Page 1

Plus AG

Installation

& Servicing

Instructions

British Gas Service Listed

G.C. No. 47 094 27 (Linea 24)

G.C. No. 47 094 28 (Linea 28)

G.C. No. 47 094 29 (Linea Plus)

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Page 2

CONTENTS

Section Subject Page no

Section 1 Introduction 1

General Layout 1

Section Subject Page no

Concluding Operations 20

Section 7 Instructing The User 20

Section 2 Design Principles & Operating

Sequence 2

Schematic Diagram 2

Central Heating Mode 2

Domestic Hot Water Mode 2

Safety Devices 2

Frost Thermosat 2

Section 3 Technical Data 3

Dimensions & Contents 3

Connection Sizes 3

Installation Requirements 3

Electrical Details 3

Performance & Limitations 3

Working Pressure (H/W & C/H) 3

Flow Rates 3

Central Heating Pump Duty 4

Section 4 General Requirements 5

Related Documents 5

Location of Appliance 5

Gas Supply 5

Flue System 5

Air Supply 6

Water Circulation (C/H) 6

Pipework 6

By-Pass 6

System Design 6

Filling Point 8

Electrical Supply 8

Showers 8

Section 5 Installation 9

Delivery 9

Unpacking 9

Preparing For Mounting 9

Mounting The Appliance 10

Fitting The Flue Horizontal - Vertical

Twin 10-11

Connecting Gas & Water Supplies 15

Electrical connections 15

Section 6 Commissioning 17

Gas Installation 17

Initial Flushing of Pipework 17

Initial Filling of System 17

System Design Pressure 17

Checking Electrical supply 17

Lighting The Boiler 17

Checking Burner Pressures 18

Range Rating C/H 19

Checking The Flue System 19

Checking The Heating Thermistor 19

Regulating The C/H System 19

Final Flushing The C/H System 19

Filling & Testing H/W System 19

Final Checks For Operation 20

Section 8 Servicing Instructions 21

General 21

Recommended Routine Servicing 21

Replacement Of Parts 21

To Gain General Access 22

To Remove:

Room Sealed Chamber Front Cover22

Main Burner & Electrode 23

Main Burner Injectors 23

Main Heat Exchanger 23

Fan 24

DAPS

Combustion Chamber Insulation Panel

Ignition PCB 25

Gas Control Valve 25

Pump 26

Domestic Flow Switch 26

Diverter

Domestic Heat Exchanger 27

Diverter Valve 27

Main Expansion Vessel 27

Safety Valve 28

Pressure Switch 28

Motorised Valve 29

Printed Circuit Board 29

Display Printed Circuit Board 29

Safety Thermostat 29

Thermistor Sensors 29

Pressure Gauge 30

Setting Gas Pressures 31

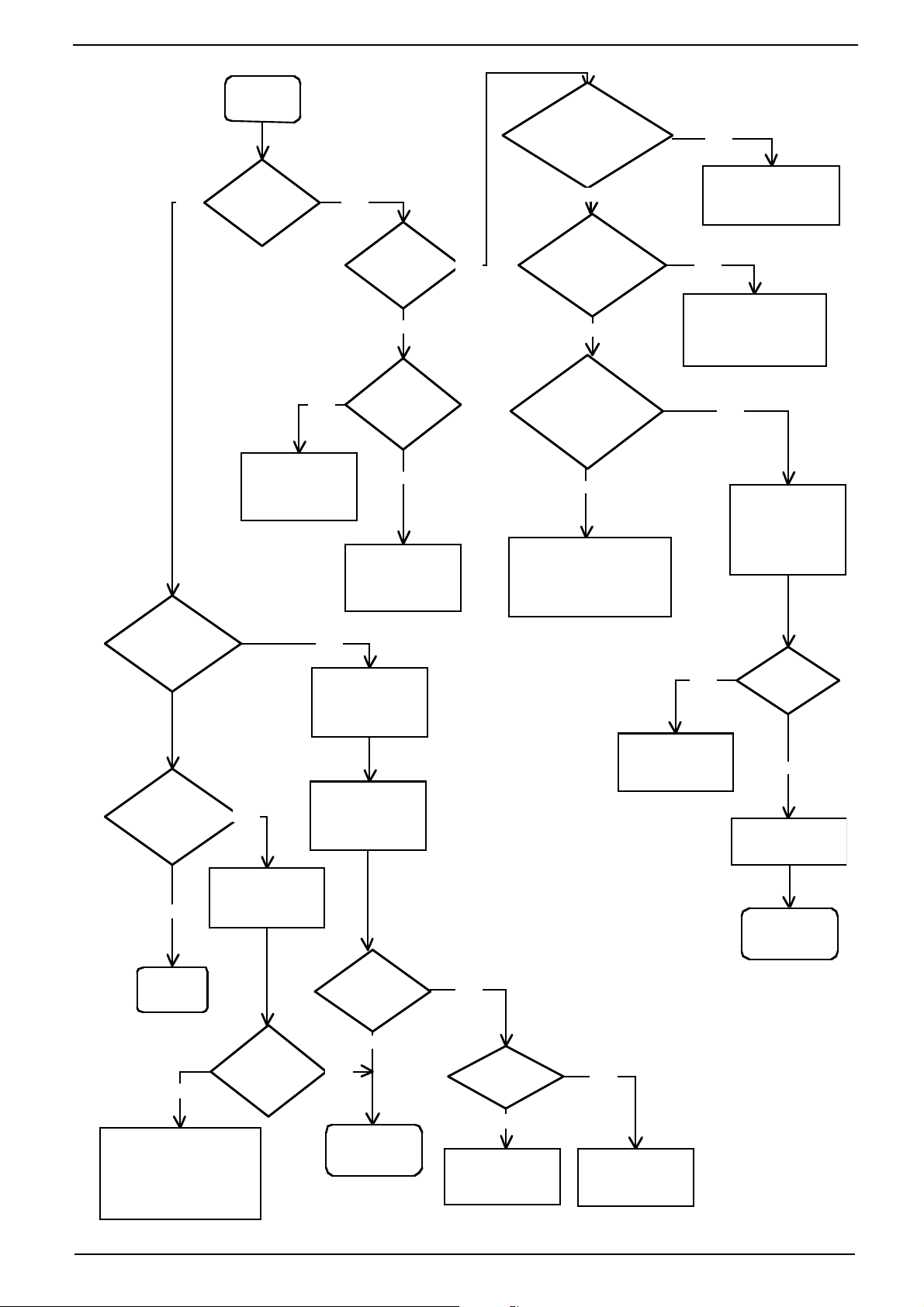

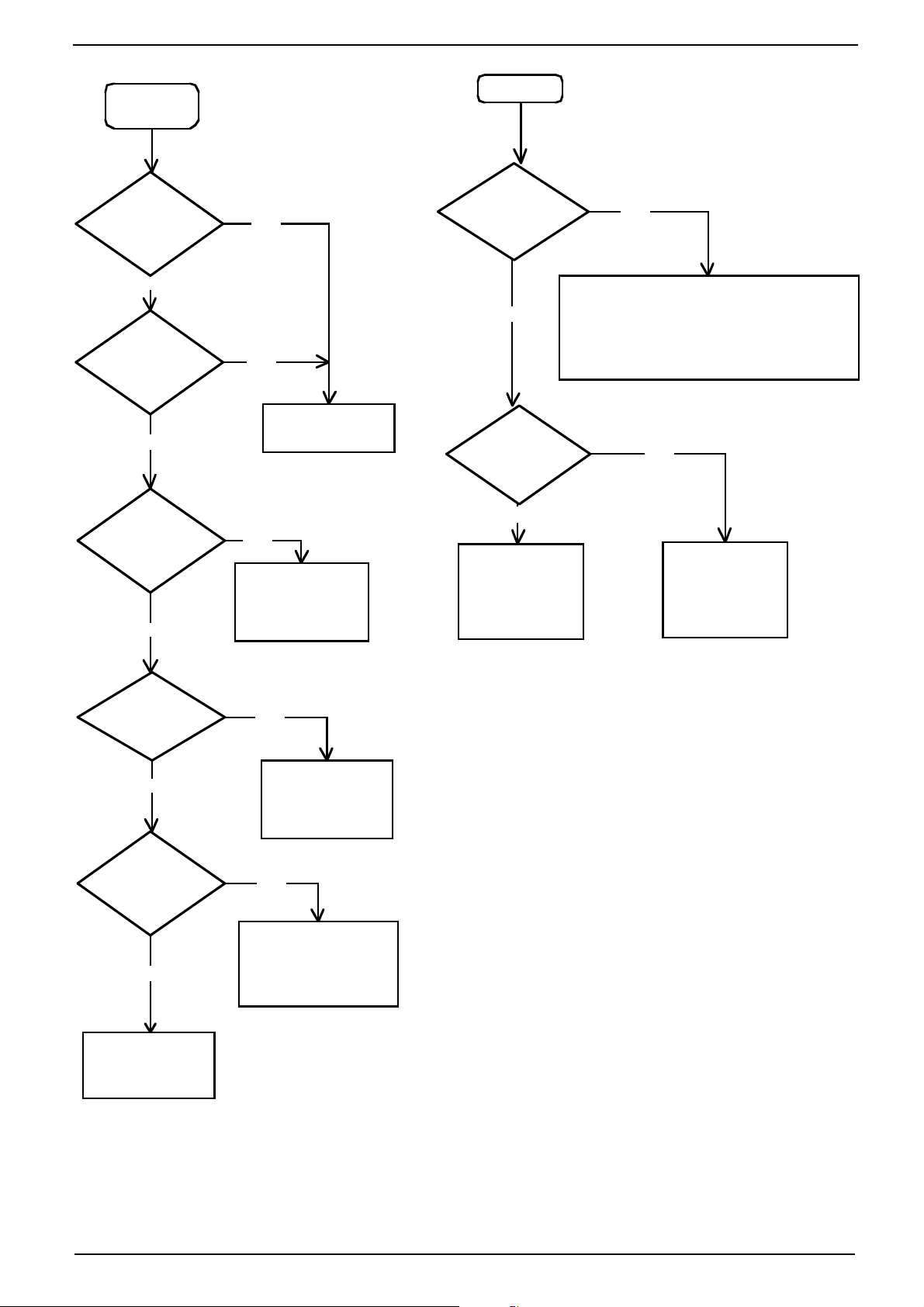

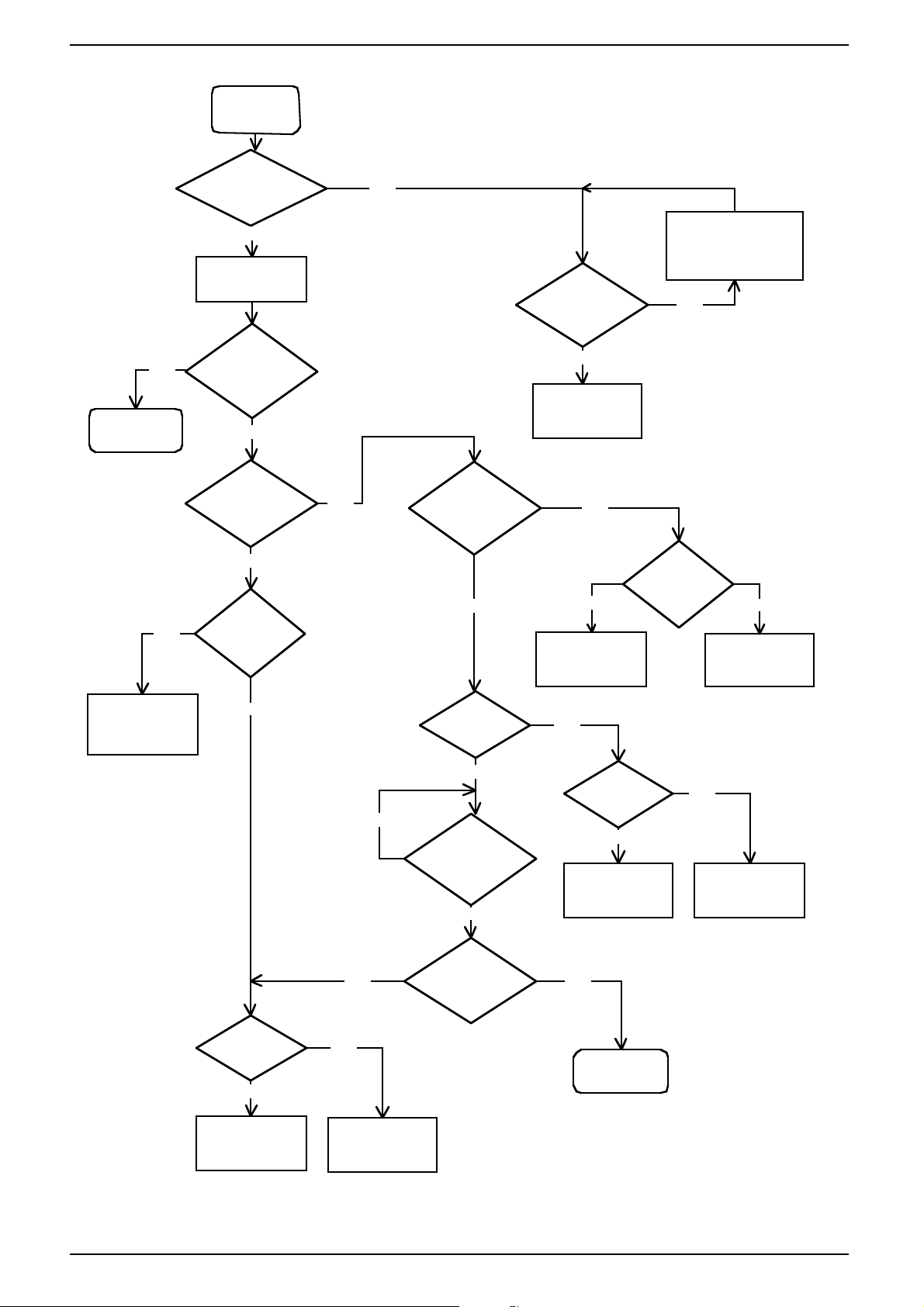

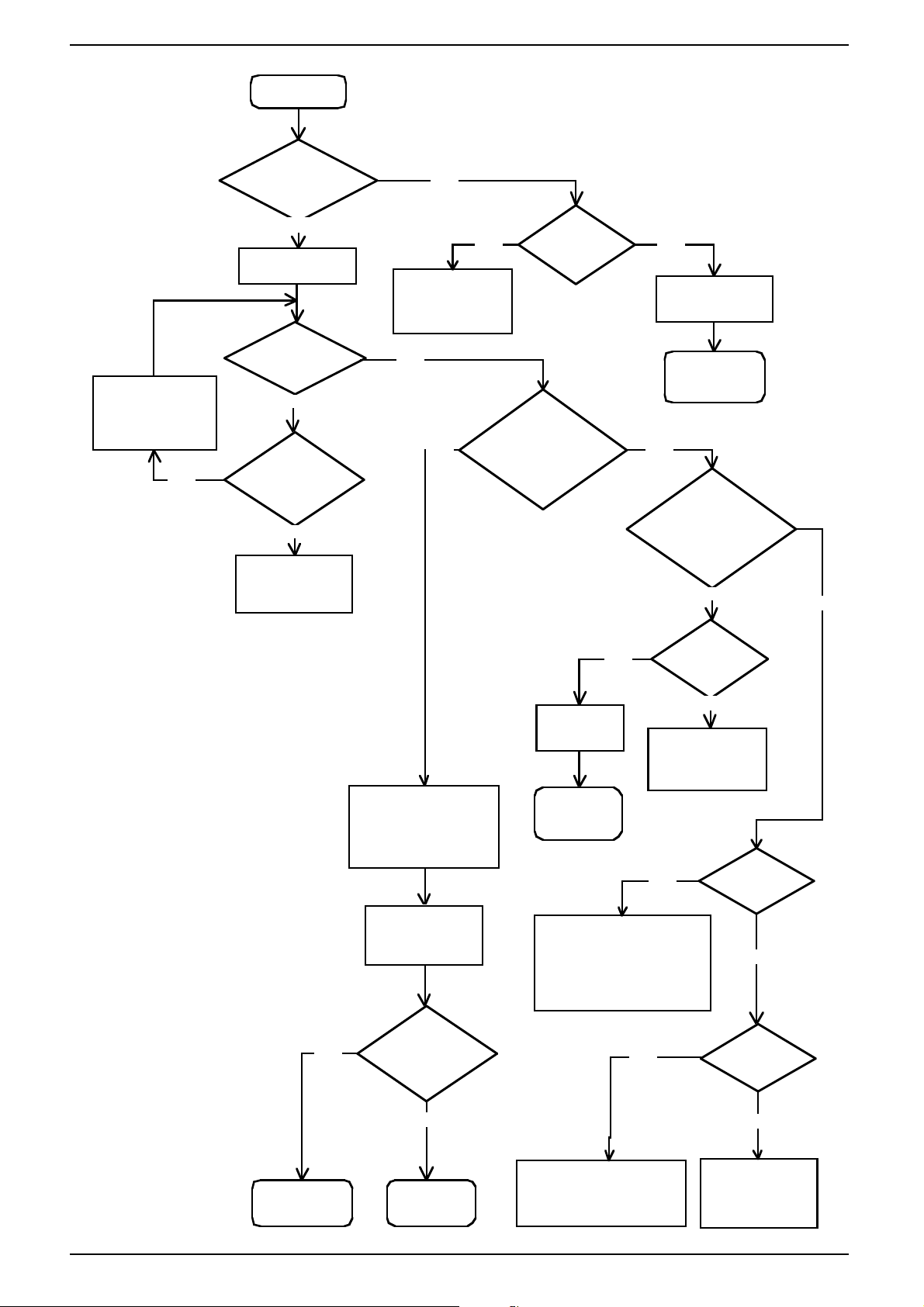

Section 9 Operational Checks & Wiring 32

Sequence of Functions 32

Diagnostic Error Codes 33

Fault Finding Guides 34-43

Section 10Appendix 44

Internal Time Clock Installation 44

External Time Clock Installation 46

S & Y Plan Installations 47

Exploded Diagrams 48-52

Abling & Disabling Controls 53

Functional Flow Diagram 54

Illustrated Wiring Diagram 55

Preliminary Electrical System Checks56

LPG Instructions 57-58

Valve 26

24

24

Page 3

SECTION 1 INTRODUCTION

The Vokèra Linea Plus is a combined central

heating and domestic hot water appliance. By

design it incorporates full sequence electronic

ignition, circulating pump, expansion vessel,

safety valve, temperature gauge, pressure

gauge and 3 port diverter valve. The Plus also

benefits from an air/gas modulation system

and has low NOx emissions.

The boiler is produced as a room sealed

appliance suitable for wall mounting applications only. It is provided with a fan powered

flue outlet with an annular co-axial combustion

air intake which can be rotated through 360

degrees. A vertical & twin flue option is available.

The appliance is designed for use with a sealed

heating system only and is not intended for use

on an open vented system.

The provision of stored domestic hot water is

possible by the addition of an indirect cylinder

with 'S' or 'Y' plan controls.

An automatic range-rating facility is incorporated in the boiler for the central heating system in conjunction with the electronic burner

modulation. The domestic hot water (dhw)

service utilises a motorised control combined

with a 3 port diverter valve to give hot water

priority which also benefits from a preheat

function.

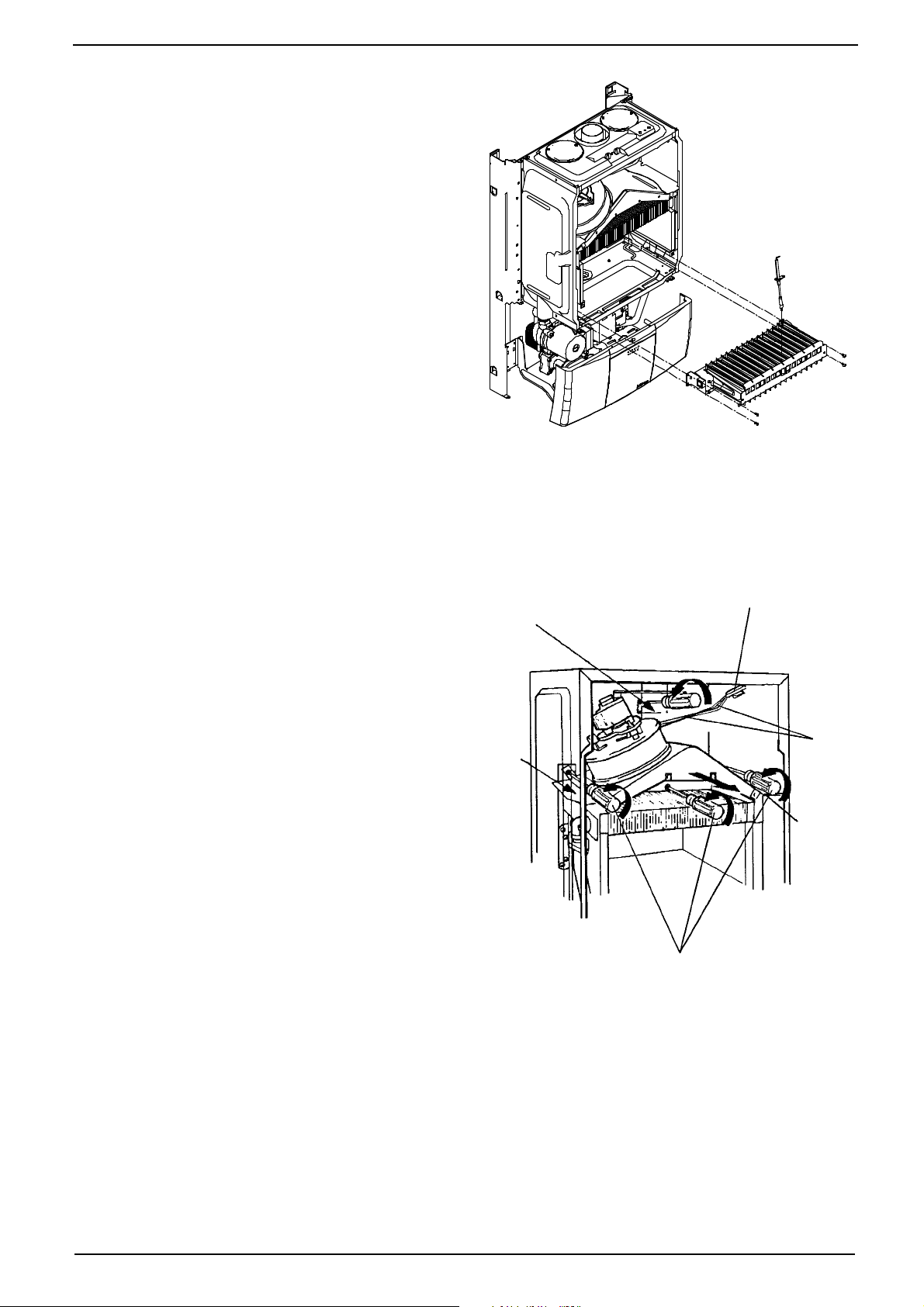

Fig.1 General Layout

1 Flue Outlet

2 Air Intake

3 Differential analog Pressure Switch (DAPS)

4 Silicone Pressure Tube

5 Silicone Negative Pressure Tube

6 Expansion Vessel

7 Main Heat Exchanger

8 Electrode

9 Burner Temperature control

9a Transformer

10 Gas Valve

11 Modulator Coil

12 Domestic Heat Exchanger

13 Domestic Hot Water Flow Switch

14 Safety Valve

15 Pressure Switch

16 Diverter Valve Motor

17 Pump

18 Automatic Air Release Valve

19 Main Burner

20 Combustion Chamber

21 Fan Assembly

22 Air Chamber (with front removed)

23 Flue Gas Analysis Test Point

24 Hot Water Temperature Control

25 Mode Selector Switch

26 Status LED

27 Temperature Indicator

28 Central Heating Temperature Control

29 Combustion Switch

30 Timeclock Aperture (optional)

31 Pressure Gauge

Linea Plus AG

1

Page 4

SECTION 2 DESIGN PRINCIPLES AND OPERATING SEQUENCE

2.1 Fig.1 illustrates the general layout of compo-

nents. Fig.2 illustrates the operating principles

described below.

2.2 Central Heating Mode

2.2.1 When the various switches and controls im-

pose a demand for heat, the pump is started.

If the primary pressure is sufficient, the

electronic circuitry is energised. The fan is

started, the gas valve is energised at an intermediate rate and the electronic ignition goes

through an ignition attempt.

2.2.2 The burner ignition is checked by the electronic

circuitry to ensure correct ignition of the burner;

once successful the gas will flow at 75% of

maximum heat input for a period of

approximately 15 minutes and then go to maximum heat input to maximise heating performance, unless the boiler nears optimum

temperature where it will modulate down to suit

system load.

2.2.3 As water temperature increases this is sensed

by the temperature sensor on the flow pipe

which modulates the fan and burner to match

the heat output to the heat requirement of the

system.

2.2.4 Depending on the load, either a) The water

temperature will continue to rise and the fan

and burner will continue to modulate down;

The burner will switch off at maximum temperature, or b) the water temperature will fall;

the fan and burner

Air Intake

Flue Outlet

3

6

NOTE

Fig. 2

18

17

16

15

A

BCD

7

19

10

12

13

will return to a higher output to match demand.

2.3 Domestic Hot Water Mode

2.3.1 The appliance incorporates a hot water

preheat facility. The appliance will therefore

ignite periodically to maintain heat within the

appliance.

2.3.2 The appliance will operate in domestic hot

water mode whenever the mode selector

switch is on regardless of mode selector

switch position and any demand for central

heating.

2.3.3 The diverter valve will automatically energise

into the hot water position after central heating demand, or will stay in the hot water

position after hot water demand. Opening a

draw off tap will energise the pump and fan

sending primary water to the domestic hot

water heat exchanger.

2.3.4 Temperature control is transferred to the domestic hot water thermostat (potentiometer)

which modulates the fan and burner output

between high and low flame to maintain an

average heat input to suit the dhw output

required.

2.3.5 An overrun is incorporated in the boiler in both

c/h & dhw modes. The fan overruns until the

boiler water cools to approximately 80°C

(176°F).

2.4 Safety Devices

2.4.1 In both central heating and hot water modes

safe operating is ensured by:

A. Differential pressure unit in the primary

circuit which prevents burner operation if water

pressure is too low.

B. An electronic device that checks the primary pressure unit for activation. Failure results in deactivation of the pump, after approximately 10 minutes of operation.

C. A safety thermostat, which interrupts the

control circuit shutting off the gas valve. At the

same time the fan will still operate.

D. A DAPS in the flue system to check the

fan's operation before allowing ignition.

2.4.2 A safety valve is provided to relieve excess

pressure from the primary circuit.

2.4.3 Frost Thermostat

The appliance has a built in frost protection

circuit. Should the boiler temperature sensed

at the primary thermistor fall below 5°C, the

boiler will operate in central heating mode and

continue to operate until the primary thermistor

reaches approximately 40°C.

KEY:

A Central Heating Return.

B Central Heating Flow.

C Hot Water Outlet.

D Cold Water Inlet.

2

NOTE: Pressure switch.

Senses water pressure in the primary circuit

and operates the pressure switch (15)

Linea Plus AG

Page 5

SECTION 3 TECHNICAL DATA

3.1 Units Dimensions and values are given in the

preferred Sl Units with Imperial units in brackets where applicable.

3.2 Dimensions and Contents

Plus AG

Height

Width

Depth

Weight dry

Weight full

820mm (32.3)

500mm (19.7)

355mm (14.0)

48kg (105.6lb)

51kg (112.2lb)

Water content: 3 litres (.66 gals)

for further dimensions see figs 12 - 16

3.3 Connection sizes

Heating flow and return: Nut and olive for

22mm o.d. Cold water inlet: Nut and olive for

15mm o.d. Hot water outlet: Nut and tail for

15mm o.d. Gas Service: Nut and tail for 15mm

o.d. Safety valve outlet: 15mm comp.or capillary

Flue outlet/Air inlet: nom dia 60/100mm specially supplied with boiler (concentric).

Flue outlet/Air inlet: nom dia 80/80mm specially supplied with boiler (twin).

3.4 Installation Requirements

3.4.1 Clearances (Horizontal or Vertical Flue)

Minimum - above casing 225mm (9in) Minimum - below casing 200mm (8in) Minimum In front 600mm (24in) Minimum - At sides

12mm (1/2in) from casing

3.4.2 Maximum heating system contents approx.

76.4 litres (16.8 gals). Acceptance capacity of

expansion vessel 10 litres (2.2 gals).

3.4.3 Means of filling sealed system: to accord with

BS and/or local Water Authority requirements.

3.4.4 The standard concentric horizontal flue allows

a maximum length of duct as follows:

Rear flue: 700mm (wall thickness)

Side flue: 890mm (to centre line of boiler).

Using extension tubes the flue may be extended to the following lengths.

Concentric

Plus AG

Horizontal

Vertical

3.0m

3.0m

Concentric Flue

Reduction in flue

Bend

45°

90°

length for each bend

0.5 m

1.0 m

Twin Flue

Reduction in flue

Bend

45°

90°

length for each bend

1.0 m

1.0 m

3.5 Electrical Details

Mains supply 230v ~ 50Hz Fused 3A

Internal fuse rating F2A and T100mA

Power consumption:160W

3.6 Performance and Limitations Plus AG

Max. input 34.9 kW (119,080 Btu/h)(net h/w)

Max. inpu 38.7 kW (132.050Btu/h)(grossh/w)

Max. input 34.9 kW (119.080 Btu/h)(net c/h)

Max. input 38.7 kW (132.050Btu/h)(gross c/h)

Min. input 9.95 kW (34.052 Btu/h)(net)(c/h)

Min. input 9.95 kW (34.052 Btu/h)(net)(h/w)

Min. input 11.07 kW (37.770 Btu/h)(gross)(c/h)

Min. input 11.07 kW (37.770 Btu/h)(gross)(h/w)

Max. output 32.00 kW (109,200 Btu/h)(h/w)

Max. output 32.00 kW (109,200 Btu/h)(c/h)

Min. output 9.0 kW (30,700 Btu/h)(h/w)

Min. output 9.0 kW (30,700 Btu/h)(c/h)

Central heating output range

Max. 32.0 kW (109,200 Btu/h)

Min. 9.0 kW (30,700 Btu/h)

Nominal hot water production

Temp. rise of 30°C 15.3l/min.

Temp. rise of 35°C 13.1l/min.

Gas Pressures

Max. gas pressure 10.1 mbar h/w

Min. gas pressure 1.1 mbar h/w

Gas Rate

Max. 3.69m3/h 138.8 ft3/h (h/w)

Min. 1.05 m3/h 35.6 ft3/h (h/w)

Note: Use gross input values when gas

rating the appliance

Twin (+ concentric terminal)

Horizontal

Vertical

The reduction in flue length for each bend

used is listed opposite.

Linea Plus AG

Plus AG

14/14m

14/14m

Burner Details Main burner:

Polidoro type Main burner injectors 16 x 1.35

3.7 Working Pressure Heating System

Maximum 1.5bar/15m w.g./50ft w.g.

Minimum 0.15bar/1.5m w.g./5ft w.g.

Safety valve setting 3bar/30m/102ft w.g.

3.8 Flow Rates Min. waterflow (dhw) 2.0l/min.

(0.45 gal/min) Min central heating flow rate

through appliance 350litres/hr (1.28 gal/min)

3

Page 6

3.9 Working Pressure Hot Water System

Maximum 6.0 bar/90psig Minimum 0.6 bar/

7psig

For LPG instructions see page 62.

3.10 Central Heating Pump Duty

Fig.3 indicates the flow rate available plotted

against system pressure drop.

N.B. When using this graph apply only the

pressure drop of the system. The curve has

been modified to allow for the pressure drop

through the appliance.

Fig. 3

4

Linea Plus AG

Page 7

SECTION 4 GENERAL REQUIREMENTS

4.0 General Requirements

This appliance must be installed by a competent person in accordance with the Gas Safety

(Installation & Use) Regulations 1998.

4.1 Related Documents

The installation of this boiler must be in accordance with the relevant requirements of

the Gas Safety (Installation & Use) Regulations 1998 the Local Building Regulations, the

current l.E.E. Wiring Regulations, the by-laws

of the local water undertaking, and in Scotland, in accordance with the Building Standards (Scotland) Regulation. In Ireland the local building regulations (IE).

It should be in accordance also with any relevant requirements of the local authority and

the relevant recommendations of the following British Standard Codes of Practice:

BS 6891 1988 Low pressure installation pipes.

BS 6798 1987 Boilers of rated input not exceeding 60kW.

BS 5449 Part 1 1990 Forced circulation hot water systems

BS 5546 1990 Installation of gas hot water supplies for domestic

BS 5440 Part 1 1990 Flues.

BS 5440 Part 2 1989 Flues & Ventilation.

BS 7074 Part 1 1989 Application, selection & installation of expansion

A compartment used to enclose the boiler

must be designed and constructed specifically for this purpose. An existing cupboard or

compartment may be used provided that it is

modified for this purpose.

Details of essential features of cupboard/ compartment design including airing cupboard installations are given in BS 6798:1987. This

appliance is not suitable for external installation.

4.3 Gas Supply

A gas meter is connected to the service pipe

by the gas supplier.

An existing meter should be checked, preferably by the gas supplier, to ensure that the

meter is adequate to deal with the rate of gas

supply required for all appliances it serves.

purposes (2nd family gases).

vessels & ancillary equipment for sealed water

systems.

4.2 Location of Appliance

The combination boiler may be installed in any

room or internal space, although particular

attention is drawn to the requirements of the

current l.E.E. Wiring Regulations, and in Scotland, the electrical provisions of the Building

Regulations applicable in Scotland, with respect to the installation of the combination

boiler in a room or internal space containing a

bath or shower.

Where a room-sealed appliance is installed in

a room containing a bath or shower, any

electrical switch or appliance control, utilising

mains electricity, should be located in such a

position that it cannot be touched by a person

using the bath or shower.

The location chosen for the boiler must permit

the provision of a satisfactory flue and termination. The location must also permit an adequate air supply for combustion purposes

and an adequate space for servicing and air

circulation around the boiler.

Where the installation of the boiler will be in an

unusual location special procedures may be

necessary and BS 6798:1987 gives detailed

guidance on this aspect.

Installation pipes should be fitted in accordance with BS 6891:1988.

Pipework from the meter to the boiler must be

of adequate size. Pipes of a smaller size than

the boiler inlet connection should not be used.

The complete installation must be tested for

soundness as described in the above code.

N.B. If the gas supply for the boiler serves

other appliances ensure that an adequate

supply is available both to the boiler and the

other appliance when they are in use at the

same time.

4.4 Flue System

The terminal should be located where dispersal of combustion products is not impeded and

with due regard for the damage or discoloration that might occur to building products in the

vicinity (see fig 4).

The terminal must not be located in a place

where it is likely to cause a nuisance.

In cold and/or humid weather water vapour

may condense on leaving the flue terminal.

The effect of such ‘steaming’ must be considered.

Linea Plus AG

5

Page 8

For protection of combustibles, refer to BS

5440:1 where the terminal is less than 2m

(6.6ft) above a pavement or platform to which

people have access (including any balcony or

flat roof the terminal must be protected by a

guard of durable material).

A suitable guard is available from Vokera Ltd.

Part No 018, G.C. No. 301 106

This guard must be fitted centrally over the

terminal. Mark the positions of the fixings, drill

the wall and secure using wall plugs and 3 of

1˚" No.8 plated screws.

Fig. 4

Terminal position for fan assisted boiler

(minimum distance) mm

A - Directly below an open window or other 300

opening (e.g. air brick)

B - Below gutters, soil pipes or drain pipes 25

C - Below eaves 25

D - Below balconies or car port roof 25

E - From vertical drain pipes and soil pipes 75

F - From internal or external corners 25

G - Above ground or below balcony level 300

H - From a surface facing a terminal 600

I - From a terminal facing a terminal 1200

J - From an opening in the car port (e.g. door

window) into dwelling. 1200

K - Vertically from a terminal on the same wall 1500

L - Horizontally from a terminal on the same wall 300

M - Horizontally from a vertical terminal to a wall 300

N - Horizontally from an opening, airbrick, openable

window, etc. 300

4.6 Water Circulation (Central Heating)

Detailed recommendations are given in S6798:

1987 and BS 5449: 1: 1990 (for smallbore and

microbore central heating systems).

4.6.1 The following notes are given for general

guidance.

4.6.2 Pipework

Copper tubing to BS 2871:1:1971 is recommended for water pipe. Jointing should be

either by capillary soldered or with compression fittings.

Where possible, pipes should have a gradient

to ensure air is carried naturally to air release

points and water flows naturally to drain taps.

It should be ensured as far as possible that the

appliance heat exchanger is not a natural

collecting point for air.

Except where providing useful heat, pipes

should be insulated to prevent heat loss and to

avoid freezing. Particular attention should be

paid to pipes passing through ventilated spaces

in roofs and under floors.

4.6.3 By-Pass

An automatic by-pass is incorporated in the

boiler, but systems should be designed to

ensure that with all radiators turned off a flow

rate of at least 350 litres/hour (1.28 gals/min)

is achieved through the system. See 6.9.4.

4.6.4 System Design

Figs 5 & 5a illustrates typical system layouts

showing options of either, pipe connection

from below as fig. 5, or pipe connection from

above utilising the purpose made duct in the

rear frame of the appliance.

4.6.5 Draining Taps

These must be located in accessible positions

to permit the draining of the whole system. The

taps must be at least 15mm nominal size and

manufactured in accordance with BS 2879:

1980.

NOTE: The flue must be terminated in a place not likely

to cause a nuisance.

4.5 Air Supply

The following notes are intended for general

guidance.

The room sealed fan flued boiler does not

require a permanent air vent for combustion

air supply.

Where installed in a cupboard or compartment

ventilation is not required.

6

Linea Plus AG

Page 9

Fig. 5

Fig. 5a

N.B. Vokèra Ltd recommend a 2-pipe system. Single pipe systems are more liable to be troublesome unless

carefullly designed and installed.

Linea Plus AG

7

Page 10

4.6.6 Air Release Points

These must be fitted at all high points where

air will naturally collect, and must be sited to

facilitate complete filling of the system.

4.6.7 The appliance has an integral sealed expansion vessel to accommodate the increase of

water volume when the system is heated. It

can accept up to 10 litres of expansion water.

If the appliance is connected to a system with

an unusually high water content. Calculate the

total expansion and add additional sealed

expansion capacity as appropriate.

In general, modern systems will present no

problem.

4.6.8 Filling Point

A method for filling the system and replacing

water lost during servicing is provided on the

appliance.

This method complies with the Water Supply

(Water Fittings) Regulations 1999.

4.7 Electrical Supply

The appliance is supplied for operation on

230V ~ 50Hz electricity supply. It should be

protected with a 3-amp fuse.

THIS APPLIANCE MUST BE EARTHED.

The method of connection to the mains elec-

tricity must allow complete isolation from the

supply.

The preferred method is by using a fused

double pole switch with a contact separation

of at least 3mm.

The switch must supply ONLY the appliance

and immediate electrical control circuits (e.g.

programmer / room thermostat)

Alternatively, use an unswitched shuttered

socket outlet with a fused 3-pin plug both

complying with BS 1363.

4.8 Showers

If a shower control is to be supplied from the

combination unit it should be of the type which

incorporates a thermostatic control and by

design is suitable for use with a combination

boiler. Check application with shower manufacturer.

C/H Flow

Valve

C/H Return

Valve

Safety valve

outlet

Filling Loop

Cold water

Inlet Stopcock/

filling valve

Gas

Cock

Hot water

Outlet

Fig.6

Fig. 7

8

Linea Plus AG

Page 11

SECTION 5 INSTALLATION

Fig. 8

Fig. 9

5.1 Delivery (fig. 8)

The appliance is delivered in a heavy duty

cardboard carton.

Lay the carton on the floor with the writing the

correct way up.

5.2 Unpacking (fig. 9)

Pull both sides of the top of the carton open.

Do not use a knife. Remove the hanging

bracket, literature pack and fittings pack, from

the packaging. Remove the package supports.

Lift the appliance from the carton and lay the

appliance down with the white frame on the

floor.

Remove the protective bag, and the

polystyrene support from the back of the

appliance.

Do not remove the insulation jacket on the

domestic heat exchanger.

The fittings pack contains

Wiring harness for optional built in timer

15mm nut & olive

Adjustable stopcock

Safety valve outlet pipe (1)

Filling loop hose (1)

Various washers

Flue kit supplied in separate carton.

5.3 Preparing for Mounting

5.3.1 Push to release front door panel and lower to

reveal controls. Loosen the 2 captive screws

securing the front control panel to the lower

part of the casing and lower to reveal inside of

boiler (fig. 10).

5.3.2 Remove two screws at base of casing, slightly

lift the casing and slide it gently towards the

top of the appliance to disengage the case

from the top suspension hooks (fig. 11).

5.3.3 Ensure the casing and screws are put to one

side in a safe place.

Fig. 10

Linea Plus AG

Case Screws

Fig. 11

Case screws

(one either side)

9

Page 12

5.4 Mounting the appliance

The appliance should be mounted on a smooth,

vertical surface, which must be capable of

supporting the full weight of the appliance. Care

should be exercised when determining the

position of the appliance with respect to hidden

obstructions such as pipes, cables, etc.

When the position of the appliance has been

decided – using the template supplied – carefully

mark the position of the fixing jig/mounting

bracket assembly (see fig. 7) and flue-hole (if

applicable).

5.4.1 Important

There are two holes on the template. The

lower hole should be used with the telescopic

flue kit (part no. 0225705 & 0225710). The

upper hole is for use with all other horizontal

flue kits.

5.4.2 Maximum flue lengths

Flue system Linea Plus AG

Concentric Horizontal 3.0m

Concentric Vertical 3.0 m

Twin flue 14m/14m + terminal

5.5 Fitting the flue

The top flue outlet permits both horizontal and

vertical flue applications to be considered,

alternatively, the Vokera twin flue system can

be utilised if longer flue runs are required.

5.5.1 Concentric horizontal flue

(For concentric vertical flue, see 5.5.2)

(For twin flue applications, see 5.5.3)

The appliance flue outlet elbow can be rotated

through 360º on its vertical axis. In addition the

flue may be extended from the outlet elbow in

the horizontal plane (see 5.4.2), however if the

flue is to be extended or additional bends are to

be fitted, the standard horizontal flue kit (part no.

2359029) must be used. A reduction must also

be made to the maximum length (see table)

when additional bends are used.

Horizontal flue terminals and accessories

Part No. Description Min-Max Length

0225705 Standard telescopic flue 380mm – 600mm

(Dimension ‘X’)

0225710 Extended telescopic flue 600mm – 920mm

(Dimension ‘X’)

2359029 Horizontal flue kit 833mm

For use with add. (Dimension ‘X’)

Bends & extensions

2359069 750mm extension 750mm

2359079 1500mm extension 1500mm

2359049 45º bend (pair) N/A

2359059 90º bend N/A

0225760 Wall bracket (5) N/A

FITTING THE TELESCOPIC FLUE KIT (0225705 &

0225710)

Carefully measure the distance from the centre of the

appliance flue outlet to the face of the outside wall

(dimension ‘X’ see fig. 12). Add 50mm to dimension ‘X’

to give the overall flue length (dimension ‘Y’). Using the

complete telescopic flue assembly adjust the length to

suit dimension ‘Y’. Once the telescopic flue terminal has

been adjusted to the correct length, secure the flue

assembly with the screw supplied.

Insert the flue assembly into the previously drilled flue

hole and locate the flue bend over the appliance flue

outlet. Push the flue bend down over the appliance flue

outlet and ensure the correct seal is made. Pull the flue

assembly towards and over the flue bend – using a

twisting action – ensuring the correct seal is made.

Check that the terminal protrudes past the finished

outside wall by the correct length (115mm).

NOTE

You must ensure that the entire flue system is properly

supported and conncented.

Reduction for bends

Bend Reduction in maximum flue length

for each bend

45º bend 0.5 metre

90º bend 1.0 metre

Using the template provided (see 5.4.1), mark

and drill a 125mm hole for the passage of the

flue pipe. The hole should have a 1º drop from

the boiler to outside, to eliminate the possibility

of rainwater entering the appliance via the flue.

The fixing holes for the wall-mounting bracket &

jig should now be drilled and plugged, an

appropriate type and quantity of fixing should

be used to ensure that the bracket is mounted

securely. Once the bracket & jig has been

secured to the wall, mount the appliance onto

the bracket.

10

Fig. 12

Seal the flue assembly to the wall using cement or a

suitable alternative that will provide satisfactory

weatherproofing. The interior and exterior trim can now

be fitted.

Linea Plus AG

Page 13

FITTING THE STANDARD (2359029)

HORIZONTAL FLUE KIT (see 5.4.1)

Carefully measure the distance from the centre

of the appliance flue outlet to the face of the

outside wall (dimension ‘X’ see fig. 13). Ensure

the inner (60mm) pipe is fully inserted into the

outer (100mm) pipe (when the inner pipe is

fully inserted, it stands proud of the outer pipe

by 7.5mm). Add 32mm to dimension ‘X’ to give

the overall flue lenghth (dimension 'Y')standard

horizontal flue kit (part no. 2359029) is suitable

for a distance (dimension ‘Y’) of up to 865mm.

Fig. 13

NOTE

Dimension ‘Y’ is measured from the end of the

terminal to the end of the outer (100mm) pipe.

The internal trim should be fitted to the flue

pipe before connection of the 90º bend.

If the horizontal flue kit (2359029) requires to

be cut to the correct size (dimension ‘Y’), you

must ensure that the inner (60mm) pipe stands

proud of the outer (100mm) pipe by 7.5mm

(see fig. 13A). Ensure any burrs are filed or

removed and that any seals are located

properly before assembly.

Connect the inner (60mm) pipe of the terminal

assembly to the push-fit end of the 90º bend

(supplied) using a twisting action. Insert the

assembled flue into the previously drilled hole.

Using the clips & screws supplied, connect the

flue assembly to the boiler, ensuring that the

terminal protrudes past the finished outside

wall by the correct length (135mm).

You must ensure that the entire flue system is

properly supported and connected.

EXTENDING THE HORIZONTAL FLUE

If the horizontal flue requires extension/s or

additional bend/s, the horizontal flue terminal

kit (2359029) must be used. Connect the bend

– supplied with the terminal kit – to the top of the

boiler using the clips, screws, & gaskets

supplied. The additional bends & extensions

have an internal push-fit connection, care should

be taken to ensure that the correct seal is made

when assembling the flue system. Connect the

required number of flue extensions or bends

(up to the maximum equivalent flue length) to

the flue terminal using the clips, screws, &

gaskets supplied (see fig. 13 & 13A).

NOTE

When cutting the horizontal flue terminal or an

extension to the required length, you must

ensure that the excess is cut from the plain end

of the terminal or extension, and that the inner

(60mm) pipe is 7.5mm longer than outer

(100mm) pipe (see fig. 13 & 13A). Remove any

burrs, and check that any seals are located

properly.

You must ensure that the entire flue system is

properly supported and connected.

Seal the flue assembly to the wall using cement

or a suitable alternative that will provide

satisfactory weatherproofing. The interior and

exterior trim can now be fitted.

5.5.2 CONCENTRIC VERTICAL FLUE

The vertical flue terminal can be connected

directly to the appliance flue outlet. Alternatively,

an extension or bend can be connected to the

appliance flue outlet if desired (see 5.4.2),

however if additional bends are fitted, a reduction

must be made to the maximum flue length (see

table below).

Reduction for bends

Bend Reduction in maximum flue length for

each bend

45º bend 0.5 metre

90º bend 1.0 metre

Seal the flue assembly to the wall using cement

or a suitable alternative that will provide

satisfactory weatherproofing. The exterior trim

can now be fitted.

Linea Plus AG

Fig. 13A

Vertical flue terminal and accessories

Part No. Description Length

2359039 Vertical flue terminal 1.0 metre

0225770 Pitched roof flashing N/A

plate

0225765 Flat roof flashing plate N/A

2359069 750mm extension 750mm

2359079 1500mm extension 1500mm

2359049 45º bend (pair) N/A

2359059 90º bend N/A

0225760 Wall bracket (5) N/A

11

Page 14

Using the dimensions given in fig. 14 as a reference,

mark and cut a 105mm hole in the ceiling and/or

roof.

Fit the appropriate flashing plate to the roof and

insert the vertical flue terminal through the flashing

plate from the outside, ensuring that the collar on

the flue terminal fits over the flashing.

The fixing holes for the wall-mounting bracket & jig

should now be drilled and plugged, an appropriate

type and quantity of fixing should be used to ensure

that the bracket is mounted securely. Once the

bracket has been secured to the wall, mount the

appliance onto the bracket & jig.

IMPORTANT

The vertical flue terminal is 1.0 metre in length and

cannot be cut; therefore it may be necessary to

adjust the height of the appliance to suit or use a

suitable extension.

Remove or discard the flue restrictor ring from the

appliance flue outlet (see fig. 1), if the total flue

length – including the allowance for any additional

bends – exceeds 1.0 metre.

Connect the vertical flue assembly to the boiler flue

spigot using the 60mm & 100mm clips, gaskets, &

screws (supplied), ensuring the correct seal is

made. The flue support bracket (supplied with the

vertical flue kit) can now be fitted.

If the vertical flue requires extension/s or additional

bend/s, connect the required number of flue

extensions or bends (up to the maximum equivalent

flue length) between the boiler and vertical flue

assembly (see fig. 13A).

5.5.3 TWIN FLUE SYSTEM

The Vokera twin flue system enables greater

flue distances to be achieved (see 5.4.2) than

that of the standard concentric flue system. It

can be used for horizontal or vertical

applications, however the twin flue system

must be converted to the dedicated concentric

flue kit for termination. It is essential that the

installation of the twin flue system be carried

out in strict accordance with these instructions.

GUIDANCE NOTES ON TWIN FLUE

INSTALLATION

• The flue must have a fall back of 1º back to

the appliance to allow any condensate that

may form in the flue system to drain via the

condensate drain. Consideration must also

be given to the fact that there is the possibility

of a small amount of condensate dripping

from the terminal.

• Ensure that the entire flue system is

adequately supported, use at least one

bracket for each extension.

• The entire flue system must be adequately

insulated to maintain heat within the flue

system thereby reducing the possibility of

condensate production.

As the exhaust outlet pipe can reach very high

temperatures it must be protected to prevent

persons touching the hot surface.

NOTE

When cutting an extension to the required length,

you must ensure that the excess is cut from the

plain end of the extension and that the inner (60mm)

pipe is 7.5mm longer than outer (100mm) pipe (see

fig. 13A). Remove any burrs, and check that any

seals are located properly.

You must ensure that the entire flue system is

properly supported and connected.

Fig. 14

Reduction for bend

Bend Reduction in maximum flue length for

each bend

45º bend 1.0 metre

90º bend 1.0 metre

Twin flue accessories

Part No. Description Length

0225805 Horizontal flue terminal 1.0 metre

0225810 Vertical flue terminal 1.0 metre

300 Twin adapter kit N/A

0225770 Pitched roof flashing plate N/A

0225765 Flat roof flashing plate N/A

0225815 Condensate drain kit N/A

0225820 0.25m extension (pair) 250mm

0225825 0.5m extension (pair) 500mm

0225830 1.0m extension (pair) 1000mm

0225835 2.0m extension (pair) 2000mm

0225840 45º bend (pair) N/A

0225845 90º bend (pair) N/A

0225850 Twin bracket (5) N/A

0225855 Single bracket (5) N/A

12

Linea Plus AG

Page 15

Mounting the boiler

The fixing holes for the wall-mounting bracket

& jig should now be drilled and plugged, an

appropriate type and quantity of fixing should

be used to ensure that the bracket is mounted

securely. Once the bracket has been secured

to the wall, mount the appliance onto the

bracket & jig.

5.5.3.1 Installation of twin adaptor kit (fig. 15)

The condensate drain kit must be fitted within

1 metre of the appliance flue outlet. It is

recommended that the condensate drain kit

should be fitted in the vertical plane, however

it can be fitted horizontally with care.

• Fit the first bend to the condensate drain kit

or exhaust connection manifold by firmly

pushing in to position.

• Using the two holes in the exhaust connection

manifold as a guide, drill a 3mm hole in each

and secure using the screws provided.

• Connect the air inlet pipe to the air baffle as

above.

• The twin flue pipes extensions and

accessories can now be installed by pushing

together (the plain end of each extension or

bend should be pushed approximately 50mm

into the female socket of the previous piece).

The condensate drain trap must be connected

to the drain in accordance with Building

Regulations or other rules in force

Fig. 15

5.5.3.2

• Remove or discard the flue restrictor ring

from the appliance flue outlet (see fig. 1).

• Insert the small restrictor ring (supplied with

the twin adapter kit) if the total flue length –

including the allowance for any bends – is

less than 8 metres.

• Insert the exhaust connection manifold onto

the appliance flue outlet.

• Place the silicone seal (supplied with twin

adapter kit) over the rim of the exhaust

connection manifold.

• Remove one of the blanking plates (located

to the left & right of the appliance flu

• Remove one of the blanking plates (located

to the left & right of the appliance flue outlet)

and – using the same screws – install the air

baffle.

Installation of condensate drain kit

(fig. 16)

5.5.3.3 Horizontal termination ( fig. 17)

The twin flue system must be converted to the

dedicated concentric flue kit for termination.

• The horizontal terminal is supplied with a

built-in converter box and cannot be

shortened.

Fig. 17

• A 130mm hole is required for the passage of

the concentric terminal through the wall.

Depending on site conditions it may be

preferable to install the terminal assembly

prior to fitting the twin flue pipes.

Fig. 16

Linea Plus AG

Mark and drill a 130mm hole for the passage

of the horizontal flue terminal, ensuring that

there is a 1º fall back to the boiler (17mm per

1000mm). Insert the terminal assembly into

the flue hole.

Push-fit the twin flue pipes onto the concentric

to twin converter ensuring that the exhaust

pipe connects to the exhaust connection on

the concentric to twin converter.

If necessary cut the plain ends (male) of the

twin flue pipes to allow connection to the

concentric to twin converter.

13

Page 16

NOTE

• Before cutting twin flue pipes ensure

allowances have been made for connection

onto the previous piece and onto the

concentric to twin converter. The last twin

flue pipes must be pushed 50mm onto the

male spigots of the concentric to twin

converter.

NOTE

You must ensure that the entire flue system is

properly supported and connected.

When cutting an extension to the required

length, you should ensure that the excess is

cut from the plain end of the extension. Remove

any burrs, and check that both seals are

located properly.

Seal the flue terminal assembly to the wall

using cement or a suitable alternative that will

provide satisfactory weatherproofing. The

interior and exterior trim can now be fitted.

5.5.3.4 Vertical termination (See fig. 18)

The twin flue system must be converted to the

dedicated concentric flue kit for termination.

• The vertical terminal is supplied with a builtin converter box and cannot be shortened.

• A 130mm hole is required for the passage of

the concentric terminal through the ceiling

and/or roof.

Depending on site conditions it may be

preferable to install the terminal assembly

prior to fitting the twin flue pipes.

Fit the appropriate flashing plate to the roof

and insert the vertical flue terminal through the

flashing plate from the outside, ensuring that

the collar on the flue terminal fits over the

flashing.

Push-fit the twin flue pipes onto the concentric

to twin converter ensuring that the exhaust

pipe connects to the exhaust connection on

the concentric to twin converter.

If necessary cut the plain ends (male) of the

twin flue pipes to allow connection to the

concentric to twin converter.

Fig. 18

• You must ensure that the entire flue system

is properly supported and connected.

• Ensure that any horizontal sections of pipe

have a 1º fall towards the appliance (17mm

per 1000mm).

• The convertor box on the vertical terminal

will have to be temporarily removed when

inserting the terminal through the flashing.

• The condensate trap must be primed with

water prior to commissioning the boiler.

• The condensate drain trap must be

connected to the drain in accordance with

building regulations or other rules in force.

14

NOTE

• Before cutting twin flue pipes ensure

allowances have been made for connection

onto the previous piece and onto the concentric

to twin converter. The last twin flue pipes must

be pushed 50mm onto the male spigots of the

concentric to twin converter.

Linea Plus AG

Page 17

5.6 Connecting the Gas and Water

5.6.1 Figs. 6 and 15 show the locations of the

fittings.

5.6.2 Do not over tighten nuts, use another spanner

to apply counter force to avoid damaging the

appliance

5.6.3 Gas Supply

Connecting the gas supply.

Connect a 15mm gas pipe to the gas service

tap and tighten the union nut securing the tap

to the appliance.

Pipework from the meter to the appliance

must be of adequate size.

A minimum gas pressure of 20mb (8 in. w.g.)

must be available at the appliance inlet at full

flow rate. See section 3.

DO NOT use pipes of a smaller size than the

appliance inlet connection.

5.6.4 Central Heating

Connect the central heating pipework (22mm

o.d) to the respective valves, right hand: flow,

left hand: return, and tighten the nuts.

5.6.5 Hot Water

Connect a 15mm pipe to the hot water outlet

connection of the appliance. Tighten the nut.

If the hot water system does not include a tap

below the hot water outlet connection, provide

a suitable drain tap to permit draining of the

appliance hot water side during servicing.

5.6.6 Cold Water

Connect a 15mm cold water service pipe to

the inlet stopcock of the appliance. Tighten the

nut.

If the cold water supply is liable to high pressure or large pressure fluctuations, a flow/

pressure regulator should be fitted in the supply pipe.

Should the appliance be subject to 'mains

knock' it would be advisable to install an non

return valve in the hot water outlet pipe to

prevent unnecessary activation of the domestic flow switch.

5.6.7 Safety Valve Discharge

Connect a 15mm pipe to the discharge outlet

of the appliance.

The discharge should terminate facing downwards outside the building in a position where

discharging (possibly boiling) water will not

create danger or nuisance; but in an easily

visible position.

5.7 Electrical Connections

5.7.1 The electricity supply must be as specified in

4.7. If controls external to the appliance are

required, design of the external electrical circuits should be undertaken by a competent

person.

See Section 10 for further advice.

N.B. IT IS ESSENTIAL THAT ALL EXTERNAL CONTROL CIRCUITS AND WIRING IS

WIRED FROM THE SAME ELECTRICAL ISOLATOR AS SERVES THE APPLIANCE.

Factory fitted internal wiring must not be disturbed when wiring external controls.

5.7.2 To gain access to the electrical terminals

Remove electrical cover by releasing four

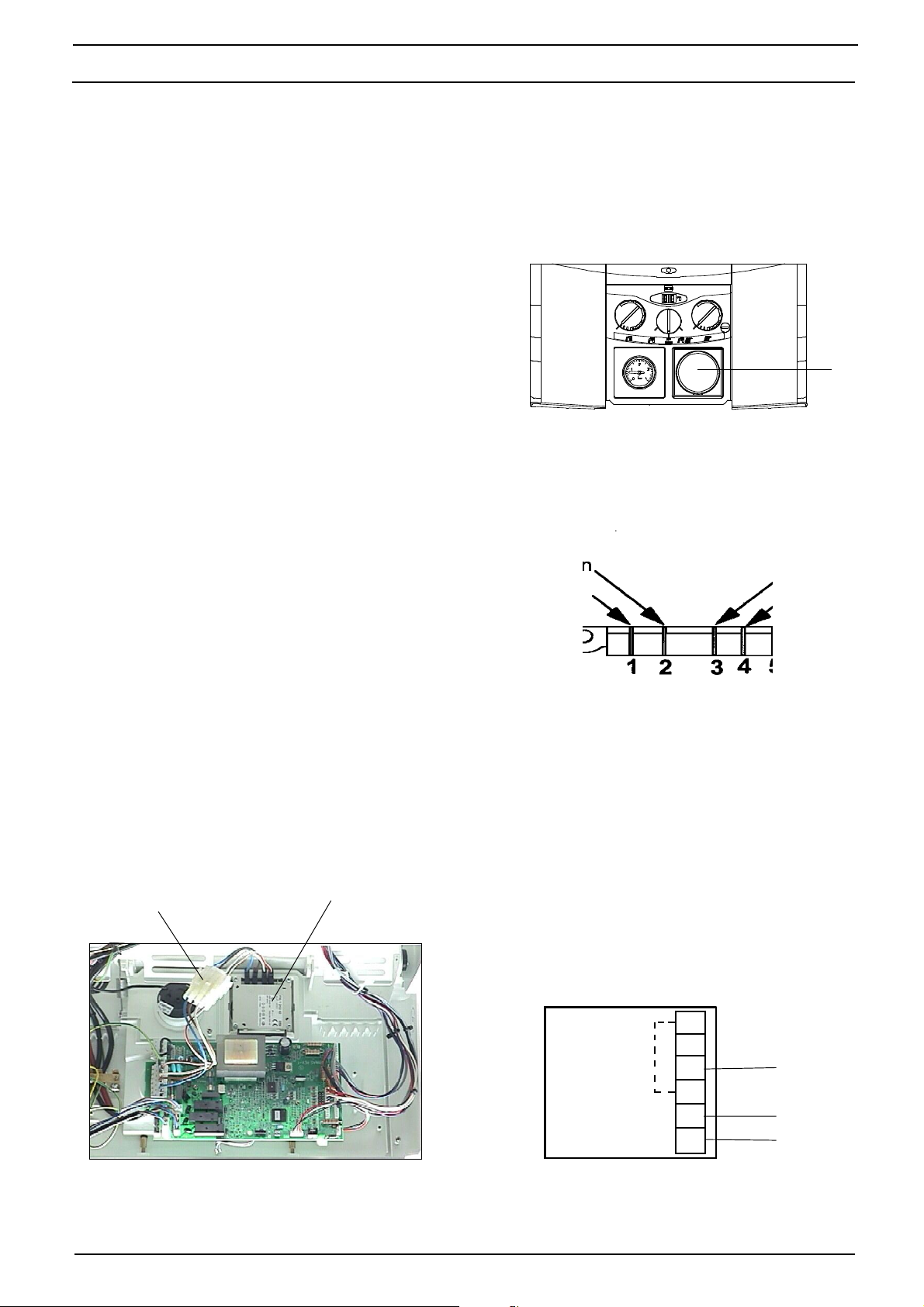

securing screws. Fig.18.

The mains input terminal block is now easily

visible (see fig. 18a).

5.7.3 The electricity supply cable from the isolator

and the appliance terminal block must be 3

core flexible sized 0.75mm˝ (24 x 0.2mm) to

BS6500.

Wiring to the appliance should be rated for

operation in contact with surfaces up to 90°C.

Electrical Cover

Screws

Fig. 18

Factory Fitted

Earth

Screw

Fig. 18a

Link Between

= & TA

Mains Input and

External Controls Terminal

Block

Linea Plus AG

15

Page 18

5.7.4 Pass the cable through one of the cord anchorage points and connect the wires Brown

to L, Blue to N, and Green/Yellow to .

Arrange the cable so that should the cable slip

the anchorage the current carrying conductors become taut before the earthing conductor.

5.7.5 Securely tighten all terminal screws and arrange the cable with slack between the cable

anchor and the terminal block. Tighten the

cord anchorage screw until the cable is secure.

5.7.6 Neatly arrange the external cable in such a

way that unrestricted opening of the controls

fascia is possible without strain on the cable.

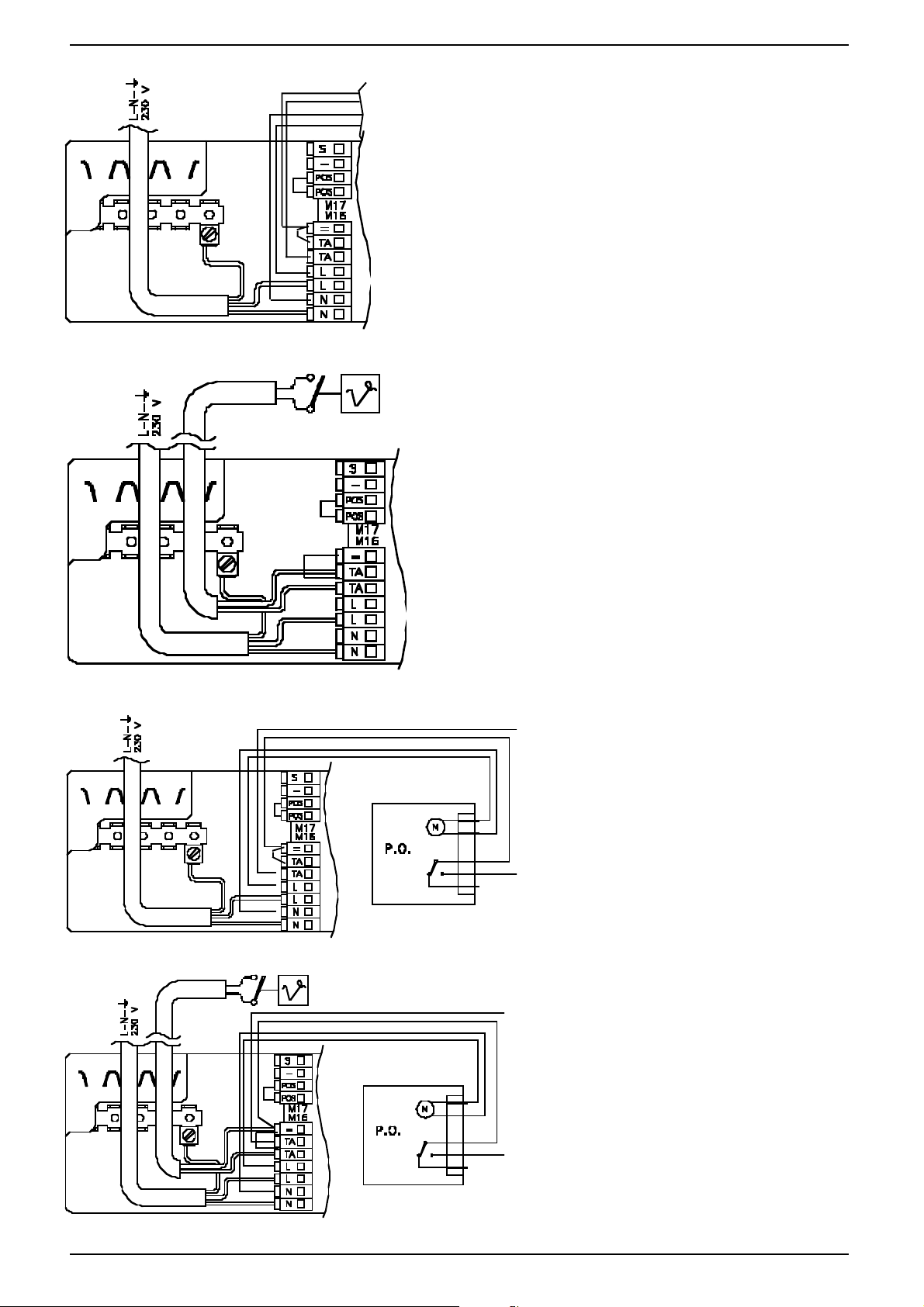

5.7.7 External controls may be wired from terminals

TA to TA after removing the factory fitted link

(see fig. 18 & pages 49 - 52 for further details).

If a neutral is needed use the terminal marked

N on the terminal strip.

DO NOT CONNECT ANY WIRES TO THE

TERMINAL STRIP MARKED 'S' '-' 'POS' 'POS'

When connecting wires to the terminal strip it

is possible to remove the terminal strip from

the circuit board: Grasp the terminal strip

firmly and slide up to clear pcb. See fig.21.

When refitting the terminal strip it is important

that it is replaced correctly (with the screws

facing left).

Section 10 gives details of fitment for external

and internal controls (ie Vokera time clock).

If required pass the external controls cable

through the spare cord anchorage and arrange the cable so that should the cable slip

the anchorage the current carrying conductors become taut before the earthing conductor.

Main Burner

Test Point

Incoming Gas

Pressure Test

Point

Closed

Position

Fig. 19

Normal

Operating

Position

Filling

Position

16

Fig. 20

Do not connect wires

to this terminal strip

Fig. 21

Controls terminal

strip

Linea Plus AG

Page 19

SECTION 6 COMMISSIONING

6.1 Where the text bears identifying numbers in

brackets, refer to figs. 1 and 2 unless otherwise instructed.

6.2 Gas Supply Installation

Inspect the entire installation including the

meter. Test for soundness and purge, all as

described in BS6891:1988.

6.3 Central Heating Systems

6.3.1 IMPORTANT DO NOT RELEASE AIR FROM

THE RED SEALED EXPANSION TANK. It is

charged with air at the factory from .75 - .80 bar

(11 - 12psig)

6.3.2 Initial filling of the System

6.3.2.1 See 3.4.3.

6.3.2.2 Open central heating flow and return valves.

Unscrew black cap on automatic air release

valve (18) one full turn. (Leave open permanently).

6.3.2.3 Close all air release taps on the central heating system.

6.3.2.4 Identify the filling/inlet valve found at the base

of the appliance. See fig.6.

The filling loop may have been disconnected

from the filling/inlet valve and heating flow

valve. If so reconnect unscrewing the caps as

necessary.

The filling/inlet valve has 3 positions. (Fig. 20)

i) Vertically up - normal operating position.

ii) Turn to the left to horizontal - closed posi-

tion.

iii) Vertically down - Filling position. To fill,

slowly turn the handle of the filling/inlet

valve from the closed position towards the

filling position. Mains water will be heard to

enter the system/boiler. As the water enters the system/boiler the pressure gauge

will be seen to rise. Pressurise to between

1bar & 1.5bar when the system is cold. DO

NOT OVERPRESSURISE.

Once the desired pressure is achieved

turn the filling/inlet valve back to the closed

position.

6.3.2.5 Starting with the lowest radiator open each air

release tap in turn closing it only when clear

water, free of bubbles, flows out. In the same

way release air from any high points in the

pipework.

6.3.2.6 Continue filling the system until at least 1.0 bar

registers on the gauge then turn the handle of

the filling/inlet valve back to the closed position.

6.3.2.7 Inspect the system for water soundness and

remedy any leaks discovered.

6.3.3 Initial flushing of Pipework

The whole of the heating system must be

flushed both cold and later hot as detailed in

6.10. Open all radiator or heating valves and

the appliance central heating valves. Drain

the boiler and system from the lowest points.

Open the drain valve full bore to remove any

installation debris from the boiler prior to lighting. Refill the boiler and heating system as

described in 6.3.2

6.3.4 Setting the System Design Pressure

6.3.4.1 The design pressure should be a minimum of

1 bar and maximum 1.5 bar.

6.3.4.2 The actual reading should ideally be 1 bar plus

the equivalent height in metres to the highest

point of the system above the base of the

appliance. (Up to the maximum of 1.5 bar

total).

N.B. The safety valve is set to lift at 3bar/ 30m/

45psig.

6.3.4.3 To lower the system pressure to the required

value, pull lever on head of safety valve (14) a

quarter turn to release water until the required

figure registers on the gauge (31).

6.3.5 Filling the Hot Water System

6.3.5.1 Close all hot water draw-off taps.

6.3.5.2 Turn filling/inlet valve to the normal operating

position (vertically up). See fig. 20

6.3.5.3 Slowly open each draw-off until clear water is

discharged.

6.4 Checking Electricity Supply

6.4.1 Carry out preliminary checks for continuity,

polarity, and resistance to earth (see page

61), gaining access as required according to

5.7.2 in this manual.

6.4.2 Leave the appliance with the control fascia

closed and with the mains electricity switched

OFF

6.5 Lighting the Boiler

6.5.1 Ensure flow and return valves are open.

(6.3.2.1)

If external and/or internal controls are fitted

(e.g Timeclock and/or Room thermostat) ensure they ‘call for heat’. The commissioning of

the appliance may be easier if the external/

internal controls are disconnected and terminals TA & TA are linked. (For access procedure turn off electricity and refer to 5.7.2 for

instructions).

6.5.2 Switch on the mains electricity and turn the on

/ off / mode switch (25) to

6.5.3 Set the c/h control knob (28) to the highest

setting.

6.5.4 The appliance will go through an ignition sequence and the burner will light.

Linea Plus AG

17

Page 20

6.5.5 If during the ignition attempt period (10 secs

approx.) the boiler fails to light, the ignition

control circuit will go to lockout. This is indicated by the status LED (26) flashing red

accompanied by a flashing error code 01

shown in the temperature indicator (27). The

gas valve is de-energised, but leaves the fan

and pump running for approximately 2 minutes after lockout.

6.5.5 In the event of the boiler going to lockout turn

the mode selector switch to the reset position

for approximately 10 seconds, then back to

the original position. The two main causes of

the boiler going to lockout during commissioning

are electrical supply polarity reversed, or air in

the gas supply. Check polarity and that the gas

supply is completely purged of air, and that

gas is reaching the boiler, then repeat from

6.5.2.

6.6 Checking Burner Pressures

6.6.1 The heat inputs for high and low gas rates are

factory set to the maximum values given in

section 3.6 for domestic hot water and central

heating but it is necessary to check them when

commissioning.

6.6.4 Turn off the main electricity supply. Gain access to the interior as instructed in 5.7.2.

6.6.5 Locate the main burner pressure test point

(fig. 19) and slacken the screw half a turn in an

anti clockwise direction. Attach a suitable U

gauge tube between the test nipple and manometer (see fig. 22).

IMPORTANT: Before measuring gas pressures it is imperitive that the protective cover

over the gas valve adjustment screw is

removed (fig. 31).

Turn on electricity supply and fully open a

domestic hot water tap to operate boiler in dhw

mode. Adjust hot water control knob to it's

maximum setting.

be:

Plus AG (N/G)

10.1 mbar

(plus or minus 1mbar)

If the pressure is wrong it should be adjusted

as instructed in 8.23 (N.B. Whenever the maximum rate is adjusted, check and adjust the

minimum rate too).

6.6.7 Turn off the electricity supply and remove one

of the grey wires connecting to the modulator

coil on the front of the gas valve. Switch on the

electricity supply. The boiler will now light at

the minimum setting.

6.6.8 When low flame is established, the pressure

reading should be:

Plus AG (N/G)

1.1 mbar

(plus or minus 0.11 mbar)

If it is different adjustment should be made in

accordance with the instructions in 8.23.

6.6.9 Turn off the electricity supply and replace the

wire onto the modulator coil.

6.6.6 The pressure reading for maximum rate should

Gas Valve

Manometer

18

U Gauge Tube

Fig. 22

Linea Plus AG

Page 21

6.6.10 Setting the Maximum Rate for Central

Heating

The maximum heat input for the central heating mode is not adjustable. When central

heating is selected the appliance will light at

75% of maximum heat input for a period of

approximately 15 minutes, whereupon the

appliance will burn at maximum rate. Should

the appliance reach temperature during the 15

minute period the burner will modulate further

to suit system load.

6.7 Checking the Flue System

6.7.1 The flue system should be visually checked

for soundness. Check all clamps and fixings

are secure and tight.

6.8 Checking the Heating Thermistor

6.8.1 Allow the system to warm up and manipulate

the c/h control knob to ensure that the burner

modulates between ‘high’ and ‘low’ and then

to ‘off’ and vice versa (scale range covers

approx. 45° - 85°C).

6.9 Regulating the Central Heating System

6.9.1 Fully open all radiator and circuit valves and

run the appliance in the central heating mode

until heated water is circulating. If conditions

are warm, remove any thermostatic valve

heads.

6.9.2 If the burner will not light, ensure that water is

in fact circulating. See 4.6.3

6.9.3 Adjust radiator return valves and any branch

circuit return valves until the individual return

temperatures are correct and are approximately equal.

6.9.4 When all is adjusted, progressively close all

radiator valves to ensure that the appliance

still operates when flow through the system is

limited.

If the burner cuts out prematurely due to lack

of water pressure through the appliance, the

system should be regulated to ensure a flow

rate of at least 350 litres/h (78 gals/h). This

may mean the addition of a small manual bypass being fitted to the system if a fully TRV

system is used.

6.10 Final Flushing of the Heating System

6.10.1 The system should be flushed in accordance

with BS 7593: 1992.Turn on the boiler for

central heating and allow the boiler and system to reach temperature. Turn off the boiler

and drain the system whilst still hot.

Refill the boiler and heating system as described in 6.3.2.

Although not necessary for correct operation

of the boiler, an inhibitor may be added at this

point. Contact the inhibitor manufacturer for

further information concerning application and

dosage.

6.10.2 Inspect the system for soundness. Turn the

appliance off at the mode selector switch (fig.

1, 25).

6.11 Filling, Testing and Regulating the

Domestic Hot Water System

6.11.1 Start with the appliance switched on having

completed the procedures described in 6.4 to

6.10.

6.11.2 Open a domestic hot water tap (preferably the

bath tap).

Ensure cold water inlet stopcock is fully open

(vertically up) and the dhw control knob (24) is

set at maximum.

6.11.3 Set the adjustable stopcock to restrict the

maximum flow of water and achieve a temperature rise acceptable to the end user.

6.11.4 The flow of water should activate the domestic

hot water flow switch (13) and drive the diverting valve (16) to its hot water position thus

heating the domestic water flowing through

the dhw heat exchanger. At the same time the

pump and fan are activated lighting the burner

on maximum rate.

6.11.5 If the burner does not light, check that the

water flow rate is above the minimum required to operate the domestic hot water flow

switch (13) 2.0 litres/min (0.45 gals/min).

6.11.6 The temperature of the water will depend on

the rate at which it flows.

The temperature of water at the tap can be

varied by adjusting the water flow rate at the

tap up to the maximum predetermined

quantity.The hot water temperature control

knob (24) will govern the maximum temperature. When the appliance is being used in hot

water mode the temperature indicator (27)

indicates the temperature of the hot water

leaving the appliance.

6.11.7 It is best to set for the lowest acceptable

temperature since the user can gain higher

temperatures by restricting flow at the tap.

N.B. If the cold supply is subject to large

fluctuations or is above the permitted maximum a suitable pressure/flow regulator should

be fitted in the cold water supply to the

appliance.

6.11.8 Turn the appliance mode selector switch (25)

to the position.

Slowly close the tap to reduce the rate of draw

to above the minimum approx. 2.0 litres/min.,

(0.45 gal/min.) Rotate the dhw control knob to

ensure the appliance modulates at its various

setting.

6.11.9 Close the draw-off tap still further. The burner

should stop when the rate falls below approximately 2.0 litres/min. (0.45 gal/min.).

6.11.10 The appliances incorporate a hot water preheat

facility. The appliance will therefore ignite periodically to maintain heat within the appliance.

Linea Plus AG

19

Page 22

6.12 Final Check for Operations

Turn mode selector switch to the OFF/RESET

position, disconnect pressure gauge, re-tighten

screw. Relight boiler.

6.12.1 Re-check for gas soundness.

6.12.2 Re examine heating and hot water systems

and cold water supply for water soundness.

6.12.3 Check the appearance of the gas flame to

assess adequacy of combustion air supply.

6.12.4 Re-check the flue system for soundness and

adequacy of supports.

6.13 Concluding Operations

6.13.1 If external/internal controls have been discon-

nected and terminals TA & TA temporarily

linked, remove the link and reconnect the

controls circuit. Check the operation of the

controls.

6.14 Refixing the boiler casing (fig. 24).

6.14.1 Offer up the front casing to the back frame in

a near vertical attitude and locate the hooks on

the casing over the hooks on the frame.

Slide the casing downwards to fully engage

the hooks and to align the bottom fixing holes.

Replace the two case retaining screws (fig.24).

6.14.2 Hinge up the control fascia and secure using

the two screws (fig.25).

6.14.3 Disconnect filling loop, fit filling loop cap. Leave

filling loop in a safe and accessible place.

6.15 Supplementary Instructions for Fitting & Removing Optional Time Clock and for Wiring to

External Controls.

Section 10 Appendices A and B at the rear of

this manual provides full instruction for fitting

and wiring the optional built-in time switches

and for wiring to external controls.

6.16 Complete details of the boiler, controls, installation and commissioning in the log book

supplied with the boiler. This is an important

document which must be correctly completed

and handed to the user. Failure to install and

commission this appliance to the manufacturers instructions may invalidate the warranty.

SECTION 7 INSTRUCTING THE USER

7.1 Hand over the copy of the Users Instructions

and boiler log book supplied with the appliance, together with these instructions. Explain

how to operate the boiler correctly and how to

use the timeclock and room thermostat if fitted.

7.2 Show the user how to switch off the appliance

and indicate the position of the electric supply

isolator.

7.3 Inform the user of the location of all drain

cocks and air vents.

7.4 Explain how to turn the appliance off for both

short and long periods and advise on the

precautions necessary to prevent damage

should the appliance be inoperative when

freezing conditions may occur.

7.5 Show the user the filling loop position its

function and how to repressurise the system

using the filling/inlet valve.

7.6 Advise the user that, for continued safe and

efficient operation, the appliance must be serviced by a competent person at least once a

year.

Fig. 24

20

Fig. 25

Case Screws

Case screws

(one either side)

Linea Plus AG

Page 23

SECTION 8 SERVICING INSTRUCTIONS

8.1 General

To ensure the continued safe and efficient

operation of the appliance, it is recommended

that it is checked and serviced as necessary at

regular intervals.

The frequency of servicing will depend upon

the particular installation conditions and usage, but in general, once per year should be

adequate.

It is the law that any servicing work is carried

out by a competent person such as a Vokèra

service engineer, approved service agent,

British Gas or other CORGI registered personnel.

The following instructions apply to the boiler

and its controls, but it should be remembered

that the central heating and domestic hot

water systems will also require attention from

time to time.

8.2 Important Notes

WARNING: having carried out preliminary

flame checks and before starting any servicing work, switch OFF the mains electricity

supply and disconnect the plug at the main

isolating switch and socket. (If a switch is used

remove the fuse.)

Turn off gas supply at the gas service tap fitted

to the appliance.

Always test for gas soundness after any service work and after exchanging any gas carrying component.

8.3 Recommended Routine Servicing

8.3.1 Annual Servicing

When servicing is required the following procedures should be carried out.

1. Inspect exterior for signs of damage and

deterioration, particularly of flue pipework and

electrical connections.

2. Turn off mains electricity and remove front

casing (see 8.4.).

3. Replace fuse if previously removed (8.2.

above) and turn on electricity. Run the boiler

for a few minutes in the domestic hot water

mode to permit inspection of its operation.

This is accomplished by opening a domestic

hot water draw off tap and inspecting burner

for yellowing of flame tip, flame lift off or

sooting.

4. Ensure central heating valves are open.

See 6.3.2.1.

Observe pressure gauge reading (fig. 1, 31

which should be approximately 1 bar when

the system is cold See 6.3.4

5. Turn off mains electricity and turn off gas

service tap on the appliance.

6. Gain general access as described in 8.4.

7. Remove main burner (see 8.6). Lightly

clean with a soft brush and inspect for damage. If during initial inspection any combustion irregularity was suspected, remove injectors and clean or replace (see 8.7).

8. Place cloth below combustion chamber to

catch debris. Clean heat exchanger using

suitable brushes and rods if necessary.

9. Inspect combustion chamber lining. The

insulating material is easily damaged. Do not

scrape, but clean off lightly.

If any panels are damaged these should be

replaced (see 8.11).

10. Replace all parts in reverse order but

leave the controls fascia open and outer casing off.

11. Undertake a complete commissioning

check as detailed in section 6.

12. Close up control fascia and refix front

casing.

13. Clean off casing using soft cloth and dilute

detergent.

14. Complete details of service undertaken in

the boiler log book.

NOTE: there is a flue gas analysis test point

incorporated in the flue outlet (fig. 1, 23).

8.3.2 Replacement of Parts

1. The life of individual components varies

and they will need servicing as and when

faults develop. The fault finding sequence

charts in section 9 will serve to locate which

component is the cause of any malfunction.

Instructions for removal, inspection and replacement of the individual parts are given in

the following pages.

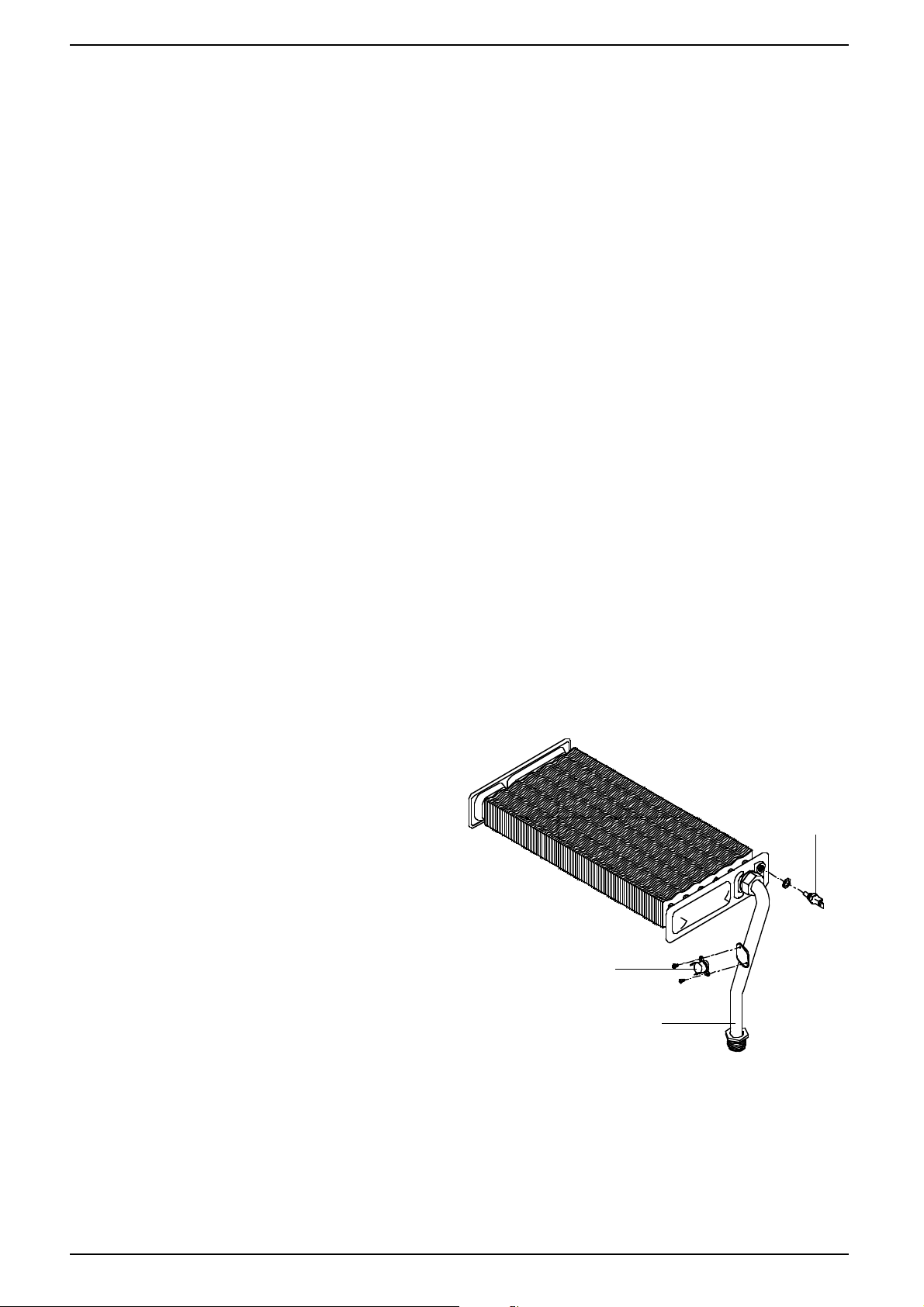

2. The domestic hot water heat exchanger

may in certain conditions become partially

blocked by scale deposits. Evidence of this

will be deterioration in performance.

This condition could well be treated using

proprietary descalants following makers' instructions without dismantling the appliance

by circulating a fluid through the dhw coil. To

do this, disconnection from hot and cold services is necessary. Reconnect only after thorough flushing with clean water.

3. Occasional maintenance of mechanical

working parts will be necessary (three port

valve, flow diaphragm). Service kits are available from your local Vokèra stockists. Vokèra

Service Kit No.T0019.

Linea Plus AG

21

Page 24

8.4 To Gain General Access/Assembly

To remove components access to the interior

is essential. Refer to figs. 10 & 11.

Ensure electricity supply is isolated before

carrying out any servicing.

8.4.1 To remove front casing.

Push to release front door panel and lower to

reveal controls. Loosen the 2 captive screws

securing the front control panel to the lower

part of the casing and lower to reveal inside of

boiler (fig. 10).

Remove two screws at base of casing, slightly

lift the casing and slide it gently towards the

top of the appliance to disengage the case

from the top suspension hooks (fig. 11).

Ensure the casing and screws are put to one

side in a safe place.

8.4.2 Reassembly is always carried out in reverse

order to dismantling, unless otherwise stated.

Electrical connections must be remade in

accordance with the wiring diagram (figs.39-

40).

8.4.3 Where gas control components are replaced,

check the burner pressures and adjust if necessary. See 8.23.

8.5 Room Sealed Chamber Front Cover

Refer to fig. 26.

8.5.1 Gain general access as 8.4.

8.5.2 Remove room sealed cover plate by releasing

two lower retaining clips and easing cover off

the top locating hooks. Inspect gasket for

damage. If damaged, replace.

NOTE: when refitting the combustion chamber front cover it is essential to correctly seat

and secure the cover in place ensuring both

clips are secured in place.

Fig. 26

Flue gas analysis

test point

Fig. 27 a

Fig. 27 b

22

Fig. 28 a

Linea Plus AG

Page 25

8.6 Main Burner and Electrodes

Main Burner Part No 0511 N.G. 0512 L.P.G

Spark/Sense Electrode Part No 1838

Refer to figs 28a - 28c.

8.6.1 Gain general access as 8.4.

8.6.2 Remove room sealed front cover as 8.5

8.6.3 Remove front of combustion chamber by re-

leasing screws (fig. 27a&b).

8.6.4 Remove four burner retaining screws (fig.

29a&b). Ease burner forward and rest on chamber base (fig. 28a&b).

8.6.5 Release electrode retaining screws & carefully

remove electrode(s).

8.6.6 Trace electrode and earth lead to electronic

ignition control and gas valve and disconnect

Trace electrode leads, 1 to pcb and 2 to elec-

tronic ignition unit and disconnect.

8.6.7 Remove main burner.

8.6.8 Reassemble in reverse order ensuring correct

location of electrode(s).

Note1. If the Ionisation electrode is replaced

the gas pressures will need resetting as instructed in 8.23.

Note 2: If difficulty is found in relocating the

burner securing screws, easier access can be

gained by removing the two side panels

(fig. 28a&b).

Note 3: See page 36 for electrode positioning.

8.7 Main Burner Injectors

8.7.1 Gain general access as 8.4.

8.7.2 Remove room sealed front cover plate and

combustion chamber front (8.5 & 8.6.3).

8.7.3 Remove main burner (8.6.4 to 8.6.8).

8.7.4 Unscrew injector(s) from burner bar.

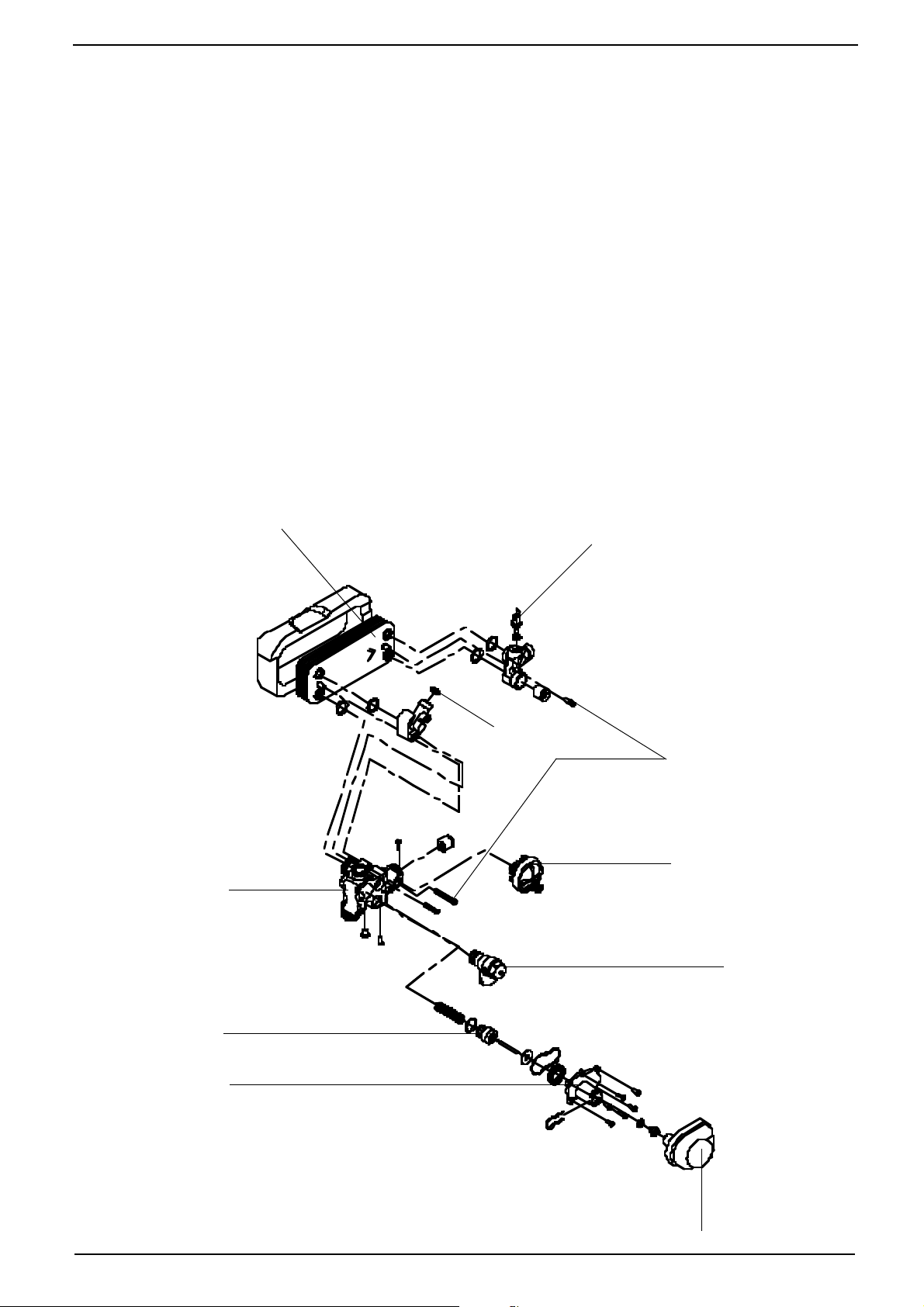

8.8.8 Unscrew unions on either side of main heat

exchanger fig. 29a&b.

8.8.9 Slide out main heat exchanger, taking care

not to damage insulation panels. Avoid spillage

of water on boiler electrics.

8.8.10 Reassemble in reverse order using new fibre

washers in unions.

Fig. 28b

Fig. 28cFig. 28c

Fig. 28c

Fig. 28cFig. 28c

8.8 Main Heat Exchanger

0513

Refer to fig. 29

8.8.1 Gain general access as 8.4.

8.8.2 Remove room sealed front cover plate (8.5).

8.8.3 Remove front of combustion chamber (8.6.3).

8.8.4 Remove two air baffle plates, 1 screw securing

each (fig. 30).

8.8.5 Remove both side panels, 2 screws each (fig.

28a&b).

8.8.6 Close heating flow and return valves by turning

1/4 turn until indicating lines are horizontal. Pull

lever on head of safety valve to drain primary

circuit to boiler.

8.8.7 Place cloth under heat exchanger to catch

surplus water.

Linea Plus AG

Fig. 29a

23

Page 26

8.9 Flue Fan

Part No. 2076.

8.9.1 Remove room sealed front cover plate (8.5)

and front of combustion chamber (8.6.3).

8.9.2 Loosen maintenance clip securing screws

(see fig. 30) and slide upwards to clear joint.

8.9.3 Remove silicone pipes from nozzles on inner

flue bend.

8.9.4 Remove 5 flue hood retaining screws (see fig.

30).

NOTE: when removing the two side screws

the two air baffle plates can be removed.

8.9.5 Carefully slide flue hood forward disconnecting

electrical leads on fan in the process.

8.9.6 Unscrew 4 screws securing fan to flue hood

and remove fan. Transfer aluminium

manifold (two screws) to new fan.

8.9.7 Reassemble in reverse order, replacing centre hood screw first.

8.10 Differential Analog Pressure Switch

Part No. 2677

Refer to Fig. 30

8.10.1 Gain general access as 8.4.

8.10.2 Remove room sealed cover (8.5).

8.10.3 Remove 2 screws holding pressure differen-

tial switch to the combustion chamber.

8.10.4 Pull off tab connectors and remove pressure

switch, disconnecting the air pressure pipes in

the process.

8.10.5 Reassemble in reverse order.

See fig. 39&40 for correct fitting of electrical

connections. When reconnecting the pressure pipes the upper nozzle on the inner flue

bend connects to the upper nozzle of the

pressure differential switch.

8.11 Combustion Chamber Insulation Boards

8.11.1 Gain general access as 8.4.

8.11.2 Remove room sealed front cover 8.5.

Remove front of combustion chamber 8.6.3.

Remove Main Heat Exchanger 8.8.

8.11.3 To remove side combustion chamber insulation boards, gently prise upwards and pull out.

8.11.4 To remove rear board, gently prise upwards

and pull out.

8.11.5 Fourth panel (front) is replaced complete with

combustion chamber front panel.

Maintenance clip

Fig. 29b

Pressure

differential switch

Air

tubes

Air

baffle

plate

Fig. 30

Hood

Retaining

Screws

24

Linea Plus AG

Page 27

8.12 Ignition PCB

8.12.1 Gain general access as 8.4.

8.12.2 Remove PCB cover.

8.12.3 Disconnect wires from ignition PCB.

8.12.4 Remove ignition PCB.

8.12.5 Replace in the reverse order ensuring wires

are replaced correctly.

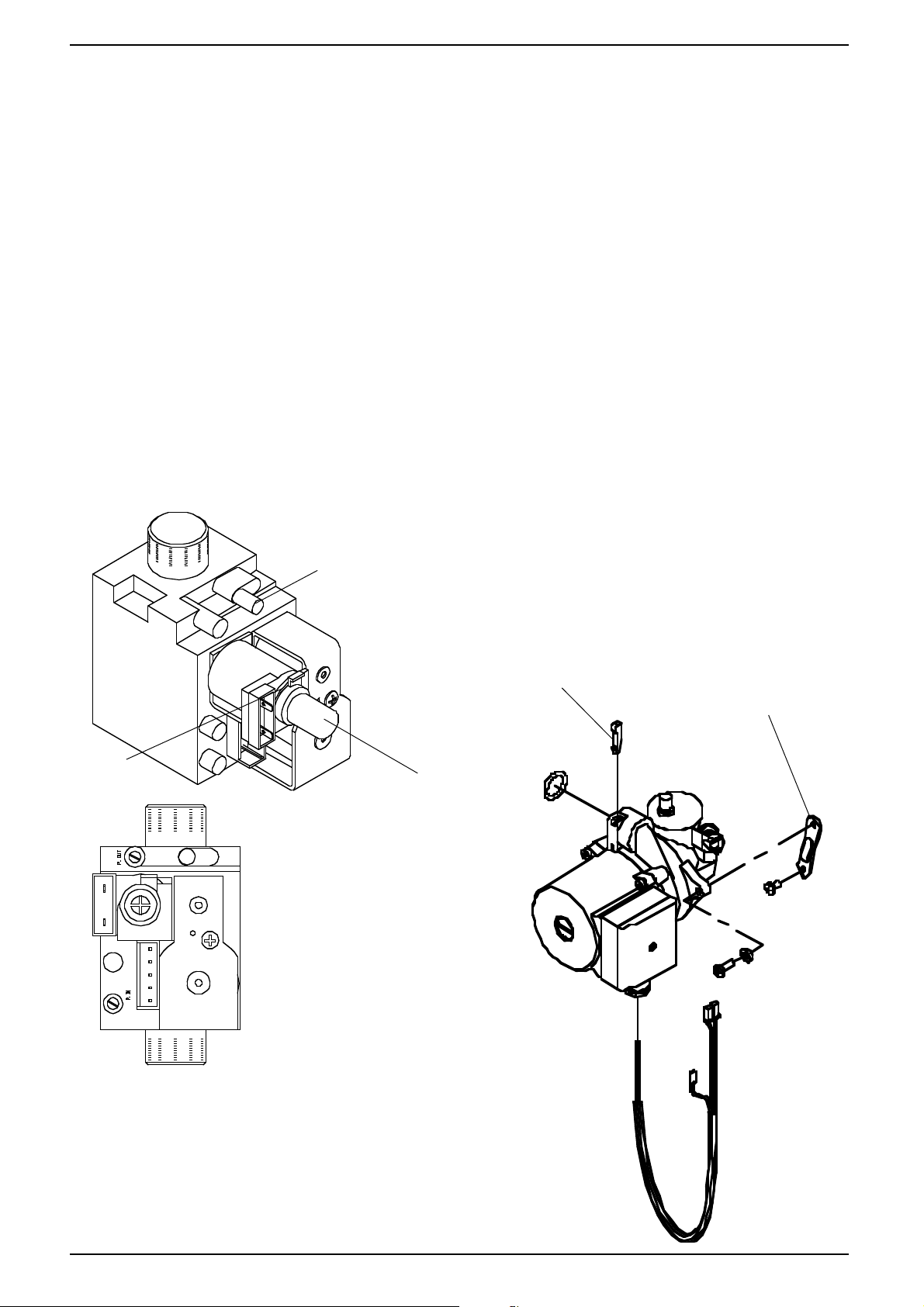

8.13 Gas Control Valve (complete)

Part No. 2471 fig. 31.

8.13.1 Turn off gas service tap.

8.13.2 Remove Ignition control box as 8.12.

8.13.3 Pull off silicone tube from gas valve regulator.

8.13.4 Disconnect earth leads from gas valve.

8.13.5 Disconnect wires from modulator coil.

8.13.6 Unscrew gas service tap union & release from

its seating.

8.13.7 Remove 2 screws securing gas valve bracket

to the base frame.

8.13.8 Undo union above the gas control valve &

withdraw gas valve.