VOKERA Aria, Aria Series, Aria 6HP, Aria 8HP, Aria 11HP Installation & Servicing Instructions Manual

Page 1

Aria

Air to water heat pump

Installation

& Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

Page 2

BUILDING REGULATIONS

This appliance must be installed and serviced

only by a competent person in accordance with

the current: IEE Regulations,

Building Regulation, Building Standards

(Scotland) (Consolidation), Building Regulations

(Northern Ireland), local water by-laws,

Health & Safety Document 63S (The Electricity at

Work Regulations 1989), IS 813 (Eire) and other

local requirements.

The relevant Standards should be followed,

including:

BS EN 15450: Heating systems in buildings –

Design of heat pump heating systems.

BS EN:12828 : Central heating for domestic

premises.

BS EN 7593 : Treatment of water in domestic hot

water central heating systems.

BS EN 14511 : Requirements heat pumps for

space heating and cooling.

BS EN 378 : Safety and environmental

requirements for heat pumps.

The Health and Safety at Work Act 1974.

The Management of Health and Safety at Work

Regulations 1999.

The Construction (Health, Safety and Welfare)

Regulations 1996.

The Construction (Design and Management)

Regulations 1994.

The Lifting Operations and Lifting Equipment

Regulations 1998.

Where no specific instruction is given, reference

should be made to the relevant codes of Practice.

There have been no banned substances

used in the manufacture of these

appliances.

________________________________________________________________

INDEX

1 GENERAL

.....................................................5

1.1 GENERAL PRECAUTIONS

....................................... 5

1.2 FUNDAMENTAL SAFETY RULES

............................ 5

1.3 DESCRIPTION OF THE APPLIANCE

....................... 6

1.4 IDENTIFICATION

...................................................... 7

1.5 TECHNICAL DATA

................................................... 8

1.6 HYDRAULIC DATA

.................................................. 9

1.7 ACCESSORIES

....................................................... 9

1.7.1 Electric heater

............................................... 9

1.8 HEAT PUMP COOLING CIRCUIT

........................... 10

1.9 ELECTRICAL PANEL AND WIRING

DIAGRAM ...... 10

1.9.1 ARIA 6HP / 8HP Models ............ 10

1.9.2 ARIA 11HP Model ........................... 12

2 INSTALLER

................................................ 13

2.1 CONTROL PANEL

................................................... 13

2.2 ACTIVATION & DEACTIVATION

............................. 15

2.2.1 Heating / Cooling activation

......................... 15

2.2.2 Heating / Cooling deactivation

..................... 16

2.3 OPERATIONS PERFORMED WITH

THE REMOTE ON-OFF “SO” and

SUMMER-WINTER “SEI” SWITCHES

..................................................... 17

2.3.1 Cooling function

............................................ 17

2.3.2 Heating function

............................................ 17

2.4 SHUTDOWN FOR LONG PERIODS

....................... 17

2.5 CLEANING

.............................................................. 17

2.6 MAINTENANCE

....................................................... 17

2.7 USEFUL INFORMATION

......................................... 18

2.8 RECEIVING THE PRODUCT

.................................. 18

2.9 DIMENSIONS WITH PACKAGING

.......................... 18

2.10 DIMENSIONS WITHOUT PACKAGING

.................. 19

Page 3

2.11 HANDLING AND TRANSPORT

............................... 19

2.12 POSITIONING

......................................................... 20

2.12.1 Fixing position of dampers

............................ 21

2.13 HYDRAULIC CONNECTIONS

................................ 22

2.14 POSITION OF THE FIXINGS

.................................. 24

2.15 ELECTRICAL CONNECTIONS

............................... 24

2.16 OUTSIDE CONNECTIONS AND

ELECTRICAL

POWER CABLE INFEED

........................................ 25

2.17 LOADING AND EMPTYING THE

SYSTEM ............ 27

2.17.2 Loading

......................................................... 27

2.17.2 Emptying

....................................................... 44

3 TECHNICAL SERVICE

............................... 28

3.1 RECOMMENDED OPERATING

CONDITIONS

.......................................................... 28

3.2 LIMIT OPERATING CONDITIONS

.......................... 28

3.3 PREPARATION FOR THE FIRST

STARTING UP

........................................................ 29

3.4 FIRST START-UP

.................................................... 29

3.6 ACTIVATION OF “SO” AND “SEI”

CONTROL ......... 30

3.6.1 Setting the “SO” remote control

.................... 30

1 GENERAL 1 GENERAL

3.6.2 Setting the “SEI” remote control

.................... 30

3.7 ANOMALY SIGNALS

............................................... 30

3.7.1 Manual anomaly reset

................................... 31

3.8 ACTIVATION and DEACTIVATION

OF THE UNIT

..........................................................31

3.9 OPERATIONS PERFORMED BY THE

ON-OFF “SO” AND SUMMER-WINTER

“SEI”

REMOTE SWITCHES

............................................. 33

3.10 DEFROSTING CHECK

............................................ 34

3.11 CONTROLS DURING AND AFTER

THE FIRST

START-UP

............................................................... 34

3.12 LONG TERM SHUTDOWN

..................................... 34

3.13 ROUTINE MAINTENANCE

..................................... 34

3.14 EXTRAORDINARY MAINTENANCE

....................... 34

3.14.1 Loading coolant gas

...................................... 34

3.14.2 Compressor

.................................................. 35

3.15 DISPLAY AND CONTROL

PARAMETERS ............. 35

3.15.1 Main parameters and variable

characteristics ...............................................

35

3.15.2 Access and modification of

parameters ........ 35

3.16 TROUBLESHOOTING

............................................. 36

Page 4

The following symbols are used in some parts of the booklet:

ATTENTION = for actions that require special precautions and an adequate preparation

FORBIDDEN = for actions that must NOT be carried out

1.1 GENERAL PRECAUTIONS

After removing the packing, check the

integrity and completeness of the contents. If

they do not correspond, contact the Vokera

agency that sold the unit.

Vokera appliances must be installed by

companies that are enabled in accordance with

legislations in force, and on completion of the

work, a declaration of conformity must be given

to the owner certifying that the installation has

been done correctly and in accordance with the

legislation in force and the indications given by

Vokera in the instruction booklet supplied with the

appliance.

These appliances have been built for

heating or climatisation of environments and

must be destined for this use, compatibly with

their performance characteristics.

These units contain R410A refrigerant

gas; take great care not to damage the gas circuit

and the finned battery. If the refrigerant gas

escapes, set the system master switch to

“OFF” and call immediately the Vokera technical

service, or other qualified personnel; do not

intervene personally on the unit.

If the equipment is not used for a long

period, the following operations should be carried

out:

- Turn the system master switch to “OFF”

- Close the water taps

- If there is the risk of freezing, make sure that

anti-freeze liquid has been added, otherwise

empty the system.

This instructions booklet is an integral part

of the unit and consequently must be kept with

care and must ALWAYS accompany the unit,

even when this is transferred to another owner or

user or transferred onto another system. If it gets

damaged or lost, request another copy from the

local Vokera technical service.

The manufacturer accepts no

responsibility, either contractual or extra

contractual, for damage to persons, animals or

property arising from incorrect installation or

adjustment, maintenance or improper use.

Should water leak from the unit, turn the

unit master switch to “OFF” and close the water

taps. Urgently call the Vokera service department

or professionally qualified personnel and under

no circumstances intervene personally on the

unit.

Repair or maintenance interventions must

only be carried out by the Vokera technical service

or personnel qualified according to the provisions

of this manual. Do not modify or tamper with the

unit as this could cause situations of danger and

the manufacturer shall not be responsible for any

damaged caused.

Page 5

1.2 FUNDAMENTAL SAFETY RULES

The use of products that use of electricity and

water requires the observation of some

fundamental safety rules such as:

Do not open the access flaps to the inner

parts of the unit without first having set the

system master switch to “OFF”.

Do not allow children to operate this unit.

Do not touch the unit if barefoot or with

parts of the body that are wet or humid.

Do not clean the unit without first

disconnecting it from the mains power supply by

switching the system master switch to “OFF”.

Do not modify or adjustment units without

authorisation and the indications of the

manufacturer.

Do not pull out or twist the electric cables

coming out of the unit, even when disconnected

from the mains power supply.

Do not introduce objects or substances

through the aspiration grills or the air outlets

Do not leave the packaging material

within the reach of children as it can be a source

of risk.

Before undertaking any maintenance

intervention on the unit, it is compulsory to cut

“OFF” the mains electrical supply by setting the

double pole master switch on the system to

“OFF”.

Do not spray or tip water directly onto the

unit.

Do not climb onto the unit or rest any

object on it.

Page 6

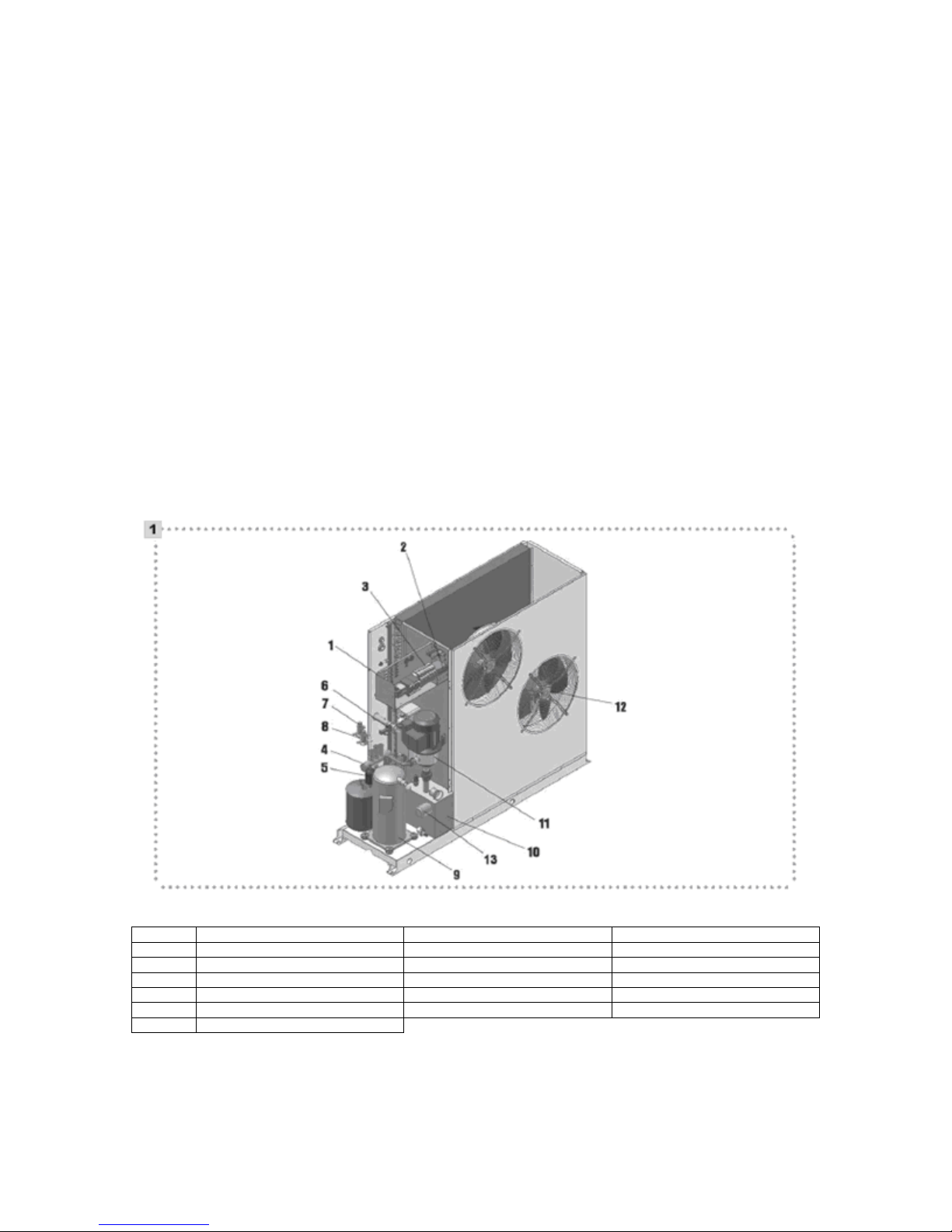

1.3 DESCRIPTION OF THE APPLIANCE

The Vokera ARIA heat pumps are available with

single phase power supplies, capable of

producing both hot water for heating and cold

water for cooling domestic, residential

environments and equipped with supplementary

electrical resistances which allow correct

functioning even in the most critical

environmental conditions They are best suited for

under floor heating or low temperature systems.

They use an internal Scroll type rotary

compressor mounted on anti-vibration supports

and located in a special compartment,

electronically controlled variable speed helical

fans that ensure silent high performance. The

user side plate exchanger in AISI 316 stainless

steel is insulated with an anti-condensation

coating and fitted with a flow regulator. The units

are fitted with various safety devices such as

pressure switches, flow gauge, sensors, specific

circuit breakers etc. An electronic device with

microprocessor control manages the operation.

The models are supplied with inertial storage built

into the unit.

Legend fig. 1

1 Electrical panel 8 Expansion valve (winter)

2 Control panel 9 Scroll compressor

3 Thermo magnetic switch 10 Hydraulic kit

4 4 way-valve 11 Pump

5 Dehydrator filter 12 Axial fan

6 Flow switch 13 Electric heater

7 Expansion valve (summer)

Page 7

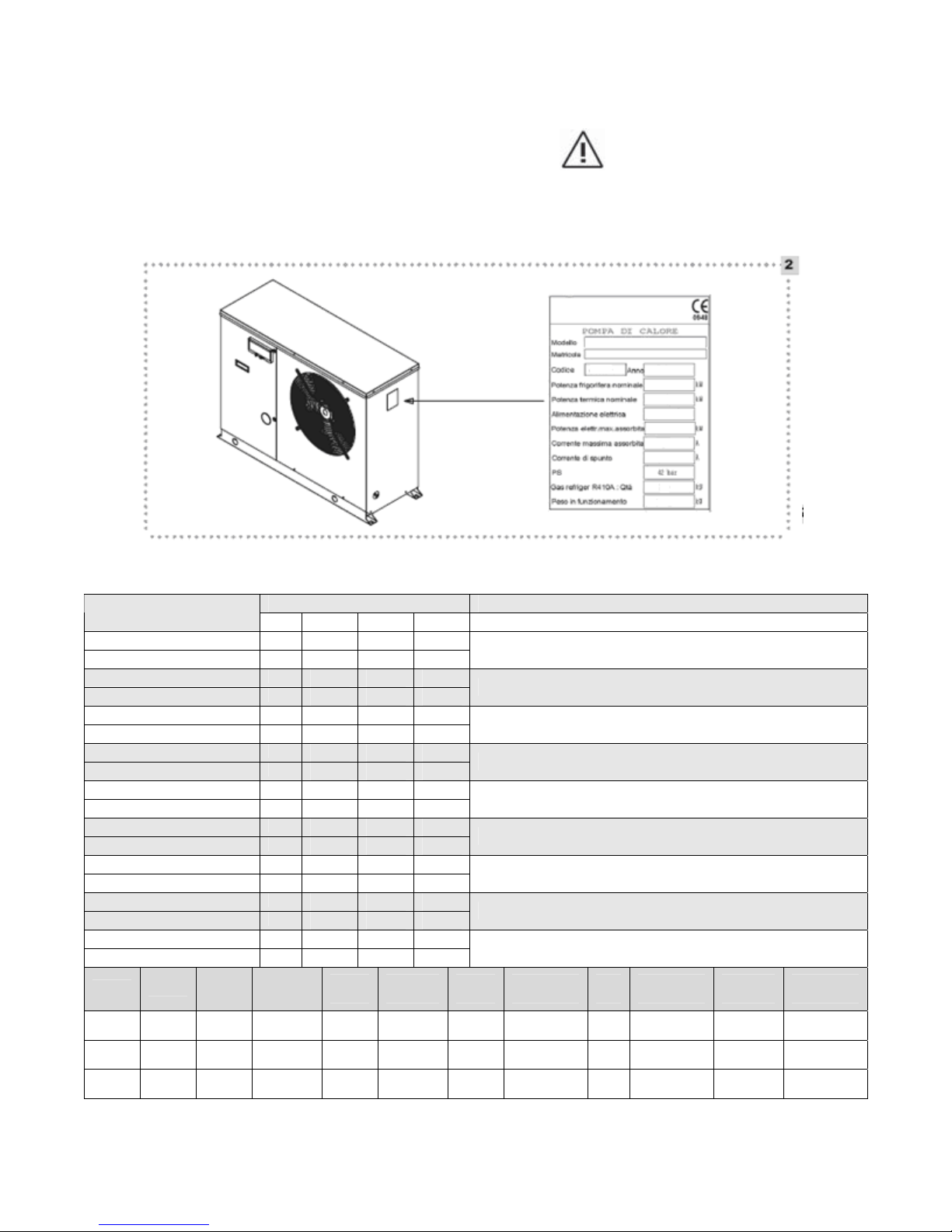

1.4 IDENTIFICATION

The Vokera ARIA unit can be identified by:

- Technical plate (fig. 2) It indicates the

technical and performance data of the

unit.

-

The tampering with, removal or

lack of the technical plate or anything

else that makes a certain product

identification impossible will make

correct maintenance or installation

operations more difficult.

1.5 TECHNICAL DATA

DESCRIPTION

Thermal power (1) kW

Absorbed power (1) kW

Thermal power (2) kW

Absorbed power (2) kW

Thermal power (3) kW

Absorbed power (3) kW

Thermal power (4) kW

Absorbed power (4) kW

Thermal power (5) kW

Absorbed power (5) kW

Thermal power (6) kW

Absorbed power (6) kW

Thermal power (7) kW

Absorbed power (7) kW

Thermal power (8) kW

Absorbed power (8) kW

Thermal power (9) kW

Absorbed power (9) kW

6HP

8HP

11HP

Empty

weight

110kg

112kg

164kg

SCRIPTIONODELLO / MODELS

Nominal

water

flow

1.0

m³/h

1.2

m³/h

1.6

m³/h

Diameter

hydraulic

fittings

¾”

¾”

Models

6HP 8HP 11HP

6.8 8.3 11.0

1.74 2.11 2.81

5.9 7.2 9.5

1.78 2.2 2.90

5.0 6.2 8.0

1.79 2.26 2.97

6.6 8.1 10.6

2.14 2.68 3.5

5.6 7.1 9.3

2.16 2.77 3.6

7.5 10.3 13.0

1.8 2.28 2.93

6.9 9.3 11.8

2.0 2.72 3.46

6.0 8.2 10.2

1.76 2.34 3.01

5.3 7.1 9.3

2.04 2.81 3.58

1”

Tank

capacity

16

litres

16

litres

36

litres

Electric

heater

3kW 230~ IP44 1 3.300 m³/h 58db (A) 1.7kg

3kW 230~ IP44 1 3.250 m³/h 58db (A) 1.9kg

6kW 230~ IP44 2 6.500 m³/h 62.8db (A) 2.7kg

(1) outside air d.b. + 7°C / w.b. + 6°C, water 35-30°C.

(2) outside air + 0°C, water 35 - 30°C

(3) outside air - 7°C, water 35 - 30°C

(4) outside air + 7°C, water 45 - 40°C

(5) outside air + 0°C, water 45 - 40°C

(6) outside air + 30°C, water 18 - 23°C

(7) outside air d.b. + 35°C / w.b. +24°C, water 18 -

23°C

(8) outside air + 30°C, water 7 - 12°C

(9) outside air d.b. + 35°C / w.b. +24°C, water 7 -

12°C

Power

voltage

Protection

rating

Axial

fan

Nominal

air flow

Noise

level

Refrigeration

load

Page 8

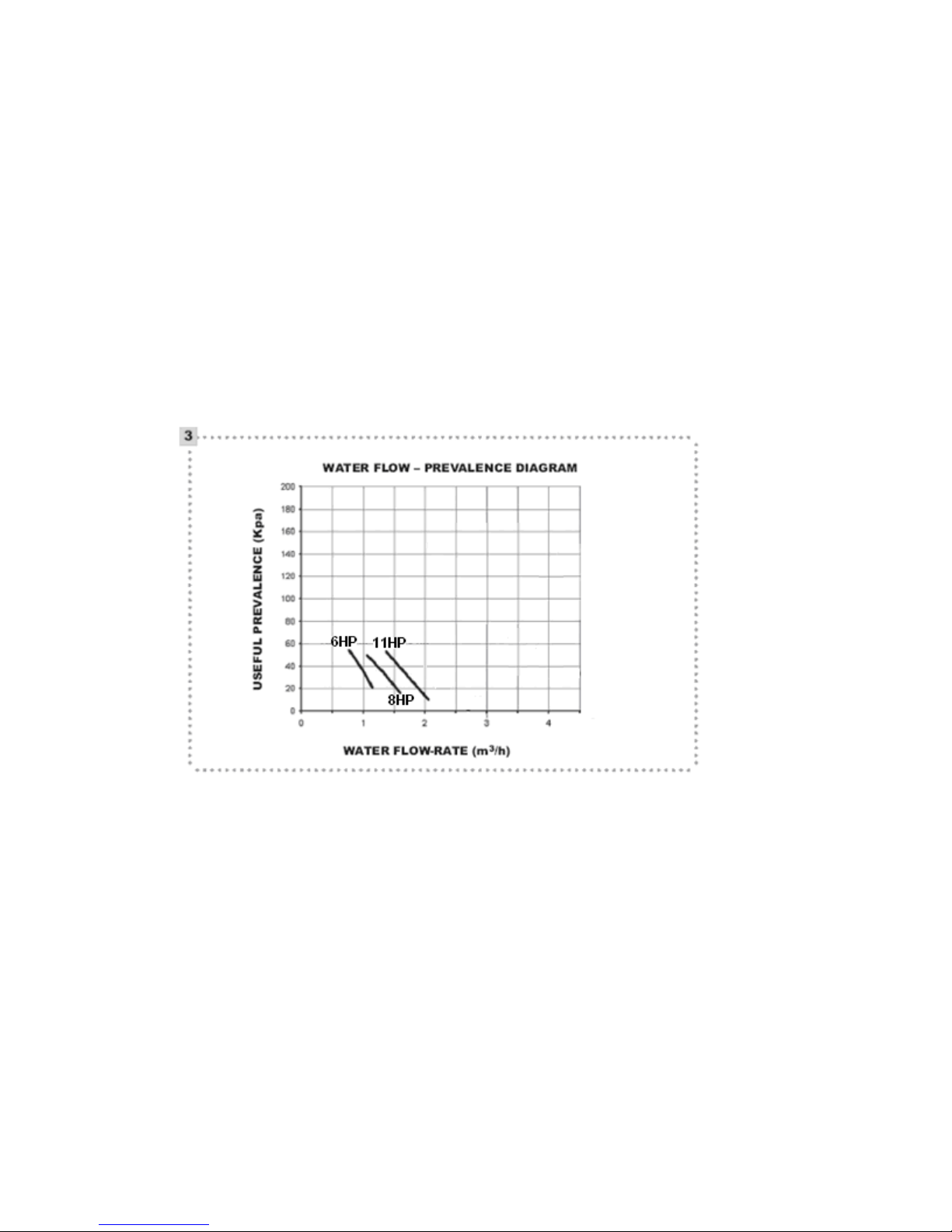

1.6 HYDRAULIC DATA

The following diagram (fig. 3) indicates the

residual prevalences with the nominal water flow

± 20%.

1.7 ACCESSORIES

The accessories indicated below must be

ordered separately

ACCESSORIES CODE

Remote control Kit 4014762

Anti-vibration supports Kit 4015360

Snow protection 6HP – 8HP 4014763

Snow protection 11HP - 4014764

Soft Start Kit 4014766

Hot water thermostat kit 4014767

1.5 kW single phase electric heater 4383270

1.7.1 Electric heater

The electric heater is integrated into the heat

pump to ensure continuity of service and is

inserted through a special plug into the storage

tank.

It is enabled to facilitate the compressor during

the start-up phase (it keeps the water at a set

temperature value (e.g. 30°C) and when the

atmospheric conditions become particularly

critical for correct machine operation (continual

frost caused by the low temperature and

excessive humidity).

Page 9

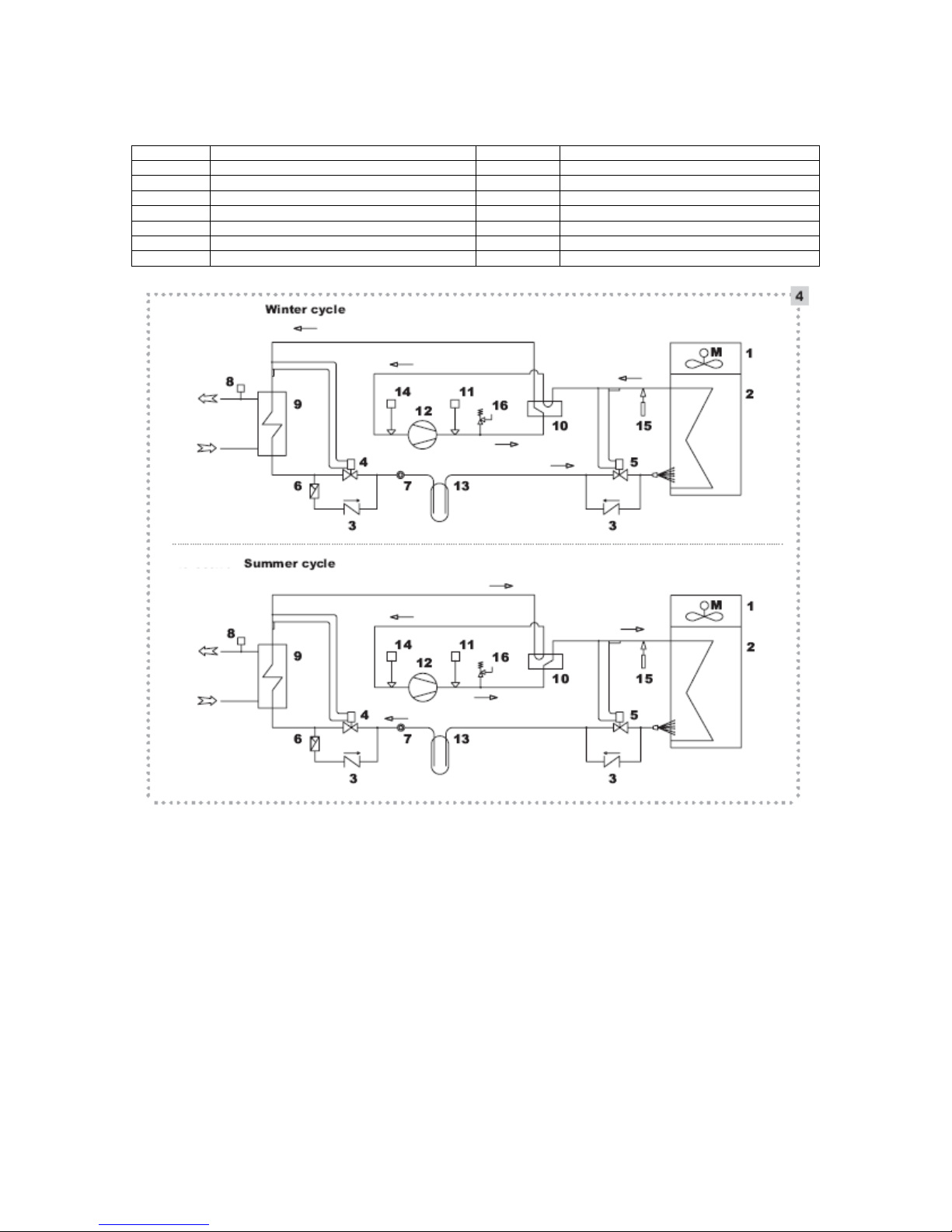

1.8 HEAT PUMP COOLING CIRCUIT

1 Fan 9 Plate exchanger

2 Finned battery (evaporator) 10 4 way-valve

3 Non-return valve 11 High pressure safety pressure-switch

4 Thermostatic valve (summer cycle) 12 Compressor

5 Thermostatic valve (winter cycle) 13 Liquids container

6 Filter 14 Low pressure safety pressure-switch

7 Fluid indicator 15 Pressure transducer

8 Flow switch 16 Safety valve

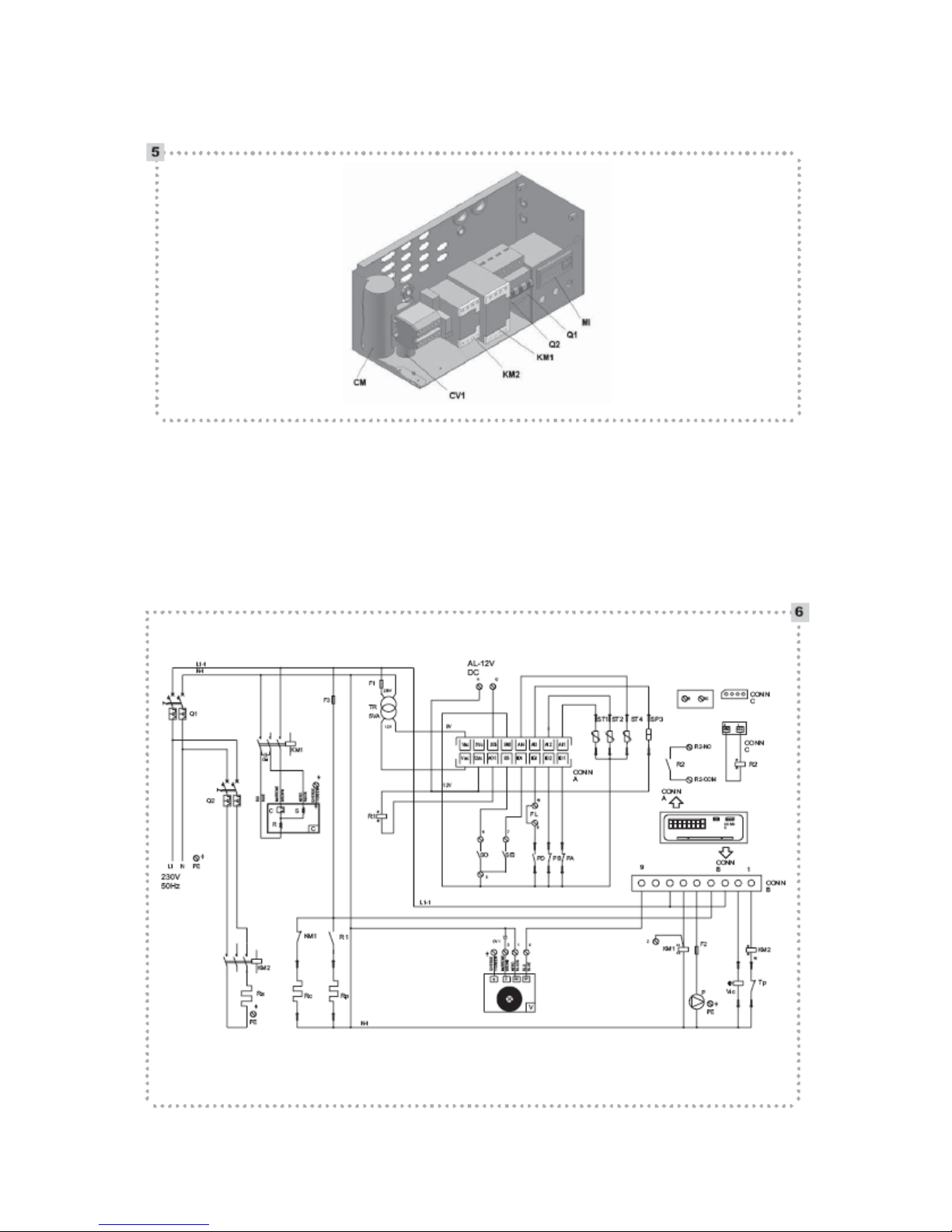

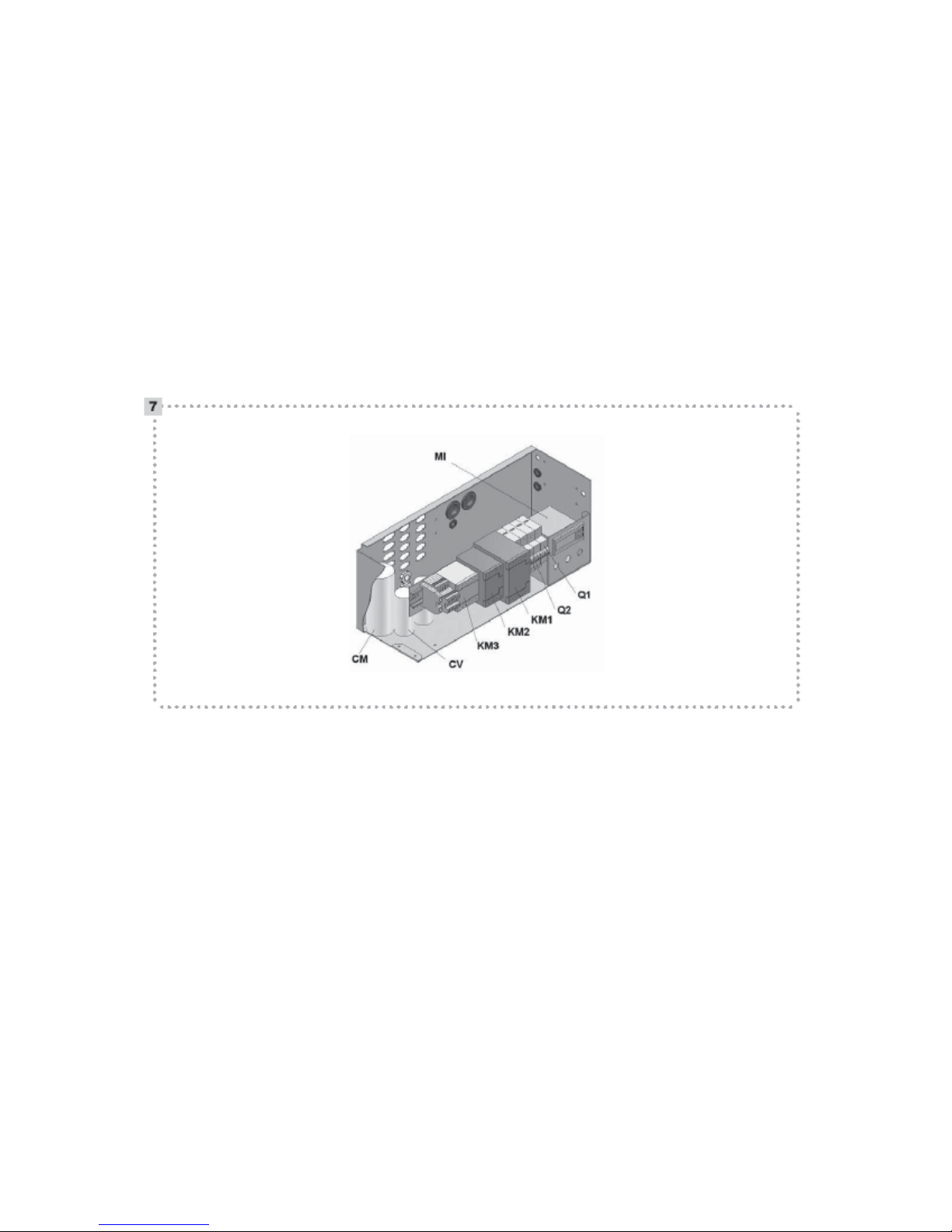

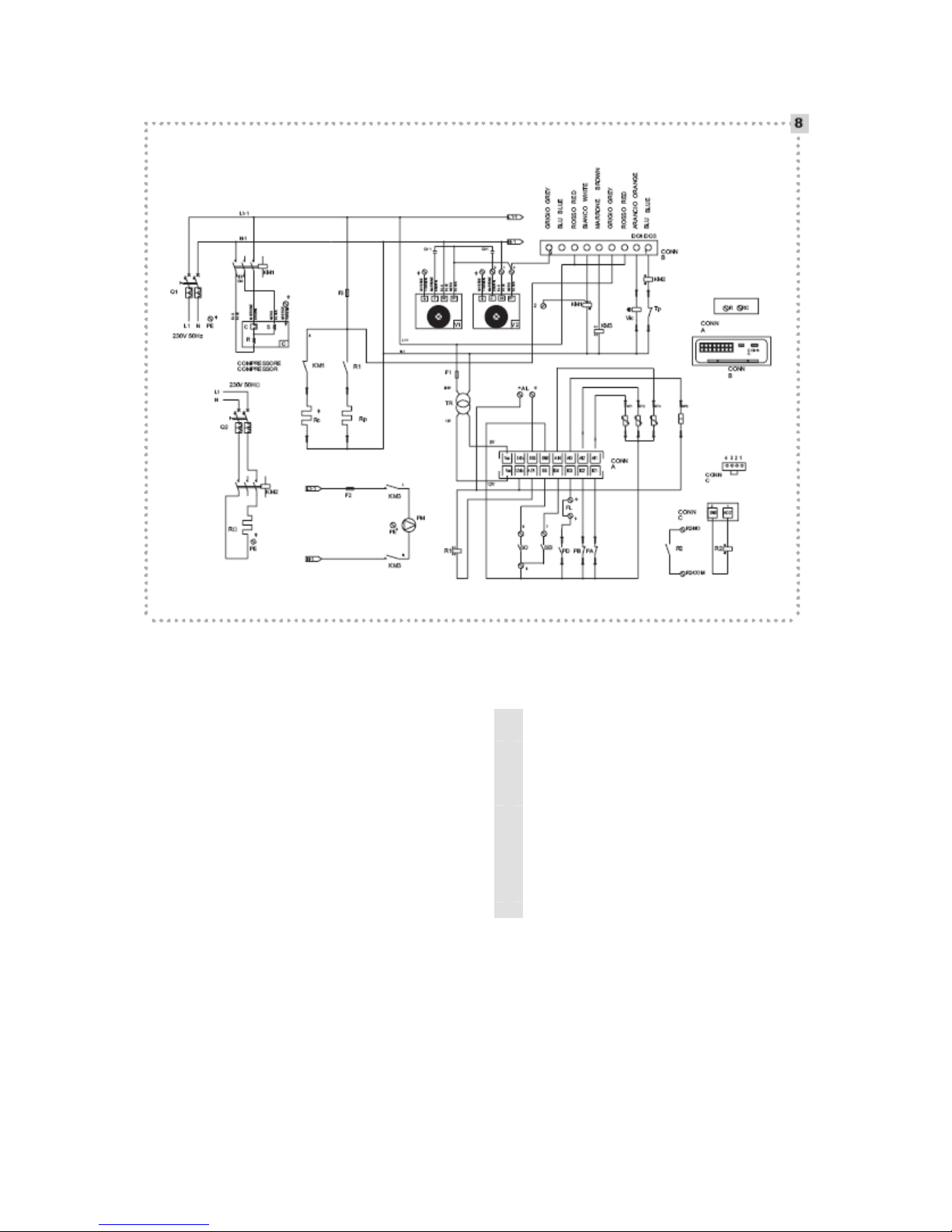

1.9 ELECTRIC PANEL AND WIRING

DIAGRAM

1.9.1 ARIA 6HP / 8HP Models

Factory installed components

CM Run condenser

CV1 Fan condenser

KM1 Compressor contactor

KM2 Resistance contactor

MI Control panel

Q1 Master circuit breaker

Q2 Support resistance circuit breaker

C Compressor

F1 Control safety fuse

F2 Pump safety fuse

F3 Resistance safety fuse

Conn.A Input terminal board

Conn.B Loads output terminal board

P Circulator

The units are equipped with an electric panel

consisting of the following components:

PD Flow switch

Tp Safety thermostat

TR Auxiliary circuits transformer

SP3 Pressure transducer

ST1 Temperature probe in exchanger inlet

ST2 Temperature probe in exchanger outlet

ST4 Outside air temperature probe

PA High pressure pressure-switch

PB Low pressure pressure-switch

VIC 4 way-valve

Rp Plate exchanger resistance

Rc Compressor cover resistance

Rs Support resistance

R1 / R2 Rp relay/boiler contact auxiliary relay

V1 Fan

Page 10

Components to mount on installation (not supplied with the unit)

AL Remote alarm signal (output 12V DC max 20mA)

FL Outside flow switch

SEI Remote SUMMER-WINTER switch

SO Remote ON-OFF switch

Page 11

1.9.2 ARIA 11HP Model

Factory installed Components

CM Run condenser

CV1/2 Fan condenser

KM1 Compressor contactor

KM2 Resistance contactor

KM3 Pump contactor

MI Control panel

Q1 Master circuit breaker

Q2 Support resistance circuit breaker

C Compressor

F1 Control safety fuse

F2 Pump safety fuse

F3 Resistance safety fuse

Conn.A Inputs terminal board

Conn.B Loads output terminal board

P Pump / Circulator

PD Flow switch

Tp Safety thermostat

TR Auxiliary circuits transformer

SP3 Pressure transducer

ST1 Temperature probe in exchanger inlet

ST2 Temperature probe in exchanger outlet

ST4 Outside temperature probe

PA High pressure pressure-switch

PB Low pressure pressure-switch

VIC 4 way-valve

Rp Plate exchanger resistance

Rc Compressor cover resistance

Rs Support resistance

R1 / R2 Rp relay/boiler contact auxiliary relay

V1/2 Fan

Components to mount on installation (not supplied with the unit)

AL Remote alarm signal (output 12V DC max 20mA)

FL Outside flow switch

SEI Remote SUMMER-WINTER switch

SO Remote ON-OFF switch

Page 12

2.1 CONTROL PANEL

The control panel can be used to make all the

adjustments necessary for the heat pump

operation and display the values of the main

parameters and the alarms. It is located on the

front panel of the electric panel inside the unit

and is accessible through a flap positioned on the

inspection panel.

Display:

During normal operation it indicates the

temperature of the water returning from the

system.

It can also indicate the value of all the set

parameters and the code of any alarms.

Fig. 15

A

Alarm

B

Mode (Heat, Cool, etc....)

C

Economy (configurable)

D

Clock

E

Unit of measure

F

Navigation in the menu

G

Resources (Compressor, Fans, etc....)

Page 13

KEYS

Pressure with immediate

release

Scrolls the items in the

menu, increases the values

of the parameters

Scrolls the items in the

menu, decreases the

values of the parameters

Manual alarm rearm

Symbol printed on

front panel

Prolonged pressure (if key

is suitably configured)

Defrosting request

Switching on/off of the unit

(and vice versa)

Access to machine status

menu (setpoint, AI, DI, DO,

hours completed, pump

hours, etc....), access to

submenus, access to

parameter value,

confirmation of parameter

value

Exit from menu, parameters

list, parameter value and

return to upper level

Accesses

programming

menu

SET

used for:

• Access to machine status menu

• Access to sub-menus

• Access to parameter value

• Confirmation of parameter value or exit

• prolonged pressure accesses the menu for the

selection of the fundamental display (if the key is

Accesses the fundamental

avail

Accesses operating

mode

Display configuration file

mode selection file

(Heat/Cool/Std-by)

configured for this function); with the up and

down keys the options present can be displayed

(with display based on the machine configuration)

and pressure on the “set” key confirms the

selection.

UP

used for:

Page 14

• scrolling up the display of files and parameters

• Increase of the parameter value (if in parameter

value modification)

• Prolonged pressure accesses the function

called manual defrosting (if the key is configured

for this function), only from fundamental display.

DOWN

used for:

• Scrolling down the display of files and

parameters

• Decrease of the parameter value (if in

parameter modification)

• Prolonged pressure switches the unit on/off

from fundamental display (if the key is configured

for this function)

operations by intervening on the control panel or

acting on the remote switch (if present).

To access the control panel, open the flap as

follows:

- Remove the locking screw (fig. 16 ref. A)

- Simultaneously press on points B (fig. 16 ref. B)

and lift the flap (fig. 16 ref. C)

When operations on the control panel are

completed:

- Close the flap and reposition the locking

screw.

After powering up the unit, “OFF” will appear

on the display.

ESC

used for:

• Exit from the menu, from the parameters list,

from the parameter value without saving the

value and return to the previous level. Prolonged

pressure from fundamental display (if the key is

configured for this function) accesses the file for

changing the mode; with the UP and DOWN keys

displays the modes present (with display based

on the machine configuration) and pressure on

the SET key to confirm the selection made.

SET

+ ESC simultaneously to

access the parameters, functions, password etc

files.

UP

+ DOWN simultaneously to

rearm alarms when present.

2.2 ACTIVATION AND DEACTIVATION

After the first start-up by the Vokera technical

service the ARIA heat pump is adjusted for

“automatic” operation and no other interventions

are necessary. Therefore the plant manager must

perform the ACTIVATION and DEACTIVATION

Press the

key to enable the machine in

stand-by, now the circulation pump should switch

on and the display will show the temperature of

water returning from the system.

Now proceed as follows:

2.2.1 Heating/cooling activation

To select the operating mode hold down the

key until the message “HEAT”, “COOL” or

“STBY” appears, according to the current

operating status of the controller.

Select with UP

function and confirm with the SET

or DOWN the HEAT

key.

Heating (WINTER CYCLE) -By selecting HEAT

the

symbol lights up.

Cooling (SUMMER CYCLE) -By selecting COOL

the

symbol lights up.

Page 15

2.2.2 Heating/cooling deactivation

Keep

pressed for a few seconds until the

message “COOL” or “HEAT” appears (cycle

enabled). Select with the

confirm with the SET

“STBY” key and

key; the symbol

lights up.

To change the Heating/Cooling operating

mode on the heat pump models, it is advisable to

call the Vokera technical service.

2.3 OPERATIONS PERFORMED WITH THE

REMOTE ON-OFF “SO” and SUMMERWINTER

“SEI” SWITCHES (IF PRESENT).

2.3.1 Cooling function

Activation

- Position the SUMMER-WINTER

remote switch (SEI) to “OFF”.

- Position the ON-OFF remote

switch (SO) to “ON”.

The warning LED on the control

panel lights up.

Deactivation

- Position the ON-OFF remote switch (SO) to

“OFF”.

The message “OFF” flashes on the

CONTROL PANEL.

In case of a power failure lasting more

than four hours, when power returns, keep the

unit powered but deactivated for at least eight

hours.

In case of a power failure lasting less than

four hours, when power returns, keep the unit

powered but deactivated for the same number of

hours that the power was out.

2.4 SHUTDOWN FOR LONG PERIODS

If the ARIA heat pump is not used for a long

period, the following operations should be

performed:

- From the control panel, deactivate the unit it

whichever mode it is operating in.

- Position the remote switch to “OFF” (if present)

After deactivating the unit:

- Deactivate the indoor terminal units by setting

the switch on each appliance to “OFF”.

- Set the system master switch to “OFF”.

- Close the water taps.

If there is a possibility that the outside

temperature falls below zero there is a risk of

freezing.

The hydraulic system MUST BE EMPTIED or

else antifreeze liquid (e.g. ethylene glycol) must

be added in the doses suggested by the

manufacturer of the liquid. It advisable to contact

the Vokera technical service.

The message “OFF” appears and

flashes on the CONTROL PANEL.

2.3.2 Heating function

Activation

- Position the SUMMER-WINTER

remote switch (SEI) to “ON”.

- Position the ON-OFF remote

switch (SO) to “ON”.

The warning LED lights up on the control

panel.

Deactivation

- Position the ON-OFF remote

switch (SO) to “OFF”.

To start the unit up again after a long

period of inactivity, contact the Vokera technical

service.

2.5 CLEANING

The only essential cleaning that the plant

manager needs to perform is on the outside

panels of the cooler; this should be done with a

cloth and soap and water. For persistent stains

damp the cloth with a solution of 50% methylated

spirit or a specific product in water. When the

cleaning is completed, carefully dry the surfaces.

Do not use sponges with abrasive

products or powder detergents.

Do not perform cleaning operations until

the unit has been disconnected form the mains

power supply by turning the master switch on the

system to “OFF”.

2.6 MAINTENANCE

Routine maintenance is indispensable to

maintain the efficiency, safety and reliability over

the years. This can be carried out every six

Page 16

months, for some interventions and annually

for

others, by a competent person or by the Vokera

technical service that is technically prepared and

authorised and always has original spare parts

available when necessary.

For installations close to the sea, perform

the maintenance interventions twice as often.

Before starting any maintenance

interve o cut off

ntion on the unit, it is compulsory t

the mains power supply by turning the double

pole master switch on the system to “OFF”

.

7 USEFUL INFORMATION

2.

Vendor:

................

...............................................................

.........

s

Addres

...............

................................................................

...............

Tel.

.....................................................................

..........

...............

Installer:

................

...............................................................

.......

.

Name

............

...................................................................

................

Address

...............

................................................................

...............

tel.

........................................................................

.......

................

Technical s

ervice and assistance:

..............................................

Name.

............

...................................................................

................

Address

...............

................................................................

...............

Dimensions (mm) 6HP 11HP

8HP

L (mm) 040 1240 1

H (mm) 805 1000

P (mm) 378 428

L1 (mm) 1100 1300

P1 (mm) 425 472

P2 (mm) 890 1040

tel.

...............................................................................

................

DATE INTERVENTION

2.8 RECEIVING THE PRODUCT

The ARIA heat pumps are delivered in a single

package on a wooden pallet, protected by

cardboard packaging and accompanied by:

- instruction manual

- warranty certificate

- label with bar code

- first start up

- spare parts list.

The instruction manual is an integral part

of the unit and it should be read and then kept

with care.

It is advisable to position the unit in the

place of installation before removing the

packaging.

Do not dump packaging materials in the

environment or leave them within reach of

children as they are potentially dangerous.

2.9 DIMENSIONS WITHOUT PACKAGING

See page 8 for the weights.

Return / inlet 3/4" 1"

(inch)

Reintegration 1/2" 1/2"

(inch)

• P2: Dimensions with snow protection

Page 17

2.10 DIMENSIONS WITH PACKAGING

Dimensions

(mm)

L (mm) 1140 1340

H (mm) 950 1150

P (mm) 480 540

6HP

8HP

11HP

2.11 HANDLING AND TRANSPORT

The handling and transport must always be

carried out with the unit in a horizontal position. If

a fork lift truck is used, insert two metal pipes in

the special holes in the base and use suitable

lifting means. If a crane is used, pass the ropes in

the upper part of the wooden base taking care

not to apply pressure on the unit (fig. 18).

It is advisable to position the unit in the place of

installation before removing the packaging.

When the packaging has been removed,

handling is done by inserting two metal pipes

(max diameter 33 mm, min thickness 3.2 mm) in

the special holes in the base and use suitable

lifting means.

The weight of the unit is unbalanced

towards the compressor side (electrical panel

side).

During transport, the unit must always be

kept in a vertical position.

Handling must be performed by qualified

personnel, adequately equipped and with tools

that are suitable for the weight of the unit.

Instructions for lifting

- Make sure that all the panels are well fixed

before moving the unit.

- Before lifting, check the weight of the unit on the

CE label.

- Use all the lifting points indicated, and only

those.

- Use ropes of equal length.

- Handle the unit with care and without jerky

movements.

Page 18

2.12 POSITIONING

The position of the ARIA appliances must be

decided by the system designer or by a suitable

expert and must consider both the purely

technical issues and any local legislation in force

which foresees special authorisations (e.g. urban

planning, building regulations, environmental

pollution etc.).

It is therefore advisable to obtain all necessary

authorizations before starting the installation.

The appliances must be:

- Positioned on a flat surface capable of

supporting the weight.

- Positioned on a slab that is sufficiently rigid and

that does not transmit vibrations to any rooms

that are adjacent or below.

It is advisable to place a rubber mat between the

appliance and the slab (hardness 60 shores,

thickness 10 mm) or use the antivibration damper

supports available as accessories.

The unit is designed to be installed outside and

must be placed in a safe area as shown in the

figure below.

The spaces indicated are necessary to avoid air

currents and allow normal cleaning and

maintenance operations.

It is advisable to avoid:

- installation in wells or enclosed areas

- obstacles or barriers that could cause the

recycling of expelled air

- installation in areas with aggressive

atmospheric conditions

- installation in narrow areas where the noise

level of the appliance could be amplified by

reverberations or resonance

- installation in areas subject to the accumulation

of dust, leaves or anything that could reduce the

efficiency of the appliance by obstructing the air

flow

- situations where the expulsion of air from the

appliance can penetrate into adjacent inhabited

areas through doors or windows, provoking

inconvenience to persons.

Page 19

Dimensions

(mm)

6HP

8HP

11HP

A 1000 1200

B 500 600

C 1000 1000

D 600 800

In the case of several appliances side by

side on the battery side, add up the safety

distances.

When the snow hood is present, recalculate the distances with the accessory

installed.

Do not position the appliances with the

inlet of the fan of the first towards the finned

battery of the second.

2.12.1 Fixing position of dampers

See figure 20 with the relative models.

Page 20

2.13 HYDRAULIC CONNECTIONS

The choice and installation of components must

be made by the installer who acts in accordance

with good technical code of practice and

legislation in force.

Before connecting the pipes, ensure that they do

not contains pebbles, sand, rust, waste or foreign

bodies that could damage the system.

Hydraulic diagram for connection to the system

- ARIA 6HP / 8HP (fig. 21)

- ARIA 11HP (fig. 22)

For the electrical connection of the 3-way

valves see the ACS thermostat kit instructions

Legend fig. 21/22

1 Pressure gauge 8 Air breather

2 Anti-vibration joint 9 Expansion tank

3 Interception valve 10 Temperature probe

4 Net filter 11 Load/Reintegration

5 Flow controller 12 Discharge tap

6 Pump 13 Calibration bypass

7 Safety valve 14 Flow switch

Page 21

Hydraulic connections must be completed by

installing:

- a 0.5 mm metallic net filter in inlet (system

return)

- a flow meter in outlet (inlet to the system) for

liquids to be sized and adjusted based on the

hydraulic characteristics of the system; to be

installed half-way along a horizontal straight pipe

section, at least 1 metre long.

REFERENCE VALUES

PH

Electrical conductivity

Chlorine ions

Sulphuric acid ions

Total iron

M alkalinity

Total hardness

Sulphur ions

Ammonia ions

Silicon ions

ppm = parts per million

- air breather valve in the highest parts of the pipelines;

- flexible elastic joints;

- interception valves;

- interception valves for chemical wash.

The calibration by-pass must be inserted

downstream of the machine for greater

adjustment of the system flow-rate and

prevalence.

Together with the flow regulator, installed on

board the machine, it must guarantee the correct

flow-rate of water in transit in the appliance (with

∆T minimum 4°C and maximum 6°C);

Special supply/particle reintegration

waters must be conditioned with suitable

treatment systems. The values shown in the table

can be considered as reference values:

6÷8

less than 200 mV/cm (25°C)

less than 50 ppm

less than 50 ppm

less than 0.3 ppm

less than 50 ppm

less than 50 ppm (5 °F)

none

none

Less than 30 ppm

obstruction, breakage and noise problems for

which the manufacturer accepts no responsibility.

The units are fitted with circulation pumps

as standard.

Install a load/reintegration system and a

unit discharge system to be connected in the

lowest part of the hydraulic circuit.

Systems with antifreeze or particular

legislative dispositions require obligatory water

disconnect devices. If filters, flow-meter and

dampers are not installed this can cause

The water flow-rate must be kept constant

during operation.

The water contained in the system must be

sufficient to prevent unbalances in the cooler

circuit operation (see tables on page 8).

Page 22

2.14 POSITION OF THE FIXINGS

M Inlet to the system

R return from the system

r water reintegration

2.15 ELECTRICAL CONNECTIONS

The ARIA heat pumps leave the factory

completely wired and only require connection to

the mains electrical supply and connection of the

flow-meter which must be done by qualified

personnel in compliance with legislation in force.

For all electrical connections, refer to the wiring

diagrams in this booklet.

The following checks are also recommended:

- Check that the characteristics of the mains

electric supply are adequate to the absorption

indicated in the electrical characteristics table

shown below, also considering any other

appliances in parallel operation.

- Check that the mains supply corresponds to the

nominal value +/- 10%.

For electrical connections use double

insulation cables.

It is compulsory:

- to use an double pole thermal magnetic master

switch to protect the power line

- to make an efficient earth connection.

It is forbidden to use the gas or water

pipes to make the earth connection.

The manufacturer is not responsible for

any damage caused by a lack of earth

connection or by the failure to observe the

indications in the wiring diagrams..

ATTENTION:

FOR THE SIZING OF THE POWER SUPPLY

LINE, IN ADDITION TO THE POWER VALUE

SHOWN IN THE TABLE ABOVE, ALSO

CONSIDER THE ELECTRICAL RESISTANCE

VALUE IN PAGE 8 (TECHNICAL DATA).

2.16 OUTSIDE CONNECTIONS AND

ELECTRICAL POWER CABLE INFEED

The appliance is supplied with suitable cable

clamps for the passage of the mains power

supply cables and the other electrical

connections.

- Insert the mains power supply cable in the

larger cable clamp

Page 23

- Insert the cables from outside, routing them

towards the electrical panel.

Avoid direct contact with the un-insulated

copper pipes and with the compressor.

It is forbidden to insert the electrical

cables from the appliance in positions not

specified in this manual.

THE APPLIANCE MUST ALWAYS BE

ELECTRICALLY POWERED TO ALLOW A

CORRECT PRE HEATING OF THE

COMPRESSOR OIL. IT IS COMPULSORY TO

KEEP THE APPLIANCE POWERED FOR AT

LEAST 8 HOURS BEFORE THE FIRST STARTUP.

The electrical panel with the connection terminal

board is situated inside the appliance, in the

upper part of the technical area dedicated to

circuit components.

Before starting

operations, set the master switch on the system

to “OFF”.

To make the electrical connections:

- Unscrew the four screws on the inspection

panel (fig. 26 ref. A)

- Remove the panel (fig. 26 ref. B)

- Set the master switch A to “OFF” (fig. 26 ref. C)

- Insert the main power supply cable in hole

(fig. 26 ref. D) and the outside connection cables

in hole (fig. 26 ref. E).

Page 24

- Make the connections as indicated in figure 27

FL Outside flow switch

SEI Remote summer winter switch

SO Remote ON-OFF switch

AL Remote alarm signal (output 12V DC - max

20mA)

When the connections are completed, block the

cables with the cable clamps, turn the master

switch to ON and remount the inspection panel

with the special fixing screws.

Page 25

2.17 LOADING AND EMPTYING THE SYSTEM

2.17.1 Loading

Check that the gaskets are watertight.

- Before starting the loading set

the master switch on the system to “OFF”.

- Check that the discharge taps on the unit and

the system are all closed.

- Open all the breather valves on the unit, on the

system and on the relative terminals.

- Open the system interception devices.

- Start filling by slowly opening the system water

filling tap (fig. 28 ref. A) positioned outside the

unit.

- When water starts coming out of the breather

valves, close them and continue filling until

reaching the pressure envisaged for the system.

It is advisable to repeat this operation

after the unit has been functioning for a few hours

and then periodically check the pressure in the

system. The reintegration must be carried out

with the machine switched “OFF” (pump “OFF”).

The system must be loaded to a pressure

of between 1 and 2 bar that can be checked on

the pressure gauge on the unit.

2.17.2 Emptying.

Page 26

- Before starting the emptying set

the master switch on the system to “OFF”.

- Check that the system water reintegration/

loading tap is closed (fig. 28 ref. A)

- Open the inspection panel on the front of the

unit.

- For the 11HP model open the by-pass valve (to

be installed downstream of the machine), the unit

discharge tap, the discharge taps on the system

and all the breather valves.

- For models 6HP and 8HP open the two

discharge taps on the unit, the system discharge

taps and all the breather valves.

If the system contains antifreeze, it must

not be freely emptied because it is a pollutant.

It must be collected and eventually re-used.

3 ECHNICAL SERVICE

T

3.1 RECOMMENDED OP

ERATING

CONDITIONS

For perfect ope

ration of the unit, the advisable

conditions must be respected:

PERATING

O

CYCLE

OUTLET

WATER T

EMP.

OUTSIDE AIR

TEMP

min. max. in. max. m

Cooling

Heating

+7°C +18°C 15°C +42°C

+35°C +45°C -15°C +25°C

3.2 LIMIT OPERATING CONDITIONS

operate within the area “A “.

It is possible to operate in the area “B”, by

modifying the operating parameters of the unit.

Do not operate outside areas “A” and “B”.

able to For perfect operation of the unit, it is advis

Page 27

3.3 PREPARATION FOR THE FIRST

TARTING UP

S

The first starting up of the unit must b

e carried

out be the Vokera technical service.

Before starting up the unit, ensure that:

- All the safety conditions have been respected.

- The unit

has been suitably fixed to the support

surface.

- The safety area has been respected.

- The hydraulic connections have been ma

de

according to the instruction manual.

- The hydrau

lic system has been loaded and

purged.

- The interc

eption valves in the hydraulic circuit

are open.

- The elec

trical connections have been made

correctly.

- The voltage is within a 10

% tolerance of the

nominal value of the unit.

- The earth connection has been made correctly.

- All the ele

orrectly.

c

ctrical connections have been made

.4 FIRST START-UP

3

THE APPLIANCE MUST ALWAYS BE

ELECTRICALLY POWERED TO ALL

OW A

CORRECT PRE-HEATING OF THE

COMPRESSOR OIL. IT IS COMPULSORY TO

KEEP THE APPLIANCE POWERED FOR AT

LEAS

T 8 HOURS BEFORE THE FIRST START-

P.

U

Before activating the appliance, ensure that:

- Set the master switch on the

system to “OFF””.

- Remove the inspection panel (fig. 30 ref. A),

removing the four fixing screws (fig. 30 ref. B)

- Set the

master switch on the unit (fig. 31 ref. A)

to “ON”

- Set the master switch on the

system to “ON”.

- Check that the Display is on

and signals the

system return temperature.

- Keep the unit powered but not operating for at

least two hours to allow the oil in the compressor

to heat up.

- Switch on the unit.

For the correct position of the inside

components, refer to pages 10 to 12.

Page 28

3.6 ACTIVATION OF “SO” and “SEI”

CONTROL

PERFORM THE FOLLOWING OPERATIONS

FROM THE

CONTROL PANEL:

The operations described below must be carried

out with maximum attention to avoid

compromising the working efficiency of the unit.

If errors are made or if there are uncertainties

concerning the interpretation during the

operations,

WAIT FOR 15 SECONDS WITHOUT

PRESSING ANY KEY.

To activate the SO and SEI control, proceed as

follows:

- Power up the unit, setting the system master

switch and the unit master switch to “ON”.

If it is the first start-up, “OFF” will appear on the

display. In this case, press the

key to set

the machine in standby.

At this point the return temperature value will

appear on the display.

3.6.1 Setting the “SO” remote control (on off):

- Now press the

and keys

simultaneously to access the user parameters.

“Par” will appear on the display to indicate access

to the user parameters.

- Now press the

key to access the CF

menu.

- CF appears on the display to indicate the

remote controls parameter menu.

- Press the key and CF19 appears, with the

arrow key move to CF20, which indicates the

“SO” parameter, that is, remote summer/winter

change.

To set the remote SO control, just press

and move the value from 0 to -13 (minus 13);

then confirm with

the key.

- Press the key, until the display indicates the

temperature of the return water.

- Cut off the power to the machine to memorise

the value. Power it back up and check with the

key.

3.6.2 Setting the “SEI” remote control (change

summer – winter cycle):

- Now press the

and keys

simultaneously to access the user parameters.

“Par” appears on the display to indicate access to

the user parameters.

- Now press the

key to access the CF

menu.

- CF appears on the display to indicate the

remote controls parameter menu.

- When the

key is pressed CF19 appears,

that indicates the “SEI” parameter that is, remote

summer/winter change.

To enable the remote control, just press

and move the value from 0 to -14 (minus 14)

(using the arrows); then confirm with the

key.

- Press the

key, until the display indicates

the temperature of the return water.

3.7 ANOMALY SIGNALS

In case of a malfunction of the unit, codes will

appear on the control panel display, consisting of

letters and numbers alternating with the system

return temperature. Part of the alarms reset

automatically while others must be reset with the

manual intervention of the Manufacturers

Technical Service.

Page 29

DESCRIPTION

High pressure

Low pressure

Flow switch

Water circuit antifreeze

High water temperature

(< 60°C)

Clock fault error Er45

Clock to be adjusted error

Inlet temperature probe

Outlet temperature probe

Outside temperature probe fault Er68 automatic

SIGNAL RESET DISPLAY

Er01 manual

Er05 manual

Er20 manual

Er30 automatic

Er35

Er46

Er60 automatic

Er61 automatic

automatic

Condensation pressure probe

Configuration error

Compressor working hours

exceeded

Pump working hours exceeded Er85 manual

Alarms archive recordings

exceeded

3.7.1 Manual anomaly reset

After having cleared the cause that provoked the

anomaly, reset as follows:

Simultaneously press the UP

keys to reset the alarms.

Er75 automatic

Er80 automatic

Er81 manual

Er90 manual

3.8 ACTIVATION and DEACTIVATION of the

UNIT

and DOWN

To perform the ACTIVATION and

DEACTIVATION of the “COOLING” and

“HEATING” functions act on the CONTROL

PANEL installed on the machine, or on the two

REMOTE ON-OFF (SO) and SUMMER-WINTER

(SEI) SWITCHES if installed.

Page 30

Fig. 32

A Alarm

B Mode (Heat, Cool, etc....)

C Economy (settable)

D Clock

E Unit of measure

F Navigation in the menu icon

G Resources (Compressor, Fans, etc....)

To select the operating mode, hold down the

key until the message “HEAT”, “COOL” or

“STBY” appears, according to the current

operating status of the controller.

Select the HEAT function with UP

DOWN

and confirm with the SET

or

key.

Heating (WINTER CYCLE)

If the code “Er 20” appears on the display

during this first phase, proceed as follows:

- Check the water flow-rate and the connection to

terminals 9 and 10 of the flow-meter.

To access the control panel, open the

inspection flap (fig. 33 ref. A):

- Remove the locking screw

- Simultaneously press on points B (fig. 33 ref. B)

and lift the flap (fig. 33 ref. C)

When the operations on the control panel are

completed:

- Close the flap and reposition the locking

screw.

Activation

By selecting HEAT the

symbol lights up.

The change in the operating mode from

Heating to Cooling must only be carried out with

the temperature of inlet water to the exchanger

plate lower than 20°C.

The change in the operating mode from

Cooling to Heating must only be carried out with

the temperature of inlet water to the exchanger

plate higher than 20°C.

Limit the change in the operating mode to

once per day.

Page 31

Cooling (SUMMER CYCLE)

By selecting COOL the

symbol lights up.

Deactivation Heating/Cooling

Select the STBY option and confirm with the SET

3.9 OPERATIONS PERFORMED BY THE

ON-OFF “SO” and SUMMER-WINTER “SEI”

REMOTE

SWITCHES (IF PRESENT)

Cooling Function

Activation

key.

The

symbol lights up.

In case of a power failure lasting more

than four hours, when power returns, keep the

unit powered but deactivated for at least eight

hours.

In case of a power failure lasting less than

four hours, when power returns, keep the unit

powered but deactivated for the same number of

hours that the power was out.

-

- Position the SUMMER-WINTER

remote switch (SEI) to “OFF”

- Position the ON-OFF remote

switch (SO) to “ON”.

The

warning LED lights up on the control

panel.

Deactivation

- Position the ON-OFF remote switch

(SO) to “OFF”.

The message “OFF” flashes on the

CONTROL PANEL.

Heating Function

Activation

- Position the SUMMER-WINTER

remote switch (SEI) to “ON

- Position the ON-OFF remote

switch (SO) to “ON”.

The warning LED lights up on the

control panel.

Deactivation

- Position the ON-OFF remote

switch (SO) to “OFF”.

The message “OFF” flashes on the

CONTROL PANEL

Page 32

In case of a power failure lasting more

than four hours, when power returns, keep the

unit powered but deactivated for at least eight

hours.

In case of a power failure lasting less than

four hours, when power returns, keep the unit

powered but deactivated for the same number of

hours that the power was out.

Limit the change in the operating mode to

once per day.

3.10 DEFROSTING CHECK

To avoid the formation of ice on the finned

battery during the winter heating phase, each

machine is fitted with an automatic defrosting

device, managed by the microprocessor through

the pressure probes and timer.

During the defrosting procedure, the

symbol flashes on the control panel indicating the

defrosting status.

3.11 CONTROLS DURING AND AFTER THE

FIRST START-UP

When the start up is completed, check that:

- The current absorbed by the compressor is

less than that indicated in the technical data table

- The unit operates within the recommended

operating conditions (see page 45).

- The hydraulic circuit is completely purged of air

- The unit stops and the restarts.

3.12 LONG TERM SHUTDOWN

From the control panel, deactivate the heat pump

from whichever mode it is operating in.

After deactivating the unit:

- Set the remote switch to “OFF” (if present)

- Deactivate the indoor terminal units by setting

the switch on each appliance to “OFF”.

- Set the master switch on the system to “OFF”.

- Close the water taps.

If there is a possibility that the outside

temperature falls below zero there is a risk of

freezing.

The hydraulic system MUST BE EMPTIED or

else antifreeze liquid (e.g. ethylene glycol) must

be added in the doses suggested by the

manufacturer of the liquid.

If the unit is connected to a boiler in

parallel, during its operation, close the taps on

the unit. The temperature of the water circulating

in the heat pump must never exceed 60°C.

3.13 ROUTINE MAINTENANCE

Routine maintenance is essential to keep the

ARIA heat pump in perfect working order, from

both a functional and energy efficiency aspect.

The maintenance plan that the Vokera technical

service will perform annually, envisages the

following checks and operations:

- Check the expansion tank pressure (2 bar)

- Water circuit filling-up

- Air presence in the water circuit

- Working efficiency of safety devices

- Power supply voltage

- Electrical absorption

- Tighten electrical connections

- State of the compressor contactor

- Plate exchanger resistance efficiency

- Compressor resistance efficiency

- Cleaning of finned battery (*)

- Cleaning of fan grills

- Cleaning of condensation collection bowl (if

installed).

(*) every three months.

For appliances installed close to the sea, the

maintenance intervals should be halved.

During maintenance operations, it might be

necessary to remove the inspection panels on

the cooler. In this case, proceed as follows:

- Unscrew the fixing screws and remove the

panels.

- When the maintenance operations have been

completed:

- Remount the panes, proceeding in the reverse

order.

3.14 EXTRAORDINARY MAINTENANCE

3.14.1 Loading coolant gas

The ARIA heat pumps are pre-loaded with R410A

coolant gas and adequately tested in the factory.

In normal conditions they do not require any

intervention by the Manufacturers Technical

Service to check the coolant gas. However, over

time small leaks could develop in the joints

allowing the gas to leak and discharge the circuit,

causing a malfunction of the appliance. In this

case, the leaks must be found and repaired and

the cooling circuit must be washed with nitrogen

or with specific products and recharged as

follows:

- Empty and dehydrate the entire cooling circuit

using a vacuum pump connected both to the low

pressure and high pressure sockets until the

vacuum gauge shows 10 Pa. Wait at least 5

minutes and check that this value does not rise

over 200 Pa.

- Connect the coolant gas cylinder or a

recharging cylinder to the liquid line socket.

- Load the quantity of coolant gas, in liquid

phase, indicated on the technical plate of the unit.

- Always check the overheating and undercooling

values of the appliance which, in nominal

operating conditions must be respectively

between 6 and 10°C (OVERH), and maximum 2

°C (UNDERH). After a few hours of operation,

check that the flow indicator indicates a dry circuit

(dry - green).

If the operating conditions are different

from the nominal ones, this could give values that

are very different.

Page 33

The coolant must only be loaded in liquid

phase.

The test of the seal or search for leaks

must only be performed using coolant gas R

410A, possibly mixed with nitrogen, and checking

with an adequate leak detector.

It is forbidden to load the coolant circuits

with a coolant that is not R410A. Use of a coolant

different from R410A could seriously damage the

compressor.

Do not use oils other than those indicated.

The use of different oils could seriously damage

the compressor.

Characteristics

3.14.2 Compressor

The compressor is installed on the machine

already loaded with oil and sealed.

Normally it does not require any particular

interventions from the Vokera technical service.

3.15 DISPLAY AND CONTROL

PARAMETERS

3.15.1 Main parameters and variable

The control panel of the unit gives direct access

It is forbidden to use oxygen or acetylene

or other inflammable or poisonous gases as they

could cause explosions.

In case of breakages, if the compressor can be

repaired only use original oils.

DESCRIPTION SIGNAL FACTORY

DISPLAY VALUE

Summer Set

Point

Summer

Differential

Winter Set Point

Winter

Differential

Return Water

Temperature

Inlet Water

Temperature

Condensation

Pressure

Outside

Temperature

COOL

tr10

HEAT 40

tr11

Ai01

Ai02

Ai03

Ai04

to the main control parameters and the display of

some variable characteristics of the unit.

ADJUSTMENT

15

3

3

DISPLAY ONLY

Access to the various menus - parameters

The perfect operation of the unit is

obtained by respecting the factory regulations

and in any case, keeping within the permitted

ranges.

3.15.2Access and Modification of

Parameters

The unit must be electrically powered and the

display must show the temperature of water that

returns from the system, or the message “OFF”.

To access and eventually modify the parameters,

perform the following procedure:

- When the set

shown on the display to indicate the pressure and

temperature parameters menu.

Scroll with the

other parameter menus: A0 (output status), CL

(clock and date parameters), SP variable

parameters set-point, Sr (real non-variable

setpoints – display only).

57

Modification of heat and cool set-points

To modify the inlet water temperature set-point

(return from the system), proceed as follows:

key is pressed, Ai is

and keys to access

Page 34

- When the key is pressed, the first Ai

menu is shown on the display, with the

go to the SP menu and press the

key

key.

At this point, the message COOL appears, to

indicate the summer set point. To modify the

summer set point, press the key, and with

the

set value. To confirm, press the

Then press

and keys change the previously

key.

to exit.

To modify the winter set point, proceed as above.

When COOL appears, press the

access HEAT (winter set-point), press

key to

and change the parameter with the

and keys.

-

Modification of the temperature differentials

in heat and cool

To modify the temperature differential of the two

cycles, proceed as follows:

- Press the

and keys

simultaneously.

PAR is shown on the display.

- Now press the

key to access the CF

menu.

- Press the

to access tr10 that indicates the

key to access the tr menu, then

temperature differential for the summer cycle.

Press

again to access the parameter and

use the arrows keys to modify the differential

value.

Save and Exit

- To save the parameters, it is always

advisable to cut off the power supply

and then power back up. The display

will indicate the “return water

temperature”.

- To modify the temperature differential of the

winter cycle, go to the tr10 parameter (see

previous point).

- Press the

appears and with the

key until parameter tr10

key go to the tr11

parameter.

Now press the

key to access the

parameter and with the arrow keys change the

value of the differential.

- Press the

key, until the value of the value

of the return water appears on the display.

Save and Exit

Press the

Press

key to confirm.

to exit.

- To save the parameters, it is always advisable

to cut off the power supply and then power back

up.

- The display will indicate the “return water

temperature”.

3.16 TROUBLESHOOTING

In case of a malfunction of the unit, codes will

appear on the control panel display, consisting of

letters and numbers (e.g.Er01) alternating with

the system return temperature. Part of the alarms

reset automatically while others require a manual

intervention, pressing the UP and DOWN keys

(see page 30).

AUTOMATIC ANOMALY RESET

Page 35

When the alarm cause is cleared, the control

panel automatically returns to the normal

operating mode.

MANUAL AN O MALY RE SET

After having cleared the cause that provoked the

anomaly, reset by pressing simultaneously the

UP and DOWN keys.

ANOMALY

The

compressor

does not start

The

compressor

stops

following

safety device

intervention

Insufficient

Performance

Noisy

Compressor

CAUSE REMEDY

Power supply

voltage too low.

Circulator

broken or

clogged.

Electrical

connections

badly tightened.

Contactor coil

fault.

Broken

electronic card.

Condenser

peak failure

(single phase

version).

Compressor

failure.

LED phase

monitor “OFF”.

(three-phase

version).

Excessive inlet

pressure (Er01).

Low suction

pressure (Er05).

Insufficient flowrate or system

not purged

(Er020).

Circulator

broken or

clogged

(Er020).

Poor flow-meter

operation.

Compressor

motor fault.

High discharge

pressure.

Low suction

pressure.

Incorrect

thermostat

calibration.

Unit sizing.

Fluid return to

the compressor.

Inadequate

fixing.

Check

Replace the

compressor

Invert two

phases

Check

Replace the

component

Check

Check

Noises and

Vibrations

Low Discharge

Pressure

High Suction

Pressure

Low Suction

Pressure

Contact

between

metallic bodies.

Weak

foundations.

Loosened

screws

Low

condensation

air/water

temperature.

Fan adjustment

malfunction.

Insufficient

coolant load.

Compressor

discharge valve

leak.

High inlet water

temperature.

Thermostatic

expansion valve

broken or open.

Low inlet water

temperature.

Thermostatic

expansion valve

broken or

clogged.

Suction line

obstructed.

Clogged filter.

Evaporator

exchanger

clogged.

Excessive

quantity of

antifreeze in the

water circuit.

Check

Reset

Tighten the

screws

Check

Replace the

component

Check

Check

Page 36

Notes..

Page 37

Registered address:

Unit 7 Riverside Industrial Estate

enquiries@vokera.co.uk

www.vokera.co.uk

Sales, General Enquires

Vokèra Limited reserve the right to change

specification without prior notice

Consumers statutory rights are not affected.

A Riello Group Company.

Company Reg No: 1047779

Vokèra Ltd

Borderlake House

London Colney

Herts AL2 1HG

www.vokera.ie

T 0844 391 099

F 0844 391 0998

Vokèra Ireland

West Court, Callan

Co Kilkenny

T 056 7755057

F 056 7755060

Loading...

Loading...