VOKERA Indirect SC 250L, Indirect SC 150L, Indirect SC 180L, Indirect SC 210L, Indirect SC 310L Installation Instructions Manual

...Page 1

AquaFlow Unvented Hot Water Cylinders

Indirect SC - 120L- 150L – 180L - 210L – 250L – 310L

Direct – 120 6kW – 150l 6kW – 180 6kW -210 6kW-250 6kW – 310 6 kW

Solar (Twin Coil) – 210L - 250L – 300L

Installation Instructions GB, IE

Page 2

Unvented Hot Water Cylinder

- 2-

INTRODUCTION

The following pages incorporate the installation instructions and must be left in a safe place adjacent to the cylinder or

given to the end user once they have been correctly instructed in the effective operation of the cylinder. The Installer has a

duty of care to instruct the end user how to operate the cylinder correctly.

Vokèra will not accept liability for any claims or damages from failure to observe these instructions.

These instructions include essential and important information for safe and correct installation, and are an integral part of

the product. As a consequence all technical documents must always accompany the product.

Vokèra are continually developing its product range and therefore reserves the right to change specification without

prior notice. All the data and instructions contained in this manual are subject to review or product update changes at any

time. They will be current at time of print. If in doubt please contact the manufacturer to ensure you have the correct and

current manual.

Please always refer to the instructions contained in this manual when installing the equipment.

The operations described in these instructions require specialised knowledge and therefore it is essential the installer has

the appropriate qualifications and competence training prior to installing the product. You should only install this product

once you have achieved such technical qualifications.

The instructions are provided in schematic form only as installations designs may vary. The diagrams used are purely

indicative and as such have no pretence of completeness and are not intended to replace the design.

Please ensure that the installer has fully completed the Benchmark Checklist on the inside back pages of the

installation instructions supplied with the product and that you have signed it to say that you have received a full and

clear explanation of its operation. The installer is legally required to complete a commissioning checklist as a means of

complying with the appropriate Building Regulations (England and Wales).

All Installations must be notified to Local Area Building Control either directly or through a Competent Persons

Scheme. A Building Regulations Compliance Certificate will then be issued to the customer who should, on receipt,

write the Notification Number on the service record / checklist. This product should be serviced regularly to ensure its

safety, efficiency and performance is maintained. The installation engineer should complete the relevant Service

Record on the Benchmark Checklist after each service. The service record / checklist is required in the event of any

warranty work and as supporting documentation relating to home improvements in the optional documents section of

the Home Information Pack This must be completed and left with the product at all times as it contains importance

commissioning reference information which is essential information for future service work. Failure to do so will result

in the warranty becoming void.

Vokèra cannot be held liable for any loss or damage arising from product specifications deviating from the standard version.

The information contained within this document has been compiled with all possible care, Vokèra cannot be held liable for

any installation errors, loss or damage or work performed by third parties.

© 2017 Vokèra reserves the right to change this document at any time. All rights reserved.

Page 3

Unvented Hot Water Cylinder

- 3-

TABLE OF CONTENTS

1.1 Personal Responsibility ................................ 4

1.2 Field of use .................................................. 4

1.3 Certifications and Markings .......................... 4

1.4 Cylinder ...................................................... 4

1.5 Meaning of the symbols used here in ............. 4

1.6 Measuring ................................................... 4

2.1 Installation site ............................................ 5

2.2 Electrical ..................................................... 5

2.3 Unvented .................................................... 5

2.4 Personal Protection ..................................... 5

2.5 Delivery and packaging ................................ 5

2.6 Transport and manual handling ..................... 5

3.1 Dimensions ................................................. 6

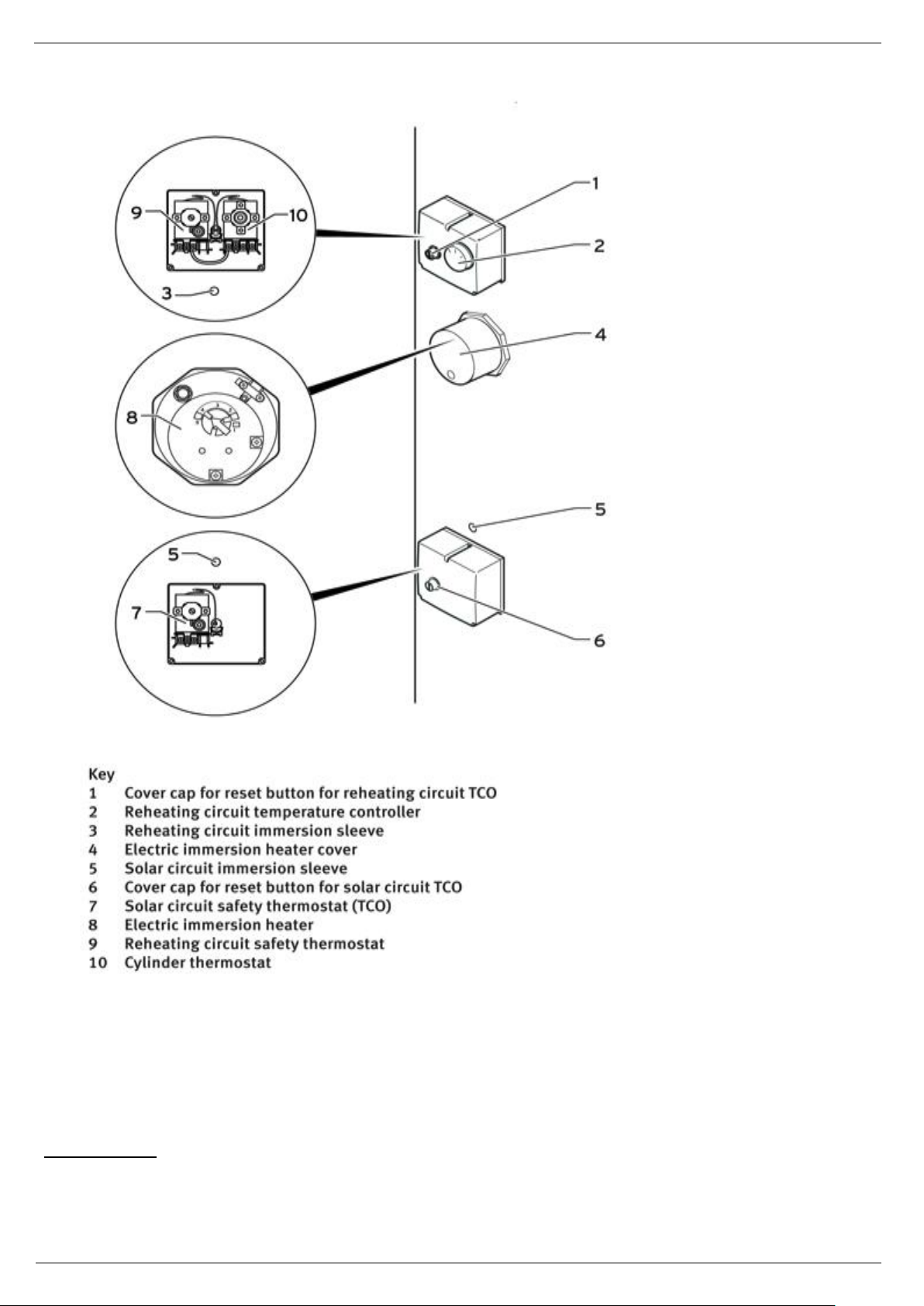

3.2 Elements of the Hot water cylinder ............... 7

3.3 Safety Devices ............................................. 7

3.4 Elements of the Twin Coil (solar) Cylinder ...... 8

3.5 Solar Heating system .................................. 9

3.6 Cylinder control components ........................ 9

3.7 Immersion Heater ...................................... 11

3.8 Technical data table ................................... 12

3.9 Pack contents ............................................ 15

3.10 Kit contents ............................................. 15

4.1 Installing pipes for the heating circuit .......... 17

4.2 Cold mains inlet ......................................... 18

4.3 Safety Assembly ........................................ 18

4.3.1 Building Regulation G3 ............................... 20

4.4 Unit filling ................................................. 22

4.5 Electrical connection .................................. 22

4.6 Safety limiting device ................................. 24

4.7 Solar controller .......................................... 25

4.8 T&P........................................................... 25

4.9 Motorized Zone Valve ................................. 25

4.10 Dual Thermostat ...................................... 25

4.11 Drainage .................................................. 25

4.12 Unit emptying .......................................... 26

4.13 Restart after a long term stop .................... 26

5.1 Electrical Check .......................................... 26

5.2 Pre-Fill Check ............................................. 27

5.3 Fitting System ........................................... 27

5.4 Drain System ............................................. 27

5.5 Cleaning The System .................................. 27

5.6 Setting And Testing Controls ...................... 27

5.7 Handing Over ............................................. 28

6.1 General ..................................................... 28

6.2 Water circuit / Condensate discharge ........... 28

6.1 Replacement of the immersion heater ......... 29

6.2 Outer cover cleaning ................................... 29

6.3 Hydraulic safety unit efficiency check ........... 29

6.4 General notes ............................................ 29

6.5 After-sales service ...................................... 29

6.6 Service record / Logbook ............................. 32

Page 4

Unvented Hot Water Cylinder

- 4-

Symbol

Meaning

Failure to comply with the provision in question may result in injuries and/or damages to people, objects,

plants or animals.

1 GENERAL NOTICE

1.1 Personal Responsibility

The manufacturer is responsible for the product’s conformity to the relevant construction directives, laws and regulations in

force at the time the product is first commercialised. The Plumbing Engineer/Electrician/Installer and User are the each

exclusively responsible in their respective fields, for knowing and observing the legal requirements and technical regulations

concerning the design, installation, operation and maintenance of the appliance. Reference to laws, regulations or technical

specifications contained in this manual is purely for information purposes; any new laws introduced or modifications to

existing laws are not in any way binding on the manufacturer towards third parties.

1.2 Field of use

The indirect water heater for the production of hot water is only intended to be used for Domestic Hot Water heating,

without exceeding the usage restrictions specified herein. To this purpose it must be hydraulically connected to a sanitary

domestic hot water delivery network. It requires a power supply to operate.

Never use the unit for any purposes other than those specified herein. Any other use is to be deemed as inappropriate and

is not allowed. The manufacturer cannot be held responsible for any installation errors and inappropriate equipment use.

1.3 Certifications and Markings

The CE marking applied to the appliance certifies that it conforms to the essential requirements of the following European

Directives:

2006/95/EC concerning the safety of electrical equipment;

2004/108/EC concerning electromagnetic compatibility

EN60335-2-21 Electrical Safety for Direct Cylinders

EMC conformity

1.4 Cylinder

The cylinder is manufactured in six sizes of direct and indirect models 120L, 150L, 180L, 210L, 250L 310L plus 3 sizes of solar

models 210L 250L 300L. The cylinders are manufactured from stainless steel AISI316L and it has Thermal insulation is

ensured by a highly biological, CFC-free rigid polyurethane foam (PUR) coating. The full compressed foam coating allows to

minimal energy losses. The external coating is made of a soft PVC material. It is supplied with all required control devices

including a 2 port motorised valve

The cylinder works utilising the main domestic water supply and does not require stored cold water to operate. The hot and

cold connections are 22mm. To enable the cylinder to work at its optimum level a cold water supply with a pressure and

flow rate appropriate for the system is required.

1.5 Meaning of the symbols used here in

1.6 Measuring

The measuring units used in this manual for dimensions are those of the International System (SI).

Page 5

Unvented Hot Water Cylinder

- 5-

2 SAFETY

2.1 Installation site

The floor on which the unit is to be standing must be capable of supporting (locally) the weight (see Technical data table) of

the full unit. Do not install the cylinder on floors made of chipboard or other flooring where the mechanical strength is

compromised when damp. If the cylinder is fitted very high in the building negative pressure may form, in this instance the

competent person must decide whether an anti-vacuum valve is required to protect the cylinder.

2.2 Electrical

The indirect water heater should have 240V-12.5A electrical supplies. All electrical terminal covers must be securely in place

before power is switched on. The unit must be earthed. The pipework to and from the unit must be earth bonded.

2.3 Unvented

No valves must be fitted between the vessel and Pressure Reducing Valve (PRV). No valves must be fitted between the

vessel and its expansion vessel.

2.4 Personal Protection

When installing and servicing the appliance, recommend the use of suitable protective clothing (i.e. gloves).

2.5 Delivery and packaging

The indirect water heater is supplied in an environment-friendly and easy to handle cardboard packaging with protective

inserts. Make sure that the packaging material is disposed of properly in compliance with the local environment-related

regulations in force. Should the cylinder show any clear signs of any transport damage, then you should inform the supplier

and return it immediately. In this instance do not attempt to install the appliance.

2.6 Transport and manual handling

When moving the Cylinder always keep your back straight, bend your knees, don’t twist, move your feet. Avoid bending

forwards or sideways and keep the load as close to your body as possible. Where possible transport the unit using a suitable

trolley, sack truck or get some assistance. Grip the Cylinder firmly and before lifting establish where the weight is

concentrated to determine the centre of gravity, repositioning yourself if necessary. When storing and transporting it,

always keep the indirect water heater vertical (straight) in its original packaging. When transporting to a second floor, it is

permissible to tilt the unit to an angle of 45°, provided utmost care is taken when moving it to its final location.

Due to the forward inclination, when using forklift trucks or other means of transport proceed slowly and fasten the

equipment to prevent it from tipping. When manually carrying and putting into position the cylinder, after removing the

packaging you need to use the auxiliary equipment/the bracket for transportation.

Page 6

Unvented Hot Water Cylinder

- 6-

Model

Unit

Dia

Height

120L. Ind / Dir

mm

554.5

1001

150L. Ind / Dir

554.5

1191

180L. Ind / Dir

554.5

1371

210L. Ind /Dir/Solar

554.5

1593

250L. Ind /Dir/Solar

554.5

1843

310L / 300L. Ind /Dir/Solar

554.5

2153

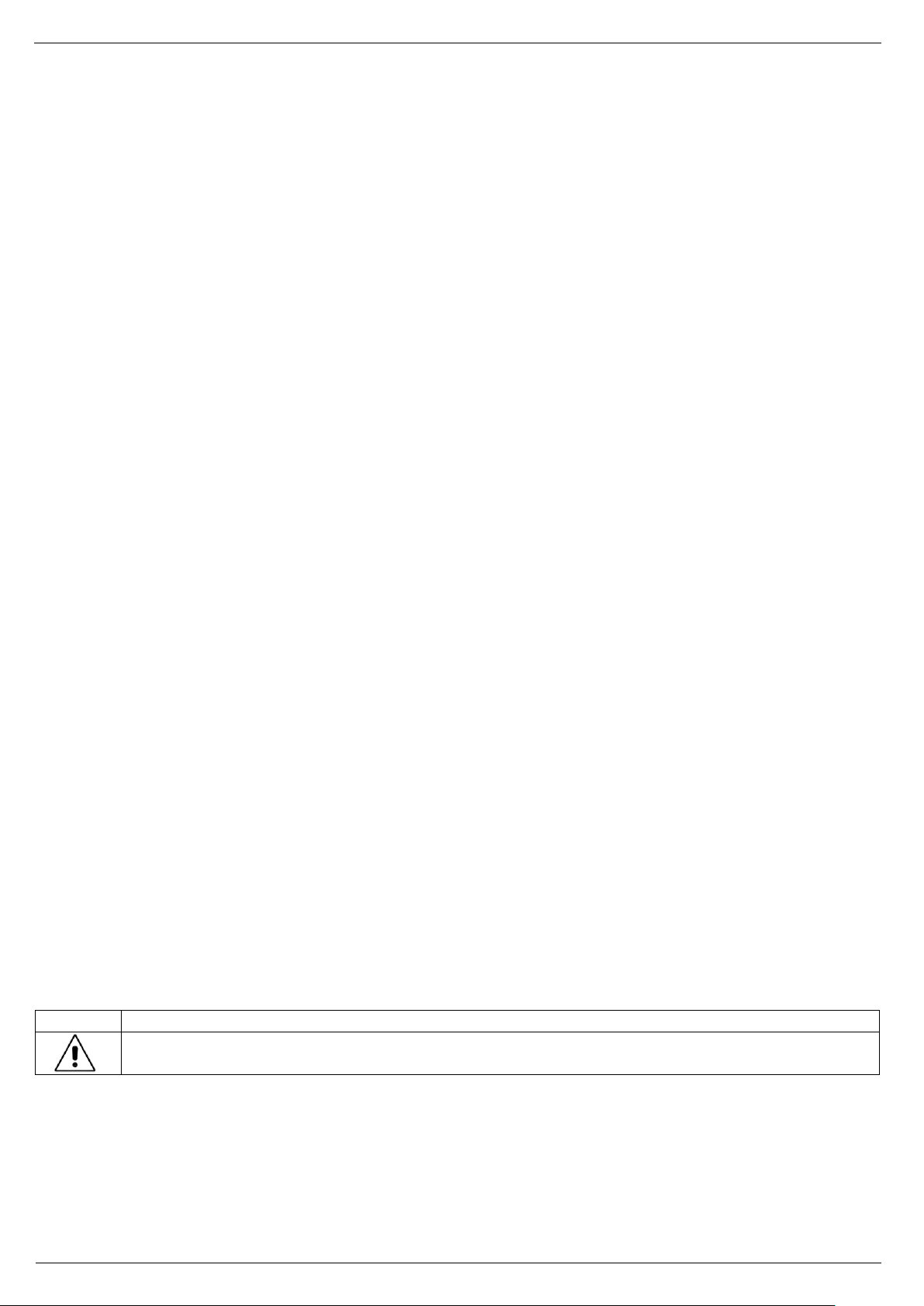

System Overview

1. Heat Source a. Heating flow

2. Cylinder b. Heating return

3. Two port motorised valve

4. Electric Immersion heater

5. Two port motorised valve

6. Auto air separator

7. Hot water expension vessel

8. Hot water thermostatic mixing valve

3 TECHNICAL DATA

3.1 Dimensions

Page 7

Unvented Hot Water Cylinder

- 7-

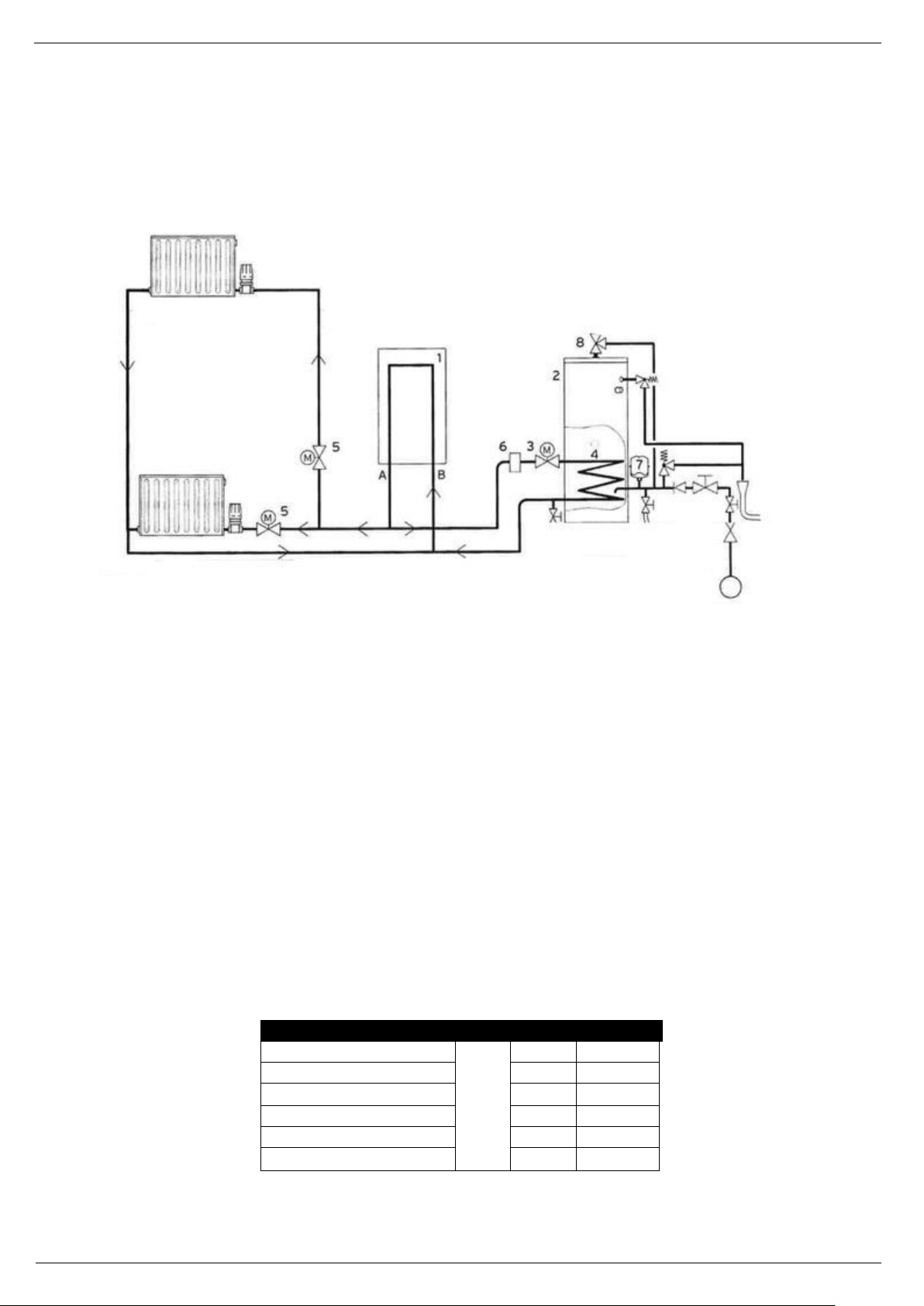

3.2 Elements of the Hot water cylinder

3.3 Safety Devices

The cylinder is delivered with all safety and control devices for the safe operation of the unvented hot water supply

system. ** denotes solar cylinder only.

Factory fitted temperature & pressure relief valve (90°C / 7 bar)

Expansion relief valve (6 bar)

Thermal cut out for immersion heater

Primary heating thermal cut out 80°C

Pressure reducing valve (3.5bar) with inline strainer

** Solar pump thermal cut-out, set at 80°C, and connected to the solar pump in order to isolate this heat

source if there is a fault in the solar controller.

** Solar cylinder thermal cut-out, set at 80°C, to be connected to the 2 port motorised valve in order to isolate

the primary heat source if the water supply thermostat fails.

Page 8

Unvented Hot Water Cylinder

- 8-

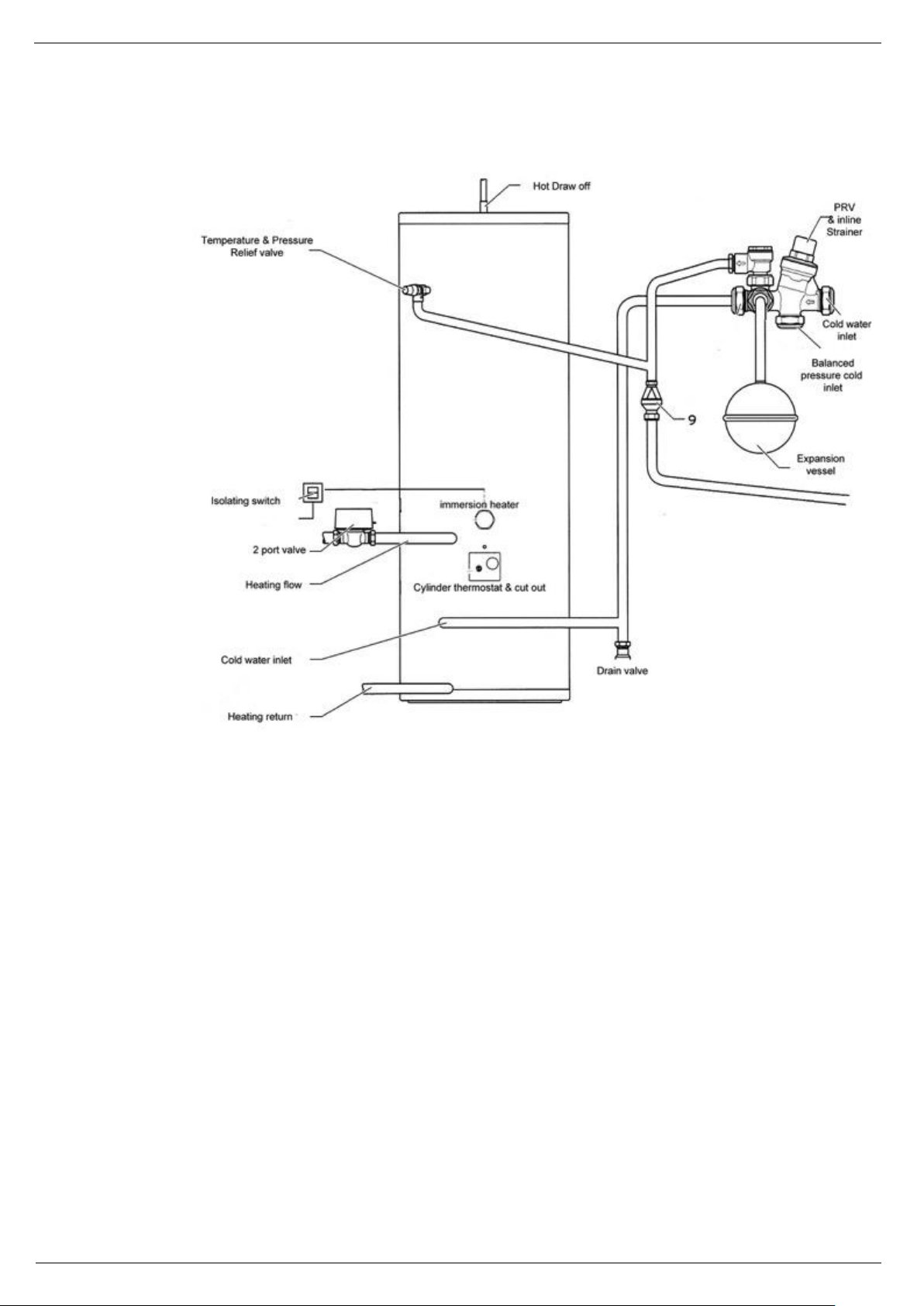

3.4 Elements of the Twin Coil (solar) Cylinder

No motorised valve is supplied for the solar pipework and it is mandatory that the solar system be supplied

with a solar hydraulic station.

The cylinder solar indirect coil can only be connected to a solar circuit that is controlled via a hydraulic

station which incorporates a pump and non-return valves.

Page 9

Unvented Hot Water Cylinder

- 9-

If a motorised valve is used this must be fitted on the primary return due to possible high temperatures of

the solar circuit.

3.5 Solar Heating system

The solar heating system is a closed hydraulic system in which the heat transfer fluid transfers the

heat to the water in the cylinder via a heat exchanger.

The water in the cylinder is heated by two separate circuits. In the lower coil the water is heated by

the solar circuit and as the water in the lower section of the cylinder is generally at a lower

temperature in enables sufficient heat transfer even when the solar radiation level is low. The

upper coil is heated by an external heat source (boiler or immersion heater) and heats the upper

section of the cylinder from which hot water is drawn for domestic purposes.

3.6 Cylinder control components

Page 10

Unvented Hot Water Cylinder

- 10-

Information inspection access to the cylinder is available by removal of the immersion heater boss.

Page 11

Unvented Hot Water Cylinder

- 11-

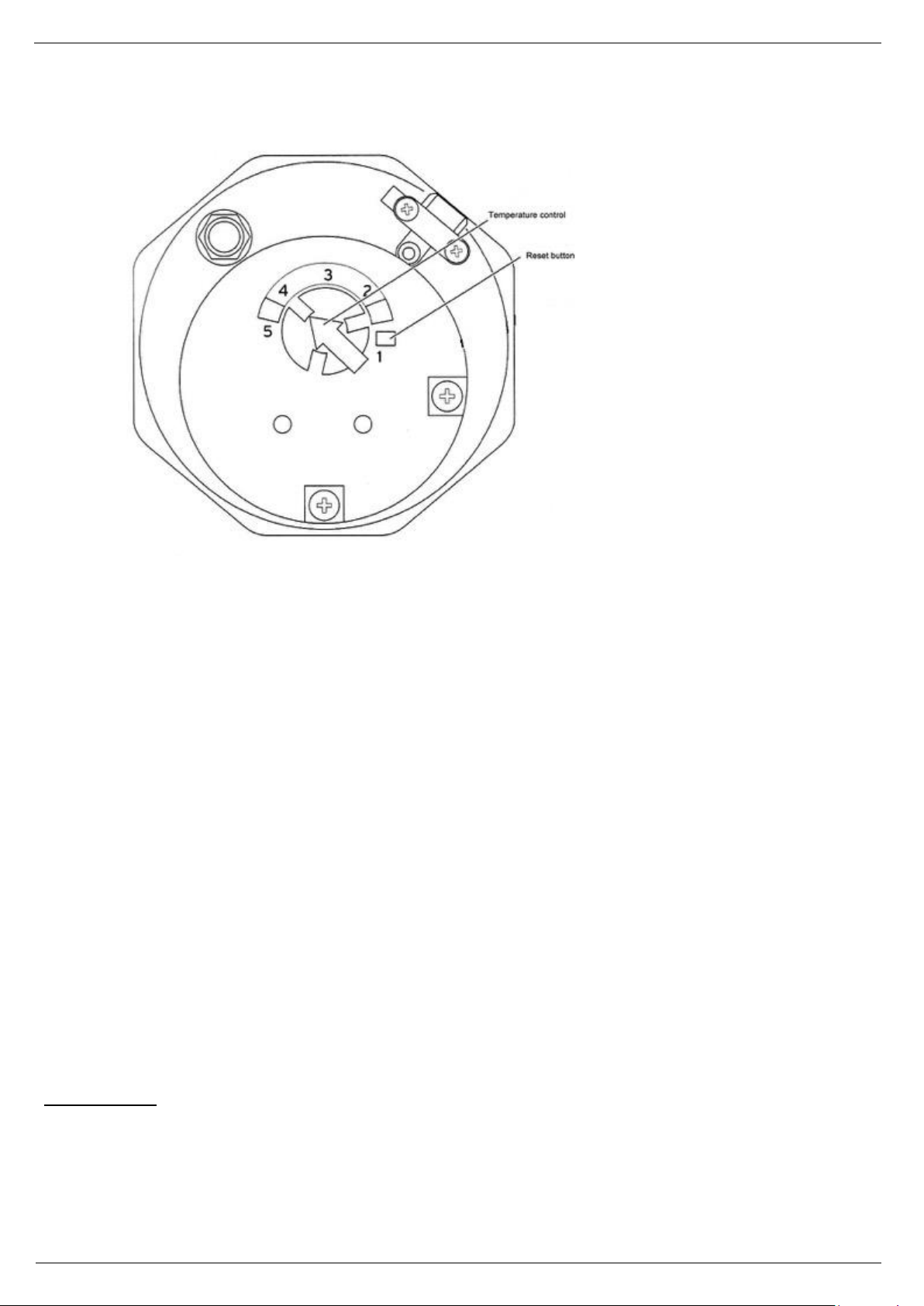

3.7 Immersion Heater

Hot water temperature Settings –

1. 20°c

2. 35°c

3. 45°c

4. 60°c

5. 68°c

The cylinder is equipped with an additional electric immersion heater with an output of 3kW. The immersion

heater will be found under the top front cladding and is designed for use in unvented cylinders. It has a

temperature controller and a thermal cut out. To set the temperature required simply turn the arrowhead so

that it points at one of the numbers between 1 and 5. The list above shows the approximate temperature for

each setting.

When required the immersion heater boss can be used as an access to view internal of the cylinder

You can also control the temperature using a separate hot water control device with a suitable dual channel

230v timer.

Information inspection access to the cylinder is available by removal of the immersion heater boss.

Page 12

Unvented Hot Water Cylinder

- 12-

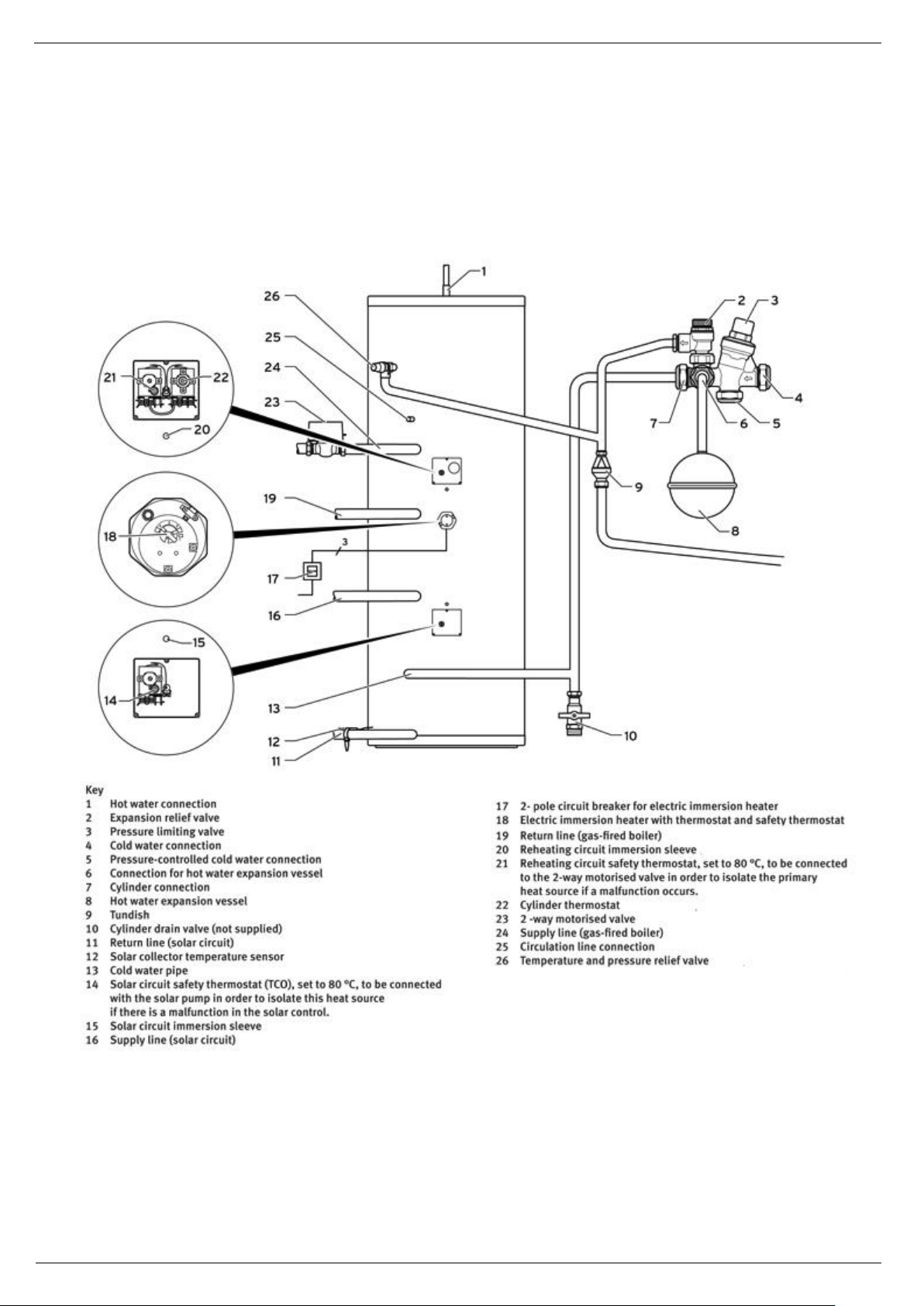

3.8 Technical data table

Page 13

Unvented Hot Water Cylinder

- 13-

Indirect single coil

120L

150L

180L

210L

250L

310L

Footprint (minimum)

m

0,55 x 0,64

Hot water capacity

l

104.9

136.7

166.4

203.9

247.5

274.7

Weight Empty

Kg

26.8

28.9

32.4

36.8

40.7

45.9

Minimum ceiling height required

m

1174

1424

1774

2034

2344

2500

Maximum design pressure

bar

10

Cylinder

Tested in accordance with

EN 12897:2006

Normal operating pressure

bar

3

Cold connection (CW)

22 mm

Hot connection (DHW)

22 mm

Pressure reducing valve pressure

bar

3

Cylinder T&P

°c/bar

90/7

Expansion Valve setting

bar

6

Expansion Vessel pressure

bar

3

Max design pressure - Coil

bar

16

Max primary operating pressure

bar

3

Max working temperature - tank

°c

85

Max operating pressure - vessel

bar

6

Max design pressure - Tank

bar

7

Indirect Cylinder

Connections

22mm

Coil Surface area

m3

0.62

0.62

.75

.75

.75

.75

Coil Rating

kW

18.4

18.8

22

22.6

22.3

20.9

Coil length

8.97

8.97

10.85

10.85

10.85

10.85

Weight when full

Kg

146

178

209

248

291

345

Reheat times 15°c– 60°c

min

18

23

24

28

35

41

Primary heater pressure drop

mb

109

109

124

124

124

124

Primary flow rate

l/h

1400

1400

1400

1400

1400

1400

Heat Loss W 51

60

67

77

89

103

Heat Loss EN 12897:2006

kWh/24h

1.22

1.43

1.62

1.86

2.13

2.53

Energy Rating

B C C C C D

Max operating temperature fluid

°c

85

Electrical Supply

Electrical Supply

V

240

Amp

A

12.5

Electric protection

IP24

Electric Heater Rating

kW 3

Electric Heater Type

Single Phase

EPS Insulation (NeoPor grade)

Thickness

mm

50

50

50

50

50

50

Direct Cylinder

6 kW Reheat time 15°c– 60°c

min

69

93

112

130

155

186

Actual water volume

l

121.3

151.2

179.3

213.9

253

301.8

Weight when full

Kg

148

180

212

251

294

348

Heat Loss W 53

62

70

80

91

105

Heat Loss EN 12897:2006 -

kWh/24h

1.27

1.48

1.68

1.92

2.19

2.53

Energy Rating

C C C C C D

Page 14

Unvented Hot Water Cylinder

- 14-

Twin Coil Solar Cylinder

210L

250L

300L

Hot water capacity

Upper Coil L 106

142

144.7

Lower Coil L 202.1

246.1

271.3

Coil Surface

Upper Coil L 0.5

0.5

0.5

Lower Coil L 0.62

0.62

0.62

Coil Length

Upper Coil m 7.25

7.25

7.25

Lower Coil m 9 9 9

Coil Rating

Upper Coil

kW

15.7

15.6

15.5

Lower Coil

kW

18.6

18.4

17.1

Reheat Time

Upper Coil

min

21

27

29

Lower Coil

min

34

40

49

Primary heater pressure

drop

Upper Coil

mb

90

91

92

Lower Coil

mb

118

117

117

Primary Flow rate

Upper Coil

l/h

1400

1400

1400

Lower Coil

l/h

1400

1400

1400

Heat Loss W

79

91

105

Weight Empty

Kg

40

43

50

Weight Full

Kg

246

288

343

Actual water volume

L

205.6

244.5

292.8

Dedicated solar Vol

L

99.6

102.5

148.1

Heat Loss

W

79

91

105

Energy Rating

C C

D

Page 15

Unvented Hot Water Cylinder

- 15-

Qty 1 Vokèra unvented water heater incorporating immersion heater & thermal controls

Qty 1 Factory fitted dual stat

Qty 1 Guarantee card

Qty 1 Installation and service manual

Qty 1 Accessories Kit

Code

Description

Quantity

29450020 / 29450021

Vokèra Kit A 120/150 S/C

12l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

tee piece 22mm comp. x 3/4" m x 3/4" f

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

rwc 2 port 22mm zone valve

1

29450022 / 29450023

Vokèra Kit B 180 /210 S/C & D/C

18l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

tee piece 22mm comp. x 3/4" m x 3/4" f

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

rwc 2 port 22mm zone valve

1

29450024 / 29450025

Vokèra Kit C Inox 250/310 S/C & D/C

24l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

tee piece 22mm comp. x 3/4" m x 3/4" f

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

rwc 2 port 22mm zone valve

1

3.9 Pack contents

3.10 Kit contents

Page 16

Unvented Hot Water Cylinder

- 16-

Vokèra Kit D Inox 180 / 210L Direct

18l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

Vokèra Kit E Inox 250/310L Direct

24l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

Vokèra Kit F Inox 210L S/C HP

18l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

rwc 2 port 22mm zone valve

1

Vokèra Kit G Inox 250/300L S0D/C HP

24l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

rwc 2 port 22mm zone valve

1

Vokèra Kit H Inox 210L HP

12l pot vessel 3.0bar c/w brkt vertical

1

1/2" mt.draincock type a

1

3/4"bsp hose c/w sealing washer-1000mm

1

15*22mm tundish slimline straight black

1

compact inlet control 3/6 bar

1

Page 17

Unvented Hot Water Cylinder

- 17-

4 INSTALLATION AND COMMISSIONING

(To be installed by qualified personnel only)

Installation site

Position the domestic hot water cylinder as near as possible to the heat source to prevent heat loss

Please adhere to the following instructions

The tundish discharge pipe must be installed with a minimum downward slope of 1:200 and must terminate in

a safe and visible place

The installation surface must be level and have the strength to bear the weight of the full cylinder

The installation must not be at risk of frost

The control system for the cylinder must be accessible to the service engineer

There must be sufficient space for installing, maintaining and replacing the expansion vessel.

There must be sufficient space for installing, maintaining and replacing the immersion heater

Choose a site that has simple access for the necessary supplies

To prevent heat loss ensure exposed pipework is insulated

4.1 Installing pipes for the heating circuit

Ensure that the pipes in the circuit have a minimum diameter of 22mm and are as short as possible from the heat

source to prevent heat loss.

The two port motorised valve prevents the cylinder from overheating and should be installed in the flow line of the heat

source, (the direction of flow is marked with arrows).

Connect the hot water pipe to the 22mm hot water draw off of the cylinder, continue the pipe until the first T junction.

Page 18

Unvented Hot Water Cylinder

- 18-

A secondary circulation line increases energy consumption, please only install if required for demand and

temperature reasons. If it is unavoidable keep operations to a minimum and connect a WRAS approved

pump together with a non-return valve and connect to the hot water pipe. (Please note that a second

expansion vessel may be required in this instance). A 15mm connection is fitted for the secondary circulation

line in the cylinder which is supplied with a cap if not being used. When a secondary return circuits are used then

an additional expansion vessel may be required

4.2 Cold mains inlet

The efficiency of an unvented cylinder depends on the available pressure of the cold mains inlet and flow

rate. The measured static pressure must be at least 2.0 bar. A corresponding flow rate of 20 – 25 l/min must

be available. If the pressure is below 1 bar please seek advice on an alternative hot water supply system.

4.3 Safety Assembly

Warning: Excess pressure can cause the cylinder to burst – ensure that there is no stop valve between the

safety assembly and the cylinder.

This one piece inlet control incorporates several different controls devices in one, it is specifically designed for

use on an unvented system to control the incoming water supply to a hot water cylinder or similar application.

Compact and lightweight in design the valve incorporates several different controls: A ‘drop tight’ pressure reducing

valve meaning the valve will hold at the pre-set pressure regardless of it being under flow or no flow conditions or

regardless of fluctuating inlet pressures, a single check valve which will protect the system for backflow prevention up

to fluid category 2, and a pre-set pressure relief valve which will prevent the system from over pressurisation. The

expansion relief valve is designed so it can rotate, to allow the discharge connection to be easily fitted in various

directions making installation simple. The valve also includes a specific connection for a balanced cold water take off

which can allow the user to connect a cold water feed direct from the inlet control valve, and a dedicated connection

for an expansion vessel.

During installation position the valves so that you can connect the 15mm connection of the expansion relief valve with

the tundish. The flow direction is marked with arrows.

Page 19

Unvented Hot Water Cylinder

- 19-

Warning : Ensure that the expansion relief valve is not covered or closed

Install the discharge pipe of the expansion relief valve with a constant fall to the outside. The discharge pipe must finish

at a safe and visible height where there is no danger of it freezing and where there is no danger of injury to persons.

Actuate the expansion relief valve regularly to prevent scaling.

Connect the cylinder via the cylinder connection

Use 22mm copper pipe to connect the cylinder from the main stop valve to ensure that the cylinder is as efficient as

possible. This is particularly important for installations with a balance cold water inlet

Install the safety assembly in the cold mains inlet on the cylinder

If necessary establish the connection to the cold water inlet with pressure compensation of the safety assembly

Dependent on the fittings used and the type of draw off points it may be necessary to install a backflow preventative

device in the cold water inlet.

WARNING: Water temperature over 50°C running from taps may immediately cause serious burns. Children,

disabled and elderly run a greater risk in this regards. Therefore it is advisable to use a thermostat mixing valve

connected to the water outlet or where preferred at the point of use.

Expansion vessel

To prevent any overpressures that might damage the equipment, frequently triggering the safety unit and causing water

dripping, it is mandatory that you install the expansion vessel included in the kit. Install it in accordance with the

instructions provided by the manufacturer. The expansion cylinder is required to keep pressure constant and avoid harmful

pressure shocks or accidental overpressures.

CAUTION! It is essential you install the expansion vessel vertically with connection at the bottom (see the figure

below)

CAUTION: Where secondary return circuits are used (SR) an additional expansion vessel may be required

Page 20

Unvented Hot Water Cylinder

- 20-

4.3.1 Building Regulation G3

The following text is reproduced from the Building Regulations.

It is included here for reference only.

Discharge pipes from safety devices

Discharge pipe D1

3.49 Each of the temperature relief valves or combined temperature and valves specified should discharge either directly

or by way of a manifold via a short length of metal pipe (D1) to a tundish.

3.50 The diameter of discharge pipe (D1) should be not less than the nominal outlet size of the temperature relief valve.

3.51 Where a manifold is used it should be sized to accept and discharge the total discharge from the discharge pipes

connected to it.

3.52 Where valves other than the temperature and pressure relief valve from a single unvented discharge by way of the

same manifold that is used by the safety devices, the manifold should be factory fitted as part of the hot water storage

system unit or package.

Tundish

3.53 The tundish should be vertical, located in the same space as the unvented hot water storage system and be fitted as

close as possible to, and lower than, the valve, with no more than 750mm of pipe between the valve outlet and the tundish

(see Diagram1).

Note: To comply with the Water Supply (Water Fittings) Regulations, the tundish should incorporate a suitable air gap.

3.54 Any discharge should be visible at the tundish. In addition, where discharges from safety devices may not be apparent,

e.g. in dwelling occupied by people with impaired vision or mobility, consideration should be given to the installation of a

suitable safety device to warm when discharge takes place, e.g. electronically operated.

Discharge pipe D2

3.55 The discharge pipe (D2) from the tundish should:

a. Have a vertical section of pipe at least 300mm long below the tundish before any elbows or bends in pipework (see

Diagram 1); and

b. Be installed with a continuous fall thereafter of least 1 in 200.

3.56 The discharge pipe (D2) should be made of:

a. Metal; or

b. Other material that has been demonstrated to be capable of safely withstanding temperatures of the water

discharged and is clearly and permanently marked to identify the product and performance standard (e.g. as

specified in the relevant part of BS 7291).

3.57 The discharge pipe D2 should be at least one pipe size larger than the nominal outlet size of the safety device unless its

total equivalent hydraulic resistance exceeds that of a straight pipe 9m long, i.e. for discharge pipes between 9m and 18m

the equivalent resistance length beat least two sizes larger than the nominal outlet size of the safety device; between 18m

and 27m at least 3 sizes larger, and so on; bends must be taken into account in calculating the flow resistance. See diagram

1, table 1 and worked example.

Note: an alternative approach for sizing discharge pipes would be to allow Annex D, section D.2 of BS 6700:2006

Specification for design, installation, testing and maintenance of devices supplying water for domestic use within buildings

and their curtilages.

Page 21

Unvented Hot Water Cylinder

- 21-

Valve outlet

size

Minimum size of discharge to

Tundish (D1)*

Minimum size of discharge pipe

from Tundish (D2)*

Maximum resistance allowed

expressed as a length of straight

pipe, i.e. elbows or bends

Resistance created by each

elbow or bend

G ½

15mm

22 mm

38 mm

35 mm

up to 9 m

up to 18 m

up to27 m

0.8 m

1.0 m

1.4 m

G ¾

22 mm

28 mm

35 mm

42 mm

up to 9 m

up to 18 m

up to27 m

1.0 m

1.4 m

1.7 m

G 1

28 mm

35 mm

42 mm

54 mm

up to 9 m

up to 18 m

up to27 m

1.4 m

1.7 m

2.3 m

Diagram 1 – Typical discharge pipe arrangement

Table 1 – Sizing of copper discharge pipe ‘D2’ for common temperature relief valve outlet sizes

*See 3.49 and 3.56 and Diagram 1

Note: The above table is based on copper tube. Plastic pipes may be of different bore and resistance.

Sizes and maximum lengths of plastic should be calculated using data prepared for the type of pipe being used.

Worked Example

The example below is for a G ½ 6 with discharge pipe (D2) having 4 No. 22mm elbows and length of 7m from the tundish to

the point of discharge.

From Table1

Maximum resistance allowed for a straight length of 22mm copper discharge pipe (D2) from a G ½ temperature relief

valves is: 9.0m

Subtract the resistance for 4 No.22mm elbows at 0.8m each=3.2m

Therefore the maximum permitted length equates to: 5.8m which is less than the length of 7m therefore calculated the next

largest size.

Maximum resistance allowed for a straight length of 28mm copper discharge pipe (D2) from a G ½ temperature relief

valve is. 18m

Subtract the resistance for 4 No.28mm elbows at 1.0m each=4m

Therefore the maximum permitted length equates to: 14m

As the actual length is 7m, a 28mm (D2) copper pipe will be satisfactory.

3.58 Where a single common discharged pipe serves more than one system, it should be at least one pipe size larger than

the largest individual discharge pipe (D2) to be connected.

3.59 The discharge pipe should not be connected to a soil discharge stack unless it can be demonstrated that the soil

discharge stack is capable of safely withstanding temperatures of the water discharged, in which case, it should:

Page 22

Unvented Hot Water Cylinder

- 22-

a. Contain a mechanical seal, not incorporating a water trap, which allows water into the branch pipe without allowing

foul air from the drain to be ventilated through the tundish;

b. Be a separate branch pipe with no sanitary appliances connected to it;

c. If plastic pipes are used as branch pipes carrying discharge from a safety device they should be either polybutylene

(PB) to Class S of BS 7291-2:2006 or cross linked polyethylene (PE-X) to Class S of BS 7291-3:2006;and

d. Be continuously marked with a warning that no sanitary appliance should be connected to the pipe.

4.4 Unit filling

WARNING: Switching on the equipment when it is not filled with water will seriously damage the electric heating

element.

WARNING: In the presence of water with a hardness degree >200ppm it is mandatory that you install a softener to

reduce limestone scaling inside the cylinder and keep the electric heating element and the hydraulic safety unit in

good working order.

To fill the equipment you need to:

• The tap present in the hydraulic unit must be put in the open position, the opening of the tap allows the equipment’s

supply. The retain system incorporated in the safety hydraulic unit prevents from the heat water return.

• open the main water supply or the equipment water supply cock;

• open a hot water tap (e.g. bathroom, wash basin, etc.) to allow the water to flow out; when the water outflow from the

tap is constant the equipment will be full;

• check that there are no leaks from the various hydraulic connections;

We recommend that you clean the pipes before laying them.

Only proceed with the electrical connection after performing this operation

4.5 Electrical connection

Wiring should be installed by a qualified, competent person in accordance with the prevailing building regulations, part P of

the current IEE regulations and all other directives.

WARNING: Switching on the equipment when it is not filled with water will seriously damage the electric

heating element.

WARNING: If the supply cable is damaged, it must be replaced by the manufacturer or by its technical support

service or a suitably qualified person.

Standard commercial cables can be used, 230 V supply lines must be laid separately above lengths of 10m.

The discharge pipes of the tundish, drain valves and motorised valves must be laid at distance from all electrical

components.

Before wiring the control components dismantle the casing to facilitate the work. Utilise the cut outs in the casing for

routing cables.

DANGER – Without earthing life threatening voltage can reach the pipework and

draw off points – it it imperative that you earth the immersion heater

Ensure that both hot and cold pipes are connected to the earth line by means of an

earth cable directly on the cylinder.

Page 23

Unvented Hot Water Cylinder

- 23-

You must also ensure that the immersion heater is connected to the earth line via

the earth terminal.

Cylinder thermostat and thermal cut-out for reheating circuit

Electrical connection of the immersion heater

Page 24

Unvented Hot Water Cylinder

- 24-

Only switch the immersion heater on when the cylinder is full

4.6 Safety limiting device (manual reset

Reset, after eliminating the causes of intervention, as follows:

- disconnect the power supply;

- remove the protection cover fixing screws;

- lightly press the thermostat reset button, using an insulated object with round tip, in the position indicated, until

hearing a click.

Page 25

Unvented Hot Water Cylinder

- 25-

Technical data

Max Pressure: 7 bar

Max Temperature: 90°C

Technical data

240V, 0.04°, 6/5W, 50/60Hz

Max Diff. Press. : 55.2kPa (8psi)

Max. Stat. Press. : 863 kPa (125 psi)

Max. Fluid Temp. : 5-88 °C (40-190°F)

Max. Ambient Temp. : 52°C (125°F)

Hot water Only

Technical data

Temperature range: 25±5 ÷ 65±3°C

Temperature differential: Δt 8±2 K

Limit temperature: FIX 80±3°C

Fail safe: YES

Differential (Manual Reset): 20±5°C

Max. body temperature: T 80°C

Max. bulb temperature: T 125°C

Ambient temperature effect: -0.12°C/°C *

Fairlead: M20x1.5

Degree of protection: IP40

Contact rating: N-A 10(2,5)A/250V~

Change in switching pint refer to maximum change of the value of ambient

temperature

4.7 Solar controller - When the solar controller is used as the normal control thermostat on

the cylinder and the cylinder incorporates a high limit thermostat for the solar circuit

4.8 T&P

4.9 Motorized Zone Valve

4.10 Dual Thermostat

4.11 Drainage

Typical drain arrangement and system design.

Page 26

Unvented Hot Water Cylinder

- 26-

4.12 Unit emptying

Should the unit be going to remain unused for a prolonged time, we recommend that you empty it. In this case proceed as

follows:

• cut off the power supply and the main water supply;

• open a hot water tap to allow air to flow in;

• turn the emptying knob on the hydraulic safety unit to the open position;

• verify that the discharge connector of the hydraulic safety unit is connected to a drain as specified in par. 3.1.1.

4.13 Restart after a long term stop

When the unit is restarted after a long term stop (trail running included), it is normal that outlet water is unclean. Keep the

tap on and the water will be clean soon.

5 COMMISSIONING SYSTEM

IMPORTANT: It is the responsibility of the installer to ensure that the system is properly commissioned and the end

user instructed in the safe operation of the equipment.

The thermostat on the immersion heater should be adjusted to trip at 60°C. This is the ideal temperature to prolong

element life in hard water areas. Scale on the sheath builds up more rapidly at temperatures above this causing the

element to overheat and premature failure can occur. Higher temperatures without additional controls would result in

scalding. In known hard water areas the use of a scale inhibitor is also recommended.

In addition to the thermostat the thermal cut-out will switch power off to the element should the thermostat

malfunction, causing an excessive rise in water temperature. The thermal cut-out can be reset manually after the fault

has been corrected

5.1 Electrical Check

Check that all wiring including earth wiring, has been installed correctly, conform to current regulation and

satisfactory electrical test and inspection certificate has been completed.

Check all electrical covers are correctly fitted;

Check Tundish is positioned so that any spillage or spray from the Tundish would not contact any electrical

components.

Check all wiring connections have been made.

Check the required earth continuity conductors have been fitted.

Page 27

Unvented Hot Water Cylinder

- 27-

5.2 Pre-Fill Check

Check the expansion vessel is fitted and that no valves are fitted between the expansion vessel and the

combination valve.

Check that no valves are fitted between indirect water heater and the combination valve.

Check the PRV, tundish and discharge pipes are corrected installed to conform to the Building Regulation G3.

Check all pipes connections are tight and no joints have been left unsoldered.

Check all drain cocks are closed.

5.3 Fitting System

Close all isolating valves.

Close all taps.

Open the incoming water mains stopcock.

Turn on mains water, allow system to fill up to first isolating valve. Turn on hot taps. Open isolating valves and allow

the indirect water heater to fill and let water pass through the system to the open hot tap, this will expel most of air

from the system and fill the indirect water heater vessel.

Systematically open all hot and cold taps to purge air.

Check system for leaks.

Check no water is discharging from T&P or PRV.

Expansion vessel – with the water supply turned off and taps open, check expansion vessel pressure and top up as

necessary.

Cylinder T&P – check its operation; with the water supply on, turn the T&P test knob and check water discharges to

tundish, ensure the valve closes after testing.

Discharge pipe (D1) – open either T&P or PRV gradually to produce all full bore discharge into tundish and D2 and

check there is no back pressure, and that the water flows freely to drain.

Pressure Reducing Valve (PRV) – check that the correct outlet pressure is being maintained by measuring the

pressure at an in-line terminal fitting e.g. a tap.

When necessary the immersion heater boss can be used as an access to view internal of the cylinder

5.4 Drain System

Turn off incoming mains stop cock.

Using hose and suitable containers, drain all water from the cylinder and pipework using drain cocks.

Remove and clean in-line strainer of combination valve.

5.5 Cleaning The System

Using proprietary chlorination product, chlorinate domestic hot water system as per manufacturer’s instruction.

Drain the system as 4.15, then fill and drain to flush as many times as recommended by chlorination product

manufacturer.

Refill system.

5.6 Setting And Testing Controls

Switch on indirect water heater electric isolating switch.

For commissioning use the factory default setting, no changes parameters should be required.

Set indirect water heater into operation, and when hot check for leaks.

Check operating of any open flue appliances that could be affected by air movement through the indirect water

heater.

Fill in details in the Benchmark Logbook.

Page 28

Unvented Hot Water Cylinder

- 28-

5.7 Handing Over

Complete the Benchmark Logbook.

The installer should re-check the system and ensure it’s completely satisfactory before demonstrating to the end

user.

The end user should be aware of the following:

The most cost effective use of the indirect hot water system using the automatic mode.

How to set the temperature of the tap hot water.

How to set the different functions.

The function of the combination valve’s PRV and that over pressure will cause steam and scalding water to be

emitted from the discharge pipes.

That the tundish is supplied as a visual identification for over pressure.

The procedure to follow in event of over pressure.

IMPORTANT: This manual must be left with the end user together with the Service record / Logbook.

6 MAINTENANCE INSTRUCTIONS

(Qualified personnel only)

WARNING: the repair and/or maintenance operations must only be performed by qualified personnel. Only use

genuine spare parts. Prior to undertaking any maintenance operations, turn off and disconnect the equipment from

the mains electrical supply before commencing any work on the Cylinder. We recommend that you purchase any

spare parts from only authorised dealers or directly from the Manufacturer.

6.1 General

• Control regularly the connection between the supply plug and wiring.

• If the system is not used for a long period, empty the cylinder in order to avoid freezing.

• It is advised to clean regularly the inside part of the cylinder and the electric heating element in order to preserve the

efficiency.

• Control the magnesium anode and change it if needed.

• Clean the air filters each month in order to preserve the heating performance.

• Before turning off the system for a long period you must:

- Remove the current supply;

- Drain all the water from the cylinder and the pipes;

- Close all valves ;

- Control regularly all inside components.

6.2 Water circuit / Condensate discharge

The water circuit check is limited to the integrated filter installed by the customer (if any; in this case follow the instructions

provided by the valve manufacturer); also check the tightness of the valves, of the screw connections, etc.; should they be

loose, have them tightened by technicians.

Page 29

Unvented Hot Water Cylinder

- 29-

6.1 Replacement of the electric immersion heater

If replacement of the electric immersion heater is required follow this procedure.

Procedure:

• Turn off the unit;

• Disconnect product from the electrical supply

• Empty the cylinder until the water level seems to be lower than the place where the electric immersion heater is joined;

• Remove the immersion heater cover. Disconnect the cable from the thermostat

• Remove the thermostat

• Disconnect and replace the electric immersion heater; Replace the O-Ring if necessary.

• Replace the thermostat

• Restore the electric connections;

• Replace the immersion heater cover

• Fill the cylinder and check for leaks;

• Restore the connection to the electric supply;

6.2 Outer cover cleaning

For the cleaning of the outer shell only use a damp cloth. Do not in any circumstances use abrasive products containing

organic thinners (alcohol, benzene, etc.).

6.3 Hydraulic safety unit efficiency check

The hydraulic unit efficiency is very important to prevent any overpressures inside the cylinder (that would damage it), and

allows the user to safely operate the equipment. Periodically check the efficiency of the hydraulic safety unit, according to

the instructions provided by the manufacturer. Follow the instructions provided by the manufacturer. During the check

clean the unit and remove any limescale.

6.4 General notes

Always use tools that are appropriate for the intended purpose.

Always replace the gaskets and/or the o-rings ensuring the hydraulic sealing.

Only use genuine spare parts.

During reinstalling make sure that:

• the resistance is properly housed and the sealing gaskets are correctly installed;

• the safety and regulation devices (thermostats) are properly installed inside their housings;

• before reconnecting the equipment to the mains fill it (referring to the appropriate section) and check that there are no

water leaks.

6.5 After-sales service

In case of errors or malfunctions, switch off the equipment and disconnect the power supply. Then contact the technical

support service.

Page 30

Unvented Hot Water Cylinder

- 30-

Fault

Cause

Remedy

The cylinder cools down at night

One pipe circulation in the case of

short tube networks with low

pressure loss

Install a non-return valve as close as

possible to the cylinder

Primary heating not working. Boiler

runs for short periods repeated until

cylinder reaches temperature

air in the reheating chamber

Vent the reheating heat exchanger.

Heat exchanger surface area too

small

Compare the data provided by the

boiler manufacturer with the cylinder

data it may be possible to cure by

setting a higher flow rate on the

boiler

Only cold or lukewarm water at draw

off

The cold and cold draw offs have

been reversed

Turn off the cold water supply and let

the water flow out via the how draw

off. Only a few litres of water will

flow if the setup is correctly. The hot

water withdrawal pipe intake is then

in air space and further draining is not

possible. If it is possible to drain the

entire cylinder via the hot draw off

then the connections are incorrect.

Change the connections.

Hot water thermostat set too low

Increase the setting

Heating insufficient – boiler doesn’t

reheat

External control device faulty

Air in the reheating heat exchanger

Check boiler is working

Check controls are working and that

the 2 port valve is in the DHW

position

Vent the reheating heat exchanger

Page 31

Unvented Hot Water Cylinder

- 31-

Cylinder sensor faulty

Check thermal cut out and replace if

faulty

Water flows from the expansion relief

valve when heating up

Dirt on the valve seat

Check and repair

PRV Faulty

Check an replace if faulty

Expansion vessel faulty

Check pressure, if insufficient repressurise and replace if pressure not

held

Expansion relief valve faulty

Check if pressure is normal and

replace if faulty

Water flows from the temperature

and pressure relief valve when

heating up

Dirt in the valve seat

Check and repair

Boiler temperature control system

faulty

Check boiler control system and that

the 2 port valve switches when

cylinder temperature reached

Cylinder sensor faulty

Check sensor and TCO replace if

faulty

T & P relief valve faulty

If water escapes when only heated by

the immersion replace the T & P relief

valve

Immersion heater faulty

Check thermal cut out and replace if

faulty

Page 32

Unvented Hot Water Cylinder

- 32-

6.6 Service record / Logbook

Page 33

Unvented Hot Water Cylinder

- 33-

Page 34

Unvented Hot Water Cylinder

- 34-

DISPOSAL OF WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (2002/96/EC – WEEE DIRECTIVE)

This symbol indicates that the appliance must not be treated as domestic waste upon disposal.

Rather, it must be delivered to an authorized collection centre for the recycling of electrical and electronic

appliances.

Proper disposal of this appliance will avoid potential health hazards and adverse consequences for the environment.

Recycling of materials helps to preserve natural resources.

For further information about the recycling of this appliance, please contact your municipal offices, your domestic waste

disposal service or the retailer/installer from whom the appliance was purchased.

The penalties for failure to comply with these disposal procedures are laid down in local legislation.

Loading...

Loading...