VOKERA AquaFlow Twin Installation & Servicing Instructions Manual

Supplied By www.heating spares.co Tel. 0161 620 6677

AquaFlow Single coil water cylinder

AquaFlow Twin Twin coil water cylinder

Installation

& Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

Supplied By www.heating spares.co Tel. 0161 620 6677

PLEASE LEAVE THIS MANUAL WITH THE UNIT AFTER INSTALLATION

00142046

00

Aquaflow 150 - 200 - 250

-

AquaFlow Twin 210 - 250

INSTALLATION MANUAL

This manual gives detailed advice for installation and should be read carefully

prior to fitting any unvented unit. This Vokera Aquaflow cylinder must be installed

by a competent person and be installed in compliance with the Vokera Aquaflow

Installation and Maintenance Instructions, all current legislation, codes of practice

and regulations governing the installation of unvented hot water cylinders in force

at the date of installation.

Components supplied with the unit for site fitting

(See also page 2/3 for component list)

* Multibloc valve, includes pressure reducing valve, line strainer, balanced cold water take off, (for

shower or bidet only) check and expansion valve.

* Tundish.

* 1/2"F x 15 x 15 tee piece.

* Flexible hose.

* 3/4" x 22 mm Elbow / Drain Cock

* Commissioning valve, 1/2" BSP male.

* Motorized valve.

* Expansion vessel

Components factory fitted

* Immersion heater(s).

* Thermostats / thermal cut-out.

* Temperature and pressure relief valve.

Manual Handling Operations Regulations 1992 defines manual

handling as: "any transporting or supporting of a load (including the

lifting, putting down, pushing, pulling, carrying or moving thereof) by

hand or bodily force" The Regulations set no specific requirements

such as weight limits. However common sense still has to be used

based on an ergonomic approach for each individual

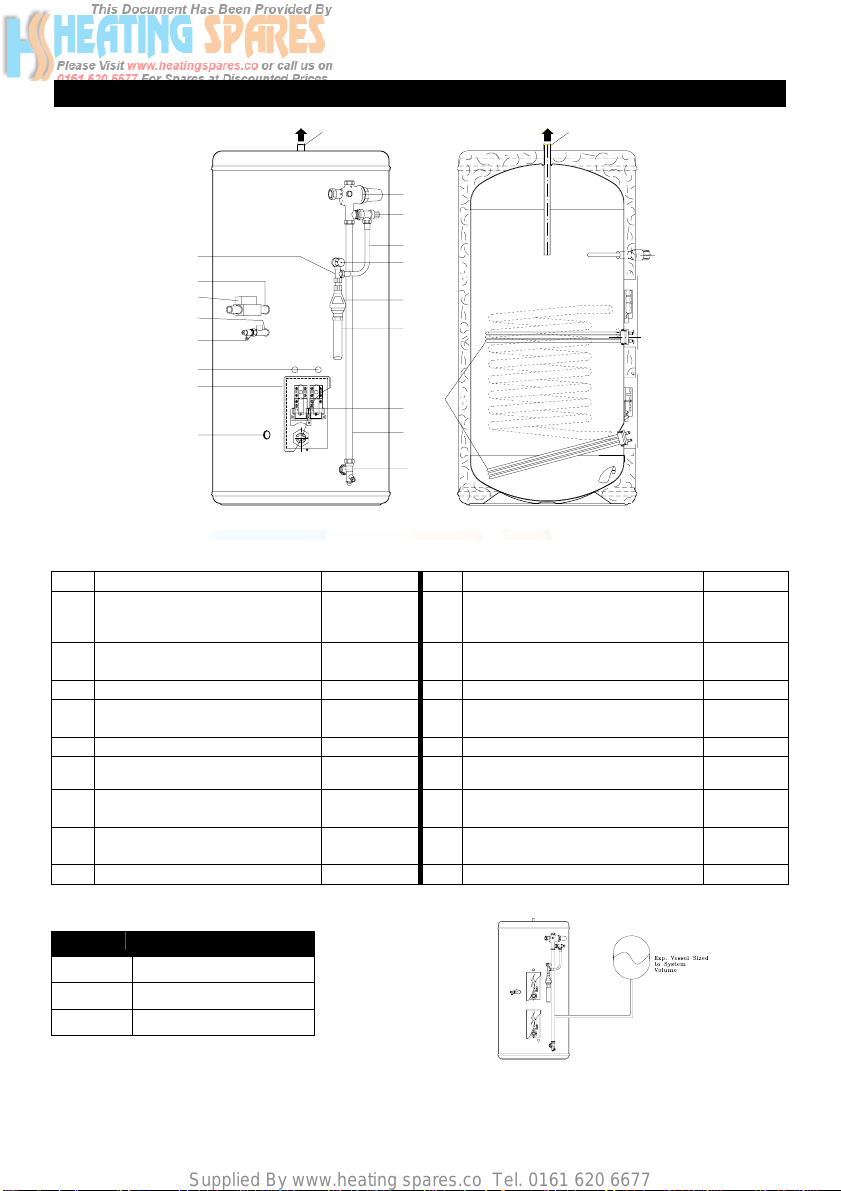

DIMENSION AND WEIGHTS TABLE 1

PRODUCT REF. 150 200 250 210T 250T

HEIGHT 900 1150 1600 1400 1600

DIAMETER 580 580 580 580 580

WEIGHT EMPTY 40 48 64 60 64

COIL RATING KW 12 26 26

UPPER COIL 12 12

LOWER COIL 12 26

Installation details

The Vokera unvented unit is designed for use with supply pressure up to 16 bar. For pressures

over 16 bar an additional pressure reducing valve must be fitted in the supply pipe to the unit. Wall

mounting brackets are available for Vokera Aquaflow unvented units 120-200 litres capacity.

Health and Safety

-1-

Supplied By www.heating spares.co Tel. 0161 620 6677

INDIRECT

2

2

RESET

1

1

2

3

3

4

1

4

2

RESET

5

1

1

1

1

General Layout Fig: 1

9

3

4

16

1

8

1

2

4

15

1

3

113

RESET

RESET

4

4

2

2

1

1

2

2

2

10

5

6

17

7

7a

8

13

KEY Part No KEY Part No

1 Flow ¾" BSPF 10 Flexible Hose 202108

2 Return ¾" BSPF 11 Secondary Return ½”BSPF

3 Pressure Reducing Valve

510503 12 Commisioning Valve / Fitting

Includes Item 4

4 Check and Expansion Valve 510505 13 Elbow / Drain Cock 250445

5 Temperature and Pressure

550803 14 Cable Entry

Relief Valve

6 Tundish 219002 15 Electrical Box

7 Immersion Heater 71255 16 Tee Piece 250006

7A Thermostat Immersion Heater

Thermostat Cylinder

8 Cold Feed Tube

80400

80511

18 Motorised Valve Not Factory Fitted)

(Not Supplied See Table 2)

9 Hot Water Outlet 22mm

Fit ½"Fx½"Mx15mm Tee piece

supplied)

(½" MI Drain Cock)

17 Discharge Pipe (Not supplied)

9

(Not

250440

92000

Series Length of tube (ø22) mm

120 480 mm

150 585 mm

200 760 mm

-2-

TABLE 2

Supplied By www.heating spares.co Tel. 0161 620 6677

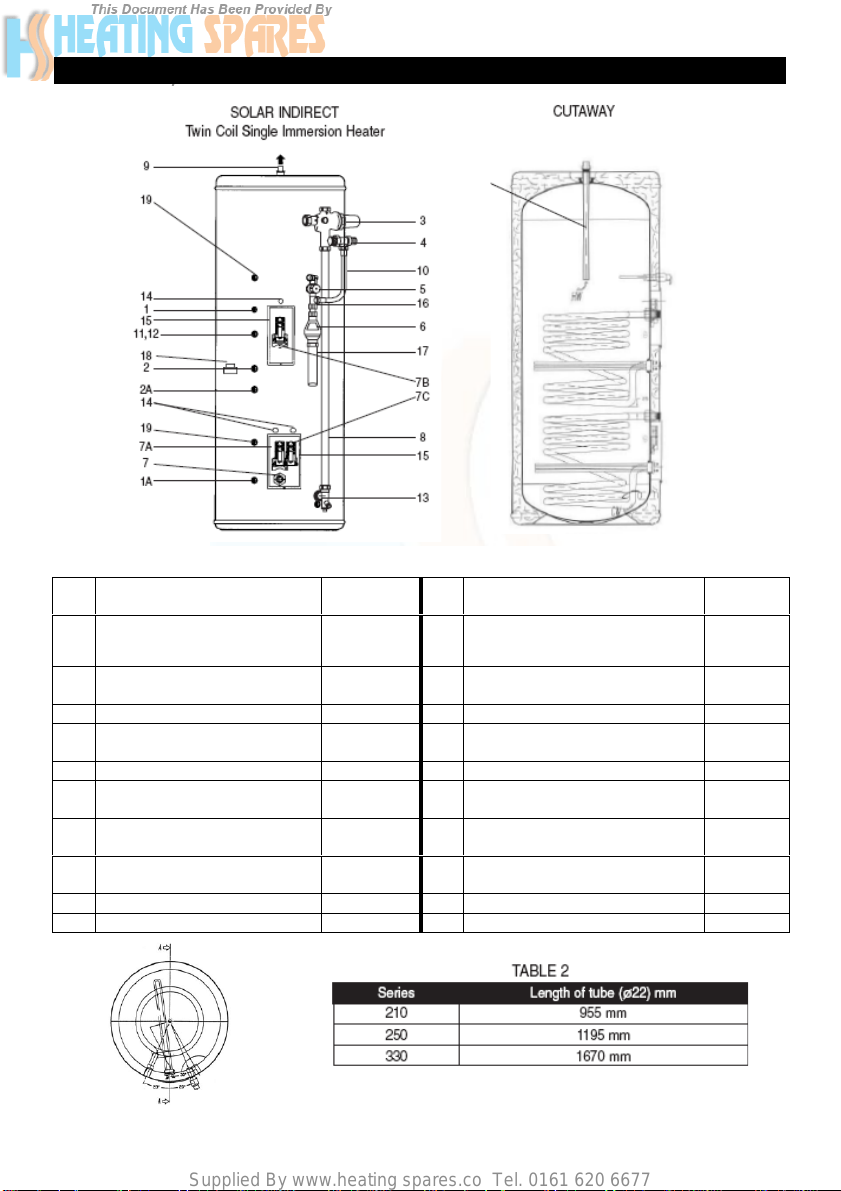

General Layout Fig: 1A

KEY Part No KEY Part No

1

Return ¾" BSP

1A

Return ¾" BSP

2

Flow ¾" BSP

2A

Flow ¾" BSP

3 Pressure Reducing Valve

Includes Item 4

4 Check and Expansion Valve 510505 13 Elbow / Drain Cock 250445

5 Temperature and Pressure

Relief Valve

6 Tundish 219002 15 Electrical Box

7

Immersion Heater

7A

Immersion Heater Thermostat

7B

Thermostat Boiler

7C

Thermostat Solar

8 Cold Feed Tube

(Not Supplied See Table 2)

9 Hot Water Outlet 22mm 19 Solar Sensor Bosses

20 Dip Pipe (removable)

10 Flexible Hose 202108

11 Secondary Return ½”BSPF

510503 12 Commissioning Valve / Fitting

550803 14 Cable Entry

71255

80020

80030

80030

18 Motorised Valve Not Factory Fitted)

-3-

20

Fit ½"Fx½"Mx15mm Tee piece

supplied)

(½" MI Drain Cock)

16 Tee Piece 250006

17 Discharge Pipe (Not supplied)

(Not

250440

92000

Supplied By www.heating spares.co Tel. 0161 620 6677

COLD WATER SUPPLY

1. To obtain the best performance from your Aquaflow unvented system it is advisable to feed

the unit with an uninterrupted supply.

Locate the water heater in a suitable po

2.

supply, discharge fittings and pipework. Also take into account

heaters and the commissioning valve.

Fit the combined male elbow / drain cock to cold supply point (13), so that the

3.

compression fitting is vertical.

Fit the commissioning valve (12) to the commissioning fitting.

4.

5. Fit both ½” male solar sensor pockets to the So

6. Fit the female outlet of the tee piece to the temperature and pres

horizontal connection facing right at approx. 45°.

Fit the tundish (6) to the tee piece using a short length of 15 mm copper tube.

7.

8. Fit the length of copper tube 22mm specified

9. Fit the pressure reducing valve (3) to the top of the copper tub e (see 7 above), so that the

black knob is facing right.

Connect the flexible hose to the 1/2" outlet of the expansion valve (4) and the horizontal outlet

10.

of the tee piece (see 5 above). Discard compression nut & ring.

If a balanced mains pressure cold water supply is required to a

11.

type only, ascending spray type requires type AA,AB or AD air gap), remove the blanking

cap from the pressure reducing valve (3) and connect to the shower or bidet cold supply.

(Major shower manufacturers advise fitting a mini expansion vessel in the balanced cold suppl y

pipework to accommodate thermal expansion and prevent tightenin g of shower controls)

the balanced cold connection to feed bath taps can reduce the flow available to the

unvented cylinder.

12. Before connecting the cold supply, flush the cold supply pipework of all flux and debris.

13. Connect the cold supply to the pressure reduction valve (Multibloc) (3).

sition to facilitate the installation of the cold water

access to the immersion

lar Sensor bosses (19).

sure relief valve (5) with the

in Table 2 to the cold feed elbow (see 3 above).

shower or

bidet (over rim

Using

Hot water supply

14. Connect the hot water supply pipe to the outlet (9). Ensure connection is water tight.

Secondary return

15. A secondary return facility is provided on all units. Fit a ½” F x ½” M x 15mm tee piece

between the commissioning valve (12) and the commissioning fitting. See also figure 4 on

page 16.

Discharge pipe

16. Connect the discharge pipe from the tundish (6.) This must have a continuous fall and be

fitted in accordance with The Building Regulations (see pages 5 and 12).

-4-

Supplied By www.heating spares.co Tel. 0161 620 6677

Primary flow & return and motorised valve

17. The boiler primary flow and return connections should be made to the unit. The motorised valve

must be fitted into the primary flow. The primary flow and return fittings are 3/4" BSP female.

18. For electrical connection of the motorised valve and immersion heater, please read Electrical

Installation Instructions. (Pages 7 – 11)

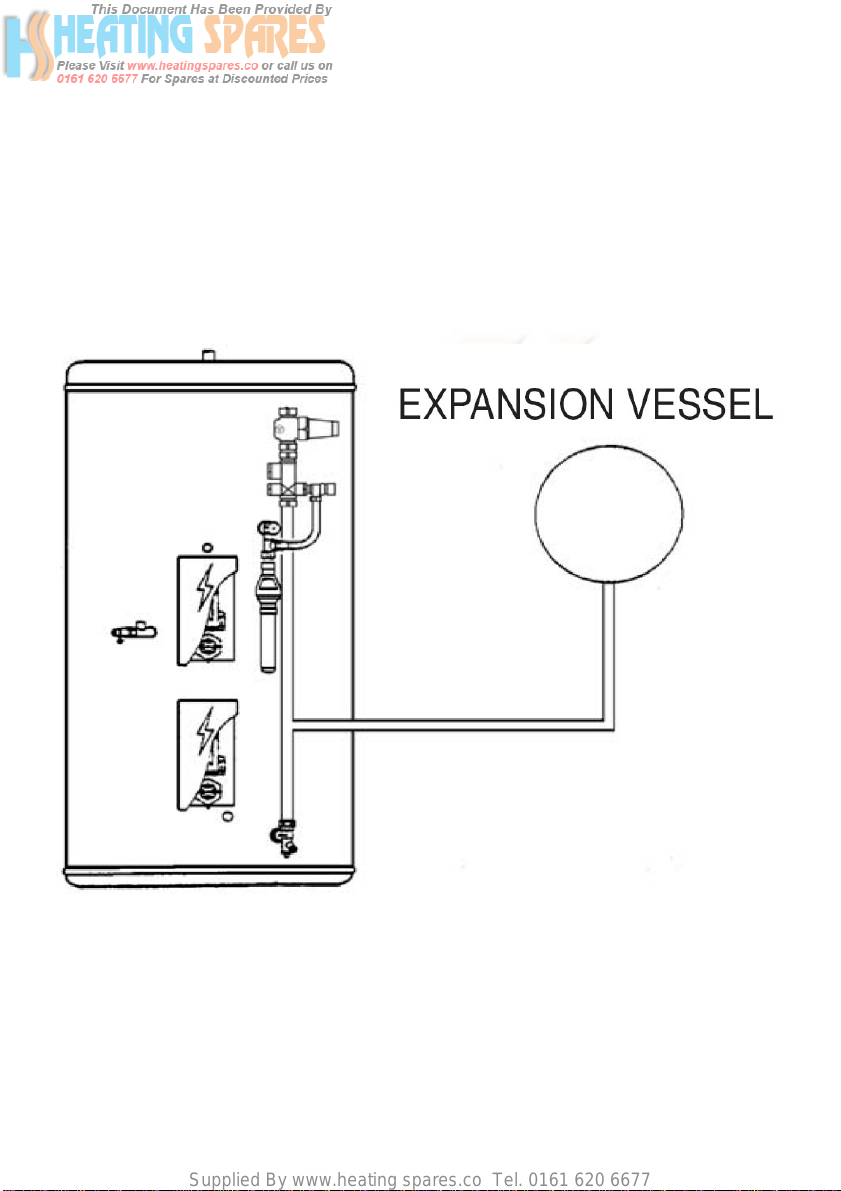

Expansion Vessel

19. Connect the expansion vessel to the cylinder as shown in the diagram below. The

vessel should be charged/pressurised to the same pressure as the PRV (Pressure Reducing

Valve).

Solar Primaries

20. The Solar flow and return connections should be made to the lower coil connections.

Temperature control from the Solar circuit is achieved using a differential solar controller.

The solar pump must be wired in series through the thermal cut-out on the Aquaflow

cylinder (see figure3 page 12).

21. If the solar primary circuit contains a mechanical shut-off device, ensure that a non return

valve in the circuit prevents thermal siphoning if the circulation is stopped. Care should be

-5-

Loading...

Loading...