Page 1

Supplied By www.heating spares.co Tel. 0161 620 6677

AquaFlow

Single coil water cyliner

Installation

& Servicing

Instructions

THESE INSTRUCTIONS

TO BE RETAINED

BY USER

Vokèra is a licensed member of the Benchmark scheme

which aims to improve the standards of installation and

commissioning of domestic hot water systems in the UK.

Page 2

Supplied By www.heating spares.co Tel. 0161 620 6677

PLEASE LEAVE THIS MANUAL WITH THE UNIT AFTER INSTALLATION

00

Aquaflow

Single coil water cylinder

INSTALLATION MANUAL

This manual gives detailed advice for installation and should be read carefully

prior to fitting any unvented unit. This Vokera Aquaflow cylinder must be installed

by a competent person and be installed in compliance with the Vokera Aquaflow

Installation and Maintenance Instructions, all current legislation, codes of practice

and regulations governing the installation of unvented hot water cylinders in force

at the date of installation.

Components supplied with the unit for site fitting

(See also page 2 for component list)

* Multibloc valve, includes pressure reducing valve, line strainer, balanced cold water take off, (for

shower or bidet only) check and expansion valve.

* Tundish.

* 1/2"F x 15 x 15 tee piece.

* Flexible hose.

* 3/4" x 22 mm Elbow / Drain Cock

* Commissioning valve, 1/2" BSP male.

• Motorized valve.

• Expansion vessel

Components factory fitted

* Immersion heater(s).

* Thermostats / thermal cut-out.

* Temperature and press

ure relief valve.

Manual Handling Operations Regulations 1992 defines manual

handling as: "any transporting or supporting of a load (including the

lifting, putting down, pushing, pulling, carrying or moving thereof) by

hand or bodily force" The Regulations set no specific requirements

such as weight limits. However common sense still has to be used

based on an ergonomic approach for each individual

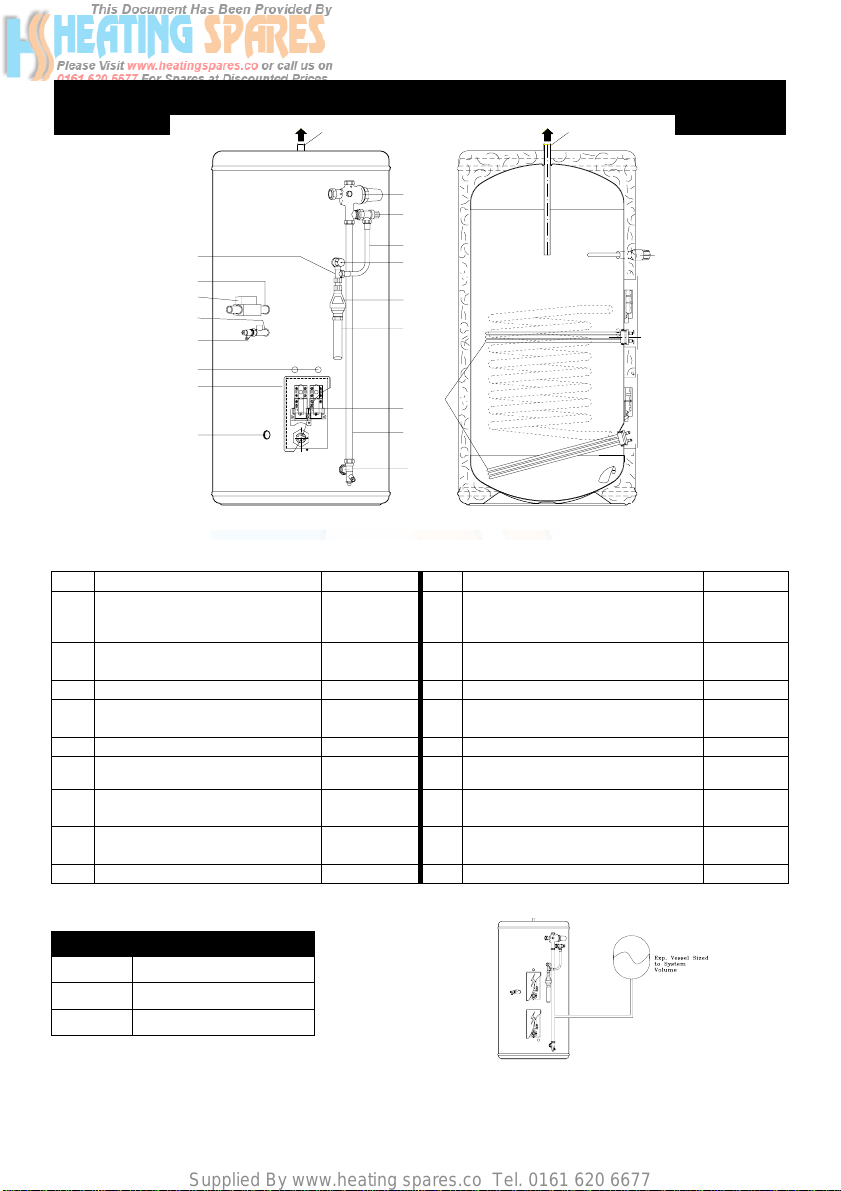

DIMENSION AND WEIGHTS TABLE 1

PRODUCT REF. 120 150 200 250

HEIGHT 720 900 1150 1600

DIAMETER 580 580 580 580

WEIGHT EMPTY 34 40 48 64

MAX WEIGHT FULL 132 163 215 303

Health and Safety

-

Installation details

The Vokera unvented unit is designed for use with supply pressure up to 16 bar. For pressures

over 16 bar an additional pressure reducing valve must be fitted in the supply pipe to the unit. Wall

mounting brackets are available for Vokera Aquaflow unvented units 120-200 litres capacity.

-1-

Page 3

Supplied By www.heating spares.co Tel. 0161 620 6677

General Layout Fig: 1

INDIRECT

2

RESET

1

1

2

3

4

1

4

2

RESET

5

1

1

1

1

9

3

4

16

1

8

1

2

4

15

1

222

1

33113

RESET

RESET

4

4

2

2

1

2

10

5

6

17

7

7a

8

13

KEY Part No KEY Part No

1 Flow BSPF * 10 Flexible Hose 202108

2 Return BSPF * 11 Secondary Return ½”BSPF

3 Pressure Reducing Valve

510503 12 Commisioning Valve / Fitting

Includes Item 4

4 Check and Expansion Valve 510505 13 Elbow / Drain Cock 250445

5 Temperature and Pressure

550803 14 Cable Entry

Relief Valve

6 Tundish 219002 15 Electrical Box

7 Immersion Heater 71255 16 Tee Piece 250006

7A Thermostat Immersion Heater

Thermostat Cylinder

80400

80511

8 Cold Feed Tube

(Not Supplied See Table 2)

9 Hot Water Outlet 22mm

Fit ½"Fx½"Mx15mm Tee piece

supplied)

(½" MI Drain Cock)

17 Discharge Pipe (Not supplied)

18 Motorised Valve Not Factory Fitted)

9

(Not

250440

92000

Series Length of tube (ø22) mm

120 480 mm

150 585 mm

200 760 mm

-2-

TABLE 2

Page 4

Supplied By www.heating spares.co Tel. 0161 620 6677

COLD WATER SUPPLY

1. To obtain the best performance from your Aquaflow unvented system it is advisable to feed

the unit with an uninterrupted supply.

2. Locate the water heater in a suitable posit

supply, discharge fittings and pipework. Also take into account access to the immersion

heaters and the commissioning valve.

3. Fit the combined male elbow / drain cock to cold

compression fitting is vertical.

4. Fit the commission

5. Fit the female outlet of the tee piece to the temperature and pressure relief valve (5) with

horizontal connection facing right at approx. 45°.

6. Fit the tundish (6) to the tee piece using a short length of 15 mm copper tube.

7. Fit the length of copper tube 22mm specified

8. Fit the pressure reducing valve (3) to the top of the copper tube (see

black knob is facing right.

9. Connect

of the tee piece (see 5 above). Discard compression nut & ring.

10. If

type only, ascending spray

cap from the pressure reducing valve (3) and connect to the shower or bidet cold supply.

(Major shower manufacturers advise fitting a mini expansion vessel in the balanced cold supply

pipework to accomodate thermal expansion and prevent tightening of shower controls)

the balanced cold connection to feed bath taps can reduce the flow available to the

unvented cylinder.

11. Before connecting the cold supply, flush the cold supply pipework of all flux and debris.

12. Connect the cold supply to the pressure reduction valve (Multibloc) (3).

the flexible hose to the 1/2" outlet of the expan

a balanced mains pressure cold water supply is required to a shower or bidet (over rim

ing valve (12) to the commissioning fitting .

type requires type AA,AB or AD air gap), remove the blanking

ion to facilitate the installation of

supply point (13), so that the

in Table 2 to the cold feed elbow (see 3 above).

sion valve (4) and the horizontal outlet

the cold water

7 above), so

the

that the

Using

Hot water supply

13. Connect the hot water supply pipe to the outlet (9). Ensure connection is water tight.

Secondary return

14. A secondary return facility is provided on all units. Fit a ½” F x ½” M x 15mm tee piece

between the commissioning valve (12) and the commissioning fitting. See also figure 4 on

page 16.

Discharge pipe

15. Connect the discharge pipe from the tundish (6)This must have a continuous fall and be

fitted in accordance with The Building Regulations (see pages 5 and 12).

Primary flow & return and motorised valve

16. The boiler primary flow and return connections should be made to the unit. The motorised

valve must be fitted into the primary flow. The primary flow and return fittings are 3/4" BSP

female.

17. For electrical connection of the motorised valve and immersion heater, please read Electrical

Installation Instructions. (Pages 7 – 11)

-3-

Page 5

Supplied By www.heating spares.co Tel. 0161 620 6677

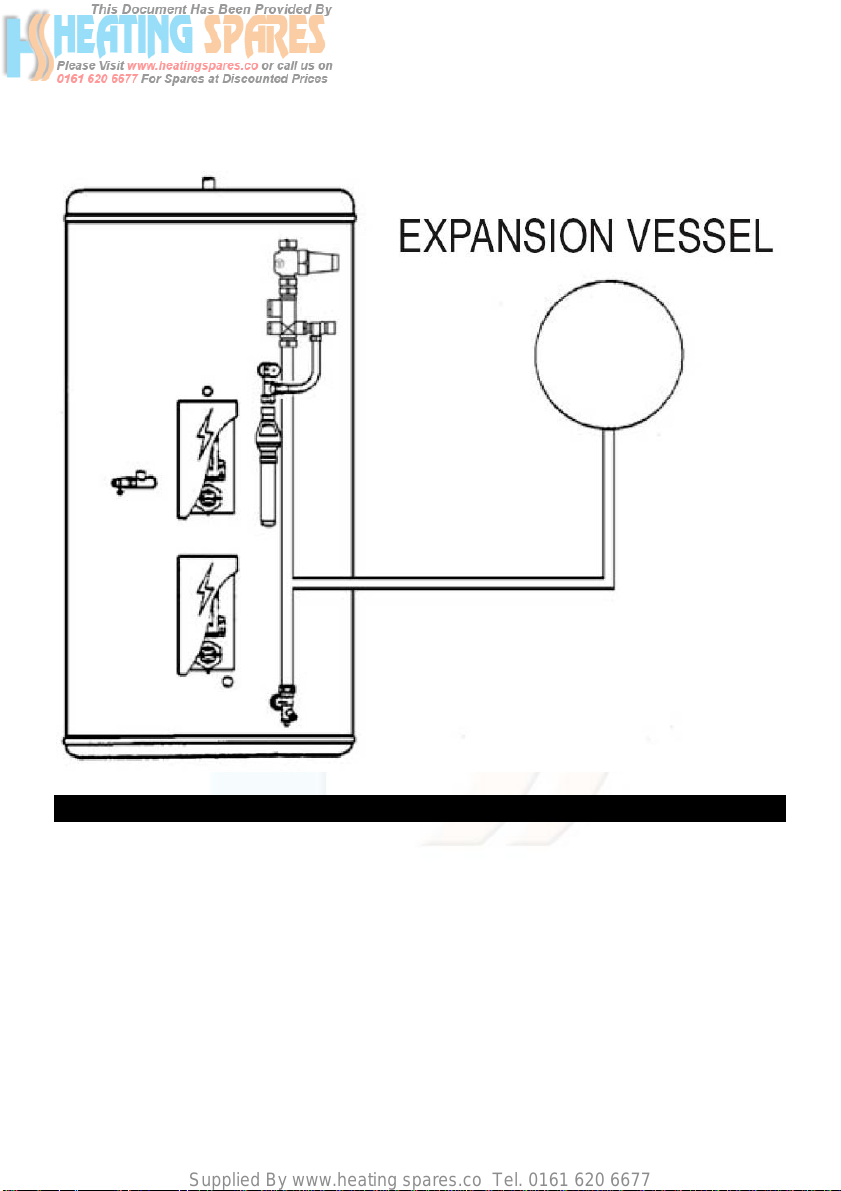

Expansion Vessel

18. Connect the expansion vessel (supplied) to the cylinder as shown in the diagram below. The

vessel should be charged/pressurised to the same pressure as the PRV (Pressure Reducing

Valve).

COMMISSIONING

Filling up

1. Close all hot water taps.

2. Open the commissioning valve (12).

3. Open the cold water supply valve.

4. When water flows from the commissioning valve (12), close the va

5. Allow system to stabilize for five mi

6. Open each hot water tap in turn to expel air from the system pipe work.

7. Check for

8. Manually operate Temperature and Pressure Relief Valve (5) to ensure free water flow through

discharge pipe.(Turn knob to left.)

leaks.

nutes.

-4-

lve.

Page 6

Supplied By www.heating spares.co Tel. 0161 620 6677

Draining

Switch off the electrical power off (Important to avoid damage to element). Isolate boiler from

Aquaflow unit. Turn off the cold water supply valve. Open hot water tap. Open drain (13). The unit

will drain.

SAFETY AND MAINTAINANCE

Safety Cut-out

1. The safety cut-out operates if:

a. Wiring is incorrect.

b. The immersion heater thermostat or cylinder thermostat fails.

c. Thermostat is set too high.

2. Remember

electrical supply to the unit prior to removal of the electrical box lid.

3. Reduce thermostat setting and press the reset button.

the lid to the electrical box is replaced correctly and the retaining screw is fitted.

4. If still out of operation,

before resetting the safety cut-out or altering the thermostat setting, iso

After adjustments are completed,

contact installer.

late

ensure

Cold or tepid water discharge from tundish

1. Turn off the electrical supply to the immersion heaters.

2. Turn off cold water supply valve.

3. Open a hot tap.

4. Drain water f

5. Turn the knob on the Temperature and P

position until water flow stops from the commissioning va

6. Close commissioning

7. Close all hot taps.

8. Open cold water supply valve.

9. Turn on electrical supply to the immersion heaters.

rom commissioning valve (12) until water flow stops.

ressure Relief Valve (5) to the left and hold in this

lve.

valve.

Hot water discharge from tundish

This indicates a malfunction of a thermal cut-out, operating thermostat or the combined temperature

and pressure relief valve. Turn off the electrical supply to the immersion heater and also isolate an

indirect unit from the boiler. Contact the installer or competent engineer.

INSTALLATION AND SERVICING INSTRUCTIONS

Cold water inlet control (Multibloc) See Page 2 Items 3 - 4

This combination consists of a pressure reducing valve with integral strainer, check valve and

expansion valve with stainless steel seat. The pressure settings are set and locked in the factory

and are shown on the top of each valve. For optimum performance the following installation

instructions should be complied with.

-5-

Page 7

Supplied By www.heating spares.co Tel. 0161 620 6677

Installation

1. Cold water supply to be 22 mm nominal size.

2. Flush supply pipework before connection to remove all flux and debris prior to fitting the inlet

controls. Failure to do this may result in irreparable damage to the controls and will invalidate

the warranty.

3. The "MULTIBLOC" can be fitted in any orientation to suit the installation as long as it is fitted in

the correct flow direction. Check the flow arrows on the side of the body.

4. The expansion valve should be e

deposited

flow arrows.

5. The black plast

monitoring to be carried out, should the system develop a fault. It is recommended that these be

accessible (the pressure reducing valve has two - only one need be accessible).

6. Expansion relief drain p

tundish and the pipework must have a continuous fall.

7. The pressure reducing valve has two outlets, the

supply, to a shower or a bidet (over rim type only, ascending spray type requires type

AA,AB or AD air gap)

the balanced cold supply pipework to accomodate thermal expansion and prevent tightening of

shower controls)

flow available to the unvented cylinder. The balanced cold supply is blanked off.

NOTE: If the unit has been commissioned and is to be unused for more than 8 weeks it is

advisable to turn off the cold supply and draw off approximately 5 litre of water through a hot

tap. NB The cold supply must be opened prior to use.

The Benchmark Log Book enclosed with the cylinder should be completed after

commissioning the syste

on the seat and cause fouling of the seat when the valve operates. Check direction of

ic plugs in the body are pressure gauge connections to enab

ipework must be connected to a safe visible discharge point via

(Major shower manufacturers advise fitting a mini expansion vessel i n

Using the balanced cold connection to feed bath taps can reduce the

ither horizontal or upright - if fitted inverted, debris may be

second one is for a balanced

m and handed to the cust

omer for future reference.

le pressure

cold water

a

MAINTENANCE

Under normal circumstances the "MULTIBLOC" combination control valve should not require any

maintenance. However, annual inspection and / or cleaning of the integral line strainer, pressure

reducing valve, cartridge, expansion relief valve cartridge and seating may be necessary depending

on local water conditions.

Pressure reducing valve

1. Isolate cold water supply.

2. Unscrew the retaining nut of the valve.

The complete operating mechanism,

including the

strainer can be removed.

3. Clean the filter mesh and the cartridge

under running water.

4. Replace cartridge ensuring that strainer

correctly located

-6-

and reassemble the unit.

is

Page 8

Supplied By www.heating spares.co Tel. 0161 620 6677

Pressure Reducing Valve cartridge and

strainer Part No. 510 501 2.1 Bar.

Expansion relief cartridge

1. Isolate cold water supply.

2. Unscrew blue expansion relief

headwork from valve body.

Pressure reducing valve

Cartridge and strainer

Part No. 510 501

Spare Parts

Expansion valve

(Cartridge)

Part No.

8.0 Bar 214009

6.0 Bar 214005

4.0 Bar 214046

Expansion valve

Part No. 510 505

8.0Bar

n valve seat face and seating - do not

3. Clea

scratch or damag

t in reverse order. Do not overtighten.

4. Refi

Expansion valve cartridge and seat Part No.

214009 8.0 Bar. Complete Expansion Valve

Part No. 510 505 8.0 Bar.

e either seal face or seating.

Tundish

Install the Tundish in a vertical position within a maximum of 500 mm from the Temperature and

Pressure Relief Valve drain connection. Ensure the expansion relief pipework discharges through

the tundish. Tundish pipework must be 22 mm with a minimum vertical length of 300 mm below

tundish. Maximum permitted length of 22 mm pipework is 9 m. Each bend or elbow is equivalent to

0.8 m of pipework.

All pipework must have continous fall and discharge in a safe, visible position. If any doubt, refer to

Building Regulation G3.

ELECTRICAL INSTALLATION

Immersion heaters

All units are fitted with one immersion heater which is located behind the electrical box.

Indirect Units

Motorised valve

To comply with regulations governing the installation of indirect unvented cylinders, a motorised

valve must be fitted in the primary flow. Your Aquaflow unit has been supplied with a two port

motorised valve, whi

motorised valve will also control the temperature of the domestic stored water via the cylinder

thermostat, which is located in the electrical box. The unit should be installed on an "S" or "Y" plan

ch will act as a positive energy cut-out should the safety cut-out operate. The

-7-

Page 9

Supplied By www.heating spares.co Tel. 0161 620 6677

system. Please follow the instructions carefully. All electrical connections must conform to

current IEE wiring regulations. The working thermostat which controls the temperature of the

domestic hot water (see fig. 2/2A) is adjustable between 45°C - 75°C. A safety cut out is also

incorporated within the thermostat and will operate at 85°C ± 3°C. Should the safety cut out be

brought into operation, the motorised valve will operate and close down the primary flow to the

cylinder. To reset the safety cut-out and the motorised valve the reset button must be pressed in

(see fig. 2/2A).If using a 6-wire 28mm or 1” BSP V4043H on either circuit the white wire is not

needed and must be made electrically safe.

Vokera can not be responsible if alternative wiring plans are used.

Important: Before resetting the

safety cut-out or altering the

thermostat setting isolate

electrical supply to the unit before removal of the lid.

’S’ Plan systems

Refer to the wiring diagrams contained within the boiler installation instructions for the wirng of ’S’Plan systems. Connect the cylinder thermostat as shown in the diagram below

-8-

Page 10

Supplied By www.heating spares.co Tel. 0161 620 6677

S Plan System Schematic

Y Plan Wiring Layout

Refer to the wiring diagrams contained within the boiler installation instructions for the wirng of ’Y’Plan systems. Connect the cylinder thermostat as shown in the diagram below

NOTE

A 10 way junction box must be used on the Y plan system.

.

-9-

Page 11

Supplied By www.heating spares.co Tel. 0161 620 6677

Y Plan System Schematic

AQUAFLOW FAULT FINDING GUIDE

FAULT POSSIBLE CAUSE REMEDY

No water flow from hot taps 1. Mains supply off. 1. Check and open stopcock.

-10-

Page 12

Supplied By www.heating spares.co Tel. 0161 620 6677

2. Strainer blocked.

3. Cold water inlet Pressure

Reducing Valve incorrectly

fitted.

Water from hot taps is cold. 1. Immersion heaters not

switched on.

2. Immersion heater thermal cutout has operated.

3. Programmer set to central

heating or not switched on.

4. Boiler not working.

5. Cylinder thermal cut-out has

operated.

6. Motorised valve not operating

correctly.

Intermittent water discharge. 1. Reduced expansion capacity.

2. Thermal control failure.

(Note Water will be hot).

Continuous water discharge. 1. Cold water inlet Pressure

Reducing Valve not

working.

2. Temperature and pressure

relief valve faulty.

3. Expansion relief valve not

working correctly.

NOTE: Disconnect electrical supply before removing any electrical equipment covers.

2. Turn off water supply. Remove

strainer and clean. (See Pressure

Reducing Valve page 6 Installation

Manual)

3. Check and refit as required.(see item

3 page 5 of installation manual)

1. Check and switch on.

2. Check and reset button. (See

thermostat diagram page

9 and safety cut-out on page 4 of

Installation manual).

3. Check and set to hot water.

4. Check boiler operation. If fault

suspected consult installer or boiler

manufacturer.

5. As at No. 2.

6. Check wiring and / or plumbing

connections to motorized valve. (See

pages 8 or 10 of the installation

manual).

1. Recharge expansion vessel to correct

charge (same as pressure reducing

valve).

2. Switch off power to immersion

heater(s) and boiler supply to the unit.

When discharge has stopped, check

thermal controls, replace if faulty.

Contact a competent person.

1. Check pressure from valve if greater

than 2.1 bar replace. (See page 6 of

installation manual)

2. As No. 2 of above.

3. Check and replace if faulty. (See

page 6 of installation manual).

-11-

Page 13

Supplied By www.heating spares.co Tel. 0161 620 6677

AQUAFLOW FAULT FINDING GUIDE

-12-

Page 14

Supplied By www.heating spares.co Tel. 0161 620 6677

-13-

Page 15

Supplied By www.heating spares.co Tel. 0161 620 6677

-14-

Page 16

Supplied By www.heating spares.co Tel. 0161 620 6677

Notes:

-15-

Page 17

Supplied By www.heating spares.co Tel. 0161 620 6677

ALTERNATIVE DISCHARGE

Downward discharges at low level, i.e. up to 100 mm above external surfaces su ch as car parks, hard st andings, grassed areas

etc. are acceptable provid ing that where ch ildren may play or ot herwise come into contact with discharges, a wire cage or similar

guard is positioned to prevent cont act, whilst maintaining visibility.

Discharge at high level, i.e. into a metal hopper and meta l down pipe

FIGURE 3

with the end of

not) or onto a roof capab le of withstanding high temperatur e

that would collect such discharges (tundish visible).

Where a single pipe serves a number of discharges, such as in

blocks of fl

6 systems so that any installation discharging can be traced

reasonably easily. The sing le common discharge pipe should be at

least one pipe size larger than the largest individual discharge pipe to

be connected. For further information contact your Building Control

Office or The British Board o f Agrément.

the discharge pipe clearly visible (tundish visible or

discharges of water and 3 m from any plastics guttering system

ats, the number

served should be limited to not more than

SECONDARY RETURN

FIGURE 4

1 Secondary Return use ½”Fx½”Mx15mm Tee (not supplied)

2 Commisioning Valve

3 Non Return Valve

4 Circulation Pump

5 Secondary Return Line

6 Balanced cold supply for showers or bidet only.

All replacement parts must be supplied by Vokera.

To obtain the address of a local stockist

Vokera Ltd. www.vokera.co.uk.

Catherine House

Boundary Way

Hernel Hempstead

Herts HP2 7RP E-mail: enquiries@vokera.co.uk

Phone: (0870) 333 0220

Fax: (01442) 281 460 A Riello Group Company.

-16-

contact:

Page 18

Supplied By www.heating spares.co Tel. 0161 620 6677

Registered address:

Unit 7 Riverside Industrial Estate

enquiries@vokera.co.uk

www.vokera.co.uk

Vokèra Ltd

Borderlake House

London Colney

Herts AL2 1HG

www.vokera.ie

Sales, General Enquires

T 0844 391 099

F 0844 391 0998

Vokèra Ireland

West Court, Callan

Co Kilkenny

T 056 7755057

F 056 7755060

Vokèra Limited reserve the right to change

specification without prior notice

Consumers statutory rights are not affected.

A Riello Group Company.

Company Reg No: 1047779

Loading...

Loading...