Page 1

ENGLISH

Operator’s Manual

REFRIGERATED DISPLAY CABINETS

Item Model Description Voltage Amps Hz

40842 RDE7136 36” Curved Drop-In Refrigerated Display 120V 3.4 Amps 60 1/5 5-15P

40843 RDE7148 48” Curved Drop-In Refrigerated Display 120V 4.2 Amps 60 1/4 5-15P

40844 RDE7160 60” Curved Drop-In Refrigerated Display 120V 4.4 Amps 60 1/4 5-15P

40852 RDE8136 36” Curved Countertop Refrigerated Display 120V 3.6 Amps 60 1/5 5-15P

40880 RDE8336 36” Curved Self-Serve Countertop Refrigerated Display 120V 3.6 Amps 60 1/5 5-15P

40853 RDE8148 48” Curved Countertop Refrigerated Display 120V 4.6 Amps 60 1/4 5-15P

40881 RDE8348 48” Curved Self-Serve Countertop Refrigerated Display 120V 4.6 Amps 60 1/4 5-15P

40854 RDE8160 60” Curved Countertop Refrigerated Display 120V 4.9 Amps 60 1/4 5-15P

40882 RDE8360 60” Curved Self-Serve Countertop Refrigerated Display 120V 4.9 Amps 60 1/4 5-15P

40862 RDE8236 36” Cubed Countertop Refrigerated Display 120V 3.9 Amps 60 1/5 5-15P

40886 RDE8436 36” Cubed Self-Serve Countertop Refrigerated Display 120V 3.9 Amps 60 1/5 5-15P

40863 RDE8248 48” Cubed Countertop Refrigerated Display 120V 5.0 Amps 60 1/4 5-15P

40887 RDE8448 48” Cubed Self-Serve Countertop Refrigerated Display 120V 5.0 Amps 60 1/4 5-15P

40864 RDE8260 60” Cubed Countertop Refrigerated Display 120V 6.0 Amps 60 3/8 5-15P

40889 RDE8460 60” Cubed Self-Serve Countertop Refrigerated Display 120V 6.0 Amps 60 3/8 5-15P

Power

(HP)

Plug

Thank you for purchasing this Vollrath equipment. Before operating the equipment, read and familiarize yourself with the following operating and safety instructions.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and packaging. Use this packaging to ship the equipment if repairs are needed.

Item No. 2350087-1 en Rev 07/14

Page 2

Safety precaUtionS

Unpacking the eqUipment and initial SetUp

To ensure safe operation, read the following statements and

understand their meaning. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or

maintenance information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others.

To reduce risk of injury or damage to the equipment:

Use only grounded electrical outlets matching the nameplate rated

voltage.

Have equipment installed by a qualied personnel in accordance with

local codes and ordinances.

Use equipment in a at, level position.

ENGLISH

Do not use an extension cord with this equipment. Do not plug this

equipment into a power strip or multi-outlet power cord.

Unplug equipment and turn off before cleaning or moving.

Do not spray controls or outside of equipment with liquids or cleaning

agents.

Do not clean the equipment with steel wool.

Keep equipment and power cord away from open ames, electric

burners or excessive heat.

Do not operate unattended.

Do not operate equipment in public areas and/or around children.

Do not operate if equipment has been damaged or is malfunctioning in

any way.

When no longer needed, dispose of all packaging and materials in an

environmentally responsible manner.

If the unit has been transported in a non-vertical position allow at least

one (1) hour before operating.

1. Remove all packing material and tape, as well as any protective plastic

from the equipment.

2. Remove bolts that secure the equipment to the pallet.

3. Clean any glue residue left over from the plastic or tape.

4. After the installation is complete the thin breather wires on the top of the

side glass panels may be trimmed and crimped closed.

5. Seal the base of the unit to the counter top with food grade silicone seal.

Coutertop (All Models)

NOTE:

There must be a minimum of 4” (10 cm) between the equipment

and any surrounding walls. The surrounding walls must be made

of noncombustible materials. The equipment must be installed in

accordance with local re and building regulations.

1. Place the equipment on a at stable surface.

2. Plug the equipment into a properly grounded electrical supply matching

the nameplate rating. Damage to the equipment can occur if incorrect

power is supplied to equipment.

Note:

Using a voltage other than the nameplate rated voltage will cause

damage to the unit. Incorrect voltage, modication to the power cord or

electrical components can damage unit and will void the warranty.

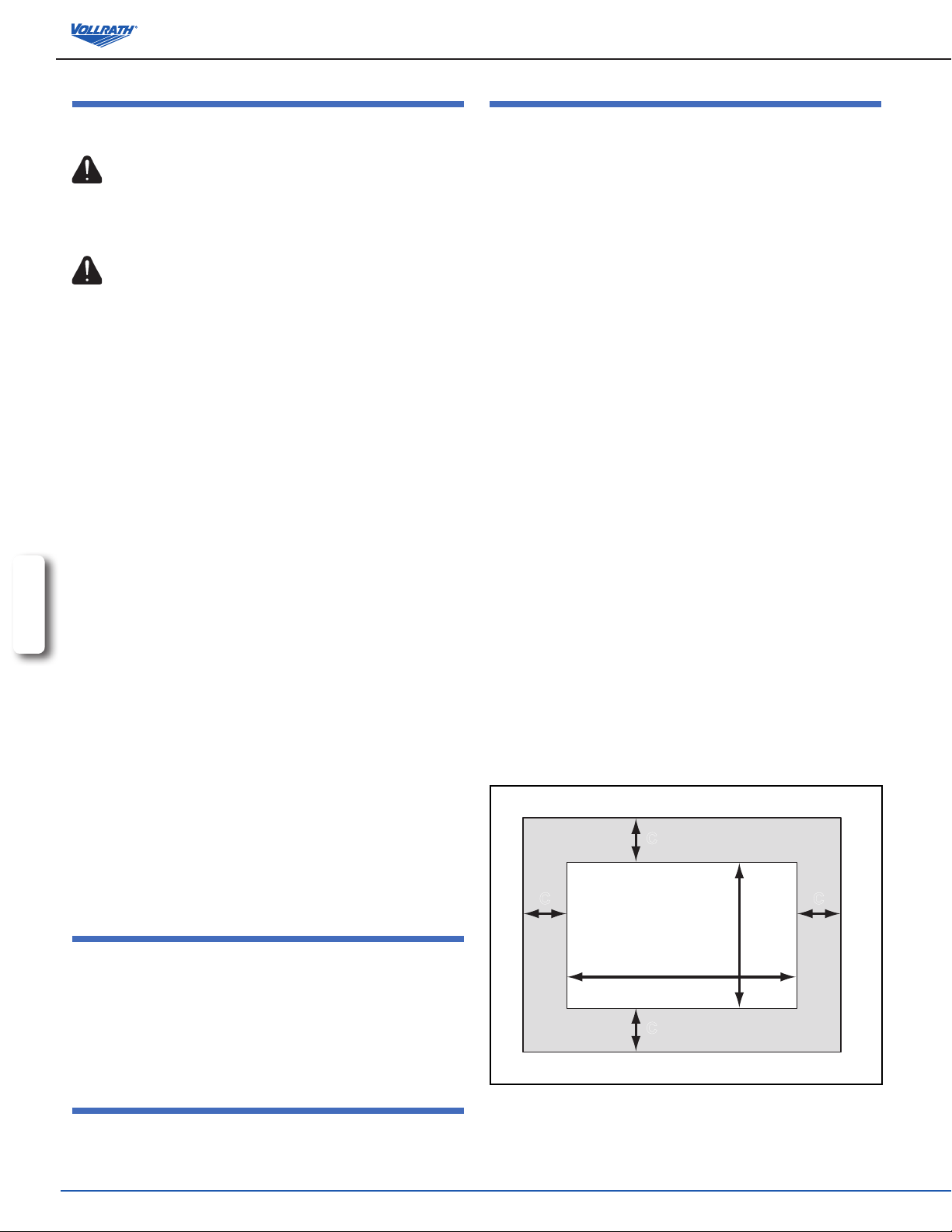

drop-In (40842, 40843 And 40844 only)

1. Choose a at, level countertop for the mounting surface.

2. Measure the area for the cutout. There must be a minimum of 4” (10 cm)

counter width around the cut out to properly support the equipment and

proper air circulation. See the illustration below.

C

2

fUnction and pUrpoSe

This equipment is designed for illuminated display of food products at

temperatures between 36°F (2°C) and 46°F (8°C). This equipment is

intended and designed to keep food at proper serving temperatures.

Food must be prepared and placed in display cabinets at proper serving

temperatures. This equipment is not intended or designed to cool or chill

food. It is not intended for household, industrial or laboratory use.

Weight Bottom Shelf capacity

The maximum weight capacity for total weight distributed evenly over the

bottom shelf, 40 lbs. (18.1 Kg) for 36” models, 48 lbs. (21.7 Kg) for 48”

models and 55 lbs. (24.9 Kg) for 60” models.

OperatOr’s Manual

Figure 1. Cutout Dimensions (40842, 40843 and 40844 only).

C C

B

A

C

Page 3

Item # A B

40842

34” (86.3 cm)

19” (48.2 cm) 4” (10 cm)

C (minimum

counter width)

operation

WARNING

40843

40844

45” (114.3 cm)

58” (147.3 cm)

19” (48.2 cm) 4” (10 cm)

19” (48.2 cm) 4” (10 cm)

featUreS and controlS

set

C

E

G

V

H

000

F

B

I

Figure 2. Refrigerated Display Cabinet Switch and Panel .

A

MAIN POWER SWITCH. Illuminated switch turns the power ON or

OFF to the equipment.

B

LIGHT SWITCH. Switches the lights ON or OFF.

C

MULTI-FUNCTION BUTTON. Depending on the mode this button turns

the power ON or OFF to the controller or increases the temperature.

D

MULTI-FUNCTION BUTTON. Depending on the mode this button

activates the defrost function or decreases the temperature.

E

SET BUTTON. Switches the temperature setting mode ON or OFF.

F

NUMBER DISPLAY. Displays the current temperature or the

temperature being programed.

G

COMPRESSOR CYCLE LIGHT. Illuminates steadily when the

compressor is running. Flashes when the compressor is in the

delay cycle, this lasts for about two minutes and is a normal part of

compressor cycling.

H

DEFROST LIGHT. Flashes when the equipment is in the defrost mode.

I

GLASS DEFROST SWITCH (some models). Switches the glass

defrost ON or OFF.

D

A

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the equipment. Liquid inside the equipment

could cause an electrical shock.

Do not spray water or cleaning products. Liquid could contact the

electrical components and cause a short circuit or an electrical

shock. Do not use equipment if power cord is damaged or has been

modied

Before using this equipment clean as described in the CLEANING section of

this document.

Before placing food product into this equipment operate to desired

temperature. Food must be prepared and placed in display cabinets at

proper serving temperatures. This equipment is not intended or designed to

cool or chill food. Regularly check the food temperature.

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that cold food be held at a

maximum of 41 ºF (5 ºC) to help prevent bacteria growth.

1. Switch the main power switch (A) to the ON position. See Figure 2.

2. Switch the light switch (B) to the ON position if desired.

To switch the controller ON or OFF:

1. To turn the controller to the OFF mode, press the multi-function

button (C) for three (3) seconds. When the number display (F) ashes

“OFF”, the controller is in the OFF mode and will not refrigerate. The unit

may be used as for ambient display.

2. To turn the controller to the ON mode, press the multi-function

button (C) for three (3) seconds. When the number display (F) is

showing temperature numbers, the controller is in the ON mode and will

refrigerate.

To set the temperature:

1. Press the set button (E) for two (2) seconds. The controller is now

switched ON. The number display (F) ashes the programmed

temperature.

2. To adjust the temperature, press the multi-function button (C) to increase

the temperature, or press the multi-function button (D) to decrease the

temperature.

3. Press the set button (E). The number display (F) is constant, showing the

current temperature.

4. The unit will now operate to the set temperatures.

Glass defrost function (some models):

1. Switch the glass defrost switch (J) to the ON position for as long as is

needed to defrost the glass. Switch the glass defrost switch (J) to the

OFF position.

Unit Defrost function:

1. Press the multi-function button (D) for three (3) seconds. The defrost

cycle will begin and the defrost light (H) will ash. The defrost cycle takes

approximately 2 hours.

2. To manually stop, press the multi-function button (D) for three (3)

seconds. The defrost cycle will end.

ENGLISH

OperatOr’s Manual

3

Page 4

cleaning

To maintain the appearance and increase the service life, clean your equipment

daily.

NOTE:

Do not use cleaning products containing aggressive

chemicals, acids, or that contain chlorine.

Do not spray water or cleaning products. Liquid could contact the

electrical components and cause a short circuit or an electrical

shock. Do not use equipment if power cord is damaged or has been

modied

NOTE:

Do not immerse the cord, plug or equipment in water

or any other liquid. Do not use a hose to clean this

equipment.

1. Unplug the equipment.

2. Use a damp cloth or sponge dipped in soapy water to clean the

equipment; rinse and dry thoroughly.

3. A high quality non-toxic glass cleaner may be used to clean the glass

components of the unit.

4. Periodical remove the rear panel and clean the coil ns with a stiff

brush.

preventative maintenance

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the equipment. Liquid inside the equipment

could cause an electrical shock.

Have condenser coils, evaporator and fans cleaned by qualied personal twice a year or as necessary

troUBleShooting

ENGLISH

troubleshootIng ChArt

Problem It might be caused by Course of Action

No power to unit.

Compressor does not run.

Compressor runs temperature inside too warm.

Faulty outlet. Have outlet replaced by qualied personal.

Circuit breaker tripped. Reset the circuit breaker.

Compressor in “delay” cycle. Wait two minutes for compressor to run.

Faulty controller.

Have unit serviced by qualied personal.Faulty compressor.

Faulty compressor starter or capacitor.

Ambient temperature too high. Ensure lower ambient temperature.

Excessive ice/frost build up on evaporator. Use manual defrost function.

Faulty controller.

Have unit serviced by qualied personal.Dirty or faulty condenser fan.

Dirty or faulty evaporator fan.

4

OperatOr’s Manual

Page 5

noteS

ENGLISH

OperatOr’s Manual

5

Page 6

Service and repair

There are no user serviceable parts within this appliance. To avoid serious injury or damage, never attempt to repair the equipment or replace a damaged power cord

yourself. Do not send equipment directly to The Vollrath Company LLC. Please contact Vollrath Technical Service from the list below.

VOLLRATH Technical Service • 1-800-628-0832

• Email: techservicereps@vollrathco.com

When contacting Vollrath Technical Service, please be ready with the item number, model number (if applicable), serial number, and proof of purchase showing the

date the unit was purchased.

Warranty Statement for the vollrath co. l.l.c.

This warranty does not apply to products purchased for personal, family or household use, and The Vollrath Company LLC does not offer a written warranty to

purchasers for such uses.

The Vollrath Company LLC warrants each of its products listed below against defects in materials and workmanship for the applicable period provided below. All

other products manufactured or distributed by The Vollrath Company LLC are warranted against defects in materials and workmanship for a period of one year. In

all cases, the warranty runs from the date of the end user’s original purchase found on the receipt. Any damages from improper use, abuse, modication or damage

resulting from improper packaging during return shipment for warranty repair will not be covered under warranty.

Refrigerated Display Cases (RDE) compressors the warranty is 3 years.

For refrigeration compressors and the second year of the warranty on Cayenne® Heat Strips and mixers, The Vollrath Company LLC will provide the part only;

and the buyer will be responsible for all labor charges incurred in performing the repair or replacement.

For complete warranty information, product registration and new product announcement, visit www.vollrath.com.

www.vollrath.com

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201

U.S.A.

Main Tel: 800.628.0830

Fax: 800.752.5620

Technical Services: 800.628.0832

Service Fax: 920.459.5462

Canada Service: 800.695.8560

© 2014 The Vollrath Company, L.L.C.

Item No. 2350087-1 en Rev 07/14

Loading...

Loading...