Page 1

AriaPRO

High efficiency heat pumps

Users Instructions

Installation &

Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

Page 2

2

Page 3

Titolo_fittizio

Titolo_fittizio

Dear Customer,

Thank you for choosing a Vokèra AriaPRO.

This booklet contains information necessary for the correct installation

of this appliance.

Thanks again.

VOKÈRA Ltd.

Compliance

Titolo_fittizio

The unit complies with the following Standards:

Electromagnetic Compatibility Directive 2004/108/EC as subsequently

amended

Machinery Directive 2006/42/EC as subsequently amended

Range

Titolo_fittizio

Warranty

Titolo_fittizio

The Vokèra product you bought has a SPECIFIC WARRANTY, valid from

the date of installation.

Conditions are specified in the WARRANTY CERTIFICATE, which we invite

you to read carefully.

Contents

Titolo_fittizio

The following symbols are used in this publication:

This booklet cod. R&S 330 - Rev. 0 - (4/11) consists of 36 pages.

WARNING = actions requiring special care and appropriate training.

DO NOT = actions that MUST ON NO ACCOUNT be carried out.

Titolo_fittizio

Heat pumps Code

AriaPRO 004 M 20033107

AriaPRO 006 M 20033108

AriaPRO 008 M 20033109

AriaPRO 012 M 20033110

AriaPRO 015 M 20033111

General

General notices

Titolo_fittizio

Check the integrity and completeness of the supplied equipment

as soon as you take it out of its packaging. If necessary, consult the

Agency that sold you the equipment.

All VOKÈRA equipment shall be installed by competent persons. The

installation must conform to current Legislation and the instructions in

this booklet.

These units must comply with their intended use, pursuant to their

performance characteristics.

VOKÈRA will not accept any liability for damages to property, people or

animals because of installation, calibration and maintenance mistakes

or erroneous usage of the equipment.

In case of abnormal operation, or leaks of liquids or refrigerant gases,

position the main switch of the system in the “off” position and close

the stop taps. Call VOKÈRA’s Technical Service or other professionally

qualified personnel immediately. Do not try to repair the unit.

This booklet must be kept carefully as it is an integral part of the

equipment and must ALWAYS be present, including in case of sale

of the equipment to another owner or user, or of transfer to another

system. Should the manual get damaged or lost, please ask for a

duplicate manual from the VOKÈRA’s Technical Service.

Repairs or maintenance actions must be carried out by VOKÈRA’s

Technical Service staff or other skilled staff, pursuant to the provisions

of this publication. Do not modify or tamper with this equipment, as

doing so might cause dangerous situation, for which the manufacturer

waives all liability.

In the installation and/or maintenance operations please adopt the

appropriate attire and accident prevention devices. The Manufacturer

waives all and any responsibility for failure to observe the safety and

accident prevention regulations from time to time in force.

Comply with the legislation in force on the country of deployment

with regard to the use and disposal of packaging, of cleaning

and maintenance products and for the management of the unit’s

decommissioning.

Pursuant to the EC standard n. 842/2006 on certain fluorinated

greenhouse gases, it is mandatory to declare the exact quantity of

refrigerant present in the installed system. This piece of information can

be found on the technical tag attached to the outdoor unit.

This unit contains fluorinated greenhouse gases covered by the Kyoto

protocol. Maintenance and disposal activities must be carried out

exclusively by skilled personnel.

The units contain refrigerant gas: handle them carefully, to avoid

damaging the gas circuit.

Fundamental safety rules

Titolo_fittizio

Do not allow children or unassisted disabled people to use the unit.

Do not open the access covers and carry out technical or cleaning

activities before disconnecting the unit from the power grid by

positioning the system’s main switch in the “off” position.

It is forbidden to modify the safety or regulation devices without the

authorisation and directions of the manufacturer.

Do not stand, sit and/or place objects on the unit.

Do not pull, detach or twist the electrical wires coming out of the unit,

even when the unit is disconnected from the power grid.

Do not spray or throw water directly on the unit.

Do not dispose of, abandon or leave the potentially hazardous

packaging materials within the reach of children.

It is strictly forbidden to touch any moving parts, interfere with them or

introduce pointed objects through the grids.

General

General notices ........................................ 3

Fundamental safety rules ................................. 3

Description ........................................... 4

Identification .......................................... 4

Technical Data ......................................... 5

Dimensions ........................................... 7

Electrical diagrams ...................................... 8

Refrigerating circuit ..................................... 18

Installer

Product delivery ........................................ 18

Handling and transportation ............................... 18

Access to inner parts ...................................... 18

Installation ............................................ 19

Hydraulic connections ................................... 20

Condensate discharge connection .......................... 20

Electrical connections ................................... 21

Control panel .......................................... 22

System’s charging ...................................... 23

Technical Service

First commissioning ..................................... 23

Stop for an extended period of time ......................... 23

System’s drainage ...................................... 23

Ordinary maintenance ................................... 23

Extraordinary maintenance ................................ 24

Control

Control panel .......................................... 25

Functions ............................................ 26

Abnormal operations

Anomalies warnings ....................................... 29

3

Page 4

Description

AriaPRO

The product is characterised by:

PAM and PWN modulation DC-INVERTER control, which allows the

compressor to modulate its performance continuously from 30% up to

120%, guaranteeing high energetic standards at all moments.

Pre-painted sheet metal cabinet.

Revolving TWIN ROTARY-type compressor mounted on antivibrating

mounts and placed in a special compartment.

Electronically controlled variable speed fan, ensuring a highly silent

operation.

AISI 316 stainless steel plate heat exchanger, utilities side, insulated

with closed cell anticondensation lining, complete with resistor and

differential pressure switch.

Exchanger made of copper pipes and aluminium corrugated fins.

Safety devices such as pressure switches, sensors, specific automatic

switches and main door-blocking switch.

Phase monitor.

Integrated hydronic module, quickly installed with the help of a few

external components.

Micro-processor electronic control regulation performance

Climate control.

Titolo_fittizio

The AriaPRO range units are designed for the production of refrigerated

water for air conditioning, heated water for heating and sanitary hot water

for homes, residential units, etc., and are used together with terminal units

for small and medium systems.

They are designed for outdoor installation, so their constituent materials

were chosen for this specific requirement.

Identification

Technical Tag

The technical tag shows all technical and performance data of the

unit. Should the tag get lost, please ask for a duplicate tag from the

VOKÈRA’s Technical Service.

Any tampering with, the removal or the lack of the Technical Tag or of

any other element whose absence prevents certain identification of

the product makes it more difficult to install and maintain the product.

8

9

10

1

2

4

6

7

4

3

6

5

5

2

4

1

7

3

4

004 - 006 - 008 012 - 015

1 Automatic air vent valve

2 Flow meter

3 Safety valve (output 1 / 2 ‘)

4 Temperature probe

5 Recirculation pump

6 Cap to release pump seizure

7 Expansion tank

8 Position 4 LED Inverter Board Diagnostics (models 012 M - 015 M)

9 Location of Diagnostic LEDs circuit board

10 Wiring terminal

4

Page 5

Technical Data

Titolo_fittizio

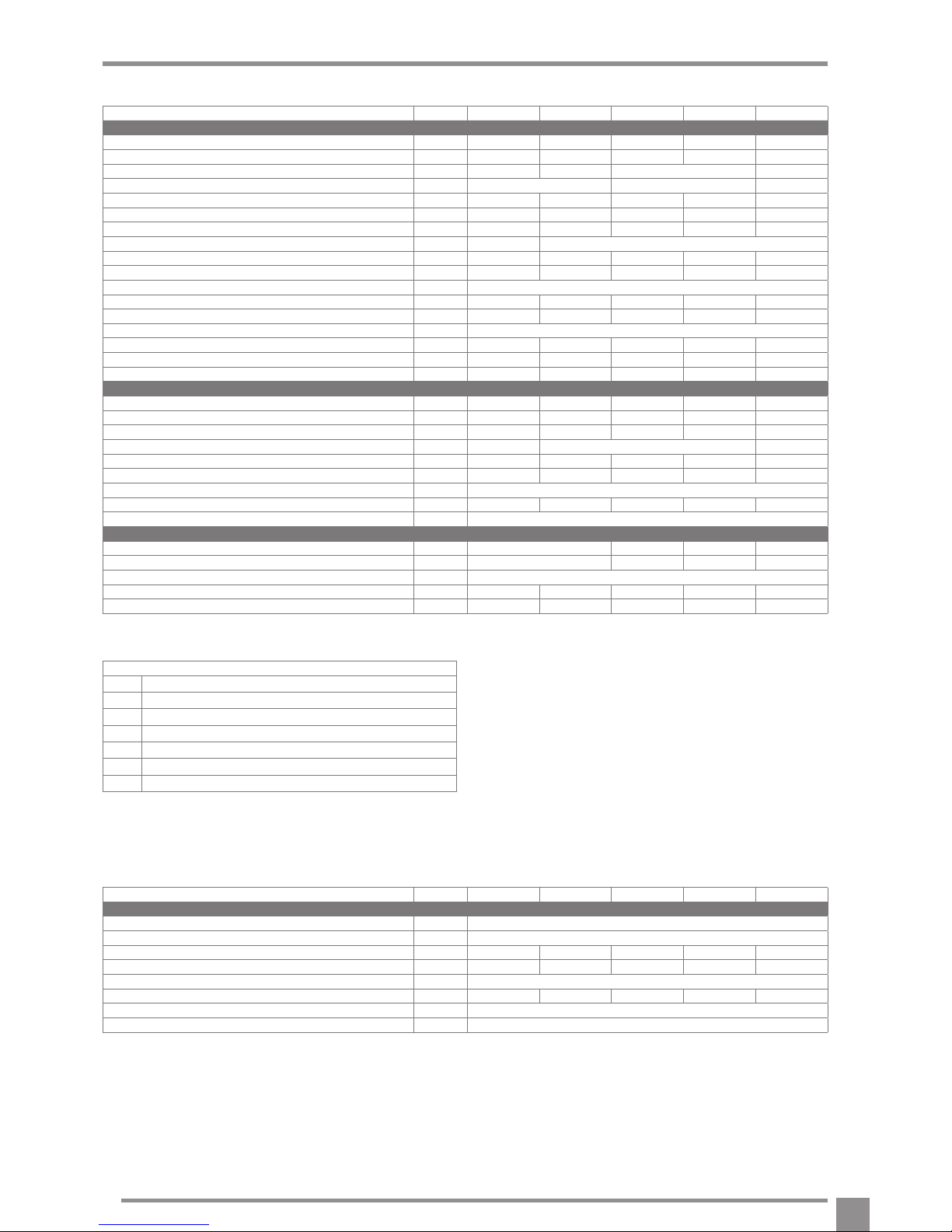

Model 004 M 006 M 008 M 012 M 015 M

Output in heating mode

Nominal capacity(1) kW 4.1 5.8 7.2 11.9 14.5

Power Consumption(1) kW 1.01 1.38 1.84 3.04 3.57

COP(1) kW 4.05 4.2 3.91 4.06

Energy class(1) A B A

Nominal capacity(2) kW 3.9 5.8 7.4 12.95 14

Power Consumption(2) kW 1.21 1.93 2.34 4.3 4.36

COP(2) kW 3.2 3.01 3.16 3.01 3.21

Energy class(2) A B

Nominal capacity(3) kW 3.5 3.8 4.1 8 10.2

Power Consumption(3) kW 1.13 1.23 1.31 2.6 3.29

COP(3) kW 3.1

Nominal capacity(4) kW 3.4 3.7 3.9 8 10.2

Power Consumption(4) kW 1.31 1.42 1.48 3.08 3.92

COP(4) kW 2.6

Nominal capacity(5) kW 4.1 5.4 6.7 11.5 11.7

Power Consumption(5) kW 1.51 2.09 2.91 4.64 4.18

COP(5) kW 2.71 2.58 2.3 2.48 2.8

Output in cooling mode

Nominal capacity(6) kW 4.9 7 7.8 13.5 16

Power Consumption(6) kW 1.21 1.94 2 3.74 4.2

EER(6) kW 4.05 3.61 3.9 3.61 3.81

Energy class(6) A B A

Nominal capacity(7) kW 3.3 4.7 5.8 10.2 13

Power Consumption(7) kW 1.13 1.61 3.03 3.5 4.47

EER(7) kW 2.91

ESEER(7) kW 4.5 4.6 4.4 4.3 4.4

Energy class(7) B

Generalities

Sound pressure in heating(1) dB(A) 42 44 47 48

Sound pressure in cooling(7) dB(A) 44 45 48 49

Compressor Rotary DC Inverter Tecnology

R410a refrigerant charge kg 1.195 1.35 1.81 2.45 3.39

Empty weight kg 63 61 71 105 130

Model 004 M 006 M 008 M 012 M 015 M

Sizing electric line

Power supply V- ph - Hz 230 - 1 -50

Allowable Voltage Range V 207 ÷ 254

Maximum power drawn kW 2 2,3 2,7 5,1 5,1

Maximum current drawn A 7,2 11 14 23 20

Type power fuses gL tipo

Power supply fuses A 10 - tipo B 15 - tipo B 15 - tipo B 25 - tipo D 25 - tipo D

Power supply cables mm2 H07RN-F 3 x 2.5mm

2

Maximum pump current external circulation A 2

Note

1 outdoor temperature D.b. + 7 °C / w.b. + 6°C, water 35 - 30 °C.

2 outdoor temperature + 7 °C / w.b. + 6°C, water 45 - 40 °C.

3 outdoor temperature D.b. + 2 °C / w.b. +1 °C, water 35 - 30 °C.

4 outdoor temperature D.b. + 2 °C / w.b. +1 °C, water 45 - 40 °C.

5 outdoor temperature D.b. + 7 °C / w.b. + 6°C, water 55 °C.

6 outdoor temperature D.b.+35 °C / w.b.+24°C, water 18 - 23 °C.

7 outdoor temperature D.b. +35 °C, water 7 - 12 °C.

Standard conditions

Sound pressure measured in a hemispheric field 4 meters in front of

the fan.

Unit performances are compliant with Directive UNI EN 14511:2004.

Fouling factor: 0.18 x 10-4 (m2 K)/W.

5

Page 6

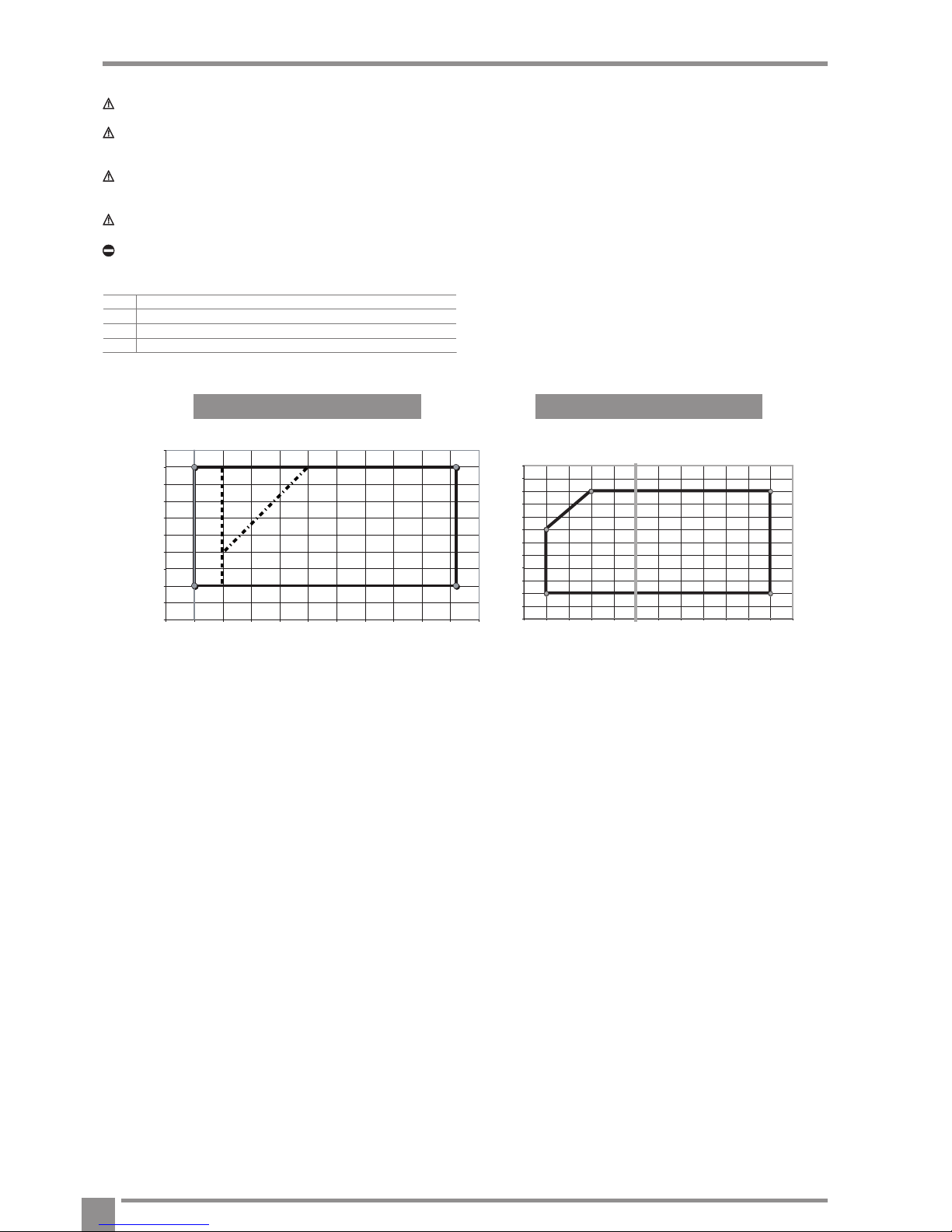

Operating conditions

With models 004 - 006, min. outdoor air temperature must be +5°C if

operating in cooling mode.

For the optimum working of the heat pump when producing hot water

in summer operation, outdoor air temperature should not exceed

30°C.

When outdoor air temperature exceeds 30°C, hot water production

may be limited according to the settings of the safety devices in the

equipment.

For technical activities, please refer to the technical tag mounted on

board the machine

It is forbidden to work outside of the working field

1 Cooling

2 Heating

A Outdoor temperature (°C)

B Outlet water temperature (°C)

1

2

10

15

20

25

30

35

40

45

50

55

60

65

70

-25-20 -15-10 -5 0510 15 20 25 30 35

A

B

A

B

0

2

4

6

8

10

12

14

16

18

20

-5 0510 15 20 25 30 35 40 45 50

008-012-015

004

006

6

Page 7

Flow-rate/head diagram

0

5

10

15

20

25

30

35

40

45

50

55

60

00,360,721,081,441,8 2,16

A

B

A

B

0

5

10

15

20

25

30

35

40

45

50

55

60

0 0,360,721,081,44 1,82,16

A

B

0

00,360,721,081,441,8 2,16 2,52 2,88 3,24

10

20

30

40

50

60

70

80

90

A

B

AriaPro 006 M

AriaPro 004 M

AriaPro 008 M AriaPro 012 M - 015 M

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

0,2 0,3 0,4 0,50,10,0

Dimensions

Titolo_fittizio

Modello 004 M 006 M 008 M 012 M 015 M

Dimensions

Empty weight kg 61 71 105

A mm 908

B mm 821 1363

C mm 326

D mm 350

E mm 87 174

F mm 356 640

G mm 466 750

H mm 40 44

L mm 60 69

7

Page 8

R

R

W

W

C

C

Y

A

Y

Y

RWC

V

C

C

W

R

C

A

B

W

Y/G

Y/G

C

W

O

C

THERMOSTAT FOR

COMPRESSOR

CN805

1

1

CN701

1

CN806

1

CN300

CN700

CN503

CN502

CN501

CN500

1

6

1

1

1

1

1

N

L

230V - 1~ - 50Hz

/2.10 / J4.1

/2.03 / J3.1

/2.08 / J1.1

1FM

1CM

RSC

40CF

12

3

7CM

123

1R

41CF

21

8CM

21

2T

12

P25

P24

P23

P22

P21

P20

P35

P34

P19

P18

P04

P05

P06

1P.C.BOARD

P11

P08

1MCC-1530

42CF

123

43CF

12

3

P33 P32

2R

44CF

21

9CM

21

P31 P30

45CF

123

1RV

F7 P03 P10 P02

1TB

1

N

46CF

3

2

1

47CF

6

5

4

3

2

1

48CF

3

2

1

49CF

2

1

50CF

3

2

1

51CF

2

1

3 L N PE

1TS

1TO

1TD

1TE

1PMV

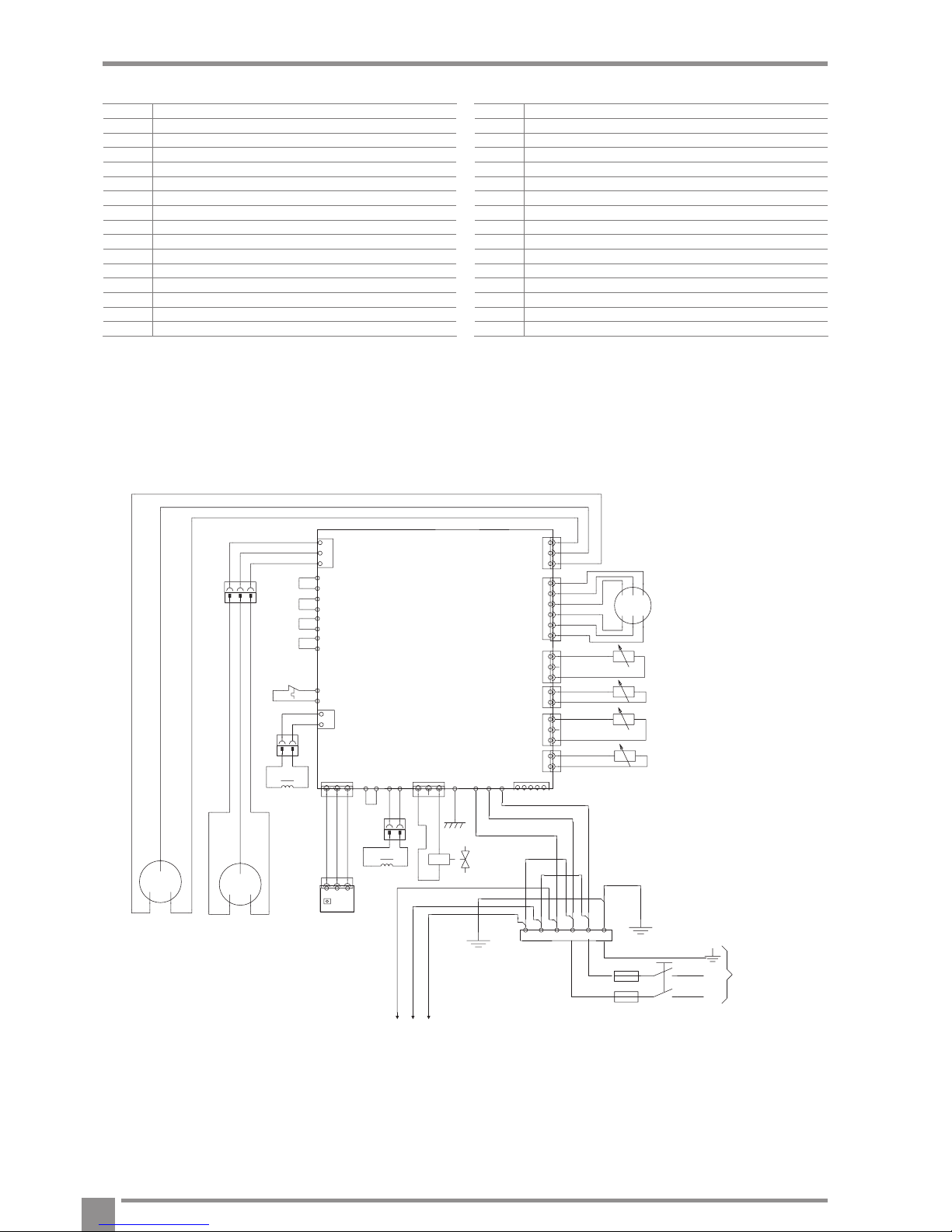

004 M Power

- Wiring of the manufacturer

---- Field wiring

CM Compressor motor

FM Fan engine

RV Reversing valve (4 way)

TS Probe temperature low-pressure pipe

TO

TD Probe temperature high pressure pipe

TE Temperature probe capacitor pipe

PMV Modulating valve engine

R Red

F Fuse

LWT Outlet water sensor

EWT Inlet water sensor

TR Refrigerant sensor

FS Flow meter

T Transformer

PS Water pump motor

E-HTR Electric Heater

AD Alarm status and defrost

OAT Outside air probe

LF Limiting frequency

IS Health input

SV Three-way health valve

Y Yellow

O Orange

A Brown

C Black

V Purple

B Blue

W White

Y/G Yellow Green

Electrical diagrams

8

Page 9

004 M Control

A

B

R

R

C

O

A

R

G

Y/G

B

A

O

W

G

Y

C

Y/G

Y/G

W

G

O

R

G

A

R

C

A

W

C

A

G

C

B

B

B

B

C

1

1

1

1

1

1

J18

J11

1

J6A

J6B

J6C

J16

J5

1

J20

1

J17

J10

11

J22

1

J13

1

J7

1

J2

1

J4

ALARM

REMOTE

CONTROL

REMOTE

CONTROLREMOTE

ALARMEHS

/

DFR

ALARM +

DFR

/

HUMIDITY

EHTR

/

WP

ALARM

INPUT

1LWT 1TR 1EWT

1T

J4.1 / /1.05

J1.1 / /1.05

1FS

1

2

/1.05 / J3.1

1OAT

1LF

1

2

1IS

1

2

24CF

12345

25CF

12

3

26CF

12

3

28CF

1

2

29CF

1

2

30CF

1

2

31CF

1

2

32CF

7

6

5

4

3

2

1

33CF

123456

34CF

7654321

35CF

1234

36CF

123456

37CF

12345

3TB

C W G Y

23 24 1

2TB

N 18 10 11 12

5TB

21 22 3 6 7 8 2

4TB

4 5 16 13 14 15

N

38CF

1

2

1PCB

J6A.1

J6A.2

J6B.1

J6B.2

J6B.1

J6B.2

J18.1

J18.2

J11.7

J11.6

J11.5

J11.4

J11.3

J11.2

J11.1

J16.1 J16.2

J5.1

J16.3

J5.2

J16.4

J5.3

J16.5

J5.4

J16.6

J5.5

J20.7 J20.6

J15.1

J20.5

J15

J17.1

J17.2

J10.1

J20.4

J10.2

J20.3

J10.3

J20.2

J10.4

J20.1

J10.5 J10.6

J22.1 J22.2 J22.3

J13.1

J22.4

J13.2 J13.3

J7.1

J2.1

J7.2

J2.2

J7.3

J2.3

J7.4 J7.5 J7.6

J1.1

J1

J4.1 J4.2 J4.3 J4.4 J4.5

J3

39CF

1

2

3

5CM

1

2

3

1PS

1SV

9

Page 10

R

R

W

W

C

C

Y

A

Y

Y

RWC

V

C

C

W

R

C

A

B

W

Y/G

Y/G

C

W

O

C

THERMOSTAT FOR

COMPRESSOR

CN805

1

1

CN701

1

CN806

1

CN300

CN700

CN503

CN502

CN501

CN500

1

6

1

1

1

1

1

N

L

230V - 1~ - 50Hz

/2.10 / J4.1

/2.03 / J3.1

/2.08 / J1.1

1FM

1CM

RSC

40CF

12

3

7CM

123

1R

41CF

21

8CM

21

2T

12

P25

P24

P23

P22

P21

P20

P35

P34

P19

P18

P04

P05

P06

1P.C.BOARD

P11

P08

1MCC-1530

42CF

123

43CF

12

3

P33 P32

2R

44CF

21

9CM

21

P31 P30

45CF

123

1RV

F7 P03 P10 P02

1TB

1

N

46CF

3

2

1

47CF

6

5

4

3

2

1

48CF

3

2

1

49CF

2

1

50CF

3

2

1

51CF

2

1

3 L N PE

1TS

1TO

1TD

1TE

1PMV

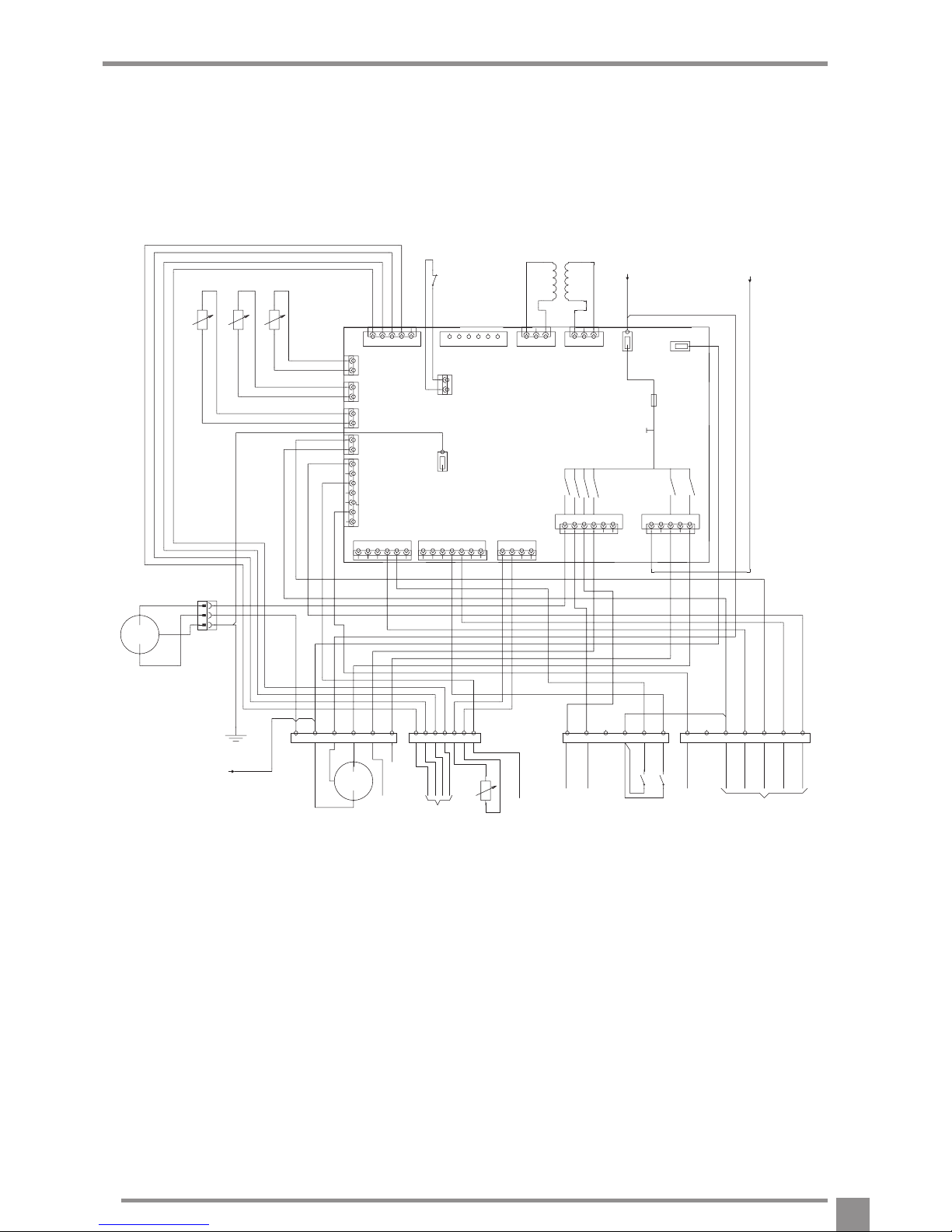

006 M Power

10

Page 11

006 M Control

A

B

R

R

C

O

A

R

G

Y/G

B

A

O

W

G

Y

C

Y/G

Y/G

W

G

O

R

G

A

R

C

A

W

C

A

G

C

B

B

B

B

C

1

1

1

1

1

1

J18

J11

1

J6A

J6B

J6C

J16

J5

1

J20

1

J17

J10

11

J22

1

J13

1

J7

1

J2

1

J4

ALARM

REMOTE

CONTROL

REMOTE

CONTROLREMOTE

ALARMEHS

/

DFR

ALARM +

DFR

/

HUMIDITY

EHTR

/

WP

ALARM

INPUT

1LWT 1TR 1EWT

1T

J4.1 / /1.05

J1.1 / /1.05

1FS

1

2

/1.05 / J3.1

1OAT

1LF

1

2

1IS

1

2

24CF

12345

25CF

12

3

26CF

12

3

28CF

1

2

29CF

1

2

30CF

1

2

31CF

1

2

32CF

7

6

5

4

3

2

1

33CF

123456

34CF

7654321

35CF

1234

36CF

123456

37CF

12345

3TB

C W G Y

23 24 1

2TB

N 18 10 11 12

5TB

21 22 3 6 7 8 2

4TB

4 5 16 13 14 15

N

38CF

1

2

1PCB

J6A.1

J6A.2

J6B.1

J6B.2

J6B.1

J6B.2

J18.1

J18.2

J11.7

J11.6

J11.5

J11.4

J11.3

J11.2

J11.1

J16.1 J16.2

J5.1

J16.3

J5.2

J16.4

J5.3

J16.5

J5.4

J16.6

J5.5

J20.7 J20.6

J15.1

J20.5

J15

J17.1

J17.2

J10.1

J20.4

J10.2

J20.3

J10.3

J20.2

J10.4

J20.1

J10.5 J10.6

J22.1 J22.2 J22.3

J13.1

J22.4

J13.2 J13.3

J7.1

J2.1

J7.2

J2.2

J7.3

J2.3

J7.4 J7.5 J7.6

J1.1

J1

J4.1 J4.2 J4.3 J4.4 J4.5

J3

39CF

1

2

3

5CM

1

2

3

1PS

1SV

11

Page 12

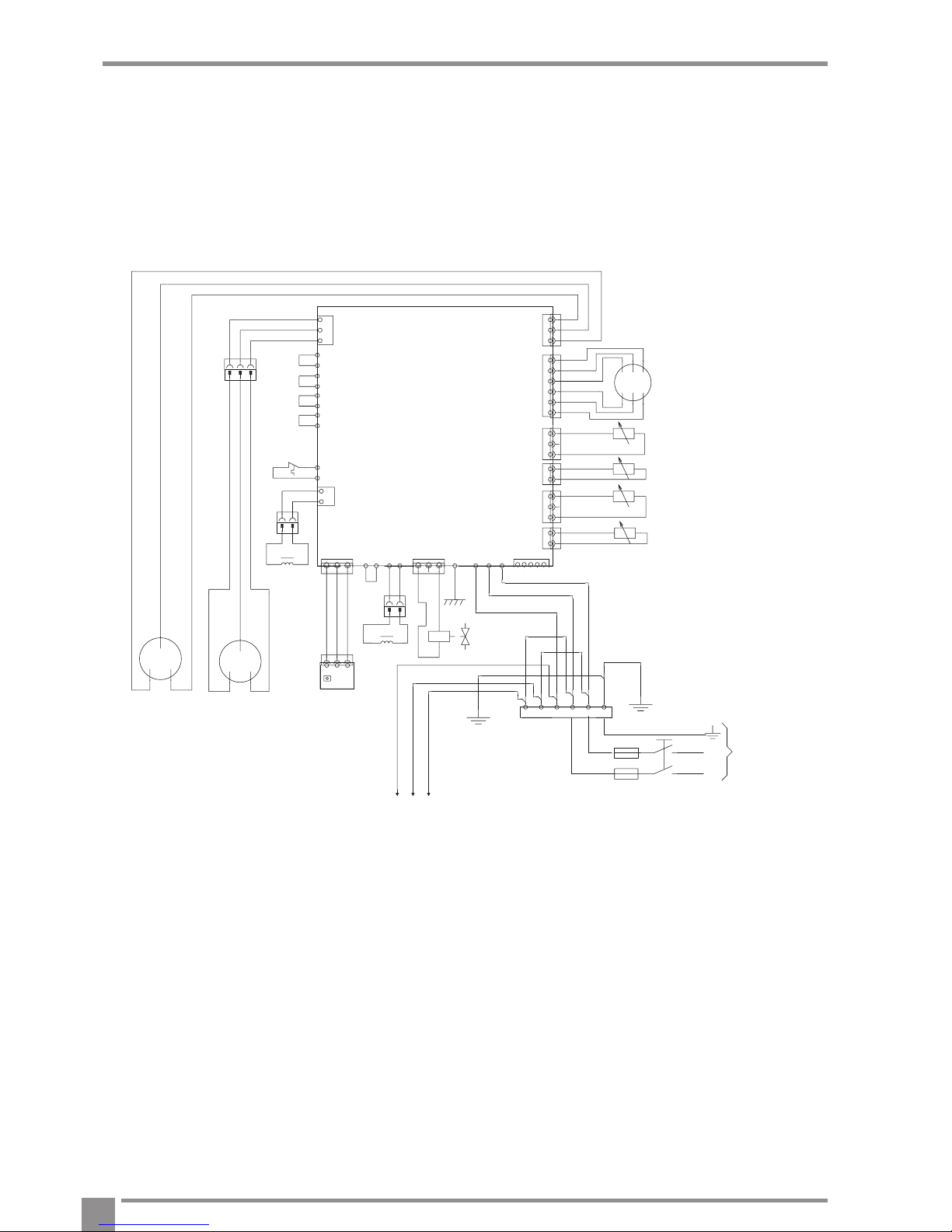

008 M Power

R

R

W

W

C

C

Y

A

Y

Y

RWC

V

C

C

C

W

W

R

W

R

Y/G

O

W

Y/G

R

C

B

A

THERMOSTAT FOR

COMPRESSOR

CN805

1

1

CN701

1

CN806

1

CN300

CN700

CN503

CN502

CN501

CN500

1

6

1

1

1

1

1

N

L

230V - 1~ - 50Hz

1FM

6CM

RSC

40CF

12

3

7CM

123

1R

41CF

21

8CM

21

2T

12

P25

P24

P23

P22

P21

P20

P35

P34

P19

P18

P04

P05

P06

1P.C.BOARD

P11

P08

1MCC-1530

42CF

123

43CF

12

3

P33 P32

2R

44CF

21

9CM

21

P31 P30

45CF

123

1RV

F7 P03

1F

12

P10 P02

3R

1TB

1

N

46CF

3

2

1

47CF

6

5

4

3

2

1

48CF

3

2

1

49CF

2

1

50CF

3

2

1

51CF

2

1

3 L N PE

1TS

1TO

1TD

1TE

1PMV

/2.10 / J4.1

/2.02 / J3.1

/2.08 / J1.1

12

Page 13

008 M Control

G

B

Y/G

Y/G

B

B

O

W

G

Y/G

Y

G

C

O

R

R

A

C

G

A

O

B

A

C

G

C

R

B

W

W

A

C

R

A

R

C

B

A

1

1

1

1

1

1

J18

J11

1

J6A

J6B

J6C

ALARM +

DFR

/

HUMIDITY

J16

EHTR

/

WP

J5

REMOTE

1

J20

1

J17

J10

11

ALARM

REMOTE

CONTROL

J22

1

J13

1

J7

EHS

/

DFR

1

ALARM

J2

1

J4

ALARM

INPUTREMOTE

CONTROL

1PS

1LWT

10CM

1

2

3

52CF

1

2

3

1TR

/1.05 / J3.1

1EWT

2TB

N

N 18

1SV

1PCB

53CF

1

2

54CF

1

2

55CF

1

2

56CF

1

2

57CF

7

6

5

4

3

2

1

J6A.1

J6A.2

J6B.1

J6B.2

J6B.1

J6B.2

J18.1

J18.2

J11.7

J11.6

J11.5

J11.4

J11.3

J11.2

J11.1

10

58CF

123 456

J16.1 J16.2

59CF

12345

J5.1

11

J16.3

J5.2

J16.4

J5.3

12

J16.5

J5.4

J16.6

3TB

J5.5

C

60CF

7654321

J20.7WJ20.6

1FS

1

2

G

61CF

1

2

J15.1

J20.5

J15

Y

J17.1

J17.2

J10.1

J20.4

23

J10.2

J20.3

24

J10.3

J20.2

1

1OAT

J10.4

J20.1

J10.5 J10.6

62CF

1234

J22.1 J22.2 J22.3

63CF

12

3

J13.1

J22.4

J13.23TJ13.3

64CF

123 456

4TB

J7.1

4

65CF

12

3

J2.1

J7.2

J2.2

J7.3

5

J2.3

J7.4 J7.516J7.6

13

J1.1

J1.1 / /1.05

J1

2FL

1

2

14

66CF

12345

J4.1 J4.2

1IS

1

2

15

J4.3 J4.4

5TB

21

J4.5

J3

22 3 6

J4.1 / /1.05

7 8 2

13

Page 14

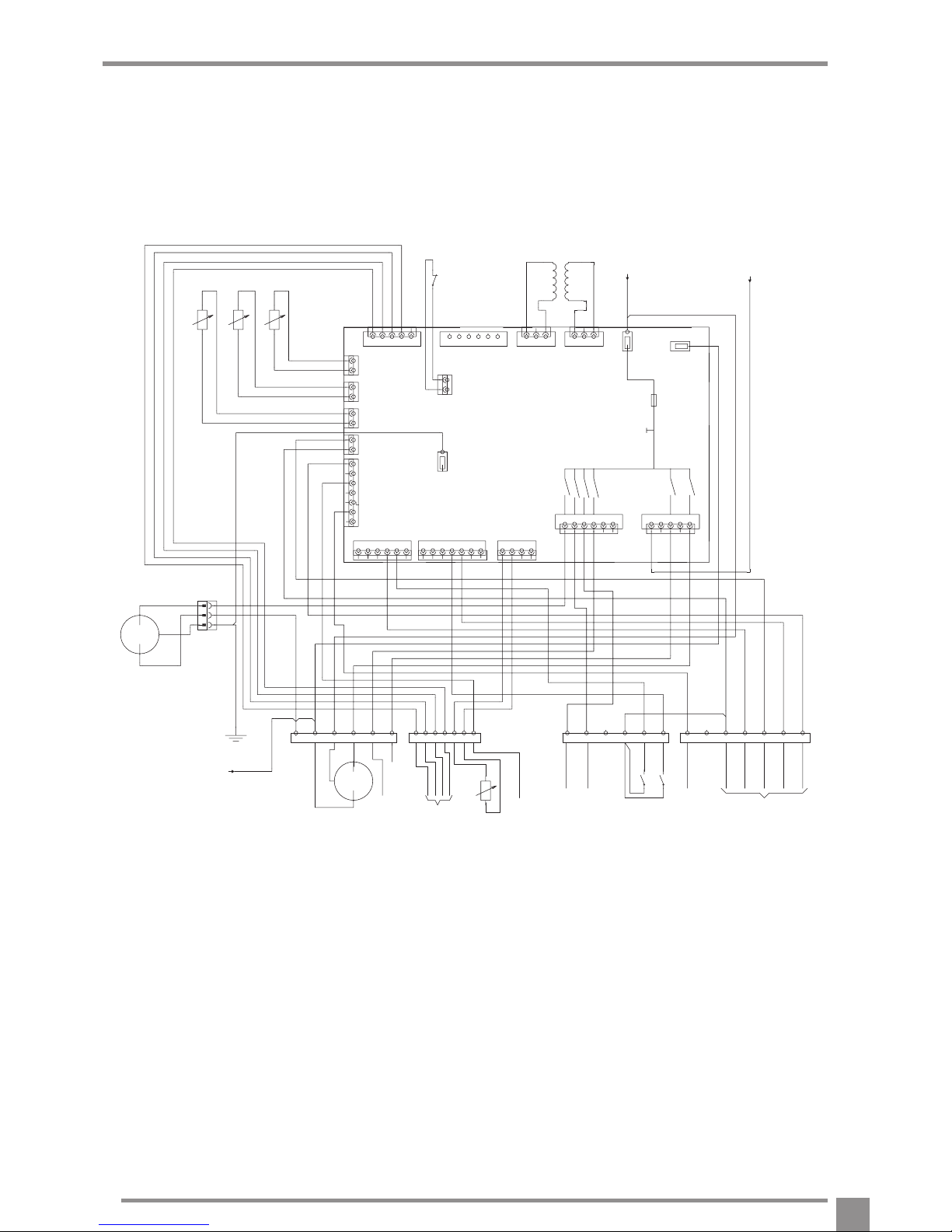

012 M Power

R

W

C

Y/G

WRWGCG

O

O

A

PRBCWC YYB

B

O

O

C

W

R

R

R

W

W

C

C

B

A

230V - 1~ - 50Hz

LN

1

CN700

1

CN02

1

1

1

R

CN13

CN01

CN702

R

1

1

CN05

CN04

1

CN303

1

1

+

CN800

CN06

-

-

-

-

ED

1

CN302

1

1

CN04

CN03

CN600

1

1

CN301

1

CN600

1

CN300

1

CN6051CN604

THERMOSTAT

FOR COMPRESSOR

1

CN500

1

CN601

1

CN606

1TB

PE

1F

1

2

L

1RV

N

39CF

1

2

3

40CF

1

2

3

4

5

CN01

CN02

CN03

1P.C.BOARD

2P.C.BOARD

7CM

123

41CF

123

P08

42CF

12345

43CF

12345

1PVM

44CF

123 456

2TB

P09

8CM

123

45CF

123

P12 P13

46CF

12

47CF

12

P21

48CF

123

P24

49CF

12345

50CF

12345

1FM

P28 P29

51CF

12345

52CF

123

53CF

12

3

P19 P20 P17 P18

54CF

123

55CF

1

2

CN09

CN10

CN11

2FM

1TH

1TD

56CF

12

3

57CF

12345

58CF

12

1TS

59CF

12

1TE

60CF

12

2T

1

2

61CF

12

3

1TO

1CM

R

C

S

1 N 3

J4.1 / /2.10

J3.1 / /2.03

J1.1 / /2.08

14

Page 15

012 M Control

G

B

Y/G

Y/G

B

B

O

W

G

Y/G

Y

G

C

O

R

R

A

C

G

A

O

B

A

C

G

C

R

B

W

W

A

C

R

A

R

C

B

A

1

1

1

1

1

1

J18

J11

1

J6A

J6B

J6C

ALARM +

DFR

/

HUMIDITY

J16

EHTR

/

WP

J5

REMOTE

1

J20

1

J17

J10

11

ALARM

REMOTE

CONTROL

J22

1

J13

1

J7

EHS

/

DFR

1

ALARM

J2

1

J4

ALARM

INPUT

REMOTE

CONTROL

1PS

1LWT

9CM

1

2

3

62CF

1

2

3

1TR 1EWT

3TB

N

N 18

1SV

1PCB

63CF

1

2

64CF

1

2

65CF

1

2

66CF

1

2

67CF

7

6

5

4

3

2

1

J6A.1

J6A.2

J6B.1

J6B.2

J6B.1

J6B.2

J18.1

J18.2

J11.7

J11.6

J11.5

J11.4

J11.3

J11.2

J11.1

10

68CF

123456

J16.1 J16.2

69CF

12345

J5.1

11

J16.3

J5.2

J16.4

J5.3

12

J16.5

J5.4

J16.6

4TB

J5.5

C

70CF

765 4321

J20.7WJ20.6

1FS

1

2

G

71CF

1

2

J15.1

J20.5

J15

Y

J17.1

J17.2

J10.1

J20.4

23

J10.2

J20.3

24

J10.3

J20.2

1

1OAT

J10.4

J20.1

J10.5 J10.6

72CF

1234

J22.1 J22.2 J22.3

73CF

12

3

J13.1

J22.4

J13.23TJ13.3

74CF

123456

5TB

J7.1

4

75CF

12

3

J2.1

J7.2

J2.2

J7.3

5

J2.3

J7.4 J7.516J7.6

13

J1.1

J1.1 / /1.05

J1

1FL

1

2

14

76CF

12345

J4.1 J4.2

1IS

1

2

15

J4.3 J4.4

6TB

21

J4.5

J3

22 3 6

J4.1 / /1.05

7 8 2

15

Page 16

015 M Power

R

C

W

C

A

B

C

W

R

G

W

R

230V - 1~ - 50Hz

L

N

UVW

CN400

(WHITE)

CN300

(WHITE)

CN609

(BLUE)

CN610

(YELLOW)

CN604

(WHITE)

CN603

(WHITE)

CN602

(YELLOW)

CN601

(WHITE)

CN600

(WHITE)

CN710

(WHITE)

SW802

SW804

SW803

ONONON

432143214321

SW801

CN704

(BLUE)

SW800

RY704

P04

CN701

(WHITE)

P05

CONTROL P.C. BOARD

MCC-1571

P06

CN04

(WHITE)

P07

CN200

F03

T10A,250V~

F01

T25A,250V~

CN201

P01

L/F

P02

CN202

P09

1TB

2TB

1 2 3

J4.1 / /2.10

J3.1 / /2.03

J1.1 / /2.08

1CM

63CF

12

64CF

12

1PCB

10CM

12

11CM

12

1R 2R

1FM

2FM

49C

12

1TL

1TD

1TO

1TE

1TS

L N

1PMV

65CF

1

2

3

66CF

1

2

67CF

1

2

68CF

1

2

3

69CF

1

2

70CF

1

2

71CF

1

2

3

72CF

123456

73CF

1234

74CF

123456

75CF

1

2

3

1RV

16

Page 17

015 M Control

A

B

R

R

A

RO

G

C

O

C

A

R

B

G

Y/G

W

O

W

G

Y

Y/G

Y/G

B

G

B

B

R

A

W

C

G

C

C

A

A

B

C

1

1

1

1

1

1

J18

J11

1

J6A

J6B

J6C

J16

J5

1

J20

1

J17

J10

11

J22

1

J13

1

J7

1

J2

1

J4

REMOTE

CONTROL

ALARM

REMOTE

CONTROL

REMOTE

ALARMEHS

/

DFR

ALARM +

DFR

/

HUMIDITY

EHTR

/

WP

ALARM

INPUT

1LWT 1TR 1EWT

1T

J4.1 / /1.07

J1.1 / /1.07

1FS

1

2

/1.07 / J3.1

1OAT

1FL

1

2

1IS

1

2

24CF

12345

25CF

12

3

26CF

12

3

28CF

1

2

29CF

1

2

30CF

1

2

31CF

1

2

32CF

7

6

5

4

3

2

1

33CF

123456

34CF

7654321

35CF

1234

36CF

123 456

37CF

12345

4TB

C W G Y

23 24 1

3TB

N 18 10 11 12

6TB

21 3 6 7 8 2

5TB

4 5 16 13 14 15

N

38CF

1

2

2PCB

J6A.1

J6A.2

J6B.1

J6B.2

J6B.1

J6B.2

J18.1

J18.2

J11.7

J11.6

J11.5

J11.4

J11.3

J11.2

J11.1

J16.1 J16.2

J5.1

J16.3

J5.2

J16.4

J5.3

J16.5

J5.4

J16.6

J5.5

J20.7 J20.6

J15.1

J20.5

J15

J17.1

J17.2

J10.1

J20.4

J10.2

J20.3

J10.3

J20.2

J10.4

J20.1

J10.5 J10.6

J22.1 J22.2 J22.3

J13.1

J22.4

J13.2 J13.3

J7.1

J2.1

J7.2

J2.2

J7.3

J2.3

J7.4 J7.5 J7.6

J1.1

J1

J4.1 J4.2 J4.3 J4.4 J4.5

J3

62CF

1

2

3

9CM

1

2

3

1PS

1SV

17

Page 18

Refrigerating circuit

Titolo_fittizio

TS sensor TS sensor

TD sensor TD sensor

Accumulator Liquid accumulator

Rotary compressor Rotary compressor

Muffler Silencer

4-way valve 4-way valve

TO sensor TO sensor

Heat exchanger Heat exchanger

TE sensor TE sensor

Distributor Distributor

TR sensor TR Sensor

BPHE Plate heat exchanger

WE Water Inlet

WL Water outlet

PWM (Pulse Motor

Valve)

Electronic expansion valve

PMV

(Pulse Motor Valve)

WL

WE

TR sensor

Distributor

TE sensor

Heat exchanger

TO sensor

TS sensor

TD sensor

muffler

Muffler

Rotary compressor

Accumulator

4-way valve

B

P

H

E

Installer

Product delivery

Preliminary instructions

We suggest to take the equipment out of its packaging only when it

has been placed in position at the installation point.

Carefully remove any adhesive strips positioned on the unit.

Do not dispose of, abandon or leave the potentially hazardous

packaging materials within the reach of children.

Scope of supply

Also supplied:

Installer manual

External probe

Barcode labels

Control panel

Strain relief (size 015M only)

List of spare parts

The supplied accessories are positioned inside the electrical panel.

Cable gland

Drain discharge pipe

Handling and transportation

Titolo_fittizio

The unit must be handled by skilled technicians, appropriately

equipped and with the appropriate tools to manage the unit’s weight in

compliance with the accident prevention regulations.

When handled, the unit must always be kept in a vertical position.

The weight of the equipment is off balance towards the compressor.

If the unit is lifted, use pipes with a diameter and thickness appropriate

for the weight of the unit.

Use all the lifting points shown.

Access to inner parts

Titolo_fittizio

- Remove the access panel.

- Loosen the fastening screw.

60015

01

50

430

400

363

37

1

2

3

1 Position 4 LED Inverter Board Diagnostics (models 012 M - 015 M)

2 Location of Diagnostic LEDs circuit board

3 Wiring terminal

18

Page 19

Installation

Preliminary instructions

The place of installation must be determined by the system’s designer

or by an expert in the field and must take into account the technical

requirements and the current standards and legislation.

We suggest to avoid:

The placement in service ducts and/or hopper windows

Obstacles or barriers that cause a recirculation of the expelled air

Places with aggressive atmospheres

Small places where the unit’s noise level can be enhanced by

reverberation and resonance.

Placement in corners, where dust, leaves and other debris may easily

deposit ma reduce the efficiency of the unit, through obstruction of the

air flows.

The airflow from the unit can penetrate in the inhabited rooms through

doors or windows, creating discomfort.

That the airflow from the unit is opposed by a contrary wind.

The units must:

Be placed on a level surface able to support their weight.

Be placed on a sufficiently rigid floor slab that does not transfer vibrations

to the rooms below or next door.

It is suggested to place a rubber plate between the slab and the unit, or

to use anti-vibrating mounts appropriate for the unit’s weight.

The unit must be installed exclusively indoors.

If there are several units placed side by side on the bank side, the

required distances must be summed.

Provide for lifting of the unit from the floor:

20mm without conveying of condensation discharge

90 - 100 mm to allow the conveying of the condensation discharge

If the unit is installed in areas subject to heavy snowfall, it shall be

necessary to avoid the unit being directly exposed to it.

150

500

1000

1000

150 300 300

300

200

1000

300

200

300

1000

1000 1500 2000

200

300

150

200

150300

500

1000

150

19

Page 20

Hydraulic connections

Preliminary instructions

The choice and installation of system components is left to the skilled

installer, who shall operate pursuant to the best practices and the

legislation from time to time in force.

Check that the pipes do not contain stones, sand, rust, debris or other

extraneous bodies that might damage the system.

It is appropriate to create a by-pass of the unit to make it possible to

wash the pipes without having to disconnect the unit.

The connection tubes must have the appropriate diameter and must

be supported, so as not to rest their weight on the unit.

Mandatory items:

Install a filter whose dimensions are appropriate for the impurities

present in the water entering the unit.

Install a flow meter for liquids, to be dimensioned and calibrated

according to the system’s hydraulic characteristics.

Install air venting valves in the highest points of the pipes.

Install flexible elastic joints to connect the pipes.

The flow meter must be positioned halfway through a stretch of

horizontal pipe with a length of at least 1 metre.

The system’s water content must prevent instabilities in the operation

of the refrigerating circuits.

Systems charges with anti-freezing agents or subject to special

regulations require the use of water disconnectors.

Failure to install filters, flow meter and anti-vibrating mounts can cause

obstruction, breakage and noise issues, for which the manufacturer

waives any liability.

Check charge losses from the unit, the system and any other in-line

mounted accessories.

The water flow must be maintained stable during operation.

The sealing of threads must be obtained using hemp and green paste.

Do not use Teflon when the unit contains anti-freeze liquid.

1 On-off valve

2 Line water filter (10 mesh / inch)

3 Pressure gauge

4 Filling valve

5 Valve exhaust system (in lowest points of the circuit)

6 Air vent (in the highest points of the circuit)

7 3-way valve

8 Storage tank for domestic water

9 House plant

10 Drain connection

1

1

2

3

3

4

6

5

7

8

9

430

10

37

Do not use the heat pump to treat the water used by industrial

processes, in swimming pools or in the house. In all these cases, an

intermediate heat exchanger is required.

Condensate discharge connection

With conveying

Connect a drainage tube to the connector on the collector tray and run it

towards and appropriate discharge area.

Without conveying

- The drainage capacity increases if the pre-cut holes in the base are

open.

In case of installation in very cold areas or areas subject to heavy

snowfall, where freezing out is a possibility, foresee appropriate

antifreeze systems.

20

Page 21

1 Position 4 LED Inverter Board Diagnostics (models 012 M - 015 M)

2 Location of Diagnostic LEDs circuit board

3 Wiring terminal

4 Electric connections inlet

Electrical connections

Preliminary instructions

The choice and installation of system components is left to the skilled

installer, who shall operate pursuant to the best practices and the

legislation from time to time in force.

The manufacturer waives all liability for damages caused by lack of

grounding or departure from the electrical diagrams.

Check that:

The characteristics of the power supply network shall be appropriate for

the unit’s power requirements, taking into account also other equipment

which might be operated in parallel.

Electrical voltage shall be equal to the nominal value +/-10%, with a

maximum phase unbalance of 3%.

Mandatory items:

The use of an omnipolar magnetothermic switch, lockable line

disconnector, compliant with CEI-EN standards (contacts open by

at least 4 mm), with adequate disconnection power and differential

protection in compliance with the electrical data table below, installed

next to the unit.

Ground the unit thoroughly.

At the end of the connections, fasten the cables with the appropriate

cable glands and replace the terminal boxes’ covers.

Do not use gas and water pipes to ground the unit.

Connection

- Punch out the connection points in the pre-cut part.

- Remove the pre-cut part.

- Remove the hole’s cutting edges.

- Insert the supplied cable protections .

- Only for size 015 use the strain relief supplied with the unit

- Thread the cables through the holes from the outside, guiding them

towards the electrical panel.

- Fasten the cables with the supplied cable grips.

Avoid any direct contact with non insulated copper pipes and the

compressor.

It is forbidden to thread the unit’s electrical wires in positions not

specifically foreseen in this manual.

4

1

2

3

Titolo_fittizio

LN

A B

15

LN

L

N

N N 18 10 11 12 4 5 16 13 14 15

C W G Y 23 24 1

2 3 6 7 8 21 22

5

9

8

1

2

3

4

6

7

S1

S2

S3

A Unit

B Control panel

S1 Off/ON

S2 Cooling/Heating

S3 Normal / Economic

1 3 Way valve

2 Alarm + defrost / Dehumidifier

3 Trace Heater / Additional Water pump

4 External heat source / Defrost

5 Alarm / Ambient temperature reached

6 Limitation frequency

7 Sanitary Input

8 Alarm Input

9 External temperature probe (NTC 3kΩ@25°C)

10 External water pump

21

Page 22

Control panel

Titolo_fittizio

The control panel makes it possible to carry out all necessary calibrations

to allow the unit to function, and to view the main parameter values and

the alarms.

Preliminary instructions

For correct installation, remember that the panel:

Must be installed on a wall, preferably not a perimeter one, and one

without any hot or cold pipes inside.

It must be mounted at 1.5 m from the floor.

It must not be placed next to doors or windows, cooking devices,

radiators, fan coils or, more generally, it must not be places in conditions

that might alter the measured temperatures.

The maximum length of the connecting cable must be taken into

account.

Use a shielded cable for the connection.

The connection cable must not be spliced; if splicing is necessary, it

shall be tinned and adequately protected.

Any trenching of the connection cable must be separated from the live

wires.

Placement

- Separate the control panel from the base.

- Mark the fastening points using the base as a template.

- Drill a hole in the wall, through which the connections shall be

threaded,

1 Fixing hole

2 Terminal box

3 Connection hole

1,5 m

OK

1

2

3

1

Connection

- Thread the connection cable of the control panel through the hole in

the base.

- Anchor the base with appropriate screws and bolts.

- Connect the cable to the clamps on the control panel, paying attention

to polarity.

- Remount the control panel on the base.

22

Page 23

System’s charging

Preliminary instructions

Do not open the access covers and carry out technical or cleaning

activities before disconnecting the unit from the power grid by

positioning the system’s main switch in the “off” position.

Check that the main power supply line is disconnected.

Check that the discharge taps are closed and that the air bleeder

screws are open

Pump’s release

In case of prolonged stop, it might become necessary to unblock the

circulation pump.

To unblock:

Access the pump.

- Rotate the impeller with a screwdriver.

Operations

- Open the hydraulic system’s stop valves.

- Start charging.

- When water starts to come out of the bleeder valves, close the valves

and bring the water’s pressure to the system’s set value.

Consider that the safety valves are calibrated at 3 bar.

When the water pressure has stabilised, close the charging valve.

Check the hydraulic sealing of the joints.

Making up of the hydraulic circuits must always take place with the pumps

stopped.

1 Pump’s release

1

Technical Service

First commissioning

Preliminary instructions

The equipment’s first commissioning must be carried out by a qualified

engineer.

Check that:

All safety conditions have been fulfilled

The unit was appropriately fastened to support base and correctly

positioned.

All connections have been made correctly

Check that the stop valves are open.

Check that the power supply values are correct

Grounding has been done correctly.

All connections have been fastened well.

Check that the voltage values fall within the pre-set limits and that the

unbalance between the phases does not exceed 3%.

Start

- Position the system’s main switch in the “on” position.

- Position the unit’s main switch in the “on” position.

- Check that the operation led on the control panel is lighted, thus

showing the presence of voltage.

- Keep the unit under power, but inactive, for at least eight hours, to

allow the compressor carter’s oil to warm up.

- Position the remote switch (if present) in the “on” position

- Start the equipment according to the directions in the control panel

section.

Checks during and after the first commissioning.

Check that:

In models with three-phase power supply, the compressor’s noise level

must not be abnormal (e.g. engine knocking).

That the suction pressure does not exceed the discharge pressure, if

so, invert a phase.

That the power absorbed by the compressor is lower than maximum

power.

That the unit is operating within the suggested operating limits.

That the unit stops and then starts again.

Do not operate the unit with an inverted phase.

Stop for an extended period of time

Preliminary instructions

Deactivate the unit exclusively from the control panel.

If there is any likelihood that the external temperature may fall below

zero, there is a risk of freeze, and the system MUST BE EMPTIED

or anti-freeze liquid (such as ethylene glycol) added , in the doses

suggested by the liquid’s manufacturer.

Operations

After deactivating the unit:

- Position the remote switch in the “off” position.

- Position the system’s main switch in the “off” position.

- Deactivate the indoor terminal units by positioning the switch of each

unit in the “off” position.

- Close the water supply taps.

- Close the hydraulic system’s stop valves.

System’s drainage

Titolo_fittizio

- Position the system’s main switch in the “off” position.

- Check that the system’s charging tap is closed.

- Open the water discharge tap outside the machine.

Any antifreeze liquid contained in the system should not be discharged

freely as it is a pollutant.

Ordinary maintenance

Preliminary instructions

Regular maintenance is essential in order to keep the unit in top

condition, and must be carried out at least once a year by the Technical

Service or by skilled technicians.

Plan the maintenance schedule according to the characteristics of

installation and the use of the unit.

For units installed in a seaside environment, the maintenance intervals

shall be halved.

After carrying out the necessary maintenance actions, the original

conditions must be restored.

23

Page 24

Do not open the access covers and carry out technical or cleaning

activities before disconnecting the unit from the power grid by

positioning the system’s main switch in the “off” position.

Cleaning

Do not open the access covers and carry out technical or cleaning

activities before disconnecting the unit from the power grid by

positioning the system’s main switch in the “off” position.

- The only necessary cleaning activity to be carried out by the system’s

user concerns the unit’s external cabinet, which must be cleaned using

exclusively a cloth wet with soapy water.

- In case of tough stains, wet the cloth with a mix of 50% water and

denatured alcohol or with specific detergents.

- After washing, dry the surfaces carefully.

Do not use sponges with scouring products or powdered detergents.

Operations

The annual maintenance plan includes the following checks:

Mesh filter cleaning

Supply voltage

Fastening of electric connections

Status of the hydraulic joints

Water circuit charging

Pump operation check

Presence of air in the hydraulic circuit

Safeties efficiency

Compressor’s remote control switch status

Plate heat exchanger’s resistor efficiency

Compressor’s resistor efficiency

Cleaning of fan grids

Preliminary instructions

Check that the main power supply line is disconnected.

Use tools appropriate for the refrigerant used.

It is strongly suggested to use safety goggles and gloves.

In case of partial leak of refrigerant gas, the circuit must be completely

emptied before being recharged, and the refrigerant must be

recovered.

Any gas leaks indoors can generate toxic gases if they come into

contact with naked flames or high temperature bodies, in case of

leaks, please air the rooms thoroughly.

Do not charge the refrigerating circuits with a different refrigerant from

the prescribed one.

Do not use oils that are different from the prescribed one. The use of

different oils may seriously damage the compressor.

Do not use oxygen or acetylene or other flammable or poisonous

gases in the refrigerating circuit, as they can cause explosions.

Operating conditions different from the nominal ones may yield values

that differ considerably.

Compressor

The compressor is installed on the unit already charged with oil and

sealed.

In case of breakages, if the compressor can be repaired, use only original

ester oil.

Do not use oils that are different from the prescribed one. The use of

different oils may seriously damage the compressor.

Refrigerant charge

Proceed as follows:

- Empty and dry the whole refrigerating circuit using a vacuum pump

connected to both the low pressure and high pressure ports, until the

value displayed on the vacuum gauge is about 10 Pa.

- Wait for a few minutes and check that such value does not go up again

to over 50 Pa.

- Connect the refrigerant gas cylinder or a charging cylinder to the low

pressure line port.

- Charge the required quantity of refrigerant gas, as shown in the unit’s

technical tag.

In case of partial leak, the circuit must be completely emptied before

being recharged.

The refrigerant must be charged into the unit only in its liquid state.

Always check the overheating and undercooling values which, in the unit’s

nominal operating conditions must fall between 5 and 10° C in refrigerators

and 4 and 8°C in heat pumps, respectively.

Extraordinary maintenance

24

Page 25

Control

Control panel

Keys

A ZONE

B BLOCK

C METHOD

D Up arrow

E Down arrow

F OK

G night

H outdoor

I indoor

J D / H / M SET TIME

K START TIME

L PERIOD

M DAYS

BLOCK

It keeps the temperature currently selected or start the

program schedule.

E Down arrow

Up arrow

Increases the temperature or increases the number of

selected items on the screen when adjusting the advanced

settings programmatically.

Down arrow

Decreases the temperature or decreases the number of

selected items on the screen when adjusting the advanced

settings programmatically.

OK

Saves the settings once the set-up or a step programming

has been carried out

night

Activates heating and cooling settings planned for the period

of “night”.

outdoor

Activates the heating and cooling settings for the planned

period away from home.

indoor

Activates the heating and cooling settings planned for the

period “at home “.

D / H / M SET

TIME

Mode for setting the date and time.

START TIME

Activates the programming menu, displaying the beginning of

the six periods of time scheduled.

PERIOD

Activates the programming menu, displaying the six periods of

time scheduled.

DAYS

Activates the programming menu, displaying the options: 1 to

7 every day, from 1 to 5 weekdays, from 6 to 7 for weekend,

day by day 1,2,3,4,5,6,7

ZONE This key is used in programming.

OK

M

P

Symbols

1 Domestic Water Supply

2 Gas boiler

3 System off

4 Air temperature inside the room

5 ZONE

6 Not used

7 Cooling Mode

8 Now

9 Outdoor temperature

10 Weekday

11 Alarm

12 system is using the “At Home” settings

13 Not used

14 system is using the “Away from home” settings

15 Not used

16 AM / PM indicator for the current time

17 The system is using the “Night” settings

18 Maintenance/installer Mode

19 Percentage relative humidity

20 Not used

21 Heating Mode

22 Keypad lock

23 Time program activated

24 Fahrenheit

25 Thermostat set on anti-freeze temperature

26 Celsius

27 Auxiliary heat source

28 Solar

29 Auxiliary electric heater

30 Heat pump functionning

31 Domestic water supply booster

32 Zone number

1

2

4

5

6

7

8

9

10

25

Page 26

The period values are pre-set by default:

To select:

- Push the Days key repeatedly.

- Select the desired time option.

- Push the period key.

- The “P” and “1” values start blinking.

- The P1 period is activated.

To change:

- Push the Start period key.

- 6:00 AM starts blinking.

- Activate the arrow keys.

- Select the desired value.

- Push the Start period key to change parameter.

- Repeat the change operations.

- Push the OK key to confirm.

The end of period value corresponds to the start or period one for the

next period.

To check:

- Push the Days key.

- Select the time option.

- Push the period key.

- Check the set times.

- Push the period key to proceed.

If the settings are incorrect:

- “--” is displayed on screen.

- The triangular icons are turned on.

If the settings are correct:

- Push the OK key to confirm.

Programming

The time slots can be associated with:

The functions:

indoor

outdoor

night

The unit’s setting modes:

ON/OFF

Frequency reduction ON/OFF.

To match:

- Set the time slot as shown in the relevant chapter

- Push the desired Touch’n’Go key.

- The triangular icon above the key starts blinking.

- Push the Zone key.

If the unit’s status is ON, you are choosing to turn the heat pump OFF

during the P1 period

If the unit’s status is OFF, you are choosing to turn the heat pump ON

during the P1 period

- Push the Maintain key.

If the unit’s status is ON, you are choosing to turn the frequency

reduction mode “OFF”

If the unit’s status is OFF, you are choosing to turn the frequency

reduction mode “ON”

To go to the second period:

- Press the Period key twice

- P2 starts blinking

- Repeat the settings

To check:

- Push the Days key.

- Select the time option.

- Push the Period key.

- Check the set times.

- Push the Period key to proceed.

If the settings are incorrect:

- “--” is displayed on screen.

Functions

Setting the current date and time.

Upon first use of the machine, it is necessary to set the current date and

time.

Push the D/H/M SET TIME key.

The selected parameter starts blinking.

Push the D/H/M SET TIME key to change parameter.

Activate the arrow keys.

Set the current value.

Push the OK key to confirm.

Setting of room temperature

- Push the mode key.

- Select the desired operation mode.

- Activate the arrow keys.

- Set the desired temperature.

- The temperature value is stored until the next programmed period.

- The icon for the timer programme blinks.

- Push the lock key.

- The set temperature shall be maintained until the user presses the lock

key again.

Keyboard lock

To lock:

- Push the Days, Period and Period Start keys concurrently for 3

seconds.

- All keys shall be disabled.

- The keyboard locked icon is displayed.

To unblock:

- Push the Days, Period and Period Start keys concurrently for 3

seconds.

Touch’n’Go functions

The Touch’n’Go functions make it possible to access simplified

programming options.

The functions values are pre-set by default on typical temperatures and

periods, different for heating and cooling.

Available functions and pre-set values:

To select:

- Push the key for the desired function.

- Push the Lock key to keep the home at one of three comfort levels

indefinitely.

To change:

- Push the key for the desired function for 3 seconds.

- The set temperature starts blinking.

- The heat or cool symbol starts blinking

- Activate the arrow keys.

- Set the desired temperature.

- The triangular icon above the key starts blinking.

To change mode:

- Push the mode key.

- Select the desired operation mode.

- Repeat the change operations.

- Push the OK key to confirm.

Reset

- Press the At home and Away keys concurrently for 10 seconds to enter

the user configuration mode.

- The number 999 is displayed in the Temperature area of the screen.

- The number 10 is displayed in the Time area of the screen.

- Activate the arrow keys.

- Set the value “0”.

- The temperature “Fd” abbreviation is displayed in the Temperature area

of the screen.

- Reset is activated.

- The Control panel is reset to the default values.

Time slots.

The Control panel can hold up to six time slots, called periods, identified

on the display as P1, P2, P3, P4, P5 and P6.

Function Heating Cooling

Indoor 20° C 24° C

Outdoor 15° C 28° C

Night 18° C 26° C

Period Start time

P1 6:00 AM

P2 8:00 AM

P3 17:00 PM

P4 22:00 PM

P5 22:00 PM

P6 00:00 AM

26

Page 27

- The triangular icons are turned on.

If the settings are correct:

- Push the OK key to confirm.

Temporary change of the programming

While the unit is in use, it might be necessary to change its programming

temporarily.

To change:

- Push the desired Touch’n’Go key.

- The function’s symbol starts blinking

The system shall start in the selected function until the following

programming or until further choice.

To go back to the original programmed period:

- Push the Touch’n’Go key that had been previously activated.

- The function’s symbol stops blinking

Settings lock

While the unit is in use, it is possible to lock the temperature values

associated with a Touch’N’Go function also for a time slot for which they

had not been meant.

To lock:

- Push the desired Touch’n’Go key.

- Push the Maintain key.

- The icon for the timer programme blinks off.

To go back to the original programming:

- Push the Maintain key.

- The icon for the timer programme starts blinking and then remains

turned on.

Change of parameters

It is possible to change the settings of different functions on the Control

Panel.

- Push the Touch’N’Go keys concurrently for 3 seconds.

- “1” starts blinking in the Time area of the screen.

- Push the mode key.

- The value of the parameter starts blinking in the Temperature area of the

screen.

- Activate the arrow keys.

- Select the desired value.

- Push the Mode key to lock the settings.

If you press the OK key the settings shall be saved and the value of

the parameter shall start blinking, with the possibility of changing it later

on.

If you press the Mode key the settings shall be saved and the change

of the next parameter shall be enabled.

To move:

- Activate the arrow keys.

To confirm:

Push the OK key to confirm.

Refer to the functions table for further details on the various

parameters.

Quick keys to activate the frequency reduction mode.

To activate:

- Push the Lock key for 10 seconds.

- The Heat pump active with frequency reduction icon lights up.

To deactivate:

- Push the Lock key for 10 seconds.

- The Heat pump active with frequency reduction icon turns off.

The frequency reduction mode has priority over other time

programmes.

Installer configuration mode:

To enter:

- Push the Zone key and the Lock key concurrently for 3 seconds.

- The number of the parameter starts blinking in the Time area of the

screen.

- The value of the parameter is shown in the Temperature area of the

screen.

To change:

- Push the mode key.

- The value of the parameter starts blinking in the Temperature area of the

screen.

- Activate the arrow keys.

Select the desired value.

Push the Mode key to lock the settings.

If you press the OK key the settings shall be saved and the value of

the parameter shall start blinking, with the possibility of changing it later

on.

If you press the Mode key the settings shall be saved and the change

of the next parameter shall be enabled.

To move:

Activate the arrow keys.

To exit without saving:

- Push the Zone key.

To confirm:

- Push the OK key to confirm.

27

Page 28

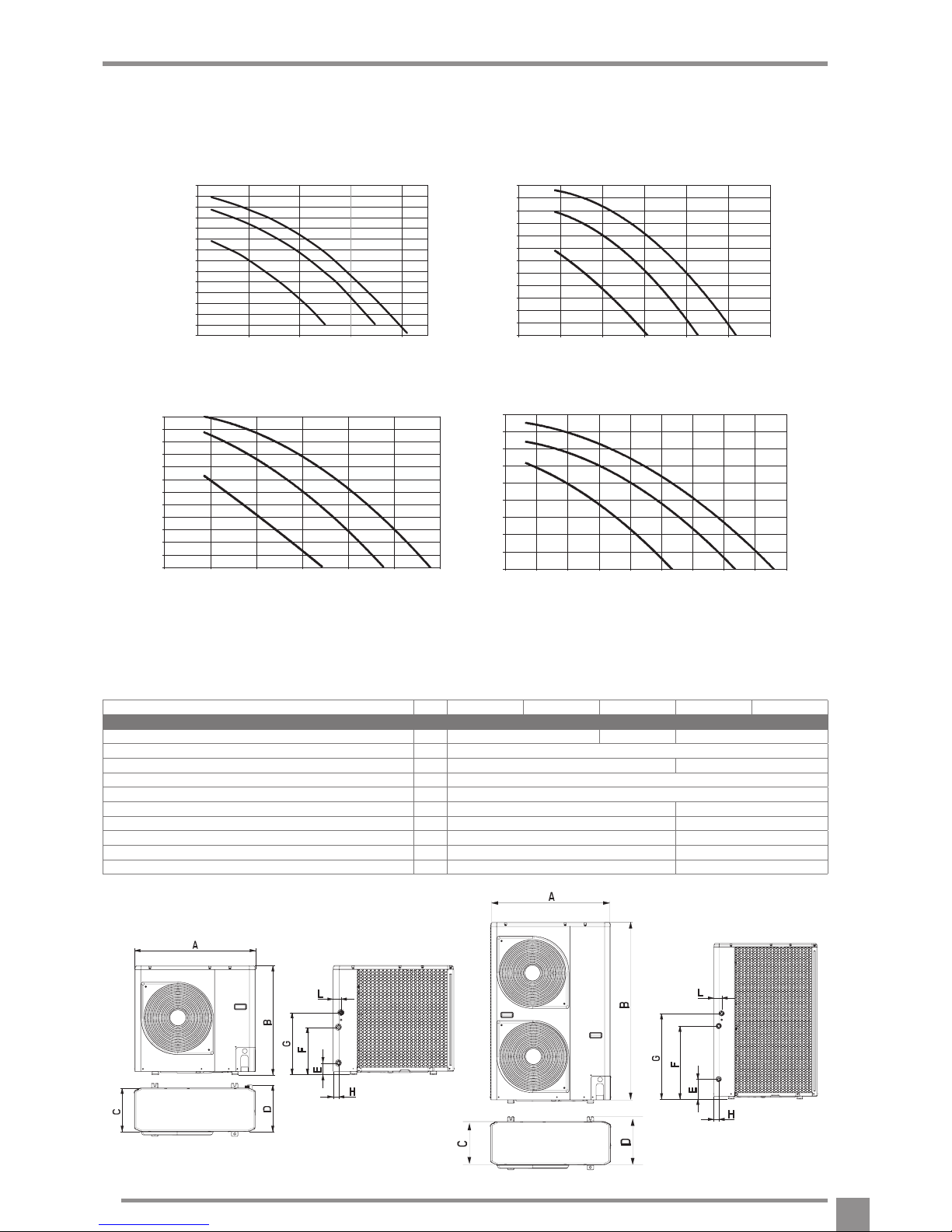

Pre-set curves

There are six available curves fro heating and two for cooling, accessible

through parameters 112 and 117 in the installer’s configuration table.

The curves are set so as to maintain and indoor temperature of 20°C.

When the external temperature reaches 20°C, the units stops providing

either heating or cooling.

1 Heating

2 Cooling

x Outdoor temperature

Y Water temperature

1

2

3

4

5

6

15

20

25

30

35

40

45

50

55

60

65

-15-10 -5 0510 15 20 25

°C

°C

Fan Coil

x

y

x

y

1

1

15

-20-15 -10-50510152025

°C

°C

20

25

30

35

40

45

50

55

60

65

7

8

9

10 11 12

1

2

0

5

10

15

20

15 20 25 30 35 40 45

°C

°C

x

y

x

2

Customised Climate Curves.

Parameters 112 and 117 set at zero make it possible to load a customised

curve in the control.

The pictures show which parameters in the installer’s configuration table

must be set to create the customised climate curves for heating and

cooling.

1 Heating

2 Cooling

x Outdoor temperature

Y Water temperature

x x

y y

1

2

0

5

10

15

20

15 20 25 30 35 40 45

par 4

1

2

3

4

15

25

35

45

55

65

-15-10 -5 0510 15 20 25

par 4

1

2

3

4

1 - MAX W T° W1 (Par No 121)

2 - NO HEAT T° W1 (Par No 120)

3 - REGION T° O (Par No 118)

4 - STOP H T° O (Par No 119)

1 - MAX COOL W T° (Par No 125)

2 - MIN COOL W T° (Par No 124)

3 - COOL STOP T° (Par No 123)

4 - MAX REGION T° (Par No 122)

28

Page 29

Adapting the heating curve.

The Control Panel adapts the water’s set-point to the actual temperature

in the room, as measured by the Control Panel’s user interface, so as

to maintain a constant temperature in the room, for comfort and energy

saving.

For this reason the actual water temperature may vary as against the

calculated set point one, by +/- 5°C.

The user can interact with this function increasing or decreasing teh setpoint, regulating the water temperature through parameter 4, as shown in

the picture.

Correction of room temperature

The user can correct the temperature measured by the Control Panel in

case of mistakes due to placement.

Through parameter 13 (see parameter’s functions table) it is possible to

correct teh temperature by +/-5°C.

Reset of default configuration

To enter:

- Push the Zone key and the Lock key concurrently for 10 seconds.

- The number 899 is displayed in the Temperature area of the screen.

- The number 10 is displayed in the Time area of the screen.

- Activate the arrow keys.

- Set the value “0”.

- The temperature “Fd” abbreviation is displayed in the Temperature area

of the screen.

- Reset is activated.

- The Control panel is reset to the default values.

Abnormal operations

Anomalies warnings.

Preliminary instructions

In the presence of operating abnormalities, the unit is secured and

blocked.

Safety block can occur randomly.

Wait for at least 10 minutes before restarting the unit.

Any repetition of the abnormal operation requires an accurate check of

the unit’s components.

Before resetting, it is necessary to remove the cause of the anomaly.

Abnormal operations are notified by the Control Panel with codes

comprising letters and numbers, which alternate with the system’s

backflow temperature.

Part of the alarms resets automatically, while others require a manual

reset by the Technical Service.

Troubles can be diagnosed by Leds on mother circuit board.

- Example: error 23

- Off for 4 seconds

- 2 blinks: first number

- Off for 2 seconds

- 3 blinks: second number

- Off for 6 seconds

- The cycle repeats until the problem is solved.

Code Description

2

Safety input alarm

3

Enter water Temperature Thermistor (EWT)

4

Actual Refrigerant Temperature Thermistor BPHE

5

Outdoor Air Thermistor of GMC

6

Loss communication to Control panel

7

Control panel Room Thermistor

8

Unit Capacity Mismatch

9

Flow Switch error / Water Pump

10

EEPROM Corrupt

11

OAT high than Stop Heat

12

OAT low than Stop Cool

13

Loss Communication to RS485 (system configuration type=6)

14

Loss of Signal From CDU

15

Leaving water Temperature Thermistor (LWT)

17

CDU Outdoor Air Thermistor (TO)

18

G-Tr short circuit protection

20

Position Detection Circuit Error

21

Current Sensor Error

22

Outdoor Heat Exchange Sensor (TE) / (TS)

23

Discharge Temperature Sensor (TD)

24

Outdoor Fan Error

26

Other Outdoor Error

27

Compressor Lock

28

Discharge Temperature Error

29

Compressor Breakdown

1 Position 4 LED Inverter Board Diagnostics (models 012 M - 015 M)

2 Location of Diagnostic LEDs circuit board

3 Wiring terminal

4 Electric connections inlet

1

2

3

29

Page 30

LED indication

Cycle control P.C. board

Cause

LED indication

D800 D801 D802 D803

D800 O: Red

D801 O: Yellow

D802 O: Yellow

D803 O: Yellow

♦: Flashing

●: Off

○: On

○ ● ● ●

Heat exchanger sensor (TE) error

● ● ○ ●

Suction sensor (TS) error

○ ○ ● ●

Hot gas discharge sensor (TD) error

● ○ ● ○

High-pressure protection error

● ○ ● ●

Outdoor air temperature sensor error (TO)

○ ○ ○ ●

Outdoor motorised fan error DC

○ ● ● ○

Communication error between IPDU (Abnormal stop)

● ○ ● ○

High-pressure release operation

● ○ ○ ●

Discharge temp. error: hot gas is too high

○ ○ ● ○

EEPROM error

● ● ○ ○

Communication error between IPDU (No abnormal stop)

♦ ● ● ●

G-Tr short-circuit protection

● ♦ ● ●

Detect circuit error

♦ ♦ ● ●

Current sensor error

● ● ♦ ●

Comp. lock error

♦ ● ♦ ●

Comp. break down

Display 1

(Initial display)

Display 2

(SW800 operation)

Error contents

●●●●●○ ●●●●●○

Normal

○○●●○○

●●◙●●○

Discharge temp. sensor (TD) error

●◙◙●●○

Heat exchanger temp. sensor (TE) error

◙◙◙●●○

Heat exchanger temp. sensor (TL) error

●●●◙●○

Outside temp. sensor (TO) error

●●◙◙●○

Suction temp. sensor (TS) error

◙●◙◙●○

Heat sink temp. sensor (TH) error

◙◙◙◙●○

Heat exchanger sensor (TE, TS) miswiring

◙◙◙◙◙○

EEPROM error

●●○●○○

◙●●●●○

Compressor break down

●◙●●●○

Compressor lock

◙◙●●●○

Current detection circuit error

●●◙●●○

Case thermostat operation

●○○●○○

●◙●◙●○

Model unset

◙●◙◙◙○

Communication error between MCU

◙◙◙◙◙○

Other error (Compressor disorder, etc.)

○○○●○○

◙◙●●●○

Discharge temp. error

◙●◙●●○

Power supply error

◙◙◙●●○

Heat sink overheat error

◙◙◙◙●○

Gas leak detection

◙◙●●◙○

4-way valve reverse error

●●◙●◙○

High pressure protective operation

●◙◙●◙○

Fan system error

●◙●◙◙○

Driving element short-circuit

◙●◙◙◙○

Position detenction circuit error

Legenda

● D800

Giallo

● D801

Giallo

◙ D802

Giallo

● D803

Giallo

● D804

Giallo

○ D805

Verde

Legenda

● Spento

◙

Lampeggiante

○

Acceso

Size 015 M only

Troubles of the inverter can be diagnosed by Leds on inverter printed

circuit board.

The error which is generating at present and the latest error (Latest error

information including present) can be confirmed by lighting led D800 to

D804 on inverter printed circuit board.

- When all DIP switch SW803 are Off the status OF error which is

generating at present is displayed.

- Only of DIP switch SW803 is turned on the error which generated

before (Latest error information including present) is displayed.

- If there is an error, any of LED D800 to D804 goes on (Display 1)

- When pushing the pushdown button switch SW800 for approx. 1

second, the display is exchanged. (Display 2)

- When pushing SW800 again or after 2 minutes, the status returns to

that of Display 1

Size 012 M only

Troubles of the inverter can be diagnosed by Leds on inverter printed

circuit board.

Before a check, confirm each bit of the DIP switch is set to off position

30

Page 31

The parameters which are Read-Only and are not editable, Key pad lock ( Lock) icon will be displayed on the screen for those parameters. The list of ReadOnly parameter numbers are given below.

Parameter Number: 7, 8, 9, 10, 11, 12, 21, 22 and 23

User feature and parameters sheet

Feature Parameter Description Icon Value range Default

value

Min Max

Mode 1 This is the selectable Mode:

0. Off

2. Cooling

3. Heating

Current Mode (and

new when changed)

- - 0

Home antifreeze 2 This parameter enables the Home Antifreeze option when the system is

Off:

1. NO. Disable

2. YES. Enable

Antifreeze 1 2 1

Home antifreeze t° 3 Home Antifreeze threshold Temperature value °C 6°C 12°C 6°C

Adjust t° z1 4 Water set point adjustment for room temperature at Control panel zone °C -5°C +5°C 0°C

Freq reduct mode 5 This code gives information whether Silence mode / Frequency Reduc-

tion/ Night mode is active

1. Not Active

2. Active

1 2 1

Freq reduct 6 Value of the frequency reduction in % of CDU 50% 100% 100%