Page 1

Model 219 Mix Pump

OWNER’S MANUAL

Manual No. 1134067-4 Dec., 2005

Page 2

Page 3

Need Parts or Service?

We stock the parts you need.

Our Technicians are factory

trained and are certified in the

Stoelting Technicare program.

CALL

Distributor: _________________________

Phone No.: _________________________

(fill in or affix label)

Model No.: _______________________

Serial No.: _______________________

Purchase Date: ____________________

Start-Up Date:____________________

Page 4

Page 5

STOELTING OWNER'S MANUAL

FOR MODEL 219

STOELTING MIX PUMP HOPPER OR

REMOTE INSTALLATIONS

This manual provides basic information about the hopper and remote installed mix pump and its

components. Instructions and suggestions are given covering its operation and care.

The illustrations and specifications are not binding in detail. We reserve the right to make changes

at any time without notice to the mix pump or components without incurring any obligation to equip

same on mix pump built prior to date of change.

DO NOT ATTEMPT to operate the mix pump until instructions and safety precautions in this manual

are read completely and are thoroughly understood. The mix pump should be operated only by

qualified personnel. If problems develop or questions arise in connection with installation, operation

or servicing of the mix pump, contact your local distributor or the company at the following location:

Stoelting, LLC Tele: 920-894-2293

502 Hwy. 67

Kiel, WI 53042-1600 Fax: 920-894-7029

Page 6

Page 7

TABLE OF CONTENTS

Section Description Page

1 INTRODUCTION .................................................................................................. 1

1.1 Description ........................................................................................................... 1

1.2 Specifications ....................................................................................................... 1

2 INSTALLATION INSTRUCTIONS ........................................................................ 3

2.1 Shipment and Transit (Remote Models) ................................................................3

2.2 National Sanitation Foundation Compliance

Requirements (Remote Pump).............................................................................. 3

2.3 Installation (Remote Models) ................................................................................ 4

2.4 Mix Pump Check Out ........................................................................................... 4

3 OPERATING INSTRUCTIONS ............................................................................. 5

3.1 Safety Precautions ............................................................................................... 5

3.2 Pump Motor Switch .............................................................................................. 5

3.3 Sanitizing Procedures .......................................................................................... 6

3.4 Operation of Mix Pump ......................................................................................... 6

3.5 Cleaning ............................................................................................................... 7

3.6 Disassembly of Mix Pump .................................................................................... 8

3.7 Assembly of Mix Pump ........................................................................................10

3.8 “O” Ring Removal and Care ..................................................................................11

4 MAINTENANCE INSTRUCTIONS ........................................................................13

4.1 Over-Run Adjustment ............................................................................................ 13

4.2 Pressure Control Switch ....................................................................................... 14

4.3 Preventive Maintenance ........................................................................................14

5 TROUBLESHOOTING .......................................................................................... 17

5.1 Pump Motor Does Not Run................................................................................... 17

5.2 Pump Operates But Cylinder Will Not Fill .............................................................17

5.3 Low Over-Run .......................................................................................................17

6 REPLACEMENT PARTS INFORMATION ............................................................ 19

6.1 How To Order Replacement Parts ........................................................................ 19

6.2 Parts List & Reference Drawings .......................................................................... 19

6.3 Hopper Pump Final Assembly .............................................................................. 20

6.4 Mix Pump Parts ...................................................................................................22

6.5 Remote Pump Final Assembly .............................................................................23

6.6 Pump Drive Assembly ..........................................................................................25

WARRANTY

Page 8

LIST OF ILLUSTRA TIONS

Figure Description Page

1 Model 219-02 Mix Pump.................................................................................................... 1

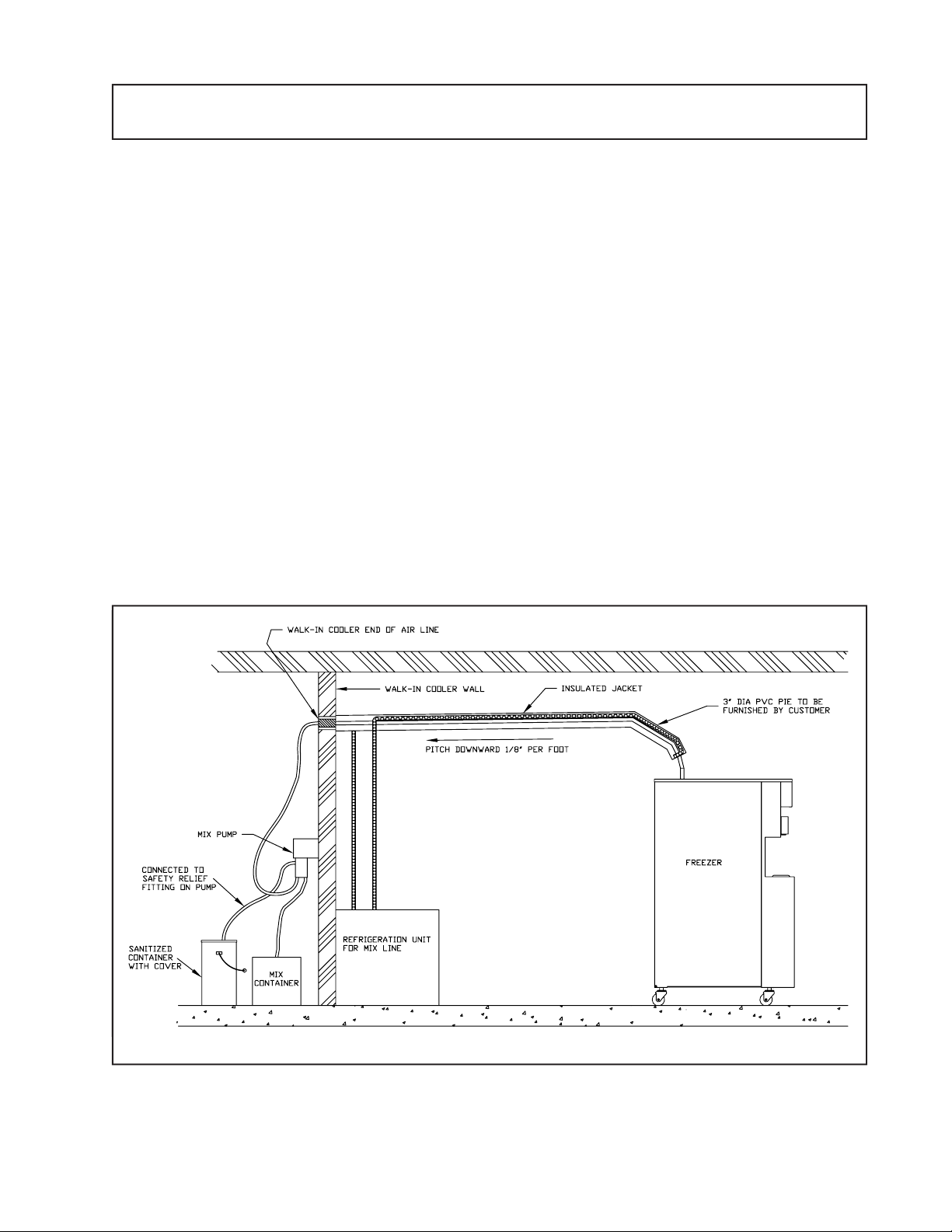

2 Refrigerated Mix Transfer Line ........................................................................................... 3

3 Pump Controls ..................................................................................................................5

4 Pump Operation ................................................................................................................ 7

5 Pump Assembly Removal.................................................................................................. 8

6 Manifold Disassembly ....................................................................................................... 8

7 Pump Disassembly Step One ........................................................................................... 9

8 Pump Disassembly Step Two ............................................................................................ 9

9 Pump Disassembly Step Three ......................................................................................... 9

10 Pump Disassembly Step Four ........................................................................................... 9

11 Mix Pump Assembly ......................................................................................................... 10

12 Removing “O” Rings ........................................................................................................... 11

13 “O”- Ring Identification ....................................................................................................... 12

14 Over-Run Adjustment ......................................................................................................... 13

15 Pressure Gauge ................................................................................................................ 14

16 Hopper Pump Final Assembly ........................................................................................... 20

17 Mix Pump Parts ................................................................................................................ 21

18 Remote Pump Final Assembly .......................................................................................... 23

19 Pump Drive Assembly ....................................................................................................... 24

Page 9

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

The Model 219 Stoelting® Mix Pump, is a high capacity

pump that will pump 45 gallons of mix per hour. The pump

is easy to clean, assemble, and operate. The pump

features a built-in pressure relief valve to prevent excessive

pressure build up in the freezer cylinder and mix lines.

The same pump (with minor variations) is used for both

hopper or remote model freezers. The instructions in this

manual will apply to both the hopper and remote types.

1.2 SPECIFICATIONS

DIMENSIONS

Height 13” (33 cm)

Width 9” (22.86 cm)

Length 13-1/2” (34.29 cm)

WEIGHT

22 lbs. (9.98 kg)

ELECTRICAL (Remote)

115v, 60 Hz: @ .74 Amps

(220V, 50 Hz is available)

TUBING SIZE REQUIRED (Remote)

1/2” (1.27 cm) I.D.

3/4” (1.90 cm) I.D.

Figure 1. Model 219-02 Mix Pump

1

Page 10

2

Page 11

SECTION 2

INTRODUCTION

2.1 SHIPMENT AND TRUST (REMOTE

MODELS)

The mix pump has been completely assembled, operated

and inspected at the factory. Upon arrival at the final

destination, the mix pump must be checked for any

damage that may have occurred during transit.

The mix pump should arrive in satisfactory condition.

THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE

IN TRANSIT, WHETHER VISIBLE OR CONCEALED.

Do not pay the freight bill until you have checked the

equipment. Have the carrier note any visible damage

on the freight bill. If concealed damage and/or shortage

is found later, advise the carrier inspector within 10

days and request inspection. The customer must place

claim for damages and/or shortages in shipment with

the carrier. Stoelting, Inc. cannot make any claims

against the carrier.

2.2 NATIONAL SANITATION

FOUNDATION COMPLIANCE

REQ’S (REMOTE PUMP)

In order to comply with “National Sanitation Testing

Laboratory, Inc.” (NSF) code #6:

A. This unit (remote pump) must be installed with

a “NSF” listed refrigerated mix transfer line.

The mix transfer line must be pitched to cooler,

with no sags or low points, to allow complete

drainage. (See fig. 2.)

B. The product at the mix pump and in transfer line

must be maintained below 45°F (7.22°C)

Figure 2. Refrigerated Mix Transfer Line

3

Page 12

2.3 INSTALLATION

2.4 MIX PUMP CHECK OUT

Typical Remote Pump Installation

The hopper mix pump is completely installed on the

freezer. The remote mix pump is designed for mounting

in a walk-in cooler. Select a location that is close to the

soft serve freezer and a grounded 115 volt (220 volt if

50 hertz) receptacle. The mix pump should not be

located near heavy traffic or in a congested area. Refer

to Figure 2 and the following steps:

REMOTE MODELS INSTALLATION

A. Install the mix pump in an upright position on the

wall. Allow clearance for a mix can under pump.

Mount by bolting bracket to wall using 1/4 inch

(64cm) diameter lag bolts of sufficient length to hold

securely.

B. Connect 5/8 inch (1.60 cm) I.D. plastic food grade

tubing between pump cylinder (inlet) and mix

container.

C. Connect 1/2 inch (1.27 cm) plastic food grade tubing

between pump body mix transfer tube (outlet) and

refrigerated mix transfer line. Secure with No. 26

hose clamp or equivalent.

The mix pump has been thoroughly cleaned and properly

lubricated at the factory. Before using, the mix pump

should be disassembled. This is necessary to remove

any foreign materials and to familiarize operators with

the correct assembly procedures.

A. The over-run adjustment is preset at the factory. If

an adjustment becomes necessary, refer to Section

4.1.

B. The pump pressure is preset at the factory. If an

adjustment becomes necessary, refer to Section 4.2.

C. On remote pumps, check for air leaks by placing

the suction line into three gallons of cold water. Place

the freezer switches in the OFF position. Close the

spigot and freezer air vents. Place mix pump switch

in the ON position and allow the system pressure to

build up and pump to shut OFF automatically. Leave

pump on for ten minutes. During this time do not

open spigot or freezer air vent s. If pump does not

automatically start again during this period, the

system is free of leaks. If the pump does start, there

is a leak in the system. Locate leak by applying a

liquid detergent or bubbles solution with a small

brush to all tubing connections and “O”-ring seals.

Correct as required.

D. Connect 1/2 inch (1.27 cm) plastic food grade tubing

between safety relief fitting to a separate pail or shot

can.

NOTE

This line allows mix to escape if the system

pressure should exceed 30 P.S.I.

E. Plug mix pump into a 115 volt grounded receptacle.

(Customer must provide plug for 220 volt, 50 hertz

remote pump.)

WARNING

TO MINIMIZE SHOCK HAZARD, THE REMOTE

MIX PUMP MUST BE PLUGGED INT O A

PROPERLY GROUNDED ELECTRICAL

RECEPTACLE WITHOUT THE USE OF A

GROUND ADAPTER PLUG.

4

Page 13

SECTION 3

OPERATION INSTRUCTIONS

3.1 SAFETY PRECAUTIONS

Do not attempt to operate the mix pump until the safety

precautions and operating instructions in the manual are

read completely and thoroughly understood.

Take notice of all warning labels on the mix pump. The

labels have been put there to help in maintaining a safe

working environment. The labels are designed to withstand

washing and cleaning. All labels must remain legible for

the life of the mix pump. Labels should be checked

periodically to be sure they have not been removed,

painted over, rubbed off, and can be recognized as

warning labels.

If replacement labels are needed, indicate the part

number, type of label, location of label, and quantity

required. Mail your name and address to:

F. Do not attempt to repair or perform maintenance on

the mix pump until the main electrical power has been

disconnected.

G. Do not operate the mix pump if unusual or excessive

noise or vibration occurs.

3.2 PUMP MOTOR SWITCH

The PUMP MOTOR switch (see Fig. 3) is located on the

mix pump assembly. When the pump motor switch is

placed in the ON position, the mix pump motor will be

actuated to pump mix into the freezer cylinder. When the

set pressure is reached, the mix pump will shut off

automatically. When the pump motor switch is placed in

the OFF position. The mix pump will be inoperative.

STOELTING, LLC

ATTENTION: CPG Customer Service

P.O. Box 127

Kiel, Wisconsin 53042-0127

Labels will be furnished and mailed at no charge.

SAFE OPERATION IS NO ACCIDENT; Observe these

rules:

A. Know the mix pump- read and understand the Owner’s

Manual.

B. Wear proper clothing - avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

C. Maintain a clean work area – avoid tripping or slipping

by cleaning up the area and keeping it clean.

The mix pump motor is equipped with an overload push

button reset switch (labeled “Drive Reset”) that will “kickout” when the motor is overloaded. Motor overloads can

be caused by several things including improper assembly

of the pump or worn parts causing binding, or electrical

probems. Pressing the reset button will return the motor

to normal operation if the overload condition is no longer

present. If the If the pump assembly seems to move freely

but the overload condition continues, contact a qualified

service person.

D. Stay alert at all times – know which switch, push

button or control you are about to use and what effect

it is going to have.

E. Turn all switches to OFF prior to making any

adjustments.

Figure 3. Pump Controls

5

Page 14

3.3 SANITIZING PROCEDURES

For sanitizing to be effective, it must be performed after

the mix pump and freezer parts have been cleaned, and

just prior to filling the hopper or storage container with

mix. Sanitizing the night before is not effective.

E. Place the freezer in the CLEAN mode (no

refrigeration).

F. After five minutes, open spigot to expel sanitizing

solution.

To sanitize, refer to local sanitary regulations for applicable

codes and recommended disinfecting products and

procedures. The frequency of cleaning must comply with

local health regulations. Use a solution containing 100

PPM of free available chlorine. Use “Stera-Sheen Green

Label Sanitizer and Cleaner”, or others in accordance

with Health Inspection Requirements.

NOTE

Stoelting, Inc. has found that STERA-SHEEN

GREEN LABEL SANITIZER AND CLEANER does

an effective job of properly sanitizing and cleaning

a soft serve freezer. We therefore include a sample

with each new freezer. For further information read

the directions on the packet. Other products may

be effective.

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MAY CAUSE CORROSION OF

STAINLESS STEEL PARTS.

G. Close the spigot and place the mix pump and freezer

switches in the OFF position.

The mix pump, connecting hoses and freezer are clean,

sanitized and ready for adding mix.

NOTE

Do not use brushes to clean hoses. Brushes can

cause scratches to interior of mix hose resulting

in areas that will harbor bacteria.

3.4 OPERATION OF MIX PUMP

This section describes the operation of the mix pump.

(See Fig. 4)

NOTE

The safety guard must be in place before the mix

pump will operate.

In general, sanitizing may be conducted as follows:

A. Prepare three gallons (11 liters) of sanitizing solution

following manufacturer’s instructions, and pour into

hopper (hopper models) or place pump suction

(inlet) line into solution (remote models).

B. Place the mix pump switch in the ON position. Allow

freezer to fill until pump stops.

C. Check for leaks when the freezer barrel is first

pressurized with sanitizing solution.

D. Clean the following parts using a sanitized soft bristle

brush or equivalent, dipped in sanitizing solution. On

remote models, clean exterior of pump and sides of

mix container. On hopper models, clean exterior of

pump, sides and under cover of hopper.

A. Sanitize just prior to use according to instructions in

Section 3.3.

B. Refer to freezer instruction manual for the operation

of the freezer.

C. Mix Operation:

1. Mix will enter pump thru mix inlet valve (A) on

position UP stroke.

2. On piston DOWN stroke, mix inlet (A) is forced

shut and mix is moved out thru mix outlet valve

(B) into the freezing chamber.

D. Air Operation:

1. Air enters pump thru air inlet check valve (C)

on piston DOWN stroke.

6

Page 15

2. On piston UP stroke, air inlet check valve (C) is

forced shut and air is moved out of air outlet

valve (D) into mix transfer tube bottom (F) and

into the freezing chamber.

E. Relief Valve Operation:

1. The relief valve (E) opens and releases pressure

if the pressure switch fails to shut off the pump

motor.

TO

PRESSURE

SWITCH

3.5 CLEANING

The mix pump must be cleaned when changing mix or

whenever the freezer is shut off for an extended period,

such as overnight or on nonbusiness days. For sanitary

reasons, mix must not be allowed to remain in the freezer

lines or mix pump when the freezer is not in operation.

NOTE

Refer to the freezer manual for freezer cleaning

procedures.

A. On remote models, remove suction tubing from the

mix container. Draw off all or most of the mix remaining

in the freezer barrel.

CYLINDER

TOP

QUAD

RING

CYLINDER

“O” RING

SEAT

AIR

INLET

MIX

TRANSFER

TUBE TOP

B. Pump 3 gallons (11 liters) of cold potable water thru

freezer until water at spigot is free of mix.

C. Pump 3 gallons (11 liters) of warm detergent solution

water thru freezer . The use of sof t water is

recommended along with dishwashing detergents

such as “Joy”, “Dawn”, or equivalent.

D. Place mix pump switch in OFF position.

E. Disassemble pump parts. (See Section 3.6.) Then

place all parts in warm, mild detergent water and wash

thoroughly using brushes provided. Again, the use of

soft water is recommended along with dishwashing

detergents such as “Joy”, “Dawn”, or equivalent. Rinse

all parts with clean hot water.

NOTE

If the mix lines or air lines are difficult to remove,

soften with hot water or a rag soaked in hot water.

Hose connections may be sprayed with Haynes

Sanitary Lubricant for ease of removal.

AIR

MIX

AIR & MIX

MIX

INLET

Figure 4. Pump Operation

AIR & MIX

OUTLET

F. Use a sanitizing solution of 100 parts per million to

sanitize the parts before assembly. Use “Stera-Sheen

Green Label Sanitizer and Cleaner”, or others in

accordance with Health Inspection Requirements.

G. Place all parts in the sanitizing solution for 5 minutes,

then remove and let air dry.

7

Page 16

CLEANING MIX LINES

The mix lines must be cleaned and sanitized whenever

changing mix or whenever the freezer is off for an

extended period of time – such as overnight, or nonbusiness

days. The mix lines are sufficiently cleaned and sanitized

when cleaning and sanitizing the pump and freezer as an

assembly.

Once every 2 weeks, if required, perform the following

steps:

A. Mix 2 gallons of milkstone remover solution according

to the directions on the container and pump through

the mix line.

B. Cut a piece of sponge slightly larger than the inside

diameter of the mix line. Place the sponge inside the

mix line and force through with tap water pressure. A

garden hose repair end clamped to the mix line works

well for this purpose.

3.6 DISASSEMBLY OF MIX PUMP

HOPPER MODEL: Remove liquid level indicator .

Remove the two wing nuts from the pressure switch

manifold retainer and remove the manifold (both

models).

C. Remove large hand nut (1), washers (2) and rear

hopper cover (3). (See Fig. 5)

SUCTION CUP

1

1

2

2

3

LEVEL

INDICATOR

CYLINDER

TOP

1

REMOTE

MODEL

Refer to your Owner’s Manual for detailed instructions on

proper freezer operation.

WARNING

THE MIX PUMP SWITCH MUST BE IN THE OFF

POSITION WHEN SERVICING OR CLEANING

PUMP.

A. Drain freezer according to freezer owner’s manual.

CAUTION

NEVER DISCONNECT HOSES FROM FREEZER

OR PUMP WITHOUT FIRST OPENING SPIGOT

TO RELIEVE PRESSURE.

B. REMOTE MODEL: Loosen hose clamps and remove

tubing from pressure relief valve. Remove suction

tubing from pump and mix bag. Remove discharge

tubing from bottom of pump. Remove drive pin by

pulling straight out.

Figure 5. Pump Assembly Removal

D. Remove quick connect (4) from manifold (5). Remove

two wing nuts (6), locking plate washer (7), and

manifold (5). Remove manifold connector O-ring (8)

from manifold (5), and manifold “O”-ring (9). Loosen

hose clamp (10) and remove hose (11). (See Fig.

6)

E. Remove two small hand nut(s) (12) and top lock plate

(13) from clamp rod (14). (See Fig. 7)

9

5

8

4

10

11

7

6

Figure 6. Manifold Disassembly

8

Page 17

12

13

17

18

19

20

24

26

14

Figure 7. Pump Disassembly Step One

F. Separate mix transfer tube (15) from cylinder (16).

(See Fig. 8)

15

16

22

21

Figure 9. Pump Disassembly Step Three

H. Remove two cylinder “O”-rings (27) from cylinder

body (28). Remove air inlet retainer (29) and air

inlet check valve (30) from cylinder top (31). Remove

cylinder top (31) from cylinder body (28), remove

“O”-ring (32) and piston quad ring (33) from cylinder

top (31). Remove piston shaft (34), and “O”-ring (35)

from piston shaft (34). Remove mix inlet valve (36)

from cylinder body (28), and remove “O”-ring (37)

from mix inlet valve (36). (See Fig. 10)

29

25

23

30

31

32

Figure 8. Pump Disassembly Step Two

G. Remove safety valve retainer (17), valve retainer “O”-

ring (18), spring (19) and safety valve (20). Remove

two air mix outlet valves (21) and two air mix outlet

springs (22). Remove mix transfer tube “O”-ring (23).

Separate air transfer tube top (24) from mix transfer

tube bottom (25). Remove cylinder “O”-ring (26).

(See Fig. 9)

33

34

35

12

37

28

Figure 10. Pump Disassembly Step

Four

9

36

27

12

Page 18

3.7 ASSEMBLY OF MIX PUMP

CAUTION

DO NOT FORCE PARTS, THEY FIT TOGETHER

EASILY WHEN PROPERLY INSTALLED.

Haynes sanitary lubricant or liquid equivalent must be

used to lubricate all “O”-rings, piston shaft and bore of

cylinder body.

29

30

31

GOOD

32

33

34

A. Place manifold “O”-ring (9) onto manifold (5) and

lubricate lightly. Place manifolds connector “O”-ring

(8) onto manifold (5) and lubricate. Place manifold

(5) into pressure switch. Position locking plate washer

(7) and secure with two wing nuts (6) finger tight.

Connect tubing (11) to quick connect (4) and tighten

hose clamp (10) finger tight. Connect quick connect

(4) to manifold (5). (See Fig. 6)

B. Install air inlet check valve (30) into cylinder top (31).

Do not lubricate. Install air inlet retainer (29) into air

inlet valve. Push into place. Check quad ring (33) for

excessive wear and replace if necessary . Spray a

thin film of lubricant in bottom of cylinder top (31).

NOTE

Quad ring must not be twisted.

Install quad ring (33) and rotate one full turn to improve

sealing. Place “O”-ring (35) onto piston shaft (34) and

“O”-ring (32) onto cylinder top (31). Spray a thin film

of lubricant onto the two “O”-rings, piston shaft and

cylinder walls. Position cylinder top (31) over piston

shaft (34). Place “O”-ring (37) onto mix inlet valve (36)

and insert inlet valve (36) into cylinder (28). Assemble

cylinder top (31) and piston (34) into cylinder (28)

and push piston fully down.

REPLACE

35

36

37

27

28

Figure 11. Mix Pump Assembly

C. Place “O”-ring (26) onto mix transfer tube bottom (25)

and lubricate. Place mix transfer tube bottom (25)

into air transfer tube top (24). (See Fig. 9)

On hopper models: place mix transfer tube “O”-ring

(23) onto bottom of mix transfer tube (25) and lubricate

lightly. Position small end of two air/mix outlet springs

(22) onto two air/mix outlet valves (21) and insert

into mix transfer tube. Place valve retainer “O”-ring

(18) onto valve retainer (17). Insert safety valve (20),

spring (19) and valve retainer (17) into top hole of

mix transfer tube. (See Fig. 9)

D. Holding valve retainer firmly in place with thumb and

forefingers, join mix transfer tube (15) to pump cylinder

(16) as shown. (See Fig. 8)

10

Page 19

E. Place top lock plate (13) and clamp rod (14) over

end of pump cylinder and mix transfer tube. Secure

with two hand nuts (12) and finger tighten.

(See Fig. 7)

lubricant on hose ends prior to installing tubing. Install

tubing onto pressure relief valve connection.

NOTE

IMPORTANT- Refer to paragraph 3.3 Sanitizing

Procedure prior to filling with mix.

F. On hopper models: position hopper rear cover over

assembled pump body. Assemble washer (2) and

large hand nut (1) onto top lock plate (3). Do not tighten

at this time. Place pump body with hopper cover into

hopper. Tilt pump forward and push toward rear of

hopper until discharge end of pump body engages

hopper outlet hole. Guide hopper rear cover under

pump drive bracket at the same time. Install suction

cup over pressure tube and connect tubing and tighten

hose clamp finger tight. Assemble liquid level indicator

by first installing “O”-ring into indicator cover and

lubricating lightly. Slide red float into adapter and install

indicator cover onto adapter. Place indicator into rear

hopper cover. (See Fig. 5)

On hopper and remote models: place pump body

under drive bracket. Slip top lock plate threaded shaft

into slot in pump drive bracket. Align top hole in piston

shaft with holes in drive clevis. Use drive pin to aid in

lifting and aligning piston shaft. When top hole in

piston shaft is aligned with hole in piston drive, insert

drive pin. Secure large hand nut (1) as tight as possible

with fingers. Install safety guard over pump drive and

secure with two black knobs. Interlock hopper front

cover with hopper rear cover. (See Fig. 5)

NOTE

The safety guard must be in place before mix

pump will operate.

3.8 O-RING REMOVAL AND CARE

Worn or damaged “O”-and “Quad” ring seals must be

replaced to ensure proper freezer operation. To prevent

undue damage to these seals, at least once a week be

sure to apply lubricant where required and avoid twisting

“O”-rings during assembly. Worn or damaged “O”-rings or

“O”-rings which are twisted after assembly will cause air

and/or mix leakage. Leaks will result in a low over-run

product.

To remove “O”-rings from parts for cleaning or servicing,

follow the steps below:

A. Remove all sanitary lubricant from “O”-ring using a

clean paper towel.

On remote models: install tubing onto suction and

discharge connections on bottom of pump and pump

body. Tighten hose clamp. For ease of removal, use

Figure 12. Removing “O”-Rings

B. Remove “O”-ring by squeezing upward as shown in

Figure 12. When a loop is formed, roll the “O”-ring

out of the “O”-ring groove.

CAUTION

DO NOT USE ANY TYPE OF SHARP OBJECT

TO REMOVE “O”-RING.

11

Page 20

Mix Inlet

Valve and Mix

Outlet Valve

(#624556-5)

Mix Transfer

Tube (Hopper)

(#624577-5)

Valve Retainer

(#624564-5)

Valve Stem

(#624520-5)

Cylinder (2)

and Mix

Transfer

Tube

(#624585-5)

Quad Ring

(#624594-5)

Manifold

(#624676-5)

Figure 13. “O”-Ring Identification (Actual Size)

(2) Cyl. Top

Piston Shaft

(#624776-5)

12

Page 21

SECTION 4

MAINTENANCE INSTRUCTIONS

4.1 OVER-RUN ADJUSTMENT

The product when served is a combination of air and

mix. Over-run is a measure of the amount of air blended

into the mix.

Over-run can be expressed in terms of the amount of

weight loss for a given volume. For example, if a pint of

liquid mix weighs 18 ounces and a pint of frozen product

with air added weighs 12 ounces, the over-run is said to

be 50 percent (18oz. – 12oz.= 6oz., (6÷ 12) x 100=

50%).

The over-run can be checked by placing a one pint

container on an ice cream scale and zeroing out the

scale. Then fill a one pint container with frozen product.

The container should be filled over the top and leveled

with a straightedge. The product should not contain any

air pockets. When weighed on an ice cream scale, one

pint of product should weigh 12 to 13 ounces.

The mix pump has been preset at the factory to produce

a product with approximately 40 percent over-run.

Because of differences in mix formulation, temperatures,

and barometric pressure, this figure may vary. A product

with the proper amount of over-run is firm and dispenses

at a smooth even rate. A product in which the over-run

is too low, is yellow, heavy, icy, hard or stiff, and

dispenses at a slow or pulsating rate. A product which

has small air pockets and dispenses smoothly, but with

an occasional popping as the product leaves the spigot,

has the over-run set too high. It will be necessary for

approximately two gallons of mix to be pumped thru the

freezer before changes in the product are noticeable

due to adjustments in over-run.

CAUTION

THE MIX PUMP SWITCH MUST BE IN THE OFF

POSITION WHEN SERVICING OR CLEANING

PUMP.

A. Remove two knobs and safety guard covering drive

mechanism.

B. The position of the stroke is adjusted by loosening

the jam nut (B) above the drive clevis (C) and then

turning the drive clevis up for a higher over-run.

CAUTION

THE DRIVE MECHANISM MUST BE

POSITIONED AT THE TOP OF THE STROKE.

THE TOP OF THE STROKE IS WHEN THE CAM

ROLLER IS IN ITS HIGHEST POSITION. PUMP

DAMAGE WOULD RESULT IF PISTON WERE

TO CONTACT CYLINDER TOP BEFORE

REACHING TOP OF STROKE. A 180 DEGREE

TURN OF THE CLEVIS IS APPROXIMATELY

AN OVER-RUN OF 2-1/2%.

CAM ROLLER

B

C

GUIDE RODS

A

DRIVE PIN

CYLINDER TOP

Over-run is controlled by the relative position of the

piston stroke within the pump cylinder. Raising the

stroke within the cylinder will increase over-run.

Conversely, lowering the stroke will decrease over-run.

To adjust the mix pump for a higher over-run, refer to

Figure 14, and follow the adjustment procedures below:

PISTON

Figure 14. Over-Run Adjustment

13

Page 22

To adjust the mix pump for a lower over-run, refer to

Figure 14, and follow the adjustment procedures below:

CAUTION

THE MIX PUMP SWITCH MUST BE IN THE OFF

POSITION WHEN SERVICING OR CLEANING

PUMP.

A. Remove two knobs and safety guard covering drive

mechanism.

CAUTION

THE DRIVE MECHANISM MUST BE

POSITIONED AT THE BOTTOM OF THE

STROKE.

Figure 15. Pressure Gauge

B. Connect electrical input power to the mix pump.

B. The position of the stroke is adjusted by loosening

the jam nut (B) above the drive clevis (C), and then

turning the drive clevis down for a lower over-run.

The drive clevis and yoke stud (A) must be engaged

by a minimum of four full threads.

4.2 PRESSURE CONTROL SWITCH

The pressure control switch control the pressure at

which the mix pump cuts in or out. This switch can not

be adjusted.

NOTE

Pressure gauge manifold accessory kit (Part No.

1156527) is available to check pressures.

CAUTION

DISCONNECT ELECTRICAL SUPPLY TO MIX

PUMP BEFORE SERVICING.

A. Install the pressure gauge kit into the pressure

switch. Figure 15.

C. The pressure check must be made with either water

or mix in the freezer cylinder.

D. Place the mix pump switch in the ON position and

check pressures.

4.3 PREVENTIVE MAINTENANCE

It is recommended that a preventive maintenance

schedule be followed to keep the mix pump clean and

operating properly. The following steps are suggested

as a preventive maintenance guide.

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM

MAINTENANCE ON MIX PUMP UNTIL ALL

MAIN ELECTRICAL POWER HAS BEEN

DISCONNECTED.

The United States Department of Agriculture and the

Food and Drug Administration require that lubricants

used on food processing equipment be certified for this

use. Use lubricants only in accordance with the

manufacturer’s instructions.

14

Page 23

A. DAILY CHECK

1. Check for any unusual noise or condition and

repair immediately.

B. WEEKLY CHECK

CAUTION

THE MIX PUMP SWITCH MUST BE IN THE OFF

POSITION WHEN SERVICING OR CLEANING

PUMP.

1. Clean and lubricate with liquid sanitary

lubricant or equivalent, the two guide rods on

the pump motor. Apply lubricant to rods with

fingers to eliminate spray accumulation on

other components. Remove the two knobs and

safety guard for access.

C. FOUR MONTH CHECK

1. Every four months, or as required, replace quad

ring in mix pump if worn, or low over-run will

result.

15

Page 24

16

Page 25

SECTION 5

TROUBLESHOOTING

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM MAINTENANCE ON MIX PUMP UNTIL THE MAIN

ELECTRICAL POWER HAS BEEN DISCONNECTED.

5.1 PUMP MOTOR DOES NOT RUN

Cause Correction

Plastic guard is not in place. ............................................ Install plastic guard.

Power to pump is off. ....................................................... Supply power to pump.

Low voltage. .................................................................... Check for low voltage.

Pump motor overloaded. ................................................... Press “Drive Reset” button.

Guide rods on pump are sticky. ....................................... Clean and lubricate. (Refer to Section 4.3B)

Frozen mix particles in liquid mix. .................................... Remove frozen mix.

Pressure switch on pump is defective. ............................. Check continuity of pressure switch. Replace.

Defective starter relay (motor buzzing). ............................ Replace starter relay. (On older models.)

Defective motor. ............................................................... Check motor amperage draw. Replace motor.

Defective toggle switch..................................................... Check continuity, repair or replace.

Defective safety switch..................................................... Check continuity, repair or replace.

Broken wire or loose connection. ...................................... Locate and replace or repair.

5.2 PUMP OPERATES BUT CYLINDER WILL NOT FILL

Cause Correction

Frozen mix particles in liquid mix. ................................... Thaw, remove frozen mix.

Foreign object blocking operation or pump. .................... Disassemble pump and clear blockage.

Mix inlet valve is stuck or “O”-ring defective. ................... Disassemble pump and check mix inlet valve and “O”-

ring.

Mix outlet valve “O”-ring is defective. .............................. Disassemble pump and check “O”-ring.

5.3 LOW OVER-RUN

Cause Correction

Foreign object blocking operation of pump. .................... Disassemble pump and clear blockage.

Air inlet check valve or retainer ....................................... Disassemble pump and check air inlet

stuck or restricting air flow. check valve and retainer.

Air outlet valve is stuck or “O”-ring .................................. Disassemble pump, check air outlet valve

is defective. and “O”-ring.

Pump quad ring is worn out. ............................................ Replace quad ring.

In the event the above Troubleshooting Guide does not help to correct the problem, the local dealer, distributor

of the factory Service Department should be contacted.

17

Page 26

18

Page 27

SECTION 6

REPLACEMENT PARTS INFORMATION

6.1 HOW TO ORDER REPLACEMENT

PARTS

To assure the receipt of the proper replacement parts,

supply your dealer, distributor or the company with the

following information:

A. Model number of equipment.

B. Serial number of Model. (Stamped on nameplate.)

C. Part number, part name, and quantity needed. Many

part names and numbers are listed in this manual.

NOTE

Minimum is $50.00.

6.2 PARTS LIST & REFERENCE

DRAWINGS

The following lists and drawings will aid the user when

ordering parts or servicing the mix pump. The parts

listed apply to both the hopper or remote pumps unless

noted otherwise.

19

Page 28

Figure 16. Hopper Pump Final Assembly

6.3. HOPPER PUMP FINAL ASSEMBLY

Ref. No. Part No. Description Qty.

1 4154611 ....................................Pump Drive ......................................... 1

2 3143083 ....................................Pump Body ......................................... 1

3 3147873 ....................................Safety Guard ...................................... 1

4 482004 ......................................Black Knobs ....................................... 2

5 3122813 ....................................Motor Mounting Plate ......................... 1

6 644106 ......................................Hex Cap Screw (1/4-20) ...................... 4

7 756190 ......................................Tubing ................................................ 1

8 264235 ......................................Hose Clamp ........................................ 2

9 324197 ......................................Wiring Diagram Decal ......................... 1

10 723530 ......................................Pressure Instruction Tag ..................... 1

11 538335 ...................................... Hex Nut (1/4-20) ................................ 4

12 2154670-01 ............................... Model I.D. Plate .................................. 1

20

Page 29

Figure 17. Mix Pump Parts

21

Page 30

6.4. MIX PUMP PARTS

Ref. No. Part No. Description Qty.

1 521185 ................................... Mix Transfer Tube Bottom (Hopper) ................ 1

521186 ................................... Mix Transfer Tube Bottom (Remote) ............... 1

2 3158258 .................................Mix Transfer Tube Top ...................................1

3 694247 ................................... Air/Mix Outlet Springs ...................................2

4 762256 ................................... Air/Mix Outlet Valves ....................................2

5 763041 ................................... Safety Valve ...................................................1

6 694635 ................................... Spring ............................................................ 1

7 2143080 .................................Valve Retainer ................................................ 1

8 600070 ................................... Pump Cylinder Body ......................................1

9 2107946 .................................Piston Shaft ...................................................1

10 2107950 .................................Mix Inlet Valve ...............................................1

11 3127452 .................................Cylinder Top ..................................................1

13 221548 ...................................Air Inlet Valve ................................................ 1

14 762274 ...................................Air Inlet Check Valve ......................................1

16 624776 ...................................“O”-Rings .......................................................2

17 624585 ...................................Transfer Tube “O”-Rings .................................3

18 624594 ...................................Piston Quad Ring ...........................................1

19 624556 ...................................“O”-Ring .........................................................1

20 624564 ...................................Valve Retainer “O”-Ring .................................. 1

21 2107959 .................................Large Hand Nut ............................................. 1

22 1115840 ................................. Small Hand Nuts ............................................2

23 2107955 ................................. Top Lock Plate ............................................... 1

24 264019 ...................................Clamp Rod .....................................................1

25 624577 ...................................Mix Transfer Tube “O”- Ring (Hopper) ............. 1

26 681511 ...................................Shield (Hopper) ..............................................1

27 1107958 .................................Flange Washer (Hopper) ................................. 1

28 2119012 ................................. Liquid Level Indicator (Hopper) ....................... 1

29 482004 ...................................Black Knob ....................................................2

30 3147873 .................................Safety Guard .................................................. 1

31 570967 ...................................Drive Pin ........................................................1

32 624676 ...................................“O”-Ring - Manifold ........................................1

33 513011 ...................................Manifold - Quick Connect ...............................1

34 1111815 .................................Locking Plate Washer ..................................... 1

35 539408 ...................................Wing Nuts ...................................................... 2

36 756190 ...................................Tubing ...........................................................1

37 264235 ...................................Hose Clamps ..................................................1

38 624545 ...................................“O”-Ring - Quick Connect Manifold.................

39 312406 ...................................Quick Connect Coupling .................................

2135520 ................................. “O”-Ring Kit ...................................................

2150861 ................................. O”-Ring & Small Parts Kit ...............................1

22

Page 31

6.5. REMOTE PUMP FINAL ASSEMBLY

Ref. No. Part No. Description Qty.

1 4154612-01 ...........................Pump Drive Remote ................................ 1

1A 4154611 ................................ Pump Drive Hopper ................................. 1

2 3143082 ................................ Pump Body Remote ................................. 1

2A 3143083 ................................ Pump Body Hopper ................................. 1

3 3147873 ................................ Safety Guard ........................................... 1

4 482004 .................................. Black Knobs ............................................ 2

5 3151630 ................................ Motor Mounting Plate – Remote ............... 1

6 644106 .................................. Hex Cap Screw (1/2-20) .......................... 4

7 756190 .................................. Tubing .................................................... 1

8 264235 .................................. Hose Clamp ............................................ 2

9 223162 .................................. Bushing .................................................. 1

10 430022 ..................................Electrical Cord ........................................ 1

12 324199 ..................................Wiring Diagram Decal ............................. 1

13 723530 ..................................Pressure Instruction Tag ......................... 1

14 324113 ..................................Grounding Decal ..................................... 1

15 723529 ..................................Grounding Instruction Tag ...................... 1

16 723526 ..................................Manual Instruction Tag ........................... 1

17 324023 ..................................N.S.F. Decal ............................................ 1

18 538335 ..................................Hex Nut (1/4-20) .................................... 4

19 2154670-02 ........................... Model I.D. Plate....................................... 1

20 739016 ..................................Tie Strap ................................................. 4

23

Page 32

Figure 19. Pump Drive Assembly

24

Page 33

6.6. PUMP DRIVE ASSEMBLY

Ref. No. Part No. Description Qty.

2154609-01 .................................... Gear Motor Ass’y. - Remote .........................................

1 2154610-01 ....................................Gear Motor Ass’y. – Hopper ......................................... 1

2 3136896 .......................................... Electrical Box ................................................................ 1

3 3153382 .......................................... Electrical Box Cover ..................................................... 1

4 1144438 .......................................... MTG Bracket (Safety Switch)........................................ 1

5 231041 ............................................Capacitor 7.5 MFD @ 440 VAC- V.W. Motor................. 1

6 718532 ............................................Toggle Switch S.P.S.T. ................................................. 1

7 324150 ............................................Decal – Pump Motor Switch ......................................... 1

* 394463 ............................................ Protector Circuit, 1.5A (* Not Shown) ........................... 1

8 717920-SV ...................................... Pressure Control Ass’y. ............................................... 1

9 513011 ............................................Manifold Assy-Pressure Control-Quick Connect ......... 1

10 1111815.......................................... Locking Plate Washer .................................................. 1

11 624676 ............................................ “O”-Ring Pressure Switch M anifold #513004 ............. 1

12 539408 ............................................ Wing Nut # 10-24 Stainless ......................................... 2

13 649000-23 ...................................... Screw, THD Forming –8-32 x 3/8 LG (S.S.) ................. 4

14 3151630.......................................... Motor Mtg. Plate ............................................................ 1

15 644115 ............................................ Hex HD. Cap Screw – ¼-20 x ¾ LG ............................. 4

16 538335 ............................................ Nut, Hex ¼-20 Locking Fl ange .................................... 4

17 M002468 ......................................... Sealant, Clear – G.E. Silicone ..................................... As Req’d

18 538296 ............................................ Hex Nut #10-24 ............................................................ 2

19 324105 ............................................ Decal – Danger – Elec. Shock Hazard ........................ 1

20 M820172 ......................................... Loctite 242 (Blue) ......................................................... As Req’d

21 647691 ............................................ Screw – 10-24 x ¾” LG ................................................. 3

22 538297 ............................................ Nut – 10-24 .................................................................. 4

23 766948 ............................................ Washer Shake Proof .................................................... 3

24 200023 ............................................ Capacitor Bracket ......................................................... 1

25 1170836-SV ....................................Switch, Safety – Cherry #E13-2L ................................. 1

26 2146015.......................................... Model Identification Plate ............................................. 1

27 647441 ............................................ Screw, Machine – 6-32 x 1” LG .................................... 2

28 766933 ............................................ Washer, Shake Proof #6 .............................................. 4

29 538265 ............................................ Nut, Hex #16-32 C.P. ................................................... 4

30 430292/430292A ............................Harness, Wire W./Terms. ............................................ 3

31 324148 ............................................ Decal – Attention – Plastic Guard ................................ 1

32 324023 ............................................ Decal – N.S.F. .............................................................. 4

33 3136897.......................................... Drive Bracket (Bison) ................................................... 1

34 644091 ............................................ Capscrew – ¼-20 x ½” LG ........................................... 4

35 538329 ............................................ Hex Nut, Nylock ¼-20 ................................................... 6

36 2108109.......................................... Cam Driver Ass’y. ......................................................... 1

37 1108112.......................................... Cam Roller ................................................................... 1

38 2112087.......................................... Drive Yoke Ass’y. .......................................................... 1

39 1108116.......................................... Guide Bushing ............................................................. 2

40 1108117.......................................... Guide Rod .................................................................... 2

41 625407 ............................................ “E”-Ring – Truarc #5133-37 ......................................... 3

42 1112082.......................................... Drive Clevis .................................................................. 1

43 538401 ............................................ Nut, Jam ½-20 .............................................................. 1

44 570967 ............................................ Cotterless Clevis Pin ¼ x 2 LG .................................... 1

45 650256 ............................................ Set Screw ¼ x ¼ ........................................................... 1

46 324113 ............................................ Decal-Caution .............................................................. 1

47 324288/324288A ............................Decal-Wiring Diagram ................................................. 1

48 223162 ............................................ Hayco Bushing #SR-7K-2 ............................................ 1

49 430022 ............................................ Electric Cord (Lyall) ...................................................... 1

50 723529 ............................................ Instruction Tag-Grounding ........................................... 1

51 739040 ............................................ Tie Strap – 7” LG .......................................................... 3

52 723530 ............................................ Instructional Tag-Pressure .......................................... 1

53 723526 ............................................ Instructional Tag-Read Manual ................................... 1

54 264235 ............................................ Hose Clamp ................................................................. 2

55 756190 ............................................ Tubing –Glitex (180-m) x 8” LG .................................... 1

56 482004 ............................................ Knob, Black W 1/4-20 Insert ........................................ 2

57 3147873.......................................... Safety Guard-Plastic .................................................... 1

58 624545 ............................................ “O”-Ring – Manifold – Quick Connect .......................... 1

59 312406 ............................................ Coupling, Quick Connect .............................................1

25

Page 34

Page 35

WARRANTY

MIX TRANSFER PUMPS / COCKTAIL / SLUSH

1. Scope:

Stoelting LLC warrants to the first user (the “Buyer”) that the evaporator assembly and compressor (if

applicable) of Stoelting mix transfer pump, cocktail and slush equipment will be free from defects in materials

and workmanship under normal use and proper maintenance appearing within five (5) years (two (2) years for

“Mirage” equipment), and that all other components of such equipment manufactured by Stoelting will be free

from defects in material and workmanship under normal use and proper maintenance appearing within twelve

(12) months after the date that such equipment is originally installed.

2. Disclaimer of Other Warranties

THIS WARRANTY IS EXCLUSIVE; AND STOELTING HEREBY DISCLAIMS ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE.

3. Remedies:

Stoelting’s sole obligations, and Buyer’s sole remedies, for any breach of this warranty shall be the repair or (at

Stoelting’s option) replacement of the affected component at Stoelting’s plant in Kiel, Wisconsin, or (again, at

Stoelting’s option) refund of the purchase price of the affected equipment, and, during the first twelve (12)

months of the warranty period, deinstallation/reinstallation of the affected component from/into the equipment.

Those obligations/remedies are subject to the conditions that Buyer (a) signs and returns to Stoelting, upon

installation, the Warranty Registration Card for the affected equipment, (b) gives Stoelting prompt written notice

of any claimed breach of warranty within the applicable warranty period, and (c) delivers the affected equipment

to Stoelting or its designated service location, in its original packaging/cratin g, also within that period. Buyer

shall bear the cost and risk of shipping to and from Stoelting’s plant or designated service location.

4. Extensions:

The warranty period for the drive motor to be free of defects in materials and workmanship extended to five (5)

years on the following models: SO218, SO318, SO328.

5. Exclusions and Limitations:

This warranty does not extend to parts, sometimes called “wear parts”, which are generally expected to

deteriorate and to require replacement as equipment is used, including as examples but not intended to be limited

to o-rings, hoses, seals and drive belts. All such parts are sold

Further, Stoelting shall not be responsible to provide any remedy under this warranty with respect to any

component that fails by reason of negligence, abnormal use, misuse or abuse, use with parts or equipment not

manufactured or supplied by Stoelti ng, or damage in transit.

THE REMEDIES SET FORTH IN THIS WARRANTY SHALL BE THE SOLE LIABILITY

STOELTING AND THE EXCLUSIVE REMEDY OF BUYER WITH RESPECT TO

EQUIPMENT SUPPLIED BY STOELTING; AND IN NO EVENT SHALL STOELTING BE

LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER FOR

BREACH OF WARRANTY OR OTHER CONTRACT BREACH, NEGLIGENCE OR

OTHER TORT, OR ON ANY STRICT LIABILITY THEORY.

File: Policy Manual/Warrantyslush1

:

AS IS.

January 30, 2003, Rev. June 1, 2006

Form 721-012, Rev, 1

Loading...

Loading...