Vollrath Onion King 502N, Onion King 501N, Onion King 503N, Onion King 500N Installation Instructions Manual

Page 1

Onion King

WARNING

Sharp Blade Hazard

Blades are sharp and can cut skin. To avoid injury from sharp

blades, wear cut-resistant gloves when using or handling this

product.

TOOLS YOU WILL NEED

• Cut-resistant gloves • Mild dish detergent and warm water

• ³⁄₈" socket and socket wrench

• Torque wrench (optional)

WASH THE NEW BLADE ASSEMBLY

Wash new blades with warm, soapy water and rinse thoroughly to

remove the thin protective oil film.

NOTICE: Keep the sharp edge away from you when handling blades.

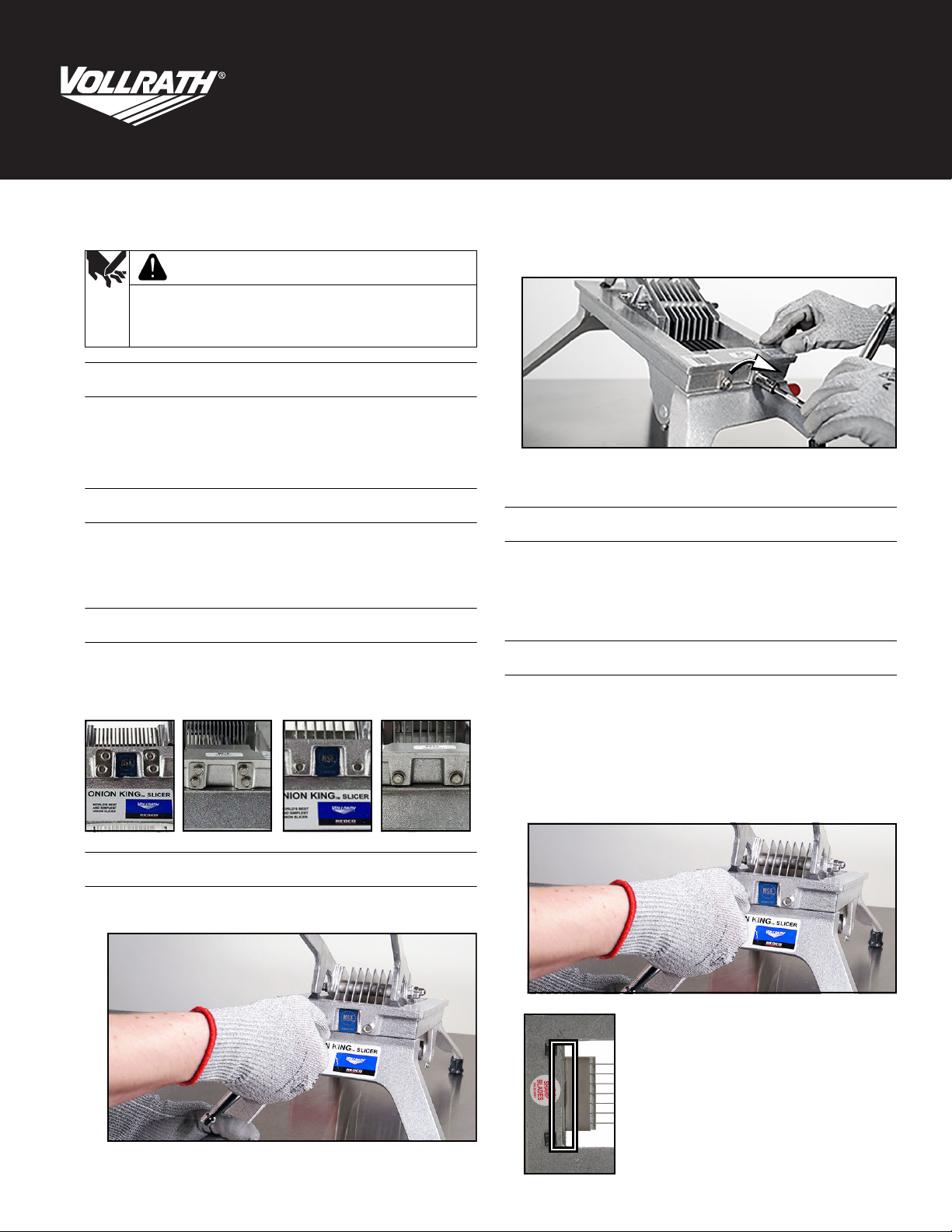

WHICH ONION KING™ SLICER DO YOU HAVE?

Installation Instructions

®

Blade Replacement

2. Remove the screws, washer plates, and o-rings from the short leg

side.

3. Remove the blade assembly by lowering it through the frame.

4. Retain the screws and o-rings for installing the new blade assembly.

INSTALL THE NEW BLADE ASSEMBLY

1. Place the new blade assembly into the base frame with the sharp

side up.

2. Reinstall all of the screws, washer plates, and o-rings to loosely

support the blade assembly in the base.

Inspect your slicer to determine which slicer you have.

500N and 501N:

4 Screws on Each End

502N and 503N:

2 Screws on Each End

REMOVE THE OLD BLADE ASSEMBLY

1. Remove the screws and washers or plates from the long leg side of

the base.

TENSION THE BLADE ASSEMBLY

NOTICE: It is important to perform the following steps in order.

Changing the sequence may damage the equipment.

NOTICE: HAND TIGHTEN ONLY. Do NOT use power tools to tighten

the screws on this equipment. Power tools may damage

the equipment.

Tension the Long Leg Side

1. Use the socket wrench to tighten the screws on the long leg side.

2. Tighten the screws until the assembly is tight against the frame.

©

2019 The Vollrath Company L.L.C. Part No. 2350115-1 ml 7/16/19

Page 2

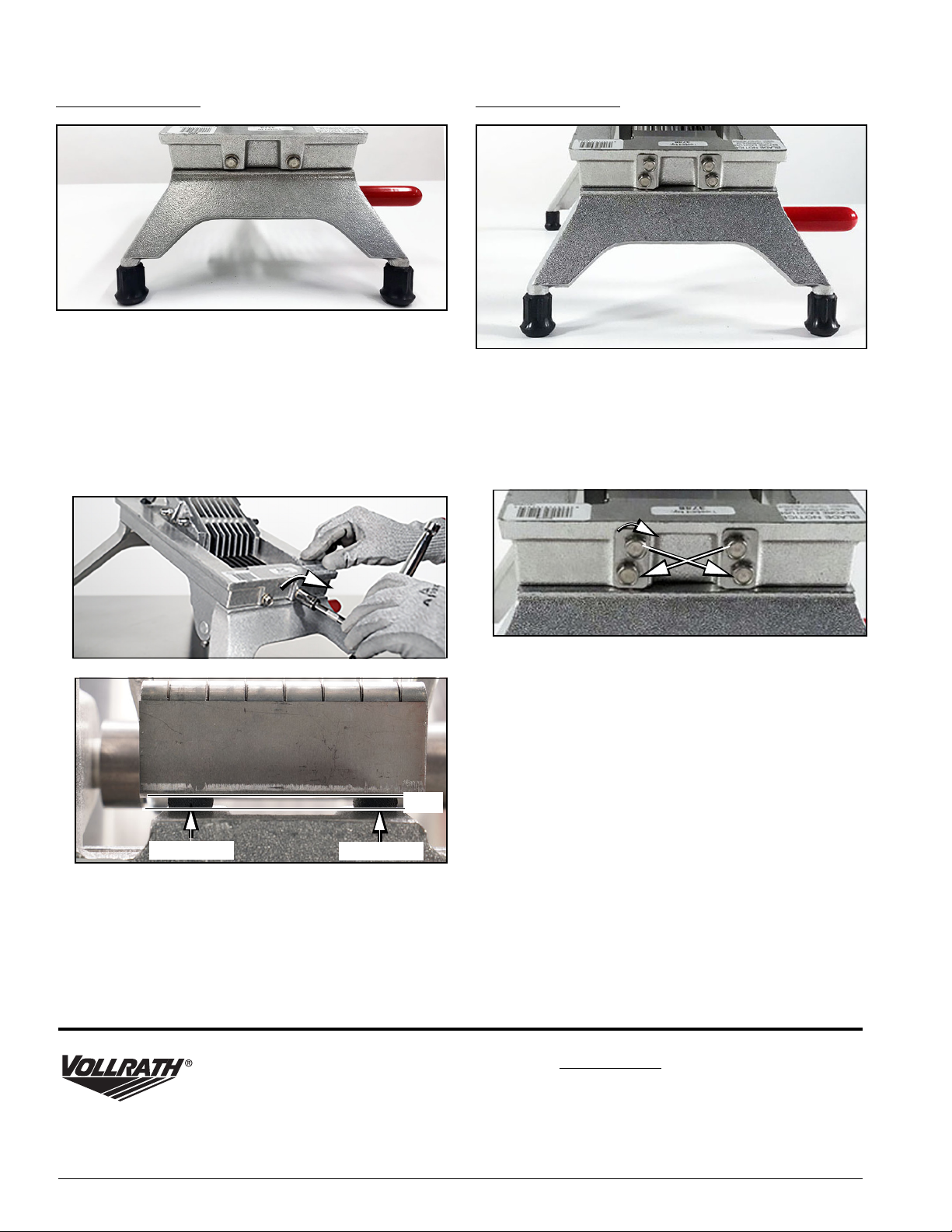

Tension the Short Leg Side

502N and 503N Slicers

These slicers have two screws on each end that hold the blade

assembly to the frame. To tension the blades, tighten the screws on the

short leg end.

NOTICE: Hand tighten only. Do NOT use power tools. Using power

tools could damage the equipment.

1. Use the socket wrench to tighten the screws as tight as possible.

Notice the corresponding o-rings located between the blade

assembly and the frame. They should be compressed to

approximately ³⁄₃₂" thick. If you have a torque wrench, use it to verify

the screws are tightened to 70 in lbs.

500N and 501N Slicers

These slicers have four screws on each end that hold the blade

assembly to the frame. To tension the blades, tighten the screws on the

short leg end.

NOTICE: Hand tighten only. Do NOT use power tools. Using power

1. Use the socket wrench to tighten the screws in a criss cross pattern.

tools could damage the equipment.

Repeat until all of the screws as tight as possible. If you have a

torque wrench, use it to verify the screws are tightened to 70 in lbs.

1

4

3

2

www.vollrath.com

Compressed

³⁄₃₂"

Compressed

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201 U.S.A.

Main Tel: 800.624.2051 or 920.457.4851

Main Fax: 800.752.5620 or 920.459.6573

Customer Service: 800.628.0830

Canada Customer Service: 800.695.8560

©

2019 The Vollrath Company L.L.C. Part No. 2350115-1 ml 7/16/19

Technical Services

techservicereps@vollrathco.com

Induction Products: 800.825.6036

Countertop Warming Products: 800.354.1970

Toasters: 800-309-2250

All Other Products: 800.628.0832

Loading...

Loading...