Page 1

Installation

& Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

CondexaPRO

Light commercial boiler

Page 2

CONDEXA PRO2

MODEL FUEL CODE

CONDEXA PRO 50 M Natural gas - LPG 50-37685-12869-4

CONDEXA PRO 100 M Natural gas - LPG 50-37685-12867-0

CONDEXA PRO 100 S Natural gas - LPG 50-37685-12868-7

The

Vokera CONDEXA PRO

boilers comply with:

• Gas Appliances Directive 90/396/EEC

• Boiler Efficiency Directive 92/42/EEC

• Electromagnetic Compatibility Directive 89/336/EEC

• Low Voltage Directive 73/23/EEC.

• EN 677 standard on condensing boilers.

0085

CONFORMITY

RANGE

Page 3

CONDEXA PRO 3

Dear Customer,

congratulations on your purchase of a

Vokera CONDEXA PRO

Boiler. You have chosen proven

technology based on

Vokera Ltd

experience in this field and if fully compliant with current

European standards. This appliance ensures maximum comfort for an extended period, with high

reliability, efficiency, quality and safety.

The purpose of this manual is to provide all the information that we feel is necessary for the correct

and simple installation of the boiler and must be preserved and made available as and when

requested to ensure correct installation, operation and maintenance.

Full warranty cover applies providing the boiler has been correctly installed, operated and commissioned by qualified personnel. The manufacturer is not liable for any damage caused by the

incorrect layout or installation of the flue system.

Vokera Ltd

The Vokera CONDEXA PRO Boiler comes with a SPECIFIC WARRANTY of 24 months (parts and

labour) starting from the date of commissioning or 3 months from date of purchase which ever soo-

ner providing it has been commissioned by

Vokera or a qualified engineer and a copy of the com-

missioning certificate has been returned and filled with

Vokera Ltd.

As a result, we suggest that you contact

Vokera Service Department or a qualified engineer for

commissioning of the boiler, as described in the conditions listed on the WARRANTY CERTIFICA-

TE supplied with the boiler, which should be read with care.

WARRANTY

Page 4

CONDEXA PRO4

GENERAL

General warnings page 5

Fundamental safety rules “ 5

Description of the appliance “ 6

Safety devices “ 6

Identification “ 7

Structure “ 8

Technical specifications “ 9

Accessories “ 9

Water circuit “ 10

Positioning the probes “ 11

Pumps “ 11

Wiring diagrams “ 14

Control panels “ 18

User interface “ 19

- Display mode “ 20

- Readout mode “ 20

- Setting the user parameters “ 21

- Monitor mode “ 22

- Installer programming mode “ 23

- Test mode “ 24

- Error mode “ 24

- Permanent lockout “ 24

INSTALLER

Receiving the product pag. 25

Dimensions and weight “ 25

Handling “ 26

Room where the boiler is installed “ 26

Installation in old systems or systems to be upgraded

“ 27

Installing the boiler “ 28

Water connections “ 28

Fuel connections “ 30

Flue gas outlet and combustion air intake “ 30

Electrical connections “ 33

Installing the outside probe “ 35

Filling and emptying the systems “ 36

Preparing for first start-up “ 38

TECHNICAL

Starting for the first time pag. 39

Checks during and after first start-up “ 41

Setting the functional parameters “ 45

Setting the central heating parameters “ 45

Setting the domestic hot water parameters “ 47

Setting the temperature controller “ 48

Setting the addresses for cascading configurations“54

Fault codes “ 56

List of parameters “ 58

Conversion from one type of gas to the other “ 60

Adjustments “ 62

Temporary shutdown “ 63

Shutting down for extended periods “ 63

Servicing “ 64

Cleaning the boiler and dismantling

the inside components “ 64

Troubleshooting “ 69

The following symbols are used in some parts of this

booklet:

bCAUTION = actions that require special care and

suitable preparation

aPROHIBITED = actions that absolutely must

NOT be carried out

This booklet, code 068464EN - Rev. 0 (09/05), contains

76 pages.

CONTENTS

Page 5

CONDEXA PRO 5

aThe boiler must not be used by children or invalid

persons without supervision.

a

Electrical devices or appliances, such as switches,

household appliances, etc. must not be used if there

is the smell of gas or unburned fuel. In this case:

- ventilate the room by opening doors and windows;

- close the fuel stopcock;

- promptly contact

Vokera Ltd, your gas supplier or

other professionally qualified personnel.

aDo not touch the boiler when barefoot or with wet

parts of the body.

aNo service or cleaning operations may be perfor-

med without first having disconnected the boiler

from the mains power supply, moving the main

system switch to "off".

aThe safety or control devices must not be adjusted

without the authorisation and written instructions

from the manufacturer of the boiler.

aThe condensate drain must not be plugged.

aDo not pull, remove or twist the electrical cables

coming out of the boiler, even if the appliance is

disconnected from the mains power supply.

aThe ventilation openings in the room where the

appliance is installed must not be plugged or reduced in size and must comply with any current standards and law applicable.

aDo not expose the boiler to the elements. It is not

designed to operate outdoors and does not have

sufficient frost protection systems.

aDo not switch the boiler off if the outside temperatu-

re may fall below ZERO (risk of freezing).

aDo not leave containers and flammable substances

in the room where the boiler is installed.

aThe packaging material must not be dispersed in

the environment or left within the reach of children

as it is a potential source of hazard. It must be

disposed of according to the legislation in force.

The use of products that operate on fuel, electricity and water requires a number of fundamental safety rules to be

observed, including:

bAfter having removed the packaging, check that the

material supplied is intact and complete; if this is

not the case, contact

Vokera Ltd.

bThe CONDEXA PRO Boiler must be installed by

qualified personnel as detailed under any current

standards and law applicable and with the instructions provided by

Vokera in the manual supplied

with the appliance.

bThe boiler must be used for the purposes it has

been expressly manufactured.

Vokera Ltd declines

all contractual and extra-contractual liability for

damage caused to persons, animals or things, due

to errors in installation, control, servicing or improper use.

bIn the event of water leaks, disconnect the boiler

from the mains power supply, close the water supply and promptly notify

Vokera Ltd or other profes-

sionally qualified personnel.

bPeriodically check that the condensate drain is free

of blockages.

bPeriodically check that the operating pressure of

the water circuit when cold is

1.5 bar and less than

the maximum limit specified for the appliance. If this

is not the case, contact

Vokera Ltd or other profes-

sionally qualified personnel.

bIf the boiler is not used for an extended period, the

following minimum operations must be completed:

- move the main system switch to "off"

- close the fuel cock and the water cocks on the central heating system

- empty the central heating system if there is the risk

of frost.

bServicing must be performed on the boiler at least

once a year.

bThis manual is an integral part of the boiler and as a

consequence must be kept with care. If the manual

is damaged or lost, contact

Vokera Ltd for another

copy.

GENERAL WARNINGS

FUNDAMENTAL SAFETY RULES

Page 6

CONDEXA PRO6

The CONDEXA PRO Boiler is a wall-hung condensing

boiler, for heating only, with a premix burner, made up of

one or two heating units, depending on the model.

The

CONDEXA PRO Boiler can be combined in a casca-

ding configuration with other heat generators to create

modular heating plants made up of boilers connected to

the same water circuit and with electronic controllers

communicating via bus. The heat output of each heating

unit reaches 48.50 kW (100%, 50°C-30°C) and can be

modulated from 30% to 100%. The efficiency reaches

108.7% and the low flue gas outlet temperature allows

the use of a flame-retardant polypropylene flue (class

B1), with a diameter of just 50 mm and a total equivalent

height of 30 metres.

The versatility of the electronic board makes quick connection possible to all types of central heating and

domestic hot water production systems with storage,

managing three circuits operating with three different

temperatures at the same time.

The individual heating units in cascading configuration

can be activated, as well as by simple rotation, in such a

way that when a certain percentage of output is reached

by the first unit, the other units start automatically, all with

the same load factor.

Specific accessories are available for the boiler, such as

two-way valves or pumps, or devices for taking in the

combustion air.

These ensure adaptability to a vast range of system configurations. Other accessories include water headers

and the flue gas header for cascading installations.

The

CONDEXA PRO Boiler is fitted with the following safety devices, installed on each heating unit:

Safety thermostat with automatic reset, activated if the

outlet temperature exceeds 90°C, shutting down the burner.

Diagnosis in the water circuit, the minimum flow-rate of

the heat exchange fluid in each heating unit is controlled

by a water differential pressure switch and an electronic

safety system, using an outlet probe and a return probe.

The appliance goes into safety mode if there is insufficient water or circulation.

Flue gas outlet safety device: the flue gas probe, located at the bottom of the exchanger, sets off an alarm in

the event of high flue gas temperatures (> 80°C). In addition, the float in the drain trap prevents the flue gas from

passing through the condensate drain.

Fan safety device: a Hall-effect sensor constantly monitors the rotation speed of the fan.

The CONDEXA PRO

Boilers are designed for cascading connection, which

allows the creation of compact and very flexible heating

plants, due to the high degree of modulation.

bThe activation of the safety devices indicates a

potentially dangerous malfunction on the boiler;

immediately contact

Vokera Ltd or other professio-

nally qualified personnel.

After a short wait, try restarting the boiler (see chapter

on starting for the first time).

aThe boiler must never be started, even temporarily,

with the safety devices not working or having been

tampered with.

bThe safety devices must be replaced by the only

using the original components supplied by the

manufacturer. See the spare parts catalogue supplied with the boiler.

After having performed the repairs or replacements,

check the correct operation of the boiler.

The main features of the

CONDEXA PRO Boiler are:

- premix jet burner with constant air-gas ratio

- output from 16.3 to 100 kW (models 100 M and 100 S)

- heat output up to 450 kW, by connecting up to 9 heating units in a cascading configuration, using the waterconnection kit (code 5037685135029), available separately

- maximum flue gas outlet temperature 80°C

- total flue gas outlet and combustion air intake length up

to 30 m, Ø 50 mm

- quick connection of the water and gas headers (optional), with outlet on the right or left

- microprocessor control with self-diagnosis, shown on

LEDs and the display

- the electronic controller can manage up to 60 heating

units in cascading

- frost protection function activated according to the outside temperature and/or the temperature of the boiler

- fitted for room thermostat in the high and low temperature zones

- outside probe to enable the climate control function

- post-circulation function for the central heating and

DHW circuits

- priority settable on the DHW, high or low temperature

circuit

- possibility to manage two circuits with fixed set point or

with climate control using two separate curves

- automatic reversal of the burner ignition order

- emergency function, which in the event of faults on the

Master board still allows the Slave boards to be controlled.

DESCRIPTION OF THE APPLIANCE

SAFETY DEVICES

Page 7

CONDEXA PRO 7

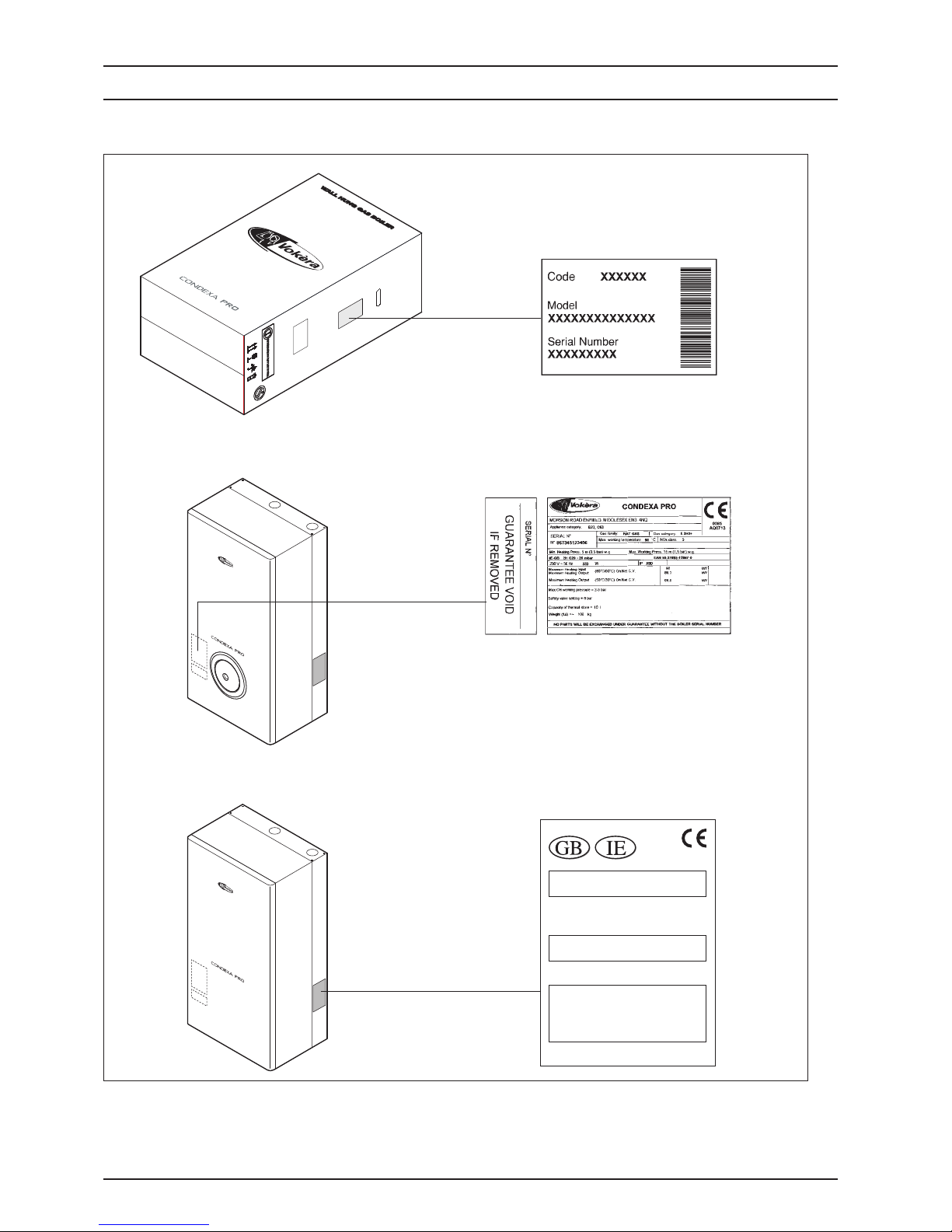

Models

50 M - 100 M

Models

100 S

The boilers can be identified by the:

bIf the plates or other means for clearly identifying the product have been tampered with, removed or are missing,

the installation and servicing operations will be much more difficult.

- Rating plate

This shows the technical and performance specifications.

- Packaging label

This shows the code, the serial number and the

barcode.

1

2

- Gas label

This is applied on the side of the frame, and

describes the type of fuel used by the boiler, and

the country of destination.

Country of destination:

Type of appliance

Boiler category::

II2H3+

Gas supply pressure:

G20

G30+G31

20 mbar

28-30/37 mbar

Manufacturer settings:

G20 - 20 mbar - 2H NATURAL GAS

WARNING

Carefully read the instruction manual before

installing and starting the appliance.

(Laterale DX)

B23, C63

068465EN_1_E0

IDENTIFICATION

Page 8

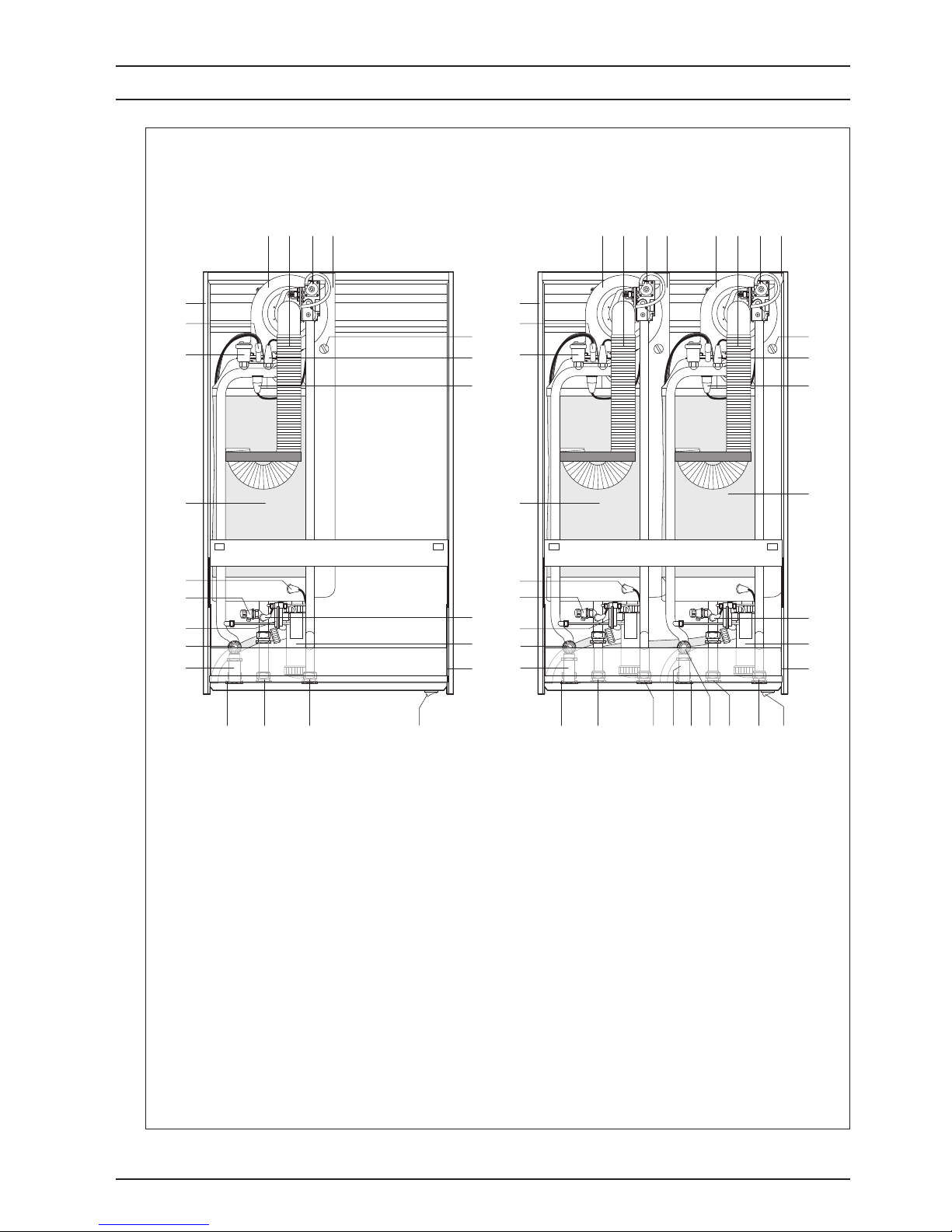

CONDEXA PRO8

1 2 3 4

6

7

8

5

10

9

11

24

22

23

21

19

20

18

1 2 3 4 1 2 3 4

6

7

5

10

9

11

24

22

23

21

19

20

18

14 13 12 15

17

16

17

16

14 13 12 1514 13 12 16 17

1 - Fan

2 - Combustion air intake fitting

3 - Gas valve

4 - Flue gas outlet fitting

5 - Flue gas analysis test point

6 - Outlet probe

7 - Safety thermostat

8 - SECOND combustion chamber

(models 100 M and 100 S)

9 - Return probe

10 - Condensate collection drain trap

11 - Control panel (90° rotation)

12 - Gas supply

CONDEXA PRO 50 M CONDEXA PRO 100 M - 100 S

13 - Central heating return inlet

14 - Central heating flow outlet

15 - Main switch

16 - Safety valve connection pipe

17 - Safety valve 6 bar

18 - Water differential pressure switch

19 - Drain cock

20 - Flue gas probe

21 - FIRST combustion chamber

22 - Automatic vent valve

23 - Ignition / detection electrode

24 - Panelling

STRUCTURE

Page 9

CONDEXA PRO 9

ACCESSORY CODE

Flue gas header kit 5037685135005

Water connection kit for installations < 100 kW 5037685135012

Water connection kit for installations > 100 kW 5037685135029

Remote control kit 5037685135036

Two-way valve kit 5037685135043

Injection pump kit 5037685135050

Conversion kit for room-sealed operation

CONDEXA PRO 50 5037685135067

Conversion kit for room-sealed operation

CONDEXA PRO 100 5037685135074

The following accessories are available to be ordered separately.

Fuel G20 - G30 - G31

Appliance category II2H3+

Type of appliance B23 - C63

Heat input ref. HHV (min - max) 16,3 - 50 16,3 - 100 16,3 - 100 kW

Heat input ref. NHV (min - max) 15 - 45 15 - 90 15 - 90 kW

Useful heat output (80°/60°C) 44,2 88,30 88,30 kW

Useful heat output (50°/30°C) 48,5 96,8 96,8 kW

Useful efficiency ref. NHV (80°C/60°C) 98,2 kW

Useful efficiency ref. NHV (50°C/30°C) 107,7 %

Useful efficiency at 30% ref. NHV (50°C/30°C) 108,7 %

Losses through the chimney with the burner operating 1,3 %

Losses through the chimney with the burner off 0,1 %

Losses through the casing (Tm=70°C ) 0,5 %

Flue gas temperature Return temp. + 5 °C

CO2 at minimum - maximum 8,4 - 9,4 %

CO without air at minimum - maximum less than 10 - 120 p.p.m.

NOx without air at minimum - maximum less than 10 - 20 p.p.m.

NOx class 5

Maximum operating pressure, central heating 6 bar

Maximum admissible temperature 90 °C

Range of boiler water temperature settings (± 3 °C) 20-80 °C

Water content 5 10 10 l

Power supply 230~50 V~Hz

Maximum power input 169 333 333 W

Index of protection X0D IP

Quantity of condensate 7,2 14,4 14,4 l/h

DESCRIPTION

CONDEXA PRO

50 M 100 M 100 S

TECHNICAL SPECIFICATIONS

ACCESSORIES

Page 10

CONDEXA PRO10

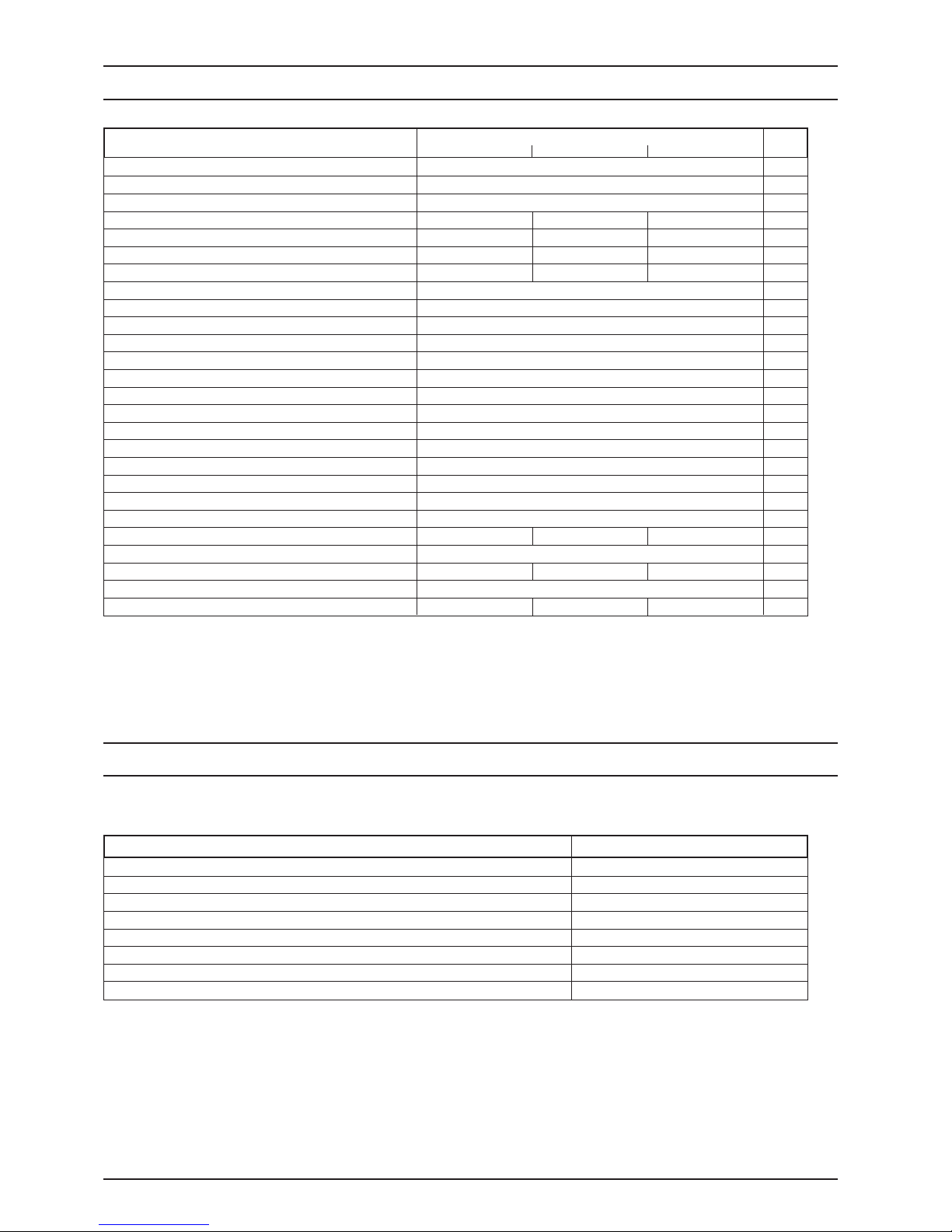

Water-side pressure drop in the boiler

The CONDEXA PRO Boiler does not come with a pump, which must be installed in the system.

When sizing the pump, refer to the water-side pressure drop in the boiler, as shown in the figure below.

MI RI GASSC2

SF

AA

1

2

3

4

5

6

7

8

SC1

9

0

Pressure drop (mbar)

Flow-rate (l/h)

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

250 500 750 1000 1250 1500 1750 2000 2250 30002500 2750

1 - Fan

2 - Gas valve

3 - Automatic vent valve

4 - Burner

5 - Heat exchanger

6 - Condensate drain trap

7 - Drain cock

8 - Water differential pressure switch

9 - Safety valve (6 bar)

AA - Air intake

SF - Flue gas outlet

SC1 - Safety valve drain

SC2 - Condensate drain

MI - Central heating flow outlet

RI - Central heating return inlet

GAS - Gas supply

WATER CIRCUIT

Page 11

CONDEXA PRO 11

CENTRAL HEATING

OUTLET PROBE

SAFETY THERMOSTAT

FLUE GAS PROBE

CENTRAL HEATING

RETURN PROBE

The following probes/thermostats are installed for each heating unit:

POSITIONING THE PROBES

80°C

60°C

50°C

30°C

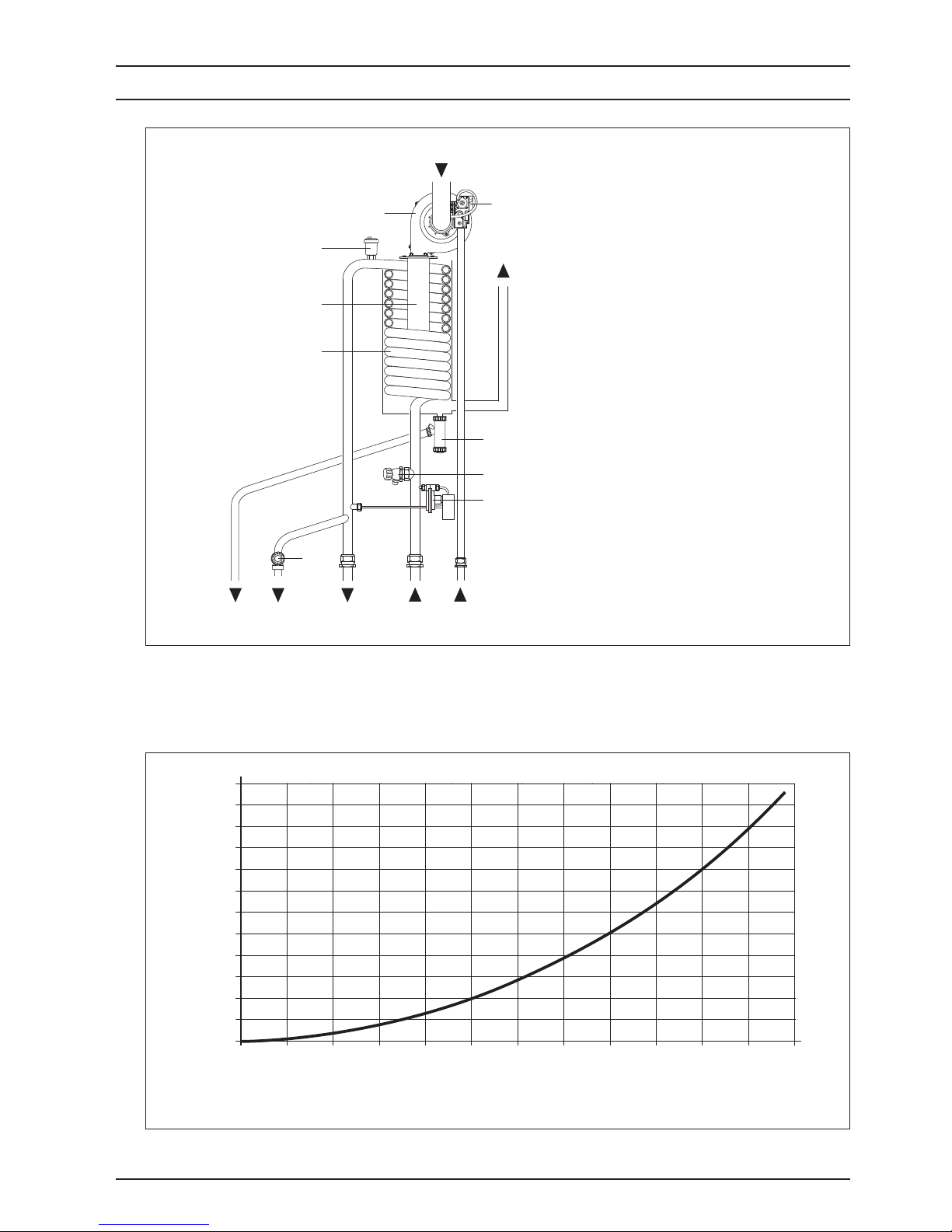

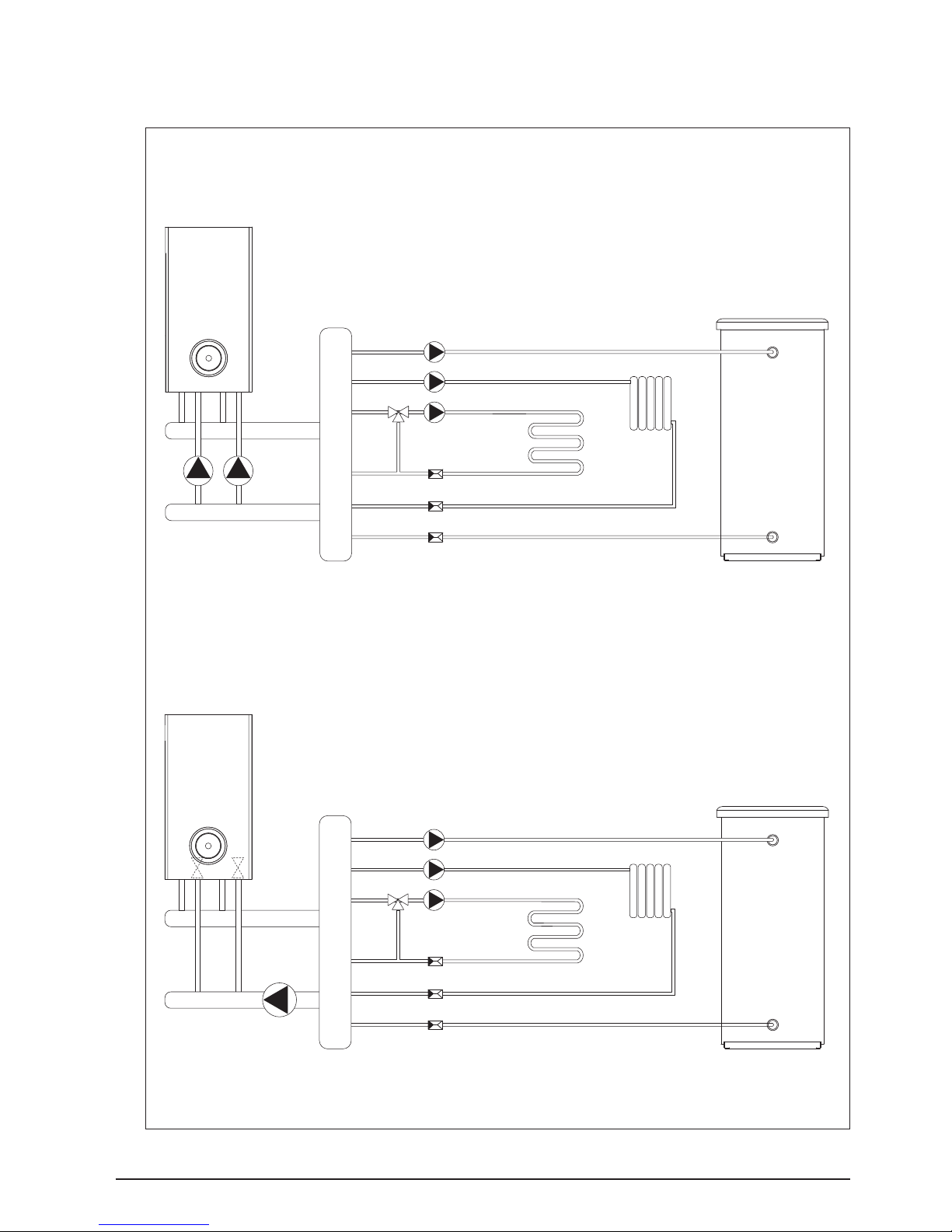

Configuration with distribution pumps

Boiler discharge head: 7 mWC

Boiler flow-rate: 2 m

3

/h for each heating unit.

Also consider the pressure drops in the individual circuit.

PB

PZ1

PZ2

V2V2

THE CONDEXA PRO Boiler

does not come with a pump, which must be installed in the system.

When choosing the pump, refer to the following system diagrams.

PB - DHW pump

PZ1 - Pump in zone 1

(high temperature)

PZ2 - Pump in zone 2

(low temperature)

V2 - Two-way valve

(accessory)

PUMPS

Page 12

CONDEXA PRO12

80°C

60°C

50°C

30°C

Configuration with injection pumps

Boiler discharge head: 6 mWC

Boiler flow-rate: 2 m

3

/h for each pump.

Recommended pump TYPE A for each heating unit.

PB

PZ1

PZ2

PP

80°C

60°C

50°C

30°C

Configuration with loop pump and valves on the heating units (*)

Boiler discharge head: 7 mWC.

Boiler flow-rate: 2 m

3

/h for each heating unit.

Recommended: p 50 M: TYPE A; 100M/S: TYPE B; 100M+100S: TYPE C.

PB

PZ1

PZ2

V2V2

(*) With this configuration the pump in the low temperature circuit is managed externally by a

thermostat (see parameter 34 on page 59).

PB - DHW pump

PZ1 - Pump in zone 1

(high temperature)

PZ2 - Pump in zone 2

(low temperature)

P - Injection pump

(accessory)

PB - DHW pump

PZ1 - Pump in zone 1 (high temperature)

PZ2 - System pump

V2 - Two-way valve (accessory)

Page 13

CONDEXA PRO 13

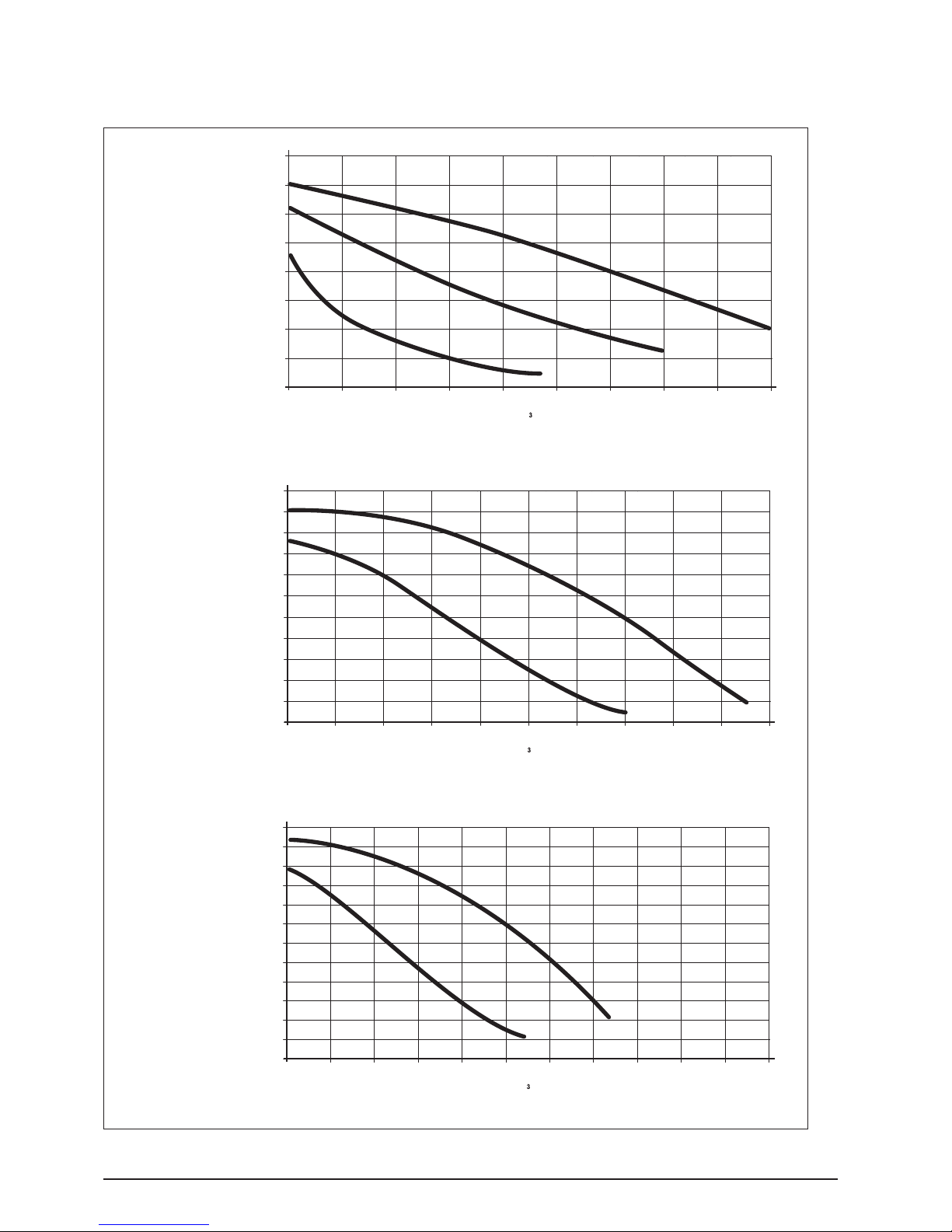

Pump TYPE A

0

Residual head (mbar)

I

II

III

100

200

300

400

500

600

700

0 1 2 3 4 5 6 7 8 9

800

Flow-rate (m /h)

Pump TYPE B

0

I

II

100

200

300

400

500

600

700

0 2 4 6 8 10 12 14 16 20

1100

18

800

900

1000

Residual head (mbar)

Flow-rate (m /h)

Pump TYPE C

0

I

II

100

200

300

400

500

600

700

0 4 8 12 16 20 24 32 36 44

800

28 40

900

1000

1100

1200

Residual head (mbar)

Flow-rate (m /h)

Page 14

CONDEXA PRO14

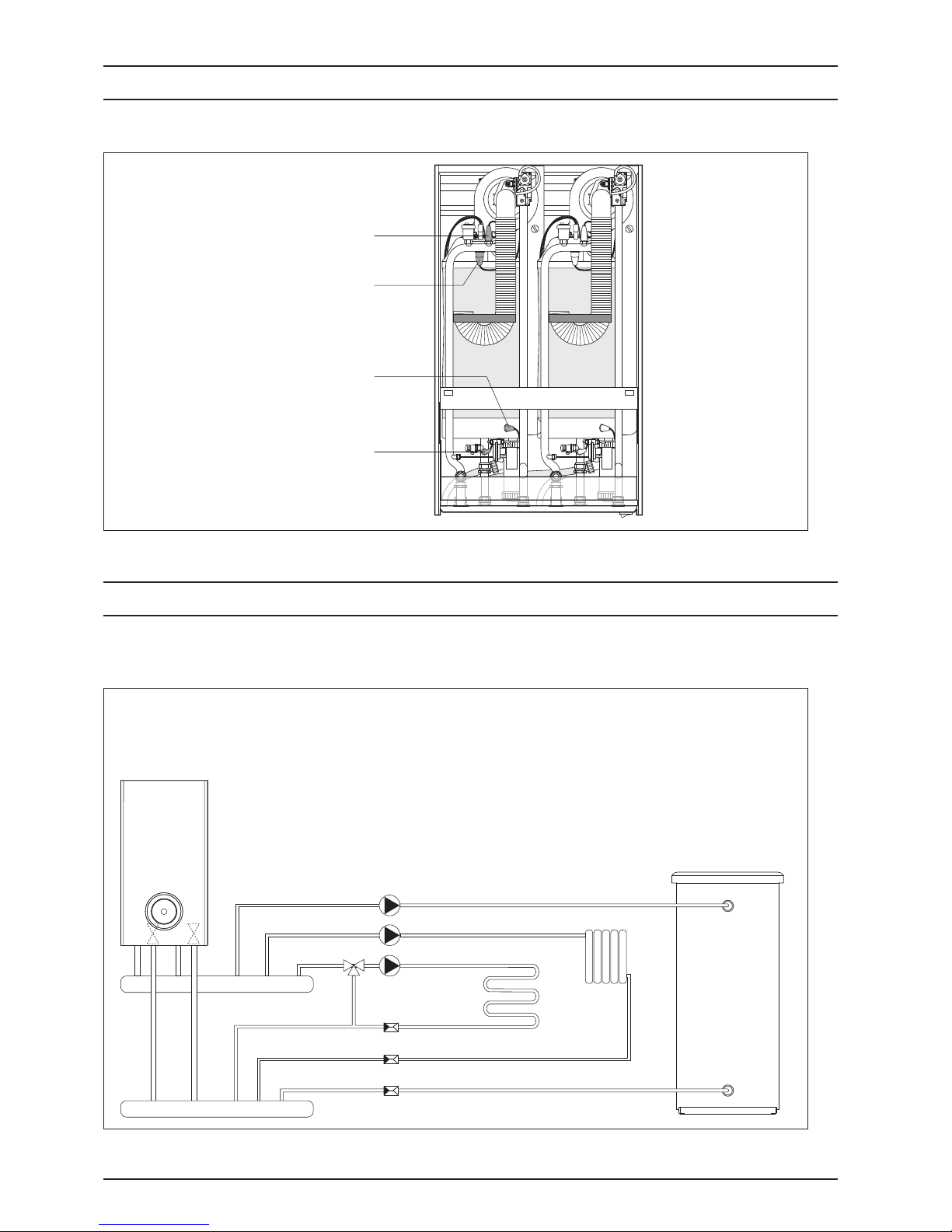

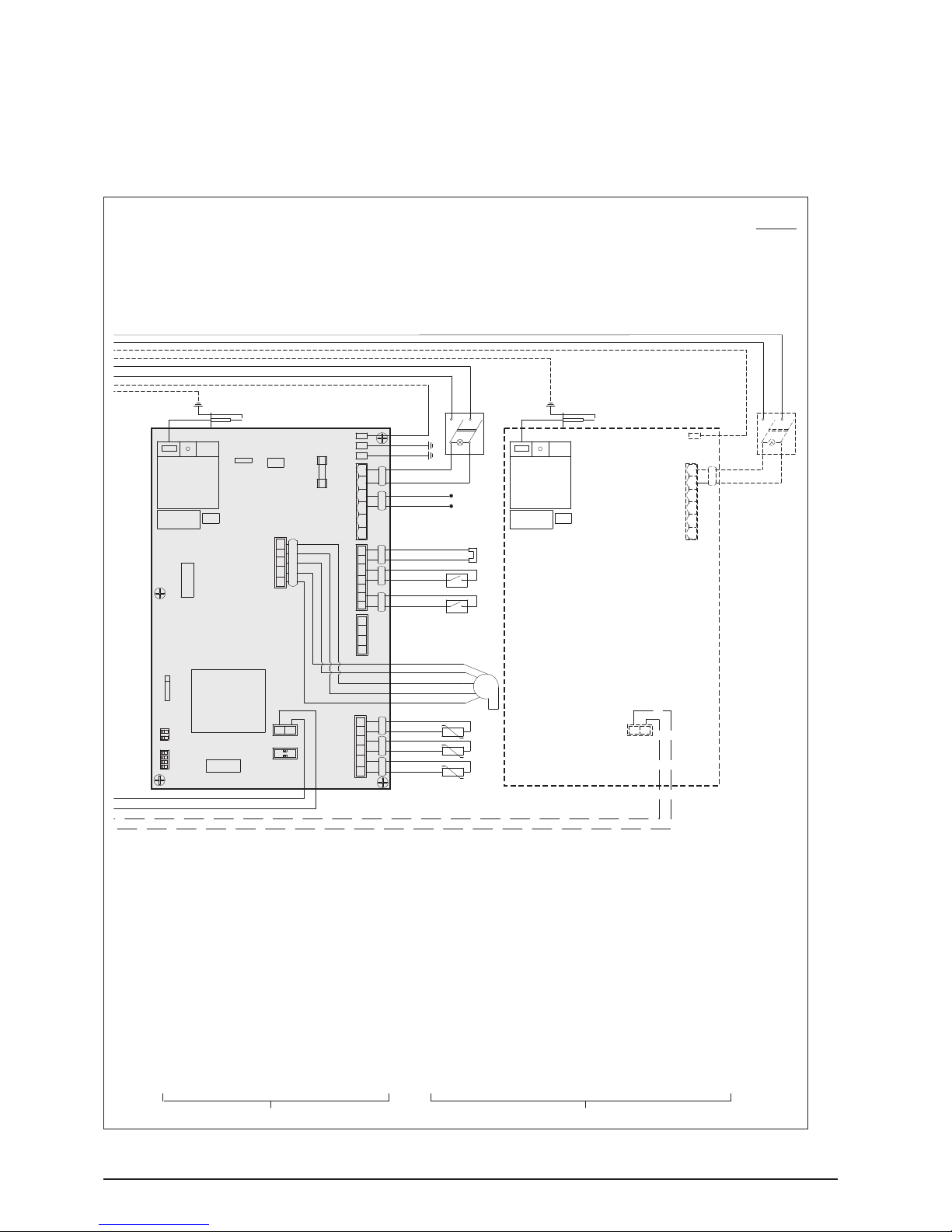

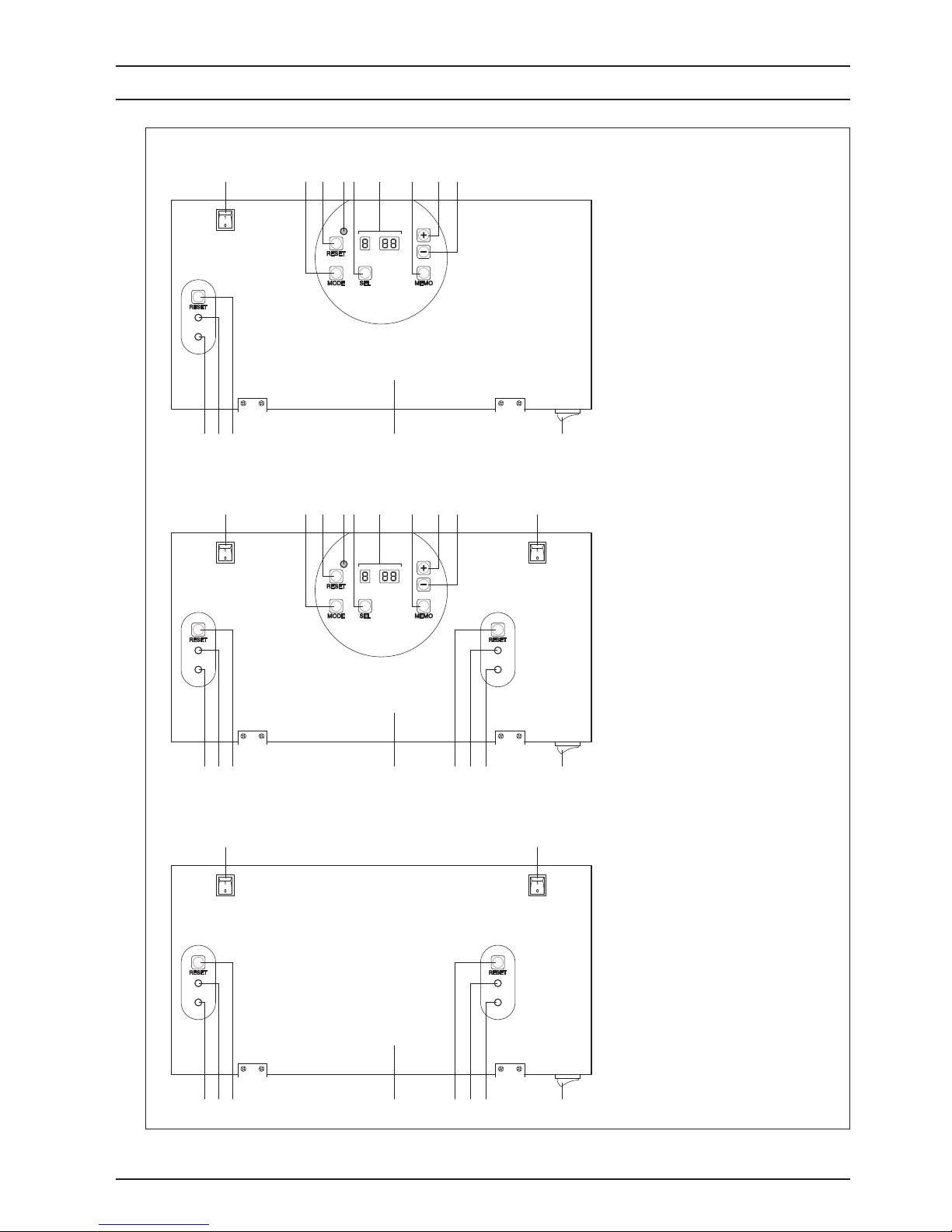

The control panel on

CONDEXA PRO

models 50 M and 100 M contains one master board and one or two slave boards,

depending on the output of the boiler. Model

100 S contain just two slave boards. If connecting a series of boilers in casca-

ding, the master board on the

CONDEXA PRO

50 M or 100 M manages all the boards on the

CONDEXA PRO

100 S boi-

lers via BUS.

CONDEXA PRO 50 M - 100 M part 1

15

Bus

16

Com.

8 7

2

1

2

3

1

J9

23

22

21

Max valve

OFF

0

20

Alarm

ON

1

18

19

J8

9

17

24V

7

6

8

1314

Input

Analogic

NTC

Circ. 2

10 9

7

6

8

12

Circ.2

11

56

J12

4 3 2 1

6

2

3

4

5

J10

28

27

Pump

25

24

26

Pump 3

Pump

1

2

5

4

3

J11

NTC

1

2

NTC

NTC

4

5

3

Off - Max. valve

a

m

gv

gv

gv

gv

Neutral 230 Vac.

Line 230 Vac.

Earth

Earth

Earth

Earth

Line Pump 1

Neutral pump 1

Line DHW pump

Neautral DHW pump

Neutral Max. valve

Line Pompa 3

Neutral pump 3

J4

1

J2

J9 J8

J10

R4

2

4

3

J3

J6

J5

J7

F1

Fuse

3.15 A

1

R6

R5

MC

R3 R2

1

5

6

342

On - Max. valve

23

Alarm

Common

21

J12

2

BUS J14

1

R1

4

3

T1

Ebus remote cont.

24V remote cont.

Common

89

Analogic Input

Common

765

R.T. circ. 1

Common

R.T. circ. 2

243

Common

1

J1

Bus line with female

connector for connection

to another model 100S

boiler.

PC

J11

BARCODE

Climate NTC

J11 8

Common

8

Outlet NTC circ. 2

Outlet NTC circ. 1

Common

4

Common

57

6

DHW NTC

Common

13 2

Main earth

pole

Joint with

sheath

gv

gv

m

a

gv

gv

gv

m

a

m

a

Line

Earth

Neutral

MASTER

230V~50Hz

PB

PZ1

PZ2

VM

SZ1

SB

SE

SZ2

TA1TA2

IG

J11 7

J11 6

J11 5

J11 4

J11 3

J11 2

J11 1

J11 1

J11 2

J11 3

J11 4

J11 5

J11 6

J11 7

J11 8

IACR

J12 1

J12 2

J12 3

J12 4

J12 5

J12 6

J12 7

J12 8

J12 9

J12 9

J12 8

J12 7

J12 6

J12 5

J12 4

J12 3

J12 2

J12 1

J10 6

J10 5

J10 4

J10 3

J10 2

J10 1

J9 3

J9 2

J9 1

J8 2

J8 1

J10 6

J10 5

J10 4

J10 3

J10 2

J10 1

J9 3

J9 2

J9 1

J8 2

J8 1

Bus line with male

connector for connection

to another model 100S

boiler.

WIRING DIAGRAMS

Page 15

CONDEXA PRO 15

SLAVE 1

PC

J5

WD

T1

1

5

6

6

Hall sensor power

J9

BUS 1

Main

J16

J12

T3

2

1

1

4

3

2

5

n

b

m

v

g

a

10

J4

21 3

a

9

m

Flue gas NTC

J11

6

1 2

5

4

m

m

a

11

4

2

4

3

1 3

5

6

7

J1

a

m

m

a

8

7

Blower (-)

Outlet NTC

Hall sensor imput

Blower (+)

Return NTC

Hall sensor common

Safety thermostat

Gas valve

g

n

v

b

m

1 2

J9

BUS 2

Fuse 4A

to main earth pole

1

3

J7

J8

F1

4

3 2 1

J2

J15

J14

J6

5

gv

gv

gv

m

a

5

Line

Neutral

Earth

Earth

Earth

1

T1

J2

J6

gv

4

123

m

a

5

Line

Neutral

Earth

SLAVE 2

IG1

TS

SM

SR

SF

EA/ER

IG2

J10

J17

to main earth pole

EA/ER

a

m

13

Diff. pressure switch

PD

VG

m

a

6

C

PB - DHW pump

PZ1 - Pump in zone 1

(high temperature)

PZ2 - Pump in zone 2

(low temperature)

VM - Mixing valve

CR - Remote control (accessory)

IA - Analogue input

SB - DHW probe

SZ1 - Probe in zone 1

SZ2 - Probe in zone 2

SE - Outside probe

TA1 - Room thermostat in zone 1

(high temperature)

TA2 - Room thermostat in zone 2

(low temperature)

VG - Gas valve

TS - Safety thermostat

PD - Water differential pressure switch

SM - Outlet probe

SR - Return probe

SF - Flue gas probe

EA/ER - Ignition/detection electrode

C - Cable for connection to two-way valve

or injection pump (accessories)

IG - Main boiler switch

IG1 - FIRST heating unit switch

IG2 - SECOND heating unit switch

J10/J17 - Microswitches for setting the address

(see page 54)

SYSTEM

b

The pumps should be connected by installing suitable contactors with manual emergency operation.

HEATING UNIT

part 2

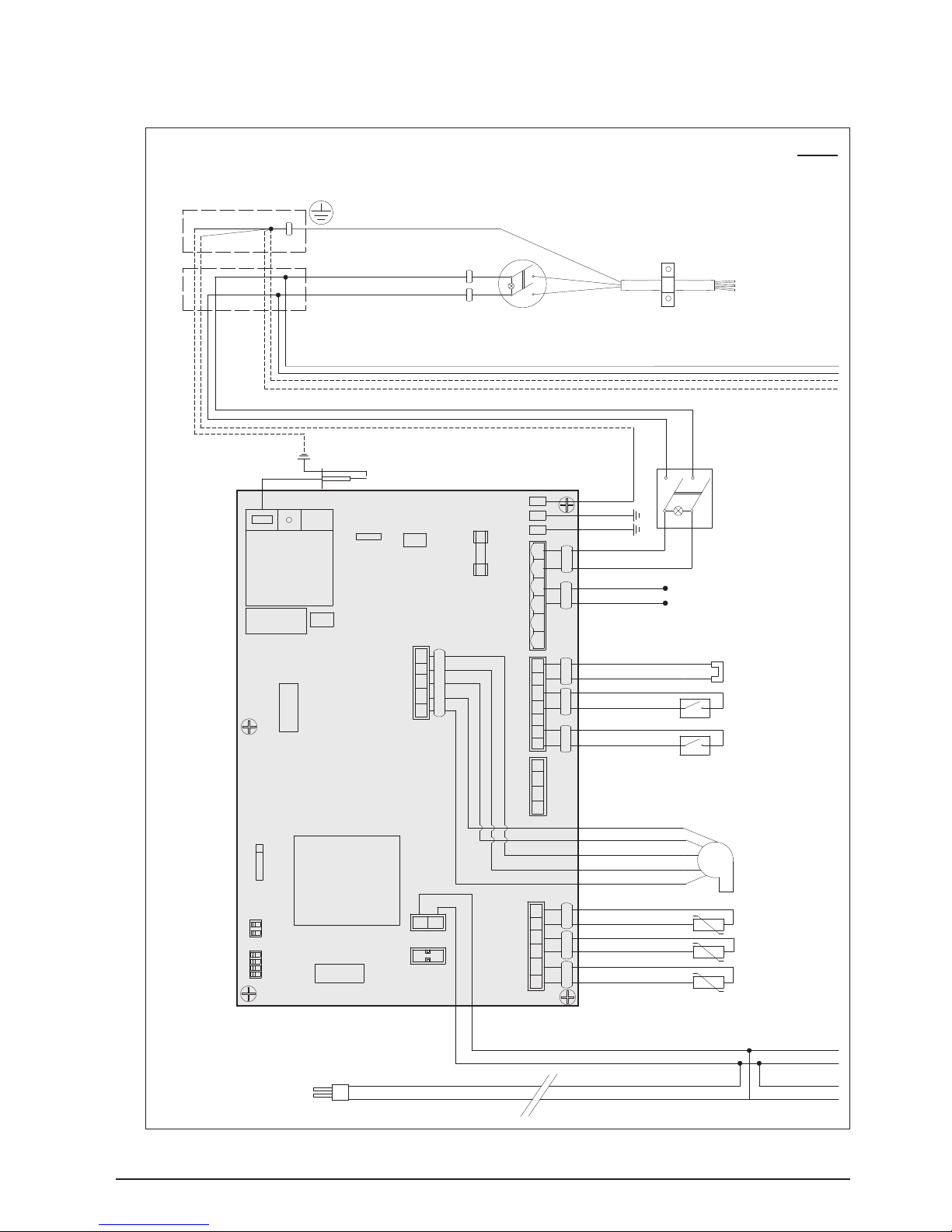

Page 16

CONDEXA PRO16

CONDEXA PRO 100 S part 1

Bus line with male

connector for connection

to another model 100S

boiler.

IG

PC

L = 1500 mm

J4

J5

Main

T3

2

BUS 1

J9

1

J16

J7

WD

1

T1

gv

1

1

5

2

3

4

J12

n

g

v

m

b

3

J8

F1

a

m

gv

1

11109

6

4

3

5

1 2

a

a

m

m

a

m

v

n

g

b

m

4

7

8

a

4

J11

31

3

4

2

2

J1

7 5

66

5

a

m

m

5

J6

J14

J2

123

J15

gv

a

m

gv

gv

gv

a

m

3

m

a

gv

gv

230V~50Hz

SLAVE 1

EA/ER

IG1

TS

SM

SR

SF

J10

J17

VG

a

13

m

PD

m

a

6

C

to main earth pole

Main earth

pole

Joint with

sheath

Earth

Line

Neutral

Fuse 4A

Earth

Neutral

Line

Earth

Earth

Gas valve

Safety thermostat

Diff. pressure switch

Hall sensor common

Blower (+)

Hall sensor imput

Blower (-)

Hall sensor power

Flue gas NTC

Return NTC

Outlet NTC

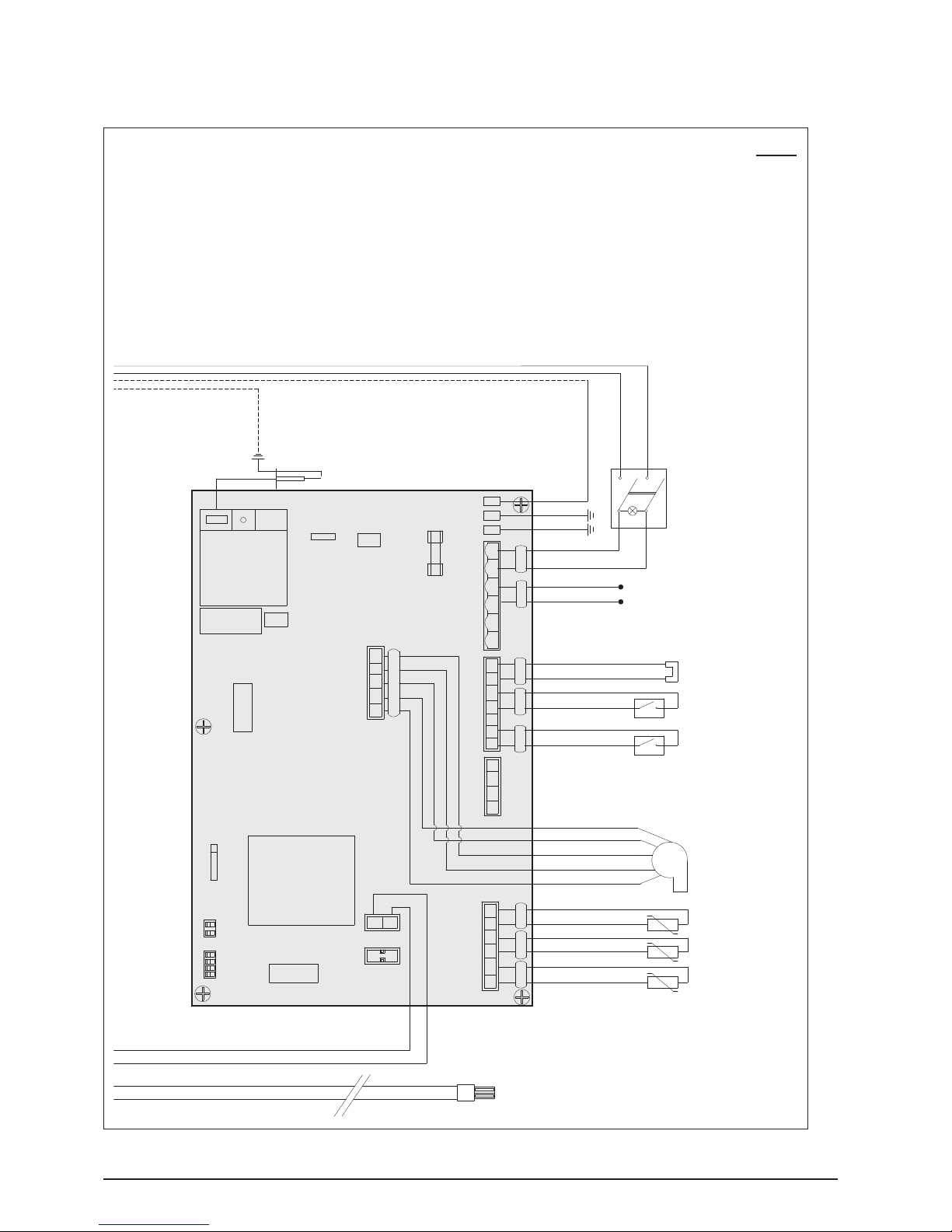

Page 17

CONDEXA PRO 17

Fuse 4A

Bus line with female

connector for connection

to another model 100S

boiler.

to main earth pole

J12

BUS 1

PC

L = 1200 mm

J5

Main

T3

1

WD

T1

gv

J7

1

3

1

J16

1 2

J9

J4

6

21

5

3

4

a

m

m

a

a

9 10 11

m

J2

J15

J14

J6

J1

J11

n

1

4

5

2

3

b

v

g

m

J8

F1

4

a

4

2 3

32

4

1 6 6

575

m

a

7

m

8

3 2 1

gv

m

a

gv

5

gv

v

b

m

n

g

SLAVE 2

EA/ER

IG2

TS

SM

SR

SF

J10

J17

a

13

m

PD

VG

m

a

6

C

Line

Neutral

Earth

Earth

Earth

Gas Valve

Safety thermostat

Diff. pressure switch

Hall sensor common

Blower (+)

Hall sensor imput

Blower (-)

Hall sensor power

Flue gas NTC

Return NTC

Outlet NTC

VG - Gas valve

TS - Safety thermostat

PD - Water differential pressure switch

SM - Outlet probe

SR - Return probe

SF - Flue gas probe

EA/ER - Ignition/detection electrode

C - Cable for connection to two-way valve or injection pump (accessories)

IG - Main boiler switch

IG1 - FIRST heating unit switch

IG2 - SECOND heating unit switch

J10/J17 - Microswitches for setting the address (see page 54)

part 2

Page 18

CONDEXA PRO18

1

11

10

12131411 12 13

1

11

2 3 4 65 7 98 10

121314 1511 12 13

1 2 3 4 65 7 98

1411 12 13

15

15

1 - FIRST heating unit switch

2 - Button for selecting

the operating mode

3 - Reset button (Master)

4 - Boiler lockout signal

5 - Button for selecting

the parameters

6 - Display

7 - Save button

8 - Button to increase values

9 - Button to decrease values

10 - SECOND heating unit switch

11 - Slave power supply signal

12 - Slave lockout signal

13 - Reset button (Slave)

14 - Instrument panel

15 - Main boiler switch

CONDEXA PRO 50 M

CONDEXA PRO 100 M

CONDEXA PRO 100 S

CONTROL PANELS

Page 19

CONDEXA PRO 19

- The domestic hot water priority function whereby when

there is demand for domestic hot water, the master

board can also serve the high or low temperature circuit.

- The fr

ost protection function, also active in standby,

which starts the pump in the high temperature circuit

and the loop pump if the temperature in the manifold

falls below 5°C.

If the outside probe is fitted, the pumps start if the outside temperature falls below 3°C.

If after 10 minutes the temperature in the manifold is

less than 5°C, one burner starts at maximum output,

until the temperature in the manifold reaches 20°C.

If after 10 minutes the temperature in the manifold

exceeds 5°C but the outside temperature is less than

3°C, the pumps stay on until the outside temperature

exceeds this value.

- The dispersion function

: the pumps in the high and low

temperature circuits remain on for 5 minutes after the

last burner has shut down. There is a 6 minute delay

from when the burner shuts down before closing the

two-way valve. When the last burner has shut down,

the valve closes only when there is no demand from the

room thermostat.

- The cascading function

: to manage the output delivered by the system, the minimum and maximum number

of burners started can be selected.

- The bur

ner on/off control function: in both cascading

modes there is a function that limits the ignition and

shutdown of the burners in the event of low heating

requirement.

Functional notes

The control panel on the CONDEXA PRO Boiler models 50 M and 100 M manages:

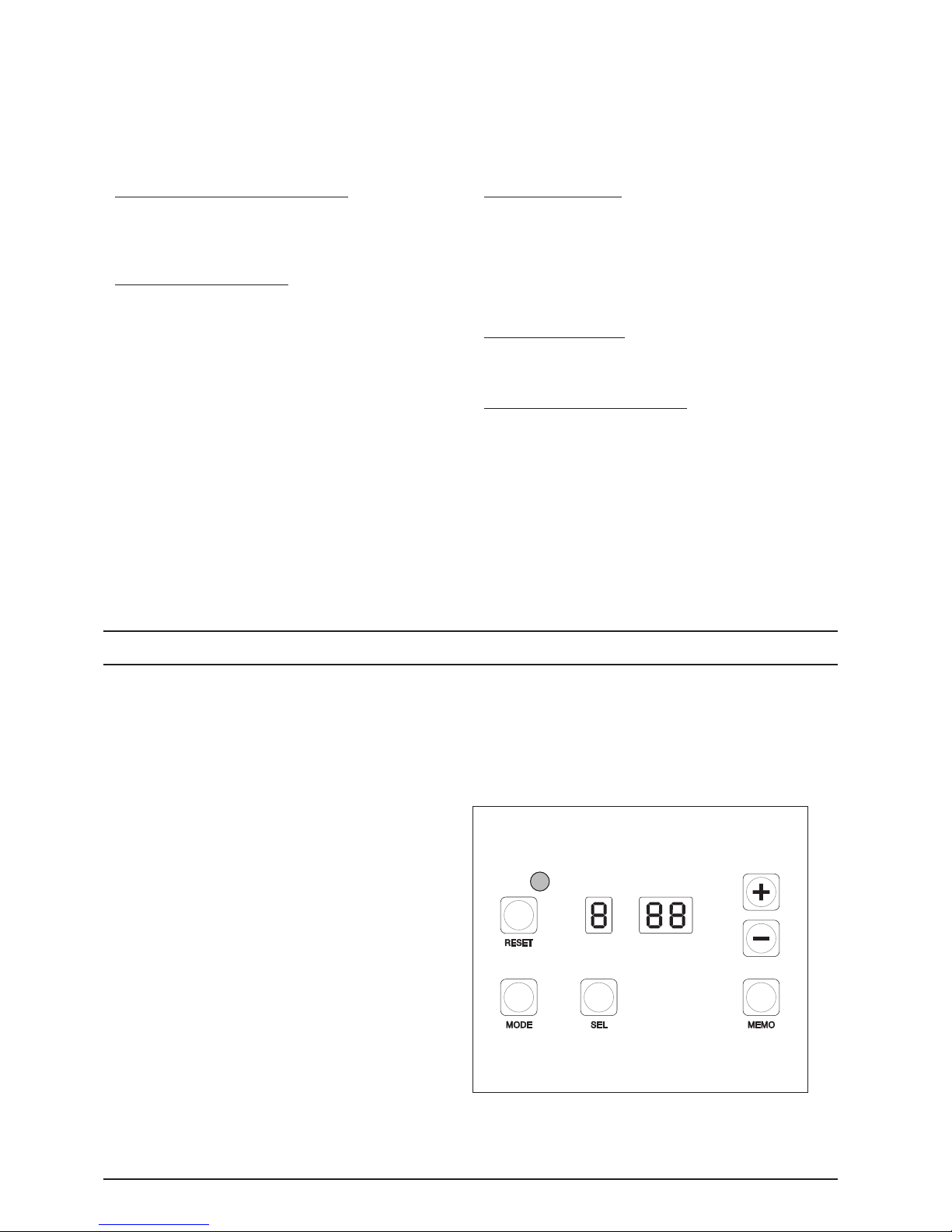

The buttons on the CONDEXA PRO 50 M and 100 M control panel have different functions in different modes. For example, the combination of two buttons corresponds to one specific function. Alternatively, a function can be activated by

pressing the button briefly or by holding it for around 5 seconds.

RESET

This resets the electronic board after a permanent

lockout.

MODE

This is used to enter parameter setting mode and monitor mode on the individual units.

SEL

This is used to display the operating status of the various

circuits managed by the Master board.

+ and -

Permettono di aumentare o diminuire un determinato

valore

MEMO

This is used to save the new values.

USER INTERFACE

Page 20

CONDEXA PRO20

DISPLAY MODE

The red LED (see ref. 4 on page 18) comes on in the event of faults that cause the permanent lockout of a heating unit

(normal operation is reset only by pressing the Master or Slave reset button).

The 3 digits with seven segments display the status of the system:

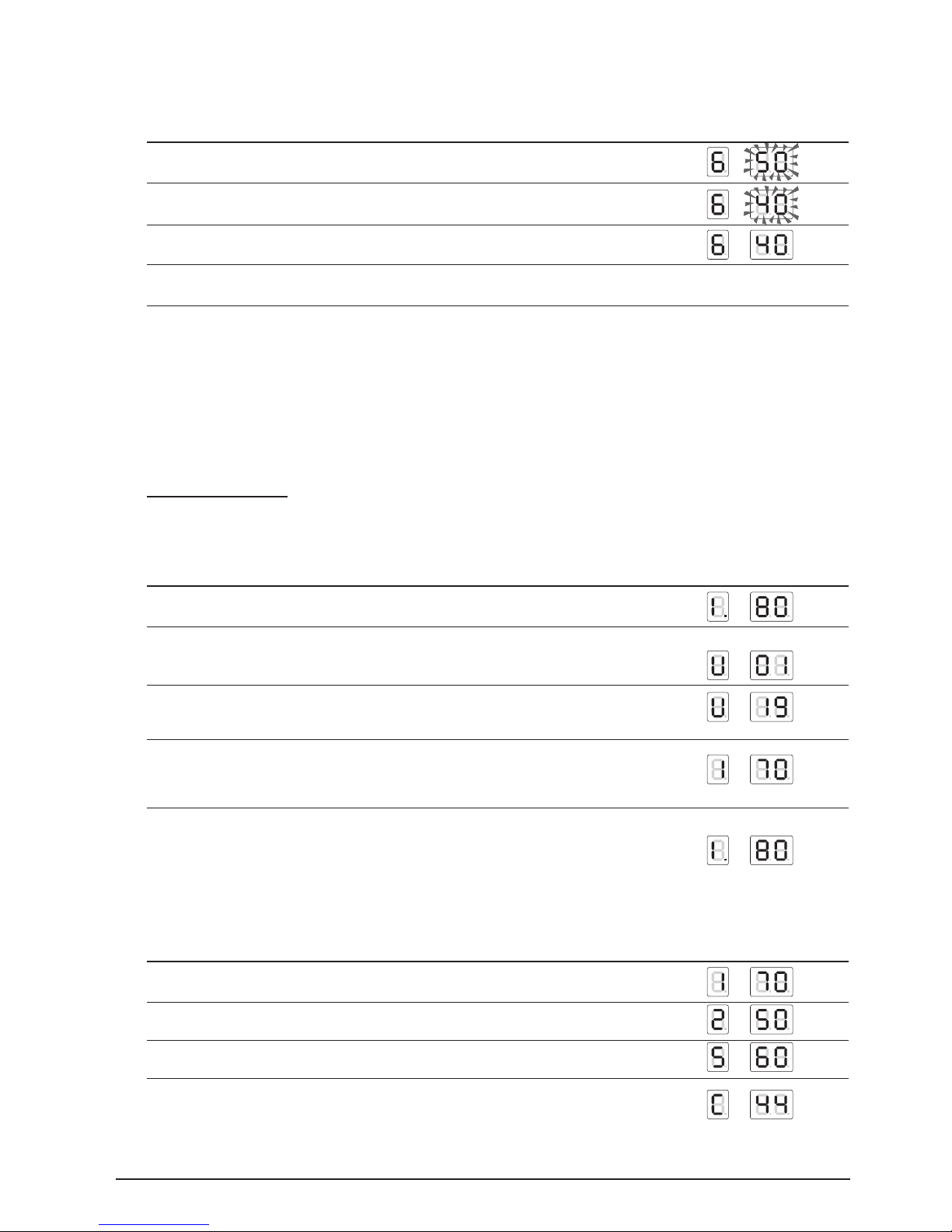

Status of the system Display

No central heating or DHW demand.

The two digits on the right display the outlet temperature T1. E.g.: T1 = 30°C

Demand from circuit no.1 or from circuits 1 and 2 together.

The two digits on the right display the outlet temp. T1. E.g.: T1 = 80°C

Demand from the DHW circuit or simultaneous operation.

The two digits on the right display the outlet temp. T1 E.g.: T1 = 80°C.

The decimal point after the 1st digit on the left flashes

Demand from the 2nd circuit

The two digits on the right display the outlet temperature T1. E.g. T1 = 80°C.

READOUT MODE

(TEMPERATURE VALUES AND OPERATING STATUS OF THE VARIOUS CIRCUITS)

Press the "SEL" button to scroll forwards and display the values set for the individual circuits.

The values listed below will be displayed in sequence when pressing the "SEL" button.

Value displayed Display

1 Outlet temperature T1 in the high temperature circuit. E.g. : T1 = 80°C

2 DHW temperature T3. E.g.: storage heater temperature = 50°C

3 Outside temperature T4. E.g. T4 = 7°C

4 Outlet temperature in 2nd circuit or low temperature circuit T6

5 Room thermostat in the 1st circuit, closed or open.

OFF = contact open

ON = contact closed

6 Room thermostat in the 2nd circuit, closed or open

OFF = contact open

ON = contact closed

7 0-10V analogue input

E.g. 5.5V, 10V

Page 21

CONDEXA PRO 21

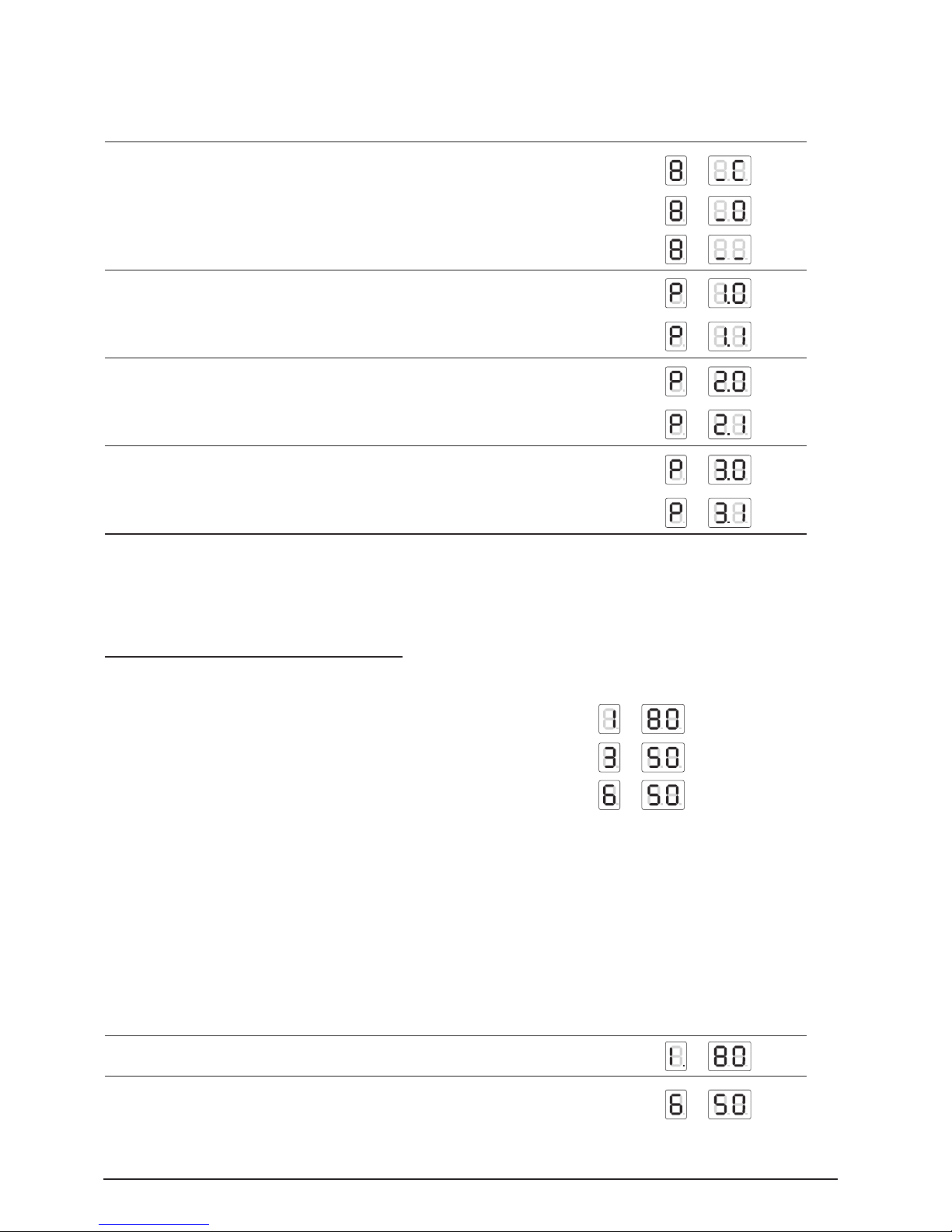

To exit the display of the values, press the "MEMO" button.

If no operation is performed for 5 minutes, the board automatically returns to Display mode.

Value displayed Display

8 Operating status of the mixing valve

E.g.: closing, opening, standby

9 Operating status of the main pump

E.g.: pump not working, pump working

10 Operating status of the DHW pump

E.g.: pump not working, pump working

11 Operating status of the secondary pump

E.g.: pump not working, pump working

SETTING THE USER PARAMETERS

Pressing "SEL" displays the following values in sequence:

- Outlet temperature T1 in the high temperature circuit

- DHW temperature T3

- Outlet temperature in the second circuit or low temperature circuit T6.

To change the corresponding set points:

- Press "

MODE", the corresponding value will be displayed and the two digits on the right will flash.

- If the value does not need to be changed, press "

MODE" again to return to Display mode.

- If the value needs to be changed, press "

+" or "-" until reaching the desired value. Press "MEMO" to save the new value.

The value displayed will stop flashing and the display will return to Display mode.

Procedure Display

1 E.g.: Value read on the display in the high temperature circuit 80°C

2 Press "

SEL" to access Readout mode, press the button again

and scroll the first digit to 6 so as to display the set value, E.g.: 50°C

Example: changing the set point in the low temperature circuit from 50°C to 40°C

Page 22

CONDEXA PRO22

If after having pressed “MODE” no change is made for 10 seconds (because the desired value is already set), the operation of the board returns to Display mode.

If after having pressed “+” or “-” no other button is pressed for at least one minute, Display mode resumes. If this hap-

pens, the new value is not saved.

Procedure Display

3 Press “MODE”

4 Press “-” to change the set point to the desired value. E.g.: 40°C.

5 Press “MEMO” to save the new value

6 After 3 seconds Display mode resumes, with the new value set.

MONITOR MODE

Press “MODE” for 5 seconds to access "Monitor" mode. This mode is used to check the operating values of each individual unit in the system (addresses from 1 to 60).

Operation Display

1 The boiler is operating with the high temperature circuit at 80°C

2 Press “

MODE” for 5 seconds. The display indicates that the values

and the operating status of unit 1 can be read.

3 Press “+” or “-” to scroll and read the values for the desired unit.

4 Pressing “

SEL” on the display shows the 1st value for the selected unit.

Pressing the "

SEL" button again displays the following values.

E.g. outlet temperature 70°C

5 To exit Monitor mode, press “

MODE”.

If within 5 minutes no button is pressed or no operation is performed,

Display mode resumes.

Value Display

1 Outlet temperature E.g.: 70°C

2 Return temperature E.g.: 50°C

3 Flue gas temperature E.g.: 60°C

4 Ionisation current (index from 0 to 99)

E.g.: ionisation current index 44

Press “SEL” to display the subsequent values for the individual unit:

Page 23

CONDEXA PRO 23

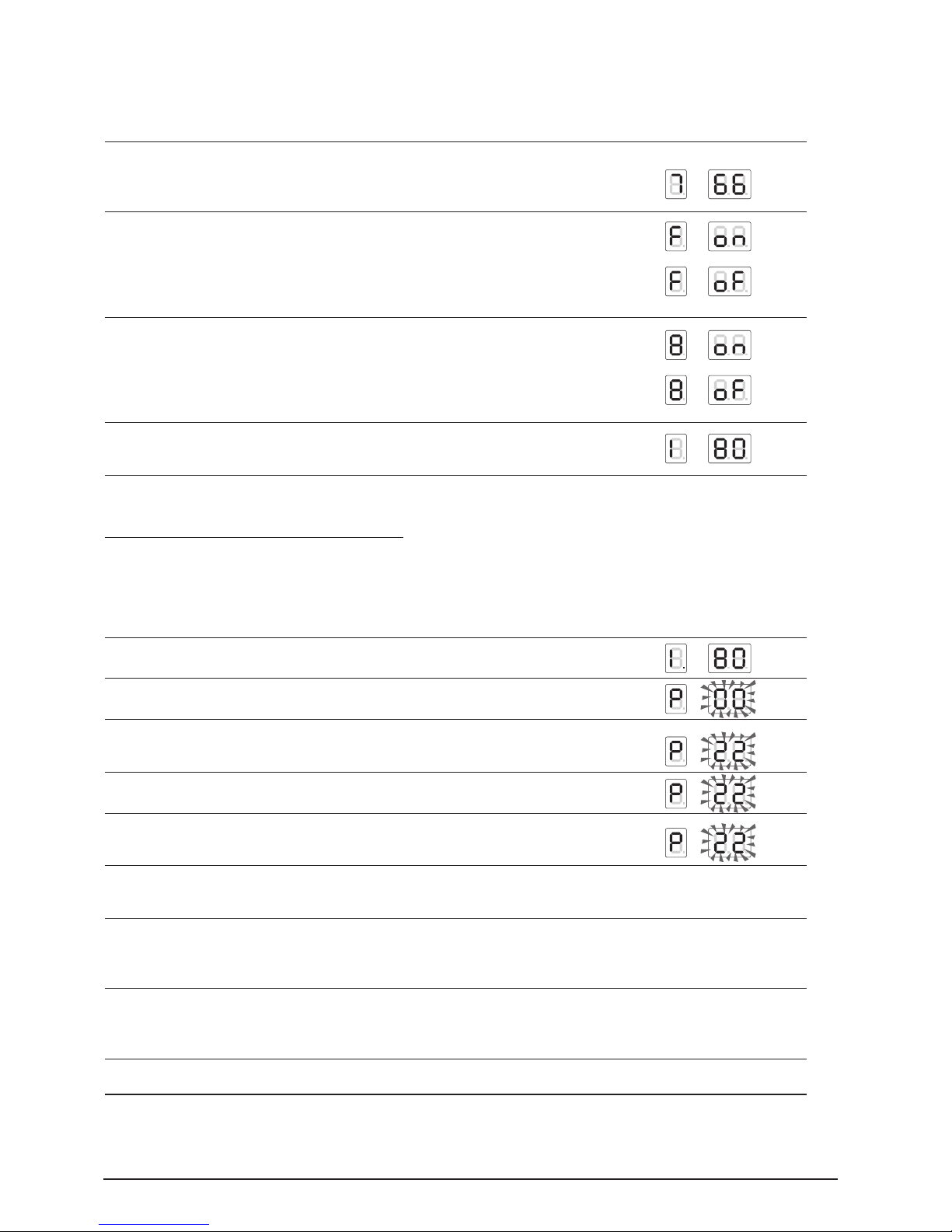

Value Display

5 Fan PWM signal (%).

If PWM = 100%, this corresponds to 99 on the display.

E.g.: 66 %

6 Flow switch contact open/closed (not active)

E.g.: contact open

7 Pump or motorised valve on the individual unit on/off

E.g.: Pump ON

E.g.: Pump OFF

8 Maximum ionisation current (range from 0 to 99) at first attempt

E.g.: maximum ionisation current 80

INSTALLER PROGRAMMING MODE

The installer parameters can be changed by entering the password (22).

The password for the installer level allows access to display and change the user and installer parameters.

Procedure to enter programming mode:

Procedure Display

1 E.g.: the outlet temperature T1 is 80°C

2 Press “MODE” and “MEMO”. After 5 seconds the second and third digit will flash.

3 Use “

+” and “-” to enter the first number in the password on the centre digit.

E.g.: password = X2

4 Press “MEMO” to save the second number in the password.

5 Use “

+” and “-” to enter the first number in the password on the centre digit.

E.g.: password = 22

5 Press “

MEMO” to confirm the password, if the password is wrong

the board returns to Display mode.

6 Press “

+” and “-” to scroll the parameters enabled by the password.

Press “

MODE” to start setting the parameters.

The code P-XX and the corresponding value will alternate on the display.

7 Use “

+” and “-” to change the value of the parameter.

Whenever a button is pressed, the alternating display of the parameter

and the corresponding value is stopped for 5 seconds and only the value is shown.

8 Press “MEMO” to save the new value of the parameter.

To exit installer programming mode press “MEMO”.

For the complete list of parameters see page 58.

Page 24

CONDEXA PRO24

TEST MODE

In Test mode, a high temperature heating demand can be generated corresponding to maximum output and minimum

output.

All the system fans must be on. If the installer switches off some of the Slaves, the others, connected to the Master, must

continue operating.

To enter Test mode from Display mode, proceed as follows:

Procedure Display

1 Press “MODE” and “+” at the same time per 5 seconds.

After 5 seconds the maximum or minimum speed

can be selected using the “+” and “-” buttons.

All the system fans will operate at the selected speed.

The first digit will show the selected speed:

H = maximum speed

L = minimum speed.

The other two digits will show the outlet temperature. E.g.: T1 = 80°C.

2 Press “MEMO” to exit Test mode and return to Display mode.

For the complete list of errors, see page 56.

ERROR MODE

The display starts flashing when there is a fault on any of the heating units. Proceed as follows to identify the faults.

PERMANENT LOCKOUT

In the event where the burners are in permanent lockout, press “RESET” to resume operation.

If “

RESET” is pressed in readout mode, all the Slave heating units will be reset.

If “

RESET” is pressed when displaying the error that caused the permanent lockout, only the heating unit in question

will be reset.

Procedure Display

1 The display starts flashing to signal one or more errors.

1.b Press “

+”: the display will show the address of the

first unit, alternating with the first error code.

Press “

+” again to display the other errors on this unit.

The errors on the following unit with faults will be displayed in sequence,

by pressing “

+” Pressing "-" displays the errors in reverse order

(E.g. unit 2 error code E02). If the errors come from the Master board,

these are displayed as errors on unit 00 (U 00 + error code).

2 Press “MODE” to exit Error mode and return to Display mode.

Page 25

CONDEXA PRO 25

The Vokera CONDEXA PRO Boiler is supplied in a single package protected by a cardboard box.

The following material is supplied with the boiler:

- Installation and operation manual

- Warranty certificate

- Water pressure test certificate

- Spare parts catalogue

- Outside probe

- Kit for conversion from natural gas to LPG

- Assembly template.

bThe Installation and operation manual is an integral

part of the appliance and must be read and kept

with care.

1

2

H

L

P

W 600 mm

D 380 mm

H 1000 mm

Net weight ~ 60 ~ 90 kg

Weight with packaging

~ 65 ~ 95 kg

Description

50 M

100 M - 100 S

RECEIVING THE PRODUCT

DIMENSIONS AND WEIGHT

Page 26

CONDEXA PRO26

Once having removed the packaging, the Vokera

CONDEXA PRO

Boiler is handled manually by tilting and

lifting it, grabbing the points shown in the figure.

bAdopt suitable safety and protection measures.

aThe packaging material must not be dispersed in

the environment or left within the reach of children

as it is a potential source of hazard. It must be

disposed of according to the legislation in force.

The Vokera CONDEXA PRO boiler must be installed in rooms used exclusively for this purpose, provided with adequately sized ventilation openings, in compliance with any current standards and low applicable. If the combustion air

is taken from outside (accessories code 5037685135067 and 5037685135074) the room where the boiler is installed,

CONDEXA PRO operates as a room-sealed appliance (type C).

bProvide enough clearance to access the safety and

control devices and to carry out the servicing operations.

bCheck that the index of protection of the boiler is

suitable for the characteristics of the room where

the appliance is installed.

bIf the boilers operate on gas fuel with a higher spe-

cific weight than air, the electrical parts must be

located at least 500 mm from the floor.

aThe boilers cannot be installed outside as they are

not designed for outdoor operation.

HANDLING

ROOM WHERE THE BOILER IS INSTALLED

Page 27

CONDEXA PRO 27

Where Vokera CONDEXA PRO Boilers are installed in

old systems or systems to be upgraded, check that:

- The flue is suitable for the temperature of the products

of combustion with condensing operation, calculated

and manufactured according to the standards, as straight as possible, airtight, insulated and not blocked or

choked. It must also be fitted with suitable condensate

collection and drain systems

- The electrical system has been installed in compliance

with the relevant standards by qualified personnel

- The fuel supply line and any cylinders or tanks (LPG)

are made and installed according to the relevant standards

- The expansion vessel can completely absorb the

expansion of the fluid contained in the system

- The flow-rate and the discharge head of the pump are

suitable for the characteristics of the system

- The system is flushed, treated, vented and pressure

tested. To clean the system, see the paragraph on

"Water connections", page 28. The manufacturer is not

liable for any damage caused by the incorrect flushing,

treatment and venting etc of the system.

- The condensate drain system (drain trap) is connected

and runs into the sewerage drain or a neutraliser, where

required by the legislation in force.

- A treatment system is available for special supply/topup water requirements (for the reference values, see

the table).

bThe manufacturer is not liable for any damage cau-

sed by the incorrect layout or installation of the flue

system which must be in-accordance with any current standards and law applicable

bThe flues for condensing boilers are made from

special material and differ from those used for standard boilers.

INSTALLATION IN OLD SYSTEMS OR SYSTEMS TO BE UPGRADED

SUPPLY WATER VALUES

pH 6-8

Conductivity less than 200 mV/cm (25°C)

Chloride ions less than 50 ppm

Sulphuric acid ions less than 50 ppm

Total iron less than 0,3 ppm

Alkalinity M less than 50 ppm

Total hardness less than 35°F

Sulphur ions none

Ammonia ions none

Silica ions less than 30 ppm

Page 28

CONDEXA PRO28

1

3

2

The Vokera CONDEXA PRO Boiler must be secured to

a solid brick wall using the bracket (1).

For installation:

- Position the bracket (1) on the wall at a height of

around 200 cm from the ground, using a spirit level to

make sure that the holes are perfectly horizontal

- Mark the fastening holes on the wall

- Drill the holes and insert the expansion plugs (2)

- Fasten the bracket to the wall using the screws (3)

- Hook the boiler to the bracket.

bThe height of the boiler should chosen so as to sim-

plify the dismantling and servicing operations.

bThe Vokera CONDEXA PRO Boiler is not designed

for outdoor installation.

MI RI GASS MI RI GAS

1

2

The Vokera CONDEXA PRO Boilers are designed and

built to be installed in central heating and domestic hot

water systems. The characteristics of the water fittings

are as follows:

MI - Central heating flow outlet 1" M

RI - Central heating return inlet 1" M

Gas - Gas supply 3/4" M

CONDENSATE COLLECTION

Identify the condensate drain (S) located at the bottom of

the boiler and then:

- remove the ring nut/nuts (1)

- pass the hose (2) through the hole and replace the ring

nut on the outside.

Pipe the condensate into the sewerage drain or a neutraliser, where required and in-accordance with any legislation in force.

bThe manufacturer is not liable for any damage cau-

sed by the failure to install the condensate drain

pipe.

bThe condensate drain pipe must be watertight.

INSTALLING THE BOILER

WATER CONNECTIONS

Page 29

CONDEXA PRO 29

250 250 300

1000

1500

MI

GAS

400

150

RI

CLEANING THE SYSTEM

This preliminary operation is required when installing the heat generator in pre-existing systems, and is also recommended in new systems, so as to remove any scale, impurities, processing residues etc. Power Flushing is recommended for system cleaning.

To clean the system, if the old heat generator is still

installed in the system, proceed as follows:

- Add scale-remover into the system water circuit;

- Operate the system with the heat generator on for

around 7 days;

- Empty the dirty water from the system and flush with

clean water. Repeat the operation until the system is

clean.

If the old heat generator is not installed or not available,

use a pump to circulate the water with the additive in the

system for around 10 days, and carry out flushing as

described in the previous point. At the end of the cleaning operations, before installing the boiler, an additive

should be introduced into the water circuit that provides

protection against corrosion and fouling.

bFor additional information on the type and the use

of the additives, contact

Vokera Ltd or a suitable

additives manufacture.

Water connection kits

To assist the construction of the water circuit, two accessory kits are available, featuring water headers and support brackets:

water connection kit for installations up to 100 kW

(code 5037685135012)

1 gas manifold, diameter 45 mm

1 central heating outlet manifold, diameter 45 mm

1 central heating return manifold, diameter 45 mm

2" female fittings.

water connection kit for installations above 100 kW

(code 5037685135029).

1 gas manifold, diameter 3"

1 insulated central heating outlet manifold, Ø 3”

1 insulated central heating return manifold, Ø 3”

DN 80 - PN 6 flanged pipes.

bIdentify the unit that is closest to the central heating

flow outlet as the Master boiler, so as to minimise

the length of the cables to the pumps, the outlet

probe and any storage heater probe.

bThe outlet probe should be fitted in the socket nea-

rest to the central heating flow outlet, in the direction of water flow.

WATER CONNECTION KIT code 5037685135012

125

700

125 200

1000

MI

RI

GAS

400

WATER CONNECTION KIT code 5037685135029

Page 30

CONDEXA PRO30

The Vokera CONDEXA PRO Boiler must be connected

to the natural gas or LPG supply in compliance with the

relevant standards in force.

Before making the connections, check that:

- the type of gas is the same that the appliance is set for

- the pipes are thoroughly clean

- the gas supply pipes are the same size or larger than

the fitting on the boiler (3/4"), with a pressure drop that

is less than the pressure drop between the gas supply

and the appliance.

When installation is completed, check that the joints are

all tight, as required by the installation standards.

A suitable filter should be installed on the gas line.

The flue and the fitting to the flue must be made in compliance with the standards and the legislation in force, as

well as with local regulations.

The pipes used must be rigid and resistant to temperature, condensate and mechanical stress, and airtight.

bNon-insulated flues are potential sources of danger.

A

S

A

S

61

275

37

275 212

C63 B23

B23 Fan upstream. Combustion air intake directly

from the room where the boiler is installed. Flue

gas exhaust through horizontal or vertical pipes,

fitted with ventilation openings.

C63 Fan upstream. Combustion air intake and flue

gas exhaust without terminals.

b

Please refer to any current standards and law

applicable to flues and ventilation.

A - Air intake Ø 50 mm

(Conversion kit for room-sealed operation

CONDEXA PRO

50 code

5037685135067

Conversion kit for room-sealed operation

CONDEXA PRO

100 code

5037685135074

)

S - Flue Ø 50 mm

FUEL CONNECTIONS

FLUE GAS OUTLET AND COMBUSTION AIR INTAKE

Page 31

CONDEXA PRO 31

20

20

50

50

20

50 20

20

20

50

230 mm

90 mm

20

20

50

50

160 mm

Square compartment

Rectangular compartment

Minimum dimensions of the compartment

for the passage of three flues, diameter 50 mm

20

20

20

90 mm

160 mm

20

20

205050

20

20

50

Ø 160 mm

20

20

50

50

Circular compartment

Rectangular compartment

Minimum inside dimensions of the compartment

for the passage of 2 flues, diameter 50 mm

20

50mm

50mm

63 mm

71 mm

Minimum inside dimensions of the compartment

for the passage of 1 flue, diameter 50 mm

Circular compartment

Square compartment

MAXIMUM LENGTH OF THE PIPES

The maximum equivalent length of the sum of the 50 mm

intake pipes and flues is 30 metres, with a pressure drop

of 2 metres for each 90° bend.

Installation of a single boiler with flue passing inside

a compartment (open flue operation).

For this type of operation, make sure that the size of the

compartment complies with the standards in force.

The figure on the side shows the minimum dimensions of

the compartment when passing one flue (model 50 M) or

two flues (models 100 M or 100 S).

bParameter 36 (see page 59) needs to be set based

on the type of gas and the length of the chimney.

model 50 M

models 50 M + 100 S

model 100 M

Page 32

CONDEXA PRO32

Minimum

distance

10 mm

Minimum

distance

300 mm

Condensate collector

(at atmospheric pressure)

i > 3%

Mains

sewers

i

i ≥ 3°

PREPARING THE CONDENSATE DRAIN

The condensate produced by the boiler during normal

operation must be drained at atmospheric pressure and

must conform to any current standards and law applicable.

- install a neutraliser where required by law.

bSpecific pipes for condensing boilers must be

used. For installation, follow the instructions

provided with the kit.

Drain trap along the drain pipe

If the vertical or horizontal section of the drain pipe

needs to be extended by more than 4 metres, a drain

trap must be installed at the foot of the pipe.

The useful height of the drain trap must be at least 300

mm. The discharge of the drain trap must then be connected to the sewerage system.

Page 33

CONDEXA PRO 33

The

CONDEXA PRO

50 M and 100 M boilers leave the factory completely wired, with the power cable already connec-

ted, and only require the connection of the room thermostats, the outside probe and the pumps used, to the corresponding terminals. For the

CONDEXA PRO

100 S boiler, only the Bus cable needs to be connected (see the wiring diagram

on page 16).

To do this:

- Move the main system switch to "off"

- Unscrew the fastening screws (1) on the front panel (2)

- Pull the base of the panel (2) outwards and then

upwards to release it from the frame and then remove

it

- Turn the control panel (3) and remove the rear cover,

taking out the locking screws (4)

2

1

4

3

ON

OFF

ELECTRICAL CONNECTIONS

Page 34

CONDEXA PRO34

- Identify the terminal block (5) and make the connections, as in the diagram shown below.

Pbas (*) Low temperature

system pump

PB (*)

28

27

26

25

24

23

22

21

20

19

18

1

2

3

4

5

6

7

8

DHW pump

PZ1 (*)

High Temperature

system pump

PZ2 (*) Loop pump or

VM (*)

Mixing valve

SB

Storage heater probe

SZ1

Probe in zone 1,

high temperature

SE

Outside probe

Contact for

alarm signal

17 16 15 14 13 12 11 10 9

TA1

High temperature

room thermostat

TA2

Low temperature

room thermostat

TERMINAL BLOCK INSIDE THE MASTER CONTROL PANEL

SZ2

Probe in zone 2,

low temperature

(*) 230V~50Hz

0-10V

analogue

input

CR

Remote

control

IA

24V

COM

BUS

b The following measures are compulsory:

1 -the use of an omnipolar thermal overload swit-

ch, mains disconnecting switch, compliant

with the CEI-EN standards (minimum contact

opening 3 mm);

2 - respect the connection L (Line) - N (Neutral).

Leave the earth wire around 2 cm longer than

the power wires;

3 -use wires with a cross-section greater than or

equal to 1.5 mm

2

, complete with pointed end

terminals;

4 -refer to the wiring diagrams in this booklet for

any operations on the electrical system;

5 -connect the appliance to an effective earth

system.

b

The pumps should be connected by installing suitable contactors with manual emergency operation.

aThe gas and/or water pipes must not be

used to earth the appliance.

aThe power supply and room thermostat

cables must not run near hot surfaces

(outlet pipes).

The manufacturer is not liable for any damage due to the failure to earth the appliance

and to observe the information provided on

the wiring diagrams.

5

Page 35

CONDEXA PRO 35

Fastening the outside probe to the wall

- Unscrew the cover on the probe protection box, turning

it anticlockwise to access the terminal block and the

fastening holes

- Trace the fastening points using the protection box as

the template

- Remove the box and drill the holes for the 5x25 expansion plugs

- Fasten the box to the wall using the two plugs supplied

- Unscrew the nut on the cable gland, pass a two-wire

cable through (cross-section from 0.5 to 1mm

2

, not

supplied) to connect the probe to terminals 7 and 8

(see the diagram on page 34)

- Connect the two wires on the cable to the terminal

block, without needing to identify the polarity

- Tighten the nut on the cable gland and close the cover

on the protection box.

bThe probe should be placed on a smooth section of

the wall; in the event of exposed brick walls or uneven walls, a smooth contact area should be used.

bThe maximum length of the connection between

the outside probe and the control panel is 50 m.

Conversion table valid for all probes

Temperature measured (°C) - Resistance of the probes (Ω).

T (°C) R (°Ω) T (°C) R (°Ω) T (°C) R (°Ω) T (°C) R (°Ω) T (°C) R (°Ω) T (°C) R (°Ω) T (°C) R (°Ω)

bThe connection cable between the probe and con-

trol panel must not have junctions; if required, these

must be sealed and adequately protected.

bAny conduits used for the connection cable must

be separate from the power cables (230Vac).

The correct positioning of the outside probe is fundamental for the correct operation of the climate control function.

The probe must be installed outside of the building being heated, at a height of around 2/3 of the wall facing NORTH or

NORTH-WEST, and away from flues, doors, windows and areas exposed to direct sunlight.

-20

-19

-18

-17

-16

-15

-14

-13

-12

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

67739

64571

61568

58719

56016

53452

51018

48707

46513

44429

42449

40568

38780

37079

35463

33925

32461

31069

29743

28481

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

27279

26135

25044

24004

23014

22069

21168

20309

19489

18706

17959

17245

16563

15912

15289

14694

14126

13582

13062

12565

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

12090

11634

11199

10781

10382

9999

9633

9281

8945

8622

8313

8016

7731

7458

7196

6944

6702

6470

6247

6033

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

5828

5630

5440

5258

5082

4913

4751

4595

4444

4300

4161

4026

3897

3773

3653

3538

3426

3319

3216

3116

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

3021

2928

2839

2753

2669

2589

2512

2437

2365

2296

2229

2164

2101

2040

1982

1925

1870

1817

1766

1717

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

1669

1622

1577

1534

1491

1451

1411

1373

1336

1300

1266

1232

1199

1168

1137

1108

1079

1051

1024

998

100

101

102

103

104

105

106

107

108

109

110

973

948

925

901

879

857

836

815

796

776

757

INSTALLING THE OUTSIDE PROBE

Page 36

CONDEXA PRO36

The Vokera CONDEXA PRO Boiler is not fitted with an

automatic filling valve, which must be installed on the

system return.

FILLING

- Open the valves (1) installed on the boiler water fittings;

- Open the caps on the automatic vent valve/valves (2)

two or three turns;

- Open the filling valve on the system until the pressure

shown on the pressure gauge is

1,5 bar;

- Close the filling valve again.

bThe air is vented from the CONDEXA PRO boiler

automatically through the automatic vent valve/valves installed on the top of the heating units.

Check that the cap on the valve is open.

MI

RI

GAS

1

2 2

FILLING AND EMPTYING THE SYSTEMS

Page 37

CONDEXA PRO 37

ON

OFF

EMPTYING

Before starting to empty the system, disconnect the

power supply by moving the main system switch to "off".

Emptying the BOILER

- Close the valves (1) installed on the boiler water fittings;

- Connect a plastic hose to the drain cock (4), on each

heating unit, and open the cock;

bBefore opening the drain cock (4), protect the elec-

trical devices underneath against water spillage.

Emptying the SYSTEM

- Check that the valves (1), installed on the water circuit,

are open;

- Connect a plastic hose to the drain cock (5), fitted on

the system return line, and open the cock.

MI

RI

GAS

1

MI

RI

GAS

1

5

4 4

Page 38

CONDEXA PRO38

Before starting the system and running the functional

tests on the

Vokera CONDEXA PRO Boiler, check that:

- The fuel valve and valves in the central heating system

are open;

- The type of gas and the supply pressure are correct for

the boiler;

- The system is filled, pressure in the water circuit, when

cold, is around 1,5 bar and the circuit has been

vented;

- The system expansion vessel is suitably pre-charged;

- The electrical connections have been performed correctly.

bThe pumps should be connected by installing sui-

table contactors with manual emergency operation.

- Check that the cap on the vent valve/valves is

unscrewed;

- The pumps turn freely: loosen the inspection screw

and check with a flathead screwdriver that the motor

shaft is rotating without impediments.

bBefore loosening or removing the seal cap on the

pump, protect the electrical devices underneath

against water spillage.

- The flues have been properly made and installed.

PREPARING FOR FIRST START-UP

Page 39

CONDEXA PRO 39

- Move the main system switch to "on";

- Move the main switch (1) on the boiler and the switches

(2) on each heating unit to "on".

The green SLAVE power supply signal (3) flashes. The

boiler performs a self-diagnosis cycle, after which it will

enter DISPLAY mode.

The display (4) shows the status of the system and the

temperature measured by the probe in the "high temperature" circuit (see Display mode on page 20).

If there are more than two boilers installed, configure

the addresses from the third boiler on. To do this, see

the paragraph "Setting the addresses for cascading

configurations" on page 54).

- Set the room thermostats in the high and low temperature zone to the desired temperature (~20°C) or if the

systems are fitted with a timer-thermostat or timer,

check that this is on and set (~20°C).

- Press the “

SEL” button: the maximum temperature of

the boiler will be displayed, that is, the maximum temperature in the high temperature circuit, preceded by

the symbol "1".

- Press “

MODE”: the corresponding set point will be

displayed and the two digits on the right will flash. To

change the value, press “

+” or “-”.

To confirm press “

MEMO”.

ON

OFF

1

2 2

3

4

STARTING FOR THE FIRST TIME

Page 40

CONDEXA PRO40

- Press the “SEL”button four times: the maximum tem-

perature in the low temperature circuit will be

displayed, preceded by the symbol "6".

- Press “

MODE”: the corresponding set point will be

displayed and the two digits on the right will flash. To

change the value, press “

+” or “-”.

To confirm press “

MEMO”.

bFor low temperature systems, select a temperature

between 20°C and 45°C.

When setting the system as "Low temperature", the

maximum outlet temperature will be limited at 50°C

(Par. 23=T_CH_Low_limit).

bChanging the outlet temperature modifies the cli-

mate control curve (see the paragraph "Setting the

temperature controller"). These settings must only

be performed by

Vokera Ltd or a suitably qualified

person.

- Press “

SEL”button twice: the DHW temperature will be

displayed, preceded by the symbol "3".

- Press “

MODE”: the corresponding set point will be

displayed and the two digits on the right will flash. To

change the value, press “

+” or “-”.

To confirm press “

MEMO”.

The boiler will start in DHW mode, until the demand is

satisfied.

If the boiler is connected to a storage heater, set parameter 6 (pre-set to 0=no DHW service).

To do this, access "Installer programming" mode and set parameter 6 to:

2 = for storage heater with probe

6 = for storage heater with thermostat.

In addition, set parameter 9 (DHW_Priority) to 2 for absolute priority.

If the storage heater is fitted with an NTC probe, the desired temperature can be set on the display, from 10°C to 50°C.

If the storage heater is fitted with a thermostat, the desired temperature should be set directly on the storage heater,

while parameter 3 must be left at 50°C.

Page 41

CONDEXA PRO 41

When the boiler is in Standby, the display on the Master

unit is in Readout mode and the three digits show the

number "1", followed by the value of the outlet temperature. The green LED (ref. 11 on page 18) flashes.

See the paragraph on "DISPLAY MODE", page 20, for

details on the various information displayed by the

system.

If ignition or operating faults occur on any heating unit,

the display on the Master boiler starts flashing and the

red LED (4) comes on.

There are two possible types of errors:

- Type A errors, which can only be deactivated by pressing RESET;

- Type E errors, which are deactivated when the causes

are no longer present (see ERROR MODE on page 24

and the "Fault codes" paragraph on page 56).

When ignition is complete, check that the CONDEXA

PRO

boiler correctly:

- Starts and stops, closing the contacts on the zone thermostats;

- Displays the DHW temperature (only if the storage heater is fitted) and central heating temperature, pressing

the “

SEL”button twice;

Check, if the storage heater is fitted, that parameter "6"

is set correctly:

2 = storage heater with probe

6 = storage heater with thermostat

and check that operation is correct, by opening a hot

water tap.

Check the complete shutdown of the boiler by moving

the main system switch to "off".

ON

OFF

CHECKS DURING AND AFTER FIRST START-UP

4

Page 42

CONDEXA PRO42

After a few minutes of continuous operation controlled by

the room thermostat, the adhesives and the processing

residues will have evaporated, and the following checks

can be completed:

- check the gas supply pressure;

- check combustion,

CHECKING THE GAS SUPPL

Y PRESSURE

- Move the main system switch to "off";

- Unscrew the fastening screws (1) on the front panel (2);

- Pull the base of the panel (2) outwards and then

upwards to release it from the frame and then remove

it;

- Unscrew the screw on the pressure test point (3), located upstream of the gas valve, around two turns, and

connect a pressure gauge;

- Power-up the boiler by moving the main system switch

and the main switch/switches on the appliance to "on".

ON

OFF

2

1

3

ON

OFF

Page 43

CONDEXA PRO 43

In TEST mode, a high temperature heating demand at

maximum output can be generated.

To do this:

- Press the “

MODE” and “+” buttons together for 5

seconds;

- Start the boiler by adjusting the room thermostat.

The boiler will operate at maximum output showing "H"

on the display, followed by the outlet temperature

(chimney sweep function);

- Check that with the burner on at maximum output the

gas pressure is the rated supply pressure, as shown in

the table to the side;

- Adjust the thermostat so as to stop the boiler;

- Press “

MEMO” to exit TEST mode;

- Disconnect the pressure gauge and tighten the screw

on the pressure test point (3) upstream of the gas

valve.

CHECKING COMBUSTION

- Power-up the boiler by moving the main system switch

and the main switch/switches on the appliance to "on";

In TEST mode, a high temperature heating demand at

maximum output can be generated.

To do this:

- Press the “MODE” and “+” buttons together for 5

seconds;

- Start the boiler by adjusting the room thermostat.

The boiler will operate at maximum output showing "H"

on the display, followed by the outlet temperature

(chimney sweep function).

ON

OFF

3

DESCRIPTION G20 G30 G31

Wobbe index 45,7 80,6 70,7 MJ/m

3

Rated supply pressure 20 28-30 37 mbar

Page 44

CONDEXA PRO44

- Combustion can be checked by unscrewing the cap

(4) and inserting the analyser probe in the available

position;

- Once having completed the check, stop the chimney

sweep function by pressing “

MEMO”;

- Adjust the thermostat so as to stop the boiler;

- Remove the analyser probe and carefully retighten the

cap (4);

FAN SPEED

The fan speed is controlled automatically based on the

type of gas and the length of the flue (L).

This information is managed by parameter 36.

To change the settings:

- Enter "INSTALLER PROGRAMMING MODE" following

the procedure described on page 23, and set parameter 36 to:

1 = natural gas and L<15 m

2 = natural gas and L>15 m

3 = LPG and L<15 m

4 = LPG and L>15 m.

The

CONDEXA PRO boilers are supplied for operation

on G20 (natural gas), with a flue L<15m (parameter

36=1).

Once the checks are complete, replace the front panel

and secure it using the same screws.

bAll checks must be performed by a suitably quali-

fied person.

4

Page 45

CONDEXA PRO 45

The functions of the central heating high temperature and low temperature circuits and the DHW circuits can be set

based on the system requirements, by setting the functional parameters.

The first three parameters are accessible at a user level, while the remaining parameters require the password to be

entered ("22", see page 23).

To access the user parameters, press the "SEL" button, after which the following values will be displayed:

- Outlet temperature in the high temperature circuit T1

- Temperature in the DHW circuit T3

- Outlet temperature in the low temperature circuit T6

To change the corresponding set points:

- Press "

MODE", the corresponding value will be displayed and the two digits on the right will flash.

- Press “

+/-” until reaching the desired value. Press "MEMO" to save the new value. The value displayed will stop fla-

shing and will be valid after 3 seconds.

For a detailed description of all the parameters and the default values see page 58.

The following functions can be set for central heating:

1 Setpoint_T_CH_High

Set point in the high temperature circuit (parameter 1)

If the operating mode is set to "fixed set point" (par. 14=CH_type_high=0), this is the objective temperature.

If the operating mode is set to "climate control" (par. 14=1), this is the maximum objective temperature for the minimum outside temperature (T_out_min=par. 37, pre-set to 0°C).

Parameter 18 (T_CH_high_foot, pre-set to 50°C) defines the minimum set point for the maximum outside temperature (T_out_max, pre-set to 18°C).

Pre-set to 70°C with upper limit set by par. 17 (T_CH_high_limit, pre-set to 80°C).

T_out_max

Outside temperature (°C)