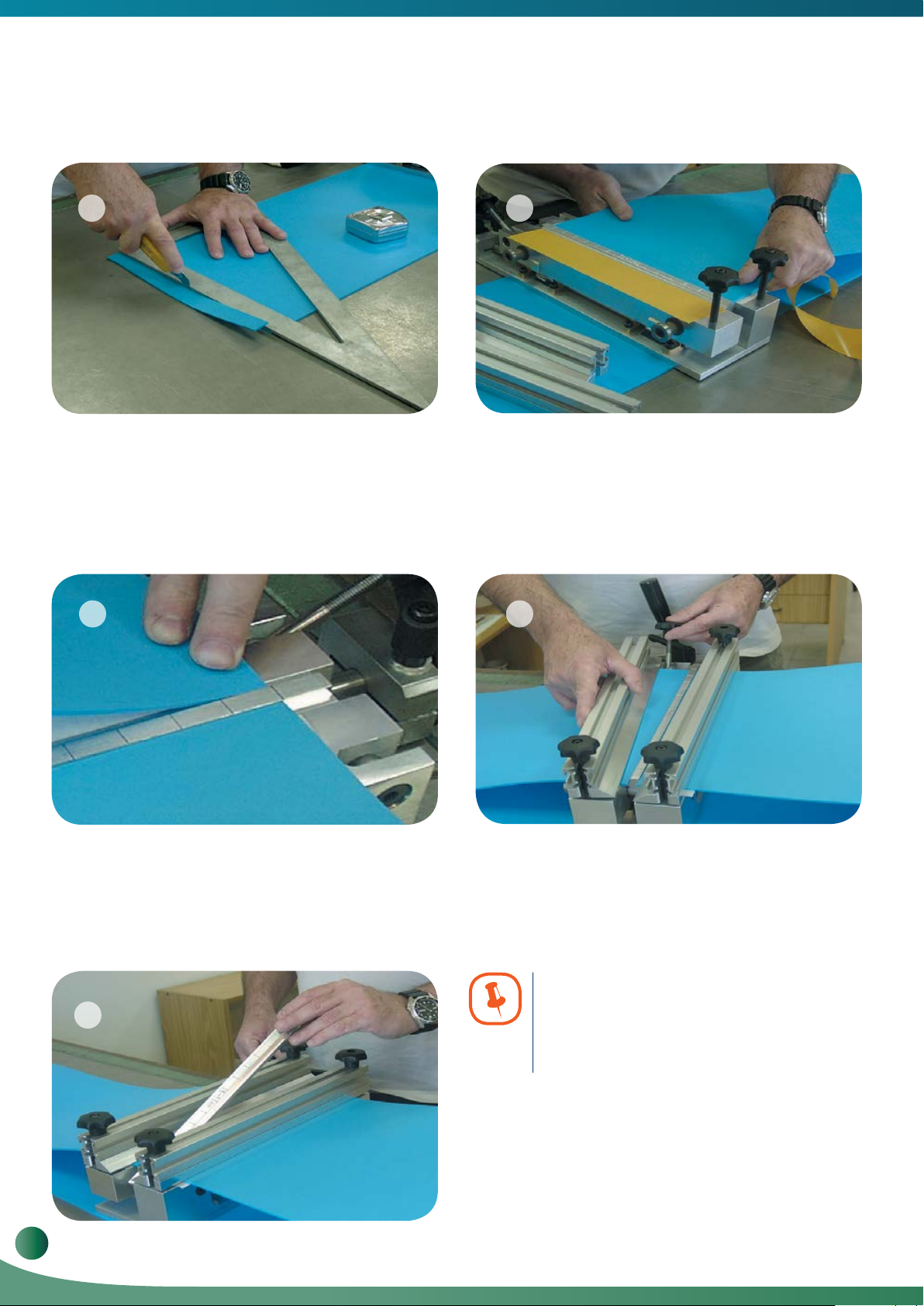

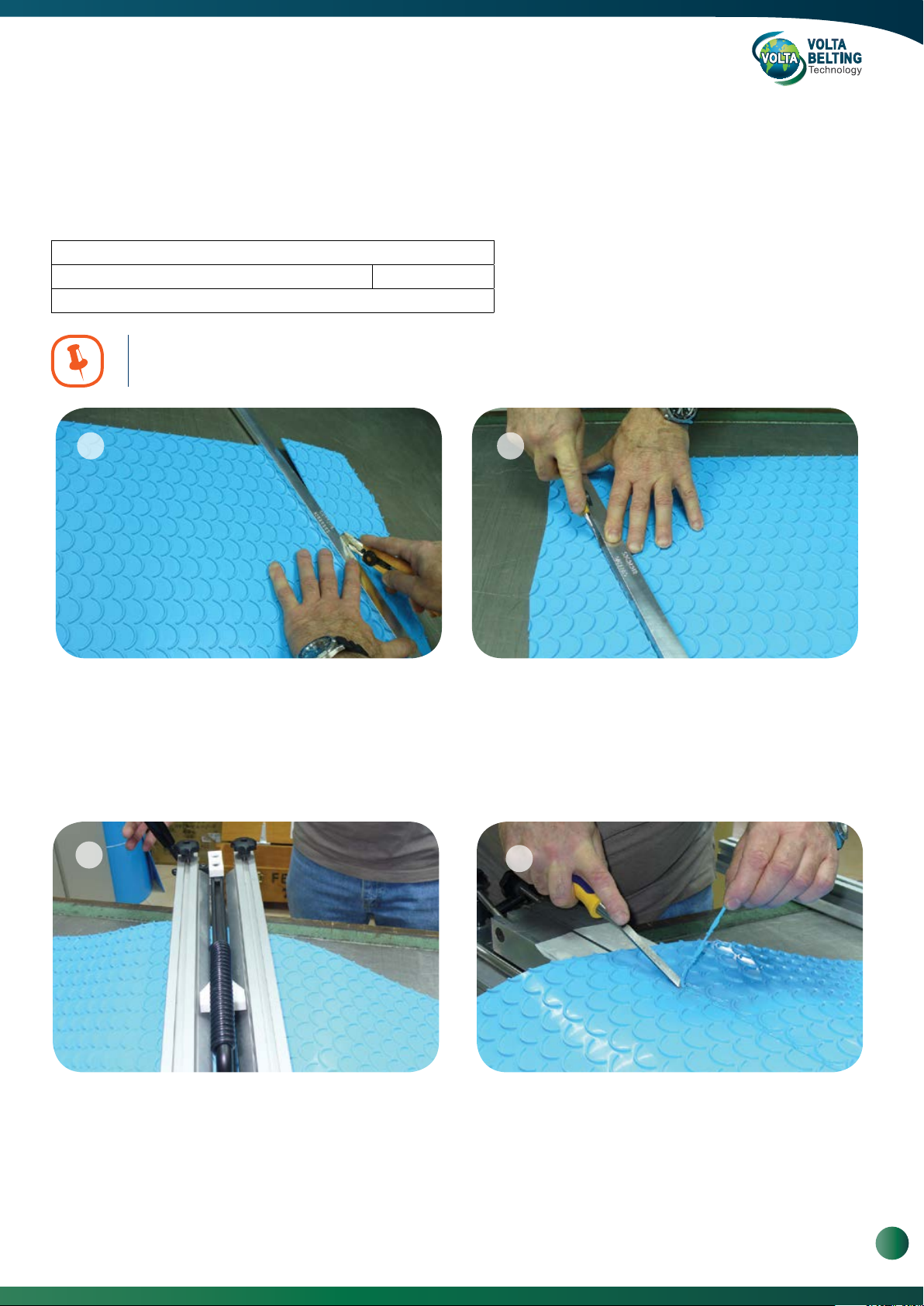

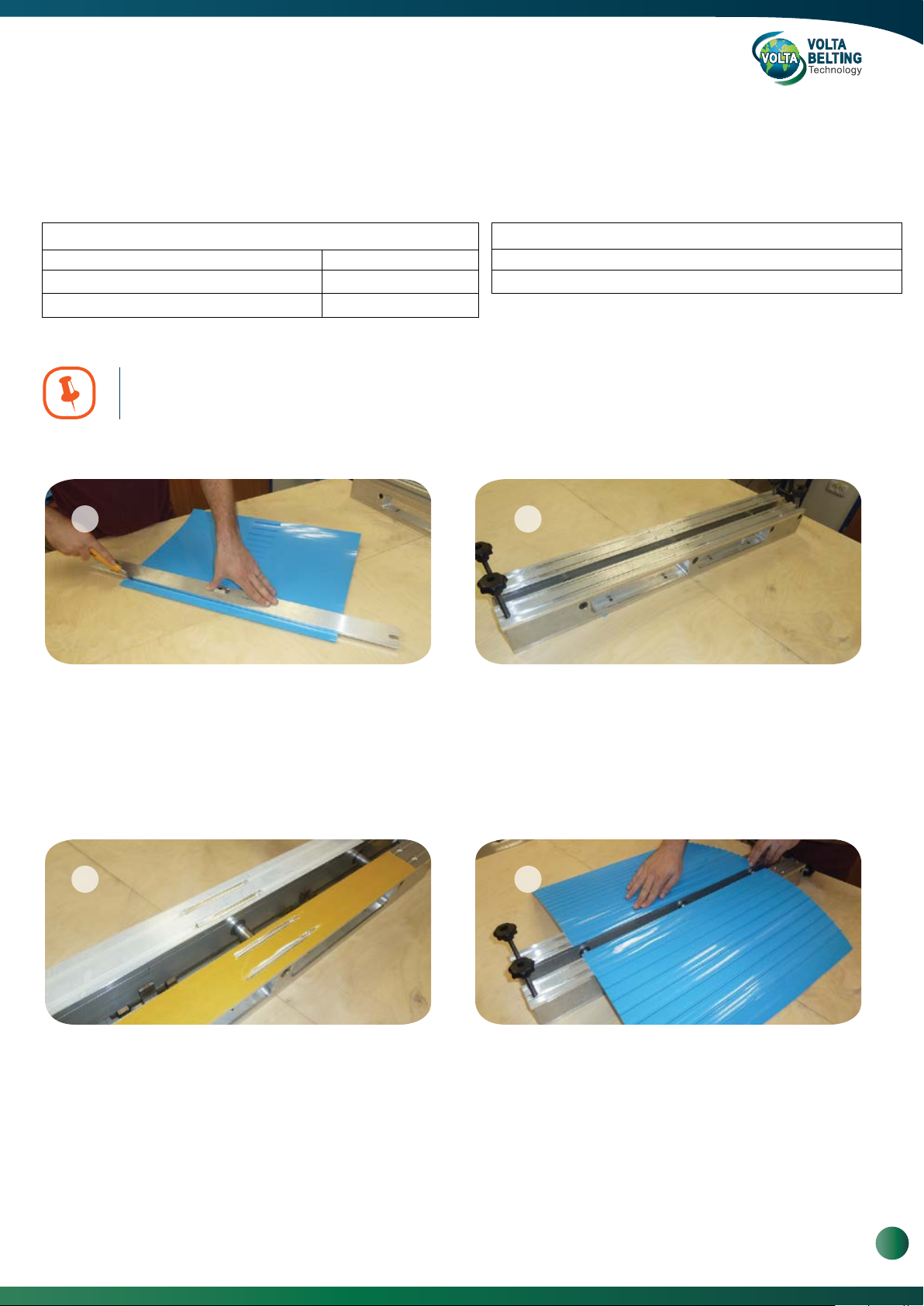

3.3. Preparing the Belt

6

Cut the two ends of the belt at 90°. Ensure that the

a.

cut is accurate and straight.

b.

Clean the belt ends with denatured alcohol. The

belt ends must be free of dirt and grease in order to

ensure a consistent, high quality weld.

8

7

c.

Remove the protective paper from one piece of the

doublesided tape and place one end of the belt against

the Locator Bar in line with a reference mark. Press the

belt onto the tape to ensure good adhesion. There

should be no gaps between the belt edge and the

Locator Bar. Gaps will produce an inconsistent weld

and lead to early failure of the weld.

9

Repeat this procedure for the opposite belt end. Make

d.

sure you align the edge of the belt with the reference

mark on the Locator Bar, to ensure a straight edge

between the two ends of the belt.

10

10

Volta Belting Technology Ltd.

Set the Crossbars in place and swing the Locking Bolt

e.

into position. Finger tighten the nuts. Be careful to

apply even pressure on Crossbars. Uneven pressure

will allow the belt to shift during welding and too much

pressure will cause the Crossbars to bend.

Note: If the belt is narrow in comparison

to the tool, add belt pieces to each side

of the belt to fill the gap. This will prevent

bending of the crossbar.

Open the Pliers and remove the Locator Bar. Leave the

f.

Pliers open The system is now ready for welding.

3.4. Welding the Belt

a. b.

Clean the belt and Welder. With the Welder cable

away from the operator, place the pre-heated Welder

between the two edges of the belt. Position the

Welder over the Pliers guide bars.

1211

Using the Operating Handle bring the two belt ends into

contact with the Welder. Apply very gentle pressure

and observe the melting of the material along both

sides of the Welder. Do not hold the Welder during the

welding process. The Welder should be free to move

with the belt. When the material is evenly melted along

the length of both sides of the Welder, move the

Operating Handle to open the Pliers. Quickly remove

the Welder and close the Pliers. This operation should

be performed quickly but without too much force.

13

c.

With the belt ends pressed together, lock the Adjusting

Lever. The weld requires approximately 5 minutes to

cool. The time required for cooling depends on the

thickness of the belt and the ambient temperature.

When removing the Welder, pull it straight up in a quick

movement. This will prevent the welder from pulling

melted material off of the belt ends.

14

d.

The cooling process can be sped up by directing

compressed air along the weld.

Amount of excess when belt ends

are properly melted.

www.voltabelting.com

11

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

15 16

e.

Clean the Welder using a clean, dry, lint-free soft Cotton

cloth while the Welder is hot. Leaving material on the

Welder will damage the Welders surface and reduce the

efficiency of the Welder and the quality of the welds.

f. When the belt is cooled, leave the Pliers closed and

remove the two Crossbars.

17

The following factors must be kept in mind

when welding:

•

The amount of pressure required to secure the ends of the

belt depends on the thickness and type of material being

welded.

During welding, air bubbles are formed in the melted ends.

•

The bubbles should be pressed out during the operation.

If too much pressure is applied during welding, the heat will

•

penetrate only a very narrow section along the edge of the

g. Welded belt with excess.

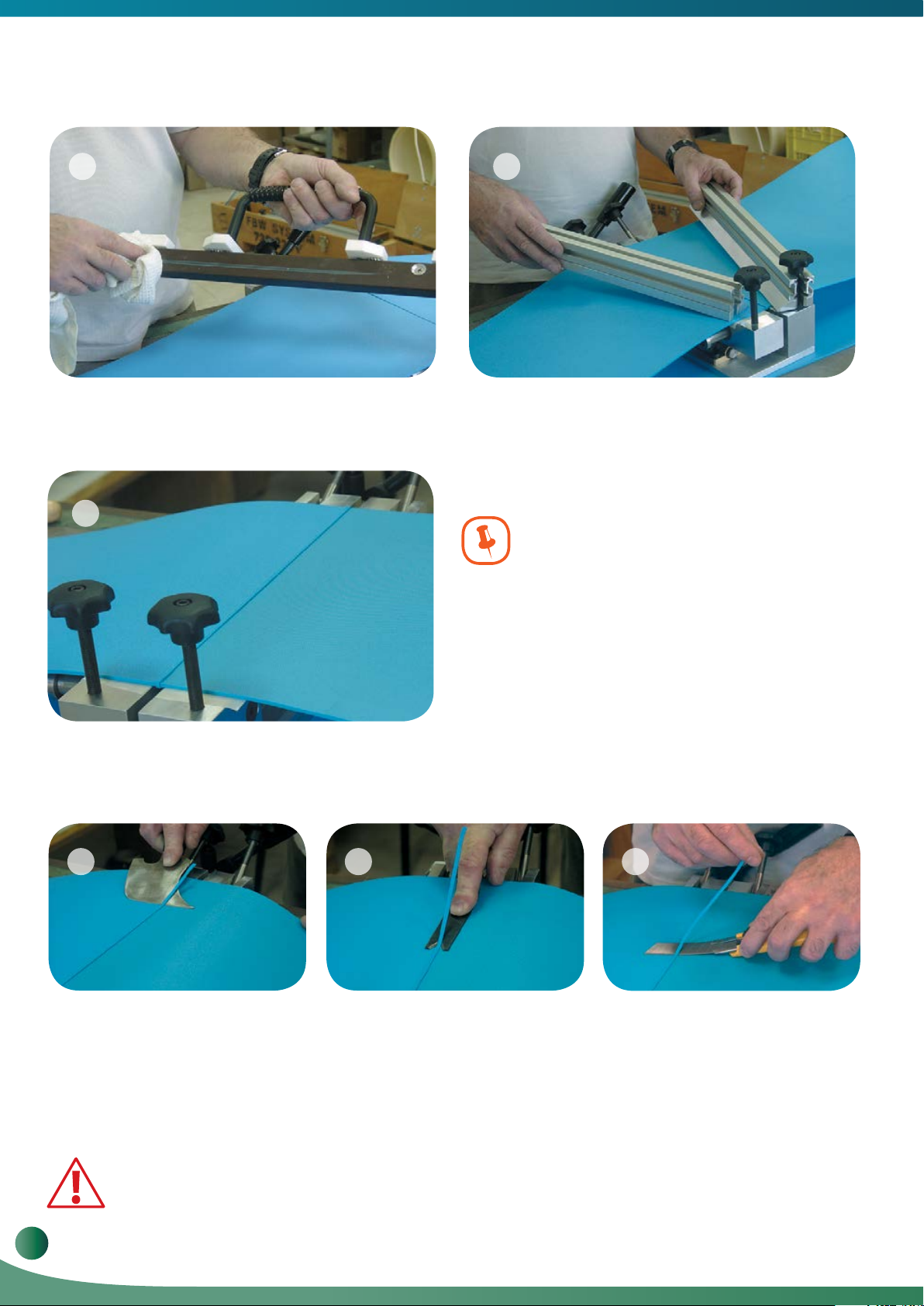

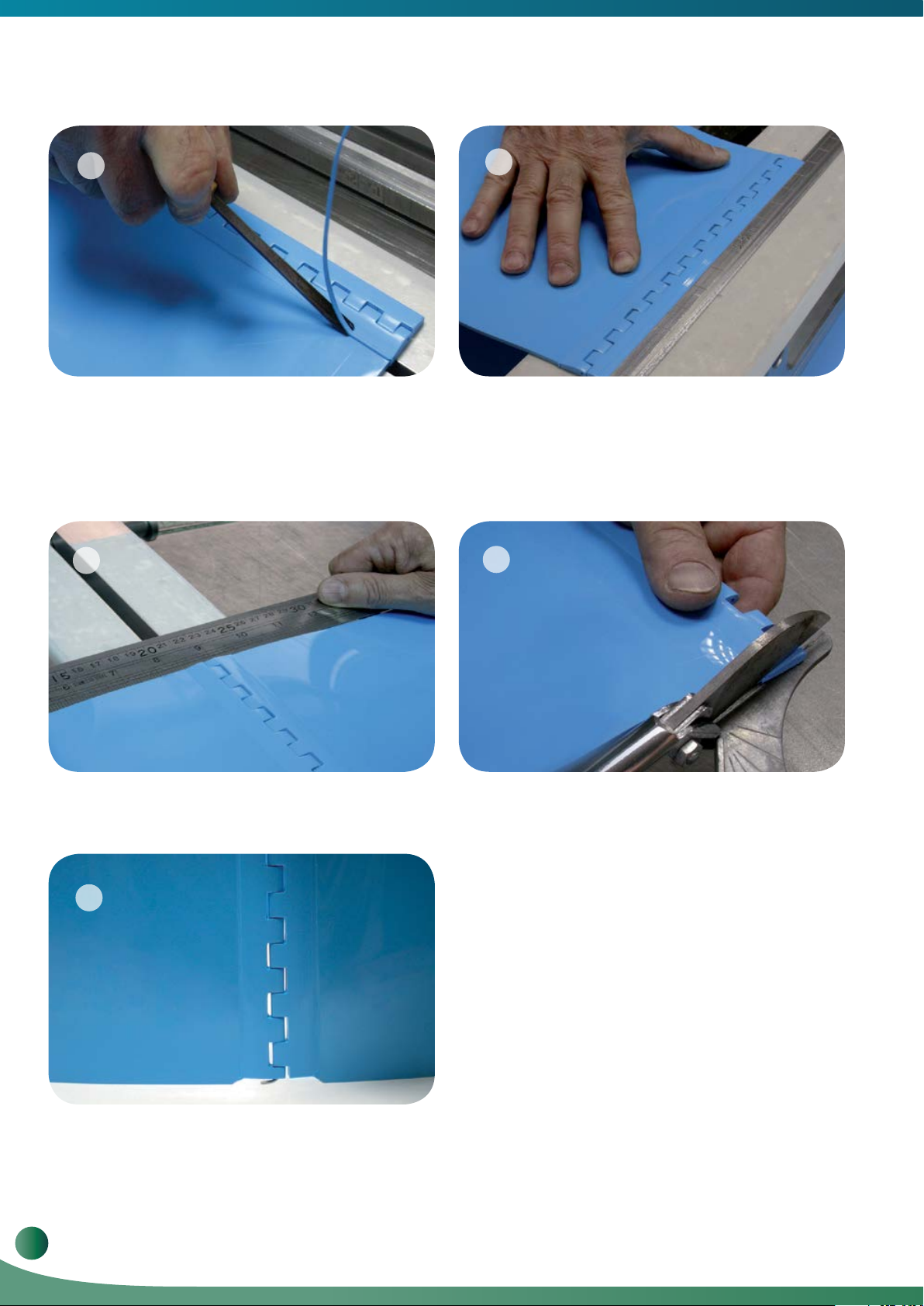

3.5. Trimming and Checking the Weld

Using a Leister Knife or other appropriate tool, trim the excess from the top of the belt.

a.

18 19 20

belt. When the Pliers are closed this small amount of melted

material will be pushed out. To ensure a quality weld, the

heat must penetrate a wide section of the belt.

Using Leister Knife to trim

excess from weld

b.

Separate the belt from the Pliers and turn it over placing

the trimmed surface on the Pliers. Trim the excess from

the bottom of the belt.

Use a finger guard when engaging in various activities that involve the use

of sharp objects. Handle the knife with care. Cut away from your body, not toward it.

12

Volta Belting Technology Ltd.

Using V-trimmer to trim

excess from weld

c.

Check the splice quality by bending the belt in both

directions. Check the quality of the splice across the

width of the belt and on both sides. A good weld will be

free of cracks and defects. In case of a bad splice repeat

the above steps (this will cause the loss of about 5 mm

of the belt’s length).

Using Utility knife to trim

excess from weld

4. Welding Texture Top Belts

4.1 Saw Tooth (IST) & Nub Top (NT)

For welding these textured top belts IST-Saw Tooth and NT-Nub Top use the same adaptor as for the flat belts.

No special adaptors required.

If you haven’t welded this product before, weld a section of a trial belt before welding your Volta conveyor belt.

Follow the instructions from Page 9 to prepare the Temperature Controller and the Pliers.

1. Welding IST-Impression Saw Tooth Belt

1 2

Cut the two ends of the belt at 90o following the instructions from the sketch below:

Center line of IST

&HQWHUOLQHRI,67

/HIWVLGH&HQWHUOLQHPP

Left side: Center line +1mm

Right side: Center line +1mm

5LJKWVLGH&HQWHUOLQHPP

2. Welding NT-Nub Top Belt

3 4

Position both sides of the belt on the Pliers

•

with the belts’ pattern facing up.

Weld the belt according to the FBW

•

Instructions Manual Page 10-12.

Trim out 1 row of Nub Top Texture on all the

width of the belt from both sides :

Cut the belt un the middle of the trimmed

•

Nub Top area at 90

Position both sides of the belt on the Pliers

•

with the belts’ pattern facing up.

Weld the belt according to the FBW

•

Instructions Manual Page 10-12.

o

.

www.voltabelting.com

13

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

4.2. Welding MiniCleat (MC)

Required Tools:

FBW Welding Kit

MC Adapter Set for FBW - 301 Cat. #813072510

MC Adapter Set for FBW - 721 Cat. #81307241

MC Adapter Set for FBW - 1061 Cat. #81310601

MC Adapter Set for FBW - 1301* Cat. #81313008

Positioner for welder** Cat.#81626342

V Trim Knife Cat. #8153108

Utility Knife

* Non-standard

** Positioner for welder FBW - 1301 and FBW - 1701 only.

Instructions on Page 22.

You must be familiar with the instructions for welding with FBW before continuing

with this procedure.

1 2

To ensure correct position on the pliers and right pitch of

thepattern, place the adapter on the belt and cut the two

ends of the belt along the “Cutting” side of the Adapter.

3

Position and then tighten the FBW Crossbars. Weld the

belt according to the FBW Instructions Manual.

Position both sides of the belt on the Pliers with the belts’

patten facing up. Position the Adapters onto the Belt.

Align the belt patten to the Adapter grooves.

4

Trim and check the weld. A good weld will be free of cracks

and defects.

14

Volta Belting Technology Ltd.

4.3. Welding Volta Spikes (SP)

21

Required Tools:

FBW Welding Kit

Spikes Adapter Set for FBW - 301 Cat. #813072535

Spikes Adapter Set for FBW - 721 Cat. #81307248

Spikes Adapter Set for FBW - 1061 Cat. #81310608

You must be familiar with the instructions for welding with FBW before continuing

with this procedure.

1 2

Spikes Adapter Set for FBW - 1301* Cat. #81313011

Positioner for welder** Cat. #81626342

V Trim Knife Narrow Cat. #8153108

Utility Knife

* Non-standard

** Positioner for welder FBW - 1301 and FBW - 1701 only.

Instructions on Page 22.

Insert the Cutting Bar at an angle between the Patterns

when the “Cutting” engraving (on the bar) and the belt

scrap is on the right-hand side. Push the cutting bar

toward the “Cutting” side and cut the first side with a

sharp knife. Measure the belt length and mark other end.

3

The weld is performed at an angle alongside the pattern.

There will be about 15 mm difference on the final length

of the belt according to the cutting line between the

patterns.

Rotate the cutting bar 180 degree, and insert the Cutting

Bar as close to the required size. Make sure that the

scrap and the “Cutting” engraving (on the bar) are on

your right-hand side. Add or deduct from the length of the

belt according to the position of the pattern.

4

Position the adapter on top of the belt with the «Welding»

side facing outward, position the belt and the adapter on

the FBW.

www.voltabelting.com

15

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

5

Insert the cross bar on the first side and repeat the same

stages on the other side. As the cut is in an angle, position

the belts ends according to reinforced belt joining

instructions (Page 13). Weld the belt according to the

instructions as described in the FBW Users Manual.

6

After the belt is cooled down, trim the weld with the ‘V’

shape knife. Use liquid soap to improve the cut if

required. Turn the belt and position it on top of the cutting

bar in a way that the spikes are inserted to the grooves,

this will allow you an easy trim of the underside. Check

the weld and perform “cosmetic” finish if necessary. A

good weld will be free of cracks and defects.

16

Volta Belting Technology Ltd.

4.4. Welding Cresent top (CT)

The weld is performed at an angle alongside the crescent pattern. There will be a 20 mm difference on the final length of

the belt according to the cutting line between the patterns.

Required Tools:

FBW Welding Kit

CT Cutting Bar for all FBW welding tool sizes Cat. # 81626365

Wood Chisel 6 mm (¼”)

You must be familiar with the instructions for welding with FBW before continuing

with this procedure.

1 2

Place the belt with the pattern facing to the left as shown

in the picture. Insert the Cutting Bar at an angle between

the patterns when the “Cutting” engraving (on the bar) and

the belt scrap is on the right-hand side. Cut the belt with a

sharp knife. If the belt is wider than the adapter, cut the

belt in two steps.

3

21

Weld the belt according to the instructions as described

in the FBW Intruction Manual (Page 13). When welding

belts made of L material, be careful and use less

pressure during the melting process and tightening after

melting.

Go to the other side of the belt and insert the Cutting Bar

as close to the required size. Make sure that the scrap and

the “Cutting” engraving (on the bar) are on your right-hand

side. To carry out this step, please stand on the opposite

side of the belt. Add or deduct from the length of the belt

according to the position of the pattern.

4

22

After cooling the belt, trim the weld with a wood chisel

when the flat side is facing the belt. Use liquid soap to

improve the cut if required. Turn the belt and trim the

bottom weld as usual. Check the weld and perform

“cosmetic” finish if necessary. A good weld will be free of

cracks and defects.

www.voltabelting.com

17

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

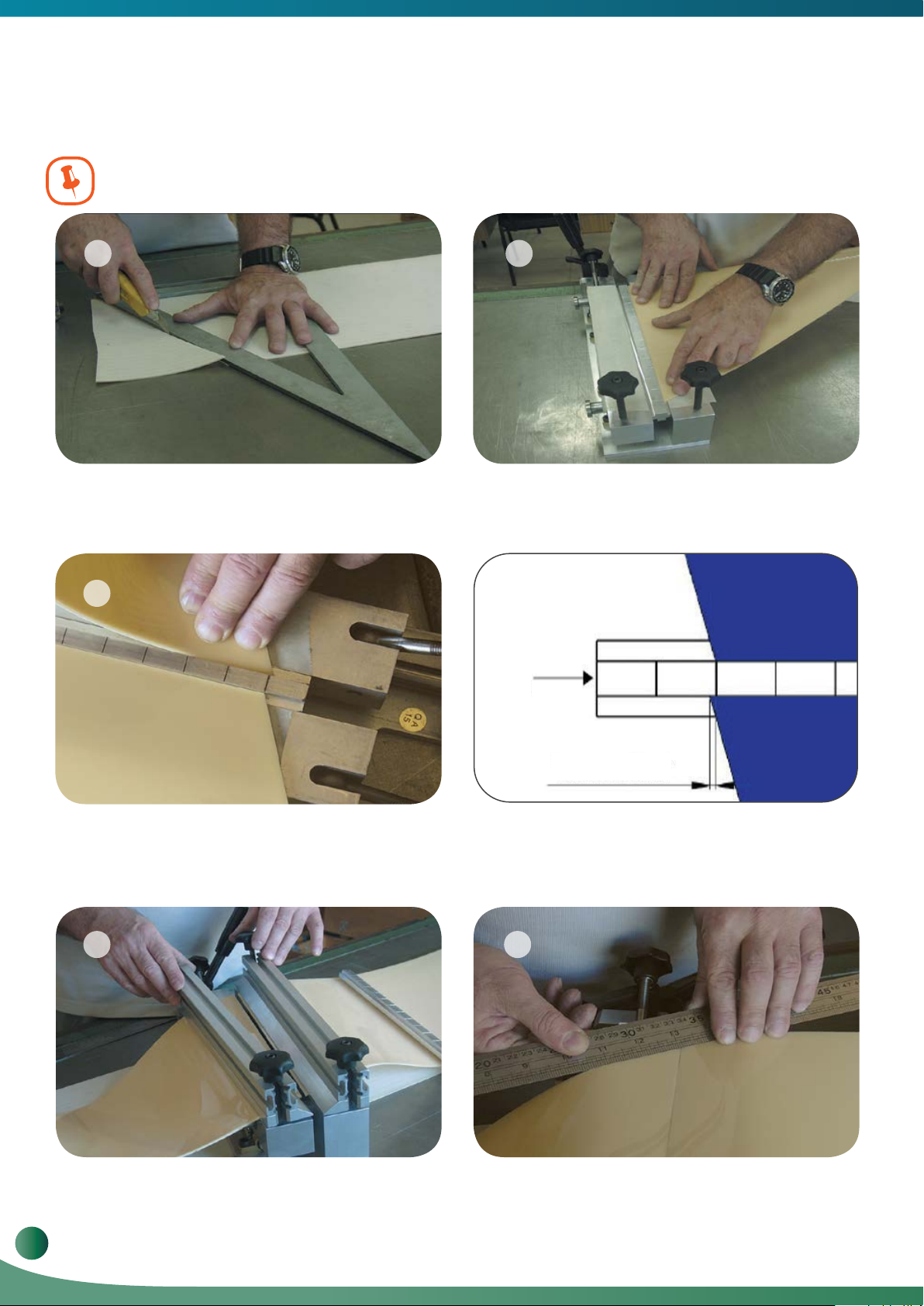

5. Instructions for Splicing Reinforced Flat Belts

Reinforced belts must be spliced in an angle (15° - 45°).

1 2

a. Prepare the Control Box and Pliers.

b. Cut both ends of the belt to the desired angle.

3

Position the second belt end on the opposite Pliers base.

c.

Ensure that there is an offset of 1 mm. This offset will

compensate for the material melted during welding and

ensure a smooth Straight edge.

Align the sharp upper edge of the belt with a reference

d.

mark on the Belt Locator Bar and press the belt onto the

doublesided tape.

Locator Bar

1 mm offset

4 5

f. Mount the Crossbars on the Pliers. Perfom weld as per

welding instructions.

18

Volta Belting Technology Ltd.

g. After trimming the weld, check that the belt edge is

aligned. A small disalignment may be trimmed.

6. Instructions for Welding Narrow Belts

The FBW models 301, 721 and 1061 can be used to weld narrow belts from 150 mm, by using double-sided tape

and without assembling the Crossbars. Observe the following rules:

a. Use good quality tape and make sure it is thoroughly adhered to the Pliers.

b. When welding reinforced belts, work upside down with the fabric facing upwards.

c. If the belt still moves while welding, raise the welding temperature by 15°C to 20°C to allow an easier melting of

the material and reduce the pressure required. When you finish, return the Temperature Controller to 220° C.

7. Instructions for Welding H Material Belts

The procedures for welding M and H family materials are basically the same. However when welding H family belts

it is necessary to be extra careful. The following are specific areas to watch out for:

a. When welding H material belts, and especially belts 4 mm thick or more, in ambient conditions of low

temperature and high humidity, it is necessary to warm the belt ends before welding.

b. With the belt ends secured in the Pliers, use a Leister Hot Air Gun to direct hot air over the belts’ ends for

approximately 2 minutes.

c. Without delay continue with the standard welding procedures described above.

d. If you do not have a Leister Hot Air Gun, you can place the Welder in the Pliers over the Pliers supports. Close

the Pliers without bringing the belt ends into contact with the Welder at least for a minute. The heat from the

Welder will warm the belt ends before you begin to weld.

e. When you bring the belt ends in contact with the Welder, press gently until the two ends have an even melt

along the entire length of both sides of the Welder. At this point stop pressing and maintain this position for

approximately 20 seconds. This allows the heat from the Welder to penetrate farther into the “H” material providing

a sufficiently large softened area to ensure a good weld. Open the Pliers quickly and with a “snap”, which will

prevent material from sticking to the Welder.

Release pressure, remove the Welder continue with the standard welding procedures described above.

f. Using the Operating Handle, quickly close the pliers, because the H material cools down quickly. When working

with H material belts, especially those that are 4 mm or thicker, apply extra pressure when closing the belt. This is

needed to force any air bubbles out of the joint. However, remember that applying too much pressure will reduce

the quality of the weld by forcing all of the melted material out of the area of the joint and leaving only cold

material.

g. The splice must be left to cool for at least 10 minutes after welding. Checking the splice by bending it too soon

will weaken or break the splice.

h. Because of the care needed to ensure a quality weld, it is important to perform several trial welds before

welding a belt. This will allow you to get the feel for the pressure required while welding and closing the Pliers after

welding. If you still have problems, please contact Volta for aditional technical advice.

www.voltabelting.com

19

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

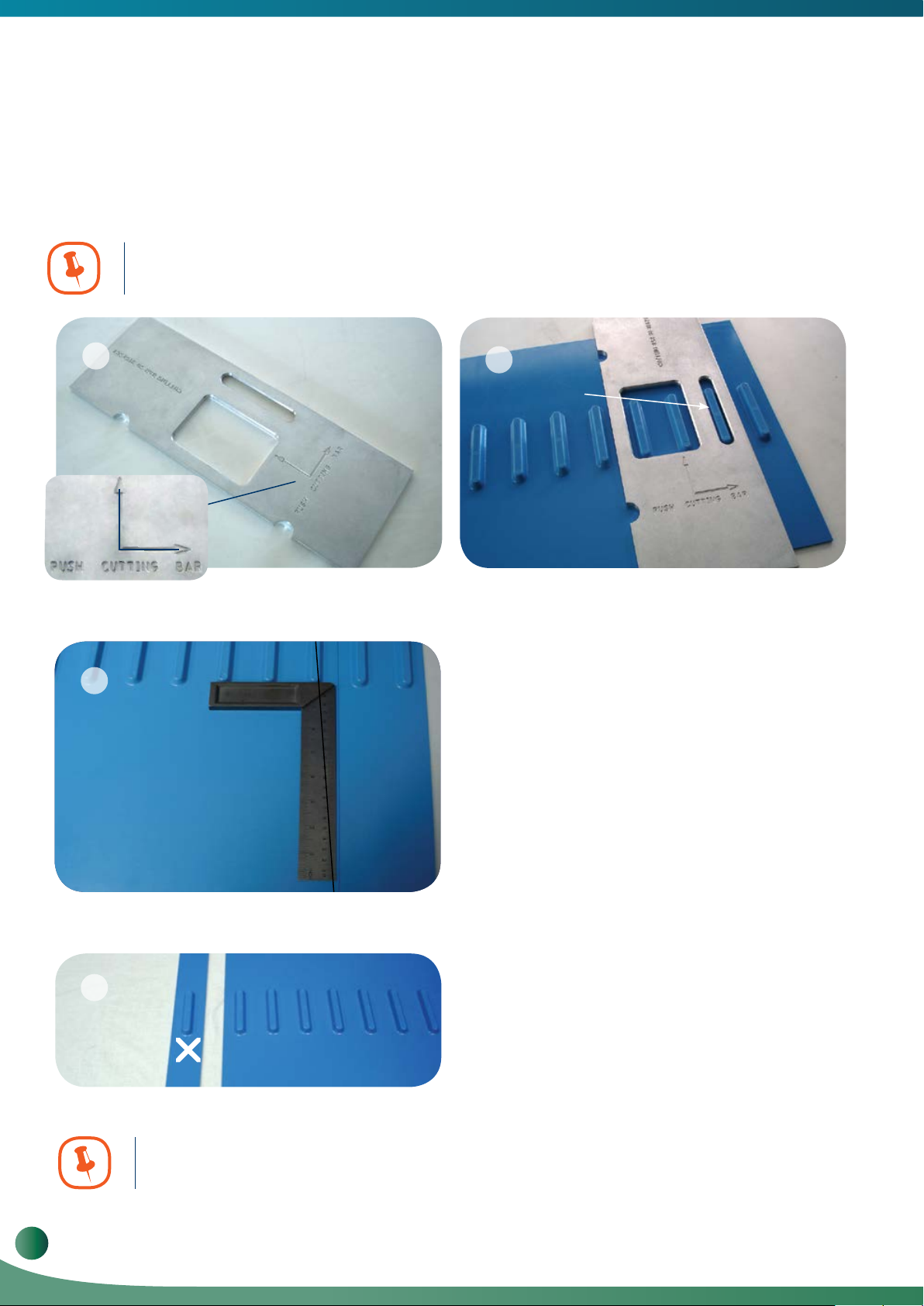

8. Welding Positive Drive Belts

8.1. Instructions for Welding SuperDrive™ H/M Material Belts

Using FBW-301, FBW-721, FBW-1061 or FBW-1301.

21

It is Essential to carry out several welding trails to become familiar with welding the

Positive Drive conveyor belts.

22

1

PUSH CUT TING BAR

The cutting bar is marked with positioning arrows as

1.

per photo 1.

3

2

No Gap

a.

Use the Cutting Bar to cut the belt between the teeth,

to ensure a 90º cut and the correct pitch. Push the

cutting bar away from you and then against the right

side until the single tooth stencil fits exactly in line with

the tooth, giving you a perfect 90º position for marking

your line.Draw a line and then check that the line is

parallel to the teeth. Photo’s 2 & 3. When cutting the

belt this line will help us to make sure that the cut is

square.

4

Tip. Use double sided tape on the bottom side of the cutting bar to prevent

slippage while cutting.

20

Volta Belting Technology Ltd.

Reposition the cutting bar make a clean cut using a

b.

sharp knife. When cutting the SD, we will have 2

ends one usable and one unusable (Photo 4, 5, 6)

this is due to the fact that we did not cut in the middle

of the pitch.

5 6

Now you must turn the cutting bar 180º and cut the

c.

second end of the belt so the scrap/unusable piece will

not be part of the belt. Both egdes of the belt must be

cut so that both the final ends are usable (1/2

pitch+2 to 3mm).

d.

7

Place double-sided tape on both sections of the Pliers.

2. 3.

Cut the tape away from the teeth grooves in the base.

The end result is that both ends of the belt will have a

combined pitch of SuperDrive™ tooth pitch + 3-4mm.

When welding the belt, those 3-4mm will melt and the

final pitch should be the exact pitch needed.

A pitch of - (Minus) 1 to 2mm is acceptable.

8

Position the locator bar as per normal operation of 3mm

-5mm belt, and then slide it until one of the positioning lines

is in the center of the groove. (Photo 8)

Remove the protective paper from the double-sided tape on one side and position the belt. The difference in working

4.

with the SuperDrive™ belt is that you must position the teeth over the groove before bringing the rest of the belt into

contact with the tape. To make this easier mark the center of the tooth on the top side of the belt and aline it against the

central positioning line.Press the belt against the locator bar and onto the tape to ensure a firm, consistant contact

(Photo 8).

Position the second belt end against the locator bar and fix

5.

the belt with the cross bar. (Photo 9)

9

Position the FBW Welder in place. Weld the belt

6.

according to the welding instructions in the FBW Manual.

Check the weld for any cracks or bubbles, if needed cut the

7.

belt and rejoin it (you will lose about 80mm from the belt length).

8.

Check the pitch; pitch larger than normal is not acceptable,

however welding results with pitch up to 2mm shorter is

acceptable.

www.voltabelting.com

21

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

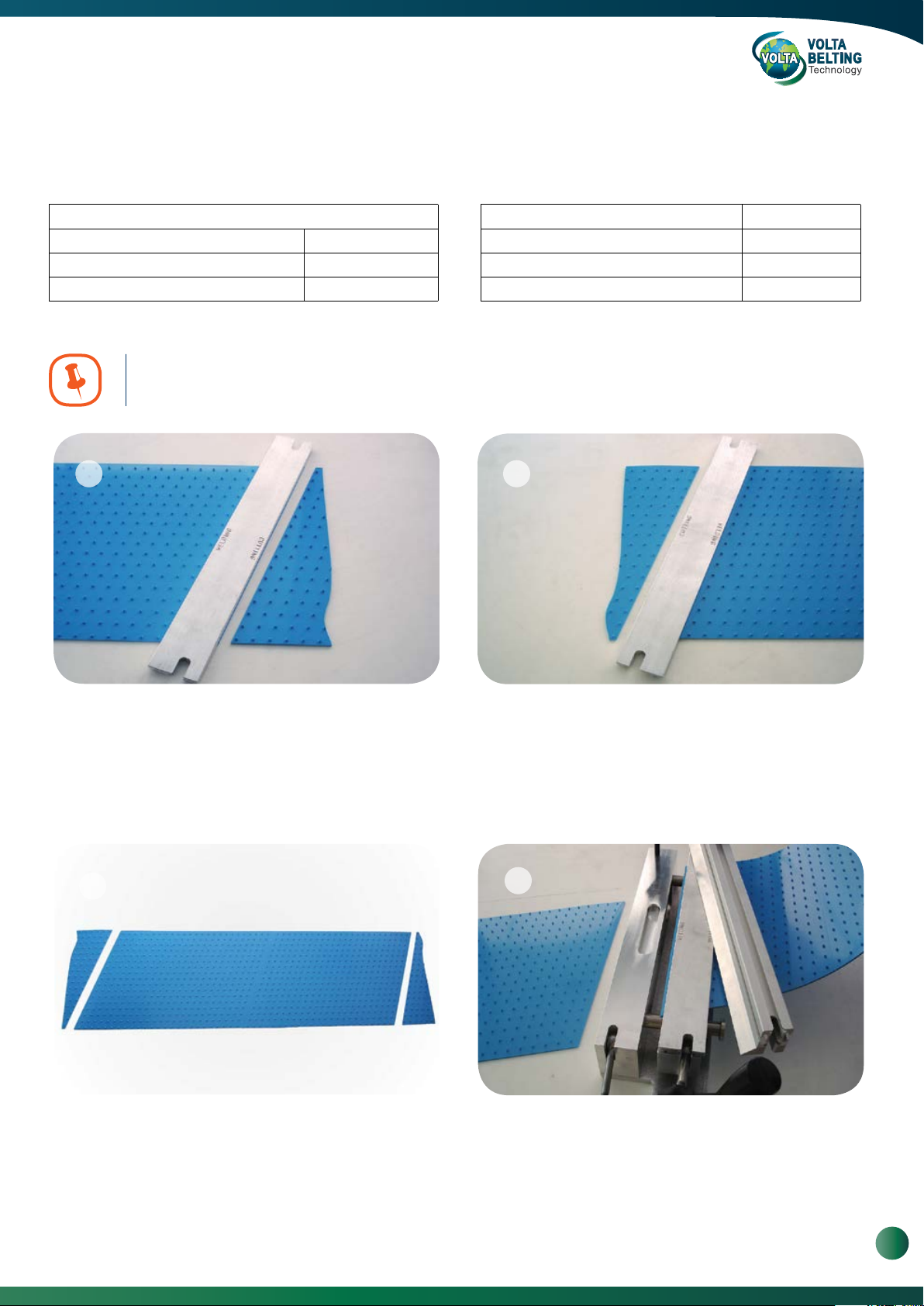

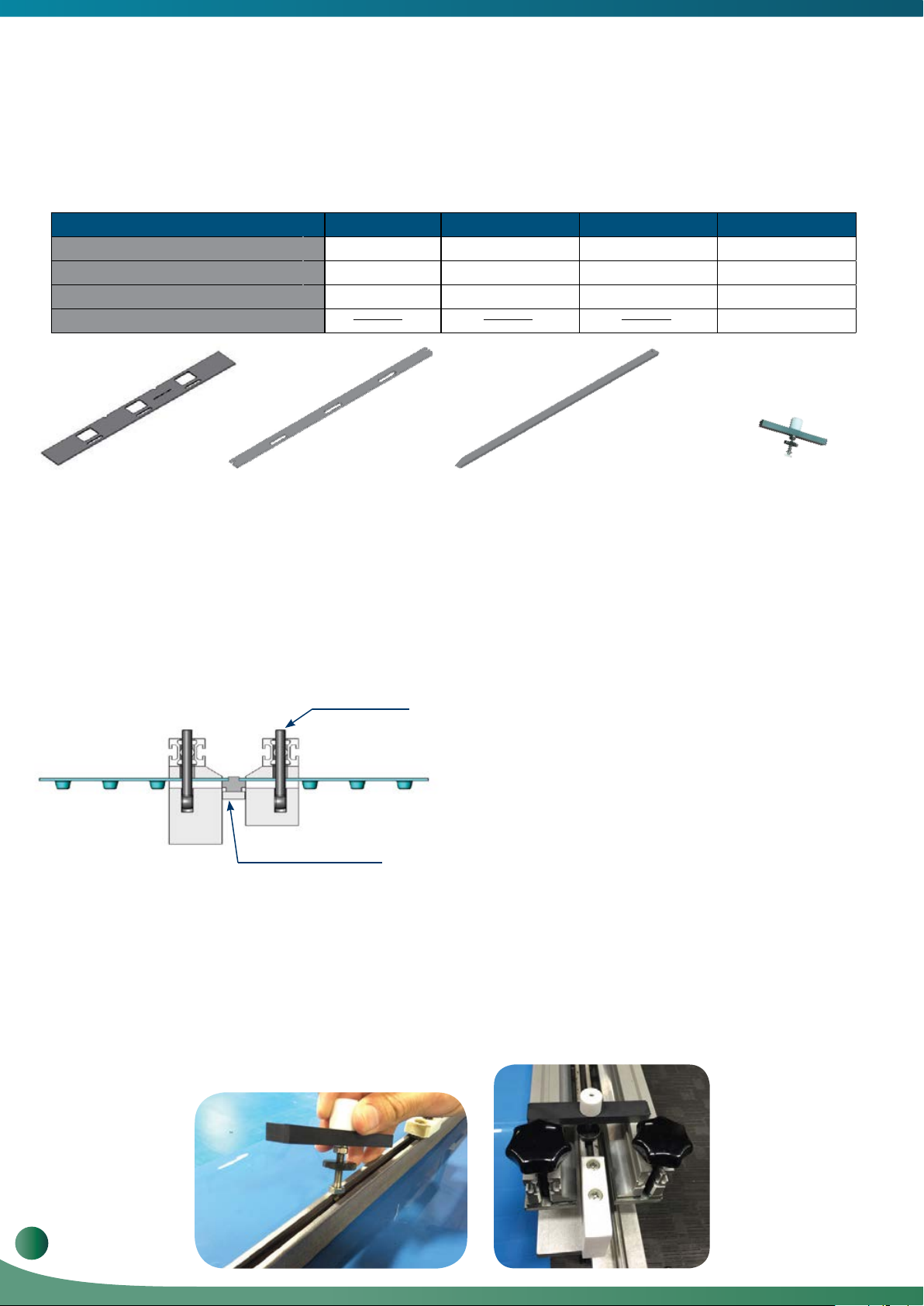

8.2. Instructions for welding SuperDrive™ Belts Using FBW Adapter

For owners of the FBW-721 FBW-1061 and FBW-1301, Volta has prepared an Adapter kit for welding SuperDrive™

21

‘H’ and ‘M’ material belts.

For FBW-301

Cutting Bar, SuperDrive™ H/M (Fig. 1)

Adapter Bar, SuperDrive™ H/M (Fig. 2)

Locator Bar Spacer, SuperDrive™ H/M (Fig. 3)

Positioner for welder (Fig. 4)

Cutting Bar -

SuperDrive™ H/M

FBW Adapter Bar -

SuperDrive™ H/M

Cat. #8162567

Cat. #81307252

Cat. #81625902

Fig. 2Fig. 1

22

For FBW-721 For FBW-1061 FBW-1301

Cat. #8 1625901 Cat. # 81625907 Cat. #81626192

Cat. #81307242 Cat. # 81310602 Cat. #81313001

Cat. # 81625903 Cat. # 81625905 Cat. #81625906

Cat.#81626342

Fig. 3

Locator Bar Spacer

- SuperDrive™ H/M

Fig. 4

Positioner for

welder

Welding Instructions:

Apply double-sided tape to the exposed surface of the

a.

Use the Cutting Bar to cut the belt between the teeth.

To ensure a 90° cut, Repeat stages a-d on page 15-16.

Position the Locator Bar Spacer and the Adapters on

b.

the Pliers Base. Raise the two hinged Locking Screws

to a vertical position and close and lock the Pliers

(see figure below).

FBW with adapters and

Locator Bar Spacer

FBW Pliers with adapters and Locator Bar Spacer in place

Locking Screws

c.

Adapters and cut away the tape from the SuperDrive™

tooth grooves.

Remove the protective paper from the double-sided tape

d.

on one side and position the belt. The difference in working

with the SuperDrive™ belt is that you must position the tooth

over the groove before bringing the rest of the belt into contact

with the tape. Press the belt onto the tape to ensure a firm

and consistent contact.

Release the Pliers and adjust the Locator Bar so that the

e.

belt edge matches one of the scribe marks and re-lock

the Pliers.

f.

Position the other belt end using the scribe mark on the

Locator Bar Spacer to align the belt.

g.

Continue the welding process as for a standard flat belt.

8.3. Positioner for Welder

Is available in the kits FBW1301 and FBW1701 PD & Mini and is used for welding all the Volta belts where an adapter

is needed .

- Prior heating the wand connect both Positioners to both end of the wand. (Pic.1)

- The adaptors of the DD, DDSP, 1" pitch positive drive belts and impression top belts elevate the belt.

21

The Positioners keep the welder leveled with the top bars. (Pic.2)

22

Volta Belting Technology Ltd.

8.4. Welding DualDriveTM with FBW and Adapter

To ensure an accurate and efficient weld of DualDriveTM belts when splicing with the FBW Welder, choose the DD

Adapter suitable to your FBW Tool from the table below. If you haven’t welded this product before, weld a section

of a trial belt before welding your Volta conveyor belt.

Required Tools:

FBW Welding Kit

DD Adapter Set for FBW - 301 Cat. #813072530

DD Adapter Set for FBW - 721 Cat. #81307245

DD Adapter Set for FBW - 1061 Cat. #81310605

You must be familiar with the instructions for welding with FBW before continuing

with this procedure.

1 2

DD Adapter Set for FBW - 1301* Cat. #81313005

DD Adapter Set for FBW - 1701*

V Trim Knife Cat. #8153105

Stoppers (2 units) Cat. #81626340

Positioner for welder**

* Non-standard

** Positioner for welder FBW - 1301 and FBW - 1701 only.

Instructions on Page 22.

Cat. #813013019

Cat. #81626342

To keep the correct pitch, place the stopper on the welder.

Loosen the screws of the Stoppers and place them in the

groove on the end sides of the Welder.

Tightly secure the screws.

Do not assemble/disassemble stoppers when welder is hot.

3

Place the adapter on the belt and push the cutting bar

against the tooth towards the cutting side. Cut the first end

of the belt along the “Cutting” side. Turn the cutting bar

180º and cut the second end of the belt.

4

For the FBW-721 and FBW-1061 apply about 10cm of

double sided tape on the center plier base, this will hold the

adaptors in place.

www.voltabelting.com

23

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

21

5

Position the Adapters onto the Pliers with the “Cutting”

sides facing outwards. Position both sides of the belt on

the Pliers. The belts’ teeth should face down and

interlock with the grooves of the adapters.

7

22

6

Position the crossbar without tightening the knobs. Close

the plier and push the two ends together, this will align the

two ends of the belt with the adaptors. Now tighten the

FBW Crossbars.

8

Position the FBW Welder in place. Apply consistent and

gentle pressure until the Stoppers do not allow you to

continue. Immediately open the Pliers. Weld the belt

according to the welding instructions in the FBW Manual.

24

Volta Belting Technology Ltd.

Trim and check the weld. A good weld will be free of

cracks and defect. Pitch tolerance should be +0 mm,

-1mm.

8.5. Welding Mini SuperDrive™ and Mini DualDrive™

To ensure an accurate and efficient weld of Mini SuperDriveTM

and Mini DualDriveTM belts when splicing with the FBW Kit,

choose the MSD/MDD Adapter suitable to your FBW Tool from

the table below.

If you haven’t welded this product before, weld a section of a trial

belt before welding your Volta conveyor belt.

Required Tools:

FBW Welding Kit

PD 1” Adapter Set for FBW - 301 Cat. #813072541

PD 1” Adapter Set for FBW - 721 Cat. #813072442

PD 1” Adapter Set for FBW - 1061 Cat. #813106042

An operator must be made familiar with the standard practice for welding with an

FBW prior to continuing with this procedure.

1

PD 1” Adapter Set for FBW - 1301* Cat. #81313017

PD 1” Adapter Set for FBW - 1701* Cat. #81313024

Positioner for welder** Cat.#81626342

V Trim Knife Narrow Cat. #8153108

Utility Knife

* Non-standard

** Positioner for welder FBW - 1301 and FBW - 1701 only.

Instructions on Page 22.

Select the PD 1” Adapter suited to your existing tool.

Place the adapter on the belt and cut each end of the belt

in turn using the adapter edge marked “Cutting”. This

ensures the correct tooth pitch. Take great care to ensure

that the cut is accurate and straight.

Position both Adapters onto the FBW belt clamp so that

2

the location lugs fit into the existing SuperDriveTM slots.

Ensure that the Adapters are aligned with each other.

Small sections of double-sided tape are essential to fix

the adapters onto the clamp bed.

www.voltabelting.com

25

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

3

Double-sided adhesive tape should be applied to the top

of the adaptors as indicated in the photo.

It is important that the whole belt width will be taped

using the double sided adhesive tape. The tape should

be trimmed to fit the pattern of the grooves.

4

Position both sides of the belt so that the teeth face down

and mesh with the adapter grooves.

5 6

Position and tighten the FBW Crossbars over both belt

edges. Weld the belt according to the FBW User Manual

Instructions.

Trim and check the weld. A good weld will be free of cracks

and defect. Pitch tolerance should be +0 mm, -1.0 mm.

26

Volta Belting Technology Ltd.

8.6. Welding Mini SuperDrive™ MiniCleat

To ensure an accurate and efficient weld of Mini SuperDrive™-MiniCleat belts when splicing with the FBW Kit, choose the

Adapter suitable to your FBW Tool from the table below. If you haven’t welded this product before, weld a section of a trial

belt before welding your Volta conveyor belt.

Required Tools:

FBW Welding kit (one of the following, according to your tool)

PD 1” Adapter Set for FBW 300/301 Cat. #813072538

PD 1” Adapter Set for FBW 720/721 Cat. #813072440

PD 1” Adapter Set for FBW 1060/1061 Cat. #813106040

You must be familiar with the instructions for welding with FBW

before continuing with this procedure.

1 2

PD 1” Adapter Set for FBW 1300/1301* Cat. #81313017

PD 1” Adapter Set for FBW 1700/1701* Cat. #81313020

MSD-MC Accessories Set Cat. #8153107MSDMC

* Non-standard

Choose the PD 1” Adapter that fits your pliers. Place the

adapter on the MSD side of the belt and cut the two ends

of the belt along the “Cutting” side. You must use this side

for cutting the belt to ensure correct pitch of the teeth.

Make sure that the cut is accurate and straight.

3 4

Place double sided tape on the top surface of the

adapters and carefully trim the tape along the MSD

grooves in the adapters with a utility knife. The double

sided tape will help achieve a better, bubble free, weld.

Position the Adapters onto the Pliers so the location block

is inserted into the SuperDrive slots on the pliers. Make

sure the Mini SuperDrive grooves in both adapters are

aligned. It is recommended to use small strips of double

sided tape to secure the adapters onto the Pliers.

Position both sides of the belt on the Pliers. The belt’s

MSD teeth should face down and interlock with the

grooves of the adapters.

www.voltabelting.com

27

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

5 6

>4mm

If the position of the MiniCleat is less than 4mm to the belt

edge, it is recommended to remove the MiniCleat from

the belt edge using the straight trim knife.

7 8

FBW inner side

Place a MDD belt (see figure 12) over the MSD-MC,

make sure the MDD tooth is close to the edge of the

FBW's inner side but does not exceed the edge. The

purpose of the MDD teeth is to apply pressure near the

welded edge to the belt to prevent the belt from moving

during the welding.

MDD "press pad" to be used as adapter

9 10

Rub a small amount of soap on the MiniCleat and on the

blade of the straight trim knife (see figure 11). Close the

FBW sides to use the second adaptor as an anvil while

carefully cutting the MiniCleat away from the belt.

4mm support strips

An alternative to using MDD as "press pad", a strip

(see figure 7) is to use a plain 4mm thik belt strip

Position and tighten the FBW Crossbars. Weld the belt

according to the FBW User Manual Instructions.

11 12

The Straight trim knife is used for cutting a Mini Cleat

away from the belt. Cat. #8153107

28

Volta Belting Technology Ltd.

Trim and check the weld. A good weld will be free of

cracks and defect. Pitch tolerance should be +0 mm,

-1.0 mm.

In order to maintain the pressure applied by means of the

FBW crossbars on the belt, we recommend using

sections of MDD belt as "press pads" with a width of

exactly 3 teeth pitch as shown in figure.

8.7.

Welding DualDrive™ SP (DDSP) Belts and DDSP Lace

To ensure an accurate and efficient weld of DualDrive

product before, weld a section of a trial belt before welding your Volta conveyor belt.

* For welding DD SP Lace follow the same instructions as seen on pages 24-25.

TM

SP belts, use FBW DualDriveTM SP Adapter Kit. If you haven’t welded this

Required Tools:

FBW Welding Kit

DDSP Adapter Set for FBW - 301 Cat. #81626317

DDSP Adapter Set for FBW - 721 Cat. #81626327

DDSP Adapter Set for FBW - 1061 Cat. #81626332

You must be familiar with the instructions for welding with FBW before

continuing with this procedure.

1

DDSP Adapter Set for FBW - 1301* Cat. #81626337

Stoppers (2 units) Cat. #81626340

Positioner for welder** Cat. #81626342

V Trim Knife Narrow Cat. #8153108

Utility Knife

* Non-standard

** Positioner for welder FBW - 1301 and FBW - 1701 only.

Instructions on Page 22.

2

To keep the correct pitch, place the stopper on the

welder. Loosen the screws of the Stoppers and place

them in the groove on the end sides of the Welder. Tightly

secure the screws.

Do not assemble/disassemble stoppers when welder is hot.

3

Heat up the Welder. Choose the DualDriveTM SP Adapter

that fits to the Pliers (see Required Tools above). Cut the

two ends of the belt along the side marked Cutting.

Ensure that the cut is accurate and straight.

4

narrow side

Apply strips of good quality Double-Sided Tape on the

Adapters on the grooved surfaces from the narrow side

inwards. Trim the unnecessary tape from the grooves.

www.voltabelting.com

29

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

5

22

Position the Adapters onto the Pliers with the narrow sides

facing inwards. Position both sides of the belt on the Pliers.

The belts’ teeth should face down and interlock with the

grooves of the adaptors, tighten the FBW Crossbars.

7

6

Position the FBW Welder in place. Apply consistent and gentle

pressure until the Stoppers do not allow you to continue.

Immediately open the Pliers. Weld the belt according to the

welding instructions in the FBW Manual.

8

Trim the excess from both sides of the belt. Apply soapy

water for easier trimming.

30

Volta Belting Technology Ltd.

Trim and check the weld. A good weld will be free of cracks

and defects. Pitch tolerance should be +0.8 mm, -0.8 mm.

8.8. Welding Volta Hinge Lace with FBW

There are occasions when it may be necessary to splice the flat belt using Volta Hinge Lace. This hinge lace is suitable for

belt thicknesses of 2.5 to 4 mm. When working with lace, it is important that you work according to the following instructions.

If you haven’t welded this product before, weld a section of a trial belt before welding your Volta conveyor belt.

You must be familiar with the welding instruction in the FBW Manual before

continuing with this procedure.

1 2

Cut the belt to the required length taking into consideration

the lace. Join the lace and cut to the belt’s width.

3

Position the lace as you did the belt. Make sure the lace

sides interlock and the flat side faces down. The lace

should be symmetrically aligned to the belt.

Position one side of the belt on the Pliers according to

the welding instructions in the FBW Manual. Remember

to use double-sided tape for this task.

4

Weld the belt to the lace according to the welding

instructions for FBW. The thicker the belt, the longer the

melt should be to match the thickness of your belt.

www.voltabelting.com

31

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

21

5

Heat a Round Chisel with the Leister Hot Air Gun and trim

the excess from the top of the belt, or apply some soapy

water for easier trimming. You may use a V-Knife or a

Lesiter Knife to trim the excess from the bottom of the belt.

7

22

6

Repeat from Step 3 to weld the other end of the belt.

8

Make sure the lace and the belt are symmetrically aligned.

9

Belt with Volta Hinge Lace.

32

Volta Belting Technology Ltd.

Trim the lace approximately 5 mm from each side. Insert

a hinge pin into the slit and check its symmetry and

adequacy.

9. General Tips

Before splicing “H” family belts, FELW 1.6, FELW-2, FRL 2 or belts with special adapters, it is strongly recommended that you

spend a few minutes practicing before welding the actual belt.

10. Troubleshooting Guide

Symptom Possible cause Suggested solution

Unstable temperature

reading

Welder overheating Thermocouple Contact a qualified technician.

Irregularity in the excess Belt not cut properly. Re-cut and re-weld.

Belt moves during

welding

Bubbles in the joint Welder Temperature is too high.

Bad or inadequate joint

on “H” material belts

Thermocouple Contact a qualified technician.

Low quality double-sided tape. Use a high-quality double-sided tape.

Inadequate or uneven pressure on the

Crossbars.

Insufficient pressure when closing the Pliers

after removing the Welder, or too slow an

action.

Pressing too hard when closing the Pliers

after welding.

Too slow an operation when closing the

Pliers after welding.

Make sure the Crossbars have been properly tightened.

Refer to Welding Instructions.

Ensure that the Temperature Controller has been

properly setup.

Perform a number of trial welds to improve closing

pressure and/ or speed.

Reduce pressure when closing the Pliers. Refer to

Page 14, Instructions for Welding “H” Material.

Repeat the procedure to increase speed Refer to

Page 14, Instructions for Welding “H” Material.

www.voltabelting.com

33

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

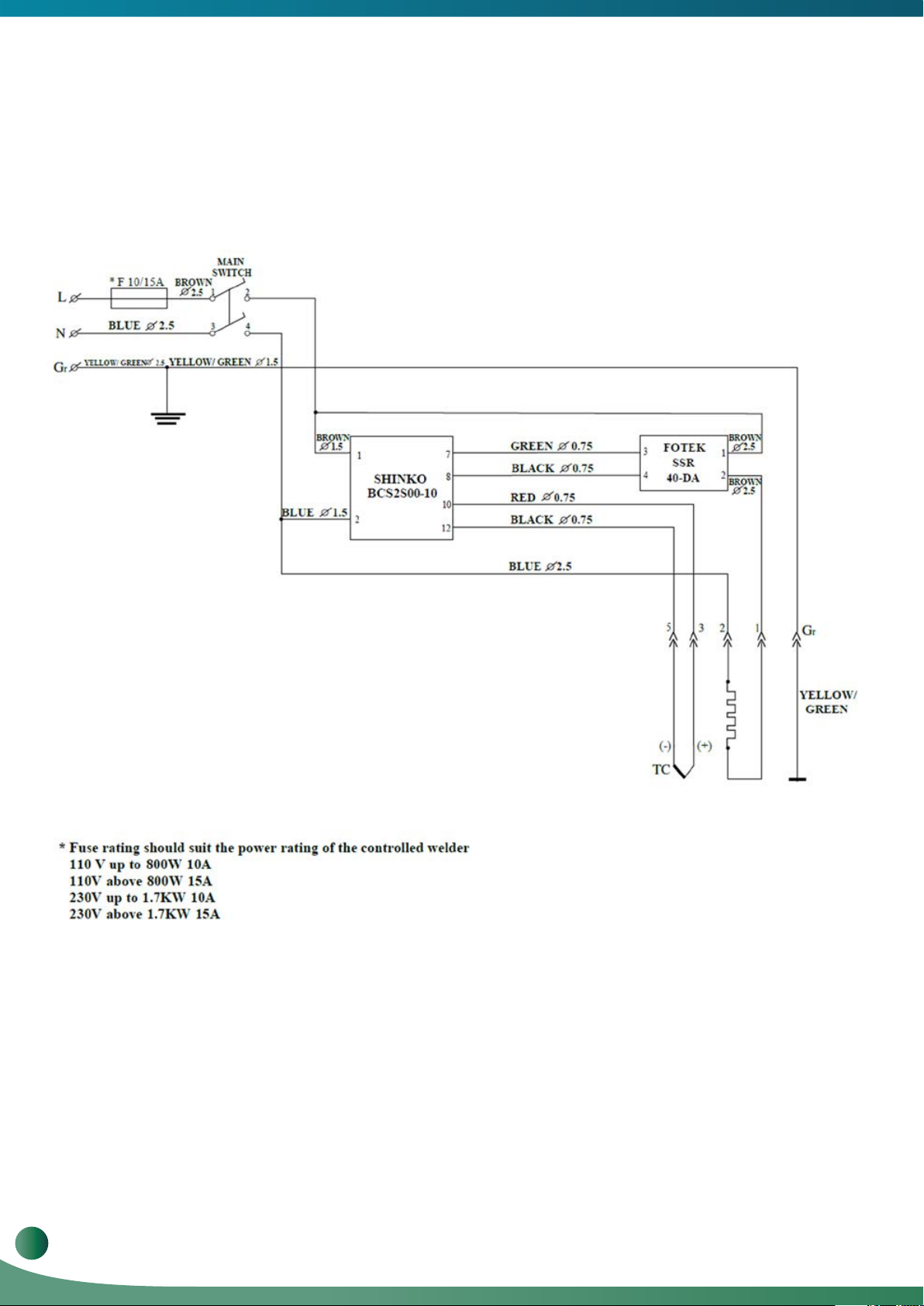

11. FBW Controller and Welder Electrical Diagram

Model SHINKO-BCS2S00-10

34

Volta Belting Technology Ltd.

FBW Welder and Temperature Controller Electrical Schematic

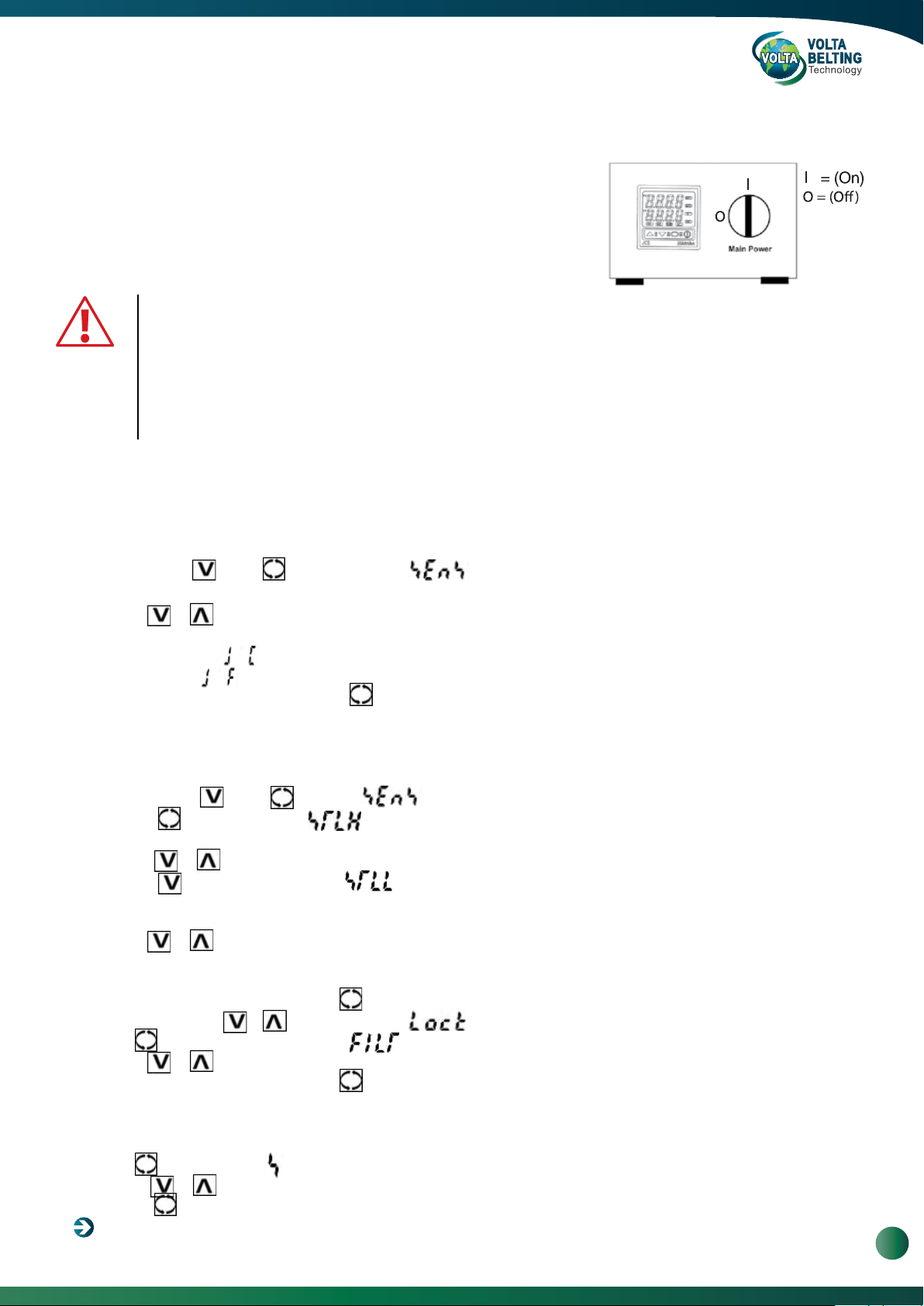

12. Calibrating the FBW/PDW Welder Control box & Welder Bar

These instructions apply to Temperature Controller Model

SHINKO-BCS2S00-10

Before calibrating the welder, make sure it is not plugged to a power source and that the

Welder Bar is at room temperature.

Connect the Welder-Bar to the controller and secure the latch on the connector.

Place the Welder Bar up-right on an even surface where it is safe for it to heat up.

DO NOT Touch the Welder Bar as it heats up. Use protective gloves and use the bar

handle to hold the Welder Bar.

1. Temperature Scale Selection

Select Fahrenheit or Celsius temperature scales.

a. Plug the control box to an appropriate outlet and Turn the Main Power switch on to ‘I’ and wait until the measured

temperature is displayed on the PV line & the SV line displays the temperature set value. This state is referred to from here

on as the "Normal Display".

b. Press and hold & then for 3 seconds until appears in the PV line.

On the SV line the selected Thermocouple Type and temperature scale are shown.

c. Use the or to scroll through the thermocouple & scale options. There are about 20 options to scroll through.

CHOOSE:

either thermocouple

or thermocouple

d. To save your selection long press on the key until the display returns to Normal display.

= Centigrade (°C) scale.

= Fahrenheit (°F) scale.

2. Temperature Limit Setting

Sets the Welder’s maximum allowable temperature.

Select the Welder limits temperature.

a. Press and holdd & then keys until appears in the PV line.

b. Press the button. The symbol will appear in the PV line.

The value on the SV line is the maximal allowable set temperature value.

c. Press on or to set the maximum allowable temperature (250°C / 482°F).

d. Press the button once. The symbol will appear in the PV line.

The value on the SV line is the minimal allowable set temperature value.

NOTE: There could be a minus (-) sign to the left of the value.

e. Use the or keys to set the minimum allowable temperatures are between

0°C / 0°F – (factory settings) to 200°C / 390°F.

Setting higher minimum may prevent error in setting the desired working temperature.

f. To save your selection press & hold on until the display changes back to Normal display.

g. Press and hold both & for 3 seconds until appears in PV line.

h. Press several times until the symbol appears in the PV line.

i. Use the or keys to set the value to (1.0).

j. To save your selection press & hold on until the display changes back to Normal display.

3. Welder Working Temperature

Set the Welder operating temperature.

a. Press until the symbol appears on the PV line.

b. Press on or to set the desired temperature (220°C / 428°F).

c. Press on key once to save and return to the Normal display.

Turn the Main Power switch off to “O”.

www.voltabelting.com

35

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

4. Temperature Correction (Off-Set)

This step provides compensation the difference between the actual temperature on Welder Bar and that measured by

the controller.

This procedure should be performed if:

• A major system component was replaced i.e. control box/controller Welder Bar/heating element.

• Change of temperature scale from °C to °F or wise-versa.

Calibrated industrial face thermometer capable of measuring temperatures in the range 150°C / 300°F to 300°C / 570°F, is

required for this step.

a. Turn the main switch on the control box on "I" and wait until the display turns to Normal.

b. Press and hold both & keys for 3 seconds until appears in the PV line and 4 non-blinking dots on the SV

line.

c. Press several times until the symbol appears on the PV line.

d. Using the or keys, set the value on SV line to 50. Make sure it is not (-50).

e. To save your selection press & hold on until the display changes back to Normal display.

f. Wait for the PV line to stabilized (even if it's not equal to the SV Line).

g. Use the thermometer and measure the temperature on the surface of the Welder Bar at a point between 200 to 250mm (8" to

10") from the cable entry side.

A large difference can be expected between this measure and the value displayed on the PV line.

Make sure you measure the temperature at about the same point every time.

h. Subtract the thermometer temp from the temperature displayed on the PV line.

Record this value (it may be negative).

If this value is less than 5°C / 9°F offset calibration is completed.

i. Press and hold both & keys for 3 seconds until appears in the PV line and 4 non-blinking dots on the SV

line and then Press

several times until the symbol appears on the PV line.

j. If this is the first iteration the value 50 appears on the SV line (as set in step c. above).

k. Subtract the recorded value from the SV value (negative values are possible).

l. Using or to change the SV value to the value you calculated in (j.) above.

m. To save your selection press & hold on until the display changes back to Normal display.

n. Allow about 10 minutes for the welder temperature to stabilize.

o. Repeat the procedure form step (g.) above.

Example:

Temperature Controller PV display shows a temperature of 428°F.

Welder temperature is measured as being 394°F.

On our first iteration the difference is 428-394 = 34.

Performing step (h.) we get the value 50.

50-34 = 16 we decrease the SV Value to 16.

And press & hold

Waiting for the temperature to stabilize it again shows 428 on the PV line.

We now measure a temperature of 408°F i.e. the difference is 20.

At Step (h.) the SV value is 16 (16-20) = -4. We decrease the SV value to (-4).

to return to normal display.

5. Auto Tuning

This step calibrates the Temperature Controller to a new Welder.

Perform the Auto-tune procedure in the following cases:

• You performed Temperature Correction (Off-Set) (section 4 above).

• The controller or the Welder Bar/heating element are replaced.

• There's a significant difference of the environment (indoor vs outdoor etc.).

a. Make sure the Welder Bar is properly connected and the latch connector is secured.

b. Make sure it is safe to let the Welder Bar to heat up.

c. Make sure the Welder Bar temperature is below 150°C / 300°F.

d. Turn the Main Power switch on “I”.

e. Press and hold & then for 3 seconds until (red) appears in the PV line and Four (4) non-blinking lights appears

on the SV line.

f. Press until the (green) appears on the SV Line.

g. Press to start the Auto Tuning cycle.

h. The display changes to Normal Display.

i. An orange "AT" is blinking on the Left side of the display.

j. Wait until the "AT" stops blinking (this process may take about 30 min.)

• Should an "Err" message appear on the display (sometimes with a code):

Turn the Power switch off "O" wait for the bar to cool and repeat from step (d.) above.

36

k. When the "AT" indication extinguishes the Welder Bar is ready for work.

13. Pitch Gauge Measuring Tool for Volta Positive Drive Belts

UPPER

LOWER

1

2

3A

WELD

PITCH IS TOO BIG

3B

WELD

PITCH IS TOO SMALL

3C

WELD

PITCH IS OK

Volta Positive drive belts need to be welded endlessly while maintaining a correct pitch tolerance between the teeth

closest to the weld. A small tool has been developed to ensure this.

The Pitch Gauge Measuring Tool is not included in the FBW Welding kit.

This tool can be purchased as a separate unit - Cat.No. - 81307570.

22

Positive Drive Pitch Gauge Tool Instructions

Replacing the belt type gauge

blocks:

Remove the four bolts using the

supplied 3mm Allen key and

reconnect upper and lower to the

desired belt type gauge block.

Calibrating the gauge:

1. Unfasten the knob and place

the gauge blocks on two adjacent

belt teeth. (Not the teeth adjacent

to the weld).

2. Push the gauge base to the

position so it sits firmly to the

outer side of the gage block. (The

gauge blocks should sit firmly on

both teeth). Tighten the knob to

lock the gauge in place.

3. Checking the weld:

Place the gauge on the two closest teeth on both sides of the weld.

The gauge should sit firmly on both teeth. If there is a small gap as seen in picture 3a the pitch is within the allowed

tolerance. In case the gauge doesn’t sits firmly on the teeth refer to pictures 3b and 3c.

www.voltabelting.com

37

With Volta Tools You Can Never Go Wrong!

•

Fast and simple belt installation.

• Unique and versatile design - compact, rugged and easy-to-use.

• Designed for both shop and field use.

• Light-weight construction.

• Usually does not require cooling water or air pressure.

• Convenient design and method of storing and carrying your tools.

• Welds and fabrications are strong, reliable and will last as long as your belt life.

Corporate Headquarters

Sales and Manufacturing

sales@voltabelting.com

Volta Belting makes no warranty with respect to any of its products for a particular purpose.

See Volta General Terms and Conditions.

USA

Tel: +1 973 276 7905

Fax: +1 973 276 7908

Toll Free: 1-877-VOLTAUS

EUROPE

Tel: +31-546-580166

Fax: +31-546-579508S

www.volta-belting.com

Copyright© Volta Belting Technology Ltd.

CAT612EN00 - Ver.A.June 2019

Loading...

Loading...