1

Vola 860HE

Also known as Pinnacle 860 / Apex 860

Installation and User Instructions

All instructions must be handed to

user for safekeeping

This is not a DIY product and must be

installed by a Gas Safe registered

installer

Edition D 11/14

Country(s) of destination - GB/IE

2

These Notes Must Be Read Before Installation

This appliance is an Inset Live Fuel Effect appliance that provides radiant or combined

radiant and convected heat; it cannot and should not be used as the main heating

source within a property.

The appliance is designed to fit most types of fireplaces with a natural draught flue as

listed in the Installation Requirements.

The appliance must be installed by a competent person in accordance with the Gas

Safety (Installation and Use) Regulations 1998.

A Gas Safety Registered installer must be used for this purpose.

Read all these instructions before any installation takes place and in conjunction with the

appliance on site.

This appliance must be installed in accordance with the rules in force and only used in a

sufficiently ventilated space.

This appliance is factory set and tested for operation on the gas type, and at the

pressure stated on the appliance data plate.

After a new gas appliance (excluding flueless cookers) has been fitted, the Building

Regulations in England and Wales require that the installation must be notified to your

Local Authority. Your Gas Safe registered engineer needs to do this, failure to register

the appliance may affect your warranty.

INSTALLATION INSTRUCTIONS

3

Stand the carton the right way up, open the box from the top.

Read all the instructions before continuing to unpack or install this appliance.

Remove the bags containing ceramic components such as coals or gravel etc. Remove the cardboard

packing pieces, and any other bags or boxes containing fittings or other parts.

When all loose parts have been removed, the appliance may be unsecured from wooden pallet and

lifted out.

Check that the components supplied correlate with the component checklist below.

If for some reason any of the listed components are missing or damaged do NOT commence with this

installation, in doing so will invalidate your warranty.

Please dispose of all the packaging materials at your local recycling centre.

Qty

Description

1

Firebox and Burner Tray

1

Decorative Trim/Frame (may be in separate carton)

1

Fuel Bed

1

Set of manufacturer’s instructions and warranty card.

4

Fixing Screws

4

Raw Plugs

1

Remote control handset and battery holder pack (for Remote Option)

OPENING THE APPLIANCE

CONTENT CHECK LIST

4

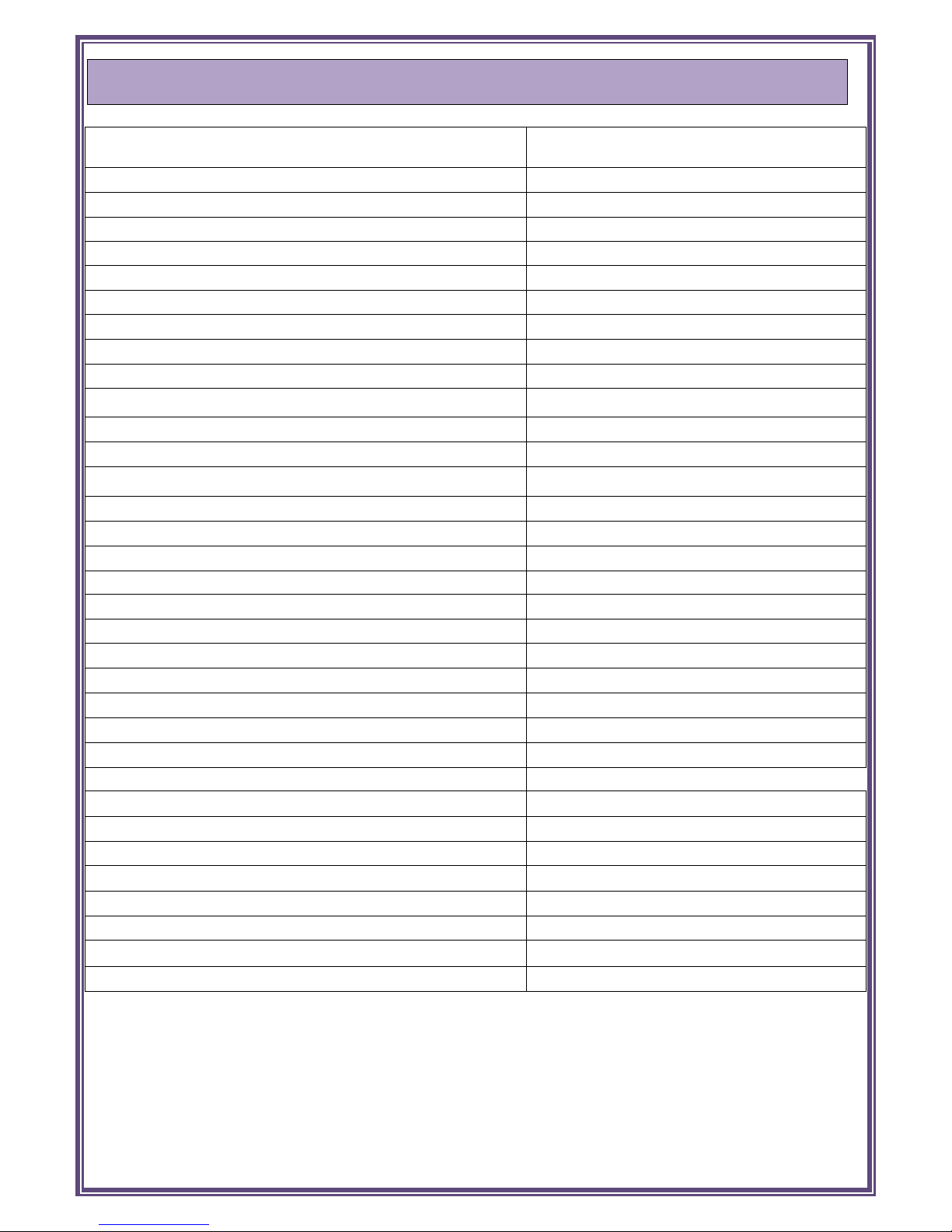

Section

Contents

Page No

1

Important Notes

5

2

Installation requirements

6

3

Appliance Information

7

4

Ventilation

8

5

Site Requirements

8/9

5.1

Pre-Fabricated Flue box

10

6

Debris Space

10

7

Installation of appliance

10

7.1

Preparing the Opening

13

7.2

Fitting the Burner Tray

14

8

Fuel Bed

14

9

Fitting The Outer Frame/ Trim

15

10

Commissioning the Appliance

15

10.1

Spark Failure

16

11

Setting Pressure

16

12

Spillage Monitoring System

16/17

13

Testing for Spillage

17

14

Briefing the Customer

17

15

Servicing

18

17

User Instructions

18/26

17a

Troubleshooting Guide

27/30

18

Cleaning the Coals

31

19

List of Spares & Contact details

32

20

Warranty Details

33

INSTRUCTION CONTENT

5

This fire is an Inset Live Fuel Effect Gas Fire providing radiant warmth. It is designed to operate on

Natural Gas.

It is the LAW that all gas appliances and fittings are installed by a competent person such as a Gas Safe

Registered fitter and in accordance with the Gas Safety (Installation and Use) Regulations 1998, the

relevant British Standards for Installation, Codes of Practice and in accordance with the manufacturers’

Instructions.

The installation shall also be carried out in accordance with the following regulations:

The Building Regulations issued by the Department of the Environment, the Building Standards

(Scotland)

(Consolidation) Regulations issued by the Scottish Development Department.

BS 4543 part2

BS 5440 parts 1&2

BS 5871 part 32

BS 6461 parts 1&2

BS 6891

BS 8303

Failure to comply with these regulations could lead to prosecution and deem the warranty Invalid.

This appliance must be installed in accordance with the rules in force and used only in a sufficiently

ventilated space.

Consult all instructions before installation and use of this appliance.

The appliance must be registered once commissioned with the regulatory governing body.

This appliance is free from any asbestos material. Refractories and coal bed are constructed from

ceramic fibre.

Note - For Republic of Ireland, reference should be made to the relevant standards governing

installation, particularly in regard to flue sizing and ventilation. See IS813, ICP3, IS327 and any other rules

in force.

Section 1: IMPORTANT NOTES

6

This appliance MUST NOT be installed into a bathroom or shower room, or where steam may be

present.

An extractor fan must not be fitted in the same room or space as the appliance as this can affect the

safety of the appliance.

The fire has been designed to fit into a fireplace or builders opening (and meeting certain dimensional

requirements), or a suitable flue box complying with the constructional requirements of BS 715.

A natural draught flue system is required, and if previously used for solid fuel or oil burning, the flue and

chimney must be swept prior to appliance installation.

The flue must be checked before installation by using a smoke pellet or similar to ensure proper draw

and that leakage is not evident at any joints. Repair and re-test as necessary before the appliance is

installed.

Any flue box used must be installed onto a suitable non-combustible insulating surface at least 12mm

thick, covering the entire base area of the box.

The flue must have an effective height of at least three metres, as measured from the hearth to the top

of the flue.

Any flue damper plates or restrictors must be removed and no other restriction fitted to the flue.

Where removal is not practical, the restriction must be fixed in the fully open position.

The flue must be connected to only one fireplace, and the flue must not vent more than one appliance.

There must be no opening in the flue apart from the one that the appliance is installed into, and the one

venting the gases into the air. A suitable terminal may be fitted, such as class GC1, as regulations allow.

In accordance with BS1289 part 1, pre-cast flues built with directly plastered faces (front or rear) are not

correctly installed as to ensure proper operation with any type of gas fire.

Depending on the flue construction, on occasions the temperature reached can cause cracking of the

surface plaster through no fault of the appliance.

An air gap or some form of insulation material should be installed to prevent normal flue temperatures

from damaging wall surfaces.

This appliance is suitable for use with a surrounding area or back panel of 150C minimum rating.

Section 2: INSTALLATION REQUIREMENTS

7

H.E Landscape

Gas Group

G20 Natural Gas CAT I2H

Inlet Pressure

20 mbar

Max Input (gross)

6.2

Min Input (gross)

3.4

Setting Pressure

20 mbar

Gas Inlet connection

8mm Compression

Overall Height

532

Overall Width

1022

Overall Depth

322

Recess Height

460

Recess Width

875

Recess Depth

300

Air Vent

N/A*

Remote Valve

TESCO01 RF868-15

Remote Pilot Assembly & Thermocouple

OXP-PG-82-370

Slide Valve

TESA3173/011

Pilot Assembly & Thermocouple

OXP-PG-82-460

Spark Generator

YD9-1D

Injector Stereomatic

440

Efficiency

74.1% Net class1 66.8% Gross

NOx

Class 3

*Not normally required might be required following spillage test see section 13

Section 3: APPLIANCE INFORMATION

8

This Appliance does not normally require purpose provided ventilation. However, a second appliance

operating within the same room or space must be taken into consideration when assessing ventilation.

When commissioning the appliance spillage is detected, then amongst other problems there may be

insufficient natural ventilation for correct operation of the flue. If spillage is detected with windows

closed, but the appliance does not spill with the windows open, this demonstrates a lack of natural

ventilation.

If spillage is still detected with the windows open, the flue is at fault. Installation of an air brick is the

best solution to lack of ventilation.

Any ventilation fitted must comply with BS 5871 part 2 and BS 5440 part 2.

Air Vents fitted under or within the immediate vicinity of the appliance must not be used as adverse

effects to the operation of the Flame Safety Device (FSD) may occur. Spillage detected during

commissioning is almost always a result of poor flue performance that cannot be corrected by any

amount of ventilation.

For Republic of Ireland ventilation may be required, see IS 813, ICP3, IS 327, and any other rules in force.

The fireplace opening should be inspected and repairs made where necessary.

The dimensional requirements for debris collection space and spigot clearances are met. See diagram

below.

This appliance requires a natural draught flue system which may be one of the following;

225mm x 225mm (9in x 9in) brick or stone

175mm (7”) Minimum diameter lined flue

125mm (5”) minimum diameter lined brick or stone.

125mm (5”) minimum diameter twin wall flue conforming to BS 715,

175mm (7”) minimum diameter twin wall flue conforming to BS 715,

Any existing draught device situated under the fireplace must be sealed off. The opening area must be noncombustible.

It is recommended that a tactile barrier should be place on the floor in front of the appliance to stop the elderly,

infirm or Children from direct contact with the hot surfaces of the appliance.

The area immediately above the outlet must form a smooth path into the flue.

The appliance can only be used in a no hearth application if the installation complies to BS 5871-2:2005 and

appliance is installed so that the height from the base of the fireplace opening to the floor is no less then

300mm.

As with all heating appliances, any decorations, soft furnishings, and wall coverings (i.e. flock, blown vinyl and

embossed paper) positioned too close to the appliance may discolour or scorch.

Section 4: VENTILATION

Section 5: SITE REQUIREMENTS

9

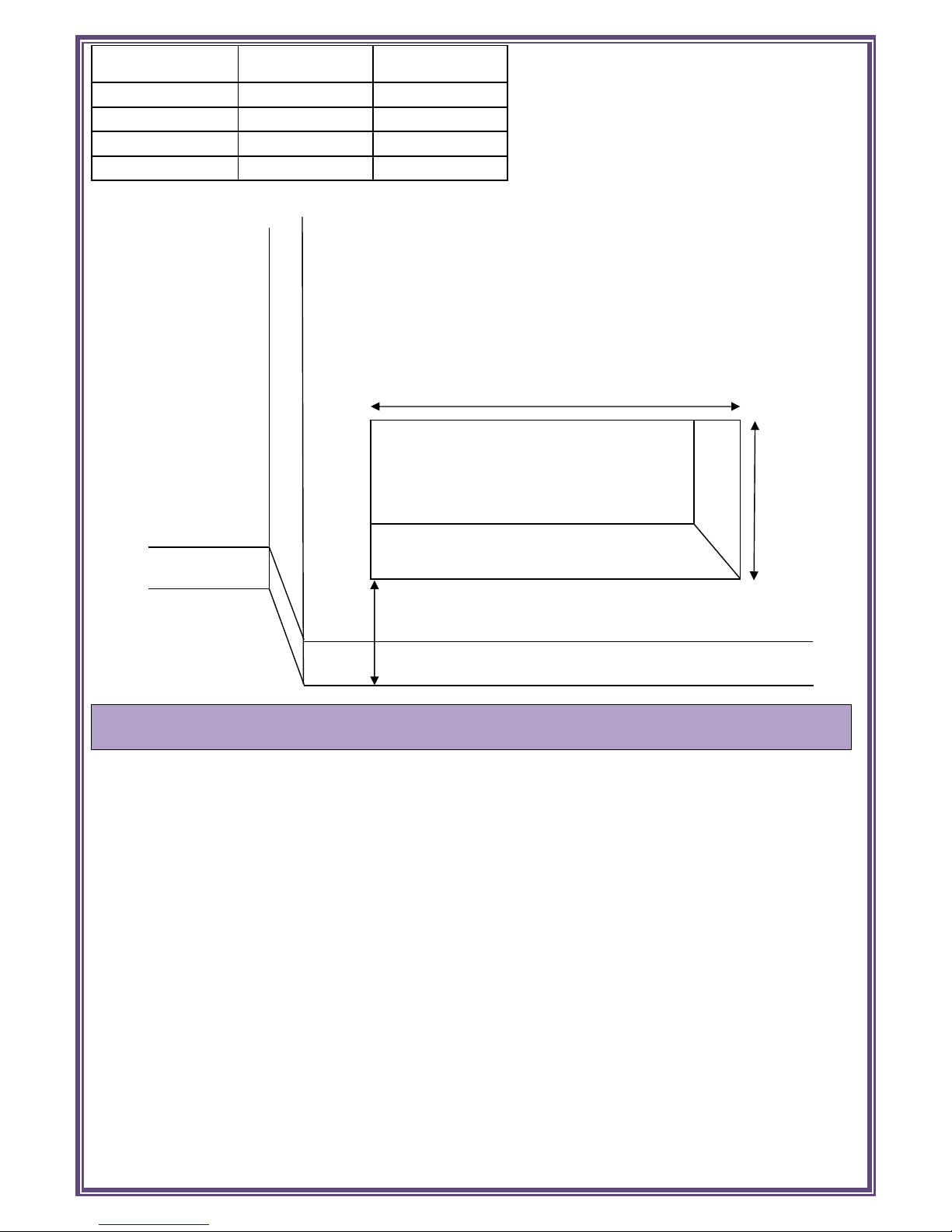

Opening

Requirements

MM

A

Width

875-895mm

B

Height

460-470mm

C

Depth

300mm

D

From Floor

300-450mm

These appliances can be fitted to a prefabricated flue system, can be fitted directly to the appliance via the flue

adaptor.

All will require a false chimney breast in which to be housed and will need to be constructed of a noncombustible material or any combustible material within 350mm must be clad with a non-combustible board.

The correct clearances to combustible materials (i.e. false chimney breast etc) must be adhered to.

The manufacturer of the prefabricated box’s instructions for fitting the prefabricated box must be complied with

at all times.

Please ensure the firebox does not obscure the flue box outlet.

It is important that the sealing requirements of the appliance are met at all times and that the flue box is sealed

D

A

B

C

Section 5.1: PREFABRICATED FLUE BOXES

10

to any back or infill panel.

In accordance with BS 5871 part 2, minimum debris collection volumes are required behind the installed

appliance.

CLAY/CEMENT LINES OR BLOCK FLUE WHICH IS NEW, UNUSED, OR PREVIOUSLY ONLY USED WITH A

GAS FIRE.

Appliance recessed depth + 20mm

UNLINED FLUE OR CHIMNEY WHICH HAS BEEN PREVIOUSLY USED FOR A SOLID FUEL OR OIL

BURNING APPLIANCE

Appliance recessed depth + 60mm

Always ensure that the gas supply is isolated before commencing installation of the appliance.

The fireplace opening and environment must be in compliance with specifications laid down in the

appropriate sections of these instructions.

Remove the appliance from its carton as described previously and stand on a dust sheet, place the

coals, ceramics and fixings safely to one side.

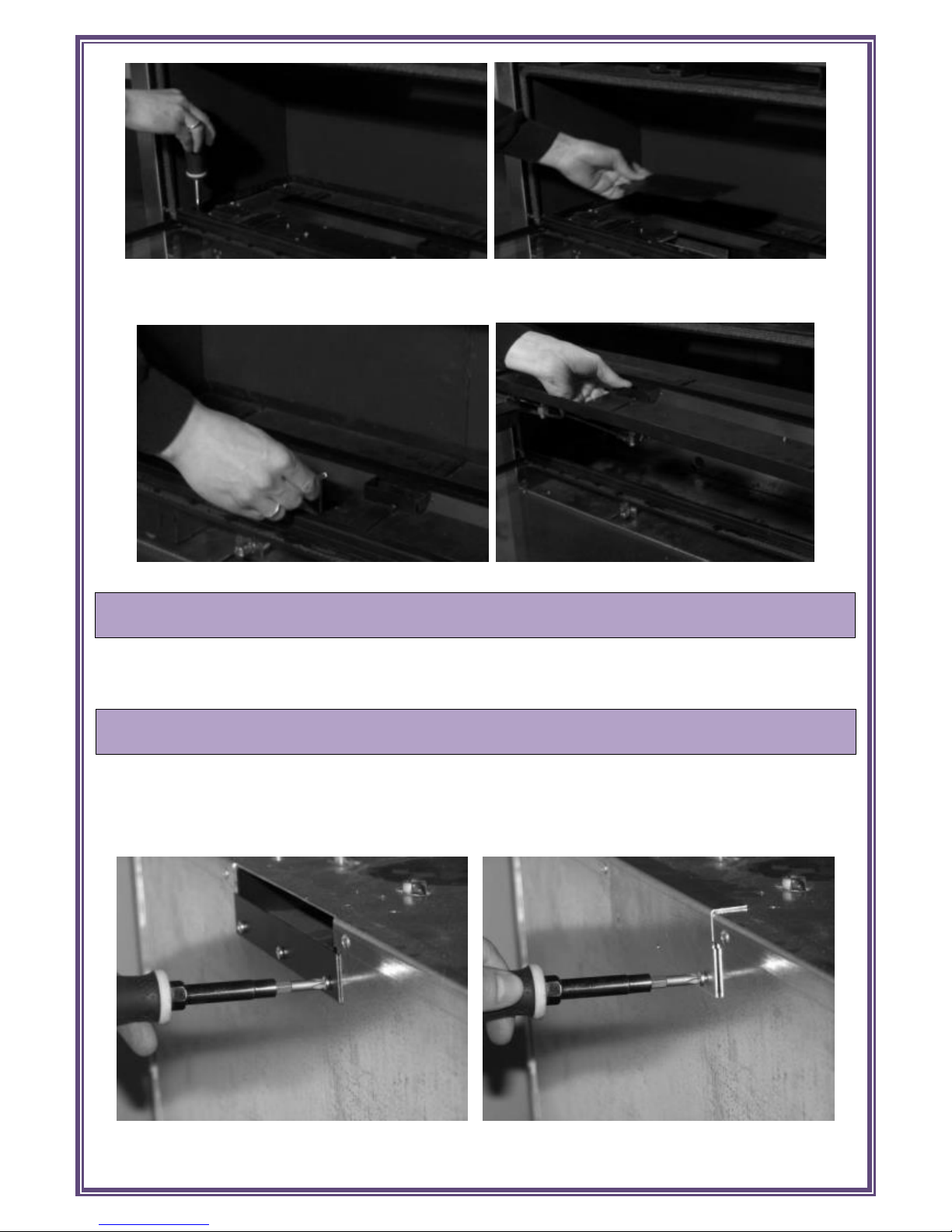

Remove the burner from the assembly by removing the 4 x Screws at the top of the glass panel, with

the glass door dropped down you can lift the door off its hinges to allow ease of access to the fire box

and the burner, start by removing the ceramic pads over the burner and gentle put this to one side to

avoid any damage.

Section 7: INSTALLATION OF THE APPLIANCE

Section 6: DEBRIS SPACE

11

Next remove the screws in each corner and the one holding down the access panel,

Next undo the nut connecting the burner to the isolation valve and tray will now lift free of the firebox.

Before installing the fire, check the flue for correct operation using a smoke pellet, all of the smoke

should be drawn up the flue and exit correctly from the terminal. If problems are found DO NOT fit the

fire until corrective measures have been completed.

At this point if required you can make some changes to the firebox to accept a flue liner.

First you must remove the flue restrictor plate at the back of the fire, and replace with the flue closure

plate supplied.

Section 7.1: PREPARING THE OPENING

Section 7.2: ADAPTING THE BOX FOR FLUE LINER

12

Next remove the top internal diverter plate from the top of the appliance by unscrewing the screws

holding either side of the box keeping the panel in place.

Remove the second plate, exposing the opening , at this point fix the fire box into place and pass the

liner through the opening in the box, connect to the flue adaptor supplied, to the liner using selftapping screws and aluminium sealing tape (not supplied) push back up into position and fix the plate

into place. Place the first plate back into position and secure internal diverter plate back into place by

folding securing into position.

13

Before running the gas supply into the opening, offer up the fire box to the fireplace to check the fit is

good, ensure that it slides in correctly, the sealing face sits flat and square to the wall and that the base

is level, apply the self-adhesive sealing strips around the edge of the rear of the firebox frame,

approximately 5mm in from the edge.

Mark and drill the fire frame in the relevant 4 points on the wall and place rawplugs in place,

alternatively you can use the tensioning cable fixing kit supplied (see separate fixing instructions with

the kit)

Whilst the opening is ready for installation of the fire, the gas supply can be routed and when in the

correct position can be connected to the isolation tap via the 8mm compression fitting.

DO NOT install or use the appliance without this seal in place.

Failure to fit this seal correctly will cause the flue suction to act upon the area under the burner

tray resulting in poor performance, and overheating of this area.

In no circumstance should you use soft soldered connections to or underneath the burner tray.

The gas pipe must be suitably protected where it passes through fireplace openings. Any

sleeving should be sealed to the pipe at its end.

Section 7.1: PREPARING THE OPENING Cont.

Note: Fibre Rawlplugs might be preferred rather than

plastic Rawlplugs as the heat from the fire might affect

their efficiency.

14

This process is a simple, reverse of the previous instructions on how to remove the burner tray.

At this point if you have the slide contoled version then you can place the slide control piece inposition

using the two scews supplied.

Fit the two brackets supplier to each side of the firebox with self-tapping screws supplied the simple lift

the trim into place.

Section 7.3: FITTING THE BURNER TRAY

Section 9: FITTING THE DECORATIVE FRAME

15

Please refer to the instructions supplied separately with each fuel bed option to remove the lining for

colour change or replacement, simply with the tray removed the top place can be removed by the two

brackets in place then gentle remove the side sections and the back to fit simply reverse the process.

Turn on and test the gas supply up to the fire for any leaks, in accordance with current Approved Codes

of Practice (ACOPs)

Section 8: FUEL BED LAYOUT and LINING REPLACEMENT

Section 10: COMMISSIONING THE APPLIANCE

16

(See Section 16: Users Instructions)

The gap between the spark electrode and the pilot should be 3.5 - 4.5mm to produce a good spark.

There should be no need to adjust this.

If under any circumstances the electric spark fails, the pilot may be lit manually by proceeding with the

ignition sequence as previously described, and after turning the control knob through the spark

position, the knob should be held in and the pilot lit with a taper.

Note: Please ensure that the electrode spark igniters’ gap on the manual version has not been misaligned

during the handling of the burner in this installation the gap should be 5mm from the burner.

Remove the pressure test point sealing screw from the isolation elbow and attach a suitable pressure gauge.

This fire is fitted with a flue spillage safety device (ODS), if the fire shuts down during use for no apparent reason

then several things may be suspected, if a door or window has been opened creating a draught, then pilot

disturbance is the problem, and removal of the draught should resolve this.

The gas pressure reaching the fire must also be checked (again, recalls your installer to check and rectify any

problem). The thermocouple connection into the back of the gas control valve may also have worked loose

during installation, simply get the installer to tighten.

Section 10.2: SPARK FAILURE

Section 11: SETTING THE GAS PRESSURE

Section 10.1: OPERATING THE APPLIANCE

SECTION 12: FLUE SPILLAGE MONITORING SYSTEM

Check that the inlet gas pressure is at 20 mbar / Working Pressure at

20 mbar (+/- 1 mbar)

Light the pilot and check the correct operation of the burner at all

the flame settings.

Always check that the gas has stopped flowing even if you hear the

FSD valve close within the 3-minute period.

Turn OFF the appliance and the gas supply and refit the pressure

test point sealing screw.

17

If pilot disturbance is not the cause, then the ODS safety system may be in operation. Switch the appliance OFF,

check the flue and carry out any remedial work required. Relight the fire and carry out a spillage test, DO NOT

allow the appliance to be used if it continues to fail a spillage test.

The aeration hole of the pilot must be carefully cleaned out on each annual service to ensure continued function

of the ODS.

The spillage monitoring system shall not be adjusted, modified, or put out of operation by the installer.

Any spare parts fitted MUST be of a type supplied for the purpose by the appliance manufacturer.

If the fire is not spilling, then further guidance should be sought, using the Troubleshooting section as a guide.

CHECKING FOR CLEARANCE OF COMBUSTION PRODUCTS

Close all doors and windows in the room, light the fire and allow to run for approximately 5 minutes on high

position.

After approximately 5 minutes, hold a smoke match just inside and below the centre of the lower front edge of

the top of the fire, as shown below in Fig 1.

All smoke generated should be drawn back into the flue, If slight spillage occurs or if in doubt, repeat the test

after a further 5-10 minutes. If the test indicates that spillage is occurring and the flue restrictor baffle has been

fitted, it should be removed and the test repeated after the fire has cooled, if spillage persists, the flue is not

functioning correctly and a fault exists.

If, after investigation the fault cannot be traced and rectified, the fire must be disconnected from the gas supply

and expert advice obtained.

After ensuring that the fire is safe to use it should be left on high position to fully warm up. During this time a

slight odour may be noticed, this is due to the "newness" of the fire and will soon disappear.

Fig 1

When the test has been completed satisfactorily, repeat with any extractor fans in the premises running on the

highest setting, and any communicating doors open, finally, repeat with all doors open.

DO NOT allow the fire to be used until the test is satisfactorily passed.

Hold smoke match in position 10mm inside and

down from top face of the central slot

SECTION 13: TESTING FOR SPILLAGE

18

All instructions must be handed to the user for safekeeping.

Show the customer how to light and operate the fire.

After commissioning the appliance, the customer should be instructed on the safe use of the appliance

and the informed for the need of regular servicing.

Frequency of service depends on usage, but MUST be carried out at least once annually.

Cleaning of the fire may be achieved when the fire is cold using a damp cloth and mild detergent on most

surfaces, with the exception of the ceramic fuel bed.

A soft brush i.e. paint brush may be used to clean the ceramic fuel bed taken care not to use excessive

pressure.

Scratched and other superficial damage to the matt black paintwork of the appliance can be covered

with matching heatproof spray.

Use only the manufacturers’ recommended spray paint.

Paint only when the fire is OFF and cold. Always mask off the surrounding area to prevent contamination

with overspray.

Ventilate the room during the use of the spray. DO NOT attempt to spray paint the coals or ceramics, or

wash them in water.

Advise that the fire will emit a “newness” smell for a time after initial commissioning and that extra

ventilation may be needed during this time.

Advise that the fire is fitted with a spillage safety device (O.D.S.). If the fire shuts down, this system may

be in operation.

If spillage is suspected, SWITCH APPLIANCE OFF and call in the installer to investigate any problems.

First Isolate the fire from the gas supply and ensure that the fire is fully cold before attempting service.

Lay out the dust sheet and tools required.

Remove Trim and Glass if applicable.

Carefully remove the ceramic components

Remove the screws that retain the tray in place and disconnect from the isolation tap.

Remove the burner tray and other components as required (i.e. remote control box)

Disconnect the gas supply, to the appliance and disconnect the isolation tap

Remove convector box, Check the fireplace opening for rubble accumulation and remove, if

debris is excessive, and initiate remedial work on the flue.

Check the flue with smoke pellet for correct operation.

Refit convector box using new seals where necessary

Strip off the burner pipes and clean thoroughly.

Clean out the injector, pilot assembly and burner tube. DO NOT remove the pilot injector.

Re-assemble and re-fit the burner tray.

Turn on the gas supply, and leak test.

Refit the decorative casting and ceramics.

Check any purpose provided ventilation is un-obstructed.

Light the fire and test for spillage.

Check setting pressure and safe operation of the appliance.

SECTION 14: BRIEFING THE CUSTOMER

SECTION 15: SERVICING

19

IMPORTANT NOTES

The installation of this fire MUST only be carried out by a competent person (such as a Gas Safe

registered fitter) in accordance with the Gas Safety (Installation and Use) Regulations 1998, the

relevant British Standards, Codes of Practice, the Building Regulations and the manufacturers’

instructions.

Failure to comply with the above recommendations could lead to prosecution and invalidate the

appliance warranty.

Please ensure you are handed all of the manufacturer’s documents on completion of the

installation. This will include these instructions.

Always keep a note of the installer’s name and address, the original purchase receipt and the

date of installation for future reference.

The fire and flue should be serviced regularly to ensure continued safe operation.

See the servicing section for further details.

Frequency of service will depend on use, but MUST be carried out at least once annually.

Parts of this appliance become naturally hot during use.

It is recommended that a suitable fire guard conforming to BS8423 is used, especially where

young children, the elderly, or infirm are concerned.

Combustible items, such as flooring and furniture, and soft wall coverings (such as blown vinyl

or embossed paper) may discolour if fitted too close to the fire.

See relevant section for further details on clearances to combustibles.

No combustible material or flooring should protrude onto the hearth.

DO NOT burn any foreign material on this fire, the coals must be of the correct type and lay out

in accordance with the relevant section of these instructions.

Failure to do so could create a hazard or lead to sooting.

Before the appliance is installed, the chimney should be swept.

All flues should be checked by the installer to ensure there are no defects or obstructions that

may prevent the flow of combustion products.

The fire is only suitable for use with the gas type for which it is supplied.

This fire is supplied with a particular style of fire front/fret.

Use of the fire front/fret will ensure an adequate airflow under the fire bed for the correct

functioning of this appliance.

Compliance with safety standards cannot be guaranteed if another style of front is used.

A combustible shelf may be fixed to the wall above the fire, providing that it complies with the

dimensions given in section 3 site requirements.

No purpose provided ventilation is normally required for this appliance.

The requirements of other appliances operating in the same space or room, and the results of a

spillage test must be taken into consideration when assessing ventilation requirements; this will

have been carried out by your Gas Safe registered installer.

For Republic of Ireland, ventilation may be required, see IS 813, ICP3, IS 327, and any other rules in

SECTION 16: USER INSTRUCTIONS

20

The Remote Control with this appliance has already been paired at

the Factory

Quick start user instructions

Fire Control

This control is situated on your fire. The drawing shows the main features of the control.

The control required 3 x AA size alkaline batteries to be inserted under the battery

compartment cover. The orientation of these is shown moulded into the battery compartment.

After fitting the batteries and replacing the cover the fire can now operate. Slide the slide switch

to the right to the ON position.

To start the fire, press the power button and hold for 1 second then release. The burner will

within around 1 to 2 seconds, adjust to the maximum power setting,

The power of the burner can be adjusted up and down by pressing the – or + buttons.

To stop the fire, simply press the power button again and the burner will stop.

If you are not intending to use the fire for a long period (i.e. over summer time months), the

battery life can be extended even more by sliding the white isolator switch to the left (away from

the on position).

Ensure the very small white slider switch on the front corner of Fire Control is in the

on position.

Grasp around the handset to unlock its functions. The green unlock light will

illuminate to show when the handset is unlocked and ready to accept commands.

(N.B. Keep a grip of handset to keep it unlocked, to continue to operate the command

buttons.)

For your safety, the fire is fitted with a Flame Supervision Device (FSD), which will shut off the

Gas supply if for any reason the pilot is extinguished.

SECTION 17: OPERATING THE APPLIANCE (Remote Control)

21

The Valve and Handset Have Already Been Paired

First set up the hand set, cup the handset the green unlock light will illuminate. Keep it held

to keep the control unlocked, to enable operation of the buttons.

3) Setting the time the display will be as shown, as the time is not set yet and will progress

automatically to the next screen shown below.

Note: the indicator at the bottom shows the battery condition of both the batteries in the hand set

and in the fire control within the fire.

RC = Remote Control / FC = Fire Control.

The control is designed to get the most out of the batteries but when eventually the display shows

they are spent (when the battery indicator is empty, we recommend you change the batteries in

the handset before they are flat, to avoid having to re-program the time of day in again. N.B.

Pairing is not lost, even if the batteries are removed or flat.

22

4) Setting the display for 12 or 24 Hour display

As always when pressing the remote control buttons keep the control held to keep the green light

on and therefore handset safety feature, unlocked. The H indicates that it is time to set the timer

to either 24 hour display or 12 Hour (AM or PM) display. Press the + or – button on the handset

to toggle between the two settings. When you are ready to confirm the setting you want press the

“SET” button to progress to setting the day of the week.

Setting the day of the week

Press and release the + and – buttons until the correct day of the week is shown on the display.

(Mo = Monday, Tu= Tuesday, We=Wednesday, Th=Thursday, Fr=Friday, Sa=Saturday and

Su=Sunday).

Press “SET” to accept the day of the week and to progress to setting the Hour of the day.

Note: Whilst doing this setup pressing “SET” advances to the next display and pressing “MODE”

will return you to the previous display setting.

Setting the Hour

Press and release the + or – button to change the hour to the correct hour and press set to store

and to move to setting the minute. Repeat this for setting the minutes.

23

Setting the temperature display to Celsius or Fahrenheit.

Press and release the + or - button to toggle between C and F.

When the display shows the desired symbol, press and releases the “SET” button to store.

As the important settings above have now been done. Press and hold (not releasing straight

away) the “SET” button for a few seconds and this will exit the setup menu.

The control is now ready for use with the Fire Control.

Quick start user instructions

First set up the hand set, cup the handset the green unlock light will illuminate. Keep it held

to keep the control unlocked, to enable operation of the buttons.

Then with the other hand touch and keep you finger on the power button for about 5 seconds.

(Upon touching the power button the green light will do a single flash to show command is

recognized – after 5 seconds the green light will flash for a second time, at which you should

release your finger). The Fire should be lit within a few seconds. (N.B. If power button is held for

more than a few seconds after second flash/beep, the command ignored for safety reasons. With

this system, the control has been designed to ensure that only intended ignition of the fire

occurs.)

To stop – with handset held to unlock it, press then release power button.

24

Mode

Man = Manual

Zzz = Snooze

Therm = Thermostat

Timed

Day of the Week

Time (12 or 24hr)

Fire Status

Battery Indicator

RC = Handset

FC = Fire Control

Light Sensor (for

Display Backlight)

To Change Mode

Press to Decrease

Power Button

In Range of the

fire

If missing out of

range or fire

switched off

Room

Temperature

Handset

Unlocked if

Illuminated

To Change

Settings see

handbook

To Increase

Flame

25

Operating instruction (Detailed)

1) Upon successful insertion of the batteries in the Handset (if the handset has not previously

paired) the display will be as shown if it has been paired already then go to No 3.

1a) If display is not as above the handset may well need to be reset before pairing.

Press and Hold “Set” Button, to enter Programing menu

When Set Up is flashing, press and release set to enter Setup Mode.

Press and Release the “Set” button several times until you see CAO displayed.

Then press and release “+” button once to change display to CA1

Press and Release the “Set” button once more to display TESC, handset is now ready to pair.

2) Pairing the Handset to the Fire Control

After fitting the batteries as above (and with the isolator slide switch on the TESC Fire control in

the ON position), simultaneously press and hold the – and + buttons on the fire control (i.e. not

the handset) until the handset makes a noise and the display shows the pattern as shown here.

Hold the handset in one hand so your fingers wrap around the back of the operating buttons area

of the handset. A green unlock light will illuminate when the handset has detected your hand. The

green light must be illuminated in this way for any of the command buttons to accept commands

to operate the fire control. Whilst the display is as shown, and holding the handset as described,

press the “SET” button with the other hand to finish off the pairing of the handset to the Fire

26

Control and to enter to setup the time of day on the handset. N.B. If the display returns to the

one shown above with the word “TESC” shown, then too much time has passed before pressing

“SET” and so the handset has not paired yet. Simply repeat pairing again.

Advanced settings Menu

In the event that you may want to change the other pre-set settings of the control features. Do

not do a long press and hold above but a normal short press and release will take you into the

advanced settings area.

Advanced settings options are:-

• Back light –

o A = Automatic (default setting). The back light comes on in the dark but not in the light.

o 0 = Light never comes on.

o 1 = Light comes on whenever handset is unlocked.

• Display contrast – 8 levels from 0 to 7 (default level 4).

• P = pairing with other devices other than the fire control.

The hand set can pair with other modules to:o L= Operate an electric light – which is the dimmable in 9 steps

o F= operate an electric fan –which can have 9 speed levels

o A= operate an auxiliary contact to operate another device.

Note:

Fitting the batteries incorrectly could lead to damaging your Valve.

Different types of batteries or old and new batteries are not to be mixed.

Only batteries of the same or equivalent type as recommended are to be used.

Batteries are to be inserted with the correct polarity.

Exhausted batteries are to be removed from the fire.

The supply terminals are not to be short-circuited.

Do not use rechargeable batteries.

Non-re-chargeable batteries are not to be recharged.

Do not mix old and new batteries.

Do not mix alkaline, standard (carbon zinc) or re-chargeable batteries.

1. From the standing position push the thumb control all the way to the right where a spark

will be heard and generated, hold for approximately 15 seconds.

SECTION 17: OPERATING THE APPLIANCE (Slide Control)

27

2. Release the pressure and the pilot light should now be established (if this fails repeat step

1 and hold down for 20 seconds).

3. Slide the control to the left to increase the flame size to the desired effect.

4. To switch the fire off simple slide the control all the way to the left, passed the positive

stop.

Code

Comment

Appearance

Possible Cause

Action

E00

TESC locked due to

failed ignition

Red Led is

permanently on

TESC unit ( and

E00 on handset, if

used)

Temporary air

disturbance

around pilot

burner

Reset control by pressing

start button for 1 second

and releasing. The press

again the same way to

attempt a normal start

command. Repeat up to 10

times as necessary to see

if this overcomes the issue

as it may resolve itself

eventually.

No gas on

appliance inlet

Check to see if gas is

present at gas appliance

inlet. (Check gas supply is

on, the gas line purged of

air and the supply

pipework is free of

blockages or

contamination)

Rectify and perform

start cycle to clear

the Error code. Try

to light the fire as

normal.

Pilot contaminated

with lint or other

materials

Clean the pilot fee of any

dirt, dust carbon granules

or lint, especially around

the brass body of the

Bunsen burner and its gas

and electrical connection

and the area around the

flame ports and the spark

plug and electrode tip.

Check the electrode gap is

3- 4 mm.

Rectify and perform

start cycle to clear

the Error code. Try

to light the fir as

normal. Replace

pilot if necessary

SECTION 17a: Remote Error Trouble Shooting Guide

28

No Spark at

Electrode (fire not

igniting pilot

burner)

Check ignition cable for

damage and listen and

watch for tracking out of

spark to see if it is present

but not making it to the

electrode tip on the pilot

burner.

If cable damaged,

replace cable. Reset

error by performing

a normal start cycle

and try to start

again. Replace pilot

if necessary.

Pilot pipe or pilot

injector could be

blocked

Clear pipe and consider

changing pilot

E01

Low current from

thermocouple but

flame: possibly CO

alarm

Flashing Red LED

on TESC Control

Pilot pipe blocked no gas reaching

pilot burner

Check pilot pipe, check

flame appearance of pilot

flames

Chimney blocked

causing Co / Co2 to

build up in the

room

Check flue

Pilot thermocouple

defective / old

Change pilot or

thermocouple

Possible

temporary air

disturbance on

pilot flame

Clear error and restart to

check ignition ok

Code

Comment

Appearance

Possible Cause

Action

E02

too high ambient

temperature ( >73 °C)

around control

Negative flue pull or

blocked flue or

similar

Occurs if started ok

then subsequently

loss of thermocouple

current. Check for

flue problems. Fire

cuts out to prevent

over heating

Reset and try again

Blocked flue

Check and clear

Reset and try again

Poor position of

Ceramic parts

Check manual for

correct placement

Reset and try again

E03

no, defective, or bad

connected

thermocouple

Bad connection

Check if connected

are correct and

terminals are sound

Reset and try again

defective

thermocouple

Replace Pilot

Reset and try again

E04

false flame signal

occurs during

stopping fire

Sensing flame on

pilot when no flame

should be there.

Investigate.

Reset and try again

E05

false flame signal

Flame sensing on

pilot before start of

ignition sequence or

after valve has shut

off. Contamination

of electrode to

ground

Check if and clean

around the area of

the pilot for lint and

other contamination

and clean. Check

where the

thermocouple

connect to the TESC

control for the same

contamination. Clean

these areas.

Reset and try again

E06

too low voltage on

power supply to start

the burner

Weak or old or

defective batteries

Replace batteries

Reset and try again

29

E07

power supply

breakdown during

peak current

consumption

check/change all the

batteries or check

power adaptor. :

Note always change

all batteries together

never only 1 or 2

Replace batteries /

power adaptor

Reset and try again

E08

error caused by

external pressure

switch

Check the pressure

switch

Replace if necessary

Reset and try again

Jumpers on back of

valve missing

Check to see if

jumpers are in 10 way

connector

Reset and try again

E09

error caused by

external pressure

switch

pressures switch

action connection or

jumpers missing or

not connected

properly

Check pressure

switch connections,

check to see if

jumpers are in place

on back of TESC.

Reset and try again

E10

error caused by

external pressure

switch

pressures witch

action connection or

jumpers missing or

not connected

properly

Check pressure

switch connections,

check to see if

jumpers are in place

on back of TESC.

Reset and try again

Code

Comment

Appearance

Possible Cause

Action

E11

short circuit on wired

thermostat (if used)

Check switch

Check switch for damage,

contamination across terminals or

damaged wiring. Disconnect

wired thermostat if fitted and try

a start, if it works replace

thermostat

Reset and try

again

E12

open circuit on wired

thermostat (if used)

Check wiring and

thermostat

Check switch for damage,

contamination across terminals or

damaged wiring. Disconnect

wired thermostat if fitted and try

a start, if it works replace

thermostat

Reset and try

again

E13

wired thermostat is

out of tolerance

Check wiring and

thermostat

Check switch for damage,

contamination across terminals or

damaged wiring. Disconnect

wired thermostat if fitted and try

a start, if it works replace

thermostat

Reset and try

again

E14

button (-) sticks

either on TESC or on

wired control panel

(if used)

Check for

contamination

around buttons

Clean as necessary. Replace

switch panel as necessary if

damaged or too contaminated.

Disconnect wired control panel

and try again – if it works replace

wired control panel

Reset and try

again

E15

button (+) is shorted

to other buttons

either on TESC or on

wired control panel

(if used)

Check for

contamination/

damage -

Clean as necessary. Replace

switch panel as necessary if

damaged or too contaminated.

Disconnect wired control panel

and try again – if it works replace

wired control panel

Reset and try

again

30

E16

button (ON/OFF) is

shorted to other

buttons either on

TESC or on wired

control panel (if

used)

Check for

contamination /

damage and

replace wired

switch panel if

necessary

Clean as necessary. Replace

switch panel as necessary if

damaged or too contaminated.

Disconnect wired control panel

and try again – if it works replace

wired control panel

Reset and try

again

E17

button (-) is shorted

to other buttons

either on TESC or on

wired control panel

(if used)

Check for

contamination /

damage and

replace wired

switch panel if

necessary

Clean as necessary. Replace

switch panel as necessary if

damaged or too contaminated.

Disconnect wired control panel

and try again – if it works replace

wired control panel

Reset and try

again

E18

button (AUX) is

shorted to other

buttons on switch

panel

Check for

contamination /

damage and

replace wired

switch panel if

necessary

Clean as necessary. Replace

switch panel as necessary if

damaged or too contaminated.

Reset and try

again

E19

Infrared receiver

defective (if used)

Check

connection of IR

or damage replace if

necessary IR eye

Check if wired correctly and

replace IR eye if necessary

Reset and try

again

E20

Incorrect setup

parameters

Check

connection of IR

or damage replace if

necessary IR eye

Check if wired correctly and

replace IR eye if necessary

Reset and try

again

Code

Comment

Possible Cause

Action

E21

tried to config a TESC

as Cluster slave while

a wired thermostat is

connected

Factory assembly warning

on setup configuration not

a maintenance error

Usually only a factory assembly error.

Could happen if done in error in

servicing.

Reset and try

again

E22

tried to calibrate

TESC with

TESCeasytest while a

wired thermostat is

connected

Not field error

Disconnect thermostat before

attempting to use Easy test unit.

Reset and try

again

E23

warning: end of life is

near, should be

replaced soon

Not field error

Indicated that control has performed

a high number of operations and so

fire should be serviced and control

replacement should be considered as

preventative maintenance. (should

not really occur before 10 years from

new, depends upon usage).

Reset and try

again

31

E24

Thermocouple

doesn't reach final

current - damaged or

aged

Replace Pilot

Check and correct Thermocouple

wiring. Replace thermocouple if

necessary

Reset and try

again

Check pilot connections

Check and correct Thermocouple

wiring. Replace thermocouple if

necessary

Reset and try

again

Pilot pipe may be blocked

completely

Clear pipe, replace pilot as necessary

Reset and try

again

E25

Poor thermocouple

signal

Tired or bad connection of

thermocouple or bad or

unstable flame on pilot or

poor grounding return

Check pilot thermocouple

connections and connections to TESC

Reset and try

again

E26

defective or wrong

wired USB-power

supply

try again and if repeatedly

fails replace

Replace with new USB power supply

of the correct type.

Reset and try

again

E48

short circuit on

thermocouple, or

thermocouple

reversed polarity

Wrongly wired

Check and correct Thermocouple

wiring. Replace thermocouple if

necessary

Reset and try

again

E49

false flame signal

Flame detected during

operation of fire when it

should not be detected contamination of electrode

circuit to ground

Check if and clean around the area of

the pilot for lint and other

contamination and clean. Check

where the thermocouple connect to

the TESC control for the same

contamination. Clean these areas.

Reset and try

again

E50

internal error

Flame detected during

operation of fire when it

should not be detected contamination of electrode

circuit to ground

Check if and clean around the area of

the pilot for lint and other

contamination and clean. Check

where the thermocouple connect to

the TESC control for the same

contamination. Clean these areas.

Reset and try

again

E51

error caused by

external pressure

switch

Check pressure switch connections,

check to see if jumpers are in place on

back of TESC.

Reset and try

again

Open the glass door

Remove the ceramic components.

Gently clean in the open air using a dry paint brush.

Be careful not to create dust from the ceramics.

Where necessary replace damaged components with genuine spares.

Seal scrap ceramic components in plastic bags and dispose at proper refuse sites as directed.

Re-fit the ceramics by referring to the relevant section of these instructions.

SECTION 18: CLEANING THE COALS

32

Before carrying out any of the following operations, ensure that the fire is OFF and completely

cold.

Debris that may form on the fire bed should be periodically removed by a competent person.

Large deposits could indicate deterioration of the flue. This should be repaired by a competent

person, and the fire serviced before further use.

FIRE FRONT/FRET - Any dust accumulating in the fire front may be removed using a vacuum

cleaner or dry cloth. Heavy stains may be removed by using a damp cloth and mild household

detergent.

Brass parts of the fire front may be cleaned using a suitable brass cleaner.

Replace the front centrally against the fire after cleaning.

PAINTED AREAS - These can be cleaned using a dry cloth.

GLASS - Remove the Glass panel as shown below and clean glass with a glass cleaner and a lint

free cloth or Microsoft cloth, if white haze or carbon discolouration is still apparent the a metal

polish such as Hotspot or Peek can be used to remove these stubborn particles.

IMPORTANT INFORMATION ABOUT WARRANTY SERVICE FOR THE

END USER

WARRANTY REGISTRATION IS REQUIRED WITHIN 28 DAYS FROM DATE OF PURCHASE

It is in your interest to register your appliance with Sirocco as soon as possible

BEFORE CONTACTING SIROCCO FOR SERVICE PLEASE READ THE FOLLOWING;

Sirocco is committed to customer care and service. To ensure we provide the best service we can we have a

policy to charge for all none warranty home visits so that all customers with a genuine manufactures fault can be

dealt with swiftly, if your appliance has recently been installed and you are experiencing any of the following;

Fumes are spilling from the flue/fire

The pilot light cuts out after a few minutes

The fire controls are getting too hot

Excessive sooting is forming on the fuel bed

Poor flame picture

Remote controls are not working

These symptoms tend to be chimney/flue or installations related and as such mostly are not covered by your

warranty and are mostly dealt with in the installation instructions, DO NOT USE YOUR APPLIANCE and in the first

instance contact your installer to investigate these further, to establish their cause before contacting Sirocco.

CONTACTING SIROCCO FOR WARRANTY SERVICE OR TO PURCHASE SPARE PARTS

In the event of a service or parts claim please note that some parts such as ceramics, batteries, trims and fronts

etc. are categorized as “user serviceable parts’ and are not carried out by a service visit.

GENERAL CLEANING

SECTION 19: WARRANTY

33

Please ensure you have the following information at hand when you contact Sirocco;

The full serial number which is located on the data badge of the appliance

Your receipt of purchase showing the date and where purchased from

Your installers details

You can contact Sirocco`s representative in the UK by phone to obtain advice and a warranty service form

on;

0843 289 4268

Or you can complete a form on line at www.siroccofires.com follow the link at the top right hand side

on the home page.

SIROCCO Sp. Zo.o Nad Lasem 8, Zelecow, 96-321 Zabia Wola, Poland. Tel 0048 22 425 8681, Fax 0048 46 857 8559.

Further information, contact details and email facilities are available through our website; www.siroccofires.com

SPARE PARTS

If you need assistance or wish to purchase spare parts

08432 890102 Mon to Fri 9:00 to 16:00

Contact our spares department by email spareparts@siroccofire.pl

Purchase spare parts direct from our website www.siroccofires.com

Spare parts are managed by our UK partner company Lodestar-Delta Ltd

Lodestar-Delta Ltd T/A Sirocco

Unit 1, 11 Weir St, Blackburn, Lancashire BB2 2AN

SIROCCO HEAD OFFICE

Telephone number for all departments 0843 289 4268 (charged at BT national rate)

Mon to Fri 10:00 to 15:00

Contact us by email adminuk@siroccofire.pl

View our latest products and use our on line services; www.siroccofires.com

SECTION 20: LIST OF SPARES

SECTION 21: CONTACT DETAILS

34

Nad Lasem 8, Zabia Wola

96-321 Zelechow

Poland

TECHNICAL HELP LINE

Speak to a Sirocco trained engineer

0904 0843473 (0904 084 FIRE)

This is a premium rate number charged at 1.00 plus vat per minute from BT lines

Mon to Fri 9:00 to 17:00

WARRANTY AND SERVICE

For warranty registration or for a home service call: www.siroccofires.com

For assistance to complete a registration or a home service

Call us on 08432-890102 Mon to Fri 9:00 to 16:00

Our warranty statement

CONDITIONS OF GUARANTEE

Sirocco (hereinafter referred to as the company) will, at its option, repair or replace free of charge any product or part

thereof which is shown to the satisfaction of the company to be defective due to faulty materials or workmanship within 12

months from the date of purchase, subject to the conditions set out below:

1. Gas fire installation and commissioning must be carried out by a GAS SAFE registered engineer that has a valid and

relevant qualification to work on such appliances in accordance with the installation instructions supplied with the

product.

2. The warranty registration form must be correctly completed and returned to Sirocco within 28 days from

date of purchase

3. A valid and correctly completed installers Commissioning Declaration form (as supplied in the warranty registration

form) relating to the installation of the product must be presented to the company in respect of any claim under

this guarantee.

4. A CP1 form must be completed on commissioning the appliance and registered with GAS SAFE

5. The product must only be operated in accordance with the user instruction book.

6. The installation must be in accordance with the installation instructions and comply with all current

legislation and building regulations.

7. The guarantee commences from date of purchase. A proof of purchase is required as part of the validation to

receive a warranty service. A sales receipt showing the original date of purchase is considered proof of purchase no

other documentation will not be accepted.

8. The guarantee shall not cover any fault or defect caused by faulty installation, including failure to observe the

installation instructions supplied with the product. Accordingly the company will charge a fee to cover the cost to

the company of travel and/or time spent to rectify a product which is incorrectly or improperly installed and for any

parts that may have been so damaged due to this. The company will advise the amount of such fee and take your

credit or debit card details prior to our engineer’s visit. The fee will be charged to your credit or debit card if the

defect is other than a manufacturing fault.

9. The guarantee is non-transferable and is made to the first retail purchaser provided that the sale is made through

an approved company stockist.

35

10. Any installation labour transportation or other related costs/expenses arising from defective parts/rapier

replacement or otherwise of same will not be covered by this guarantee nor shall the company assume

responsibility for same. Furthermore the company shall not be responsible for any indirect or consequential

damages except as provided by law.

11. The appliance must be kept free from dust, dirt and debris by the user, in accordance with the cleaning

instruction

12. All other guarantees expressed or implied with respect to the product, its components, and accessories or any

obligations/liabilities on the part of the company are hereby expressly excluded so far as permitted by law.

13. The company neither assumes nor authorises any third party to assume on its behalf any other liabilities with

respect to the sale of the appliance.

14. The guarantee does not apply to other non-Sirocco products such as prefabricated flue boxes and flues.

15. The company will not be responsible for: (a) Inadequate or inappropriate flueing, chimneys etc.; (b) down drafts or

spillage caused by environmental conditions such as nearby trees, buildings, rooftops, hills or mountains; (c)

inadequate ventilation or negative air pressure caused by mechanical systems such as extraction fans, cooker

extraction hoods, clothes driers etc.

16. The guarantee is void if: (a) the fire has been operated in atmospheres contaminated by chlorine, fluorine, or other

damaging chemicals; (b) the fire is subjected to long periods of dampness or condensation.

17. The guarantee shall not cover: (a) any damage to the combustion chamber or the heat exchanger or other

components due to water or weather damage which is the result of, but not limited to improper chimney/venting

installation; (b) any fault or defect caused by failure to observe the user instructions supplied with the product or

by any alteration, modification, wilful abuse, accident, careless operation or miss-use of the product or by any

external sources e.g. transit damage or weather..

18. The guarantee will not cover an appliance that has been found damaged or incomplete prior to installation but is

there after installed without being corrected by sirocco beforehand or removed from the installation prior to

Sirocco inspecting.

19. The guarantee will not cover an appliance that has been subsequently removed without Sirocco having the

opportunity to inspect the appliance or without the prior written consent of Sirocco

20. Validation of your installation will be required prior to warranty service/repair; there will be a fee for this.

No other validation will be accepted by Sirocco.

21. The guarantee shall not cover: (a) surface crazing of fibre components e.g. matrix, coals liners etc.; (b) batteries; (c)

cosmetic blemishes to polished metal and painted surfaces.

22. Some components are categorised as “user serviceable parts” and will not be carried out as a service visit, these

include ceramic components, decorative trims and fronts, batteries, some electrical and electronic components etc.

23. Repairs carried out under the guarantee do not extend the guarantee period. Any parts removed during guarantee

repairs become the property of the company.

24. The guarantee is in addition to, and does not affect, your statutory and other legal rights.

In Addition to the above the following terms and conditions apply to extended 5 year warranty;

25 Extended 5 year parts warranty has to be issued by an appointed Sirocco Premier stockiest, no other stockists are

authorised to issue these warranties

26 The warranty approval number issued by the stockist must be entered at the time of registration (this can be

completed on our website)

27 The extended warranty gives an addition 4 years parts only warranty commencing from the 1

st

anniversary of the

date on purchase, this is limited to the repair or replacement of parts found to be defective in material or

workmanship only after confirmation of the defect by a Sirocco engineer or an appointed Sirocco engineer,

provided that such parts have been subject to normal conditions of use

28 Any installation, labour, transportation or any other related or expenses arising from defective parts, repair or

otherwise of the same are not covered by this warranty, nor shall Sirocco assume responsibility for any incidental

indirect or consequential damages, except as provided by law.

29 It is essential that your Sirocco appliance is serviced, by a suitably qualified Gas Safe engineer or a Sirocco

authorised appointed engineer to carry this out at least every twelve months, as part of your 5 year

36

30 warranty in addition the flame failure devise or ODS and ceramics on some models will need to be

replaced in the 3rd year service as part of the conditions of your 5 year warranty, these items are

purchased from the Sirocco internet website “Spares shop” and are shown as 3rd year service packs, the

invoice for these items must be provided at the time of making the claim.

31 The service log found in the installation instructions must be completed by the service engineer at the

time of the service and an appropriate invoice issued for this and supplied to Sirocco on any claim being

made under the warranty

32 The following are not covered by this extended warranty: paint work in the fire chamber, fire fronts, and

decorative trims, ceramic components, glass and batteries, electronic or electric/mechanical components

such as remote controls.

Loading...

Loading...