Vollrath MIRAGE 74702D, MIRAGE 74703D, MIRAGE 74704D, MIRAGE 74705D, MIRAGE 741102D Operator's Manual

...Page 1

ENGLISH

Operator’s Manual

MIRAGE® DROP-IN INDUCTION

RETHERMALIZERS

Item Description Voltage Watts Amps Plug

74702D

74703D

74704D

74705D

741102D

741103D

741104D

741105D

7 qt. Induction Drop-in Rethermalizer - Schuko

7 qt. Induction Drop-in Rethermalizer - UK

7 qt. Induction Drop-in Rethermalizer - China

7 qt. Induction Drop-in Rethermalizer - Australia

11 qt. Induction Drop-in Rethermalizer - Schuko

11 qt. Induction Drop-in Rethermalizer - UK

11 qt. Induction Drop-in Rethermalizer - China

11 qt. Induction Drop-in Rethermalizer - Australia

230 800 3.4 Schuko, EU1-16P, CEE7/7

230 800 3.4 UK, UK1-13P, BS1363A

230 800 3.4 China, CH1-10P

230 800 3.4 AU, AU1-10P, AS 3112

230 800 3.4 Schuko, EU1-16P, CEE7/7

230 800 3.4 UK, UK1-13P, BS1363A

230 800 3.4 China, CH1-10P

230 800 3.4 AU, AU1-10P, AS 3112

Thank you for purchasing this Vollrath Equipment. Before operating the equipment, read and familiarize yourself with the following operating

and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and packaging. Use this

packaging to ship the equipment if repairs are needed.

Item No. 2350231-1 en Rev 06/14

Page 2

Safety PrecautionS

Before using this equipment it must be cleaned and dried thoroughly. This

equipment is not intended for household, industrial or laboratory use.

To ensure safe operation, read the following statements and

understand their meaning. This manual contains safety precautions

which are explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or

maintenance information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others.

To reduce risk of injury or damage to the unit:

Plug only into grounded electrical outlets matching the nameplate rated

voltage. Each induction unit should have a separate circuit.

Do not use an extension cord with this equipment. Do not plug this

equipment into a power strip or multi-outlet power cord.

As a precaution, persons using a pacemaker should stand back 12”

ENGLISH

(30 cm) from an operating unit. Studies have shown that the induction

element will not disrupt a pacemaker.

Keep all credit cards, driver licences and other items with a magnetic

strip away from an operating unit. The unit’s magnetic eld will damage

the information on these strips.

Do not put water in the rethermalizer. It is intended to run dry. Water will

damage the unit and void the warranty.

Use only Vollrath induction-ready insets with this unit. Failure to use

Vollrath Induction-ready insets may damage unit and void the warranty.

Do not spray controls or outside of unit with liquids or cleaning agents.

Unplug when not in use.

Keep unit and power cord away from open ames, electric burners or

excessive heat.

Do not operate unattended.

Closely supervise units operating in public areas and/or around

children.

Do not operate if unit has been damaged or is malfunctioning in any

way.

unPacking the equiPment and inStallation

When no longer needed, dispose of all packaging and materials in an

environmentally responsible manner.

1. Remove all packing material and tape, as well as any protective plastic

from the equipment.

2. Clean any glue residue left over from the plastic or tape.

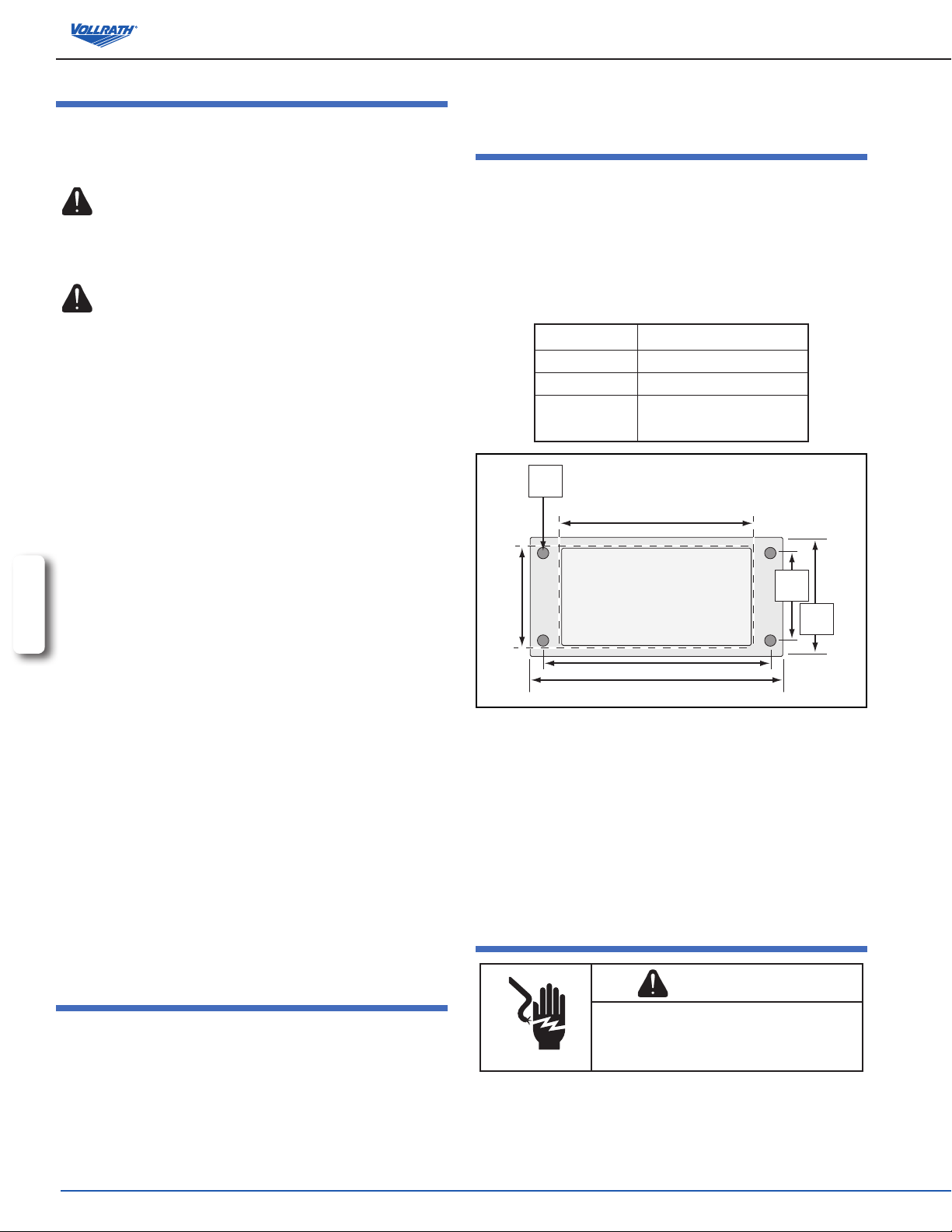

Have the unit installed only by qualied service personnel. The cutout

opening in counter must be in accordance with the chart below. All openings

must be within 1/8” of the stated dimension.

Model/Size Cut-out Opening

7 Quart 10-5/8” (27.0 cm) Diameter

11 Quart 12-5/8” (32.1 cm) Diameter

Control Box 2-5/8” (6.6 cm) x 5” (12.7 cm)

(stud locations shown below)

13/64”

(0.51)

5” (12.7)

2-5/8”

(6.6)

5-13/16” (14.8)

6-7/16” (16.4)

2-3/16”

(5.6)

3-1/16”

(7.8)

Figure 1. Control Panel Cutout

NOTE

All cutout openings must be within 1/8” of listed opening sizes.

3. Plug the power cord into a grounded electrical outlet with the matching

nameplate rated voltage.

NOTE:

Using a voltage other than the nameplate rated voltage will cause

damage to the unit. Incorrect voltage, modication to the power

cord or electrical components can damage unit and will void the

warranty.

oPeration

function and PurPoSe

The 800W models are intended and designed to rethermalize containers of

refrigerated, previously cooked food and hold containers of hot food at safe

serving temperatures. All Models are intended and designed to keep food

product at proper serving temperatures. For hot food holding food must be

prepared and placed in at proper serving tempratures. These units are not

designed to cook raw food.

Use only Vollrath induction-ready insets (item 88184 or 88204). Failure to

use Vollrath Induction-ready insets may damage unit and void the warranty.

This equipment is not intended or designed to cook raw food product.

2

OperatOr’s Manual

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the unit. Liquid inside the unit could cause

an electrical shock.

NOTE:

Pre-heat empty insets for 5 minutes or less when necessary.

Because of the speed and efciency of the induction range, insets

can very quickly overheat and be damaged.

Page 3

WARNING

Burn Hazard.

Do not touch cookware, heating surface, food, or

liquid while heating.

Hot food and liquids can burn skin. Induction heating surfaces heat

very rapidly. Use caution when adding pre-heated oil, liquid or other

food already in the cookware.

NOTE:

Do not put water in the rethermalizer. It is intended to run dry. Water

will damage the unit and void the warranty.

NOTE:

Removal of induction-ready inset will cause the display to blink.

Reinserting the induction-ready inset will cause the display to

remain constant.

E

A

B

Figure 1. Control Panel

A

ON/OFF button. Press to turn unit on. The display will illuminate

B

FUNCTION button. Used to change the function or mode of

C

ARROW DOWN button. Used to lower the temperature setting.

D

ARROW UP button. Used to raise the temperature setting.

E

DISPLAY panel. This displays the preset program, temperature,

F

WARMING light. Illuminates when unit is operating in the

G

STIR light. Flashes when the food product should be stirred.

H

LOCK light. Illuminates when the lock function is in operation.

on

o

function

warming

H

when switched on.

operation.

or an error code, depending upon the mode selected.

warming mode. Blinks while the food product heats to

temperature.

F

000

000

°F

°C

D

C

G

5. Press the arrow up (D) or arrow down (C) to select the temperature value

program above 155 ºF (68 ºC). The warming light (F) blinks until the food

product heats to temperature.

6. During the hot food holding process, monitor the food temperature

closely for food safety.

Food Safety Precautionary Note:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that hot food be held at a minimum

of 140 ºF (60 ºC) to help prevent bacteria growth.

Manually setting the warming temperature

1. Press the ON/OFF button (A) to turn on the unit. See Figure 1.

2. Press the function button (B) to choose ºF to ºC temperature on the

display (E).

3. Press the arrow up (D) or arrow down (C) to select the temperature value

program. The warming light (F) blinks until the food product heats to

temperature.

4. While in the warming mode press the arrow up (D) or arrow down (C)

to select temperature you desire. The warming cycle will reach and

maintain that temperature until the temperature is reset again.

Changing the temperature from ºF to ºC or ºC to ºF

1. Press the ON/OFF button (A) to turn on the unit. See Figure 1.

2. Press the function button (B) to change from ºF to ºC.

Locking and Unlocking the unit

1. Press the ON/OFF button (A) to turn on the unit. See Figure 1.

2. Select the preset program or warming temperature desired.

3. To lock the unit: At the same time press and hold the function button

(B) and the arrow down button (C) until the lock light (H) appears. The

control can not be changed until the unit is unlocked.

4. To unlock the unit: At the same time press and hold the function

button (B) and the arrow down button (C) until the lock light (H)

disappears. Tuning the unit off does not disable the lock feature.

ENGLISH

cleaning

To maintain the appearance and increase the service life, clean your

induction range daily.

WARNING

Burn Hazard.

Do not touch cookware, heating surface, food, or

liquid while heating.

Hot food and liquids can burn skin. Induction heating surfaces heat

very rapidly. Allow the heating surface to cool before handling.

Hot Food Holding

1. Press the ON/OFF button (A) to turn on the unit. See Figure 1.

2. Press the function button (B) to choose ºF to ºC temperature on the

display (E).

3. Allow the unit to heat for 5 minutes.

4. Place a container of pre-heated food product above 155 ºF (68 ºC) to be

held into equipment.

OperatOr’s Manual

3

Page 4

1. Unplug the unit and let it completely cool.

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the unit. Liquid inside the unit could cause

an electrical shock.

Do not spray water or cleaning products. Liquid could contact the

electrical components and cause a short circuit or an electrical

shock.

2. Wipe the unit exterior with a clean damp cloth.

NOTE:

Do not put water in the rethermalizer. It is intended to run dry. Water

will damage the unit and void the warranty.

3. Wipe the inside of the unit with a clean damp cloth.

4. Do not use abrasive materials, scratching cleansers or souring pad to

clean the unit. These can damage the nish.

5. Thoroughly wipe off any mild soap or chemical cleaners. Residue could

corrode the surface of the unit.

troubleShooting

Problem It might be caused by Course of Action

The unit is on, but not heating. The inset may be too small or may not be induction-

ready.

The digital display lights are ashing.

Alarm buzzer is sounding.

The unit suddenly stopped working.

No induction-ready inset in unit. Place induction-ready inset in the unit.

The unit may be too close to an external heat source

or the air intake may be restricted.

The overheat-protection feature may have activated. Remove inset. Let cooking surface cool.

Make sure the inset is induction ready. See the

FUNCTION and PURPOSE of this manual.

Relocate the unit away from any external heat

source. Clear any obstructions to the air intake.

Flashing Message (F code) It might be caused by Course of Action

Add Pan (Add Pan)

ENGLISH

Bad Pan (Bad Pan - F9)

TOO HOT (Too Hot - F2)

BAD FLO (Bad Flow - F8)

HT SNC (Heat Sync - F4)

No inset has been detected on the induction

rethermalizer

The inset may be too small or is not a Vollrath

induction-ready inset.

The overheat-protection feature may have activated.

The unit may be too close to an external heat source

or the air intake may be restricted.

The overheat-protection feature may have activated.

Place induction-ready inset in the heating area..

Turn the unit “OFF” and “ON”. Use a Vollrath

induction-ready inset. See the FUNCTION and

PURPOSE of this manual.

Remove inset. Let cooking surface cool. Clear any

obstructions to the air intake.

Relocate the unit away from any external heat

source. Clear any obstructions to the air intake.

Remove inset. Let cooking surface cool. Clear any

obstructions to the air intake.

4

HT TH (Heat Therm - F5)

HOT

OperatOr’s Manual

The overheat-protection feature may have activated.

No defect. This is part of normal operation.

Remove inset. Let cooking surface cool. Clear any

obstructions to the air intake.

Indicates the heating area is hot after a heating cycle

has completed. Allow time for the heating area to

cool (about 5-10 minutes) before cleaning.

Page 5

Service and rePair

There are no user serviceable parts within this appliance. To avoid serious injury or damage, never attempt to repair the induction range or replace a damaged power

cord yourself. Do not send units directly to the Vollrath Company. Please contact the qualied professional repair service listed below.

Vollrath Technical Service • 1-920-457-4851

• Email: techservicereps@vollrathco.com

When contacting the Authorized Professional Service Center, please be ready with the item number, model number (if applicable), serial number, and proof of

purchase showing the date the unit was purchased.

Warranty Statement for the vollrath co. l.l.c.

This warranty does not apply to products purchased for personal, family or household use, and The Vollrath Company LLC does not offer a written warranty to

purchasers for such uses.

The Vollrath Company LLC warrants each of its products listed below against defects in materials and workmanship for the applicable period provided below. All

other products manufactured or distributed by The Vollrath Company LLC are warranted against defects in materials and workmanship for a period of one year. In

all cases, the warranty runs from the date of the end user’s original purchase found on the receipt. Any damages from improper use, abuse, modication or damage

resulting from improper packaging during return shipment for warranty repair will not be covered under warranty.

Induction Warmers and Rethermalizers – The warranty period is (1) year.

For complete warranty information, product registration and new product announcement, visit www.vollrath.com.

www.vollrath.com

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, Wisconsin

53081-3201 USA

Main Tel: 920-457-4851

Main Fax: 800-752-5620 or

920-459-6573

US Service Tel: 800-628-0832

Canada Service Tel: 800-695-8560

Service Fax: 920-459-5462

Vollrath Europe BV

Beneluxbaan 7

5121 AD RIJEN

The Netherlands

+31161870005

Vollrath of China

Vollrath Shanhai Trading Limited

29D, 855 South Pu Dong Road

Shanghai, China 200120

Tel: 86-21-50589580

Vollrath de Mexico S. de R.L. de C.V.

Periferico Sur Edicio 2-C

Col. Santa Maria Tequepexpan

45601 Tlaquepaque, Jalisco Mexico

Tel: (52) 333-133-6767

Tel: (52) 333-133-6769

Fax: (52) 333-133-6768

Item No. 2350231-1 en Rev 6/14

Loading...

Loading...