Page 1

SIGNATURE SERVER® SERVING EQUIPMENT

Hot Food Stations

Bain Marie Stations

Refrigerated Cold Stations

Non Refrigerated Cold Stations

Frost Top Stations

Entree Carts

Hot/Cold Stations

Milk Stations

Beverage Stations

Utility Stations

Cashier Stations

ENGLISH

Operator’s Manual

Thank you for purchasing this Vollrath serving equipment. Before operating the unit, read and familiarize yourself with the following operating and safety

instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

RegisteR youR pRoduct on-line at www.vollRath.com

Item No. 2350100-1 en Rev 08/14

Page 2

Safety PrecautionS

To ensure safe operation, read the following statements

and understand their meaning. This manual contains safety

precautions which are explained below. Please read carefully.

NOTE:

When moving or transporting this unit use caution to not damage the

electrical power cord.

lighting information (Some modelS)

If lighting is used, it is recommended that plastic coated type lamps or

equivalent are used to reduce the possibility of breakage.

WARNING

Warning is used to indicate the presence of a hazard that can

cause severe personal injury, death, or substantial property

damage if the warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or

can cause minor personal injury or property damage if the caution

is ignored.

NOTE

Note is used to notify people of installation, operation, or

maintenance information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others.

To reduce risk of injury or damage to the unit:

Plug only into grounded electrical outlets matching the nameplate

rated voltage.

Do not use an extension cord with this equipment. Do not plug this

equipment into a power strip or multi-outlet power cord.

Unit should only be used in a at, level position.

ENGLISH

Unplug unit and let it cool before cleaning or moving.

Do not spray controls or outside of unit with liquids or cleaning

agents.

Unplug when not in use.

Keep unit and power cord away from open ames, electric burners

or excessive heat.

Do not operate unattended.

Closely supervise units operating in public areas and/or around

children.

Do not use food pans deeper than 4” (10 cm).

Do not operate if unit has been damaged or is malfunctioning in any

way.

Do not place any objects inside the air intake or exhaust panels.

Do not place weight on controls.

Do not operate hot well without water.

function and PurPoSe

This unit is intended and designed to keep food at proper serving

temperatures. Hot food stations are not intended or designed to cook raw

food or to reheat prepared food. Cold food stations are not intended or

designed to cool or chill food. Food must be prepared and placed in food

stations at proper serving temperatures.

unit inStallation

This unit is to be used on a at, level surface. If this unit has controls and

drains they need to be accessible at all times of operation. If the unit has a

vent the vent needs to face an open area so that air can circulate.

NOTE:

Do move the unit by pushing or pulling on the breath guard.

There must be a minimum of 24” (61 cm) of space between one side

of solid surfaces and on two sides for heating units.

There must be a minimum of 24” (61 cm) of space between the vents

and any solid surfaces for units with vents.

Sufcient airow must be allowed around the unit. Blocking the

airow could cause the unit to overheat.

oPeration

drain ValVe and acceSS door - all modelS

B

A

E

D

C

Figure 1. Drain Valve and Drain Valve Access Door

A

DRAIN VALVE ACCESS DOOR. Covers the drain opening.

B

DRAIN VALVE OPENING. Access opening for the drain

valve.

C

DRAIN VALVE. Used to empty water from the well(s).

D

DRAIN VALVE CLOSED position. When the valve is in this

position the drain is closed.

E

DRAIN VALVE OPEN position. When the valve is in this

position the drain valve is open.

WARNING

2

unPacking the equiPment and initial SetuP

Carefully remove crating or packaging materials from the unit. Dispose of

all packaging, materials in an environmentally responsible manner.

Free the power cord from its secure shipping location. It is usually coiled

inside the cabinet.

OperatOr’s Manual

Burn Hazard.

Do not touch heating surfaces, liquid, or food while

unit is heating or operating.

Hot food, steam and liquids can burn skin. Allow the hot liquid,

spillage pans and trays to cool before handling. Use gloves, mitts or

pot holders if it is necessary to handle hot pans.

Page 3

A

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the unit. Liquid inside the unit could cause

an electrical shock. Do not damaged power cord.

Do not over ll wells, pans or trays. Liquid could contact the

electrical components and cause a short circuit or an electrical

shock. Unplug unit before performing service, draining or removing

spillage pans and trays. Do not spray water or cleaning products.

Do not use a power cord that has been modied or damaged.

digital hot Station controlS

(The discontinued Touch Panel Control is shown in the back of this manual.)

A

B

D

C

B

hot Station oPeration

1. Open the valve access door (A) and check that the drain valve (C) is in

2. Fill each well with about 2 quarts (1.9 lt), until water level is

3. Plug electrical power cord into a grounded outlet matching the nameplate

4. Preheat the water in the wells by covering wells with empty food

5. Remove empty food containers or covers. Place containers rated for hot

6. Place covers on food containers. Leave covers on food containers unless

7. Set the heat setting switch(es) (C) to maintain proper hot holding

TEMPERATURE CONTROL dial. Used to set or adjust the

temperature of the well. The higher the number the higher the

temperature, the lower the number the lower the temperature.

The “0” position is off.

POWER light. Illuminates when the well is in the heating mode.

the closed position (D). See Figure 1.

approximately 3/8” (.95 cm) deep. Do not overll. Always maintain water

in well.

rated voltage.

containers or covers. Turn the power switch (A) to the “ON” position and

set the heat setting switch(es) (C) to the maximum setting. See Figure 2.

Or, turn the temperature control (A) to the maximum heat setting. See

Figure 3. Preheat for 45 minutes. The water will be boiling.

food that contain hot food into the preheated wells. Do not use food pans

deeper than 4” (10 cm).

serving food.

temperature for food safety. Regularly check food temperature.

ENGLISH

Figure 2. Digital Hot Station Controls

A

ON/OFF switch. Press and hold the ON/Off switch for two (2)

seconds to turn the unit On or OFF. The wells will be set to the

previously used setting.

B

WELL SETTING DISPLAY. Illuminates with the well heat

setting.

C

HEAT SETTING SWITCHES. Used to set or adjust the

temperature of the well. Push and hold arrows for each well

until the desired setting appears on the well setting display. The

“0” position is off. The heat settings range between 0 and 9.

0 = Off --- 9 = High.

D

LOW WATER light. Illuminates when the well needs water. If

the light illuminates during operation, clean fresh water must be

added to the well.

dial control hot Station controlS

A

0

3

○

○

1

○

2

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that hot food be held at a minimum

of 140 ºF (60 ºC) to help prevent bacteria growth. Maintain correct water

level and temperature setting. Periodically remove food container and

check the water level. Add water if needed.

8. When nished using the unit. Turn the heat setting switch(es) (C) to

“0” setting, turn the power switch (A) to the “OFF” position and unplug.

See Figure 2. Or, turn the temperature control (A) to the “0” setting and

unplug. See Figure 3. When removing hot food containers from unit use

gloves, mitts or pot holders to protect hands.

9. Allow the unit and water to cool completely.

10. Open access the drain valve access door (A). See Figure 1.

11. Place a suitable container directly under the drain valve (C). Turn the

drain valve (C) to the open position (E) monitoring the ow of liquid going

into the container. Use caution to avoid spills that may create a slippery

condition. Turn drain valve (C) to the closed position (D) off before the

container is full. Dispose of the drained water. This procedure may need

to be repeated.

12. Turn drain valve (C) to the closed position (D) and close the drain valve

access door (B).

Figure 3. Manual Hot Station Controls

B

OperatOr’s Manual

3

Page 4

refrigerated WellS and froSt toP controlS and oPeration

A

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that cold food be held at a

maximum of 41 ºF (5 ºC) to help prevent bacteria growth.

6. When nished using the unit. Turn the ON/OFF switch (A) to the

“OFF” position and unplug. See Figure 4.

7. Open access the drain valve access door (A). See Figure 1.

8. Place a suitable container directly under the drain valve (C). Turn the

drain valve (C) to the open position (E) monitoring the ow of liquid

going into the container. Use caution to avoid spills that may create

a slippery condition. Turn drain valve (C) to the closed position (D)

off before the container is full. Dispose of the drained water. This

procedure may need to be repeated.

9. Turn drain valve (C) to the closed position (D) and close the drain

valve access door (B).

Figure 4. Refrigerated Well and Frost Top Control

A

ON/OFF switch. Set switch to the up position for “ON”.

Set switch to the down position for “OFF”. The switch will

illuminate when in the “ON” position.

1. Open the valve access door (A) and check that the drain valve (C) is

in the closed position (D). See Figure 1.

2. Plug electrical power cord into a grounded outlet matching the

nameplate rated voltage.

3. Turn the ON/OFF switch (A) to the “ON” position. See Figure 4. This

unit does not have an adjustable temperature setting. Allow the unit

to run for approximately 30 minutes. For the best performance when

using ice with this unit, allow unit to run for approximately 2 hours

before adding ice. This will help the ice remain solid.

4. Place containers of properly chilled food into the pre-chilled unit.

ENGLISH

5. Regularly check the food temperature.

troubleShooting

Problem It might be caused by Course of Action

Switch does not light up when in the “ON”

position.

Unit does not get to correct temperature or

to a high temperature.

cleaning

all modelS

To maintain the appearance and increase the service life, clean your

equipment daily.

1. Turn off and unplug the unit.

2. Begin cleaning after hot well units have completely cooled or cold well

units have been drained.

3. Wipe the unit exterior with a clean damp cloth.

4. Do not use abrasive materials, scratching cleansers or souring pad to

clean the unit. These can damage the nish.

5. Thoroughly wipe off any mild soap or chemical cleaners. Residue

could corrode the surface of the unit.

Unit is not plugged in. Plug unit in.

Low or incorrect voltage to unit. Verify that voltage rating in unit matches the source voltage. If not

have qualied electrical personal install proper source voltage.

No water or incorrect water level. Add water to correct level.

4

OperatOr’s Manual

Page 5

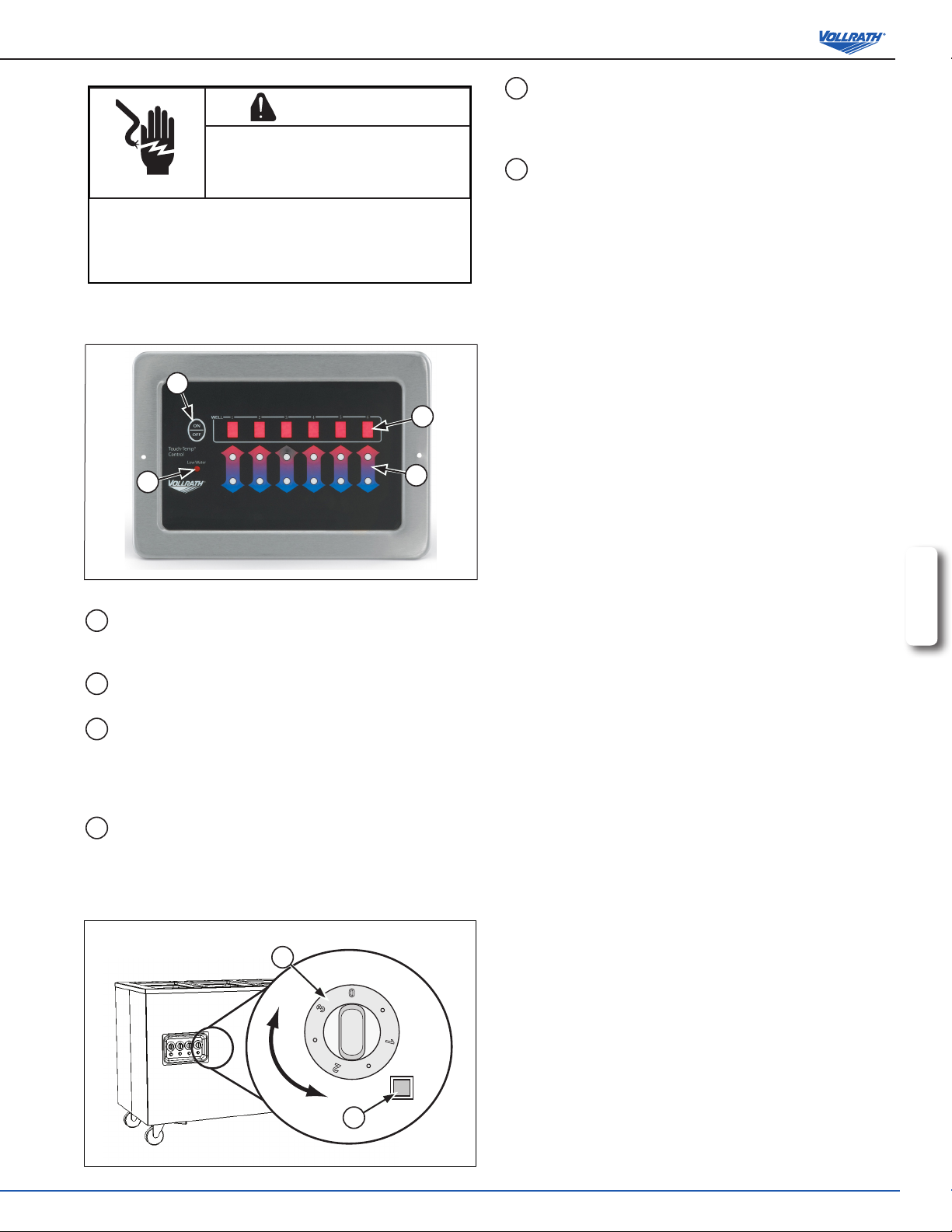

diScontinued touch Panel control featureS and function

1

11

15

13

6

12

16

14

8

9

10

2

4

5

7

3

The discontinued touch panel control features and function are described below.

Figure 5. Discontinued Touch Panel Control

1. Electronic control panel.

2. Individual well Start/Stop switch. Push and hold to turn individual well on

and set heat level. Push again to turn well off.

3. Well indicator light. Lights when well is activated.

4. Well temperature display switch. Push and hold to display heat setting

selected for each individual well.

5. Master Start/Stop switch. Push to turn off all the wells at one time. Green

light indicates that the master switch may be used to reactivate all the

wells at the previous setting.

6. Heat setting display. Red lights indicate setting selected.

7. Clock. Used for time of day setting and Start/Stop programming.

8. Hour Set.

9. Minute Set.

10. Automatic Programming Start switch. Push to activate auto Start/Stop

Program. Clock must be set and operating to use this function.

11. Auto Start set switch.

12. Auto Stop set switch.

13. Preheat switch. Sets automatic 45 minute preheat when in automatic

mode. When used outside of automatic mode, pressing the automatic

preheat switch will give a 45 minute preheat at the high setting and then

revert to the selected temperature. Press for one second to engage.

14. Automatic heat switch. Used to set well heat setting when using auto

mode.

15. Auto start time display. Push to display start time preset.

16. Auto stop time display. Push to display stop time preset.

Control Panel Operation (Refer to Touch

Panel control diagram)

Start/Set Wells:

1. Push (2) and hold until desired heat setting (6) is displayed. (3) lights to

indicate well is on.

2. Push (4) to display heat setting for well.

3. Repeat for remaining wells.

Stop/Turn off Wells:

1. Push (2) to turn off well. (3) turns off to indicate well is off

OR

2. Push (5) to turn off all wells at once. This option allows you to

reactivate all of the wells at the previous setting by pressing (5).

Preheat Function:

1. Push (13) either before or after setting individual well. The unit will

operate on HIGH for 45 minutes and then revert to the previously

selected setting. If (4) is pushed while in pre-heat mode, (6) will

display the HIGH indicator light #9 and the light for the level previously

selected.

2. Push (13) a second time to remove the unit from preheat mode.

Set Clock:

NOTE: the clock does not need to be set for normal operation.

1. Push (8) to set hour. PM is indicated by a light in the upper right hand

corner of the window.

2. Push (9) to set minute.

Set Wells for Auto Mode:

NOTE: This can only be used with the auto START/STOP program.

1. Push (14) SET/HEAT/DISPLAY switch. “A” will appear in the left half

of the display window (7).

2. Push (2) INDIVIDUAL WELL SET/HEAT/DISPLAY switch for wells

that are to be activated at the start time. Hold until desired setting is

reached.

3. Push (14) to program desired well settings.

Temperatures may be reset by repeating this procedure. Automatic

heat settings may be set while unit is operating. Once entered, heat

settings remain until changed or the power is interrupted.

ENGLISH

OperatOr’s Manual

5

Page 6

Set Preheat in Auto Mode:

1. Push (14) SET/HEAT/DISPLAY switch. “A” will appear in the left half of

display window (7).

2. Push (13) PREHEAT. “P” will appear in the right half of display (7)

3. Repeat procedures to remove from preheat mode.

Check Auto Mode Heat Settings:

1. Push (14) SET/HEAT/DISPLAY switch. . “A” will appear in the left half of

display window (7).

2. A green light (3) will come on above each well that has been preset.

3. Push (4) below each well to view programmed setting.

4. If PREHEAT has been selected, the HEAT DISPLAY SETTING (6) will light

#9 and programmed setting.

5. Push (14) and unit will return to AUTO mode

Program Auto Start Time:

Program Auto Stop Time:

NOTE: Clock function must be set to use this feature.

1. Push (12) AUTO STOP button to clear display (7). 00:00 will appear in the

display window.

2. Push (8) to set desired hour.

3. Push (9) to set minute. The display will advance in 5-minute increments.

4. Push (10) AUTO START button. The time of day will appear in the display

window. The green stop time indicator light will ash to indicate start time

has been programmed.

The MASTER START/STOP light will come on when stop time has been

reached and the wells have turned off.

Check Auto Start/Stop Time:

1. Push (15) to see start time in display.

2. Push (16) to see stop time in display

NOTE: Clock function must be set to use this feature.

1. Push (11) AUTO SET button to clear display (7). 00:00 will appear in the

display window.

2. Push (8) to set desired hour.

3. Push (9) to set minute. The display will advance in 5-minute increments.

4. Push (10) AUTO START button. The time of day will appear in the display

window. The green start time indicator light will ash to indicate start time

has been programmed. The light will turn off when start time has been

reached.

Cancel Auto Start/Stop Time:

1. Push (11) auto set button to clear display.

2. Push (12) auto stop button to clear display.

Repeat Auto Start/Stop Times:

After unit has cycled off from the AUTO MODE, push (10) to repeat times and

heat settings. Green start and stop time indicator lights will ash

SerVice and rePair

There are no user serviceable parts within this appliance. To avoid serious injury or damage, never attempt to repair the equipment or replace a damaged power cord

yourself. Do not send equipment directly to The Vollrath Company, LLC. Please contact Vollrath Technical Service from the list below.

VOLLRATH Technical Service • 1-800-628-0832 • Email: techservicereps@vollrathco.com

When contacting Vollrath Technical Service please be ready with the item number, model number (if applicable), serial number, and proof of purchase showing the

date the unit was purchased.

Warranty Statement for the Vollrath co. l.l.c.

This warranty does not apply to products purchased for personal, family or household use, and The Vollrath Company LLC does not offer a written warranty to

purchasers for such uses.

The Vollrath Company LLC warrants each of its products listed below against defects in materials and workmanship for the applicable period provided below. All

other products manufactured or distributed by The Vollrath Company LLC are warranted against defects in materials and workmanship for a period of one year. In

all cases, the warranty runs from the date of the end user’s original purchase found on the receipt. Any damages from improper use, abuse, modication or damage

resulting from improper packaging during return shipment for warranty repair will not be covered under warranty.

Refrigeration compressors – The warranty period is 5 years.

For refrigeration compressors and the second year of the warranty on Cayenne® Heat Strips and mixers, The Vollrath Company LLC will provide the part only;

and the buyer will be responsible for all labor charges incurred in performing the repair or replacement.

Replacement parts – The warranty period is 90 days.

Warranty does not cover: Glass, Breath Guard Glass

For complete warranty information, product registration and new product announcement, visit www.vollrath.com.

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201

U.S.A.

www.vollrath.com

Main Tel: 800.628.0830

Fax: 800.752.5620

Technical Services: 800.628.0832

Service Fax: 920.459.5462

Canada Service: 800.695.8560

© 2014 The Vollrath Company, L.L.C.

Item No. 2350100-1 en Rev 08/14

Loading...

Loading...