High-performance Universal Joint Shafts

including ATEX certification

Series: S, R, CH, E

Instruction manual (Translation) G853 en 07/2013, Version 1

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Publisher

Document number

Date of issue

Copyright

If you have questions regarding the product, please contact us

specifying the serial number and parts list number:

J.M. Voith SE & Co. KG/VTA

Universal Joint Shafts

Alexanderstr. 2

89522 Heidenheim, Germany

Additional contact information:

Telephone +

Fax

E-Mail

Web

49 7321 37-8283

+49 7321 37-7106

UJShafts@Voith.com

www.voith.com

J. M. Voith SE & Co. KG/VTA

Universal Joint Shafts

Alexanderstr. 2

89522 Heidenheim, Germany

E-Mail: UJShafts@Voith.com

G853 en 07/2013 Version 1

July 16, 2013

© 2013, J. M. Voith SE & Co. KG/VTA

This documentation including all of its parts is protected by

copyright. Any use or change outside of the narrow boundaries of

copyright law is not permitted without the agreement of J.M.

Voith SE & Co. KG/VTA and is punishable by law.

This applies especially to copying, translations, microfilming, and

the saving and processing on electronic systems.

2

G853 en 07/2013, Version1

-performance universal joint shaft

J. M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Table of contents

Contents

1 About this instruction manual .....................................................................................7

1.1 Target groups ................................................................................................................ 7

1.2 Product observation ..................................................................................................... 7

1.3 Other applicable documents ....................................................................................... 8

1.4 Additional documents .................................................................................................. 9

1.5 Symbols and markings..................................

.............................................................10

1.6 Warning ........................................................................................................................11

1.6.1 Levels of danger ...........................................................................................................11

1.6.2 Safety symbols ..............................................................................................................12

2 Basic Safety Information ........................................................................................... 13

2.1 Product safety .............................................................................................................13

2.2 Proper use ...................................................................................................................13

2.3 Remaining risks ..........................................................................................................14

2.4 Safety information for the operator ..........................................................................15

2.5 Safety information for the personnel ........................................................................17

2.6 Personal protective equipment .................................................................................21

2.7 Spare parts ..................................................................................................................21

3 High-performance Universal Joint Shafts ..............

................................................. 22

3.1 Structure ......................................................................................................................22

3.2 Application ..................................................................................................................25

3.3 Series ...........................................................................................................................26

3.3.1 Type designations .........................................................................................................26

3.3.2 S Series ........................................................................................................................27

3.3.3 R Series ........................................................................................................................27

3.3.4 CH Series ......................................................................................................................28

3.3.5 E Series ........................................................................................................................28

4 Packaging, transport ................................................................................................. 29

4.1 Packaging ....................................................................................................................29

G853 en 07/2013, Version1

4.2 Unpacking the universal joint shaft and checking the delivery .............................29

4.3 Lifting, transporting, setting down the universal join

-performance universal joint shaft

t shaft ..................................30

3

Table of contents

High

Instruction m

J.M. Voith SE & Co. KG/VTA | Instruction Manual

5 Storage and preservation ......................................................................................... 33

5.1 Storing the universal joint shaft ................................................................................33

5.2 Preserving the universal joint shaft ..........................................................................34

6 Installation .................................................................................................................. 35

6.1 Additional regulations for flange bolted connections ............................................35

6.1.1 Requirements of connecting flange and bolted connections .........................................35

6.1.2 Checking bolted connections and tightened parts .......

.................................................41

6.2 Installing the universal joint shaft .............................................................................42

6.2.1 Removing preservation .................................................................................................44

6.2.2 Transport universal joint shaft to the installation location .............................................44

6.2.3 Cleaning the universal joint shaft and connecting flange .............................................45

6.2.4 Checking, aligning, and fastening connecting flange ...................................................45

6.2.5 Checking the differential angle of the front faces of the connecting flange (with Z

arrangement) ................................................................................................................46

6.2.6 Checking the differential angle of the front faces of the connecting flange (with

W arrangement) ............................................................................................................47

6.2.7 Bolting together the universal joint shaft and the connecting flange ............................47

6.2.8 Final work ......................................................................................................................48

6.3 Additional regulations for Hirth serration ................................................................49

6.4 Additional regulations for use in paper machines ..................................................50

7 Commissioning and operation ................................................................................. 51

7.1 Commissioning the universal joint shaft ...............

..................................................51

7.2 Operating the universal joint shaft ...........................................................................52

8 Eliminating errors ...................................................................................................... 53

9 Maintenance ............................................................................................................... 55

9.1 General notes about the maintenance and inspection of universal joint shafts .56

9.2 Intervals for maintenance and inspections ..............................................................57

9.3 Inspections ..................................................................................................................58

9.3.1 Checking axial clearance of the journal cross set ........................................................58

9.3.2 Checking deflection play of the center part...................................................................59

9.4 Lubrication ..................................................................................................................61

9.4.1 Lubricants .....................................................................................................................61

9.4.2 Lubricating the universal joint shaft .................

.............................................................61

9.5 Main overhaul ..............................................................................................................64

anual (Translation) G853 en 07/2013, Version1

-performance universal joint shaft

4

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Table of contents

9.6 Life span of ATEX universal joint shafts ..................................................................64

10 Removal ...................................................................................................................... 65

11 Repair .......................................................................................................................... 67

12 Disposal ...................................................................................................................... 67

13 Declaration of incorporation ........................

............................................................. 68

14 Declaration of conformity ......................................................................................... 69

15 Index ............................................................................................................................ 70

G853 en 07/2013, Version1

-performance universal joint shaft

5

Table of contents

High

Instruction m

List of figures

Table index

J.M. Voith SE Co. KG/VTA| Instruction Manual

Fig. 3.1: Structure of the universal joint shaft (example of type

RT) ............................................................................ 22

Fig. 3.2: Nameplate of an ATEX-certified universal joint shaft 23

Fig. 3.3: Schematic structure of temperature monitoring ....... 24

Fig. 3.4: Z arrangement .......................................................... 25

Fig. 3.5: W arrangement ......................................................... 25

Fig. 4.1: Attaching the universal joint shaft ............................. 32

Fig. 6.1: Dimensions of the connecting flange and bolted

connections ............................................................... 36

Fig. 6.2: Dimensions of a stud screw ..........................

............ 41

Fig. 6.3: Universal joint shaft .................................................. 44

Fig. 6.4: Checking the difference in joint angle between the

faces of the connecting flanges ................................ 46

Fig. 6.5: Permissible differential angle (with Z arrangement) . 46

Fig. 6.6: Seals for Hirth serration ............................................ 49

Fig. 6.7: Checking radial offset and flange distance (with use in

paper machines) ....................................................... 50

Fig. 9.1: Checking axial clearance of the journal cross set on

two levels .................................................................. 58

Fig. 9.2: Checking deflection play of the center part .............. 59

Fig. 9.3: Reading off deflection dimension ............................. 60

Fig. 9.4: Lubrication points of the universal joint shaft ........... 62

Tab. 1.1: Target groups ............................................................. 7

Tab. 1.2: Other applicable documents ....................................... 9

Tab. 1.3: Symbols and markings ............................................. 10

Tab. 1.4: Meaning of the danger levels ................................... 11

Tab. 1.5: Meaning of the safety symbols .......................

.......... 12

Tab. 2.1: Personal protective equipment ................................. 21

Tab. 6.1: Dimensions of the connecting flange and bolted

connections (key) ....................................................... 37

Tab. 6.2: Dimensions of the connecting flange and bolted

connections ............................................................... 40

Tab. 6.3: Permissible differential angle (with Z arrangement) . 46

Tab. 6.4: Permissible differential angle (with W arrangement) 47

Tab. 6.5: Permissible radial offset and flange distance (for use

in paper machines) ................................................... 50

Tab. 8.1: Eliminating errors ...................................................... 54

Tab. 9.1: Intervals for maintenance work and inspections ...... 58

Tab. 9.2: Checking axial clearance of the journal cross set .... 59

Tab. 9.3: Permissible deflection ratio....................................... 60

Tab. 9.4: Permissible lubricant quantity for the re-lubrication of

standard center parts. ............................................... 64

anual (Translation) G853 en 07/2013, Version1

-performance universal joint shaft

6

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

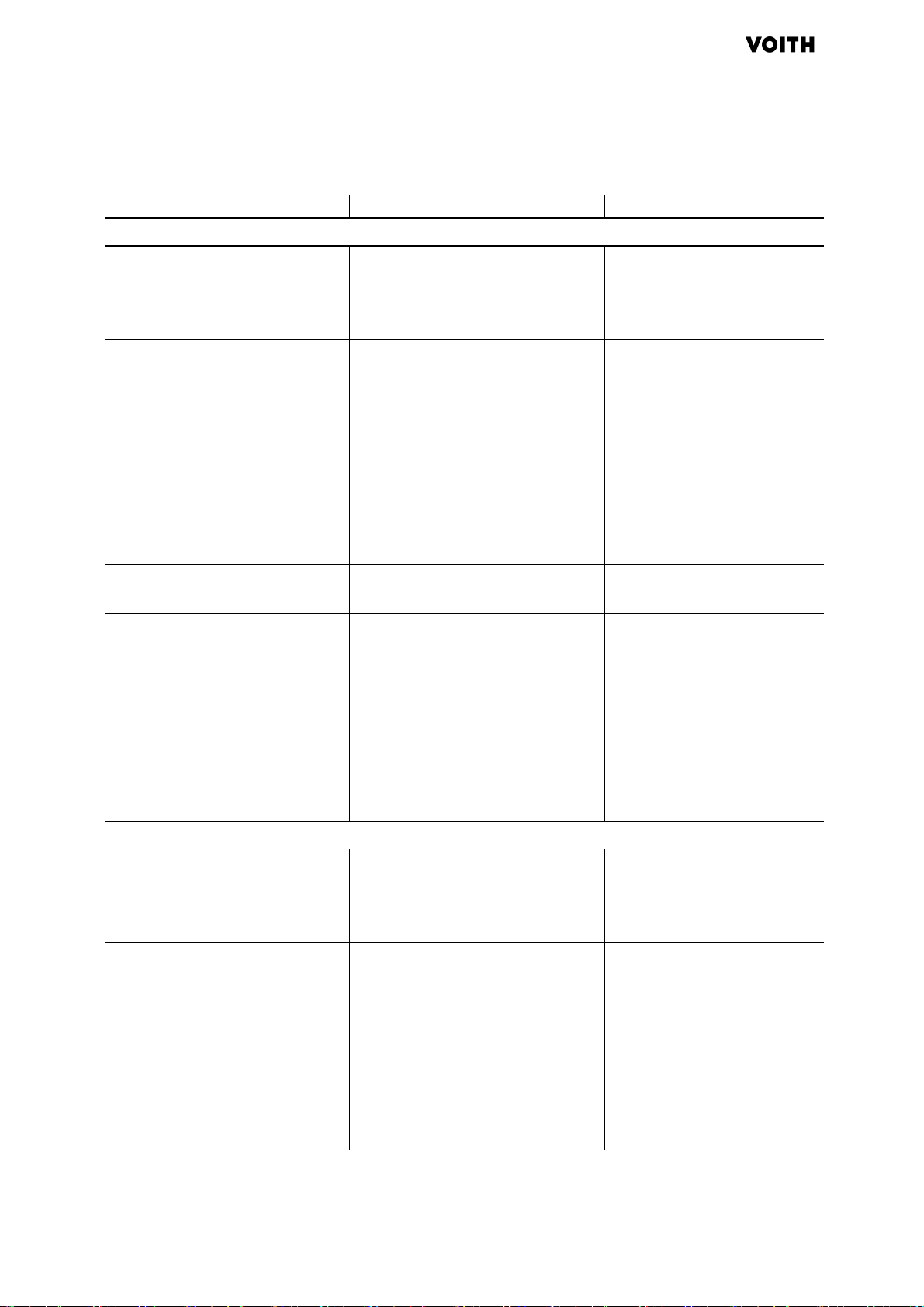

Target group

Task

About this instruction manual

1 About this instruction manual

Before you use the universal joint shaft, you must read this

instruction manually carefully and understand it.

This instruction manual is part of the product and familiarizes you

with the basic work on the universal joint shaft – from installation to

disposal.

It contains information about the safe and proper use of the

universal joint shaft.

1.1 Target groups

Operator Keep this instruction manual accessible to personnel at all

times.

Make sure that employees read and heed the instruction

manual and the other applicable documents, especially the

basic safety instructions and warnings.

Specialized personnel, service

engineer

1.2 Product observation

Heed additional system-related details and regulations.

Read, heed, and follow this instruction manual and the other

applicable documents, especially the basic safety instructions

and warnings.

Tab. 1.1: Target groups

We are under legal obligation to observe our products, even after

ipment.

sh

Therefore, please inform us about anything that might be of

interest, e.g.:

− Change in operating data

− Experience gained with the universal joint shaft

− Recurring problems

− Damage to the universal joint shaft

− Problems with the instruction manual

G853 en 07/2013, Version1

-performance universal joint shaft

7

About this instruction manual

High

Instruction manual (Translation)

Document

Information

Source

1.3 Other applicable documents

Documents for all designs

J.M. Voith SE & Co. KG/VTA| Instruction Manual

System documentation • System-specific information

about the removal and

installation of the universal joint

shaft.

Dimensional drawing of the

universal joint shaft

• Dimensions of the connection

flange.

• Tightening torques of the

bolted connections of the

flange connections.

• Weight of the universal joint

shaft.

• Shortest and maximum

permissible length of the

universal joint shaft.

Delivery note • Weight of the universal joint

shaft

Repair instructions for the

respective designs and sizes

For the manufacturer's authorized

service personnel:

• Information about repair of the

universal joint shaft

Operator

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

Balancing instruction For the manufacturer's authorized

service personnel:

• Information about the

balancing of the universal joint

shaft

Documents for special designs

Mounting and dismounting

instructions for split flange yokes

For designs with split flange yokes:

• Information about installing and

removing the universal joint

shaft

Mounting and dismounting

instructions for tripod center parts

For designs withtripod center parts:

• Information about installing and

removing the universal joint

shaft

Mounting and dismounting

instructions for spring-mounted

center parts

For designs with spring-mounted

center part:

• Information about installing and

removing the universal joint

shaft

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

G853 en 07/2013, Version1

-performance universal joint shaft

8

J.M. Voith SE & Co. KG | Instruction Manual

High

Instruction manual (Translation)

About this instruction manual

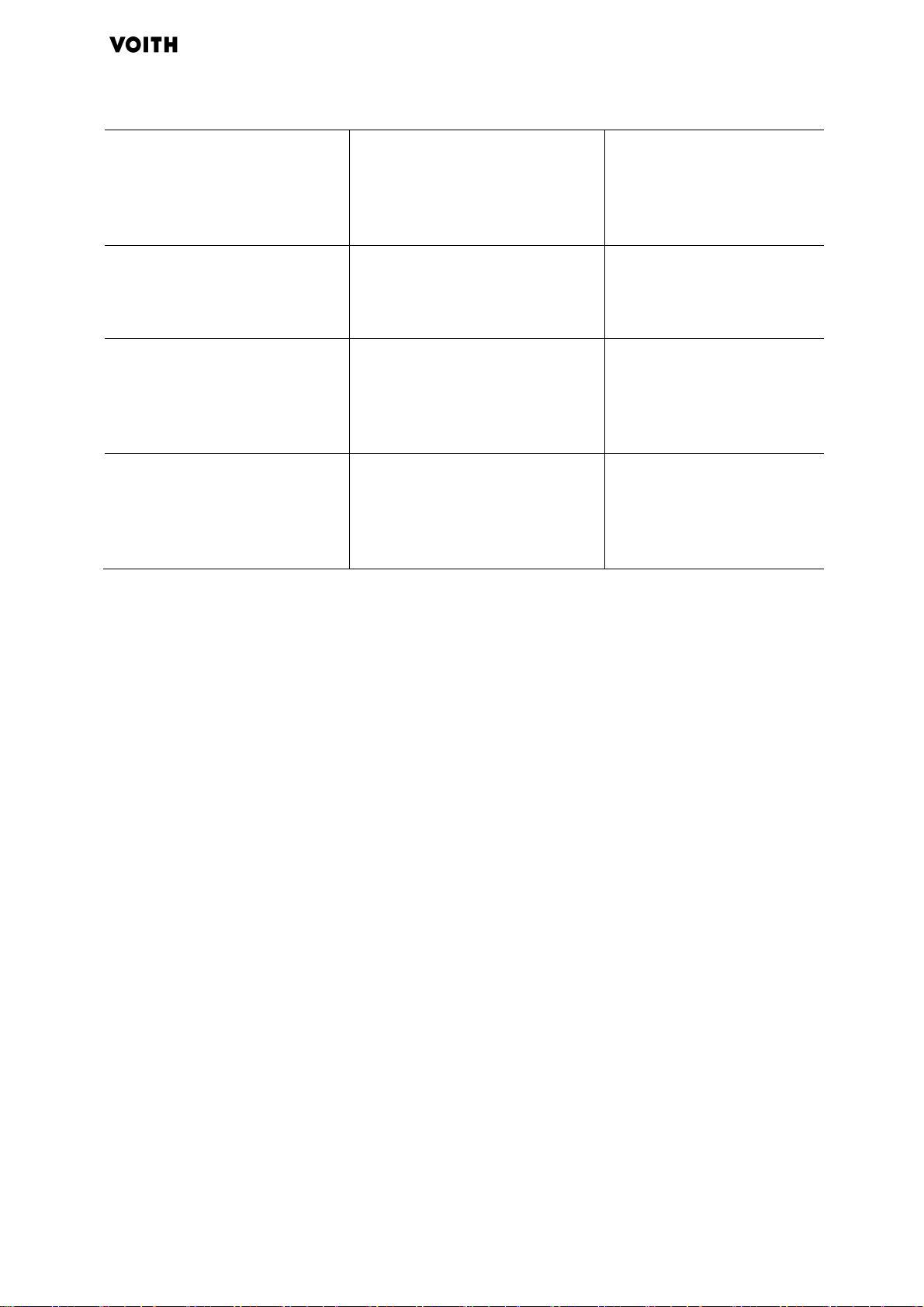

Mounting and dismounting

instructions for hydraulicallymovable center parts

Mounting and dismounting

instructions for deflection brakes

Mounting and dismounting

instructions for shaft angle

limiters

Mounting and dismounting

instructions for quick-release

couplings

For designs with hydraulic center

part:

• Information about installing and

removing the universal joint

shaft

For designs with deflection brake:

• Information about installing and

removing the universal joint

shaft

For designs with shaft angle

limitation:

• Information about installing and

removing the universal joint

shaft

For designs with quick-release

coupling:

• Information about installing and

removing the universal joint

shaft

Tab. 1.2: Other applicable documents

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

1.4 Additional documents

For additional information about the universal joint shafts, please

see the following documents:

• High-performance universal joint shafts catalogue

• General delivery conditions

• Hirth serrations

Order from: UJShafts@Voith.com

G853 en 07/2013, Version1

-performance universal joint shaft

9

About this instruction manual

High

Instruction manual (Translation)

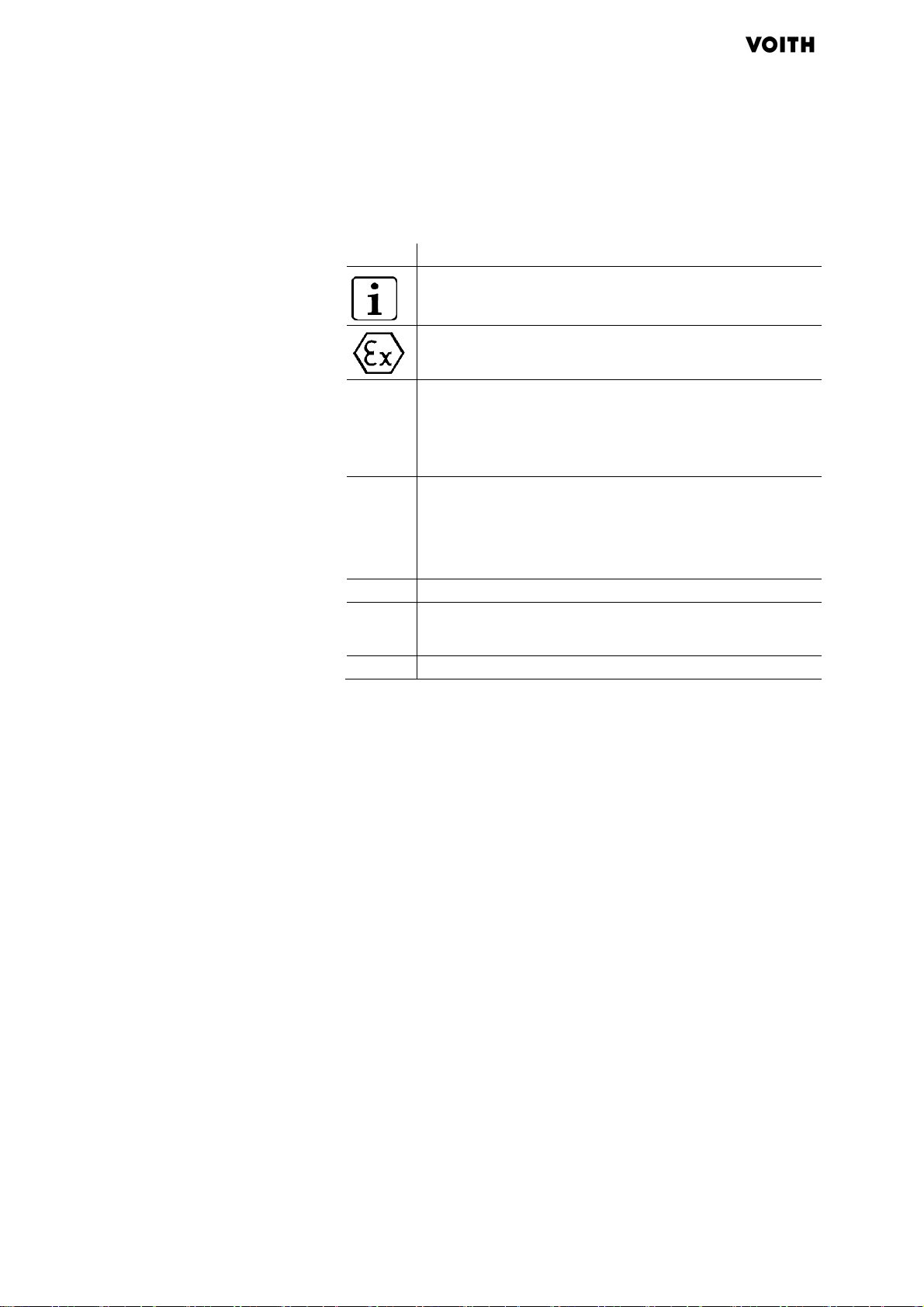

Symbol

Meani

ng

1.5 Symbols and markings

Symbols and markings are used in this instruction manual in order

to allow you quick access to information.

J.M. Voith SE & Co. KG /VTA| Instruction Manual

Note about the effective use of the universal joint shaft

and this instruction manual

Note for ATEX certified universal joint shafts

1.

Action with several steps, whose sequence is relevant

2.

3.

Action with one step

–or–

Action with several steps, whose sequence is not

relevant

Prerequisite

•

List (first level)

−

List (second level)

Cross-reference to additional information

Tab. 1.3: Symbols and markings

G853 en 07/2013, Version1

-performance universal joint shaft

10

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

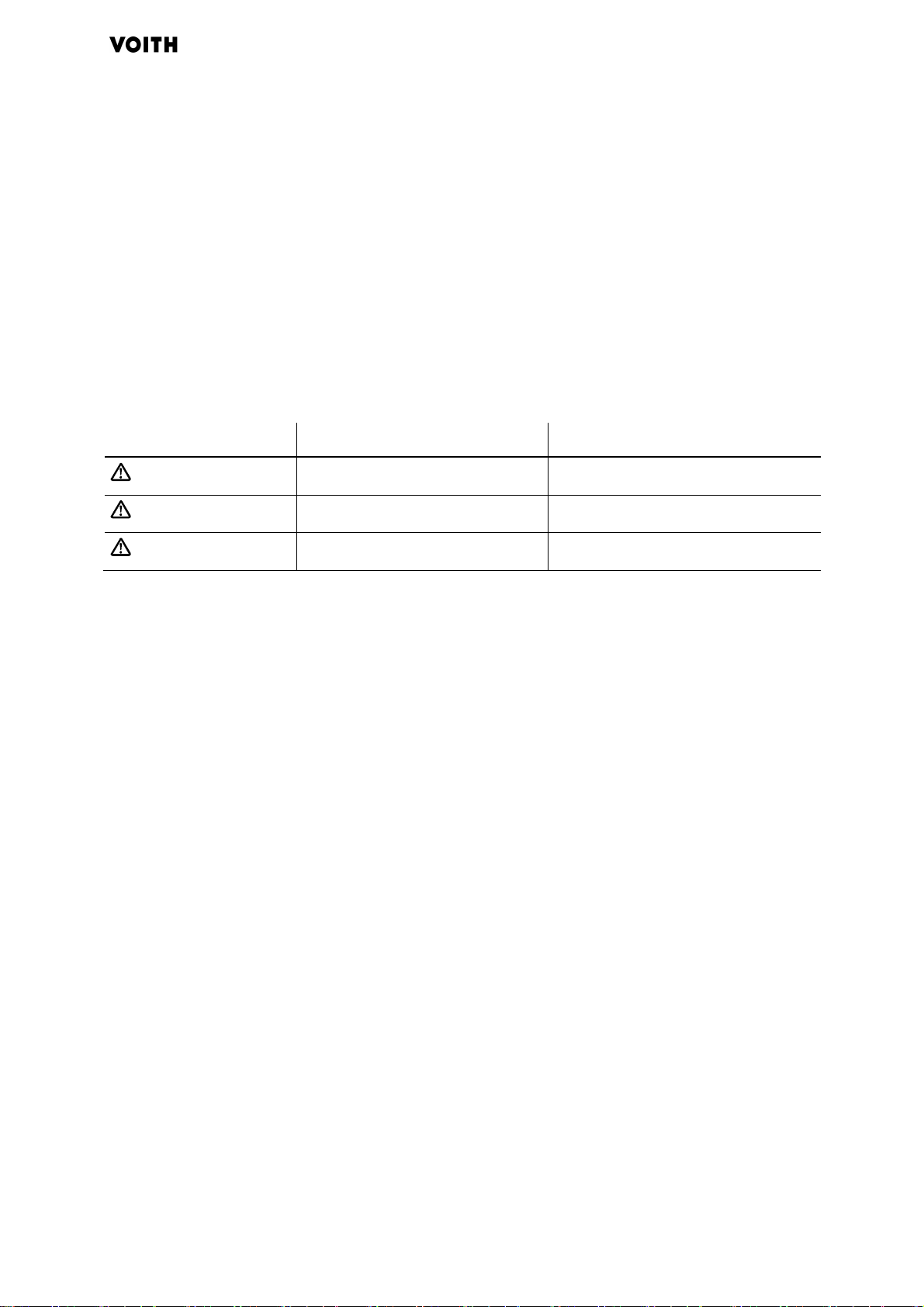

Level of danger

Likelihood of occurrence

Consequences if not heeded

DANGER

WARNING

CAUTION

1.6 Warning

For your safety, warnings are used in this instruction manual. The

warnings are next to the appropriate action instruction.

Depending on the likelihood of occurrence and consequences if

the instructions are not heeded, various danger levels are used.

The warnings are indicated with safety symbols, which depict the

type of danger visually.

1.6.1 Levels of danger

Imminent danger Death, severe bodily harm

Possible imminent danger Death, severe bodily harm

About this instruction manual

Possible imminent danger Slight bodily harm

Tab. 1.4: Meaning of the danger levels

G853 en 07/2013, Version1

-performance universal joint shaft

11

About this instruction manual

High

Instruction manual (Translation)

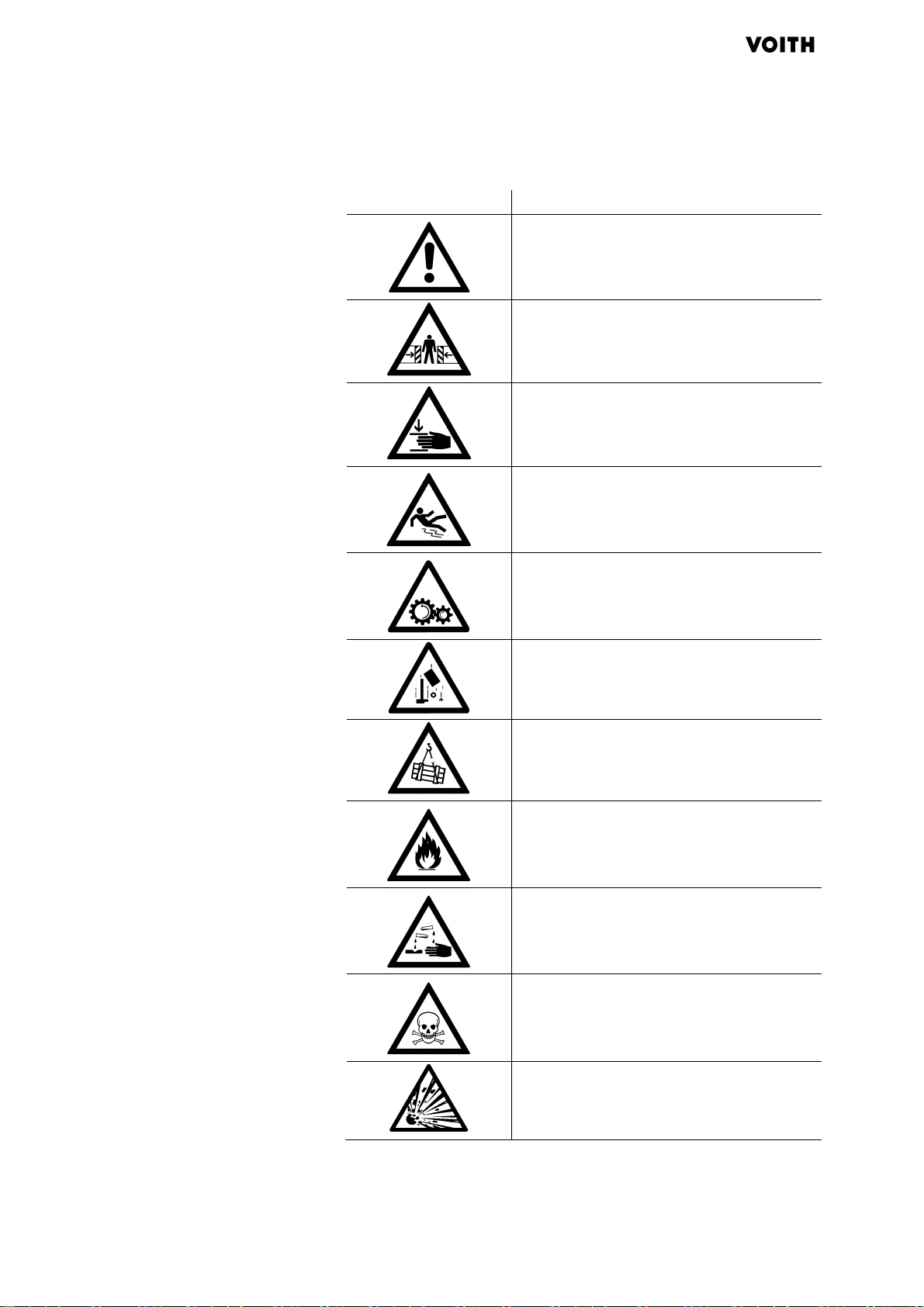

Safety symbols

Warning about

1.6.2 Safety symbols

J.M. Voith SE & Co. KG/VTA | Instruction Manual

General dangers

The type of danger is described in more

detail in the warning.

ushing

Cr

Hand injuries

Slipping

Rotating parts

Falling parts

Suspended loads

Flammable materials

Acidic materials

Poisonous materials

12

nger of explosion

Da

Tab. 1.5: Meaning of the safety symbols

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Foreseeable misuse

2 Basic Safety Information

Please heed the following safety information before engaging

in any activities.

2.1 Product safety

The universal joint shaft has been developed and built according to

he state of technology as well as the applicable safety regulations

t

at the time it was put on the market.

Nevertheless, its use can result in danger to life and limb of the

user or damage to the universal joint shaft itself and other property.

Only install the universal joint shaft if it is in proper condition

and only for the designated use, in a safety-conscious

manner that complies with the instruction manual.

Basic Safety Information

2.2 Proper use

Immediately correct (or have corrected) any defects that

adversely affect safety.

Universal joint shafts transmit torques between defined drive and

machine components. Therefore, the universal joint shaft is

intended for installation in the specific machine/system for which it

was selected.

Any other use, especially installation in other machines, is not

proper and forbidden.

Voith universal joint shafts are not approved for use in the food

industry.

In liquid media, universal joint shafts may only be used with written

permission of the manufacturer.

The universal joint shaft type we make and size can only be

regarded as recommendations.

Any improper use or activities on the universal joint shafts not

described in this instruction manual are impermissible misuse

outside of the legal liability limits of the manufacturer.

G853 en 07/2013, Version1

-performance universal joint shaft

Heed the following measures to avoid misuse:

nly operate the universal joint shaft within the specified

O

speed and torque range.

13

Basic Safety Information

High

Instruction manual (Translation)

J.M. Voith SE & Co. KG/VTA | Instruction Manual

Universal joint shafts are resiliently-flexible bodies that are

designed for bending vibrations and bending-critical speeds.

Therefore, for safety reasons, the maximum operating speed

must be significantly below the critical-bending speed 1st and

2nd order (see universal joint catalog G830).

For sufficient balance and security for the universal joint

shaft, it must be ensured that the operating speed does not

exceed the maximum permissible value depending on the

shaft angle (see universal joint catalog G830) and that the

driving and driven system parts are aligned with one another

(plan and concentric run-out see page 40)

Do not exceed permissible shaft angles of the universal joint

shaft.

Adhere to the lengths and temperatures specified for the

selection of the universal joint shaft.

For universal joint shafts with length compensation, make

sure that the maximum permissible movement path is not

exceeded.

2.3 Remaining risks

A local heating of the universal joint shaft, e.g. due to the

burning off of old color remnants is not permissible in order to

change the run-out properties.

Protect components coated with Rilsan against too-high

temperatures, chemical solvents, steam, and mechanical

damage.

Attaching parts to the universal joint shaft by welding or other

connection types is not permissible.

Adhere to the manufacturer's specifications with respect to

operation, maintenance, and repairs.

Have work on universal joint shafts done by the manufacturer

or by service technicians authorized by the manufacturer.

Do not make any unauthorized modifications or changes.

In areas subject to explosion (atmosphere), only use ATEXcertified universal joint shafts. Here, heed certification ( Chapter

3.1, page 22).

Before beginning construction and planning, the remaining risks of the

niversal joint shaft were analyzed and evaluated.

u

G853 en 07/2013, Version1

Remaining risks that could not be avoided during the entire life cycle

of the universal joint shafts are:

-performance universal joint shaft

14

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Safety

-

conscious working

• Risk of death and injury due to

− Misuse

− Improper handling

− Improper transport

− Missing protection systems

− Defective or damaged mechanical parts

• Environmental hazard, e.g. due to

− Improper handling of preserving agents and lubricants

• Property damage to the universal joint shaft due to

− Improper handling

− Hazardous environmental influences, application

− Operating specifications not adhered to

− Unsuitable operating materials (e.g. bearing grease)

• Property damage to other assets due to improper handling

Basic Safety Information

conditions

• Performance or functional limitations due to

− Improper handling

− Improper maintenance or repair

− Subsequent damage due to overload

Avoid existing remaining risks with the practical imp

heeding of the following specifications:

• Basic safety instructions and warnings in this instruction manual

• Work instructions from the operator

• Technical data for the system ( system documentation)

2.4 Safety information for the operator

The operator must take appropriate safety precautions in

order to prevent the endangering of people and materials due

to rotating universal joint shafts and their parts.

For the operation of the universal joint shaft within a machine,

the EU machine directive must be heeded.

Ensure adherence and monitoring:

lementation and

G853 en 07/2013, Version1

-performance universal joint shaft

− Of proper use

− Of laws and regulations for accident prevention and

environmental protection

− Of safety regulations for the handling of hazardous

materials

− Of applicable standards and guidelines for the country of

operation

15

Basic Safety Information

High

Instruction manual (Translation)

Organizational measures

Selection and qualification of

J.M. Voith SE & Co. KG/VTA | Instruction Manual

Make protective equipment available ( Chapter 2.6, page

21).

For telescopic lengths without profile guard: provide guard in

the system.

Keep this instruction manual and all applicable documents

accessible to personnel at all times.

Specify responsibilities of the personnel clearly and monitor

adherence.

staff

All activities on the universal joint shaft may only

be performed by

authorized personnel.

Ensure that the staff members

− are at least 18 years old.

− have read and understood the "Basic safety information"

chapter.

− can apply and implement the contents of the "Basic safety

instructions" chapter.

− have the bodily and mental abilities to perform their

responsibilities, tasks, and activities on the universal joint

shaft.

− are trained according to their responsibilities, tasks, and

activities on the universal joint shaft.

− have understood and can practically implement the

technical documentation with respect to their

responsibilities, tasks, and activities on the universal joint

shaft.

− is familiar with and can apply the components of the

system and their function.

16

− is familiar according to his responsibilities with the

instructions for cleaning, preserving, lubricating, and using

hazardous materials and taking first aid measures in case

of accidents.

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Warranty

Safety

-

conscious wo

rking

The warranty is voided in case of any change to the universal

joint shaft without our written permission.

During the warranty, obtain the manufacturer's permission

before making repairs to the universal joint shaft.

Only use original parts or parts approved by the

manufacturer.

2.5 Safety information for the personnel

The consumption of alcohol, drugs, medications or other mind-

ltering substances is forbidden.

a

Protect universal joint shaft against unauthorized operation.

Adhere to applicable accident prevention regulations.

If necessary or required by regulations, wear personal

protective equipment ( Chapter 2.6, page 21).

Basic Safety Information

Keep unauthorized personnel out of the danger area of the

universal joint shaft.

Keep safety and notice signs on the universal joint shaft in

easily-legible condition, e.g. lubrication points.

Follow the supervisor or safety officer's safety and work

instructions.

Only linger in the workplaces provided in the danger area

( system documentation).

Do not make any constructional changes to the universal joint

haft.

s

Handle hazardous materials according to the safety data

sheets. Heed safety measures and wear personal protective

equipment.

G853 en 07/2013, Version1

-performance universal joint shaft

17

Basic Safety Information

High

Instruction manual (Translation)

Lifting, transport, setting down

Pr

eservation

installation

J.M. Voith SE & Co. KG /VTA| Instruction Manual

Depending on the design, universal joint shafts can weigh up to 80

tons.

Heed weight ( Delivery note/Dimensional drawing of the

universal joint shaft).

Only lift and transport universal joint shafts with sufficiently-

dimensioned transport equipment ( Fig. 4.1, page 32).

Heed common attachment regulations.

Do not load profile guard.

Heed the center of gravity (hoist axis).

Only store universal joint shafts

− on floors with sufficient load capacity

− on suitable bases

Secure universal joint shaft against rolling away.

Only transport universal joint shaft in areas not subject to explosion

(atmosphere).

Unsecured universal joints can tip during lifting, tr

ansport, setting

down.

Secure universal joints against tipping, e.g. with a suitable

rope or wedge.

Never reach between the universal joint, even if there is a

deflection guard present.

For telescopic lengths: an unsecured telescoping part

can be

pulled apart when lifting, transporting or setting down.

Secure telescoping part against being pulled apart, e.g. with

a suitable rope.

Cleansers and anti-corrosion agents are usually flammable in their

liquid form.

Ensure sufficient ventilation.

Prevent direct bodily contact and inhalation.

Heed the manufacturer's safety data sheets.

18

Heed additional regulations for flange bolted connections

( Chapter 6.1, page 35).

Heed safety instructions for lifting, transport, setting down.

Secure drive against starting up.

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Commissioning and operation

Keep personnel who are not participating away, e.g. using

supervisory personnel, enclosures, fences.

Only install universal joint shaft in areas not subject to explosion

(atmosphere).

For specially-designed universal joint shafts, improper installation

and removal can cause severe injuries or even death.

Heed and if necessary order additional documentation

( Chapter 1.3, page 8).

Only put a completely functional and safe universal joint

shaft/system into operation.

Before commissioning, remove deflection and transport

braces.

Before commissioning, check tightening torques and null

markings.

Basic Safety Information

Only operate universal joint shaft with appropriate guards

( system documentation).

For telescopic lengths: protect gearing of the telescopic parts

against dirt and foreign bodies.

In case of changed operating state and faults, take the

universal joint shaft out of commission immediately. Report

changed operating states and faults to the responsible

office/person immediately.

Do not perform cleaning work when operation is ongoing.

If it is not possible to prevent people from lingering in the

danger radius of the universal joint shaft while it is in

operation, special safety measures must be taken in case of

a universal joint shaft break.

If there can be blockages or collisions with resulting personal

injury as a result of a universal joint break in the case of

mobile drives, appropriate arresting devices must be

provided for the universal joint shafts.

In case of ATEX-certified universal joint shafts, it must be ensured

that

G853 en 07/2013, Version1

-performance universal joint shaft

The surface temperature in the field of joint bearings not

exceed 140°C.

Voith recommends at both joints, to attach a temperature

monitoring in the field of the joint bearings.

19

Basic Safety Information

High

Instruction manual (Translation)

Maintenance work and

Repair

Decommissioning

Removal

Disposal

J.M. Voith SE & Co. KG/VTA | Instruction Manual

inspections

The operator's service personnel may only perform the maintenance

work and inspections described in this instruction manual. Other

maintenance work (especially overhauls) may only be performed by

the manufacturer's service personnel or personnel authorized by the

manufacturer.

Observe specified intervals ( Chapter 9.2, page 57).

Do not perform any maintenance work or inspections during

ongoing operation.

Before maintenance and inspection work, secure the drive

against starting up.

Do not remove any safety equipment as long as the universal

joint shaft/system is not standing still and secured against

starting up again.

When the universal joint shaft is standing still, do not load it

with high lifting or attachment forces and do not place any

objects on the universal joint shaft or hang or attach anything

to it.

Before reattaching the universal joint shaft/system, reattach

all safety equipment.

The universal joint shaft must be checked regularly for

changed running noises and vibrations.

Repairs may only be made by the manufacturer's servic

e

personnel or personnel authorized by the manufacturer.

Only make repairs after consultation with the manufacturer.

Do not make any repairs when operation is ongoing.

Only repair universal joint shaft in areas not subject to explosion

(atmosphere).

See system documentation

See repair instructions/system documentation

ly remove universal joint shaft in areas not subject to explosion

On

(atmosphere).

Dispose of packaging material according to the applicable

regulations in the place of use.

Dispose of operating and hazardous materials separately

according to the locally-applicable regulations. Heed the

manufacturer's safety data sheets.

G853 en 07/2013, Version1

20

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Activity

Protective equipment

2.6 Personal protective equipment

Heed additional notices in the system documentation.

Heed additional operator-side regulations.

In order to prevent injuries, wear personal protective

equipment according to the following table:

Re-installation • Safety helmet

Basic Safety Information

• Safety shoes with slip-proof, oil-resistant

soles

• Protective gloves

• Fall protection

• Safety glasses

Commissioning

and operation

• Closely-fitting clothing

• Ear protection

• Safety shoes with slip-proof, oil-resistant

soles

• Safety glasses

Transport • Safety helmet

• Safety shoes with slip-proof, oil-resistant

soles

• Safety glasses

Preservation • Safety glasses

• Protective gloves

Maintenance • Safety helmet

• Protective gloves

• Safety shoes with slip-proof, oil-resistant

soles

• Fall protection

• Safety glasses

Tab. 2.1: Personal protective equipment

2.7 Spare parts

G853 en 07/2013, Version1

-performance universal joint shaft

Spare parts must meet the technical specifications of the

manufacturer. Same is guaranteed if original parts are used, as

these are subject to a regular quality control. Spare parts from

other suppliers may, in some cases, change the characteristics of

the machine and result in substantial defects, for which Voith

cannot assume any responsibility.

21

High-performance Universal Joint Shafts

High

Instruction manual (Translation)

Link head

Journal cross set

Flange yoke

Telescopic length with

J.M. Voith SE & Co. KG/VTA | Instruction Manual

3 High-performance Universal Joint Shafts

3.1 Structure

standard center part

Fig. 3.1: Structure of the universal joint shaft (example of type RT)

The link head consists of:

• an integral flange yoke

–or–

a semi-integral flange yoke

A journal cross set constits of:

• a journal cross

• four bearing units

The flange yokes depend on the universal joint shaft type

( Chapter 3.3, page 26).

Depending on the size, the telescopic length is eithe

r equipped

with an involute profile or a diameter-centered SAE profile with

length compensation.

The involute profile can optionally be provided with a lowmaintenance Rilsan® plastic coating.

G853 en 07/2013, Version1

22

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Telescopic length with

Fixed length universal joint

ATEX

-

certified universal joint

High-performance Universal Joint Shafts

tripod center part

shafts

shaft

The tripod shaft consists of two standard joints and one special

center part for length compensation.

At the free end of the guide shaft, three bolts offset by 120° with

roller bearings are arranged radially.

Accordingly, the guide hub has three grooves for accommodating

the roller bearings.

The fixed center part has a fixed length.

In contrast to standard universal joint shafts, ATEX-certified

universal joint shafts have:

A nameplate that clearly identifies the ATEX-certified

universal joint shaft.

G853 en 07/2013, Version1

-performance universal joint shaft

Fig. 3.2: Nameplate of an ATEX-certified universal joint shaft

− Pos. 1: Manufacturer's name

− Pos. 2: Serial number

− Pos. 3: ATEX identification

− Pos. 4: Year of manufacture

− Pos. 5: Designation according to the type designation

− Pos. 6: Date for next primary examination

23

High-performance Universal Joint Shafts

High

Instruction manual (Translation)

EX identifier

Equipment group

Equipment category

Type of ignition protection

Temperature range

For ATEX-certified universal joint shafts, the surface temperature

in the field of joint bearings should not exceed 140°C.

Voith recommends at both joints to attach a temperature

J.M. Voith SE & Co. KG/VTA | Instruction Manual

The ATEX identifier shown in Pos. 3 of the nameplate is

composed as follows, in accordance with DIN 13463-1:

II 2GD c T3

monitoring in the field of joint bearings (Fig. 3.3, page 24).

24

Fig. 3.3: Schematic structure of temperature monitoring

The temperature monitoring is not included in the Voith scope

of delivery and must be provided by the operator.

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Z arrangement

W arrangement

3.2 Application

The universal joint transfers torque from axes tilted toward one

another at a shaft angle β.

Universal joint shafts with two universal joints transfer torques

between a drive motor and a machine. Here, only a Z or W

arrangement is permitted, for which the angles β1 and β2 must be

equal (Fig. 3.4, page 25 and Fig. 3.5, page 25).

High-performance Universal Joint Shafts

Fig. 3.4: Z arrangement

1 Input side/flange G1 Universal joint 1

2 Center part G2 Universal joint 2

3 Output side/flange b1 Shaft angle (G1)

b2 Shaft angle (G2)

Fig. 3.5: W arrangement

1 Input side/flange G1 Universal joint 1

2 Center part G2 Universal joint 2

3 Output side/flange b1 Shaft angle (G1)

b2 Shaft angle (G2)

G853 en 07/2013, Version1

-performance universal joint shaft

25

High-performance Universal Joint Shafts

High

Instruction manual (Translation)

Series

3.3 Series

For detailed information about the respective series:

3.3.1 Type designations

The design of standard universal joint shafts can be read off using

he type designation. The design of special joint shafts must be

t

taken from the dimensional drawing.

Example R T 250.8 S 285/ S 315 R 2560

S,R,CH,E

Center-section design

T,TL,TK,TR,F,GK,FZ,Z

J.M. Voith SE & Co. KG/VTA | Instruction Manual

See catalogs for High-performance universal joints (G830)

from Voith Turbo GmbH & Co. KG.

Size. Bearing type

Flange design (S,K,Q,H)

S: friction flange

K: flange with split sleeve

Q: flange with face key

H: flange with Hirth connections

Flange size

input side/output side

Profile coating

S: Steel (Standard)

R: Rilsan®

P: PTFE

Length l

min

or l

z min

in mm

G853 en 07/2013, Version1

-performance universal joint shaft

26

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Type

Description

Type

Description

3.3.2 S Series

Size: 58–225

Torque transmission: 0.25 - 35 kNm

Flange design: standard design with friction fit

Area of application: marine drives, pumps, locomotives, motor

cars, paper machines, general mechanical engineering

ST Telescopic length with standard center part

STK 1–4 Telescopic length with shortened center part

SF Fixed length universal joint shaft

SGK Joint coupling; short, separable fixed length universal

High-performance Universal Joint Shafts

joint shaft

3.3.3 R Series

SFZ

Intermediate shaft with a joint head and bearing

SZ Intermediate shaft with dual bearings

Size: 198–550

Torque transmission: 32 - 1000 kNm

Flange design: standard design of the sizes 198 - 390 with friction

fit, optionally with face-key or Hirth serration, standard design of

the sizes 440 - 550 with face-key, optionally with Hirth serration.

Area of application: general mechanical engineering, railway

drives, rolling mills, conveyor systems, paper machines, marine

drives

RT Telescopic length with standard center part

RTL Telescopic length with extended center part

-performance universal joint shaft

RTK 1–2 Telescopic length with shortened center part

RF Fixed length universal joint shaft

RGK Joint coupling; short, separable fixed length universal

joint shaft

RFZ Intermediate shaft with a joint head and bearing

RZ Intermediate shaft with dual bearings

G853 en 07/2013, Version1

27

High-performance Universal Joint Shafts

High

Instruction manual (Translation)

Type

Description

Type

Description

3.3.4 CH Series

Size: 350–1460

Torque transmission: 260 - 19440 kNm

Flange design: Hirth serration or face-key

Area of application: rolling mill main drives, heavy machinery,

heavily-loaded drives in mechanical engineering

CHT Telescopic length with standard center part

CHF Fixed length universal joint shaft

CHGK Joint coupling; short, separable fixed length universal

3.3.5 E Series

J.M. Voith SE & Co. KG/VTA | Instruction Manual

joint shaft

Size: 590–1220

Torque transmission: 1600 - 14000 kNm

Flange design: 2-part flange yoke with coupling splines

arranged on an axis of symmetry, Hirth

serration on the flange

Area of application: rolling mill drives, heavy machinery

ET Telescopic length with standard center part

EF Fixed length universal joint shaft

EGK Joint coupling; short, separable fixed length universal

joint shaft

G853 en 07/2013, Version1

-performance universal joint shaft

28

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Europe

Sea freight

4 Packaging, transport

Universal joint shafts are ready to install on delivery.

4.1 Packaging

table wood packaging/wood frame

• S

• Secured with appropriate shims

• Stable wood packaging

• Secured with appropriate shims

• Sealed with permanent plastic film

• Addition of drying agents

Packaging, transport

4.2 Unpacking the universal joint shaft and checking the delivery

If the load capacity of the fork lift is at least 125% of the weight of

the universal joint shaft:

Transport packaged universal joint shaft to the installation

location with a fork lift. Heed weight (Delivery

note/dimensional drawing of the universal joint shaft).

1. Check delivery immediately upon receipt:

− Packaging for transport damage

− Universal joint shaft for damage

− Delivery for completeness, that is, compare delivery to

order

2. Report transport damage to delivery service and document,

e.g. with photos.

3. Report complaints to the manufacturer.

4. Dispose of packaging material according to the applicable

regulations in the place of use.

-performance universal joint shaft

G853 en 07/2013, Version1

29

Packaging, transport

High

Instruction manual (Translation)

Transport with a fork lift

Transport with truck/crane

J.M. Voith SE & Co. KG/VTA | Instruction Manual

4.3 Lifting, transporting, setting down the universal joint shaft

Access to the installation location is possible freely and without

hindrances

Heed the load capacity of the lifting devices, the load lifting

and transport equipment: min. 125% of the weight of the

universal joint shaft ( Delivery note/ dimensional drawing of

the universal joint shaft).

Only transport universal joint shaft in areas not subject to explosion

(atmosphere).

If the load capacity of the fork lift is at least 125% of the weight of

the universal joint shaft:

Transport universal joint shaft to the installation location with

a fork lift. Heed weight ( Delivery note/ dimensional drawing

of the universal joint shaft).

DANGER

Severe to deadly injuries due to swinging or rolling universal

joint shaft!

Place universal joint shaft securely on the forks of the fork lift.

Secure universal joint shaft against rolling off the forks.

DANGER

Severe to deadly injuries due to swinging or falling universal

joint shaft!

Heed common attachment regulations.

Only lift universal joint shafts at the prescribed attachment

points ( Fig. 4.1, page 32).

Do not attach universal joint shaft in marked area

( Fig. 4.1, page 32).

Only use sufficiently dimensioned and tested lifting appliance.

30

Secure danger zone under the universal joint shaft against

entry.

Wear safety helmet, safety shoes, gloves, safety glasses, and

fall protection.

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

DANGER

In case of telescopic lengths: Severe to deadly injuries due to

falling parts!

Secure telescoping part against being pulled apart, e.g. with a

suitable rope.

DANGER

Severe crushing or crushing of limbs due to tipping universal

joint!

Secure universal joints against tipping, e.g. with a suitable

rope or wedge.

Never reach between the universal joint, even if there is a

deflection guard present

Packaging, transport

DANGER

Severe to deadly injuries due to rolling universal joint shaft!

Only set universal joint shaft down on suitable bases.

Secure universal joint shaft against rolling away.

DANGER

In case of ATEX-certified universal joint shafts: severe to

deadly injuries due to spark formation in case of:

• Equipotential bonding

• Impact-like touching of adjacent metal parts

Only transport universal joint shaft in areas not subject to

explosion (atmosphere).

G853 en 07/2013, Version1

-performance universal joint shaft

31

Packaging, transport

High

Instruction manual (Translation)

J.M. Voith SE & Co. KG/VTA | Instruction Manual

Fig. 4.1: Attaching the universal joint shaft

Universal joint shafts are, as much as possible, balanced at the

factory.

Protect universal joint shaft against damage.

Transport universal joint shaft without impact.

Do not attach universal joint shaft in marked area

(Fig. 4.1, page 32).

Heed the center of gravity (hoist axis).

Transport universal joint shaft as horizontally as possible.

In case of vertical transport of the universal joint shaft, secure

the universal joint shaft from separating with suitable

restraints.

For attaching, use plastic fiber ropes if possible in order not

to damage the universal joint shaft. Heed sufficient edge

protection.

Only set universal joint shaft down on a suitable base and

secure it against rolling away.

Universal joint shafts are delivered balanced and lubricated

so they are ready for installation and operation and.

To guarantee that the system documentation, the delivered

universal joint shaft must not be changed.

G853 en 07/2013, Version1

-performance universal joint shaft

32

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

5 Storage and preservation

You can store universal joint shafts for up to 3 months after

delivery without re-coating the preservation.

5.1 Storing the universal joint shaft

If not otherwise specified, the packaging is design for a storage

ime of max. 4 weeks.

t

In case of longer-term storage, heed the following:

Heed ambient conditions of the storage room:

− dry

Storage and preservation

− frost-free

− relative humidity max. 70%

− even temperature

In case of horizontal storage: place universal joint shaft on

suitable underlay (e.g. of wood) to prevent rolling away.

In case of vertical storage: place universal joint shaft in a

suitable frame (e.g. of wood) to prevent tipping over.

Check bare metal parts for corrosion every 6 weeks. If

necessary, treat parts with anticorrosion agent, e.g. oil or

wax.

Lubricate universal joints at least once a year. Move the

universal joints back and forth on both directions in order to

distribute the grease ( Chapter 9.4, page 61).

Put telescopic section into shortest length at least once a

year and move back and forth in order to distribute the

grease ( Chapter 9.4, page 61).

After a storage period of 18 months before installation, have

the universal joint shafts examined by authorized service

personnel since the seals are subject to aging.

G853 en 07/2013, Version1

-performance universal joint shaft

33

Storage and preservation

High

Instruction manual (Translation)

5.2 Preserving the universal joint shaft

DANGER

Anticorrosion agents can contain acidic materials and

additives!

Wear safety glasses and suitable protective gloves.

Heed the manufacturer's safety data sheets.

DANGER

There is a danger of fire due to use/processing of flammable

cleaning/anticorrosion agents!

Ensure sufficient ventilation.

J.M. Voith SE & Co. KG/VTA | Instruction Manual

Prevent direct bodily contact and inhalation.

Heed the manufacturer's safety data sheets.

For telescopic lengths: push telescopic part entirely together.

Treat all bare metal parts with anticorrosion agent, e.g. oil or

wax.

G853 en 07/2013, Version1

-performance universal joint shaft

34

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Design of connecting flange

Material

Dimensions

of the connecting

6 Installation

6.1 Additional regulations for flange bolted connections

6.1.1 Requirements of connecting flange and bolted connections

For fixed length universal joint shaft or joint coupling:

A connecting flange can move lengthwise through a floating

bearing in order to be able to push the universal joint shaft

over the centering collar and compensate for possible length

changes (e.g. due to heat elongation).

The use of universal joint shafts with length compensation

assumes that the connecting flange sits firmly on the shaft of

the connecting units.

Installation

flanges and bolted

connections

Select material that permits the use of bolts of the property

lass 10.9 ( Fig. 6.1, page 36, Pos. m).

c

With the use of materials with lower property class values, the

torques that can be transmitted by the flange connection and thus

also the universal joint shaft are reduced.

With use of materials with lower property class values:

reduce prescribed tightening torque of the bolts accordingly

( Tab. 6.2, page 40, area A, column 5)

The dimensions of the connecting flange ( F

Tab. 6.2, page 40) correspond to those of the universal joint shaft.

Exception:

Execute locating diameter c with clearance: fit H7/h6

( Tab. 6.2, page 40, area A, column 11).

For universal joint shafts with rota > 550 mm: dimensions of

the connecting flange and bolted connections as well as

tightening torques see dimensional drawing of the universal

joint shaft.

ig. 6.1, page 36 and

G853 en 07/2013, Version1

-performance universal joint shaft

The relief diameter fg on the universal joint shaft flange is not

suitable for locking hexagon head bolts or nuts.

A relief diameter fa on the connection flange is suitable for

protection against twisting.

35

Installation

High

Instruction manual (Translation)

Pos.

Description

Additional information (

Tab.

6.2, page

40)

Hex. nut in accordance with

J.M. Voith SE & Co. KG | Instruction Manual/VTA

Fig. 6.1: Dimensions of the connecting flange and bolted connections

Ø a Flange diameter Dimensions ( "Dimensions of the connecting flange" area)

Ø b Bolt circle diameter

Ø c Locating diameter

Ø fa Flange diameter, bolt side

Ø fg Flange diameter, nut side

g Flange thickness

mmin Minimum distance • Length of the hexagon head bolt m including the height of the

bolt head

• Dimensions of the hexagon head bolt m ( area A, column 4)

m Hexagon head bolt in

accordance with ISO 4014 -

10.9

• Number per connecting flange for universal joint shaft flange:

− Standard design ( area A, column 1)

− with face-key ( area A, column 2)

− with Hirth serrations ( area A, column 3)

DIN 985

• Dimensions ( area A, column 4)

• Tightening torque for a coefficient of friction µ = 0.12 and 90

% utilization of the bolt yield point ( area A, column 5)

n Hexagon head bolt in

accordance with ISO 4014 -

8.8

Hex. nut in accordance with

• Number per connecting flange ( area B, column 6)

• Dimensions ( area B, column 7)

• Tightening torque for a coefficient of friction µ = 0.12 and 90

% utilization of the bolt yield point ( area B, column 5)

DIN 985

o Split sleeve Dimensions ( area B, column 8)

p Washer Dimensions ( area B, column 9)

t Deep centering Dimensions ( "Dimensions of the connecting flange" area)

36

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Pos.

Description

Additional information (

Tab.

6.2, page

40)

v Length from the bearing

surface of the nut to the end

of the bolt

x face-key width

ya face-key depth

Z1 Axial run-out Permissible values for deviation in axial runout Z1 and

Z2 Radial run-out

concentricity Z2 at operating speeds < 1,500 min-1

rpm ( column 10)

Halve values at higher speeds up to 3000 min-1.

Tab. 6.1: Dimensions of the connecting flange and bolted connections (key)

Installation

G853 en 07/2013, Version1

-performance universal joint shaft

37

38

High

Instruction manual (Translation)

Installation

A ( Fig. 6.1)

Column

a

2

1

-

-

-

3

-

Size

[mm]

Types: ST/STK 1-4/ SF/ SGK/ SFZ/ SZ

058.1

065.1

075.1

090.2

100.2

120.2

120.5

150.2

58

4

65

75

90

100

120

120

150

4

6

4

6

8

8

8

M5 x 16

M6 x 20

M6 x 25

M8 x 25

M8 x 25

M10 x 30

M10 x 30

M12 x 40

4

m

2

2

c

11

c

[mm]

30

35

42

47

57

75

75

90

B ( Fig. 6.1)

5

MA

[Nm]

6

z

7

n

8

o

9

p

5

MA

[Nm]

7

13

13

31

31

63

63

109

Dimensions of the connecting flanges

b±0.1

[mm]

47

52

62

74.5

84

101.5

101.5

130

f

a-0.3

[mm]

38.5

41.5

51.5

61

70.5

84

84

110.3

fg

[mm]

g

[mm]

3.5

4

5.5

6

7

8

9

10

t

[mm]

1.2

1.5

2.3

2.3

2.3

2.3

2.3

2.3

-0.15

-0.25

-0.2

-0.2

-0.2

-0.2

-0.2

-0.2

v

[mm]

9

12

14

13

11

14

13

20

X P9

[mm]

Y

[mm]

Z1,Z

10

0.5

+

Z1,Z

a

[mm]

0.05

0.05

0.05

0.05

0.05

0.05

0.05

0.05

-performance universal joint shaft

150.3

150.5

180.5

225.7

150

150

180

225

8

8

8

8

G853 en 07/2013, Version1

M12 x 40

M12 x 40

M14 x 45

M16 x 55

109

109

175

265

4

M12 x 60

21 x 28

13

80

130

130

155.5

196

110.3

110.3

132.5

171

15

9

12

12

14

15

2.3

2.3

2.3

4

-0.2

-0.2

-0.2

-0.2

18

18

21

25

0.05

0.05

0.05

0.06

90

90

110

140

J.M. Voith SE & Co. KG/VTA | Instruction

Manual

High

-performance universal joint shaft

Instruction manual (Translation)

Types: RT/ RTL/ RTK 1

Types: RT/ RTL/ RTK 1

G853 en 07/2013, Version1

Column

J.M. Voith SE & Co. KG/VTA | Instruction Manual

A ( Fig. 6.1)

6

3

2

1

-

4

5

B ( Fig. 6.1)

7

8

9

5

Dimensions of the connecting flanges

Z1,Z

10

c

2

11

Size

225

250

285

315

350

390

435

225

250

a

[mm]

225

250

285

315

350

390

435

225

250

-

8

8

8

8

10

10

10

-

-

m

MA

z

n

o

[Nm]

-2/ RF/ RGK/ RFZ/ RZ (design with friction flange)

M16 x 55

M18 x60

M20 x70

M22 x75

M22 x80

M24 x100

M27 x120

265

365

515

695

695

890

1310

-2/ RF/ RGK/ RFZ/ RZ design with split sleeves)

4

4

M12 x 60

M14 x 70

21 x 28

25 x 32

p

13

15

MA

[Nm]

80

1

28

b±0.1

[mm]

196

218

245

280

310

345

385

196

218

f

a-0.3

[mm]

171

190

214

247

277

308

342

171

190

fg

[mm]

159

176

199

231

261

290

320

159

176

g

[mm]

15

18

20

22

25

32

40

15

18

t

[mm]

4

-0.2

5

-0.2

6

-0.5

6

-0.5

7

-0.5

7

-0.5

8

-0.5

4

-0.2

5

-0.2

v

[mm]

25

24

30

31

30

36

40

15

24

X P9

[mm]

+0.5

Y

a

[mm]

Z1,Z

[mm]

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

0.06

2

c

[mm]

140

140

175

175

220

250

280

140

140

39

285

315

350

390

435

285

315

350

390

435

M16 x 75

4

M16 x 80

4

M18 x 90

4

M18 x 110

4

M20 x 110

4

28 x 36

30 x 40

32 x 45

32 x 60

35 x 60

17

17

19

19

21

195

195

270

270

380

245

280

310

345

385

214

247

277

308

342

199

231

261

290

320

20

22

25

32

40

-0.5

-0.5

-0.5

-0.5

-0.5

30

31

30

36

40

6

6

7

7

8

0.06

0.06

0.06

0.06

0.06

175

175

220

250

280

Installation

40

High

Instruction manual (Translation)

[mm]

Z

Z

[mm]

Y

X P9

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

c

A ( Fig. 6.1)

B ( Fig. 6.1)

Dimensions of the connecting flanges

1,Z2

Installation

lumn

a

3

2

1

-

-

-

-

4

m

5

MA

6

z

7

n

8

o

Size

Types: RT/ RTL/ RTK 1-2/ RF/ RGK/ RFZ/ RZ (design with cross-key)

265

365

515

695

695

890

225

250

285

Tab. 6.2: Dimensions of the connecting flange and bolted connections

315

350

390

440

480

550

225

250

285

315

350

390

435

480

550

8

8

8

10

10

10

10

10

10

M16 x 65

M18 x 75

M20 x 80

M22 x 95

Types: RT/ RTL/ RTK 1-2/ RF/ RGK/ RFZ/ RZ (design with Hirth serration)

208

250

225

250

4

4

M16 x 65

M18 x 75

270

372

9

p

5

MA

[mm]

196

218

245

280

310

345

385

425

492

196

218

f

a-0.3

171

190

214

247

277

308

342

377

444

171

190

1,Z2

11

c

105

105

125

130

155

170

190

205

250

180

200

J.M. Voith SE & Co. KG/VTA | Instruction Manual

10

+0.5

a

[

mm]

9.5

13

15.5

15.5

16.5

18.5

20.5

23

23

0.06

0.06

0.06

0.06

0.06

0.06

0.1

0.1

0.1

18

20

32

40

40

40

50

70

80

90

100

v

g

fg

159

176

199

231

261

290

320

350

420

159

175

20

25

27

32

35

40

42

47

50

20

25

t

-0.2

-0.2

-0.5

-0.5

-0.5

-0.5

-0.5

-0.5

-0.5

25

25

26

31

30

40

38

46

40

4

5

6

7

7

7

9

25

25

-performance universal joint shaft

285

315

350

390

440

480

550

285

315

350

390

435

480

550

G853 en 07/2013, Version1

4

4

6

6

6

8

8

M20 x 80

M22 x 95

526

710

710

906

225

199

245

280

310

345

385

425

492

214

247

277

308

342

377

444

230

261

290

322

350

420

27

32

35

40

42

47

50

26

31

30

40

36

36

40

21

23

24

25

28

31

32

250

280

315

345

370

440

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Checking bolts

Checking threads

Checking washers

Checking tightened parts

Check

ing stud screws

6.1.2 Checking bolted connections and tightened parts

Ensure that bearing surfaces and threads of the bolts are in

perfect condition, that is,

− edges are burr-free

− no impact points (plastically deformed) present

− surface black anhealed, oiled, yet free from scale

For completely-rolled threads: do not re-cut thread for

asons of endurance strength.

re

Check threads of the bolts and nuts for accumulations or

soiling, e.g. rust, paint or hardened oil.

In case of accumulations or soiling: clean bolts and nuts and

lightly oiled with thin machine oil (12–38 mm2/s at 50 °C, ISO

VG 15 to ISO VG 46).

Installation

If you are using washers:

Make sure that the hardness of the washers is appropriate for

the property class of the bolts, e.g. washers HV 300

according to ISO 7089.

Ensure that the bearing surfaces are in good condition, that

is,

− edges burr-free

− no impact points present

Ensure that part joints and bearing surfaces of the bolts and

ts are even, at right angles, parallel, burr-free and that nuts

nu

are mounted so that the designation is visible and in case of

self-locking nuts, not visible.

Fig. 6.2: Dimensions of a stud screw

G853 en 07/2013, Version1

-performance universal joint shaft

To order stud screws, the measurement d and the

measurement l must be measured and specified with the

order.

41

Installation

High

Instruction manual (Translation)

6.2 Installing the universal joint shaft

The following instructions describe the installation of a universal

joint shaft with standard flange.

Heed additional regulations:

− for Hirth serration ( Chapter 6.3, page 49)

− for use in paper machines ( Chapter 6.4, page 50)

Only install universal joint shaft in areas not subject to explosion

(atmosphere).

DANGER

For specially-designed universal joint shafts, improper

installation and removal can cause severe injuries or even

death.

J.M. Voith SE & Co. KG/VTA | Instruction Manual

Heed and if necessary request additional documentation

( Chapter 1.3, page 8).

DANGER

Severe to deadly injuries due to rotating parts!

Secure drive against starting up.

Keep personnel who are not participating away, e.g. using

supervisory personnel, enclosures, fences.

DANGER

Severe to deadly injuries due to swinging or falling universal

joint shaft!

Heed common attachment regulations.

Only lift universal joint shaft at the prescribed attachment

points ( Fig. 4.1, page 32).

Do not attach universal joint shaft in marked area

( Fig. 4.1, page 32).

Only use sufficiently dimensioned and tested lifting appliance.

Secure danger zone under the universal joint shaft against

entry.

G853 en 07/2013, Version1

Wear safety helmet, safety shoes, gloves, safety glasses, and

fall protection.

-performance universal joint shaft

42

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

DANGER

In case of telescopic lengths: Severe to deadly injuries due to

falling parts!

Secure telescoping part against being pulled apart, e.g. with a

suitable rope.

DANGER

In case of ATEX-certified universal joint shafts: severe to

deadly injuries due to spark formation in case of:

• Equipotential bonding

• Impact-like touching of adjacent metal parts

• Slipping screw drivers

• Hammer blows

Only install universal joint shaft in areas not subject to

explosion (atmosphere).

Installation

DANGER

Severe crushing or crushing of limbs due to tipping universal

joint!

Secure universal joints against tipping, e.g. with a suitable

rope or wedge.

Never reach between the universal joint, even if there is a

deflection guard present.

DANGER

Severe to deadly injuries due to rolling universal joint shaft!

Only set universal joint shaft down on suitable bases.

Secure universal joint shaft against rolling away.

G853 en 07/2013, Version1

-performance universal joint shaft

43

Installation

High

Instruction manual (Translation)

6.2.1 Removing preservation

J.M. Voith SE & Co. KG/VTA | Instruction Manual

DANGER

Cleaning agents can contain acidic materials and additives!

Wear safety glasses and suitable protective gloves.

Heed the manufacturer's safety data sheets.

DANGER

There is a danger of fire due to use/processing of flammable

cleaning/anticorrosion agents!

Ensure sufficient ventilation.

Prevent direct bodily contact and inhalation.

Heed the manufacturer's safety data sheets.

Remove the anticorrosion agent with cleaning agents.

6.2.2 Transport universal joint shaft to the installation location

Fig. 6.3: Universal joint shaft

1 Screw 4 Grease/lubricating nipple N Zero marking, e.g. arrow

2 Connecting flange

(output, input side)

5 For telescopic lengths:

profile guard

Z1 Axial run-out

Z2 Radial run-out

3 Flange yoke 6 Screw plug

G853 en 07/2013, Version1

-performance universal joint shaft

44

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

For universal joint shafts with sliding part

Do not load profile guard (5).

1. Transport universal joint shaft to the installation location

( Chapter 4.3, page 30).

2. Remove transport braces.

3. Seal threaded holes of the transport braces with plugs.

Installation

6.2.3 Cleaning the universal joint shaft and connecting fla

For the cleaning of the universal joint shaft:

− Do not use any aggressive cleaning agents

− Do not clean seal elements and grease/lubricating nipple

with a high-pressure or steam cleaner.

1. Clean universal joint shafts and connecting flanges, that is,

centering and plane surfaces must be free of dirt, grease,

preserving agent, paint, and burrs.

2. Clean grease/lubricating nipples (4).

6.2.4 Checking, aligning, and fastening connecting flange

Do not use pry bars to turn the universal joint shaft in the joint

since otherwise bearing seals and the grease/lubricating

nipple could be damaged.

The universal joint shaft must be arranged so that the key

profile is protected against dirt and humidity. If possible,

installation should be so that the opening of the profile guard

(seal) points downward.

nge

If two or more universal joint shafts are arranged next to one

another, it is recommended that you install them turned by

90° to one another. Thus the mass acceleration torques

caused by the cardan error of the universal joint shaft center

part toward the outside are negated at least somewhat.