Page 1

Users Instructions

Installation &

Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

Compact A

High efficiency combi boiler

Page 2

Users instructions

Things you should know Page

1.1 Gas appliances 1

1.2 Electrical supply 1

1.3 Guarantee registration card 1

1.4 Appliance Log Book (UK only) 1

1.5 How does it work? 1

1.6 Dimensions 1

1.7 Clearances required 1

1.8 Frost protection system 1

1.9 Appliance status indicators 1

Getting started Page

2.1 Before switching ON 3

2.2 Appliance controls 3

2.3 Lighting the boiler 3

2.4 Adjusting the heating temperature 3

2.5 Adjusting the hot water temperature 3

2.6 Explanation of features 3

2.7 Automatic temperature control 3

How to... Page

3.1 How to top-up the system pressure 3

3.2 How to reset the appliance 3

3.3 How to shut down the system for short periods 3

3.4 How to shut down the system for long periods 3

3.5 How to care for the appliance 3

What if... Page

4.1 What if I suspect a gas leak 4

4.2 What if I have frequently top-up the system 4

4.3 What if the appliance is due its annual service 4

4.4 What if I need to call an engineer 4

Setting the Vokèra Page

5.1 Setting the Vokèra mechanical clock 4

Installation and Servicing instructions

Design principles & operating sequence Page

1.1 Principle components 6

1.2 Mode of operation (at rest) 6

1.3 Mode of operation (heating) 6

1.4 Mode of operation (Hot water) 6

1.5 Safety devices 6

Technical data Page

2.1 Central heating 7

2.2 Domestic hot water 7

2.3 Gas pressures 7

2.4 Expansion vessel 7

2.5 Dimensions 7

2.6 Clearances 7

2.7 Connections 7

2.8 Electrical 7

2.9 Flue details (concentric) 7

2.9A Flue details (twin pipes) 7

2.9B Flue details (80/125) 7

2.10 Efficiency 7

2.11 Emissions 7

2.12 Pump duty 8

General requirements (UK) Page

3.1 Related documents 9

3.2 Location of appliance 9

3.3 Gas supply 9

3.4 Flue system 9

3.5 Air supply 9

3.6 Water circulation 9

3.7 Electrical supply 10

3.8 Mounting on a combustible surface 10

3.9 Timber framed buildings 10

3.10 Inhibitors 10

3.11 Showers 10

General requirements (EIRE) Page

3A.1 Related documents 10

3A.2 Location of appliance 10

3A.3 Gas supply 10

3A.4 Flue system 10

3A.5 Air supply 11

3A.6 Water circulation 11

3A.7 Electrical supply 11

3A.8 Mounting on a combustible surface 11

3A.9 Timber framed buildings 11

3A.10 Inhibitors 11

3A.11 Showers 11

3A.12 Declaration of conformity 11

Installation Page

4.1 Delivery 12

4.2 Contents 12

4.3 Unpacking 12

4.4 Preparation for mounting the appliance 12

4.5 Fitting the flue 12

4.6 Connecting the gas & water 15

4.7 Electrical connections 16

Commissioning Page

5.1 Gas supply installation 17

5.2 The heating system 17

5.3 Initial filling of the system 17

5.4 Initial flushing of the system 17

5.5 Pre-operation checks 17

5.6 Initial lighting 17

5.7 Checking gas pressure & combustion analysis 17

5.8 Final flushing of the heating system 17

5.9 Setting the boiler operating temperature 17

5.10 Setting the system design pressure 17

5.11 Regulating the central heating system 18

5.12 Final checks 18

5.13 Instructing the user 18

Servicing Page

6.1 General 18

6.2 Routine annual servicing 18

6.3 Replacement of components 18

6.4 Component removal procedure 18

6.5 Pump assembly 19

6.6 Safety valve 19

6.7 Lower automatic air release valves 19

6.8 Water pressure switch 19

6.9 Flow thermistor 19

6.10 Return thermistor 19

6.11 Printed circuit board 19

6.12 Gas valve 20

6.13 Electrodes 20

6.14 Flue fan & mixer 20

6.15 Burner 20

6.16 Main heat exchanger 21

6.17 Automatic by-pass & DHW non-return valve 21

6.18 Expansion vessel removal 21

6.19 Condense trap removal 21

6.20 Flue collector removal 22

Checks, adjustments and fault finding Page

7.1 Checking appliance operation 23

7.2 Appliance modes of operation 23

7.3 Checking the CO2 & adjusting the valve 23

7.4 Combustion analysis test 24

7.5 Checking the expansion vessel 24

7.6 External faults 24

7.7 Electrical checks 24

7.8 Fault finding 25

7.9 Component values & characteristics 25

Wiring diagrams Page

8.1 External wiring 26

8.2 Typical control applications 26

8.3 Other devices 26

8.4 Vokèra twin-channel programmer 26

Exploded diagrams Page

9.1 Table 1 28

9.2 Table 2 29

9.3 Table 3 30

9.4 Table 4 31

9.5 Table 5 32

L.P.G. instructions Page

10.1 Related documents 33

10.2 Technical data 33

10.3 Converting the appliance gas type 33

10.4 Gas supply 33

10.5 Gas supply installation 33

10.6 Checking the CO2 and adjusting the gas valve 33

Benchmark 35-36

Page 3

1

USERS INSTRUCTIONS

1.1 GAS APPLIANCES

Gas Safety (Installations and Use) Regulations (UK).

In the interests of your safety and that of others it is a legal

requirement that all gas appliances are installed and correctly

maintained by a competent person and in accordance with the

latest regulations.

1.2 ELECTRICAL SUPPLY

Please ensure that this appliance has been properly connected to the electrical supply by means of a double pole

isolator or un-switched socket, and that the correct size of fuse

(3 AMP) has been fitted.

Warning: this appliance must be earthed!

1.3 GUARANTEE REGISTRATION CARD

Please take the time to fill out your guarantee registration card.

The completed warranty card should be posted within 30 days

of installation.

1.4 APPLIANCE LOG BOOK (UK only)

A logbook section can be found at the rear of the appliance

installation booklet. This important document must be completed

during the installation/commissioning of your boiler. All GAS

SAFE registered installers carry a GAS SAFE ID card, and have

a registration number. These details should be recorded in the

Benchmark logbook section within the installation booklet. You

can check your installers details by calling GAS SAFE direct on

08004085500. Failure to install and commission the appliance

in accordance with the manufacturers instructions may

invalidate the warranty. This does not affect your statutory

rights.

1.5 HOW DOES IT WORK?

Your Compact boiler supplies heated water to your radiators

and hot water to your hot water taps.

The central heating is controlled via a time clock and any

thermostats that your installer may have fitted. The boiler will

light when it receives a request from the time clock via any

thermostat that may be installed, or whenever a hot water outlet

(tap) is opened.

Your Compact boiler lights electronically and does not have a

pilot light.

In the unlikely event of a fault developing with your boiler, the

supply of gas to the burner will be terminated automatically.

Dear Customer

Your Vokèra Compact boiler has been designed to meet and exceed the very latest standards in gas central heating technology,

and if cared for, will give years of reliable use and efficiency.

Please therefore take some time to read these instructions carefully.

Do’s and Don’t’s

- Do ensure that the system pressure is periodically checked

- Do ensure that you know how to isolate the appliance in an emergency

- Do ensure that you are familiar with the appliance controls

- Do ensure that your installer has completed the appliance log book section

- Do not attempt to remove the appliance casing or gain internal access

- Do not hang clothes etc. over the appliance

- Do not forget to have the appliance serviced annually.

This booklet is an integral part of the appliance. It is therefore necessary to ensure that the booklet is handed to the person

responsible for the property in which the appliance is located/installed. A replacement copy can be obtained from Vokèra

customer services.

INTRODUCTION

1.6 DIMENSIONS

1.7 CLEARANCES REQUIRED

ABOVE 150 mm

BELOW 150 mm

LEFT SIDE 12 mm

RIGHT SIDE 12 mm

FRONT 600 mm

Compact 25-29

HEIGHT 715 mm

WIDTH 405 mm

DEPTH 248 mm

1.8 FROST PROTECTION SYSTEM

The Compact is equipped with a built-in frost protection system,

this enables the boiler to over-ride the time controls – even if

switched off – and operate the burner and/or pump, should the

temperature drop below 5

0

C for the main and for the DHW line.

In particular the burner will be in ON status until the main

temperature reaches 35°C for CH appliance and 55°C for DHW

appliance.

Please note that the frost protection system is designed to

protect the appliance only, should frost protection be required

for the heating system, additional controls may be required.

NOTE

The frost protection system is reliant on the appliance having

a permanent electrical supply, and being in a non-fault

condition.

1.9 APPLIANCE STATUS INDICATORS

Your boiler is equipped with 3 status LED indicators, the Green

LED indicates that the flame is present, the Red LED indicates

the appliance has detected a fault, whilst the Yellow LED

indicates that there is Servicing operation in progress.

1. THINGS YOU SHOULD KNOW

Page 4

2

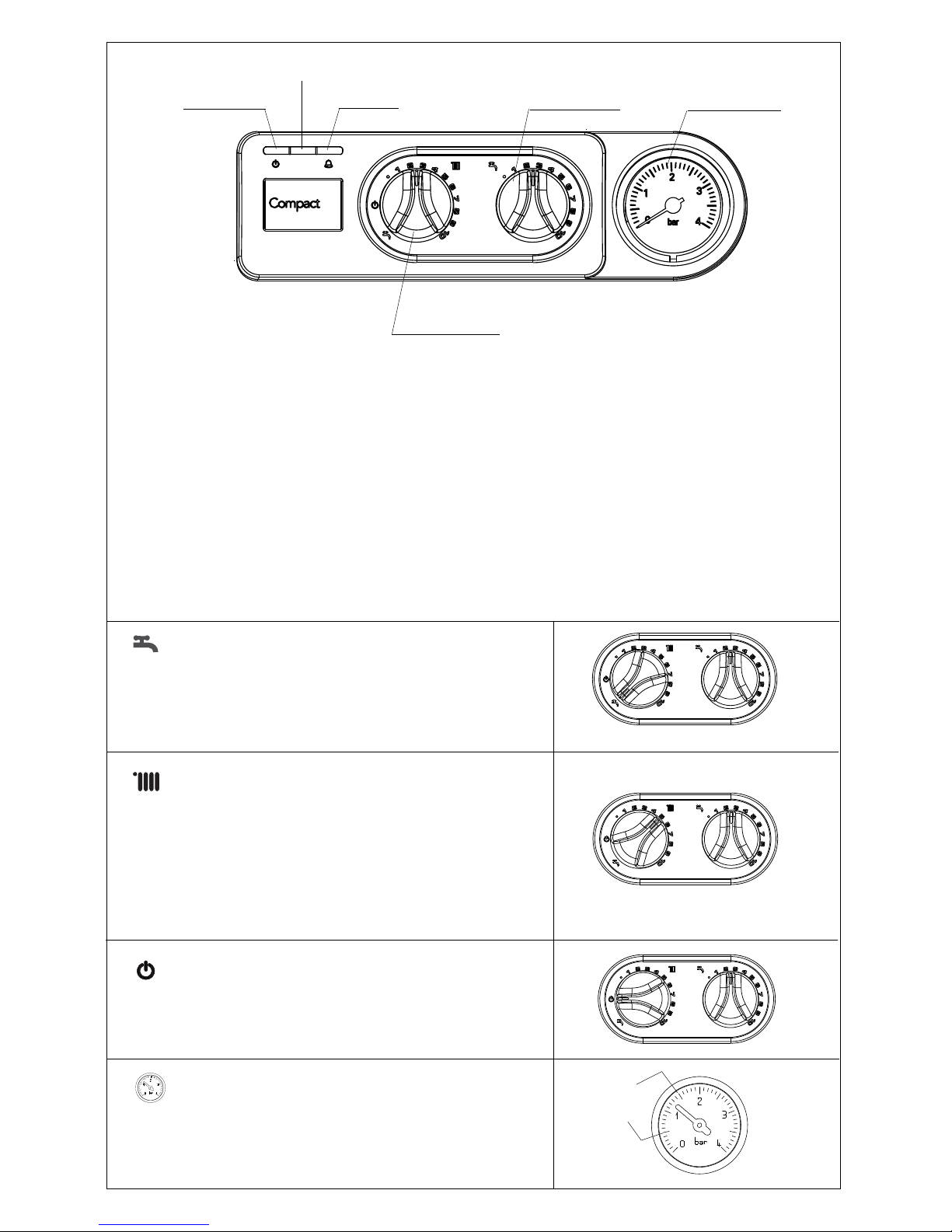

Fig. 1

BOILER STATUS LED

Green LED Boiler is working/responding to a heating/hot water request

Red LED Boiler has identified a fault and has failed-safe. Refer to instructions on how to reset

Yellow LED Service operation

DHW TEMPERATURE SELECTOR

Move the selector clockwise to increase the hot water outlet temperature, or counter-clockwise to reduce the temperature

PRESSURE GAUGE

Ensure the system pressure is set correctly (minimum 0.5-bar)

MODE SELECTOR SWITCH/HEATING TEMPERATURE SELECTOR

Mode selector switch:

MODE

SELECTOR

SWITCH

RED LED

GREEN LED

HEATING

TEMPERATURE

SELECTOR

HYDROMETRE

DHW

TEMPERATURE

SELECTOR

YELLOW LED

Hot water only - Select this position if you want the boiler

to supply hot water only (no heating)

Hot water temperature selector: move the selector

clockwise to increase the heating outlet temperature, or

counter-clockwise to reduce the temperature (range:

37°C-60°C)

Boiler at OFF/standby - Select this position when you

want the boiler to be switched off for short periods (days)

or if the boiler requires to be reset

Heating & hot water - Select this position when you

want the boiler to respond to a heating and hot water

request from the time-clock programmer

Heating temperature selector: move the selector

clockwise to increase the heating outlet temperature, or

counter-clockwise to reduce the temperature (range:

40°C-80°C for standard central heating).

The automatic temperature control function (SARA) is

set within position 4 and 6.

Pressure gauge shows the current pressure of your

heating system, the gauge should be set between 1 and

1.5 BAR. When the appliance is operating the gauge may

rise or fall slightly, this is quite normal. The minimum

permissible level for the safe and efficient operation of the

appliance is 0.5 BAR. Should the pressure fall below 0.5

BAR, the boiler may lockout.

correct

pressure

value

Page 5

3

2.1 BEFORE SWITCHING ON

Before switching the appliance on, please familiarise yourself with:

- how to isolate the appliance from the gas, water, and electricity supplies;

- how to check and top-up – if necessary – the system water

pressure;

- the time clock or programmer (if fitted);

- any external thermostats and their functions;

- the appliance controls.

2.2 APPLIANCE CONTROLS (see fig. 1)

The appliance controls are situated on the lower front of the

appliance. The appliance controls include:

- pressure gauge;

- appliance mode selector;

- temperature selector;

- burner ON mode (green);

- fault indicator (red);

- servicing mode indicator (yellow)

- optional integral time clock/programmer (if fitted).

NOTE

The appliance frost protection is active in all the boiler modes.

The temperature selectors can be used to vary the temperature

of the water that circulates around your radiators and the water

that flows from your hot water taps. The temperature range is

adjustable between 40

o

C and 80oC for the central heating, and

between 37oC and 60oC for the hot water.

The 3 LED normally shows the operating temperature of the

appliance.

When the status indicator (Green) is lit it indicates that the

flame is present and the burner is ON.

When the fault indicator (Red) is lit it indicates that the

appliance has identified a possible fault and performed a safety

lockout.

When the fault indicator (Yellow) is lit it indicates that there is

a Servicing operation in progress.

The integral time clock (when fitted) can be used to switch the

heating on and off at pre-determined intervals.

2.3 LIGHTING THE BOILER

Ensure the gas and electrical supply to the boiler are turned on.

Turn the mode selector switch to the ON position. When there

is a request for heating or hot water via the time clock or

programmer, the boiler will begin an ignition sequence. When

the appliance reaches the CH set temperature, the burner will

go off for a minimum period of approximately 3 minutes.

When the programmer/time clock or external thermostats

heating request has been satisfied, the appliance will switch

off automatically.

2.4 ADJUSTING THE HEATING TEMPERATURE

Rotate the temperature selector – clockwise to increase,

counter-clockwise to decrease – to the desired temperature

setting. The temperature can be set from a minimum of 40°C

to a maximum of 80°C (if standard CH mode is selected).

2.5 ADJUSTING THE HOT WATER TEMPERATURE

Rotate the temperature selector – clockwise to increase,

counter-clockwise to decrease – to the desired temperature

setting. The temperature can be set from a minimum of 37°C

to a maximum of 60°C. If the temperature at the outlet is still not

sufficiently hot enough, it may be necessary to reduce the flow

of water at the hot water outlet (tap).

NOTE

If the appliance fails to ignite during the ignition sequence, it will

enter a lockout condition. Should this occur, please allow a

period of at least two minutes before re-setting the appliance.

2.6 EXPLANATION OF FEATURES

Although the Vokèra Compact has been designed for simplicity

of use, it utilises the latest in boiler technology, enabling a host

of functions to be carried out simultaneously.

2.7 AUTOMATIC TEMPERATURE CONTROL

The automatic temperature control function (SARA), permits

the boiler (when the heating temperature selector is set within

4 and 6 sector) to automatically adjust (raise) the heating.

The activation and the disable of the function is visualized by

blinking the green led.

2. GETTING STARTED

3.1 HOW TO TOP-UP THE SYSTEM PRESSURE

(fig. 1-2)

The system pressure must be checked periodically to ensure

the correct operation of the boiler. The needle on the gauge

should be reading between 1 and 1.5 BAR when the boiler is

in an off position and has cooled to room temperature. If the

pressure requires ‘topping-up’ use the following instructions

as a guide.

- Locate the filling valve connections (usually beneath the

boiler, see fig. 2).

- Attach the filling loop to both connections.

- Open the filling valve slowly until you hear water entering the

system.

- Close the filling valve when the pressure gauge (on the

boiler) reads between 1 and 1.5 BAR (see fig. 1).

- Remove the filling loop from the connections.

3.2 HOW TO RESET THE APPLIANCE

When the red fault LED is illuminated, the appliance will require

to be reset manually. Before resetting the boiler, check what

action is required to be taken, using the information on the

fault code table below. Allow a period of two minutes to

elapse before rotate the mode selector knob across the

position (see fig. 1).

IMPORTANT

If the appliance requires to be reset frequently, it may be

indicative of a fault, please contact your installer or Vokèra

Customer Services for further advice.

3. HOW TO...

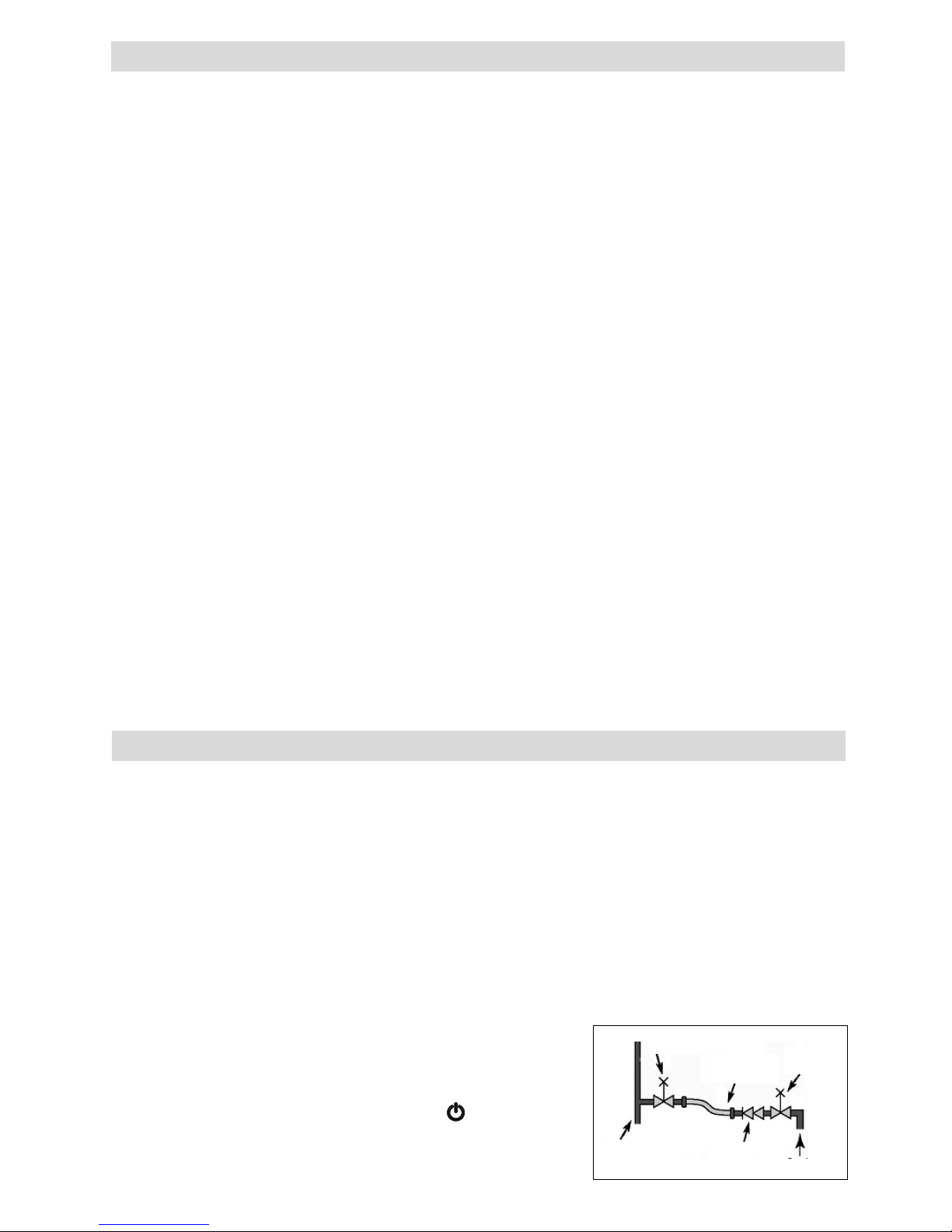

Fig. 2

control

valve

temporary

connection

control

valve

supply pipe

double

check valve

flow/return

pipe

3.3 HOW TO SHUT DOWN THE SYSTEM FOR

SHORT PERIODS

The system and boiler can be shut down for short periods by

simply turning the time clock to the off position. It is also

advisable to turn off the main water supply to the house.

3.4 HOW TO SHUT DOWN THE SYSTEM FOR

LONG PERIODS

If the house is to be left unoccupied for any length of time –

especially during the winter – the system should be thoroughly

drained of all water. The gas, water, and electricity supply to the

house should also be turned off. For more detailed advice

contact your installer.

3.5 HOW TO CARE FOR THE APPLIANCE

To clean the outer casing use only a clean damp cloth. Do

not use any

scourers or

abrasive

cleaners.

Page 6

4

4.1 WHAT IF I SUSPECT A GAS LEAK

If you suspect a gas leak, turn off the gas supply at the gas meter

and contact your installer or local gas supplier. If you require

further advice please contact your nearest Vokèra office.

4.2 WHAT IF I HAVE FREQUENTLY TO TOP-UP

THE SYSTEM

If the system regularly requires topping-up, it may be indicative

of a leak. Please contact your installer and ask him to inspect

the system.

4.3 WHAT IF THE APPLIANCE IS DUE ITS ANNUAL SERVICE

Advice for tenants only

Your landlord should arrange for servicing.

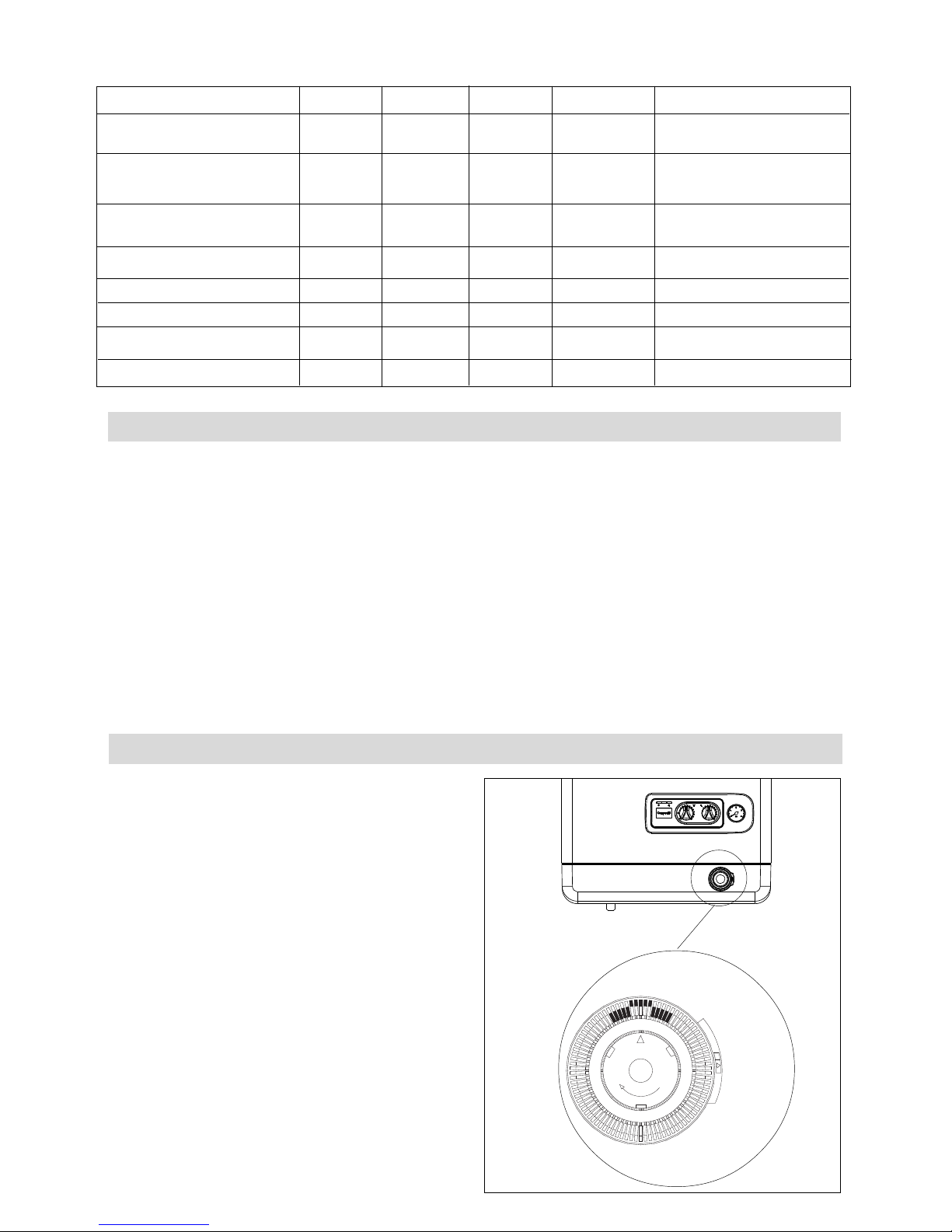

5.1 - SETTING THE VOKÈRA MECHANICAL

CLOCK

If your boiler has been installed with the Vokèra mechanical

clock, it can be used and adjusted as follows:

Setting the time

The time of day can be set by grasping the outer edge of the

black dial and turning it in a clockwise direction until the correct time is in line with the white pointer.

Setting the “switching times”

The “ON” periods are set by sliding the black tappets, adjacent to the time periods required, to the outer edge of the dial.

The tappets that remain at the centre of the dial will be the

“OFF” periods.

The smallest switching time (ON or OFF) is 15 minutes.

To select “AUTO” mode move the selector switch in central

position.

To select “ON” mode move the selector switch in the bottom

position.

To select “OFF” mode move the selector switch in the upper

position.

APPLIANCE STATUS LED AND FAULT CODES

Alarm type Led RED Led YELLOW Led GREEN Action

Purge cycle mode active NA BLINKING BLINKING BLINKING

Alarm high limit thermostat Final BLINKING OFF OFF Reset appliance. Call

engineer if fault re-occurs

Alarm system water pressure Final ON OFF ON Check/refill system pressure,

reset, check.

Call engineer if fault re-occurs

Alarm safety shutdown and/or Final ON OFF OFF Reset appliance. Call

internal fault engineer if fault re-occurs

Temporary fault Temporary OFF OFF BLINKING None

Service operation NA OFF BLINKING OFF None

Flame ON NA OFF OFF ON None

Fault sensors Final BLINKING OFF BLINKING Reset appliance. Call

engineer if fault re-occurs

Boiler stand-by NA OFF OFF BLINKING None

AUTO

ON

OFF

Fig. 3

4. WHAT IF...

5. SETTING THE VOKÈRA...

Advice for homeowners

Please contact Vokèra Customer Service (0844 3910999 (UK)

or 056 7755057 (ROI) if you would prefer a Vokèra service

engineer or agent to service your appliance. Alternatively your

local GAS SAFE registered engineer may be able to service the

appliance for you.

4.4 - WHAT IF I NEED TO CALL AN ENGINEER

If you think your boiler may have developed a fault, please

contact your installer or Vokèra Customer Services (0844

3910999 (UK) or 056 7755057 (ROI) have all your details to

hand including full address and postcode, relevant contact

numbers, and your completed appliance log book.

Page 7

5

The Compact comprises a range of high-efficiency

combination boilers with outputs to DHW of 25kW and 30kW

respectively. These appliances – by design – incorporate

electronic ignition, circulating pump, expansion vessel,

safety valve, pressure gauge and automatic by-pass.

The Compact range is produced as room sealed, category

II2H3P appliances, suitable for internal wall mounting

applications only. Each appliance is provided with a fan

powered flue outlet with an annular co-axial combustion air

intake that can be rotated – horizontally – through 360 degrees

for various horizontal or vertical applications. The Compact can

also be used with the Vokèra twin flue system.

The Compact is approved for use with C13 & C33 type flue

applications.

These appliances are designed for use with a sealed system

only; consequently they are not intended for use on open

vented systems.

This booklet is an integral part of the appliance. It is therefore

necessary to ensure that the booklet is handed to the person

responsible for the property in which the appliance is located/

installed. A replacement copy can be obtained from Vokèra

customer services.

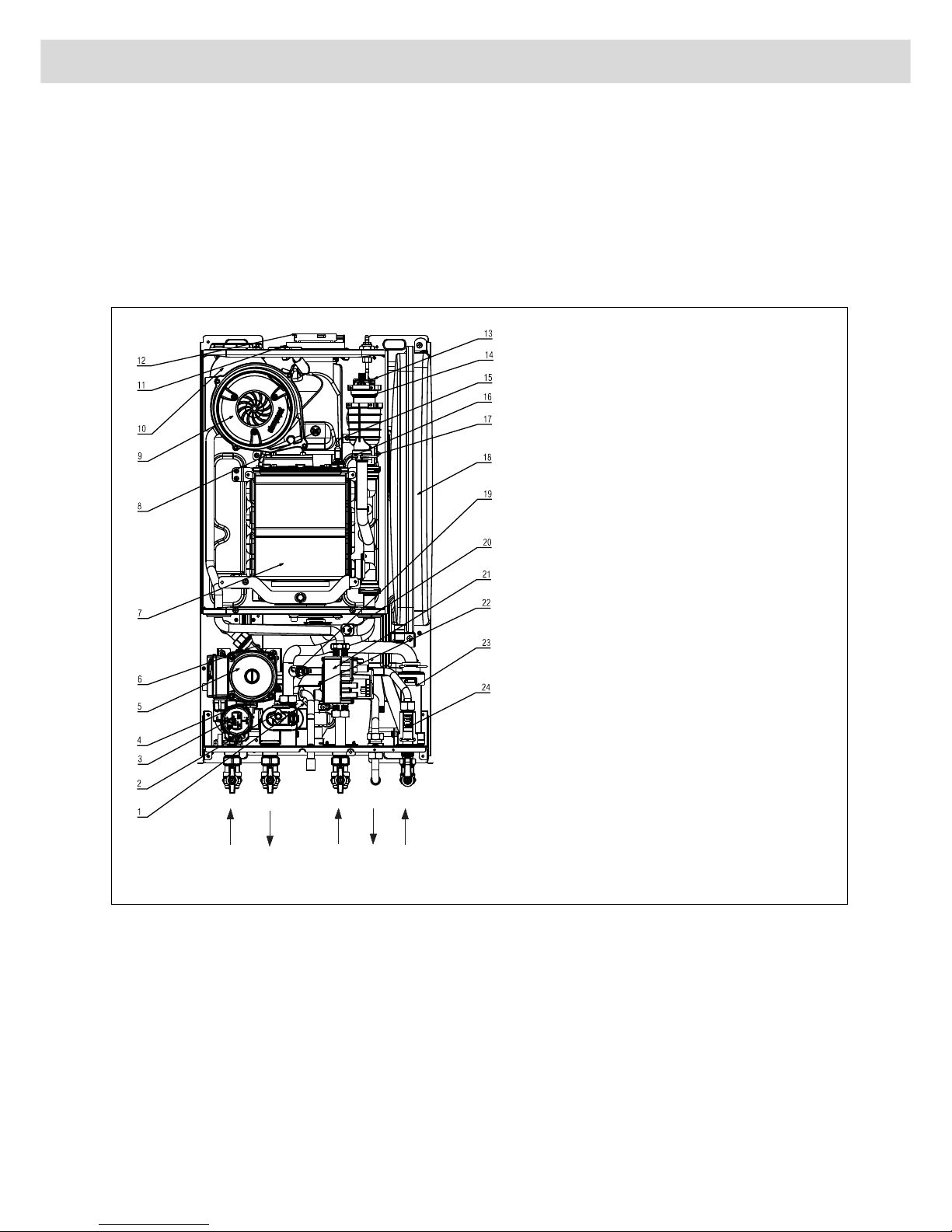

Fig. 4

General layout

1 Domestic hot water heat exchanger

2 Drain valve

3 Three porte valve actuator

4 Safety valve

5 Pump

6 Bottom auto air vent (AAV)

7 Main heat exchanger

8 Flues thermistor (NTC)

9 Fan assembly with mixer

10 Silencer

11 Flue gas analysis test point

12 Flue outlet & air intake

13 Top AAV

14 De-aerator

15 Spark Electrode - Sensing Electrode

16 Ignition transformer

17 Flow thermistor (NTC) - High limit thermostat

18 Expansion vessel

19 Pressure switch

20 Return thermistor (NTC)

21 Gas valve

22 Domestic hot water sensor

23 Condense trap

24 DHW flow switch

R Heating return connection

F Heating flow connection

G Gas connection

O Hot water outlet

I Cold water inlet

INTRODUCTION

INSTALLATION AND SERVICING INSTRUCTIONS

R F G O I

Page 8

6

1.1 PRINCIPLE COMPONENTS

• A fully integrated electronic control board featuring electronic

temperature control, anti-cycle control, pump over-run, selfdiagnostic fault indicator, full air/gas modulation

• Aluminium heat exchanger

• Electronic ignition with flame supervision

• Integral high-head pump

• Fan

• Expansion vessel

• Water pressure switch

• Flue sensor

• Pressure gauge

• Safety valve

1.2 MODE OF OPERATION (at rest)

When the appliance is at rest and there are no requests for

heating or hot water, the following functions are active:

• frost-protection system – the frost-protection system protects

the appliance against the risk of frost damage both for CH and

DHW. For CH line, if the main temperature falls to 5°C, the

appliance will function on minimum power until the

temperature on main reaches 35°C.

Moreover if the DHW temperature falls to 5°C, the appliance

will function on minimum power until the temperature on

main reaches 55°C.

• anti-block function – the anti-block function enables the

pump and divertor valve actuator to be energised for short

periods, when the appliance has been inactive for more than

24-hours.

1.3 MODE OF OPERATION (Heating)

When there is a request for heat via the time clock and/or any

external control, the pump and fan are started, the fan speed

will modulate until the correct signal voltage is received at the

control PCB. At this point an ignition sequence is enabled.

Ignition is sensed by the electronic circuit to ensure flame

stability at the burner. Once successful ignition has been

achieved, the electronic circuitry increases the gas rate to 75%

for a period of 15 minutes. Thereafter, the boiler’s output will

either be increase to maximum or modulate to suit the set

requirement. When the appliance reaches the desired temperature the burner will shut down and the boiler will perform

a three-minute anti-cycle (timer delay).

When the request for heat has been satisfied the appliance

pump and fan may continue to operate to dissipate any residual

heat within the appliance.

1.4 MODE OF OPERATION (Hot water)

When there is a request for DHW via a hot water outlet or tap,

the pump and fan are started, the fan speed will modulate

until the correct signal voltage is received at the control PCB.

At this point an ignition sequence is enabled.

Ignition is sensed by the electronic circuit to ensure flame

stability at the burner. Once successful ignition has been

achieved, the electronic circuitry increases the gas rate to

maximum or will modulate output to stabilise the temperature.

In the event of the appliance exceeding the desired

temperature (set point) the burner will shut down until the

temperature drops. When the request for DHW has been

satisfied the appliance pump and fan may continue to operate

to dissipate any residual heat within the appliance.

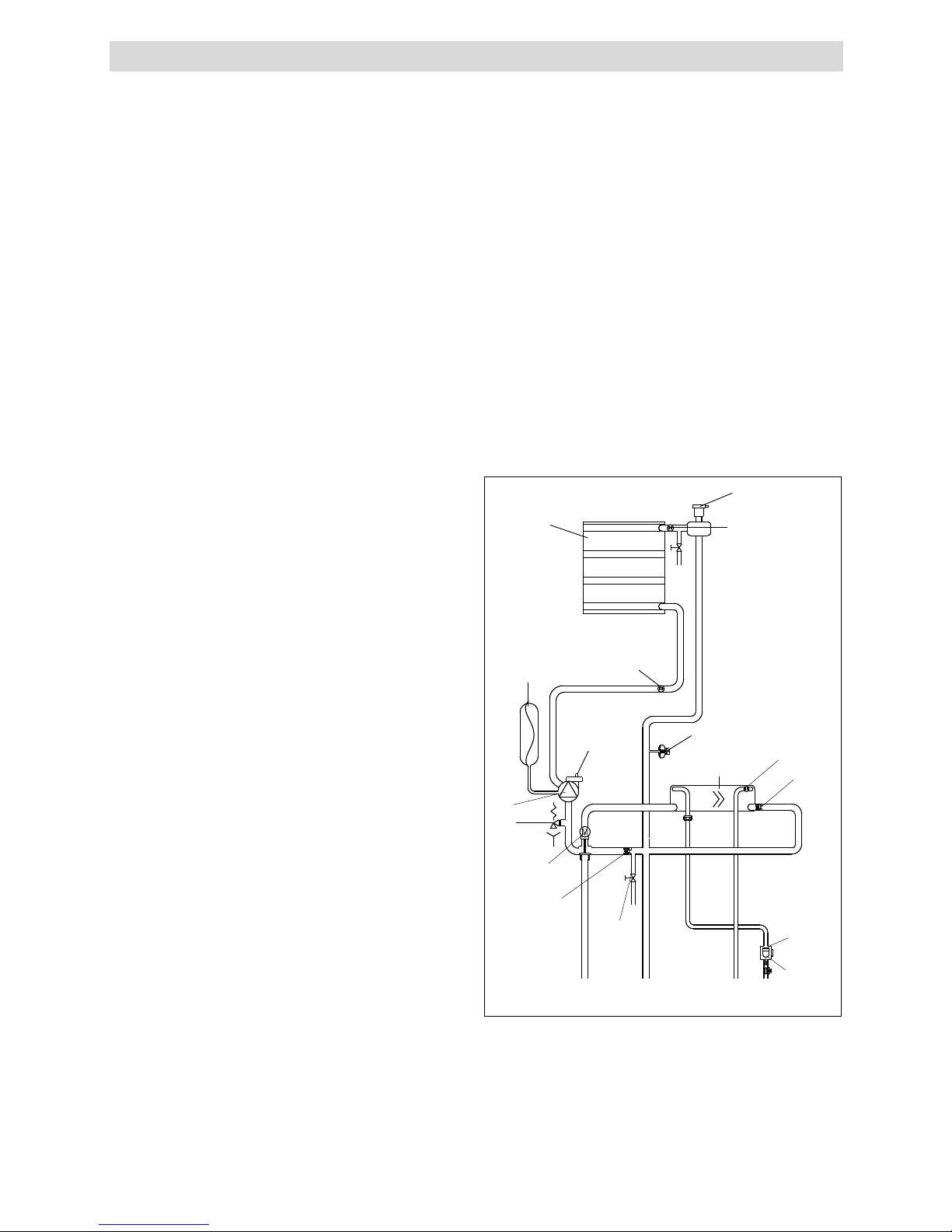

Fig. 5

Expansion

vessel

Safety

valve

Pump

Return

temperature

sensor

Main heat

exchanger

Bottom

AAV

Pressure

switch

DHW heat

exchanger

Diverter

valve

Drain

valve

DHW

temperature

sensor

Flow temperature

sensor

Top AAV

Automatic

by-pass

DHW

non return

valve

CH

return

CH

flow

DHW

inlet

DHW

outlet

Flow

regulator

DHW flow

switch

SECTION 1 - DESIGN PRINCIPLES AND OPERATING SEQUENCE

1.5 SAFETY DEVICES

When the appliance is in use, safe operation is ensured by:

• a water pressure switch that monitors system water pressure

and will de-activate the pump, fan, and burner should the

system water pressure drop below the rated tolerance;

• fan speed sensor to ensure safe operation of the burner;

• a high limit thermostat that over-rides the temperature control

circuit to prevent or interrupt the operation of the burner;

• flame sensor that will shut down the burner when no flame

signal is detected;

• flue sensor;

• a safety valve which releases excess pressure from the

primary circuit.

Page 9

7

2.1 Central Heating Compact 25 Compact 29

Heat input (kW) 20.00 25

Maximum heat output (kW) 60/80°C 19.50 24.40

Minimum working pressure 0.5 bar

Maximum working pressure 2.7 bar

Minimum flow rate 350 l/h

2.2 Domestic Hot Water Compact 25 Compact 29

Heat input (kW) 25.00 29.50

Flow Rate: ΔT35oC 10.2 l/min 12.1 l/min

Maximum inlet pressure 6 bar

Minimum inlet pressure 0.15 bar

Minimum flow rate 2 l/min

2.3 Gas Pressures Compact 25 Compact 29

Inlet pressure (G20) 20.0 mbar

Heating maximum gas rate (m3/hr) 2.12 2.64

DHW maximum gas rate (m3/hr) 2.64 3.12

Minimum gas rate (m3/hr) 0.53 0.63

Injector size (mm) 4.8 5.7

Silencer flange (ø mm) (fitted) 27 31

2.4 Expansion Vessel Compact 25 Compact 29

Capacity 8 litres

Maximum system volume 74 litres

Pre-charge pressure 1 bar

2.5 Dimensions Compact 25 Compact 29

Height (mm) 715

Width (mm) 405

Depth (mm) 248

Dry weight (kg) 30 32

2.6 Clearances COMPACT Range

Sides 12mm

Top 150mm from casing or 25mm above flue elbow (whichever is applicable)

Bottom 150mm

Front 500mm

2.7 Connections COMPACT Range

Flow & return 22mm

Gas 22mm

DHW hot & cold 15mm

Safety valve 15mm

Condense 21mm

2.8 Electrical Compact 25 Compact 29

Power consumption (Watts) 123W 140W

Voltage (V/Hz) 230/50

Internal fuse 3.15A T (for PCB) - 3.15A F (for connections block)

External fuse 3A

2.9 Flue Details (concentric) Compact 25 Compact 29

Maximum horizontal flue length (60/100mm) 4.0m

Maximum vertical flue length (60/100mm) 5.0m

2.9A Flue Details (twin pipes) Compact 25 Compact 29

Maximum horizontal flue length (80mm/80mm) 20m/20m

Maximum vertical flue length (80mm/80mm) 20m/20m

2.10 Efficiency Compact 25 Compact 29

SEDBUK (%) 90.0 90.1

2.11 Emissions Compact 25 Compact 29

CO2 @ maximum output (%) 9.0 9.0

CO2 @ minimum output (%) 9.5 9.5

CO @ maximum output (ppm) 200 160

CO @ minimum output (ppm) 30 35

NOx rating class 5 class 5

SECTION 2 - TECHNICAL DATA

Page 10

8

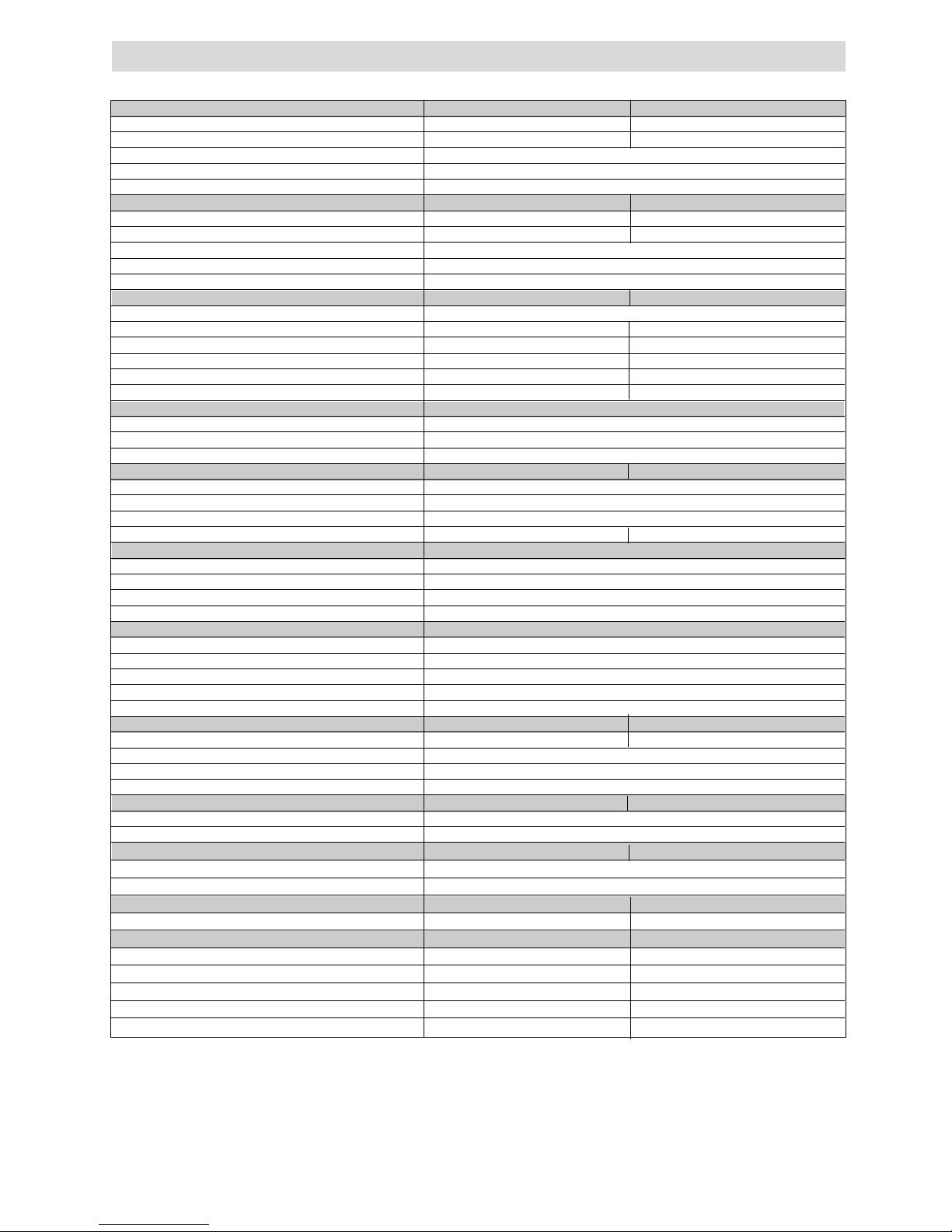

Key Location Minimum distance

A Below an opening (window, air-brick, etc.) 300 mm

B Above an opening (window, air-brick, etc.) 300 mm

C To the side of an opening (window, air-brick, etc.) 300 mm

D Below gutter, drain-pipe, etc. 25 mm

E Below eaves 25 mm

F Below balcony, car-port roof, etc. 25 mm

G To the side of a soil/drain-pipe, etc. 25 mm (60mm for 80/125 - 5” flue)

H From internal/external corner 25 mm (60mm for 80/125 - 5” flue)

I Above ground, roof, or balcony level 300 mm

J From a surface or boundary facing the terminal 600 mm

K From a terminal facing a terminal 1200 mm

L From an opening in the car-port into the building 1200 mm

M Vertically from a terminal on the same wall 1500 mm

N Horizontally from a terminal on the same wall 300 mm

P From a structure to the side of the vertical terminal 300 mm

Q From the top of the vertical terminal to the roof flashing As determined by the fixed collar

of the vertical terminal

R To the side of a boundary 300 mm

S To the side of an opening or window on a pitched roof 600 mm

T Below an opening or window on a pitched roof 2000 mm

V From a vertical terminal to an adjacent opening (window, air-brick, etc.) (call Vokera technical for advice)

W From a vertical terminal to an adjacent vertical terminal 300 mm (only if both terminals are the same hight)

Fig. 6

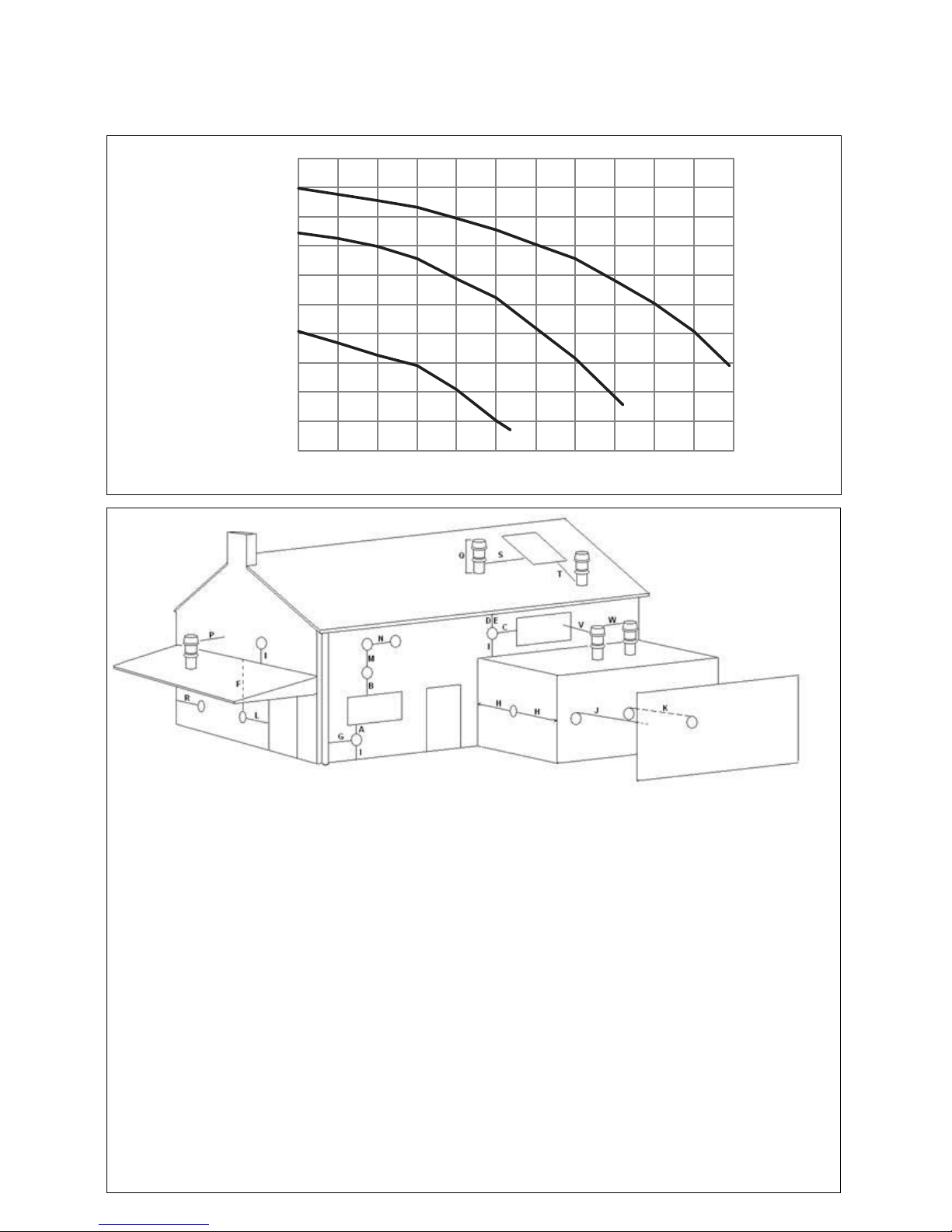

2.12 PUMP DUTY

Fig. 6 shows the flow-rate available – after allowing for pressure

loss through the appliance – for system requirements. When

using this graph, apply only the pressure loss of the system. The

graph is based on a 20

o

C temperature differential.

Fig. 7

Flow rate (l/h)

Residual head (x 100 mbar)

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

5,0

0 100 200 300 400 500 600 700 800 900 1000 1100

1st speed

2nd speed

3rd speed

Page 11

9

SECTION 3 - GENERAL REQUIREMENTS (UK)

This appliance must be installed by a competent person in

accordance with the Gas Safety (Installation & Use)

Regulations.

3.1 RELATED DOCUMENTS

The installation of this boiler must be in accordance with the

relevant requirements of the Gas Safety (Installation & Use)

Regulations, the local building regulations, the current I.E.E.

wiring regulations, the bylaws of the local water undertaking,

the Building Standards (Scotland) Regulation and Building

Standards (Northern Ireland) Regulations.

It should be in accordance also with any relevant requirements

of the local authority and the relevant recommendations of the

following British Standard Codes of Practice.

3.2 LOCATION OF APPLIANCE

The appliance may be installed in any room or internal space,

although particular attention is drawn to the requirements of the

current I.E.E. wiring regulations, and in Scotland, the electrical

provisions of the Building Regulations, with respect to the

installation of the appliance in a room or internal space

containing a bath or shower.

When an appliance is installed in a room or internal space

containing a bath or shower, the appliance or any control

pertaining to it must not be within reach of a person using the

bath or shower. The location chosen for the appliance must

permit the provision of a safe and satisfactory flue and

termination. The location must also permit an adequate air

supply for combustion purposes and an adequate space for

servicing and air circulation around the appliance. Where the

installation of the appliance will be in an unusual location

special procedures may be necessary, BS 6798 gives detailed

guidance on this aspect. A compartment used to enclose the

appliance must be designed and constructed specifically for

this purpose. An existing compartment/cupboard may be utilised

provided that it is modified to suit. Details of essential features

of compartment/cupboard design including airing cupboard

installations are given in BS 6798. This appliance is not

suitable for external installation.

3.3 GAS SUPPLY

The gas meter – as supplied by the gas supplier – must be

checked to ensure that it is of adequate size to deal with the

maximum rated input of all the appliances that it serves.

Installation pipes must be fitted in accordance with BS 6891.

Pipe work from the meter to the appliance must be of adequate

size. Pipes of a smaller size than the appliance gas inlet

connection must not be used. The installation must be tested

for tightness in accordance with BS6891.

If the gas supply serves more than one appliance, it must be

ensured that an adequate supply is maintained to each

appliance when they are in use at the same time.

3.4 FLUE SYSTEM

The terminal should be located where the dispersal of

combustion products is not impeded and with due regard for the

damage and discoloration that may occur to building products

located nearby. The terminal must not be located in a place

where it is likely to cause a nuisance (see fig. 7). In cold and/

or humid weather, water vapour will condense on leaving the

terminal; the effect of such pluming must be considered.

If installed less than 2m above a pavement or platform to which

BS 5440 PART 1 FLUES

BS 5440 PART 2 FLUES & VENTILATION

BS 5449 PART 1 FORCED CIRCULATION HOT WATER SYSTEMS

BS 5546 INSTALLATION OF GAS HOT WATER SUPPLIES FOR DOMESTIC PURPOSES

BS 6798 INSTALLATION OF BOILERS OF RATED INPUT NOT EXCEEDING 60kW

BS 6891 LOW PRESSURE INSTALLATION PIPES

BS 7074 PART 1 APPLICATION, SELECTION, AND INSTALLTION OF EXPANSION VESSELS

AND ANCILLARY EQUIPMENT FOR SEALED WATER SYSTEMS

people have access (including balconies or flat roofs) the

terminal must be protected by a guard of durable material.

The guard must be fitted centrally over the terminal. Refer to BS

5440 Part 1, when the terminal is 0.5 metres (or less) below

plastic guttering or 1 metre (or less) below painted eaves.

3.5 AIR SUPPLY

The following notes are intended for general guidance only.

This appliance is a room-sealed, fan-flued boiler, consequently

it does not require a permanent air vent for combustion air

supply. When installed in a cupboard or compartment, ventilation

for cooling purposes is also not required.

3.6 WATER CIRCULATION

Detailed recommendations are given in BS 5449 Part 1 and BS

6798. The following notes are for general guidance only.

3.6.1 PIPEWORK

It is recommended that copper tubing to BS 2871 Part 1 is used

in conjunction with soldered capillary joints. Where possible

pipes should have a gradient to ensure air is carried naturally

to air release points and that water flows naturally to drain

cocks. Except where providing useful heat, pipes should be

insulated to avoid heat loss and in particular to avoid the

possibility of freezing. Particular attention should be paid to

pipes passing through ventilated areas such as under floors,

loft space and void areas.

3.6.2 AUTOMATIC BY-PASS

The appliance has a built-in automatic by-pass, consequently there

is no requirement for an external by-pass, however the design of the

system should be such that it prevents boiler ‘cycling’.

3.6.3 DRAIN COCKS

These must be located in accessible positions to facilitate

draining of the appliance and all water pipes connected to the

appliance. The drain cocks must be manufactured in accordance

with BS 2879.

3.6.4 AIR RELEASE POINTS

These must be positioned at the highest points in the system

where air is likely to be trapped. They should be used to expel

trapped air and allow complete filling of the system.

3.6.5 EXPANSION VESSEL

The appliance has an integral expansion vessel to

accommodate the increased volume of water when the system

is heated. It can accept up to 8 litres of expansion from within

the system, generally this is sufficient, however if the system

has an unusually high water content, it may be necessary to

provide additional expansion capacity (see 6.18).

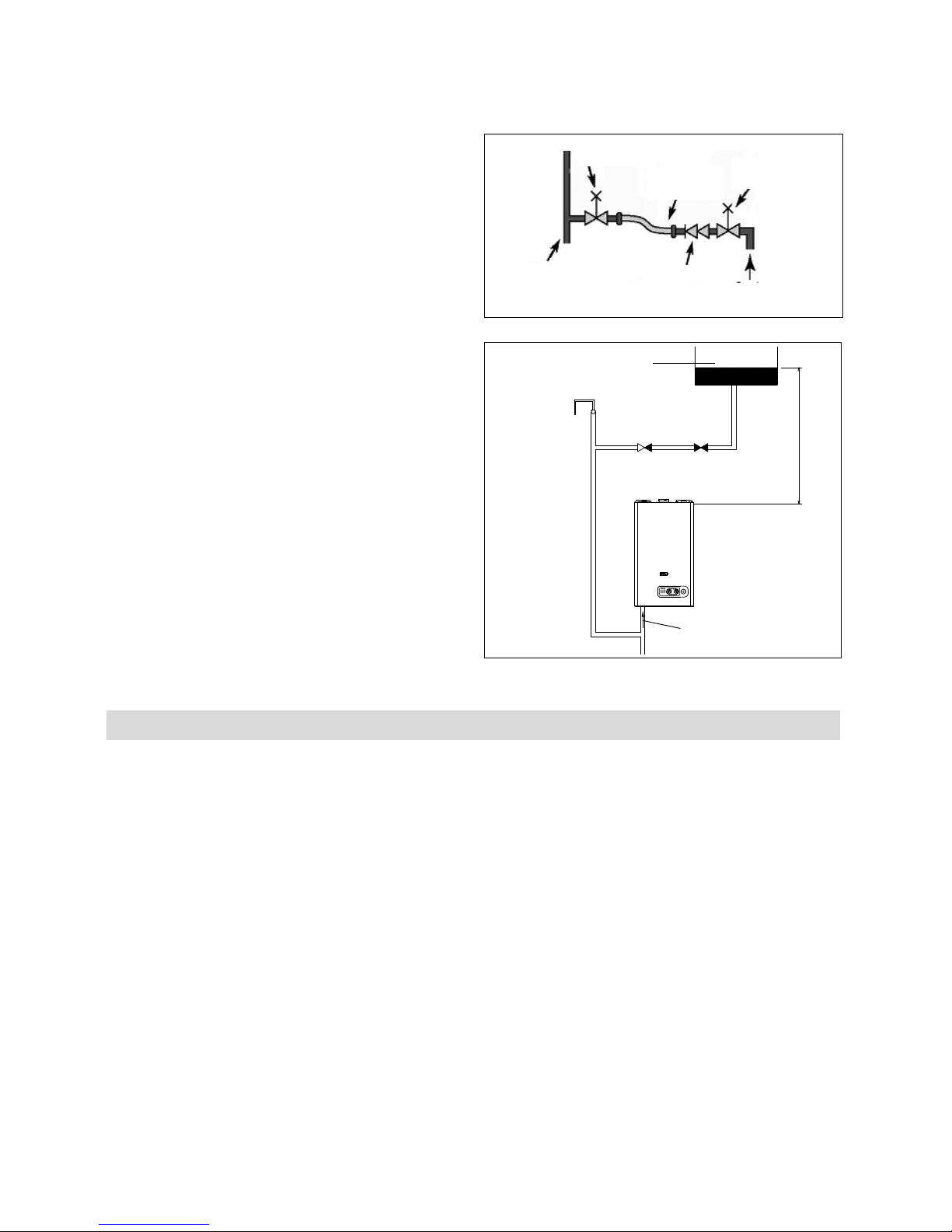

3.6.6 FILLING POINT

A method for initial filling of the system and replacing water lost

during servicing etc. directly from the mains supply, is provided

(see fig. 8). This method of filling complies with the current Water

Supply (Water Fittings) Regulations 1999 and Water Bylaws

2000 (Scotland). If an alternative location is preferred, it should

be connected as detailed in fig. 8.

3.6.7 LOW PRESSURE SEALED SYSTEM

An alternative method of filling the system would be from an

independent make-up vessel or tank mounted in a position at

least 1 metre above the highest point in the system and at

least 5 metres above the boiler (see fig. 9).

The cold feed from the make-up vessel or tank must be fitted

Page 12

10

This appliance must be installed by a competent person in

accordance with and defined by, the Standard Specification

(Domestic Gas Installations) Declaration (I.S. 813).

3A.1 RELATED DOCUMENTS

The installation of this boiler must be in accordance with the

relevant requirements of the local building regulations, the

current ETCI National Rules for Electrical Installations and the

bylaws of the local water undertaking.

It should be in accordance also with any relevant requirements

of the local and/or district authority.

3A.2 LOCATION OF APPLIANCE

The appliance may be installed in any room or internal space,

although particular attention is drawn to the requirements of

the current ETCI National Rules for Electrical Installations,

and I.S. 813, Annex K.

When an appliance is installed in a room or internal space

containing a bath or shower, the appliance or any control

pertaining to it must not be within reach of a person using the

bath or shower.

The location chosen for the appliance must permit the provision

of a safe and satisfactory flue and termination. The location

must also permit an adequate air supply for combustion

purposes and an adequate space for servicing and air circulation

around the appliance. Where the installation of the appliance

will be in an unusual location special procedures may be

necessary, refer to I.S. 813 for detailed guidance on this aspect.

A compartment used to enclose the appliance must be designed

SECTION 3A - GENERAL REQUIREMENTS (EIRE)

with an approved non-return valve and stopcock for isolation

purposes. The feed pipe should be connected to the return

pipe as close to the boiler as possible.

3.6.8 FREQUENT FILLING

Frequent filling or venting of the system may be indicative of a

leak. Care should be taken during the installation of the

appliance to ensure all aspects of the system are capable of

withstanding pressures up to at least 3 bar.

3.7 ELECTRICAL SUPPLY

The appliance is supplied for operation on 230V @ 50Hz

electrical supply; it must be protected with a 3-amp fuse. The

method of connection to the mains electricity supply must allow

for complete isolation from the supply. The preferred method

is by using a double-pole switch with a contact separation of at

least 3,5mm (3° high-voltage category). The switch must only

supply the appliance and its corresponding controls, i.e. time

clock, room thermostat, etc. Alternatively an un-switched

shuttered socket with a fused 3-pin plug both complying with

BS 1363 is acceptable.

3.8 MOUNTING ON A COMBUSTIBLE SURFACE

If the appliance is to be fitted on a wall of combustible material,

a sheet of fireproof material must protect the wall.

3.9 TIMBER FRAMED BUILDINGS

If the appliance is to be fitted in a timber framed building, it

should be fitted in accordance with the Institute of Gas Engineers

publication (IGE/UP/7) ‘Guide for Gas Installations in Timber

Frame Buildings’.

3.10 INHIBITORS

Vokèra recommend that an inhibitor - suitable for use with

aluminium heat exchangers - is used to protect the boiler and

system from the effects of corrosion and/or electrolytic action.

The inhibitor must be administered in strict accordance with

the manufacturers instructions*.

*Water treatment of the complete heating system - including the

boiler - should be carried out in accordance with BS 7593 and

the Domestic Water Treatment Association’s (DWTA) code of

practice.

flow/return

pipe

control

valve

temporary

connection

control

valve

supply

pipe

double

check valve

Fig. 8

Fig. 9

Make-up vessel

or tank

Automatic

air-vent

Non-return

valve

Stopcock

5.0 metres minimum

Heating

return

3.11 SHOWERS

If the appliance is intended for use with a shower, the shower

must be thermostatically controlled and be suitable for use

with a combination boiler.

and constructed specifically for this purpose. An existing

compartment/cupboard may be utilised provided that it is

modified to suit.

This appliance is not suitable for external installation.

3A.3 GAS SUPPLY

The gas meter – as supplied by the gas supplier – must be

checked to ensure that it is of adequate size to deal with the

maximum rated input of all the appliances that it serves.

Installation pipes must be fitted in accordance with I.S. 813.

Pipe work from the meter to the appliance must be of adequate

size. Pipes of a smaller size than the appliance gas inlet

connection must not be used. The installation must be tested

for tightness in accordance with I.S. 813.

If the gas supply serves more than one appliance, it must be

ensured that an adequate supply is maintained to each

appliance when they are in use at the same time.

3A.4 FLUE SYSTEM

The terminal should be located where the dispersal of

combustion products is not impeded and with due regard for the

damage and discoloration that may occur to building products

located nearby. The terminal must not be located in a place

where it is likely to cause a nuisance (see I.S. 813).

In cold and/or humid weather, water vapour will condense on

leaving the terminal; the effect of such pluming must be

considered.

If installed less than 2m above a pavement or platform to which

people have access (including balconies or flat roofs) the

Page 13

11

terminal must be protected by a guard of durable material. The

guard must be fitted centrally over the terminal. Refer to I.S. 813,

when the terminal is 0.5 metres (or less) below plastic guttering

or 1 metre (or less) below painted eaves.

3A.5 AIR SUPPLY

The following notes are intended for general guidance only.

This appliance is a room-sealed, fan-flued boiler, consequently

it does not require a permanent air vent for combustion air

supply.

When installed in a cupboard or compartment, ventilation for

cooling purposes is also not required.

3A.6 WATER CIRCULATION

Specific recommendations are given in I.S. 813. The following

notes are for general guidance only.

3A.6.1 PIPEWORK

It is recommended that copper tubing be used in conjunction

with soldered capillary joints.

Where possible pipes should have a gradient to ensure air is

carried naturally to air release points and that water flows

naturally to drain cocks.

Except where providing useful heat, pipes should be insulated

to avoid heat loss and in particular to avoid the possibility of

freezing. Particular attention should be paid to pipes passing

through ventilated areas such as under floors, loft space and

void areas.

3A.6.2 AUTOMATIC BY-PASS

The appliance has a built-in automatic by-pass, consequently

there is no requirement for an external by-pass, however the

design of the system should be such that it prevents boiler

‘cycling’.

3A.6.3 DRAIN COCKS

These must be located in accessible positions to facilitate

draining of the appliance and all water pipes connected to the

appliance.

3A.6.4 AIR RELEASE POINTS

These must be positioned at the highest points in the system

where air is likely to be trapped. They should be used to expel

trapped air and allow complete filling of the system.

3A.6.5 EXPANSION VESSEL

The appliance has an integral expansion vessel to

accommodate the increased volume of water when the system

is heated. It can accept up to 8 litres of expansion from within

the system, generally this is sufficient, however if the system

has an unusually high water content, it may be necessary to

provide additional expansion capacity (see 6.18).

3A.6.6 FILLING POINT

A method for initial filling of the system and replacing water lost

during servicing etc. is provided (see fig. 8). You should ensure

this method of filling complies with the local water authority

regulations.

3A.6.7 LOW PRESSURE SEALED SYSTEM

An alternative method of filling the system would be from an

independent make-up vessel or tank mounted in a position at

least 1 metre above the highest point in the system and at least

5 metres above the boiler (see fig. 9). The cold feed from the

make-up vessel or tank must be fitted with an approved nonreturn valve and stopcock for isolation purposes. The feed pipe

should be connected to the return pipe as close to the boiler as

possible.

3A.6.8 FREQUENT FILLING

Frequent filling or venting of the system may be indicative of a

leak. Care should be taken during the installation of the

appliance to ensure all aspects of the system are capable of

withstanding pressures up to at least 3 bar.

3A.7 ELECTRICAL SUPPLY

The appliance is supplied for operation on 230V @ 50Hz

electrical supply; it must be protected with a 3-amp fuse. The

method of connection to the mains electricity supply must allow

for complete isolation from the supply. The preferred method

is by using a double-pole switch with a contact separation of at

least 3,5 mm (3° high-voltage category). The switch must only

supply the appliance and its corresponding controls, i.e. time

clock, room thermostat, etc.

3A.8 MOUNTING ON A COMBUSTIBLE

SURFACE

If the appliance is to be fitted on a wall of combustible material,

a sheet of fireproof material must protect the wall.

3A.9 TIMBER FRAMED BUILDINGS

If the appliance is to be fitted in a timber framed building, it

should be fitted in accordance with I.S. 813 and local Building

Regulations.

The Institute of Gas Engineers publication (IGE/UP/7) ‘Guide

for Gas Installations in Timber Frame Buildings’ gives specific

advice on this type of installation.

3A.10 INHIBITORS

Vokèra recommend that an inhibitor - suitable for use with

aluminium heat exchangers - is used to protect the boiler and

system from the effects of corrosion and/or electrolytic action.

The inhibitor must be administered in strict accordance with

the manufacturers instructions*.

*Water treatment of the complete heating system - including the

boiler - should be carried out in accordance with I.S. 813 and

the Domestic Water Treatment Association’s (DWTA) code of

practice.

3A.11 SHOWERS

If the appliance is intended for use with a shower, the shower

must be thermostatically controlled and be suitable for use

with a combination boiler.

3A.12 DECLARATION OF CONFORMITY

A Declaration of Conformity (as defined in I.S. 813) must be

provided on completion of the installation.

A copy of the declaration must be given to the responsible

person and also to the gas supplier if required.

Page 14

12

Fig. 11

4.1 DELIVERY

Due to the weight of the appliance it may be necessary for two

people to lift and attach the appliance to its mounting. The

appliance is contained within a heavy-duty cardboard carton.

Lay the carton on the floor with the writing the correct way up.

4.2 CONTENTS

Contained within the carton is:

• the boiler

• the wall bracket

• carton template

• an accessories pack containing appliance service

connections and washers

• the instruction pack containing the installation, servicing & user

instructions, guarantee registration card and a 3-amp fuse.

4.3 UNPACKING

At the top of the carton pull both sides open – do not use a knife

– unfold the rest of the carton from around the appliance,

carefully remove all protective packaging from the appliance

and lay the accessories etc. to one side. Protective gloves

should be used to lift the appliance, the appliance back-frame

should be used for lifting points.

4.4 PREPARATION FOR MOUNTING THE AP-

PLIANCE

The appliance should be mounted on a smooth, vertical, noncombustible surface, which must be capable of supporting the

full weight of the appliance. Care should be exercised when

determining the position of the appliance with respect to hidden

obstructions such as pipes, cables, etc.

When the position of the appliance has been decided – using

the template supplied – carefully mark the position of the wallmounting bracket (see fig. 10) and flue-hole (if applicable).

4.5 FITTING THE FLUE

The top flue outlet permits both horizontal and vertical flue

applications to be considered, alternatively, the Vokèra twin

flue system can be utilised if longer flue runs are required.

4.5.1 CONCENTRIC HORIZONTAL FLUE

(For concentric vertical flue, see 4.5.2).

(For twin flue applications, see 4.5.3).

The appliance can be used with either the Vokèra condensing

60/100mm concentric flue system or the optional 80/125mm

concentric flue system.

NOTE

These instructions relate only to the Vokèra condensing 60/

100mm concentric flue system. For specific details on the

installation of the 80/125mm concentric flue system please

refer to the instructions supplied. The appliance flue outlet

elbow can be rotated through 360º on its vertical axis. In addition

the flue may be extended from the outlet elbow in the horizontal

plane (see 2.9). A reduction must also be made to the maximum

length (see table below) when additional bends are used.

Reduction for additional bends

Bend Reduction in maximum flue length for each bend

45º bend 0.5 metre

90º bend 1.0 metre

Horizontal flue terminals and accessories

Part No. Description Length

29450120 Horizontal flue kit 900mm

29450121 Telescopic flue kit 350/530mm

522 Plume management kit 1370mm

29450123 90-degree bend N/A

29450124 45-degree bends (pair) N/A

29450125 500mm extension 500mm

29450126 1000mm extension 1000mm

29450127 2000m extension 2000mm

29450128 Telescopic extension 350/730mm

529 Wall bracket pack (5) 208mm

Using the template provided (A), mark and drill a 125mm hole for

the passage of the flue pipe. The hole should be drilled to ensure

any condense fluid that forms, is allowed to drain back to the

appliance (see fig. 12). The fixing holes for the wall-mounting

bracket should now be drilled and plugged, an appropriate type

and quantity of fixing should be used to ensure that the bracket

is mounted securely. Once the bracket has been secured to the

wall, mount the appliance onto the bracket.

FITTING THE TELESCOPIC HORIZONTAL FLUE KIT

In some instances It may necessary to cut the inner 60mm pipe

of the flue bend at the point indicated (fig.13 pos. A) to allow for

easier insertion to the boiler flue spigot.

FITTING THE HORIZONTAL FLUE KIT

Carefully measure the distance from the centre of the appliance

flue outlet to the edge of the finished outside wall (dimension

X). Add 65mm to dimension X to give you Dimension Y (see fig

12). Measure dimension Y from the terminal end of the concentric

flue pipe and cut off the excess ensuring any burrs are removed.

Pass the concentric flue pipe through the previously drilled

hole. Fit the flue bend to the boiler flue outlet and insert the

concentric flue pipe into the flue bend ensuring the correct seal

is made. Using the clamp, gasket, and screws supplied, secure

the flue bend to the appliance flue spigot.

NOTE

Fit the internal (white) trim to the flue assembly prior to

connecting the flue pipe to the bend.

You must ensure that the entire flue system is properly supported

and connected. Seal the flue assembly to the wall using cement

or a suitable alternative that will provide satisfactory weatherproofing. The exterior trim can now be fitted.

SECTION 4 - INSTALLATION

Fig. 10

A

Terminal or

extension

Outer clamps

Page 15

13

Fig.13

EXTENDING THE FLUE

Connect the bend – supplied with the terminal kit – to the top

of the boiler using clamp (supplied) see fig. 11. The additional

bends & extensions have push-fit connections, care should

be taken to ensure that the correct seal is made when assembling the flue system. Connect the required number of flue

extensions or bends (up to the maximum equivalent flue

length) to the flue terminal (see fig. 11-14). The flue system

should have a minimum of 1º; maximum of 3º rise from the

boiler to outside, to ensure any condense fluid that forms, is

allowed to drain back to the appliance.

NOTE

When cutting an extension to the required length, you must

ensure that the excess is cut from the plain end of the extension

(see fig. 11-14). Remove any burrs, and check that all seals

are located properly. You must ensure that the entire flue

system is properly supported and connected. Seal the flue

assembly to the wall using cement or a suitable alternative

that will provide satisfactory weatherproofing. The interior and

exterior trim can now be fitted.

4.5.2 CONCENTRIC VERTICAL FLUE

The appliance can be used with either the Vokèra condensing

60/100mm concentric flue system or the optional 80/125mm

concentric flue system.

NOTE

These instructions relate only to the Vokèra condensing 60/

100mm concentric flue system. For specific details on the

installation of the 80/125mm concentric flue system please

refer to the instructions supplied.

The vertical flue terminal can be connected directly to the

appliance flue outlet. Alternatively, an extension or bend can

be connected to the appliance flue outlet if desired, however

if additional bends are fitted, a reduction must be made to the

maximum flue length (see table below).

Reduction for bends

Bend Reduction in maximum flue length for each

bend

45º bend 0.5 metre

90º bend 1.0 metre

Vertical flue terminal and accessories

Part No. Description Length

29450122 Vertical flue terminal 1000mm

531 Pitched roof flashing plate N/A

532 Flat roof flashing plate N/A

29450123 90-degree bend N/A

29450124 45-degree bends (pair) N/A

29450125 500mm extension 500mm

29450126 1000mm extension 1000mm

29450127 2000mm extension 2000mm

29450128 Telescopic extension 350/730mm

529 Wall bracket pack (5) 208mm

Using the dimensions given in fig. 12 as a reference, mark and

cut a 125mm hole in the ceiling and/or roof.

Fig. 10

Fig. 15

“X”

12/15/20HE = 202mm

25/30/35HE = 218mm

130mm

Fit the appropriate flashing plate to the roof and insert the

vertical flue terminal through the flashing plate from the outside,

ensuring that the collar on the flue terminal fits over the flashing.

The fixing holes for the wall-mounting bracket should now be

drilled and plugged, an ‘appropriate type and quantity of fixing

should be used to ensure that the bracket is mounted securely.

Once the bracket has been secured to the wall, mount the

appliance onto the bracket.

A

Fig. 12

Page 16

14

IMPORTANT

The vertical flue terminal is 1.0 metre in length and cannot be

cut; therefore it may be necessary to adjust the height of the

appliance to suit or use a suitable extension.

Connect the vertical flue assembly to the boiler flue spigot using

the 100mm clip, gasket & screws (supplied), ensuring the

correct seal is made. The flue support bracket (supplied with the

vertical flue kit) can now be fitted.

If the vertical flue requires extension/s or additional bend/s,

connect the required number of flue extensions or bends (up

to the maximum equivalent flue length) between the boiler and

vertical flue assembly (see fig. 14).

Ensure that any horizontal sections of the flue system have a

minimum 1º; maximum 3º fall back to the boiler (1º = 17mm per

1000mm).

NOTE

When cutting an extension to the required length, you must

ensure that the excess is cut from the plain end of the extension.

Remove any burrs, and check that any seals are located

properly.

You must ensure that the entire flue system is properly supported

and connected.

4.5.3 TWIN FLUE SYSTEM

The Vokèra twin flue system enables greater flue distances to

be achieved than that of a concentric flue system. It can be used

for horizontal or vertical applications, however the twin flue

system must be converted to the dedicated concentric flue kit

for termination. It is essential that the installation of the twin flue

system be carried out in strict accordance with these instructions.

GUIDANCE NOTES ON TWIN FLUE INSTALLATION

• The flue must have a have a minimum 1º; maximum 3º (1º =

17mm per 1000mm) fall back to the appliance to allow any

condensate that may form in the flue system to drain via the

condensate drain. Consideration must also be given to the

fact that there is the possibility of a small amount of condensate

dripping from the terminal.

• Ensure that the entire flue system is adequately supported,

use at least one bracket for each extension.

• The entire flue system must be adequately insulated to

maintain heat within the flue system thereby reducing the

possibility of condensate production.

• As the exhaust outlet pipe can reach very high temperatures

it must be protected to prevent persons touching the hot

surface.

• The condensate drain pipe must be connected in accordance

with building regulations.

Reduction for bends

Bend Reduction in maximum flue length for

each bend

45º bend 1.0 metre

90º bend 1.0 metre

Twin flue accessories

Part No. Description Length

0225805 Horizontal flue terminal 1.0 metre

0225810 Vertical flue terminal 1.0 metre

359 Twin adapter kit N/A

531 Pitched roof flashing plate N/A

532 Flat roof flashing plate N/A

0225815 Condensate drain kit N/A

0225820 0.25m extension (pair) 250mm

0225825 0.5m extension (pair) 500mm

0225830 1.0m extension (pair) 1000mm

0225835 2.0m extension (pair) 2000mm

0225840 45º bend (pair) N/A

0225845 90º bend (pair) N/A

0225850 Twin bracket (5) N/A

0225855 Single bracket (5) N/A

MOUNTING THE BOILER

The fixing holes for the wall-mounting bracket should now be

drilled and plugged, an appropriate type and quantity of fixing

should be used to ensure that the bracket is mounted securely.

Fig. 12

HORIZONTAL TERMINATION (fig. 14)

The twin flue system must be converted to the dedicated

concentric flue kit for termination.

• The horizontal terminal is supplied with a built-in converter

box and cannot be shortened.

• A 130mm hole is required for the passage of the concentric

terminal through the wall.

• The air inlet pipe must always be level with or below, that of

the exhaust pipe.

Depending on site conditions it may be preferable to install the

terminal assembly prior to fitting the twin flue pipes.

Mark and drill a level 130mm hole for the passage of the

horizontal flue terminal. Insert the terminal assembly into the

flue hole.

Push-fit the twin flue pipes onto the concentric to twin converter

box ensuring that the exhaust pipe connects to the exhaust

connection on the concentric to twin converter.

If necessary cut the plain ends (male) of the twin flue pipes to

allow connection to the concentric to twin converter.

NOTE

Before cutting twin flue pipes ensure allowances have been

made for connection onto the previous piece and onto the

concentric to twin converter. The last twin flue pipes must be

Once the bracket has been secured to the wall, mount the

appliance onto the bracket.

INSTALLATION OF TWIN ADAPTOR KIT (fig. 12 & 13)

• Insert the exhaust connection manifold (A) onto the

appliance flue outlet.

• Remove the blanking plate (located to the left of the appliance

flue outlet) and – using the same screws – install the air inlet

plate (B).

• Using the hole in the exhaust connection manifold as a

guide, drill a 3mm hole in the appliance flue spigot and

secure the exhaust manifold connection to the flue spigot

using the screw provided (C).

• Using the two holes in the air inlet plate as a guide, drill a 3mm

hole in each and secure the air inlet pipe/bend using the

screws provided.

The twin flue pipes extensions and accessories can now be

installed by pushing together (the plain end of each extension

or bend should be pushed approximately 50mm into the female

socket of the previous piece).

B

A

C

Fig. 13

Page 17

15

pushed 50mm onto the male spigots of the concentric to twin

converter.

NOTE

Seal the flue terminal assembly to the wall using cement or a

suitable alternative that will provide satisfactory

weatherproofing. The interior and exterior trim can now be

fitted.

VERTICAL TERMINATION (fig. 15)

The twin flue system must be converted to the dedicated

concentric flue kit for termination.

• The vertical terminal is supplied with a built-in converter box

and cannot be shortened.

• A 130mm hole is required for the passage of the concentric

terminal through the ceiling and/or roof.

Depending on site conditions it may be preferable to install the

terminal assembly prior to fitting the twin flue pipes.

Fit the appropriate flashing plate to the roof and insert the

vertical flue terminal through the flashing plate from the outside,

ensuring that the collar on the flue terminal fits over the flashing.

Push-fit the twin flue pipes onto the concentric to twin converter

ensuring that the exhaust pipe connects to the exhaust

connection on the concentric to twin converter.

If necessary cut the plain ends (male) of the twin flue pipes to

allow connection to the concentric to twin converter.

NOTE

• Before cutting twin flue pipes ensure allowances have been

made for connection onto the previous piece and onto the

concentric to twin converter. The last twin flue pipes must be

pushed 50mm onto the male spigots of the concentric to twin

converter.

• You must ensure that the entire flue system is properly

supported and connected.

• Ensure that any horizontal sections of pipe have a 1º fall

towards the appliance (17mm per 1000mm).

Fig. 14

Fig. 15

4.6 CONNECTING THE GAS AND WATER

The appliance is supplied with an accessory pack that includes

service valves.

The service valves are for welding. The accessory pack contains

sealing washers’ etc, for use with the service valves.

NOTE

It will be necessary to hold the valve with one spanner whilst

tightening with another

4.6.1 GAS (fig. 16)

The appliance is supplied with a 22mm service valve, connect

a 22mm pipe to the inlet of the valve and tighten both nuts.

NOTE

It will be necessary to calculate the diameter of the gas supply

pipe to ensure the appliance has an adequate supply of gas.

4.6.2 FLOW & RETURN (fig. 16)

The appliance is supplied with 22mm service valves for the flow

and return connections, connect a 22mm pipe to the inlet of

each valve and tighten both nuts.

NOTE

Depending on system requirements, it may necessary to

increase the size of the flow & return pipe work after the service

valve connections.

4.6.3 COLD WATER INLET (fig. 16)

The appliance is supplied with a 15mm combined stopcock

and double check-valve, connect a 15mm pipe to the inlet of

the stopcock and tighten both nuts.

4.6.4 HOT WATER OUTLET (fig. 16)

The appliance is supplied with a 15mm outlet connection,

connect a 15mm pipe to the outlet connection and tighten

both nuts.

1-deg = 17mm

Page 18

16

4.6.5 SAFETY VALVE (fig. 16)

Connect the safety valve connection pipe to the safety valve

outlet. Connect a discharge pipe to the other end of the safety

valve connection pipe and tighten. The discharge pipe must

have a continuous fall away from the appliance to outside and

allow any water to drain away thereby eliminating the possibility

of freezing. The discharge pipe must terminate in a position

where any water – possibly boiling – discharges safely without

causing damage or injury, but is still visible.

4.6.6 CONDENSE PIPE

During normal operation the boiler produces condense which

is collected in a trap located in the lower part of the boiler. A

flexible pipe (condense outlet pipe) is connected to the outlet

of the trap. The flexible pipe must be connected to a plastic

waste pipe only. The plastic waste pipe must have a minimum

of a 3º fall towards the drain. Any external run of pipe should

be insulated to prevent the risk of freezing.

4.6.7 CONNECTING THE CONDENSATE OUTLET

Gently pull the condense outlet pipe down from its location

inside the boiler until approximately 100mm protrudes from the

underside of the boiler. Connect a suitable plastic (not copper)

pipe (no less than 20mm diameter) to the outlet pipe and ensure

it discharges in accordance with building regulations or other

rules in force.

4.7 ELECTRICAL CONNECTIONS

The boiler is supplied with a 2-metre fly-lead. This lead can be

used for connection to the electrical supply. Connect the flylead to a fused plug or fused isolator in the following way:

••

••

• brown wire to LIVE supply

• blue wire to NEUTRAL supply

• green/yellow to EARTH connection.

Insert the supplied 3-AMP fuse into the fused isolator or fused

plug.

Should the fly-lead be unsuitable, refer to 4.7.3 for details on

how to connect the electrical supply directly to the boiler.

The electrical supply must be as specified in section 3/3A. A

qualified electrician should connect the appliance to the

electrical supply. If controls - external to the appliance - are

required, a competent person must undertake the design of any

external electrical circuits, please refer to section 8 for detailed

instructions. ANY EXTERNAL CONTROL OR WIRING MUST

BE SERVED FROM THE SAME ISOLATOR AS THAT OF THE

APPLIANCE. The supply cable from the isolator to the appliance must be 3-core flexible sized 0.75mm to BS 6500 or

equivalent. Wiring to the appliance must be rated for operation

in contact with surfaces up to 90 ºC.

4.7.1 CASING REMOVAL (fig. 17)

To gain internal access to the appliance you must first remove

the casing, proceed as outlined below:

• locate and unscrew the 2-screws (A) that secure the outer

casing to the appliance

• lift the casing upward to disengage it from the top locating

hooks and then remove

Fig. 16

• store the casing and screws safely until required. Re-fit in

the reverse order

• gently lower the control fascia until it rests.

4.7.2 APPLIANCE TERMINAL BLOCK

The appliance terminal block is located on the rear of the

control fascia. Remove the casing as described in 4.7.1. Gently

pull the control panel forwards and down. Locate the terminal

block cover (fig. 18).

NOTE

The appliance comes with a factory fitted link (‘TA’) to allow

basic operation of the boiler via the mode selector switch. If it

is anticipated that external controls will be required please refer

to the wiring diagrams in section 8 for more detailed information.

4.7.3 CONNECTING THE MAINS (230V) INPUT

Unhook and remove the terminal block cover (230V). Pass the

cable through the cable anchorage point. Connect the supply

cable wires (LIVE, NEUTRAL, & EARTH) to their corresponding

terminals (L, N, & E) on the appliance – high voltage – terminal

block. When connecting the EARTH wire, ensure that it’s left

slightly longer that the others, this will prevent strain on the

EARTH wire should the cable become taut. Do not remove the

link wire unless additional external controls are to be fitted (see

section 8). The securing screw on the cable anchorage should

now be tightened. This must be done before the terminal block

cover is re-fitted in its position.

NOTE

It is the installer’s responsibility to ensure that the appliance is

properly Earthed. Vokèra Ltd. cannot be held responsible for

any damages or injuries caused as a result of incorrect Earth

wiring.

Hot water

outlet

Cold water inlet

stopcock/filling

valve

Gas

cock

C/H flow

valve

C/H return

valve

Safety valve outlet

Fig. 17

A

Fig. 18

Page 19

17

5.1 GAS SUPPLY INSTALLATION

Inspect the entire installation including the gas meter, test for

tightness and purge. Refer to BS 6891 (I.S. 813 in ROI) for

specific instruction.

5.2 THE HEATING SYSTEM

The appliance contains components that may become

damaged or rendered inoperable by oils and/or debris that

are residual from the installation of the system, consequently

it is essential that the system be flushed in accordance with

the following instructions.

5.3 INITIAL FILLING OF THE SYSTEM

Ensure both flow and return service valves are open, remove

appliance casing as described in 4.7.1, identify the automatic

air release valves (AAV) and loosen the dust cap/s by turning

the cap anti-clockwise one full turn. Ensure all manual air

release valves located on the heating system are closed.

Connect the filling loop as shown in fig. 5, slowly proceed to fill

the system by firstly opening the inlet valve connected to the

flow pipe, and then turning the lever on the fill valve, to the open

position. As water enters the system the pressure gauge will

begin to rise. Once the gauge has reached 1 BAR close both

valves and begin venting all manual air release valves, starting

at the lowest first. It may be necessary to go back and top-up the

pressure until the entire system has been filled. Inspect the

system for water tightness, rectifying any leaks.

5.3.1 MANUAL AIR RELEASE (fig. 19)

When the boiler has been filled for the first time or the system

has been drained and refilled, it will be necessary to release

any air that may have become trapped within the appliance

heat exchanger. Slacken the bleed screw until water is

released and then close.

IMPORTANT, THERE ARE NO OTHER MANUAL AIR

RELEASE VALVES LOCATED ON THE APPLIANCE.

5.4 INITIAL FLUSHING OF THE SYSTEM

The whole of the heating system must be flushed both cold and

hot as detailed in 5.8. Open all radiator or heating valves and

the appliance flow & return service valve. Drain the boiler and

system from the lowest points. Open the drain valve full bore to

remove any installation debris from the boiler prior to lighting.

Refill the boiler and heating system as described in 5.3.

5.5 PRE-OPERATION CHECKS

Before attempting the initial lighting of the appliance, the

following checks must be carried out:

• ensure all gas service valves from the meter to the appliance

are open and the supply pipe has been properly purged;

• ensure the proper electrical checks have been carried out,

Fig. 19

(see 7.8) particularly continuity, polarity and resistance to

earth;

• ensure the 3 AMP fuse – supplied with the appliance – has

been fitted;

• ensure the system has been filled, vented and the pressure

set to 1 BAR;

• ensure the flue system has been fitted properly and in

accordance with the instructions;

• ensure all appliance service valves are open.

5.6 INITIAL LIGHTING

Ensure the electrical supply to the appliance is switched on.

Ensure any external controls are switched to an ‘ON’ position

and are calling for heat. Move the selector switch to the ON

position, the appliance will now operate as described in 1.2.

Should the appliance fail to ignite, refer to 5.6 and/or section 7

(mode of operation, parameter setting & faultfinding).

5.7 CHECKING GAS PRESSURE AND COM-

BUSTION ANALYSIS

The appliance is factory set and requires no additional

adjustment once installed. However to satisfy the requirements

of GSIUR 26/9 (I.S. 813 ROI), it will be necessary to gas rate the

appliance using the gas meter that serves the appliance.

If the installation does not include a gas meter (for example

LPG) and there are no means by which to calculate the gas rate,

then a combustion analysis test must be carried out in

accordance with BS 7967 (UK) to ensure the appliance is left

working safely and correctly.