Page 1

E111/F111 IntelliTec Models

OPERATORS MANUAL

Manual No. 513532-5 Rev.1

Page 2

Page 3

Service Manual

For E/F111I

Stoelting Counter Model Gravity

Soft Serve Machine

This manual provides basic information about the freezer. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the freezer without notice, and without incurring any obligation to modify or provide

new parts for freezers built prior to date of change.

DO NOT ATTEMPT to operate the freezer until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the freezer, contact the company

at the following location:

STOELTING Ph: 800-558-5807

502 Hwy. 67

Kiel, WI 53042 Fax: 920-894-7029

© 2013 Stoelting, LLC, All Rights Reserved

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting equipment. There are hazards associated with

the operation of this machine. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution. Attention is required in order to avoid serious personal

injury. The message that follows the symbol contains

important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTICE

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety or personnel or equipment/property.

Page 5

TABLE OF

CONTENTS

Section Description Page

1 Introduction

1.1 Description ..................................................................................................1

1.2 Specifi cations .............................................................................................1

2 Installation Instructions

2.1 Safety Precautions .....................................................................................3

2.2 Shipment and Transit ..................................................................................3

2.3 Machine Installation ....................................................................................3

3 Initial Set-Up and Operation

3.1 Operator’s Safety Precautions ...................................................................5

3.2 Operating Controls and Indicators ..............................................................5

3.3 Important Information Regarding Cleaning and Sanitizing .........................7

3.4 Disassembly of Machine Parts ...................................................................8

3.5 Cleaning Disassembled Parts ....................................................................9

3.6 Sanitizing Machine Parts ............................................................................9

3.7 Cleaning the Machine .................................................................................9

3.8 Assembling Machine ..................................................................................10

3.9 Sanitizing ....................................................................................................11

3.10 Initial Freeze Down and Operation .............................................................11

3.11 Normal Freeze Down and Operation ..........................................................12

3.12 Mix Information ...........................................................................................13

4 Maintenance and Adjustments

4.1 Machine Adjustment ...................................................................................15

4.2 Product Consistency Adjustment ................................................................15

4.3 Locking the Control Panel ..........................................................................15

4.4 Obtaining Readings and Modifying Settings (Service Personnel Only) ......15

4.5 Readings (Service Personnel Only) ...........................................................17

4.6 Adjustments (Service Personnel Only) .......................................................18

4.7 Other Settings (Service Personnel Only) ....................................................18

4.8 Drive Belt Tension Adjustment ....................................................................19

4.9 Condenser Cleaning ...................................................................................20

4.10 Preventative Maintenance ..........................................................................20

4.11 Extended Storage .......................................................................................20

5 Troubleshooting

5.1 Error Codes ................................................................................................21

5.2 Troubleshooting ..........................................................................................21

5.3 Troubleshooting - Machine .........................................................................23

6 Replacement Parts

6.1 Decals and Lubrication ...............................................................................25

6.2 Auger Shaft and Faceplate Parts ...............................................................26

6.3 Hopper Covers and Trays ...........................................................................27

Page 6

Page 7

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

The Stoelting E1 11 and F1 1 1I counter machines are gravity fed. The machines are equipped with fully automatic

controls to provide a uniform product. They are designed

to operate with almost any type of commercial soft serve

or non-dairy mixes available, including: ice milk, ice cream,

yogurt, and frozen dietary desserts.

This manual is designed to assist qualifi ed service person-

nel and operators in the installation, operation and maintenance of the Stoelting E1 11 and F1 1 1 gravity machines.

Figure 1-1 E111 / F111 Machine

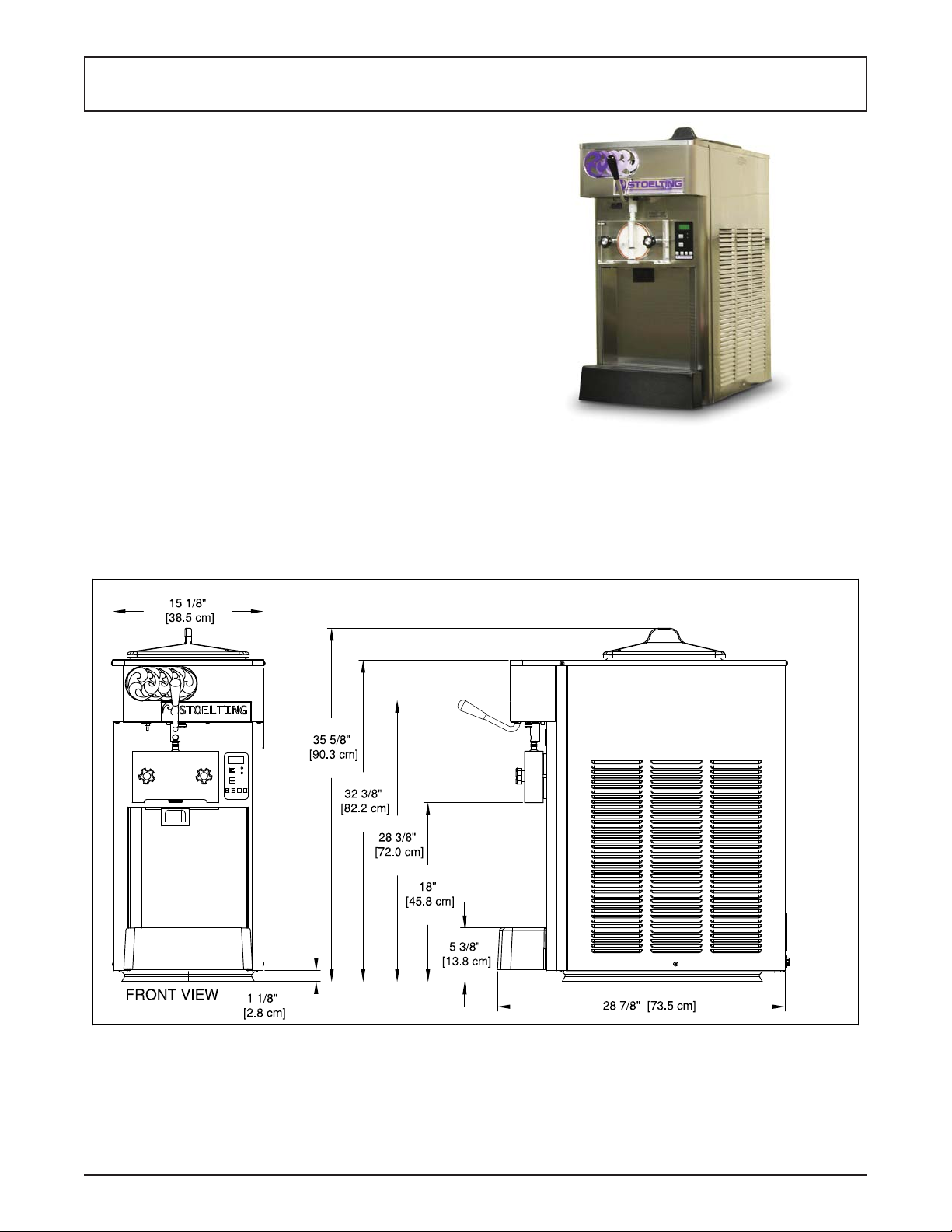

1.2 SPECIFICATIONS

Figure 1-2 Specifi cation

Owner’s Manual #513532-5 Rev.1 1 E111I/F111I Model Machines

Page 8

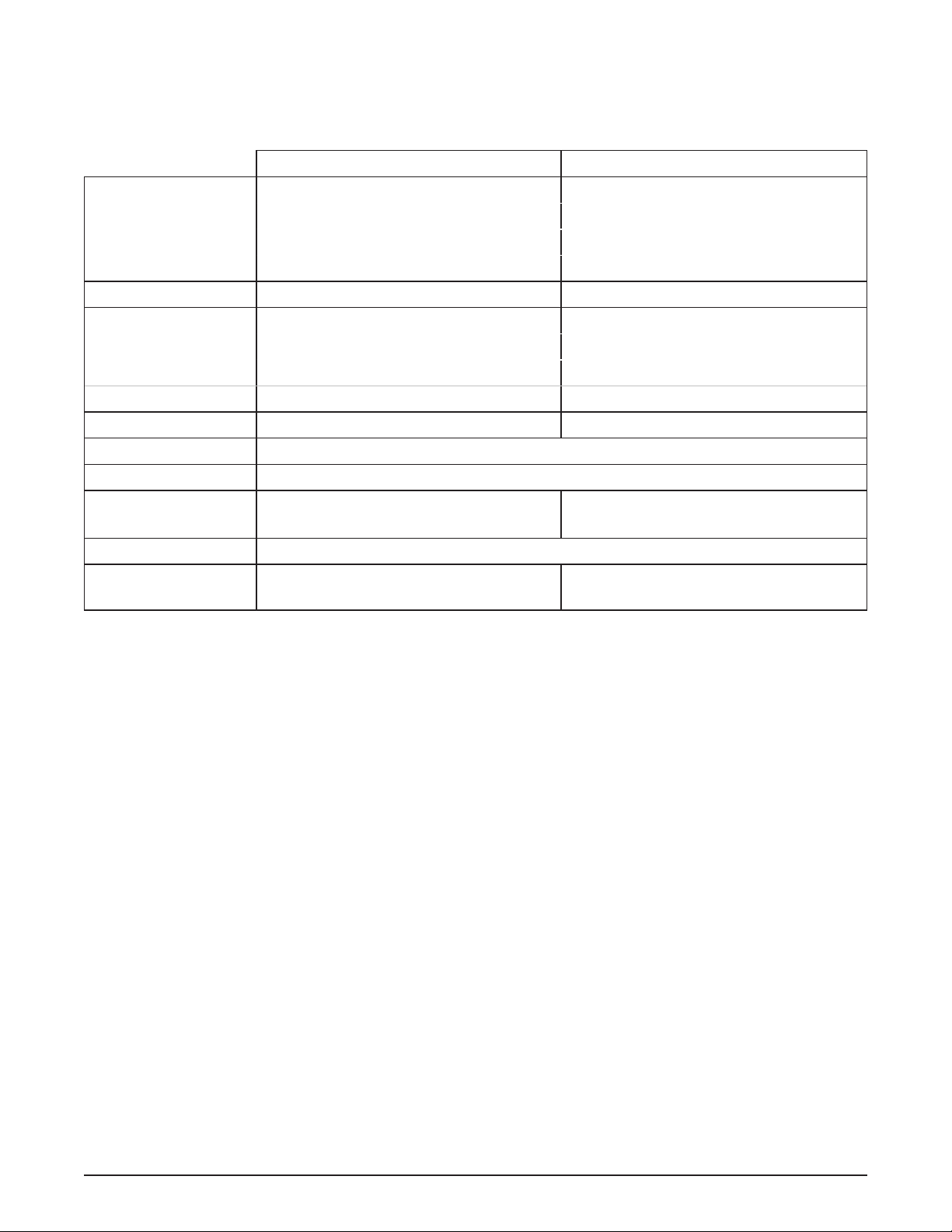

1.2 SPECIFICATIONS (CONTINUED)

Model E111I Model F111I

Dimensions Machine with crate Machine with crate

width 15-1/8’’ (38,4 cm) 19-1/2’’ (49,5 cm) 15-1/8’’ (38,4 cm) 19-1/2’’ (49,5 cm)

height 35-5/8’’ (90,5 cm) 43’’ (109,2 cm) 35-5/8’’ (90,5 cm) 43’’ (109,2 cm)

depth 28-7/8’’ (73,3 cm) 33-1/2’’ (85,1 cm) 28-7/8’’ (73,3 cm) 33-1/2’’ (85,1 cm)

Weight 220 lbs (99,7 kg) 265 lbs (120,2 kg) 230 lbs (104,3 kg) 275 lbs (124,7 kg)

Electrical 1 Phase, 115 VAC, 60Hz 1 Phase, 208-240 VAC, 60Hz

running amps 14A 8A

connection type NEMA5-20P power cord provided NEMA6-15P power cord provided

International Option 1 Phase, 220-240 VAC, 50Hz 1 Phase, 220-240 VAC, 50Hz

Compressor 3,550 Btu/hr 5,450 Btu/hr

Drive Motor 3/4 hp

Air Flow Air cooled units require 3” (7,6 cm) air space on both sides

Plumbing Fittings N/A

Hopper Volume 3 gallon (11,35 liters)

Freezing Cylinder

Volume

0.65 gallon (2,46 liters) 0.85 gallon (3,22 liters)

Water cooled units require 3/8” N.P.T.

water and drain fi ttings.

Owner’s Manual #513532-5 Rev.1 2 E111I/F111I Model Machines

Page 9

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the machine until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the machine. The labels have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the machine. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and quantity

required along with your address and mail to:

STOELTING

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

2.2 SHIPMENT AND TRANSIT

The machine has been assembled, operated and inspected

at the factory. Upon arrival at the fi nal destination, the

entire machine must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the machine should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill

until the machine has been checked for damage. Have

the carrier note any visible damage on the freight bill. If

concealed damage and/or shortage is found later, advise

the carrier within 10 days and request inspection. The

customer must place claim for damages and/or shortages

in shipment with the carrier. Stoelting, Inc. cannot make

any claims against the carrier.

2.3 MACHINE INSTALLATION

WARNING

Installation must be completed by a qualifi ed

electrician/refrigeration specialist.

Incorrect installation may cause personal injury,

severe damage to the machine and will void factory warranty.

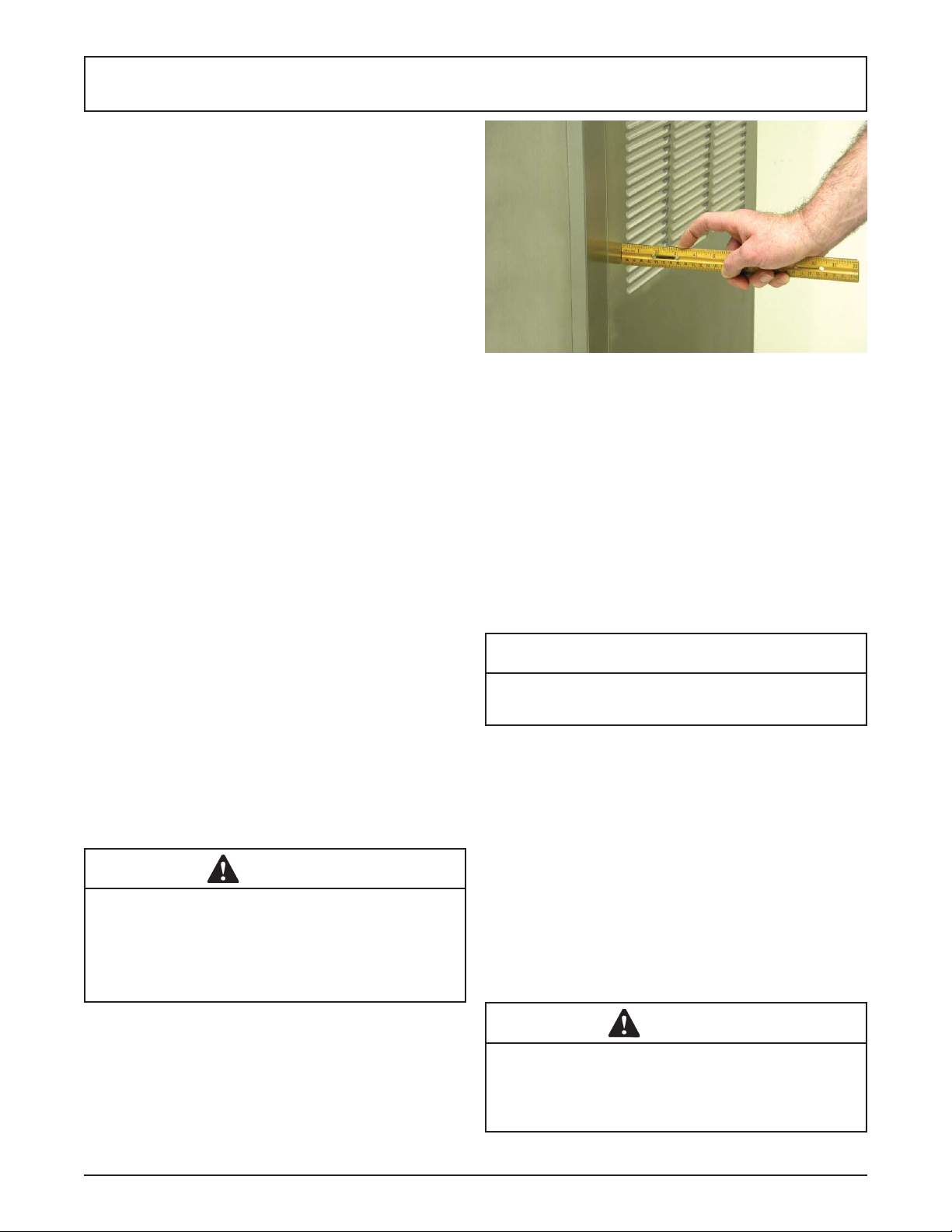

Figure 2-1 Space and Ventilation Requirements

Place a bubble level on top of the machine at each

corner to check for level condition. If adjustment

is necessary, level the machine by turning the

bottom part of each leg in or out.

C. The machine has a base gasket that must be

installed. Separate the gasket and install it with

the seam to the back. Make sure the angled side

of the gasket is facing up.

D. Correct ventilation is required. The right side of

the machine is the air intake and left side is the

discharge. Both sides must have 3” clearance.

CAUTION

Failure to provide adequate ventilation will void

warranty.

E. Place the Main Freezer Power Off/On switch in

the OFF position.

F. Connect the power cord to the proper power

supply. The E111 has a NEMA5-20P and the

F1 11 has a NEMA6-15P . Check the nameplate on

your machine for proper supply . The unit must be

connected to a properly grounded receptacle. The

electrical cord furnished as part of the machine

has a three prong grounding type plug. The

use of an extension cord is not recommended,

if necessary use one with a size 12 gauge or

heavier with ground wire. Do not use an adapter

to circumvent the grounding requirement.

Installation of the machine involves moving the machine

close to its permanent location, removing all crating, setting in place, assembling parts, and cleaning.

A. Uncrate the machine.

B. Accurate leveling is necessary for correct drainage

of machine barrel and to insure correct overrun.

Owner’s Manual #513532-5 Rev.1 3 E111I/F111I Model Machines

Do not alter or deform electrical plug in any way.

Altering the plug to fi t into an outlet of different con-

fi guration may cause fi re, risk of electrical shock,

product damage and will void warranty.

WARNING

Page 10

Owner’s Manual #513532-5 Rev.1 4 E111I/F111I Model Machines

Page 11

SECTION 3

INITIAL SETUP AND OPERATION

3.1 OPERATOR’S SAFETY PRECAUTIONS

SAFE OPERATION IS NO ACCIDENT; observe these

rules:

A. Know the machine. Read and understand the

Operating Instructions.

B. Notice all warning labels on the machine.

C. Wear proper clothing. Avoid loose fi tting garments,

and remove watches, rings or jewelry that could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F . Disconnect electrical cord for maintenance. Never

attempt to repair or perform maintenance on the

machine until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the machine if unusual or excessive

noise or vibration occurs.

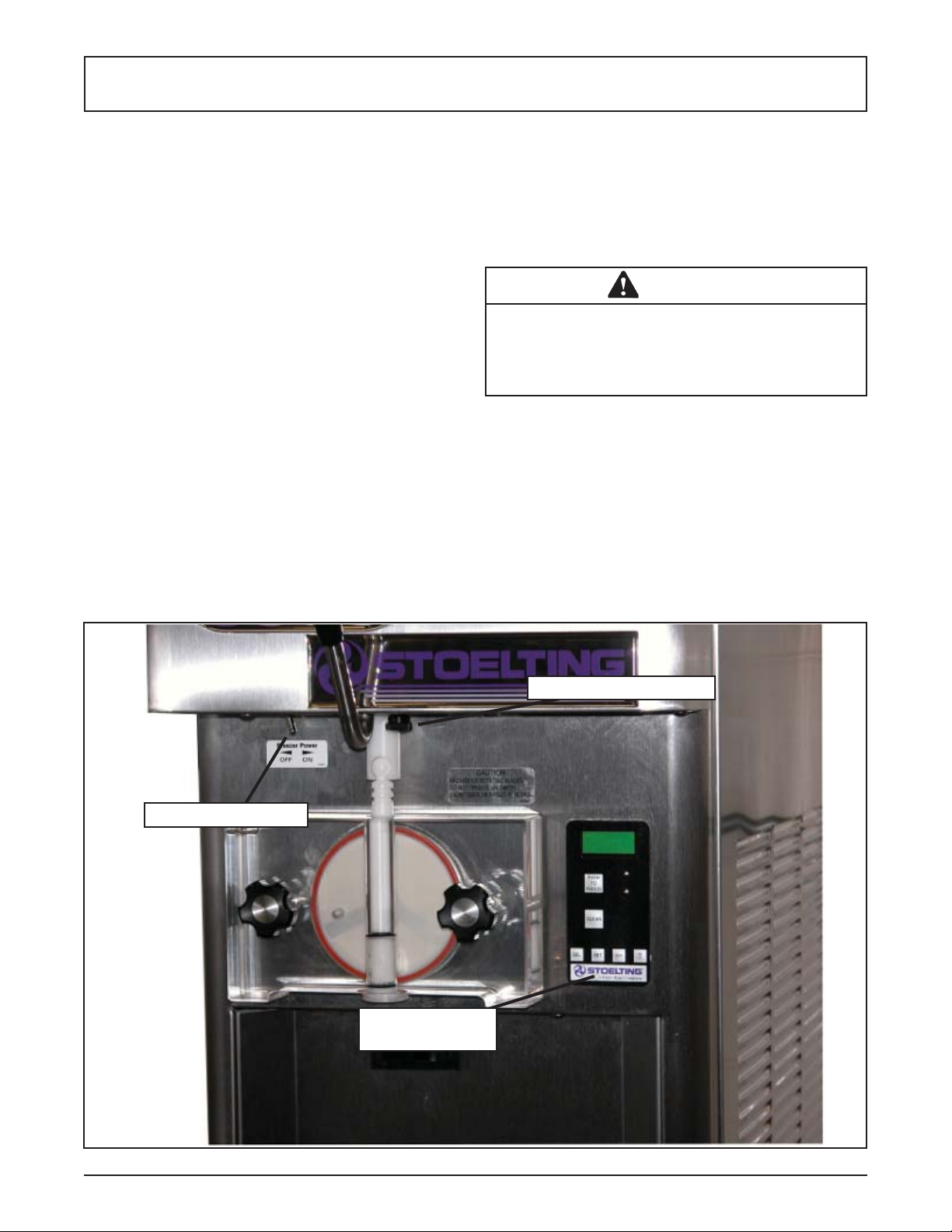

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the machine, it is required that the operator know the function of each operating control. Refer

to Figure 3-1 for the location of the operating controls on

the machine.

A. SPIGOT SWITCH

WARNING

High voltage will shock, burn or cause death. The

OFF-ON switch must be placed in the OFF position

prior to disassembling for cleaning or servicing. Do

not operate machine with cabinet panels removed.

The spigot switch will automatically actuate the

auger drive and refrigeration systems when the

spigot is opened to dispense product. When the

spigot is closed, the drive motor and compressor

will remain “on” until the product in the barrel

reaches the proper consistency.

Main Power OFF-ON

Dispense Rate Adjustor

IntelliT ec Control

(See Figure 3-2)

Figure 3-1 E111 & F111 Controls

Owner’s Manual #513532-5 Rev.1 5 E111I/F111I Model Machines

Page 12

B. MAIN FREEZER POWER OFF-ON SWITCH

The Main Freezer Power OFF-ON switch is a

two position toggle switch used to supply power

to the control circuit. When the switch is in the

OFF position, power will not be supplied to the

control board or refrigeration system. When the

switch is in the ON position, the machine will

operate in the freezing mode or cleaning mode.

The machine will be in the sleep mode until a

switch is activated.

C. PUSH TO FREEZE BUTTON

The PUSH TO FREEZE button is used to initiate

the serve mode. To start the machine, place the

Main Freezer Power OFF-ON switch in the ON

position and press the PUSH TO FREEZE button.

NOTE

After the drive motor starts, there is a 3 second

delay before the compressor starts.

D. LEDS

The membrane switch features two lights; a

green LED and an amber LED. The green LED

is lit during serve mode. During freeze down, the

green LED is not lit. When product consistency

approaches 75% in the freezing cylinder, the

green LED fl ashes. The amber LED is lit during all

other modes. In the event of an error or when the

freezing cylinder is off, both LEDs will alternatively

fl ash.

NOTE

If the machine shuts off, and alternating green and

amber lights are fl ashing, the machine is in an error

condition. If the LCD displays an error, turn the Main

Freezer Power OFF-ON switch to the OFF position,

correct the problem (Refer to Troubleshooting in

Section 4) and turn the machine back on.

E. CLEAN BUTTON

The CLEAN button will stop all refrigeration and

start auger rotation. A CLEAN message will display

on the LCD screen and a 5 minute timer begins.

To exit the CLEAN mode, press the CLEAN

button again. If the machine is left in CLEAN for

more than 20 minutes, it will go into an error to

prevent damage to the freezing cylinder. When

this error occurs, refrigeration will start to prevent

mix spoilage. To reset, place the Main Freezer

Power OFF-ON switch in the OFF position and

back in the ON position.

F. MIX LOW LIGHT INDICATOR

The MIX LOW message will appear on the

LCD display to alert the operator to a low mix

condition. The message will display when there is

approximately one gallon of mix left in the hopper.

When the MIX LOW message is displayed, refi ll

hopper immediately.

NOTE

Failure to refi ll hopper immediately may result in

operational problems.

G. DISPENSE RATE ADJUSTOR

The dispense rate adjuster limits the opening of

the spigot. To adjust product dispense rate, turn

the adjusting knob clockwise for slower fl ow and

counterclockwise for faster fl ow. It takes at least

fi ve complete turns of the adjusting knob to make

a noticeable difference in the dispense rate.

H. FRONT DOOR SAFETY SWITCH

The front door safety switch prevents the auger

from turning when the front door is removed. The

switch is open when the door is not in place and

closed when the door is properly installed.

I. MENU NAVIGATION BUTTONS

The Menu Navigation Buttons allow the user to

display information regarding the machine’s status

of operation as well as adjust product consistency.

Selection Button (SEL) The SEL button is not

functional in the normal operation mode. This

button is only used by service technicians for

machine calibration.

Set Button (SET) Pressing this button will save a

change made to the product consistency setting.

Refer to Section 3-15 for consistency adjustment

procedures.

Left Arrow Button () Pressing any button on

the control panel will automatically illuminate the

display . The backlight will turn off several seconds

after use. T o keep the display constantly lit, press

and hold the left () button for fi ve seconds. The

backlight function can be reset to normal operation

in the same manner.

Up Arrow Button () Pressing this button will

change the value of the product consistency.

Refer to Section 3-15 for consistency adjustment

procedures.

Push to Freeze

Green Light

Amber Light

Clean Switch

SEL Button

SET Button

Left Arrow Button

Up Arrow Button

Figure 3-2 IntelliTec Control

Owner’s Manual #513532-5 Rev.1 6 E111I/F111I Model Machines

Page 13

3.3 IMPORTANT INFORMATION REGARDING

CLEANING AND SANITIZING

Soft serve and shake machines require special consideration when it comes to food safety and proper cleaning

and sanitizing.

The following information specifi cally covers issues for

cleaning and sanitizing frozen dessert machines. This

information is meant to supplement a comprehensive

food safety program.

Soil Materials Associated with Frozen Dessert Machines

MILKFAT/BUTTERFAT – As components of ice-cream/

frozen custard mix, these soils will accumulate on the

interior surfaces of the machine and its parts. Fats are

diffi cult to remove and help attribute to milkstone buildup.

MILKSTONE – Is a white/gray fi lm that forms on equip-

ment and utensils that are exposed to dairy products.

These fi lms will accumulate slowly on surfaces because of

ineffective cleaning, use of hard water , or both. Milkstone

is usually a porous deposit, which will harbor microbial

contaminants and eventually defy sanitizing efforts.

Once milkstone has formed, it is very diffi cult to remove.

Without using the correct product and procedure, it is

nearly impossible to remove a thick layer of milkstone.

(NOTE: general-purpose cleaners DO NOT remove

milkstone.) This can lead to high bacteria counts and a

food safety dilemma.

IT IS BEST T O CONTROL MILKSTONE ON A DAIL Y BASIS BEFORE IT CAN BECOME A SIGNIFICANT FOOD

SAFETY PROBLEM.

In addition to food safety, milkstone can cause premature wear to machine parts, which can add to costs for

replacement parts or possibly more expensive repairs

if worn machine parts are not replaced once they have

become excessively worn.

Important Differences Between Cleaning and Sanitizing

CLEANING vs. SANITIZING

It is important to distinguish between cleaning and sanitiz-

ing. Although these terms may sound synonymous, they

are not. BOTH are required for adequate food safety and

proper machine maintenance.

CLEANING

• Is the removal of soil materials from a surface.

• Is a prerequisite for effective sanitizing.

NOTE

An UNCLEAN surface will harbor bacteria that can

defy sanitizing efforts.

Bacteria can develop and resist sanitizing efforts within

a layer of soil material (milkstone). Thorough cleaning

procedures that involve milkstone removal are critical for

operators of frozen dessert machines.

SANITIZING

• Kills bacteria.

• Can be effective on clean surfaces only.

NOTE

Using a SANITIZER on an unclean surface will not

guarantee a clean and safe frozen dessert machine.

Proper Daily Maintenance:

The Only Way to Assure Food Safety and Product Quality

Proper daily maintenance can involve a wide variety

of products and procedures. Overall, the products and

procedures fall into three separate categories. (Please

note that this is a brief overview intended for informational

purposes only.)

1. CLEANING – This involves draining mix from

the freezing cylinder and rinsing the machine

with water. Next, a cleaner is run through the

machine. Then, the machine is disassembled

and removable parts are taken to the sink for

cleaning.

2. MILKSTONE REMOVAL – Since most cleaners

do not have the ability to remove milkstone, the

use of a delimer becomes necessary. Although

this procedure may not be needed on a daily

basis, it will usually follow the cleaning procedure.

It requires letting a delimer solution soak in the

machine for an extended period. Individual parts

are also soaked in a deliming solution for an

extended period of time (more about delimers in

Additional Information).

3. SANITIZING – After the machine has been

cleaned and contains no milkstone, the machine

is reassembled. Then a FDA-approved sanitizing

solution is run through the machine to kill bacteria.

The machine is then ready for food preparation.

As a recommended cleaner and sanitizer for your frozen

dessert machine, STERA-SHEEN has proven to be one

of the best daily maintenance products for:

• CLEANING – Thorough removal of all solids

including butterfat and milk fat.

• MILKSTONE REMOV AL – Complete removal of

milkstone.

• SANITIZING – FDA-approved no rinse sanitizer

for food contact surfaces.

Additional Information

THE USE OF DELIMERS

A delimer is a strong acid that has the ability to dissolve

milkstone. This type of chemical may become necessary

once high levels of milkstone have developed. While these

products are very effective for removing HIGH levels of

milkstone, they are not ideal for two reasons:

1. PRODUCT SAFETY – Strong acids are dangerous

chemicals. Carefully follow safety instructions

provided with delimer products.

Owner’s Manual #513532-5 Rev.1 7 E111I/F111I Model Machines

Page 14

2. MACHINE DAMAGE – Strong acids will attack

metal and rubber causing premature wear of

parts. The use of a delimer needs to be closely

monitored to avoid damage to machine surfaces

and parts.

With proper daily use of STERA-SHEEN or its equivalent,

there is no need for the use of a DELIMER.

DO NOT USE BLEACH

• BLEACH HAS ABSOLUTELY NO CLEANING

PROPERTIES.

• BLEACH IS CORROSIVE. It will damage

components of the machine causing premature

wear and metal corrosion.

GENERAL PURPOSE CLEANERS

General purpose cleaners do not have the ability to re-

move milkstone. Milkstone will become a problem if not

remedied with additional products and procedures.

THE USE OF CHLORINE TEST STRIPS

“Test strips” are used to determine concentrations of

active chlorine in sanitizing solutions. To use the strips,

tear off a small portion and submerge it into the sanitizing

solution. Then, compare the color change to the color key

on the side of the test strip dispenser to determine the

approximate chlorine concentration.

The ideal concentration of chlorine needs to be 100 ppm

(as stated by the FDA).

NOTE

Follow the directions on the container for proper

concentration.

Two main factors contribute to falling chlorine concentrations in a sanitizing solution.

1. PRODUCT USE – As the chlorine in the solution

is being used, chlorine concentrations fall.

2. TIME – As time passes, small amounts of chlorine

“evaporate” from the solution. (That is why you

can smell it.)

Sanitizing solutions should not be allowed to fall below

100 ppm chlorine. New solutions should be mixed once

old solutions become ineffective.

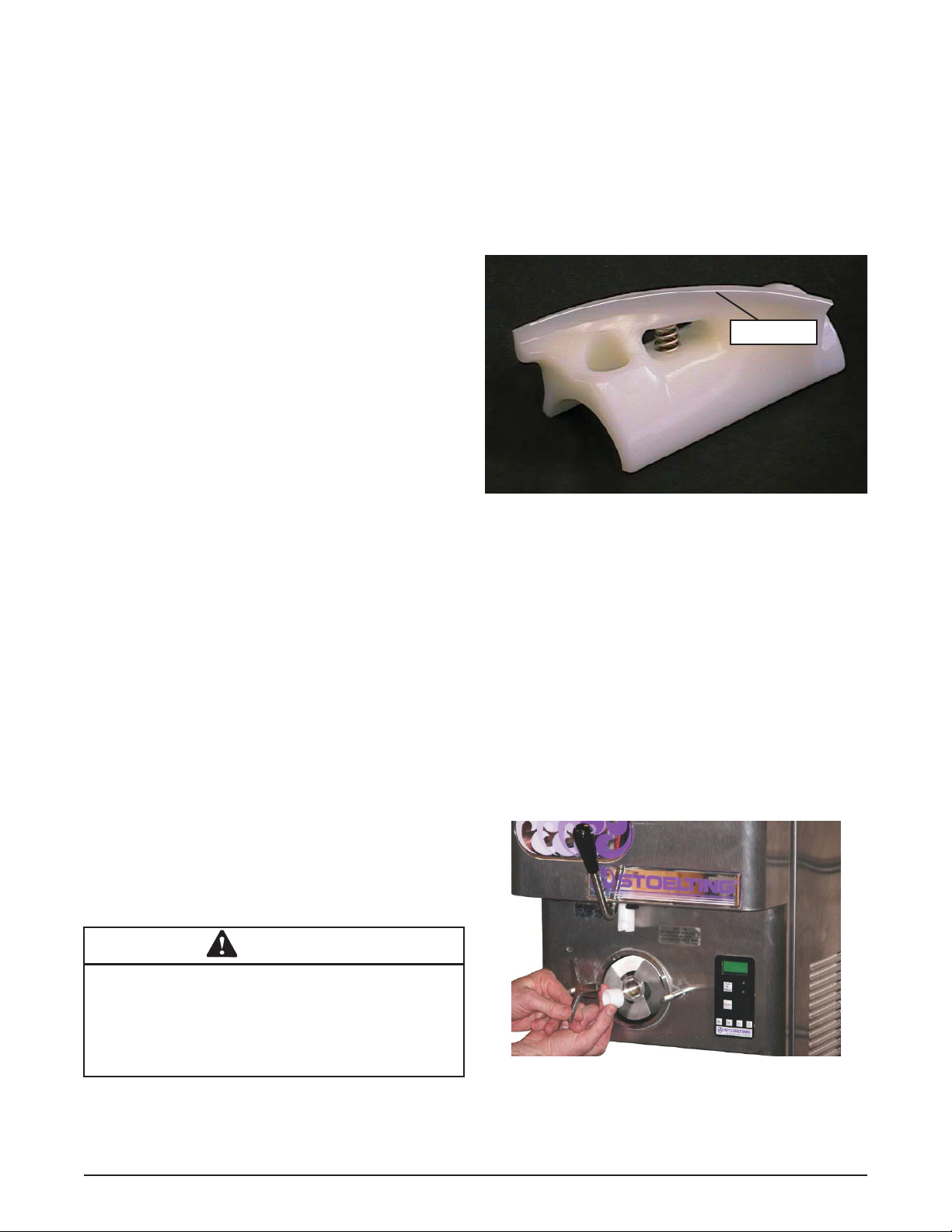

3.4 DISASSEMBLY OF PARTS

Inspection for worn or broken parts should be made each

time the machine is disassembled. All worn or broken

parts should be replaced to ensure safety to both the

operator and the customer and to maintain good machine

performance and a quality product. Check the wear line on

the auger fl ights on a regular basis (Fig. 3-3) and replace

as needed. Frequency of cleaning must comply with the

local health regulations.

Wear Line

Figure 3-3 Auger Flight Wear

T o disassemble the machine, refer to the following steps:

A. Remove hopper cover and drain tray.

B. Remove the mix inlet regulator from the hopper

by pulling straight up.

C. Remove the front door by turning the circular

knobs and then pulling the front door off the studs.

D. Remove the rosette cap from the front door. Push

the spigot body through the bottom of the front

door and remove.

E. Remove the front auger support and bushing (Fig.

3-4).

WARNING

Hazardous Moving Parts

Revolving auger shaft can grab and cause injury.

Place the Main Freezer Power OFF-ON switch in

the OFF position before disassembling for cleaning

or servicing.

Owner’s Manual #513532-5 Rev.1 8 E111I/F111I Model Machines

Figure 3-4 Removing Auger Support

Page 15

Figure 3-5 Removing Auger Shaft and Flights

F. Remove the auger assembly from the machine

(Fig. 3-5). Pull the auger out of the machine barrel

slowly . As the auger is being pulled out, carefully

remove each of the plastic fl ights with springs.

G. Keep the rear of the auger shaft tipped up once

it is clear of the machine to avoid dropping rear

seal.

H. Remove the rear seal.

I. Wipe socket lubricant from the drive end (rear)

of the auger with a cloth or paper towel.

J. Remove all o-rings from parts by fi rst wiping off

the lubricant using a clean paper towel. Then

squeeze the o-ring upward with a dry cloth (Fig.

3-6). When a loop is formed, roll out of the o-ring

groove.

3.5 CLEANING DISASSEMBLED PARTS

Disassembled parts require complete cleaning, sanitizing and air drying before assembling. Local and state

health codes will dictate the procedure required. Some

state health codes require a four sink process (pre-wash,

wash, rinse, sanitize, air dry), while others require a three

sink process (without the pre-wash step). The following

procedures are a general guideline only. Consult your

local and state health codes for the procedures required

in your location.

A. Disassemble all parts. (Refer to Section 3.4 for

the disassembly of machine parts.)

B. Place all front door and auger parts in clean 90° to

1 10°F (32°C to 43°C) water and wash thoroughly

(four sink procedure only).

C. Place all parts in 90° to 110°F (32°C to 43°C) mild

detergent water and wash thoroughly.

D. Rinse all parts with clean 90° to 110°F (32°C to

43°C) water.

E. Sanitize all machine parts following procedures

outlined below.

3.6 SANITIZING PARTS

A. Use a sanitizer, mixed according to manufacturer’s

instructions, to provide a 100 parts per million

strength solution. Mix sanitizer in quantities of

no less than 2 gallons of 90° to 110°F (32°C to

43°C) water. Any sanitizer must be used only in

accordance with the manufacturer’s instructions.

B. Place all parts in the sanitizing solution for 5

minutes, then remove and let air dry completely

before assembling in machine.

3.7 CLEANING THE MACHINE

CAUTION

Do not use any type of sharp object to remove the

o-rings.

Figure 3-6 Removing O-Ring

Owner’s Manual #513532-5 Rev.1 9 E111I/F111I Model Machines

The exterior should be kept clean at all times to preserve

the luster of the stainless steel. A high grade of stainless

steel has been used on the machine to ease cleanup. To

remove spilled or dried mix, wash the exterior with 90° to

110°F (32°C to 43°C) soapy water and wipe dry.

Do not use highly abrasive materials, as they will mar the

fi nish. A mild alkaline cleaner is recommended. Use a soft

cloth or sponge to apply the cleaner. For best results, wipe

with the grain of the steel.

A. Clean the rear seal surface from inside of the

freezing cylinder.

B. Using sanitizing solution and the large barrel

brush provided, sanitize the freezing cylinder by

dipping the brush in the sanitizing solution and

brushing the inside of the freezing cylinder.

C. Remove the drip tray by pulling from the front

panel. Clean and replace the drip tray.

Page 16

3.8 ASSEMBLING MACHINE

T o assemble the machine parts, refer to the following steps:

NOTE

Petrol Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specifi ed.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lubricants used on food processing equipment be certifi ed for this use. Use lubricants only in accordance

with the manufacturer’s instructions.

A. Assemble all o-rings onto parts dry, without

lubrication. Then apply a thin fi lm of sanitary

lubrication to exposed surfaces of the o-rings.

Apply a thin fi lm of sanitary lubricant to metal

part of rear seal. Also apply a thin fi lm of sanitary

lubricant inside and outside of the front auger

support bushing.

B. Assemble the rear seal onto the auger with the

large end to the rear. Be sure the o-ring is in place

before installing the rear seal.

C. Lubricate the auger drive (rear) with a small

amount of white socket lubricant. A small container

of socket lubricant is shipped with the machine.

D. Screw the springs onto the studs in plastic

fl ights. Springs must be screwed into the fl ights

completely to provide proper compression (Fig.

3-7).

Figure 3-8 Front Door Parts

F . Install the remaining plastic fl ights, push the auger

into the machine barrel and rotate slowly until the

auger engages the drive shaft.

G. Install the bushing and auger support into the front

of the auger with one leg of the support pointing

straight down (“Y” position).

H. Install the spigot body with o-ring into the front

door from bottom (Fig. 3-8). Push straight up until

the spigot is in place.

I. Install the front door on the machine.

J. Install the circular knobs on the machine studs.

K. Look for the proper seal between the freezing

cylinder, o-ring, and front door.

CAUTION

Overtightening or uneven tensioning of circular

knobs may cause damage to front door and cause

leaking. Hand tighten circular knobs evenly.

Figure 3-7 Auger Springs

E. Install the two plastic fl ights onto rear of the auger

and insert part way into machine barrel.

Owner’s Manual #513532-5 Rev.1 10 E111I/F111I Model Machines

Page 17

3.9 SANITIZING

Sanitizing must be done after the machine is cleaned and

just before the hopper is fi lled with mix. Sanitizing the night

before is not effective. However , you should always clean

the machine and parts after each use.

THE UNITED STATES DEPARTMENT OF AGRICULTURE AND THE FOOD AND DRUG ADMINISTRATION

REQUIRE THAT ALL CLEANING AND SANITIZING

SOLUTIONS USED WITH FOOD PROCESSING EQUIPMENT BE CERTIFIED FOR THIS USE.

When sanitizing the machine, refer to local sanitary regulations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations.

Mix sanitizer according to manufacturer’s instructions to

provide a 100 parts per million strength solution. Mix sanitizer in quantities of no less than 2 gallons (7.5 liters) of

90° to 1 10°F (32° to 43°C) water. Allow sanitizer to contact

the surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the manufacturer’s

instructions.

In general, sanitizing may be conducted as follows:

A. Prepare Stera-Sheen Green Label Sanitizer

or equivalent according to manufacturer’s

instructions to provide a 100ppm strength solution.

Mix the sanitizer in quantities of no less than 2

gallons of 90° to 1 10°F (32° to 43°C) water . Any

sanitizer must be used only in accordance with

the manufacturer’s instructions.

B. Push the mix inlet regulator into hopper with air

inlet (long) tube toward the front of the machine

(Fig. 3-9).

Figure 3-9 Mix Inlet Regulator

C. Place the Main Freezer Power OFF-ON toggle

switch in the ON position and press the CLEAN

switch. Check for leaks.

Figure 3-10 Sanitizing Hopper

D. Clean sides of hopper, mix inlet regulator and

underside of hopper cover using a sanitized soft

bristle brush dipped in the sanitizing solution.

(Fig. 3-10).

E. After fi ve minutes, place a bucket under the spigot

and open spigot to drain sanitizing solution. When

solution has drained, press the CLEAN button to

stop the auger. Allow the machine barrel to drain

completely.

3.10 INITIAL FREEZE DOWN AND OPERATION

Every Stoelting soft serve machine needs to be set on site.

The following adjustment will provide optimal product

consistency while prolonging product life.

NOTE

The machine is designed for correct operation in

ambient temperatures between 50°F and 110°F.

T emperatures out of that range may cause refrigeration problems and product quality issues.

A. ADDING MIX

1. Sanitize the machine immediately before use.

2. Make sure the Main Freezer Power OFF-ON

switch is in the OFF position.

3. Fill the hopper with at least 2.5 gallons of mix.

4. Place a container under the spigot and open the

spigot to allow the mix to fl ush out about 8 ounces

(0.23 liters) of sanitizing solution and liquid mix.

Close the spigot.

B. PREPARING THE INTELLITEC CONTROL

5. On the IntelliTec control, press and hold the SEL

button for 8 seconds. While still holding the SEL

button, press the up arrow () button. The LCD

will read “DISPLAY”.

6. Press the left arrow () button once. The display

will read “BASIC”.

7. Press the up arrow () button once. The display

will read “CutOut amps”.

Owner’s Manual #513532-5 Rev.1 11 E111I/F111I Model Machines

Page 18

8. Press the SET button. A cursor will start blinking

under the far right digit.

9. Change the value to 8.0. Press the left arrow ()

button to move the cursor. Press the up arrow ()

button to increase the digit. When a digit reaches

9, pressing the up arrow () button again will

change the value to 0.

10. After entering 8.0, press SET to save this value.

The LCD will read “CutOut Set -- OK”.

1 1. Press the SEL button. The LCD will read “CutOut

amps 8.0”.

12. Press the SEL button twice. The LCD will read

“DISPLAY”.

13. Press the up arrow () button to navigate to the

“°F” and “amps” readings.

C. INITIAL FREEZE DOWN

14. Place the Main Freezer Power OFF-ON switch

in the ON position.

15. Press the PUSH TO FREEZE button.

NOTE

After the drive motor starts, there is a 3-second

delay before the compressor starts.

16. As the product freezes, the “amps” value on the

display will increase. When it reaches 2.8A, open

the spigot, take a 6-8 ounce sample and measure

the temperature. For most soft serve mixes,

the desired temperature is between 19.0°F and

19.5°F.

17. Draw samples at every increase of 0.2A until

reaching the desired consistency and temperature.

NOTE

Show the sample to the customer and make sure it

meets their required consistency and temperature.

18. Record the “amps” value.

19. Place the Main Freezer Power OFF-ON switch

in the OFF position.

D. ADJUSTING THE INTELLITEC CONTROL

20. Press the SEL button. The display will read

“DISPLAY”.

21. Press the left arrow () button once. The display

will read “BASIC”.

22. Press the up arrow () button once. The display

will read “CutOut amps”.

23. Change the value to the recorded value by

pressing the SET button. A cursor will start blinking

under the far right digit.

24. Press the left arrow () button to move the cursor.

Press the up arrow () button to increase the digit.

When a digit reaches 9, pressing the up arrow

() button again will change the value to 0.

25. Press the SET button to save the value. The LCD

will read “CutOut Set -- OK”.

26. Press the SEL button. The LCD will read “CutOut

amps” along with the programmed value from the

previous step.

27. Press the SEL button three times. The LCD will

read “EXITMENU”.

28. Press the up arrow () button to exit the menu.

29. Adjustment to the control is completed.

E. SERVING PRODUCT

30. Place the Main Freezer Power OFF-ON switch

in the ON position.

31. Press the PUSH TO FREEZE button.

32. When the product is at 75% consistency, the

display will read “SERVE”.

33. For normal dispensing, move the spigot handle

fully open.

34. The machine dispenses product at a reasonable

draw rate. If the machine is overdrawn, the result

is a soft product or a product that will not dispense

at all. If this occurs, allow the machine to run for

approximately 30 seconds before dispensing more

product. A dispense rate adjustor is located under

the header panel, to the immediate right of the

spigot handle. Turning the knob counterclockwise

will decrease the dispense rate.

35. Do not operate the machine when the MIX LOW

message is displayed. Refi ll the mix container

immediately.

NOTE

The machine has a standby and sleep mode. After

a preset number of freezing cycles, it will enter the

standby mode (followed by sleep mode) and remain

there until someone draws product or presses the

PUSH TO FREEZE button. In the sleep mode, the

machine will keep the product below 41°F (4.4°C).

Sleep modes do not take the place of cleaning

and sanitizing. Federal, State, and local regulatory

agencies determine frequency of cleaning and

sanitizing.

3.11 NORMAL FREEZE DOWN AND

OPERATION

The following section contains the recommended operating procedures for the safe operation of the machine.

A. Sanitize immediately before use.

B. Make sure the Main Freezer Power OFF-ON

switch is in the OFF position.

C. Fill the hopper with at least 2.5 gallons of mix.

D. Place a container under the spigot and open the

spigot to allow the mix to fl ush out about 8 ounces

(0.23 liters) of sanitizing solution and liquid mix.

Owner’s Manual #513532-5 Rev.1 12 E111I/F111I Model Machines

Page 19

E. Place the Main Freezer Power OFF-ON switch

in the ON position.

F. Press the PUSH TO FREEZE button.

NOTE

After the drive motor starts, there is a 3-second

delay before the compressor starts.

G. When the product is at 75% consistency, the

display will read “SERVE”. Open the spigot to

dispense product.

H. The machine dispenses product at a reasonable

draw rate. If the machine is overdrawn, the result

is a soft product or a product that will not dispense

at all. If this occurs, allow the machine to run for

approximately 30 seconds before dispensing more

product. A dispense rate adjustor is located under

the header panel, to the immediate right of the

spigot handle. Turning the knob counterclockwise

will decrease the dispense rate.

I. Do not operate the machine when the MIX LOW

message is displayed. Refi ll the mix container

immediately.

NOTE

The machine has a standby and sleep mode. After

a preset number of freezing cycles, it will enter the

standby mode (followed by sleep mode) and remain

there until someone draws product or presses the

PUSH TO FREEZE button. In the sleep mode, the

machine will keep the product below 41°F (4.4°C).

Sleep modes do not take the place of cleaning

and sanitizing. Federal, State, and local regulatory

agencies determine frequency of cleaning and

sanitizing.

Figure 3-11 During Freezing Cycle

3.12 MIX INFORMATION

Mix can vary considerably from one manufacturer to

another. Differences in the amount of butterfat content

and quantity and quality of other ingredients have a

direct bearing on the fi nished frozen product. A change

in machine performance that cannot be explained by a

technical problem may be related to the mix.

Proper product serving temperature varies from one

manufacturer’s mix to another. Mixes should provide a

satisfactory product in the 17°F to 24°F range. Diet and

low-carb mixes typically freeze to proper consistency at

higher temperatures.

When checking the temperature, stir the thermometer in

the frozen product to get an accurate reading.

Old mix, or mix that has been stored at too high a temperature, can result in a fi nished product that is unsatisfactory .

Owner’s Manual #513532-5 Rev.1 13 E111I/F111I Model Machines

Page 20

Owner’s Manual #513532-5 Rev.1 14 E111I/F111I Model Machines

Page 21

SECTION 4

MAINTENANCE AND ADJUSTMENTS

4.1 MACHINE ADJUSTMENT

This section is intended to provide maintenance personnel

with a general understanding of the machine adjustments.

It is recommended that any adjustments in this section

be made by a qualifi ed person.

4.2 PRODUCT CONSISTENCY

ADJUSTMENT

The operator can adjust product consistency by modifying the Fine Adjustment setting on the membrane switch.

This is the only adjustment that can be made by the operator without using a pass code key sequence. Product

consistency fi ne adjustment allows a 0.4 amp maximum

adjustment to the drive motor amp draw cutout. Increasing

this setting will increase the drive motor amperage cutout

and increase product consistency . Follow the instructions

below to make fi ne adjustments to product consistency.

A. Place the Main Freezer Power switch in the ON

position.

B. Press the SET button on the Control Panel once.

Fine Adj will appear on the LCD screen.

C. Press the up arrow button until the desired

consistency setting is displayed. The higher the

number, the fi rmer the product consistency. The

control may be set from 1 to 9. The value increases

by 1 each time the up arrow button is pressed.

After the value reaches 9, numbering restarts at

0. The 0 setting cannot be set.

D. Press the SET button once to save the setting

and return to the current mode display.

4.3 LOCKING THE CONTROL PANEL

The IntelliT ec control has a tamper proof mode to prevent

unauthorized use. When set, all buttons on the control

panel are disabled. Follow the instructions below to lock

the control panel

A. Press and hold the PUSH TO FREEZE button

for at least 5 seconds.

B. While still holding the PUSH TO FREEZE button,

press the CLEAN button once.

C. Release both buttons. An asterisk (*) will appear

on the bottom line of the display, indicating that

the control is in the lock out mode.

NOTE:

Repeat steps A, B, and C to unlock the control

panel.

4.4 OBTAINING READINGS AND

MODIFYING SETTINGS (SERVICE PERSONNEL

ONLY)

Readings and settings on the IntelliTec control are accessed through the IntelliT ec Control Menu Settings (Refer

to Figure 4-2). Locating machine readings and system

function settings are completed using the up arrow ()

and left arrow () buttons on the membrane switch. A

printed IntelliTec Menu Settings sheet is located in the

information pouch behind the header panel.

IntelliTec Control Readings

To obtain machine readings, locate the value on the machine’s menu settings sheet and follow the steps below.

A. Press and hold SEL button for 8 seconds. While

still holding the SEL button, press the up arrow

button (). The LCD Screen will read DISPLAY.

B. Release both buttons.

C. Press the up arrow button () to navigate to the

correct reading under DISPLA Y or press the left

arrow () button to navigate to the ERRCODES

menu.

D. Press the up arrow () and left arrow () buttons

to navigate through the rest of the readings as

needed.

E. When all readings have been obtained, press

the up arrow button () from ExitMenu to return

to the current mode display.

Figure 4-1 Membrane Switch

Owner’s Manual #513632-5 Rev.1 15 E111I/F111I Model Machines

Page 22

Figure 4-2 IntelliTec Control Menu Settings

Owner’s Manual #513632-5 Rev.1 16 E111I/F111I Model Machines

Page 23

Modifying Control Settings

To change the value of a system function, locate the

function on the IntelliTec Settings Menu and follow the

steps below.

IMPORTANT:

Before making changes to any settings, record

the original values. If the setting changes do not

achieve desired results, revert settings to their

original values.

A. Press and hold SEL button for 8 seconds. While

still holding the SEL button, press the up arrow

button (). The LCD Screen will read DISPLAY.

B. Release both buttons.

C. Press the left arrow button () to get to the correct

menu (Basic, Advanced, or Storage).

D. Press the up arrow button () to navigate to the

value that needs to be changed.

E. Press SET button to enter edit mode.

F. Press the up arrow button () to change setting.

G. Press SET button to save the setting and exit the

edit mode.

H. Press the up arrow () and left arrow () buttons

to navigate through the rest of the settings as

needed.

I. When all changes have been completed, press

the up arrow button () from ExitMenu to return

to the current mode display.

4.5 READINGS (SERVICE PERSONNEL

ONLY)

The IntelliTec control continuously monitors and records

temperatures, voltages, amps, and error code details.

Each of these readings are benefi cial to service personnel

when troubleshooting.

DISPLAY READINGS

Following are the readings available under the DISPLA Y

menu:

Hopper (°F)

The temperature of the hopper is constantly

monitored by the IntelliTec control.

Cycles (count)

This reading counts down the number of cycles

in the current “Serve Mode”. The starting value

is dependant upon the Cycles setting on the

IntelliTec control.

°F and amps

The suction line temperature on the freezing

cylinder and the drive motor amps are available

on the same screen to assist with setup and

troubleshooting.

Aux. Temp (°F)

This reading provides the ambient temperature

around the IntelliTec control.

Supply V (VAC)

A calculated input voltage is recorded.

ERROR CODE READINGS

The following details are recorded under the ERRCODES

menu for each of the last 25 error codes received:

Err1 (hours)

A numerical count of the last 25 error codes is

recorded. When the 26th error has occurred

the earliest error code is erased. A timer also

begins when an error occurs. The timer records

the number of hours since the error occurred. If

power to the machine is interrupted, the timer will

stop until power has been restored.

°F and amps

The suction gas temperature on the freezing

cylinder and the drive motor amps are recorded

at the time of the error.

Aux. Temp (°F)

Ambient temperature of the IntelliTec control is

recorded at the time of the error.

Str (°F)

The storage temperature is recorded at the time

of the error.

VAC and Mode

A calculated input voltage and mode at which

the error occurred are recorded. Following are

descriptions of each mode:

Mode Description

0 Start of freezing cycle

1 Compressor and drive motor on

2 Stir Cycle

3 Compressor off

4 “Standby Mode”

5 “Sleep 1 Mode”

6 “Sleep 2 Mode”

7 “Clean Mode”

8 Startup

9 Storage only refrigeration

10 Freezing cycle is shut down

11 Door safety switch triggered

12 High pressure cutout

Owner’s Manual #513632-5 Rev.1 17 E111I/F111I Model Machines

Page 24

Up Time (hours)

This value is a record of the total time the machine

has been in service. If power is interrupted, the

timer will stop until power is restored. This timer

does not reset.

RUN STATISTICS

In addition to dynamic readings and recorded

error code details, the IntelliTec control records

rolling averages of run statistics. Following are the

readings available under the RUNST ATS menu:

On Times (sec)

The control records the time of each freezing

cycle and provides a rolling average.

Off Times (sec)

The control records the time between freezing

cycles and provides a rolling average.

Brl. Min (°F)

The lowest average barrel temperature is

recorded.

Brl. Max (°F)

The highest average barrel temperature is

recorded.

Stor Min (°F)

The lowest average hopper temperature is

recorded.

Stor Max (°F)

The highest average hopper temperature is

recorded.

Power On (hrs)

This value is a record of the time the machine

has been in service. If power is interrupted, the

timer will reset.

4.6 ADJUSTMENTS (SERVICE PERSONNEL

ONLY)

The following adjustments directly affect product consistency and length of time in “Serve Mode”. The default

settings have been created using a 5% milkfat soft serve

mix and provide optimal product consistency while prolonging product life.

CutOut (amps)

It is recommended to change the CutOut value

at initial startup and when changing mix types.

Adjustments to this setting directly affect the

length of the freezing cycle which changes product

consistency. To properly set the CutOut value,

refer to Section 3.

Cut In T (°F)

After the consistency value has been determined,

the Cut In T value can be adjusted. The Cut In

T is the temperature of the refrigerant gas in the

evaporator. Changing this setting changes the

temperature at which the freezing cycle starts. This

value along with the CutOut value determines the

range of temperatures (or “temperature window”)

of the product. Decreasing the temperature

decreases the temperature window and, under

normal use, increases the amount of freezing

cycles. This creates a greater chance of product

breakdown by stirring the product often. Increasing

the Cut In T increases the temperature window

which decreases freezing cycles and increases

the chance of heat shock within the product.

Cycles (count)

This setting determines the number of freezing

cycles during “Serve Mode”. Increasing the value

will increase the total time in “Serve Mode”. Factory

default is 16 cycles. This results in “Serve Mode”

lasting about 2 to 2-1/2 hours without the PUSH

TO FREEZE button being pressed or a spigot

handle being pulled. If the PUSH TO FREEZE

button is pressed or the spigot handle is pulled at

any time during “Serve Mode”, the Cycles count

will reset.

4.7 OTHER SETTINGS (SERVICE

PERSONNEL ONLY)

Changing any setting on the IntelliTec control will alter

machine operation and affect the product temperature,

consistency , or life. Refer to the IntelliT ec Control System

Settings sheet located in the information pouch behind

the header panel of the machine. If any of the following

settings on the IntelliTec control differ from the System

Settings sheet, it is recommended to revert those settings

to factory defaults.

Stir On (sec)

Adjustments to this setting affect the amount of

time the auger rotates in the stir cycle. The stir

cycle occurs in “Serve Mode”, “Standby Mode”,

and “Sleep 2 Mode”.

Stir Off (sec)

Adjustments to this setting affect the time between

stir cycles. The stir cycle occurs in “Serve Mode”,

“Standby Mode”, and “Sleep 2 Mode”.

On Time (sec)

Increasing this value will increase the length of the

freezing cycle during “Standby Mode” and result

in a decrease of average product temperature in

the barrel.

Owner’s Manual #513632-5 Rev.1 18 E111I/F111I Model Machines

Page 25

Off Time (sec)

Increasing this value will increase the time between

freezing cycles in “Standby Mode” and result in

an increase of product temperature in the barrel.

Stb Time (sec)

This setting determines the total amount of time

in “Standby Mode”.

Sl1DrvOn (sec)

Adjustments to this setting affect the amount of

time the auger rotates in the stir cycle. This stir

cycle only occurs in “Sleep 1 Mode”.

Sl1DrOff (sec)

Adjustments to this setting affect the time between

stir cycles. The stir cycle only occurs in “Sleep 1

Mode”.

Sl2CutIn (°F)

Changing this setting affects the temperature at

which the freezing cycle starts in “Sleep 2 Mode”.

Sl2CtOut (°F)

Changing this setting affects the temperature at

which the freezing cycle stops in “Sleep 2 Mode”.

DftOffTm (sec)

In “Serve Mode”, this value determines the

maximum time without a freezing cycle. If this

value is met, a freezing cycle will start. In the event

of a freezing cylinder temperature sensor failure,

this value affects the amount of time between

freezing cycles during “Serve Mode”.

Refriger

This setting changes how the control handles

the storage refrigeration cycle. The setting for

the E111 & F111 is 1 Hopper.

HprCutIn (°F)

This setting determines the temperature at which

the hopper refrigeration cycle starts. This setting

is only available on the left control.

HprCtOut (°F)

This setting determines the temperature at which

the hopper refrigeration cycle stops. This setting

is only available on the left control..

Hpr Off (min)

If the temperature sensor in the hopper fails,

this setting determines the time between hopper

refrigeration cycles. This setting is only available

on the left control..

Hpr On (sec)

If the temperature sensor in the hopper fails,

this setting determines the length of the hopper

refrigeration cycle. This setting is only available

on the left control..

4.8 DRIVE BELT TENSION ADJUSTMENT

(SERVICE PERSONNEL ONLY)

To check belt tension, refer to Figure 4-3 and follow the

steps below:

WARNING

Hazardous voltage

The Main Freezer Power switch must be placed in

the OFF position when disassembling for servicing.

The machine must be disconnected from electrical

supply before removing any access panel. Failure

to disconnect power before servicing could result

in death or serious injury.

WARNING

Pinch point

Moving parts can crush or cut. Keep hands clear of

belt and pulleys. Follow proper lockout procedures

before servicing.

A. Remove the back panel.

B. Use a Burroughs Belt Tension Gauge to set the

tension for the drive belt. Set the belt tension to

the following:

E111: 30-40 lbs.

F111: 15-25 lbs.

C. If an adjustment is necessary, loosen the four

motor plate retaining nuts, adjust belt tension

then retighten the four nuts.

D. Using a straightedge, check that the drive motor

pulley is aligned with the speed reducer pulley.

Align the pulley if necessary.

NOTE

Belt life will be increased if new drive belts are

tightened after two or three weeks of operation.

Belt Tension

Adjustment Nut

Figure 4-3 Belt Tension Adjustment

Owner’s Manual #513632-5 Rev.1 19 E111I/F111I Model Machines

Page 26

4.9 CONDENSER CLEANING

The air-cooled condenser is a copper tube and aluminum

fi n type. Condensing is totally dependent upon airfl ow .

A plugged condenser fi lter, condenser, or restrictions in

the louvered panel will restrict airfl ow. This will lower the

capacity of the system and damage the compressor. The

condenser must be kept clean of dirt and grease. The

machine must have a minimum of 3” (7.5 cm) of ventilation on the right and left sides of the unit for free fl ow of

air. Make sure the machine is not pulling over 100° F (37°

C) air from other equipment in the area.

The water-cooled condenser is a tube and shell type. The

condenser needs a cool, clean supply of water to properly

cool the machine, inlet and discharge lines must be 3/8”

I.D. minimum.

The condenser and condenser fi lter require periodic clean-

ing. To clean, refer to the following procedures.

1. Remove the right side panel and the rear panel.

2. T o remove the condenser fi lter, grasp the top and

pull off. Visually inspect for dirt. If the fi lter is dirty,

shake or brush excess dirt off the fi lter and wash

in warm, soapy water. Once the fi lter is clean rinse

thoroughly in warm, clear water and shake dry,

taking care not to damage the fi lter in any way.

3. Visually inspect the condenser for dirt by shining

a light through the coil from the back (inside) of

the condenser.

4. If the condenser is dirty, place a wet towel over

the outside of the condenser.

5. Using compressed air or a CO2 tank, blow out

the dirt from the inside of the condenser. Most of

the dirt will cling to the wet towel.

NOTE

If the condenser is not kept clean, refrigeration effi ciency will be lost.

4.10 PREVENTATIVE MAINTENANCE

It is recommended that a preventative maintenance

schedule be followed to keep the machine clean and

operating properly . The following steps are suggested as

a preventative maintenance guide.

The United States Department of Agriculture and the Food

and Drug Administration require that lubricants used in

food zones be certifi ed for this use. Use lubricants only in

accordance with the manufacturer’s instructions.

A. Daily checks

Check for any unusual noise or condition and

repair immediately.

Inspect for worn or broken parts and replace

as necessary. Check the wear line on the auger

fl ights and replace as needed.

B. Monthly checks

Check the condenser fi lter for dirt. (Refer to section

4.9).

C. Quarterly Checks

Check drive belts for wear and tighten belts if

necessary. (Refer to section 4.8)

4.11 EXTENDED STORAGE

Refer to the following steps for storage of the machine

over any long period of shutdown time:

A. Clean thoroughly with warm detergent all parts

that come in contact with mix. Rinse in clear water

and dry all parts. Do not sanitize.

NOTE

Do not let cleaning solution stand in machine barrel

or mix pump during the shutdown period.

B. Remove, disassemble, and clean the front door,

and auger shaft. Leave disassembled during the

shutdown period.

C. Place the auger fl ights and auger support bushing

in a plastic bag with a moist paper towel. This will

prevent them from becoming brittle if exposed to

dry air over an extended period of time (over 30

days).

D. For water-cooled machines that are left in unheated

buildings, or buildings subject to freezing, the water

must be shut off and disconnected. Disconnect

the water inlet fi tting. The fi tting is located at the

rear of the machine. Run the compressor for 2 - 3

minutes to open water valve (the front door must

be attached for the compressor to run). Blow

out all water through water inlet. Drain the water

supply line coming to the machine. Disconnect

the water outlet fi tting.

E. Place the Main Freezer Power OFF/ON switch

in the OFF position.

F. Disconnect the machine from the source of

electrical supply.

Owner’s Manual #513632-5 Rev.1 20 E111I/F111I Model Machines

Page 27

SECTION 5

TROUBLESHOOTING

5.1 ERROR CODES

When the machine experiences a problem, one of the

following error codes will be displayed on the control

panel. Each error code directs you to the system location

of the malfunction.

ERROR CODE MALFUNCTION

1 Soft

2 High Torque

3 Run Time

4 Clean

5 Freezing Cylinder Sensor

6 Hopper Sensor (single hopper machines)

7 Drive Motor

8 Cab Sensor

9 High Pressure Cutout

10 Auxiliary Sensor

11 Low Temperature

12 Left Hopper Sensor

13 Right Hopper Sensor

To return the machine to normal operation, any error

causing condition must be corrected and the Freezing

Cylinder Off-On switch must be placed in the Off position

and back in the On position before the affected side of

the machine will return to normal operation.

5.2 TROUBLESHOOTING

Error Code 1 - Soft Error

The Soft Error (E1) is an internal control board error

that is logged for future analysis. The refrigeration

is never stopped and the machine will continue

to operate normally.

Error Code 2 - High Torque

If the control panel displays a High Torque Error

(E2), the controller has sensed that the drive motor

is running at a high load for 10 or more seconds.

This may be due to the product consistency

adjustment being set too high. Place the Main

Power OFF/ON switch in the OFF position, wait

until the product in the freezing cylinder thaws

and return the switch to the ON position. Follow

the instructions in Section 3 to reduce the product

consistency by a few levels. If the error persists,

contact your Authorized Stoelting Distributor for

further assistance.

Error Code 3 - Run Time

The Run Time Error (E3) occurs when the

compressor runs continuously for an extended

period or if the product does not reach proper

temperature in “Sleep 2 Mode”. This error is

generally caused by very low mix levels in the

machine’s hopper or from product breakdown.

Another common cause results from a restriction

preventing mix from entering the freezing cylinder.

Check the mix in the hopper. If the level mix is

low, add mix. If there is a possibility that the mix

has broken down, clean and sanitize the machine

and replace the mix with fresh product.

Ice crystals in the hopper can clog the mix inlet

system and prevent mix from entering the freezing

cylinder. Thoroughly thaw mix per manufacturer’s

recommendations. T o check for ice crystals, pour

a small amount of product from the mix container

through a clean and sanitized sieve or strainer.

If ice crystals are in the mix, check temperature

of the walk-in cooler where the mix is stored.

In air cooled machines, the Run T ime Error may

indicate that airfl ow within the machine has

reduced or stopped. Check the sides and top

of the machine for anything that would restrict

airfl ow.

If the error persists after attempting to clear it,

contact your Authorized Stoelting Distributor for

further assistance.

Error Code 4 - Clean

If the machine is left in the Clean Mode for more

than 20 minutes, the control panel will display a

Clean Error (E4). This condition does not refl ect a

problem with the machine itself. The Clean Error

has been programmed into the controller as a

safeguard to protect the machine from potential

damage caused by the machine being accidentally

left in "Clean Mode". The control will attempt

to restart itself after 5 minutes. The display will

then fl ash and read Restart. To clear the Clean

Error, turn the Freezing Cylinder Off-On switch

Off and back On. After restarting the machine,

a refrigeration cycle will begin. This protects the

product in case the clean button was pressed by

mistake.

Owner’s Manual #513532-5 Rev.1 21 E111I/F111I Model Machines

Page 28

Error Code 5 - Freezing Cylinder Sensor

The Freezing Cylinder Sensor Error (E5) indicates

a failure of the barrel sensor or that the sensor

is out of range. If the control panel displays an

E5, place the Freezing Cylinder Off-On switch

Off and back On. If the error persists, contact

your Authorized Stoelting Distributor for further

assistance.

NOTE

When the machine encounters a Freezing Cylinder

Sensor Error, the machine will continue to run using

preset timers. This mode will allow the operator to

continue serving product until the machine can be

serviced.

Error Code 6 - Hopper Sensor (single hopper machines)

The Hopper Sensor Error (E6) indicates a failure

of the hopper sensor or that the sensor is out of

range. If the control panel displays an E6, turn

the left Main Power Off-On switch Off and back

On. If the error persists, contact your Authorized

Stoelting Distributor for further assistance.

Error Code 7 - Drive Motor

If the control panel displays a Drive Motor Error

(E7), the control does not sense current coming

from the drive motor. T urn the Freezing Cylinder

Off-On switch Off and back On. If the error persists,

contact your Authorized Stoelting Distributor for

further assistance.

Error Code 8 - Cab Sensor

A Cab Sensor Error (E8) will not occur on the

machine.

Error Code 9 - High Pressure Cutout

High Pressure Cutout Errors (E9) are usually

caused by a dirty or ineffi cient condenser. If the

control panel displays an E9 on an air cooled

machine, check for proper air clearance around

the machine. If the error persists, contact your

Authorized Stoelting Distributor for further

assistance.

Error Code 10 - Auxiliary Sensor

An Auxiliary Temperature Sensor Error (E10)

occurs if the temperature sensor on the control

board fails. Turn the Freezing Cylinder Off-On

switch Off and back On. If the error persists,

contact your Authorized Stoelting Distributor for

further assistance

Error Code 11 - Low Temperature

The Low Temperature Error (E11) occurs when

the temperature of the gas refrigerant at the barrel

sensor falls below -20°F. Although the machine

will not shut down, the active freezing cycle

will immediately end. This error usually occurs

when the machine continues to run in a low mix

condition or if the machine runs out of mix. The

product towards the front of the barrel tends to

freeze solid.

Error Code 12 - Left Hopper Sensor

The Left Hopper Sensor Error (E12) will not occur

on the machine.

Error Code 13 - Right Hopper Sensor

The Right Hopper Sensor Error (E13) will not

occur on the machine.

Alternating Flashing Control Panel Lights

The display panel lights will fl ash in an alternating

sequence under any error codes. Clear the error

and place the Freezing Cylinder Off-On switch in

the Off position and back in the On position.

Owner’s Manual #513532-5 Rev.1 22 E111I/F111I Model Machines

Page 29

5.3 TROUBLESHOOTING - MACHINE

PROBLEM POSSIBLE CAUSE REMEDY

Machine does not

run.

Machine will not

shut off.

Product is too fi rm.

Product is too soft.

Product does not

dispense.

Drive belt slipping

or squealing.

Rear auger seal

leaks.

Front door leaks.

1 Power to machine is off. 1 Supply power to machine.

2 Freeze-up (auger will not turn). 2 Turn machine off for 15 minutes, then restart.

3 Front door not in place. 3 Assemble front door in place.

1 Drive belt failure. 1 Replace drive belt.

2 CutOut setting too high 2 Adjust the CutOut (See Section 4)

3 Refrigeration problem. 3 Check system. (Call distributor for service)

1 CutOut setting too high 1 Adjust the CutOut (See Section 3)

1 No vent space for free fl ow of cooling

air.

2 Condenser is dirty. 2 Clean the condenser. (See Section 4)

3 CutOut setting too low 3 Adjust the CutOut (See Section 4)

4 Auger is assembled incorrectly. 4 Remove mix, clean, reassemble, sanitize and

5 Refrigeration problem. 5 Check system. (Call distributor for service)

1 No mix in hopper. 1 Add mix to the hopper.

2 Drive motor overload tripped. 2 Wait for automatic reset. (If condition

3 Drive belt failure. 3 Replace drive belt.

4 Freeze-up (Auger will not turn). 4 Turn machine off for 15 minutes, then restart.

1 Worn drive belt. 1 Replace drive belt.

2 Freeze-up (Auger will not turn). 2 Turn machine off for 15 minutes, then restart.

3 Not tensioned properly. 3 Adjust belt tension

1 Outside surface of rear auger seal is

lubricated.

2 Rear seal missing or damaged. 2 Check or replace.

3 Seal o-ring missing, damaged or

installed incorrectly.

4 Worn or scratched auger shaft. 4 Replace auger shaft.

1 Front door knobs are loose. 1 Tighten knobs.

2 Spigot parts are not lubricated. 2 See Section 3.

3 Chipped or worn spigot o-rings. 3 Replace o-rings.

4 O-rings or spigot installed wrong. 4 Remove spigot and check o-ring.

5 Inner spigot hole in front door nicked

or scratched.

1 A minimum of 3” of air space on the sides.

(See Section 2)

freeze down.

continues, call distributor for service.)

1 Clean lubricant from outside of rear seal and

thoroughly clean rear of freezing cylinder.

Lubricate inside of seal and reinstall.

3 Check or replace.

5 Replace front door.

Owner’s Manual #513532-5 Rev.1 23 E111I/F111I Model Machines

Page 30

Owner’s Manual #513532-5 Rev.1 24 E111I/F111I Model Machines

Page 31

6.1 DECALS AND LUBRICATION

Part Description Quantity

208135 Brush - 4” X 8” X 16” (Barrel) 1

208380 Brush - 1/4” X 3” X 14” 1

208401 Brush - 1” X 3” X 10” 1

208467 Brush - 3/8” X 1” X 5” 1

236040 Card - Cleaning Instruction 1

324065 Decal - Water Inlet 1

324105 Decal - Caution Electrical Shock 1

324106 Decal - Caution Electrical Wiring Materials 1

324107 Decal - Caution Hazardous Moving Parts 1

324141 Decal - Caution Rotating Blades 1

324208 Decal - Attention Refrigerant Leak Check 1

324509 Decal - Cleaning Instructions 1

324566 Decal - Wired According To 1

324584 Decal - Adequate Ventilation 3” 1

324594 Decal - Attention Heat Sensitive 1

324612 Decal - Control 1

324686 Decal - Danger Automatic Start 1

324803 Decal - Domed Stoelting Logo (Large) (Header Panel) 1

324804 Decal - Domed Stoelting Swirl (Header Panel) 1

324806 Decal - Domed A & W Logo (Header Panel) 1

324825 Decal - Main Freezer Power 1

368140 Filter - Air (Condenser) 1

396240 Gasket - Freezer Base 1

508048 Lubricant - Spline (2 oz Squeeze Tube) 1

508135 Petrol Gel - 4 oz Tube 1

1159584 Mix Out Audible Signal Kit 2177917 Brush Kit -

SECTION 6

REPLACEMENT PARTS

Owner’s Manual #513532-5 Rev.1 25 E111I/F111I Model Machines

Page 32

6.2 AUGER SHAFT AND FACEPLATE PARTS

666786

381804

2187812

624598-5

482019

3170644

2177698

625133

694255

149003

624678-5

E111 - 4157952

F111 - 4157968

Quantity

Part Description E111 F111

149003 Bushing - Front Auger Support 1 1

381804 Auger Flight 3 4

482019 Knob - Front Door (Black) 2 2

624598-5 O-Ring - Spigot Body - Black (5 Pack) 2 2

624678-5 O-Ring - Rear Seal - Black (5 Pack) 1 1

625133 O-Ring - Front Door - Red 1 1

666786 Seal - Rear Auger - Black 1 1

694255 Spring - Auger Flight 3 4

2177698 Door w/Pins 1 1

2187812 Spigot Body 1 1

3170644 Support - Front Auger 1 1

4157952 Auger Shaft 1

4157968 Auger Shaft 1

Owner’s Manual #513532-5 Rev.1 26 E111I/F111I Model Machines

Page 33

6.2 HOPPER COVERS & TRAYS

744606

314452

744284

624677-5

2149238

744283-SV

Quantity

Part Description E111 F111

232734 Cap - Rosette 1 1

314452 Cover - Hopper 1 1

624677-5 O-Ring - Mix Inlet - Black (5 Pack) 2 2

744283-SV Tray - Drip 1 1

744284 Insert - Drip Tray 1 1

744606 Tray - Drain (Black Plastic) 1 1

2149238 Mix Inlet Assembly - 3/16” Hole - Standard Length (3A) 1 1

232734

Owner’s Manual #513532-5 Rev.1 27 E111I/F111I Model Machines

Page 34

Owner’s Manual #513532-5 Rev.1 28 E111I/F111I Model Machines

Page 35

WARRANTY

SOFT SERVE / SHAKE FREEZERS

1. Scope:

Stoelting, LLC warrants to the first user (the “Buyer”) that the freezer cylinders, hoppers, compressors, drive

motors, speed reducers, augers and auger flights of Stoelting soft serve / shake freezers will be free from defects

in materials and workmanship under normal use and proper maintenance appearing within five (5) years, and that

all other components of such equipment manufactured by Stoelting will be free from defects in material and

workmanship under normal use and proper maintenance appearing within twelve (12) months after the date that

such equipment is originally installed.

2. Disclaimer of Other Warranties:

THIS WARRANTY IS EXCLUSIVE; AND STOELTING HEREBY DISCLAIMS ANY