Page 1

Users

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 2

2

Dear Customer

Your Vokera Hydra boiler has been designed to meet and exceed the very latest standards in gas central heating

technology , and if cared for, will give years of reliable use and efficiency.

Please therefore take some time to read these instructions carefully .

Do’s and don’t’ s

● Do ensure that the system pressure is periodically checked

● Do ensure that you know how to isolate the appliance in an emergency

● Do ensure that you are familiar with the appliance controls

● Do ensure that your installer has completed the appliance log book

● Do not attempt to remove the appliance casing or gain internal access

● Do not hang clothes etc. over the appliance

● Do not forget to have the appliance serviced annually.

Contents

Introduction Page

Dear customer 2

Do’s and don’t’s 2

Things you should know Page

1.1 Gas appliances 3

1.2 Electrical supply 3

1.3 Guarantee registration card 3

1.4 Benchmark log book 3

1.5 How does it work? 3

1.6 Dimensions 3

1.7 Clearances required 3

1.8 Frost protection system 3

1.9 Additional controls 3

Getting started Page

2.1 Before switching on 3

2.2 Appliance controls 3

2.3 Lighting the boiler 4

2.4 Adjusting the operating temperature 4

2.5 Digital display 5

2.6 Fault code table 5

How to... Page

3.1 Top-up the system pressure 6

3.2 Reset the appliance 6

3.3 Shut down the system for short periods 6

3.4 Shut down the system for long periods 6

3.5 Care for the appliance 6

3.6 Regulate the hot water temperature 6

What if... Page

4.1 I suspect a gas leak 7

4.2 I frequently have to top-up the system 7

4.3 The status led is red 7

4.4 The appliance is due its annual service 7

4.5 I need to call an engineer 7

Setting the Vokera Page

5.1 Mechanical clock 8

5.2 Digital clock 8

INTRODUCTION

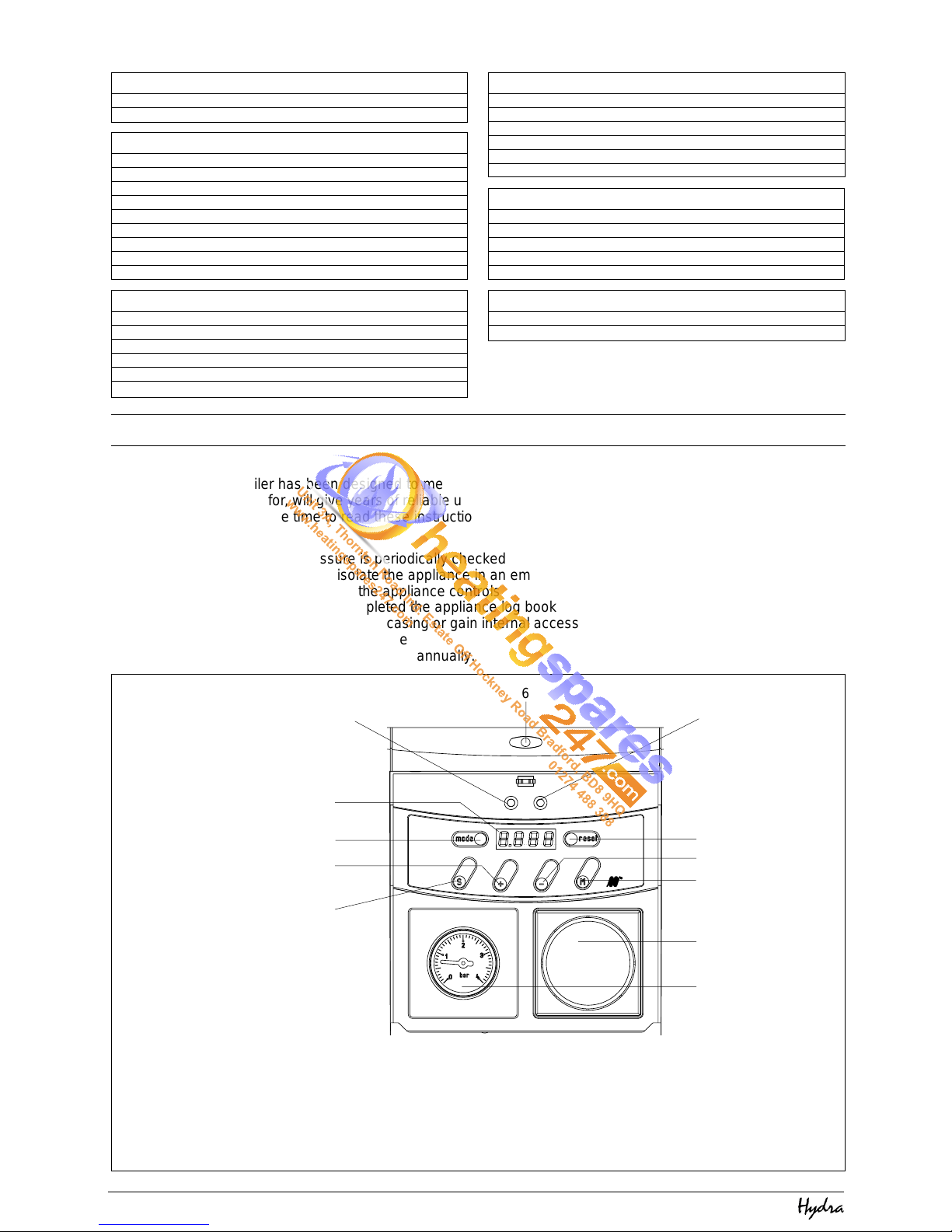

Fig. 1

1= hot water selection

2= increase button

3= mode button

4= digital display

5= hot water LED

6= status LED

7= heating LED

8= reset button

9= decrease button

10= heating selector

11= clock aperture

12= pressure gauge

1

2

3

4

6

8

9

10

11

12

5

7

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 3

3

THINGS YOU SHOULD KNOW

1.1 GAS APPLIANCE

Gas Safety (Installations and Use) Regulations.

In the interests of your safety and that of others it

is a legal requirement that all gas appliances are

installed and correctly maintained by a competent

person and in accordance with the latest

regulations.

1.2 ELECTRICAL SUPPLY

Please ensure that this appliance has been

properly connected to the electrical supply by

means of a double pole isolator or un-switched

socket, and that the correct size of fuse (3 amp)

has been fitted.

Warning: this appliance must be earthed!

1.3 GUARANTEE REGISTRATION CARD

Please take the time to fill out your guarantee

registration card. The completed warranty card

should be posted within 30 days of installation.

1.4

BENCHMARK

LOG BOOK

The

Benchmark

Log Book is supplied with your

boiler. This important document must be

completed during the installation/commissioning

of your boiler. All CORGI Registered Installers

carry a CORGI ID card and have a registration

number. Both should be recorded in your

Benchmark

Log Book. You can check your

installer by calling CORGI direct on 01256 372300.

Failure to install and commision the appliance in

accordance with the manufacturers instructions

may invalidate the warranty. This does not affect

your statutory rights.

1.5 HOW DOES IT WORK?

Your Hydra boiler is a high efficiency combination

boiler, which supplies heated water to your

radiators and hot water to your taps.

The central heating is controlled via a time clock

and/or any thermostats that your installer may

have fitted. The boiler will light when a hot water

outlet (a tap) is opened. The boiler also functions

periodically to pre-heat the hot water heat

exchanger. The Hydra boiler lights electronically

and does not have a pilot light. In the unlikely

event of a fault developing with your boiler, the

supply of gas to the burner will be terminated

automatically.

1.6 DIMENSIONS

HEIGHT

WIDTH

DEPTH

820 mm

450 mm

355 mm

1.7 CLEARANCES REQUIRED

ABOVE

BELOW

SIDES

FRONT

150 mm

120 mm

25 mm

600 mm

1.8 FROST PROTECTION SYSTEM

The Hydra is equipped with a built-in frost

protection system, this enables the boiler to override the time controls – if switched off – and

operate the burner and/or pump, should the

temperature drop below 7

°

C.

Please note that the frost protection system is

designed to protect the appliance only, should

frost protection be required for the central heating

system, additional controls may be required.

NOTE

The frost protection system is reliant on the

appliance having a permanent electrical supply,

and being in a non-fault condition.

1.9 ADDITIONAL CONTROLS

Additional controls such as an external temperature sensor kit or under floor heating safety

thermostat are available as optional accessories

for this appliance. Y ou should consult your installer

and/or the supplementary instructions supplied,

on their use (if installed).

GETTING STARTED

2.1 BEFORE SWITCHING ON

Before switching the appliance on please

familiarise yourself with:

● how to isolate the appliance from the gas,

water, and electricity supplies;

● how to check and top-up – if necessary – the

system water pressure;

● the time clock;

● any external thermostats and their functions;

● the appliance controls.

2.2 APPLIANCE CONTROLS (fig. 1)

The appliance controls are concealed behind the

front cover. To gain access to the controls simply

press the cover inwards to release the catch. The

appliance is equipped with a simple keypad that

can be used to alter the following function:

● the outlet flow temperature to the central heating

system;

● the outlet flow temperature for domestic hot

water

The pressure gauge shows the current pressure

of the system, the gauge should be set between

1 and 1.5 bar. When the appliance is operating

the gauge may rise or fall slightly, this is quite

normal. The minimum permissible level for the

safe and efficient operation of the appliance is 0.5

bar. Should the pressure fall below 0.5 bar, the

boiler may lockout.

Depending on the type of controls specified by

your installer you may have an integral Vokera

time clock fitted to the appliance, if so, instructions

can be found on page 8-9. If an external time

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 4

4

clock or programmer has been fitted, please refer

to the instructions supplied with such.

2.3 LIGHTING THE BOILER

Ensure the gas and electrical supply to the boiler

are turned on.

The boiler will now go through a self-test and

purge sequence indicated by the letter ‘A’ shown

on the left side of the digital display.

2.3.1 ON/OFF MODES (heating)

The heating mode can be switched ON or OFF at

the boiler irrespective of the current time clock

setting. This is indicated by the heating LED (fig. 1).

If the heating LED is illuminated, this indicates

that the heating mode is enabled and is controlled

via the time clock and any external controls such

as a room thermostat.

If the heating LED is unlit, the boiler will not

respond to any heat requests from the time clock

or room thermostat etc.

To switch the heating mode ON or OFF, press

and hold the button (fig. 2) whilst looking at

the digital display:

●

c OF

indicates the heating mode is switched

OFF

●

c 55

(or any other number, indicating the central

heating operating temperature), indicates the

heating mode is switched ON.

2.3.2 ON/OFF MODES (hot water)

The hot water mode can be switched ON or OFF

at the boiler. This is indicated by the hot water

LED (see fig. 1).

If the hot water LED is illuminated, this indicates

that the hot water mode is enabled.

If the hot water LED is unlit, the boiler will not

respond to any hot water requests whenever a

hot water outlet (tap) is opened.

To switch the hot water mode ON or OFF , press

and hold the button (fig. 3) whilst looking at

the digital display:

●

d OF

indicates the hot water mode is switched

OFF

●

d 40

(or any other number, indicating the

domestic hot water operating temperature),

indicates the hot water mode is switched ON.

The boiler will pre-heat the DHW heat exchanger

if it is below 55ºC, however should a hot water outlet

be opened the boiler will operate in the domestic

hot water mode to supply hot water to the tap.

On completion of the pre-heat function, the boiler

will revert to the stand-by mode indicated by ‘0’

shown in the left side of the digital display.

2.3.3 HEATING REQUEST

When there is a demand for heating via the time

clock, the boiler will go through an ignition

sequence, whereby the burner will light.

When the appliance reaches the set temperature,

the burner will go off for minimum period of

approximately 90 seconds.

When the programmer/time clock or external

thermostats heating request has been satisfied,

the appliance will switch off automatically.

2.3.4 HOT WA TER REQUEST

When a hot water outlet or tap is opened, the

boiler senses a change of inlet temperature and

initiates an ignition sequence. The boiler will

modulate the output according to the temperatu-

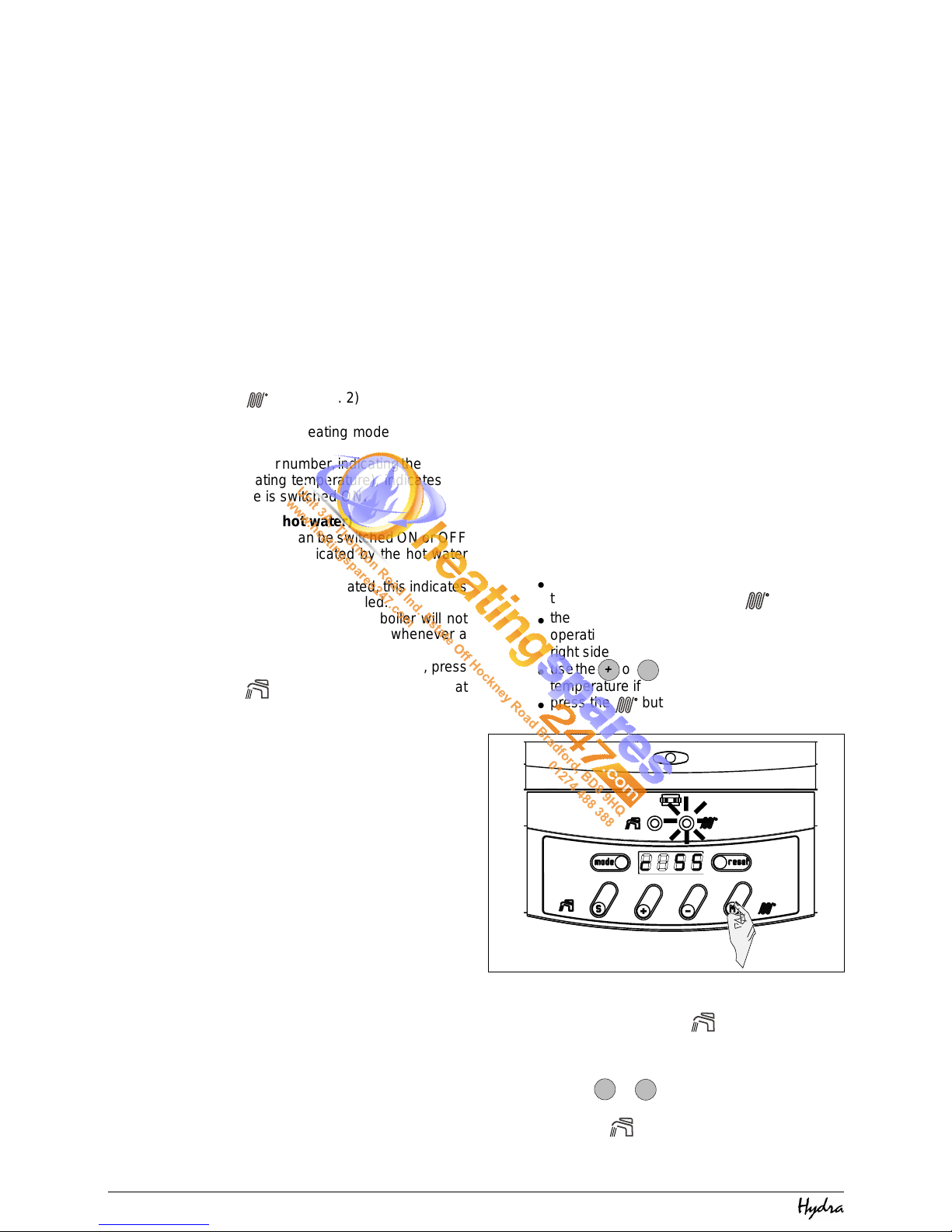

Fig. 2

re required, when the hot water request has been

satisfied, the boiler may continue to operate if

the pre-heat function is required.

NOTE

If the appliance fails to ignite during the ignition

sequence, it will re-attempt ignition several times

before going to a lockout condition. Should this

occur, please allow a period of two minutes before

re-setting.

2.3.5 STATUS LED (fig. 1)

The appliance status LED indicates whether the

boiler is in OFF mode, ON mode or fault condition.

Status LED flashing Green

Indicates the appliance is in the OFF mode, with

electrical supply and frost protection active.

Status LED permanently Green*

Indicates the appliance is ON mode, with heating

or hot water or both activated.

Status LED permanently Red

This indicates that the appliance is in a permanent

fault condition and may require to be reset

(indicated by the relevant fault code displayed)

see 2.6.

*Also illuminated during a temporary fault

condition.

2.4 ADJUSTING THE OPERATING PARAMETERS

Usually your installer will have adjusted the

operating temperatures to suit your requirements,

however should you wish to view or alter them,

please use the following procedure:

Central heating temperature

● to view or alter the heating operating

temperature, briefly press the button;

● the central heating LED will now flash and the

operating temperature will be shown on the

right side of the display (see fig. 2);

● use the

+

or - button to adjust the operating

temperature if required;

● press the button to save the new setting.

Hot water temperature

● to view or alter the hot water operating tempe-

rature, briefly press the button;

● the hot water LED will now flash and the

operating temperature will be shown on the right

side of the display (see fig. 3);

● use the

+

or - button to adjust the operating

temperature if required;

● press the button to save the new setting.

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 5

5

Current status

Stand-by mode

Purging

Ignition

Heating mode

Hot water mode

Fan operation

Timer delay

Pump over run (CH)

Pump over run (HW)

Self check

Left display shows

0

1

2

3

4

5

6

7

8

A

Reason

Ignition anomaly

No flame detected

Internal fault

Power failure

Internal fault

Internal fault

Internal fault

Internal fault

Appliance overheat

Internal fault

Internal fault

Internal fault

Internal fault

Internal fault

Appliance overheat

Appliance overheat

Appliance overheat

Appliance overheat

Temperature anomaly

Temperature anomaly

Temperature anomaly

Condensate pipe blocked

Insufficient fan speed

Fan problem

Fan speed problem

Fan problem

Temperature anomaly

Temperature anomaly

Internal fault

Internal fault

Internal fault

Internal fault

Internal fault

Internal fault

Internal fault

Programming fault

Insufficient fan speed

Code

E 00

E 02

E 03

E 04

E 05

E 06

E 07

E 11

E 12

E 13

E 14

E 15

E 16

E 17

B 18

E 18

B 19

E 19

B 24

B 25

E 25

B 26

B 28

E 28

B 29

E 29

B 30

E 30

E 31

E 32

E 33

E 36

E 37

E 38

E 44

E 60

B 65

2.6 FAULT CODE TABLE

Action required

Reset appliance, if fault continues, call engineer

Check gas is on, reset appliance, if fault continues, call engineer

Call engineer

Reset appliance, if fault continues, call engineer

Call engineer

Call engineer

Call engineer

Call engineer

Reset appliance, if fault continues, call engineer

Call engineer

Call engineer

Call engineer

Call engineer

Call engineer

Ensure radiators are on

Reset appliance, if fault continues, call engineer

Ensure radiators are on

Reset appliance, if fault continues, call engineer

If fault continues, call engineer

Check pressure gauge

Check pressure gauge, reset appliance, if fault continues, call engineer

Check outlet of condense pipe, if problem persists, call engineer

If fault continues, call engineer

Reset appliance, if fault continues, call engineer

If fault continues, call engineer

Reset appliance, if fault continues, call engineer

Check pressure gauge

Check pressure gauge, reset appliance, if fault continues, call engineer

Call engineer

Call engineer

Call engineer

Call engineer

Call engineer

Call engineer

Call engineer

Call engineer

If fault continues, call engineer

2.5 DIGITAL DISPLAY

The digital display shows the current mode of

operation and/or status of the boiler.

Should a fault develop, the display will show a

unique fault code that can be used to help rectify

the cause of the fault.

During the normal operation, the left side of the

display indicates the current mode of operation,

whilst the right side will show the current

temperature.

Fig. 3

Should a fault occur, the left side of the display

will show whether the fault is temporary or

permanent (indicated by ‘b’ or ‘E’), whilst the right

side of the display indicates the unique fault

code.

Should a fault code be displayed, check the

fault code table to identify the cause and

course of action to take.

Always wait 2-minutes before pressing the

reset button.

Displays during normal operation

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 6

6

HOW TO...

3.1 HOW TO TOP-UP THE SYSTEM PRESSURE (fig. 4)

The system pressure must be checked periodically

to ensure the correct operation of the boiler. The

needle on the gauge should be reading between

1 and 1.5 bar when the boiler is in an off position

and has cooled to room temperature. If the

pressure requires ‘topping-up’ use the following

instructions as a guide.

● Locate the filling/inlet valve found at base of the

boiler (see fig. 4 & fig. 5).

● The fillig loop (fig. 4) may have been

disconnected from the filling/inlet valve and

heating flow valve. If so reconnect unscrewing

the caps as necessary.

● The filling valve has 3 positions (see fig.5):

i) Vertically up - normal operating position.

ii) Turn to the left to horizontal - closed position.

iii) Vertically down - filling position.

To fill, slowly turn the handle of the filling/inlet

valve towards the filling position. Mains water

will be heard to enter the system/boiler. As the

water enters the system/boiler the pressure

gauge will be seen to rise. Pressurise to between 1bar & 1.5 bar when the system is cold.

DO NOT OVERPRESSURISE.

Once the desired pressure is achieved turn the

filling/inlet valve into the normal position.

3.2 HOW TO RESET THE APPLIANCE

When the status light is illuminated red, the

appliance will require to be reset manually. Before

resetting the boiler ensure that the pressure

gauge is indicating the correct level. Allow a

period of two minutes to elapse before pressing

the reset button.

IMPORTANT

If the appliance requires to be reset frequently, it

may be indicative of a fault, please contact your

installer or Vokera Customer Services for further

advice.

3.3 HOW TO SHUT DOWN THE SYSTEM FOR

SHORT PERIODS

Turn the time clock to the off position. Switch the

boiler to OFF mode (see section 2.3.1 & 2.3.2). It

is also advisable to turn off the main water supply

to the house.

3.4 HOW TO SHUT DOWN THE SYSTEM FOR

LONG PERIODS

If the house is to be left unoccupied for any length

of time – especially during the winter – the system

should be thoroughly drained of all water.

The gas, water and electricity supply to the house

should also be turned off. For more detailed

advice contact your installer.

3.5 HOW TO CARE FOR THE APPLIANCE

To clean the outer casing use only a clean damp

cloth. Do not use any scourers or abrasive

cleaners.

normal

operating

position

filling

position

closed

position

Fig. 5

Fig. 4

Heating valves

Filling loop

Filling/

inlet valve

Gas cock

3.6 HOW TO REGULA TE THE HOT WATER TEMPERATURE

Usually your installer will have adjusted the hot

water output to suit your requirements, however

if you would like to adjust the outlet temperature,

please follow the instructions in section 2.4.

NOTE

If you find that the hot water temperature is still

insufficient, try reducing the flow of water through

the tap.

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 7

7

CORGI registered engineer may be able to service

the appliance for you.

4.5 WHAT IF I NEED TO CALL AN ENGINEER

If you think your boiler may have developed a

fault please contact your installer or Vokera

Customer Services (0870 333 0220 (UK) or

05655057 (ROI) have all your details to hand

including full address and postcode, relevant

contact numbers, and your completed appliance

log book.

WHAT IF...

4.1 WHAT IF I SUSPECT A GAS LEAK

If you suspect a gas leak, turn off the gas supply

at the gas meter, and contact your installer or

local gas supplier. If you require further advice

please contact your nearest Vokera office.

4.2 WHAT IF I HAVE FREQUENTLY TO TOP-UP

THE SYSTEM

If the system regularly requires topping-up, it may

be indicative of a leak. Please contact your installer

and ask him to inspect the system.

4.3 WHAT IF THE STATUS LED IS RED

If the status led is illuminated red it indicates that

the boiler has failed to ignite or has overheated,

when this happens the boiler automatically shuts

down and requires to be reset manually (see 3.2).

4.4 WHAT IF THE APPLIANCE IS DUE ITS

ANNUAL SERVICE

Advice for tenants only

Your landlord should arrange for servicing.

Advice for homeowners

Please contact Vokera Customer Services (0870

333 0220 (UK) or 05655057 (ROI) if you would

prefer a Vokera service engineer or agent to

service your appliance. Alternatively your local

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 8

8

5.2.1 BEFORE PROGRAMMING

Gently press and release the ‘Res.’ button with a

pencil or similar, this will clear the memory of all

information. This should only be done when you

want to change or insert a complete new

programme.

5.2.2 SETTING THE TIME OF DAY

The ‘real time’ clock has to be set to the actual

day of the week and time of day, to do this:

● Press and hold the button (see fig 7).

● Press the ‘Day’ button until the actual day

shows in the display (1= Monday , 2= T uesday,

3= Wednesday, etc.).

● If setting the clock during ‘British summertime’

press the ‘+/-1h’ button once (use a pencil or

similar).

● Press the ‘h’ button until the actual hour is

shown in the display.

● Press the ‘m’ button until the actual minutes

are showing in the display.

● Now release the button.

● The ‘:’ symbol between the hours and minutes

display will start to flash, this indicates that the

clock is now keeping time (see fig. 8).

5.2.3 ENTERING (on) COMMANDS

● Repeatedly press the Prog. Button until the —

:— symbol appears in the clock display (see

fig. 9).

● Press the Day button until the desired group of

days or desired day is shown.

● Press the ‘h’ button until the desired hour for

switching the boiler on is shown.

5.1 VOKERA MECHANICAL CLOCK

Setting the time

The time of day can be set by grasping the outer

edge of the black dial and turning it in a clockwise

direction until the correct time is in line with the

white pointer.

Setting the ‘switching times’

The ‘ON’ periods are set by sliding the black

tappets, adjacent to the time periods required, to

the outer edge of the dial.

The tappets that remain at the centre of the dial

will be the ‘OFF’ periods.

The smallest switching time (ON or OFF) is 15

minutes.

To select ‘Timed’ mode move the selector switch

in the middle of the clock face to the ‘ ‘ position.

To select ‘Constant’ mode move the selector switch

in the middle of the clock face to the ‘I’ position.

To select ‘Off’ mode move the selector switch in

the middle of the clock face to the ‘O’ position.

5.2 VOKERA DIGITAL CLOCK

The Vokera digital time clock will automatically

switch your boiler on and off. It has a total of

twenty different switching commands, consisting

of ten ‘on’ commands and ten ‘off’ commands.

Each ‘on’ or ‘off’ command can be used to switch

the boiler ‘on’ or ‘off’ at the same time:

● Every day of the week

● Monday to Saturday

● Monday to Friday

● Saturday and Sunday

● Any particular day

Group of days On Off Commands

used

Mon. to Fri. 06.00 09.00 2

Mon. to Fri. 16.00 21.00 2

Sat. & Sun. 08.30 10.30 2

Sat. & Sun. 17.00 23.00 2

Total 8 used

Commands ‘free’ 12 unused

Example

Fig. 6

Select button

Reset button

“British summertime”

button

Hour button

Minute button

Display

Day button

Programme

button

Clock button

VOKERA DIGITAL TIME CLOCK

VOKERA TIMECLOCKS

Fig. 5

ON period

OFF period

Selector

switch

Fig. 7 Fig. 8

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 9

9

● Press the ‘m’ button until the desired minutes

are shown.

● Press the Select button until the symbol is

shown (see fig. 10).

● Press the button.

5.2.4 ENTERING (off) COMMANDS

● Repeatedly press the Prog. Button until the —

:— symbol appears in the clock display (fig. 5).

● Press the Day button until the desired group of

days or desired day is shown.

● Press the ‘h’ button until the desired hour for

switching the boiler off is shown.

● Press the ‘m’ button until the desired minutes

are shown.

● Press the Select button until the symbol is

shown (see fig. 11).

● Press the button.

Once the programming has been completed you

will have to press the Select button – once only

– to the (on) position if the boiler has been

programmed to be ‘on’ at that particular time.

5.2.5 ADVANCING OR LOCKING PROGRAMME

COMMANDS

By pressing the Select button you can advance the

time clock to the next command setting (from ‘on’ to

‘off’ or ‘off’ to ‘on’) or lock the time clock to a particular

command (‘on’ continuously or ‘off’ continuously).

● - ON

● - OFF

● [ ] – ON CONTINUOUSLY

● [ ] – OFF CONTINUOUSLY

NOTE

The actual time can be changed to account for

British summertime by simply pressing then releasing the +/- 1h button.

HELPFUL HINTS

● You can check and/or alter the programme

settings at any time by pressing the Prog button.

● The number of unused ‘commands’ can be checked

by pressing the Prog button until FR is displayed

alongside the number of unused commands.

● In the event of a power failure, the clock has a

battery back-up. The programme will be held

in the memory for approximately 2 weeks.

Charging time is 70 hours.

● Take a note of the settings you have pro-

grammed, as local power surges can sometimes reset the memory of the clock.

Fig. 9 Fig. 10

Fig. 11

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 10

10

NOTE

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 11

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Page 12

Vokèra Ltd.

4th Floor, Catherine House, Boundary Way, Hemel Hempstead, Herts, HP2 7RP

Email: enquiries@vokera.co.uk Web: www.vokera.co.uk

Sales, Technical Advice, General Enquiries - Tel: 0870 333 0520 Fax: 01442 281403

After Sales Service - Tel: 0870 333 0220

Vokèra Ireland

West Court, Callan, Co Kilkenny

Tel: 05677 55057 Fax: 05677 55060

Vokèra Ltd. reserve the right to change the specifications without prior notice. Consumers’ statutory rights are not affected.

A Riello Group Company

energizing home heating

“Vokèra”

supports Benchmark

COLLECTIVE MARK

Cod. 10023776 - 49/03 - Ed. 2

Unit 3A, Thornton Road Ind. Estate Off Hockney Road Bradford, BD8 9HQ

01274 488 388

www.heatingspares247.com

Loading...

Loading...