Page 1

User Guide

Patented

V3.2, 01.02.2018

Page 2

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 2 / 48

Table of Contents

1 General information .................................................................................................................................... 4

1.1 Guarantee ................................................................................................................................................. 4

1.2 Safety instructions ..................................................................................................................................... 4

1.3 Transport ................................................................................................................................................... 5

1.4 Storage ...................................................................................................................................................... 5

2 Product description .................................................................................................................................... 5

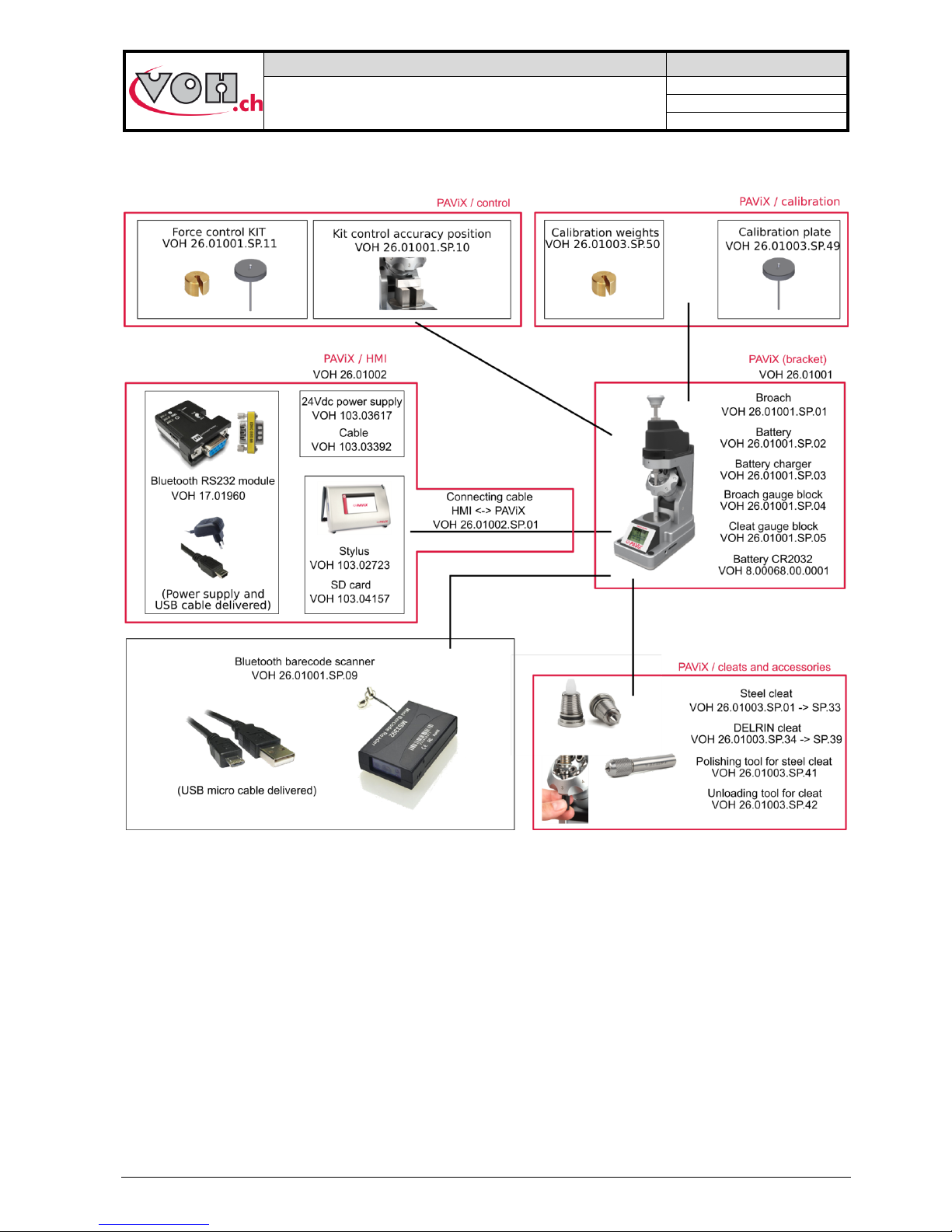

3 Content, accessories and options ............................................................................................................ 6

4 PAViX – HMI ................................................................................................................................................. 7

4.1 Barrel configuration ................................................................................................................................... 7

4.2 Generation and creation of hand-setting programs .................................................................................. 7

4.2.1 Entering family names and programs .................................................................................................. 8

4.2.2 Recording a working reference ............................................................................................................ 8

4.2.3 Editing the program ............................................................................................................................. 8

4.2.4 Edition of hand-setting programs ......................................................................................................... 9

4.2.5 Authorisation to correct hand fitting heights ........................................................................................ 9

4.3 Management of the bar code database .................................................................................................. 10

4.3.1 Bluetooth interface for HMI ................................................................................................................ 10

4.3.2 Bar codes or QR code ....................................................................................................................... 10

4.3.3 Scanner .............................................................................................................................................. 10

4.3.4 Pairing a scanner to the HIM ............................................................................................................. 12

4.3.5 Bar codes <-> program link ............................................................................................................... 13

4.4 Strategic management of traceability ...................................................................................................... 14

4.5 Program import / export .......................................................................................................................... 15

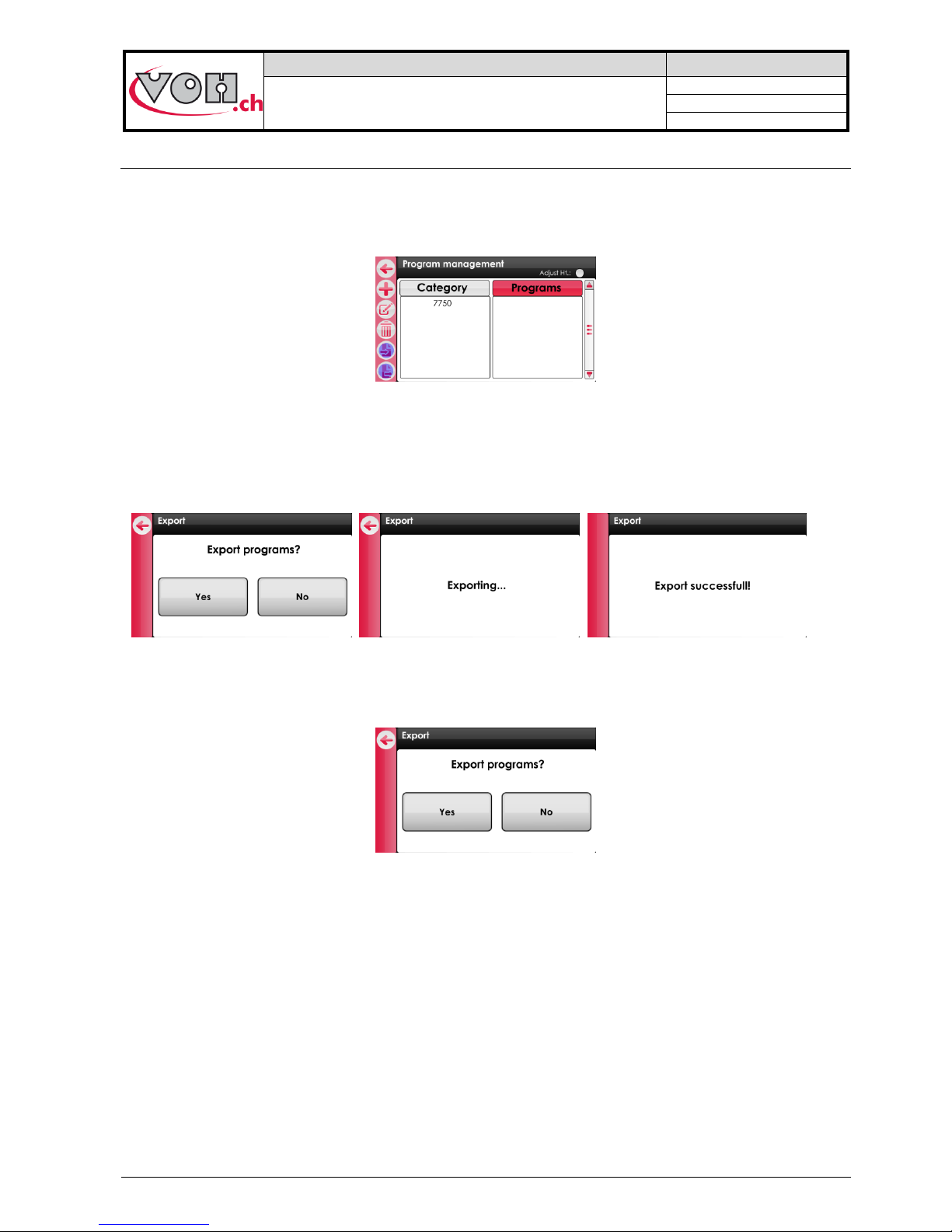

4.5.1 Exporting ............................................................................................................................................ 15

4.5.2 Importing ............................................................................................................................................ 16

4.6 Software update ...................................................................................................................................... 17

5 PAViX - staking-tool.................................................................................................................................. 18

5.1 Cleat loading / changing .......................................................................................................................... 18

5.2 Battery change and recharging ............................................................................................................... 19

5.3 Battery change (CR2032) ....................................................................................................................... 19

5.4 PAViX LCD .............................................................................................................................................. 19

5.5 Start up .................................................................................................................................................... 21

5.6 Configuration of PAViX settings .............................................................................................................. 21

5.6.1 Barrel configuration ............................................................................................................................ 22

5.6.2 Recording cleat references ................................................................................................................ 22

5.6.3 Time/Date .......................................................................................................................................... 23

5.6.4 Spindle reference ............................................................................................................................... 23

5.6.5 User type change ............................................................................................................................... 25

5.6.6 Buzzer ................................................................................................................................................ 25

5.6.7 LED .................................................................................................................................................... 25

5.6.8 Screen contrast .................................................................................................................................. 25

5.6.9 Sleep timer ......................................................................................................................................... 26

5.6.10 Bluetooth ........................................................................................................................................ 26

5.6.11 Use of a bar code reader (Bluetooth scanner) .............................................................................. 26

5.6.12 Information ..................................................................................................................................... 27

5.6.13 Language ....................................................................................................................................... 28

5.6.14 Traceability ..................................................................................................................................... 28

5.7 Program and data management ............................................................................................................. 29

5.7.1 Access to the ADMIN menu ............................................................................................................... 29

Page 3

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 3 / 48

5.7.2 Program updates ............................................................................................................................... 30

5.7.3 Recovery of hand fitting results ......................................................................................................... 30

5.8 Software update ...................................................................................................................................... 32

6 Hand-setting .............................................................................................................................................. 33

6.1 User identification .................................................................................................................................... 33

6.2 Selection of the hand-setting program .................................................................................................... 33

6.2.1 Manual selection ................................................................................................................................ 33

6.2.2 Automatic loading of the bar code program ....................................................................................... 34

6.3 Performing a hand-setting operation ....................................................................................................... 35

6.3.2 Hand-setting....................................................................................................................................... 37

6.3.3 Hand-setting operation results ........................................................................................................... 39

6.3.4 Height corrections .............................................................................................................................. 40

7 Exclusion of liability/guarantee ............................................................................................................... 41

8 Maintenance and service ......................................................................................................................... 41

8.1 Cleaning of the spindle ............................................................................................................................ 41

8.2 Cleaning of spindle smooth bearings ...................................................................................................... 42

8.3 Replacement of the backup battery (CR2032) ........................................................................................ 42

8.4 Sensor inspection .................................................................................................................................... 43

8.4.1 Access to the Maintenance menu ..................................................................................................... 43

8.4.2 Verifying force measurement accuracy ............................................................................................. 44

8.4.3 Force calibration ................................................................................................................................ 46

8.4.4 Distance validation ............................................................................................................................. 47

9 Representation/distribution ..................................................................................................................... 48

Tracked Changes:

Ver.

Date

Drafted

by

Changes

IHM

POT

Valid.

V3.0

10.10.2017

JSA

Pre-validation

V4_00

V4_00

V3.1

24.10.2017

BAP

Publication of V4.0 SW

V4_00

V4_00-

02

RVA

V3.2

01.02.2018

BAP

Traceability: continuous ID

V4_00

V4_00-

03

Page 4

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 4 / 48

1 General information

1.1 Guarantee

VOH SA warrants this product against any defects in manufacturing or in materials under normal conditions of

use and service for a duration of two years from the date of commissioning at the client’s premises. If, at any

time during the guarantee period, the product is found to be defective or fails, VOH SA shall repair or replace it

(at the discretion of VOH SA).

If the product is defective, please call VOH Customer Service on +41(32) 945 17 45.

The warranty shall not apply if VOH SA proves the default or failure is due to improper use of the equipment.

The product is equipped with seals of warranty. Breaking or severing these seals leads to cancellation of the

warranty.

Figure 1: Seal of warranty

The scope of VOH SA’s liability is limited to the repair or the replacement of the product under the terms set out

above.

VOH SA SHALL NOT BE HELD LIABLE FOR ANY LOSS OR DAMAGES, INCLUDING INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING DIRECTLY OR INDIRECTLY FROM A BREACH OF THE

GUARANTEE, EXPRESS OR IMPLIED, OR ANY OTHER FAILURE OF THIS PRODUCT. THIS GUARANTEE

IS THE ONLY EXPRESS GUARANTEE PROVIDED BY VOH SA FOR THIS PRODUCT.

This guarantee only covers the initial buyer and is not transferable.

If you have any questions regarding the guarantee, please write to VOH SA at the following address:

VOH SA

La Praye 5a

CH-2608 Courtelary

Telephone: +41(32) 945 17 45

Fax: +41(32) 945 17 55

e-Mail: customer-service@voh.ch

Internet: http://www.voh.ch

1.2 Safety instructions

Warning

Do not use the PAViX if it is damaged. Before using the PAViX, inspect its enclosure, the condition of its

battery as well as its electrical connections.

The PAViX must be used according to the manufacturer’s recommendations.

Do not use the PAViX in a dirty environment.

The PAViX should only be used by people who have been trained to use the device.

Caution!!!

Please read the information contained in this manual prior to using the equipment. Improper use may

damage the system or lead to incorrect results.

When not using the device for extended periods, remove the battery.

Do not disassemble the device. The manufacturer reserves the right to replace or repair a defective

component.

Use this device at a temperature between 10°C and 40°C (140 °F).

Page 5

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 5 / 48

1.3 Transport

This device is not designed for frequent transport. However, if it is necessary to move the device, take care not

to expose it to shocks that could deteriorate its mechanics. Similarly, in the event of transport over long

distances, use shock-protecting packaging.

1.4 Storage

The PAViX must be stored in a dry and dust-free environment. Storage temperature must be between 10°C and

40°C. It is recommended to cover the device in order to protect it from dust and moisture.

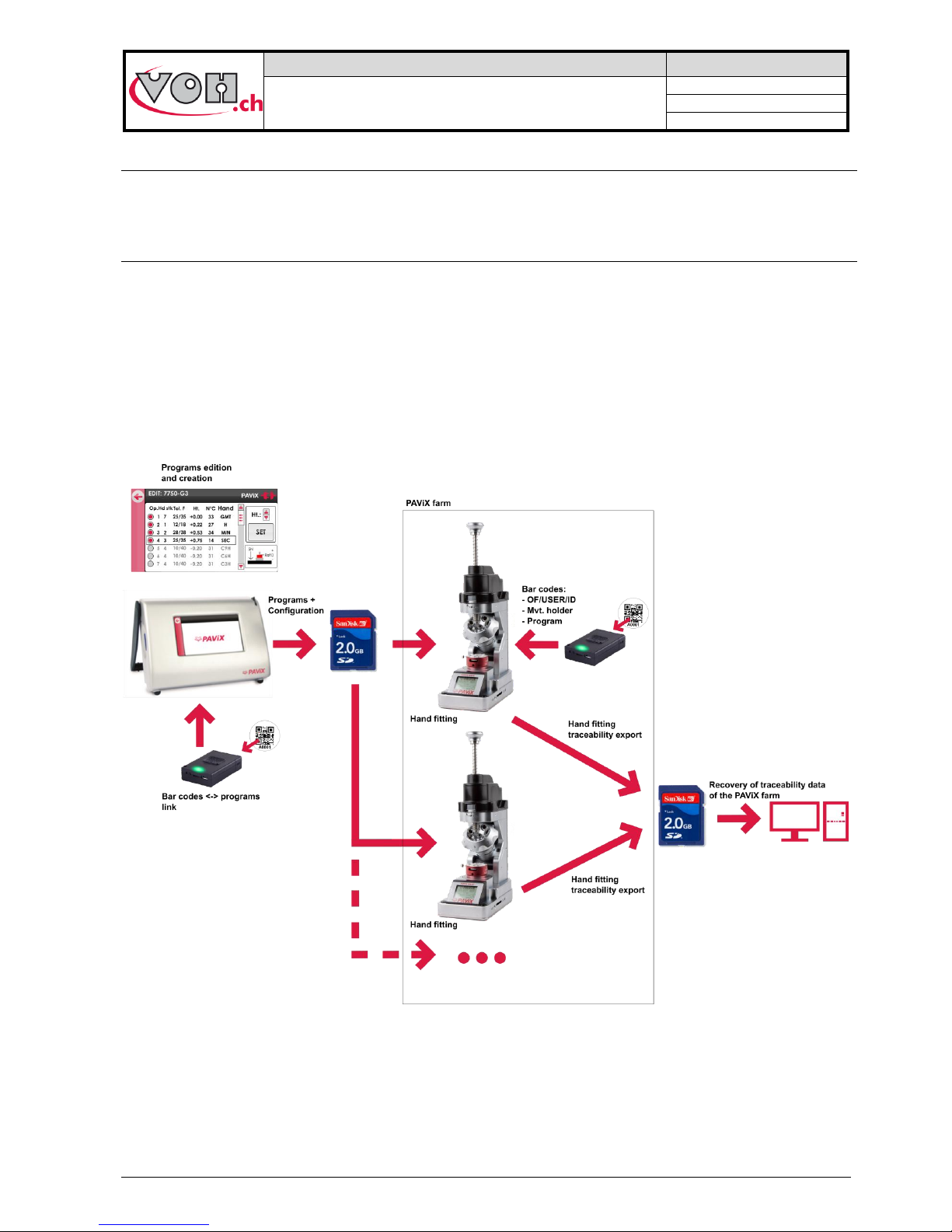

2 Product description

The PAViX is a staking-tool with smart and universal hands. It enhances operator skills while supplying, in a

non-intrusive way, the technical means required for hand-setting operations.

Hand-setting operations are therefore well mastered and traceability of these operations is ensured.

Set out below is the PAViX workflow:

Figure 2: PAViX workflow

Page 6

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 6 / 48

3 Content, accessories and options

Figure 3: PAViX and accessories

Page 7

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 7 / 48

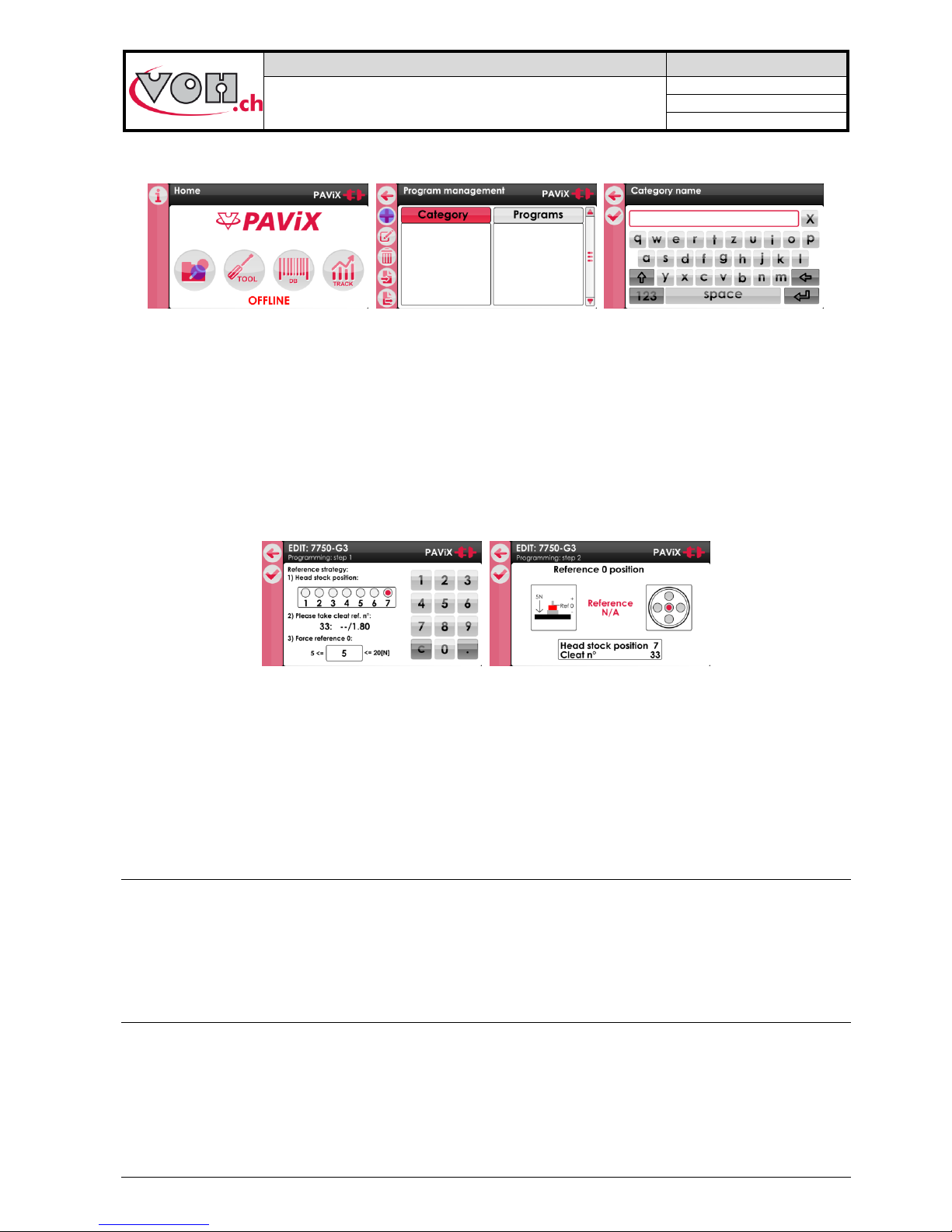

4 PAViX – HMI

The generation, edition and management of PAViX programs is conducted via an HMI. A unique HMI screen

allows for the management of an unlimited number of PAViXs.

Figure 4: HMI and connectors

4.1 Barrel configuration

The programs use a common barrel configuration. It is managed from the PAViX HMI that is then automatically

transferred to the SD card when the programs are exported.

Figure 5: Barrel configuration management

In order to change the numbers of the cleats present on the barrel, simply click on the fields located around

them then link a standard cleat by clicking in the list located on the right-hand side of the screen.

To “remove” a cleat, simply double-click on the corresponding field. The number then becomes ‘---‘ meaning: no

cleat mounted in this position of the barrel.

4.2 Generation and creation of hand-setting programs

Program management and creation is conducted via the PAViX HMI. The transfer of programs on the PAViX

staking-tool is performed with an SD card.

Hand-setting programs are classified by family then by program.

Figure 6: Home screen and program management

In order to create programs, the PAViX may or may not be connected to the HMI using the supplied cable. La

status of the staking-tool <-> HMI connection is displayed on the top right-hand corner of the screen.

Figure 7: Unconnected staking-tool / Connected staking-tool

Page 8

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 8 / 48

4.2.1 Entering family names and programs

On the home screen, select the navigation icon then press the "+" icon in the left column.

Figure 8: Home screen with navigation icon / Home screen with “+” icon / Creating a calibre

4.2.2 Recording a working reference

It is required, for each created program, to define a height reference for the part-holder movement assembly.

This reference is done using a defined cleat.

The user defines a point on the part-holder that will be used for the reference as well as the height. It is

recommended to set this reference on the hour hand’s hour-wheel or on the minute-wheel.

The user selects the tool position. The cleat number is automatically populated, on the basis of the information

entered in the barrel configuration.

In order to compensate a potential flexion in the movement, the strength of reference “0” can be set to 5 - 20 N.

Figure 9: Selecting the parameters to record the working-program reference

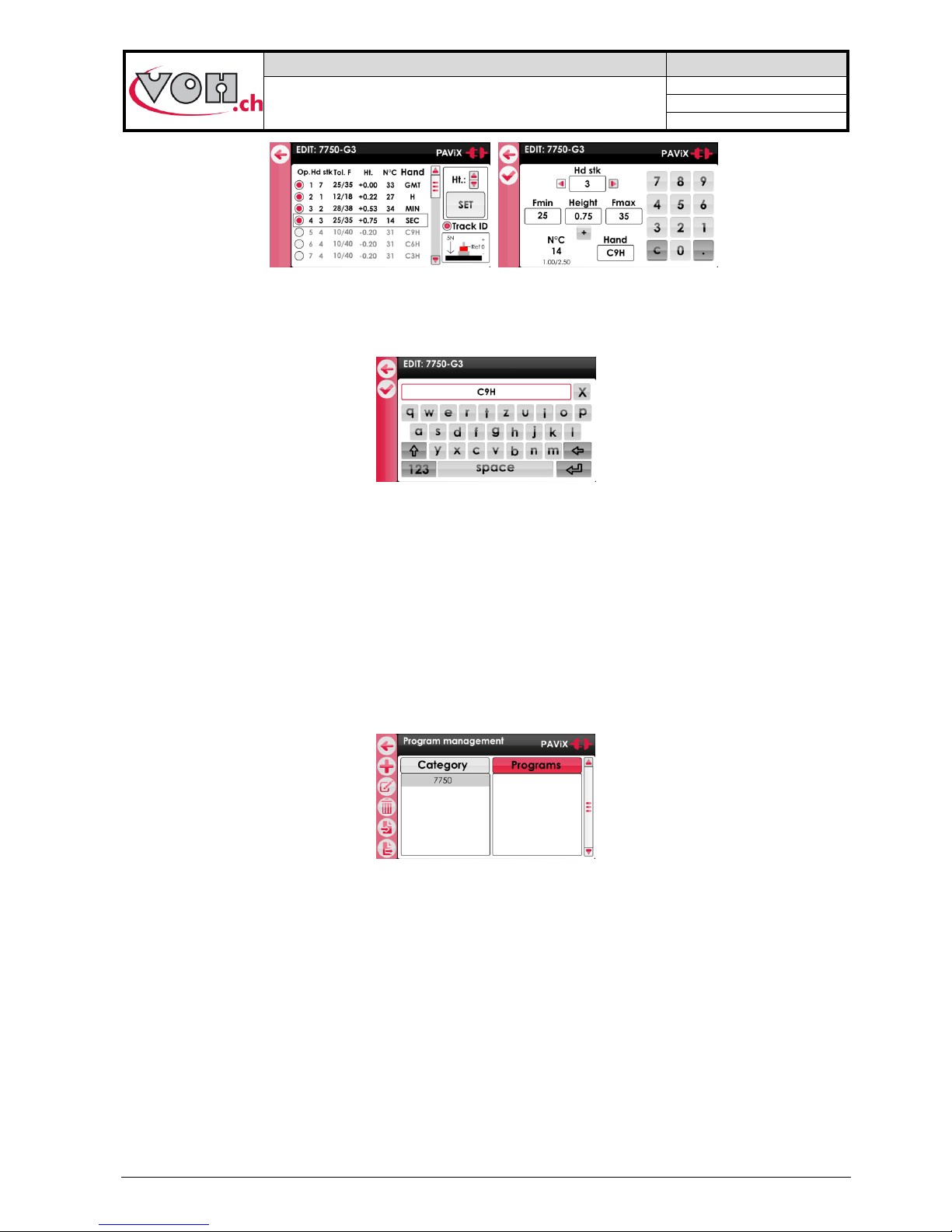

4.2.3 Editing the program

Once the working reference is recorded, the user can enable the stages of the sequence required to set the

hands. A program allows for the setting of up to 14 different hands. Each stage has the following settings:

- Tolerance of min and max force (mandatory)

- Stop height (mandatory)

- Barrel position (mandatory)

- Type of hands set (optional)

4.2.3.1 Programming by learning (ONLINE mode)

Height teaching is carried out with the wheel stop. The height is displayed in real-time and saved using the

“SET” button. To change force, cleat no. and hand type settings, simply select the field concerned.

NOTE: To adjust the height, the position of the barrel on the staking-tool must match that of the selected

operation. If the position of the barrel does not match that of the selected operation, the height is displayed in

red and cannot be changed.

4.2.3.2 Programming by theoretical values (OFFLINE mode)

Height values are determined on the basis of a plan and are manually entered on the hand’s detail page.

Note: All height values can be changed OFFLINE by 0.01mm increments and saved.

Page 9

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 9 / 48

Figure 10: Editing the program

To enter the hand type, simply click on the corresponding field to access the page below. A hand name can

have a maximum of 4 characters.

Figure 11: Entering a hand name

4.2.4 Edition of hand-setting programs

Once the programs are developed, simply double click on a program to start its edition. The edition process can

be performed with or without a connected staking-tool.

4.2.5 Authorisation to correct hand fitting heights

Once the programs are created on the HMI, it is generally no longer necessary to correct hand fitting heights

when using the staking-tool.

However, it is possible for the operator to authorise a temporary height correction: simply activate the “Ht

correction” radio button on the Family/Program page:

Figure 12: Height correction

Use of the option to correct heights when carrying out hand fitting operations is detailed here: spindle (refer to: §

5.6.4 Spindle reference, page 23).

Page 10

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 10 / 48

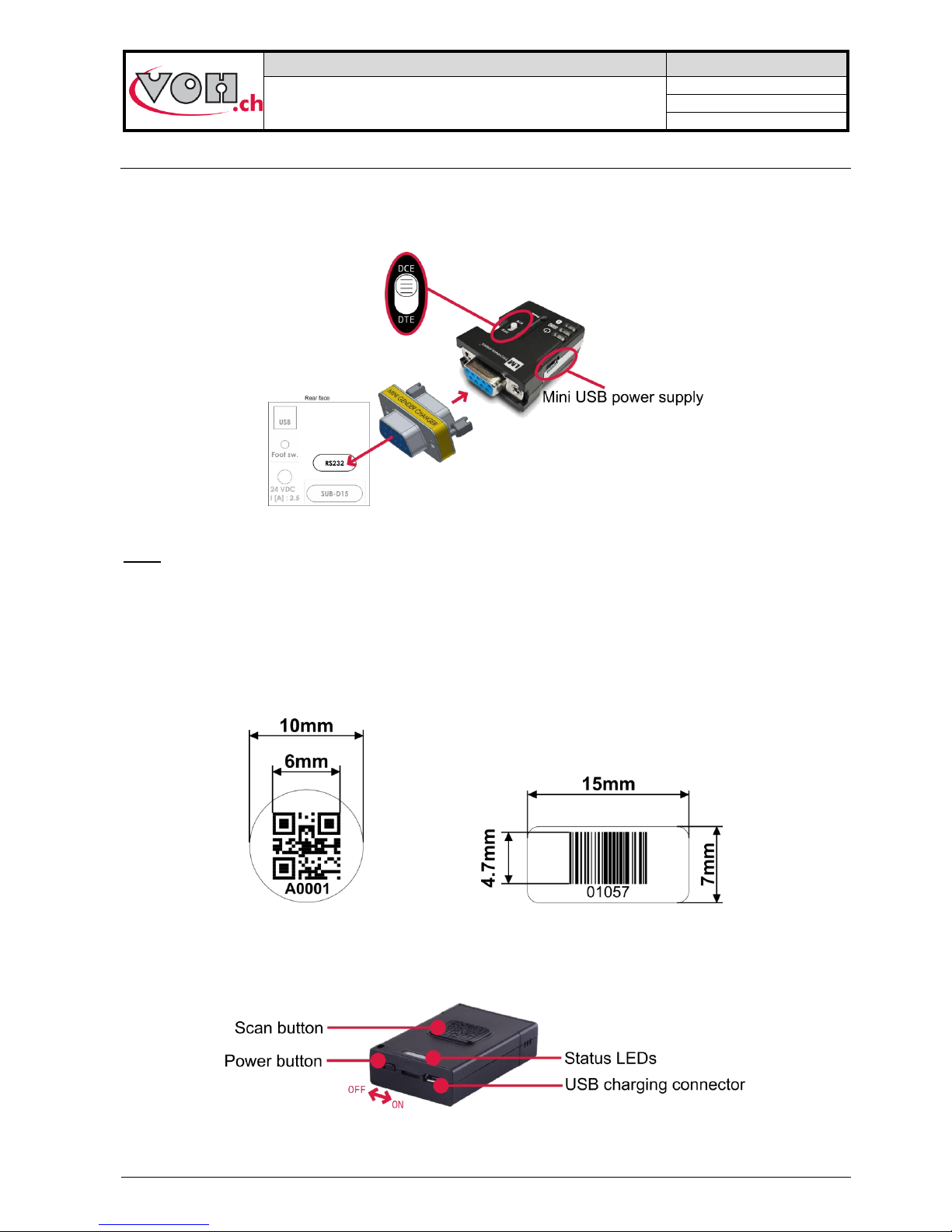

4.3 Management of the bar code database

4.3.1 Bluetooth interface for HMI

This optional interface allows direct communication between the scanner and the HMI. We recommend using a

dedicated scanner (to use with the HMI) in order to facilitate the work (VOH Scanner 26.01001.SP.09)

Figure 13: Adapter assembly

Note:

- In order to work, the Bluetooth interface for HMI must be powered with the supplied USB power supply.

- The small white button on the “LM” module must be placed on the “DCE” side

4.3.2 Bar codes or QR code

Below can be found the minimum dimensions in order for the QR codes (ISO 18004) and bar codes (Code 128)

to be readable by the PAViX Scanner:

Figure 14: Bar code and QR code dimensions

4.3.3 Scanner

The 1D/2D VOH (VOH 26.01001.SP.09) scanner is capable of scanning simple bar codes and QR codes.

Figure 15: VOH Scanner

Page 11

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 11 / 48

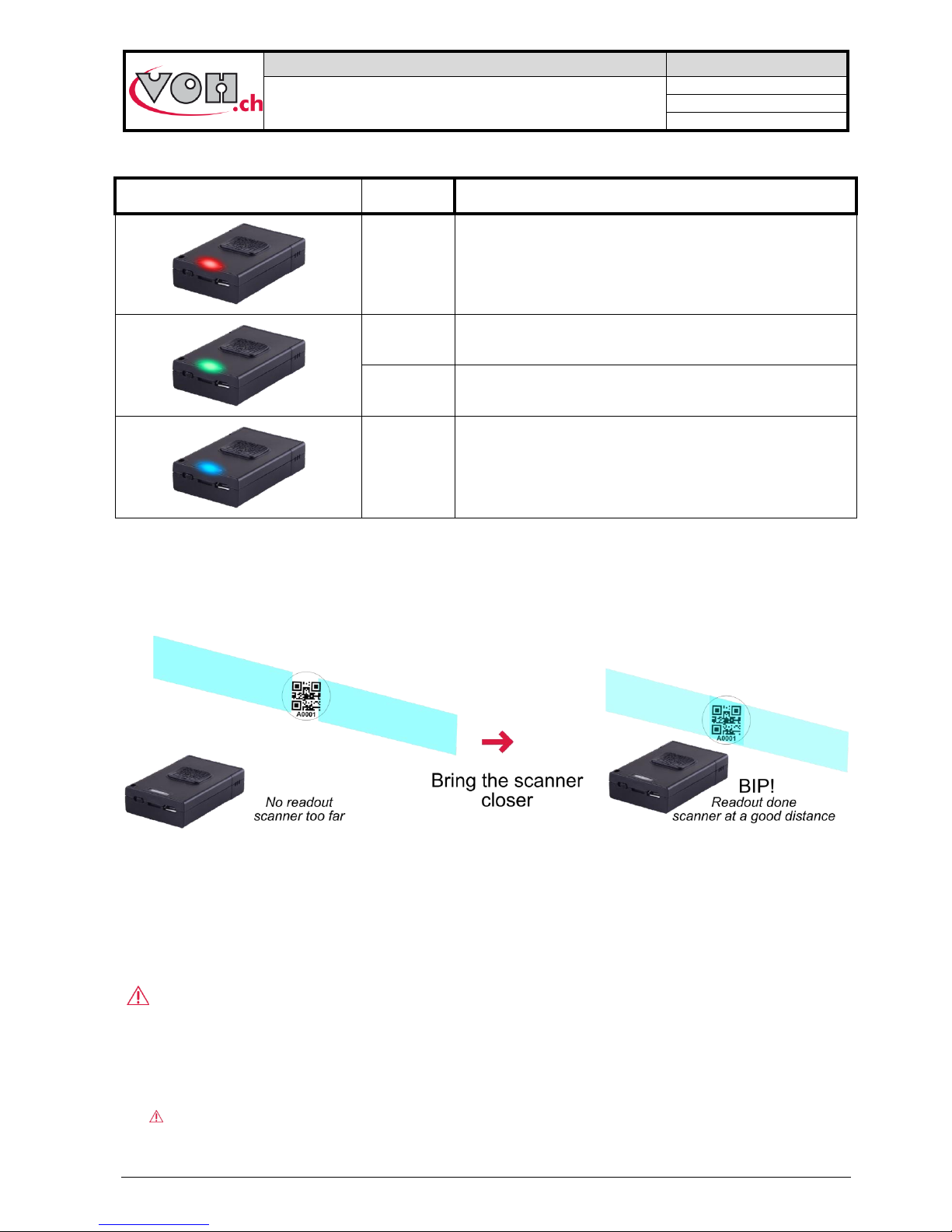

Scanner statuses:

Status LED

Status

Comment

Continuous

Charging (button on the ON or OFF position)

Short flash

Press scan button

Long flash

Scan successful

Flashing

Not connected, discoverable

Scanning area:

When pressing the “Scan button”, the scanner projects 2 blue strips.

Figure 16: scan and blue strips

By varying the distance between the scanner and the target, it becomes possible to make both strips overlap in

the centre: in order to read the code, it must be located at the intersection of the 2 strips!

When reading is successful, a “bip” from the scanner can be heard.

To facilitate the scan, start close to the bar code and gently move away until a long “bip” can be heard.

Battery life:

2 hours charging time.

2 days of operation (1 scan per minute) without having been set to “OFF” at night.

Charging the scanner every night is recommended.

Page 12

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 12 / 48

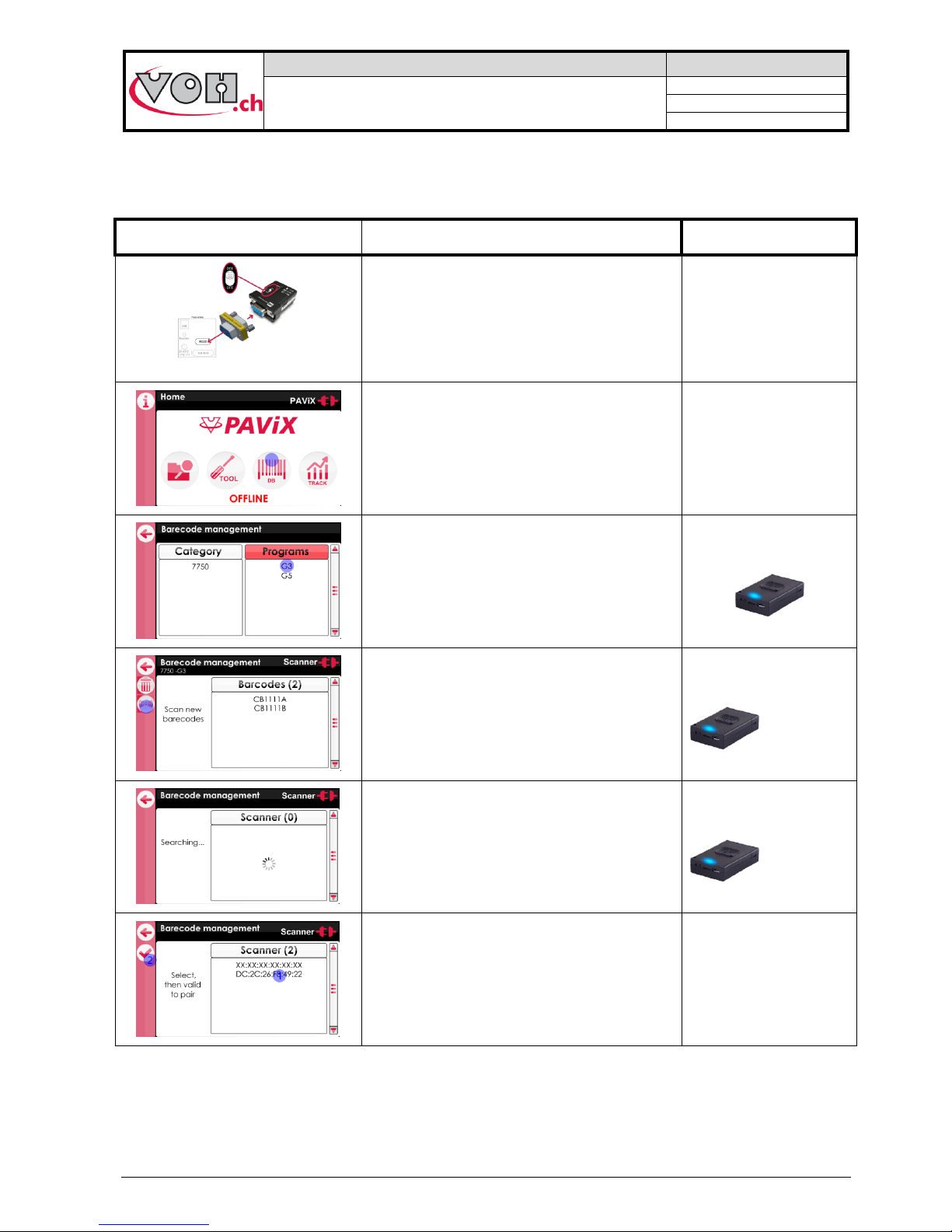

4.3.4 Pairing a scanner to the HIM

Like any other Bluetooth device, the scanner must be paired before use.

PAViX HMI screen

Comment(s)

Scanner + USB power supply

Check for the presence of the Bluetooth

adapter at the back of the PAViX HMI

Power it with the supplied USB power supply

OFF

Click on the “DB” button to access the

bar codes <-> programs linking pages

OFF

Select any program.

The number of bar codes already linked to the

various programs is specified in brackets.

ON

Blue LED flashes

By clicking on the left-hand side button, the

HMI will start searching for a Bluetooth

scanner

ON

Blue LED flashes

The search may take up to 30 seconds.

ON

Blue LED flashes

The list of detected scanners appears.

The selected MAC address (1) must match the

address engraved at the back of the scanner.

Validate the selection (2).

Page 13

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 13 / 48

Pairing then proceeds without user action.

Once pairing is

successful, the

scanner’s blue LED

turns off: it is ready to

be used.

The scanner’s connection indicator, on the top

right-hand corner of the screen, then becomes

green.

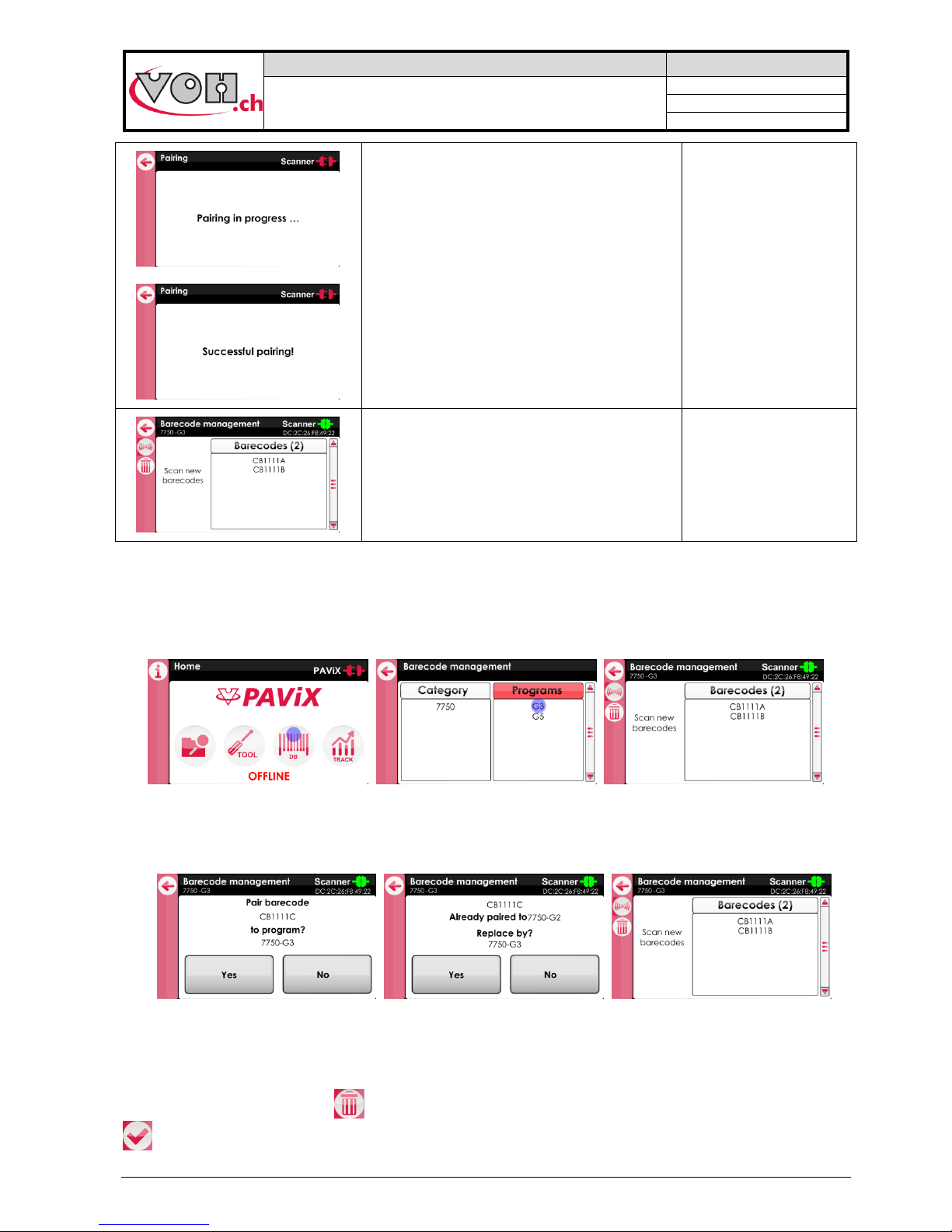

4.3.5 Bar codes <-> program link

The PAViX automatically calls the programs when scanning bar codes. Several bar codes may be assigned to

the same program (family + program). Management is conducted via the HMI. Press the “DB” button to access

then select the desired program.

Figure 17: Accessing the bar code management section

If it isn’t the case, connect the staking-tool or the scanner’s interface module to the HMI and then scan the bar

code to be assigned to the selected program.

Figure 18: Scanning a bar code

Note: Linking the same bar code to several programs is not possible. A bar code may not contain more than 20

characters, including spaces.

To delete a bar code, press the “ ” after selecting the bar code to delete. Confirm selection by pressing the “

” key.

Page 14

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 14 / 48

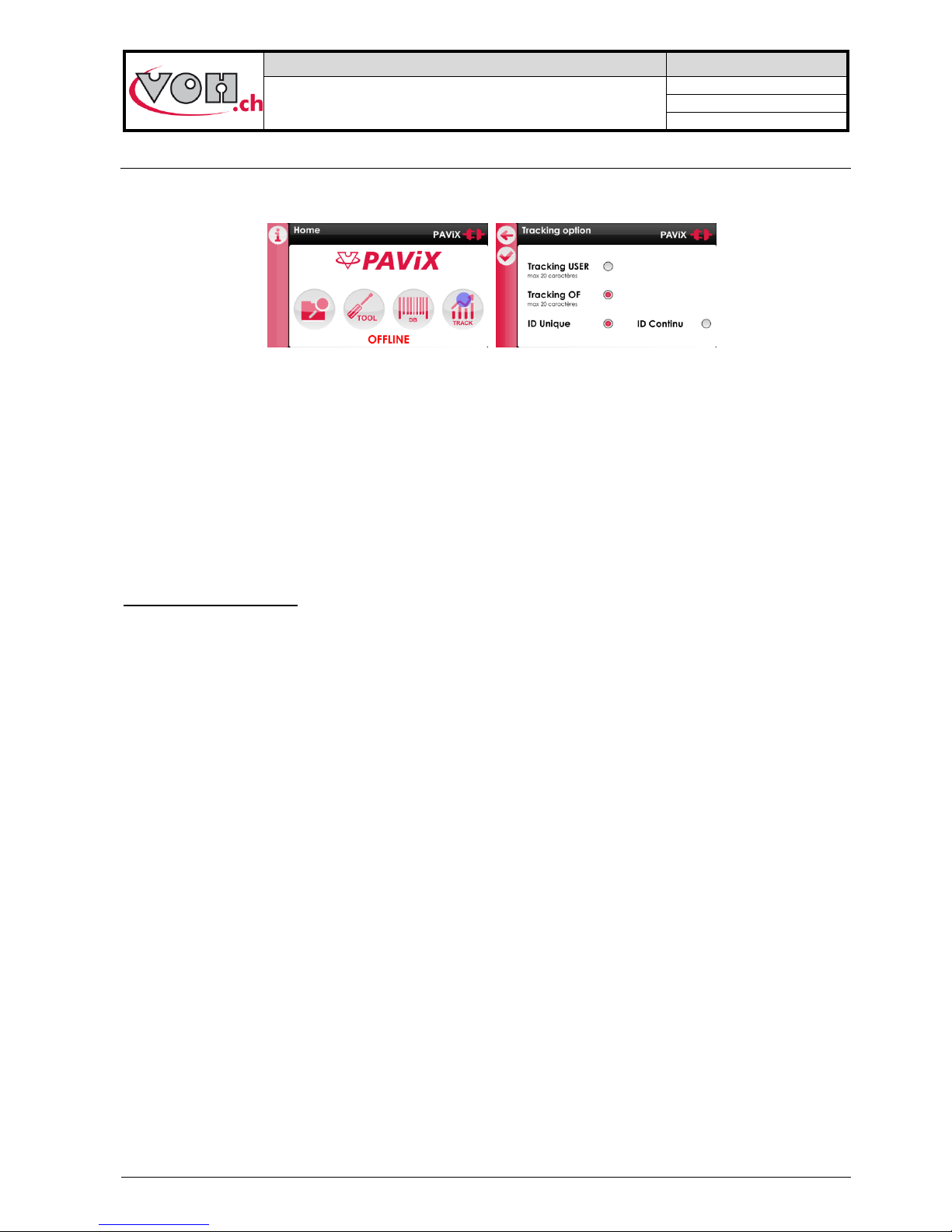

4.4 Strategic management of traceability

The PAViX offers full operation traceability. General traceability options can be configured from the home page

of the PAViX HMI. Press the “TRACK” button to access.

Figure 19: Access to traceability options management

Traceability is based on a bar code or QR code system.

User traceability (USER) is guaranteed for a maximum of 20 characters, its activation being specific to the

staking-tool.

MO traceability is guaranteed for numbers containing up to 20 characters, its activation being specific to the

staking-tool.

Traceability by movement serial numbers is guaranteed for numbers containing up to 10 characters. Activation

of serial number traceability is done in the programs via the “TRACK ID” radio button on the program’s main

page.

Unique or continuous ID:

If « TRACK ID » is activated in the program, it is possible to set a continuous or unique traceability :

- Unique : the ID is requested on each movement (for example: useful for movement traceability)

- Continuous : the ID is kept in memory until a new one is scanned (for example: useful for needle

supplier traceability)

-

These settings are automatically transferred to PAViX staking-tools when updating the hand-setting programs.

Note: These options may be temporarily changed in the staking-tool’s “Traceability” menu.

Page 15

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 15 / 48

4.5 Program import / export

When programs are updated/developed, they may be transferred on a SD card using the SD reader located on

the left-hand side of the HMI.

Similarly, programs contained on the SD card may be transferred to an HMI. This operation is carried out using

the Import/Export buttons located in the left column in the program management page.

Figure 20: Import and export commands in the navigation pane

4.5.1 Exporting

After having pressed the “Export” button on the “Program Management” page, confirmation of export is

requested.

Figure 21: Exporting

Exporting program-related bar codes is optional.

Figure 22: Export, question

NOTE (1): barrel configuration is always exported to the external SD card.

NOTE (2): non-initialised programs (listed in red on the “Program Management” page) are not exported.

NOTE (3): any program potentially present of the SD card is deleted. The HIM programs are then exported.

Export ->

Import ->

Page 16

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 16 / 48

4.5.2 Importing

Below, the program import procedure from the external SD card.

The families and programs that do not exist in the HIM are created.

Figure 23: Importing

If a program already exists in the HMI, the operator is required to reply to the question below:

Figure 24: Import, question

By clicking on “Yes”, the program present on the SD card replaces the one present on the HMI. The operator

can specify whether he wishes to perform the action (“Yes” or “No”) for all future cases which may arise.

NOTE: When importing, the barrel configuration is always imported from the external SD card.

The SD cards used must be formatted to FAT32, allocation unit size 1024 for full formatting.

Page 17

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 17 / 48

4.6 Software update

If a software update is available, the administrator will receive an e-mail from VOH SA containing a ZIP file

called “PAViX_HMI_vx_xx”. In order to update the HMI, open the ZIP file containing a folder called “BL”. Move

this folder to an empty SD card then insert this SD card to the HMI (turned off). The update starts when the HMI

is turned on.

Figure 25: HMI software update

Caution: Do turn off or remove the SD card during the update!

Once the update complete, the HMI automatically displays the home screen.

Caution: After the update is successfully completed, restart the HMI.

Various error screens may be displayed:

PAViX screen

Comment(s)

The HMI is not programmed, please insert a

SD card with the corresponding BL folder.

The SD card was removed during the

programming process. Replace the card in its

holder.

The program contained on the SD card is not

valid. Copy the appropriate program to the SD

card.

NOTE (1): If the SD card contains the same version as the one already present on the HMI, no message shall

be displayed and the HMI will start normally.

Page 18

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 18 / 48

5 PAViX - staking-tool

The PAViX is equipped with all the technology required to master the setting of hands. It has an adjustable stop

driven by a motor, a force sensor and a cleat selection system.

Figure 26: PAViX

5.1 Cleat loading / changing

The PAViX is equipped with a barrel that can accommodate up to 7 cleats.

Figure 27: Cleat properly positioned in the barrel, position no. 1 / cleat

NOTE: Be careful not to soil the end of the cleats when handling them so as to avoid transferring dirt to set

hands.

Page 19

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 19 / 48

5.2 Battery change and recharging

The PAViX is powered by a battery accessible from the back of the staking-tool. It may be removed using the

opening located under the device.

Batteries are charged in a dedicated charger.

Figure 28: Battery and charger / Changing the battery

5.3 Battery change (CR2032)

The PAViX is equipped with a sensor that measures the height of the stop. This sensor is powered by a

CR2032 battery located at the back of the staking-tool. To change this battery, simply remove its holder by

unscrewing both its retainer screws.

Figure 29: CR2032 battery holder

NOTE: After having replaced the battery, recording the spindle reference again is required, as per the procedure

set out in § 5.6.4 Spindle reference, page 23.

Note: The lifespan of a CR2032 battery is of approximately 1 year.

5.4 PAViX LCD

The PAViX is equipped with a LCD screen where information relating to ongoing operations is displayed. The

screen’s different sections are used as follows:

Figure 30: PAViX LCD information sections

Page 20

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 20 / 48

There are two types of buttons for the left and right sections: simple or double buttons. The bar located under

the button’s icon means the length of pressure required to perform the function: a short impulse for the short

bar, a 1.5 second pressure for the long bar:

Figure 31: Simple button (right) and double button (left). To enable the “PAViX settings” function, press and hold down the button

The following buttons and icons are used on the PAViX display

Buttons

Description

Validation

Back to the previous page

ON / OFF

“Guest” identification

“Expert” identification

Manual program selection

Height change

Back to the previous

operation

Exit the program

Back

Edition of part-holder

reference

Icons

Description

Barrel selection

PAViX settings

Height

Height difference

Bluetooth

Battery

Program updates

Traceability DATA export

PAViX memory eraser

SD card

Current operation

Memory usage (here ¼

still available)

Page 21

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 21 / 48

5.5 Start up

Before starting the PAViX, ensure a properly charged battery is in place in the holder located at the rear of the

staking-tool.

To start the PAViX, simply press and hold the button located on the right-hand side of the LCD screen.

Figure 32: Starting the PAViX - press and hold the right-hand side button

5.6 Configuration of PAViX settings

PAViX basic settings are accessible through the “settings” icon during startup of the staking-tool.

Figure 33: PAViX - “settings” icon to the left

Navigation in the “settings” menu is done with the barrel.

Figure 34: PAViX configuration menus

The icon located at the bottom centre of the screen represents the barrel function.

Page 22

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 22 / 48

5.6.1 Barrel configuration

The system uses a barrel configuration common to all programs. This configuration can be displayed from the

barrel configuration menu. Furthermore, when this menu is displayed, the PAViX motorised stop places itself in

the upper position so as to facilitate the loading/unloading of cleats.

Figure 35: Barrel configuration

5.6.2 Recording cleat references

The height of the cleats present in the barrel may vary (replacement or polishing of a cleat). It is therefore

necessary to save these heights by teaching.

NOTE: Cleat references cannot be recorded before the spindle reference (refer to § 5.6.4 Spindle reference,

page 23).

PAViX screen

Comment(s)

PAViX

Teaching of cleat heights is done from the cleat

references menu

Select the barrel position for which a cleat reference is

required.

Once selection is made, the staking-tool will move the

stop to the low position.

Place the standard cleat (PAViX ET) on the plate.

Height reference is taken using a given force, which is

why the staking-tool tares the force before height

reference is performed (please do not touch the tray

during this phase).

Press the spindle down so the cleat comes into contact

with the movement and the light turns green (meaning the

force has been reached). When it is green for >2s, the

PAViX records the reference.

Page 23

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 23 / 48

The user must hold the spindle in position while the

reference is being recorded.

NOTE: If the force becomes too great or too weak when

the reference is being recorded, the process is

interrupted.

Once the reference is recorded, the user can release the

spindle. A check mark appears under the barrel position

for which reference was taken.

Repeat the above operations for each cleat.

If one barrel position is not used, the display will indicate it

as void.

It is crucial to perform the operation on all active positions

5.6.3 Time/Date

The PAViX offers extended traceability options. For these to be relevant, it is required to set the time on the

PAViX clock. This setting is done from the “Time/Date” menu. The selected field is underlined. To change its

value, use the barrel and validate with the right-hand side button.

Figure 36: Setting the time and date

5.6.4 Spindle reference

The PAViX is equipped with an absolute height measuring system. This system is powered by a CR2032

battery located at the back of the staking-tool. When the battery voltage drops below the operational threshold,

the PAViX notifies the user for him/her to replace it.

Figure 37: Low battery warning and battery housing for the height measuring function (CR2032)

Page 24

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 24 / 48

Once the battery has been replaced, the PAViX requires a height reference record. This height reference must

be carried out with the standard spindle. The procedure to apply is as follows.

PAViX screen

Comment(s)

PAViX

After the CR2032 battery has been replaced, the PAViX

cannot be used until the height reference has been

recorded

Remove a cleat or place an empty barrel slot under the

spindle. Place the standard spindle on the plate (PAViX

EB)

Manually lower the stop using the wheel and validate

when this operation is complete

Press the spindle down so the cleat comes into contact

with the movement and the light turns green (meaning the

force has been reached). When it is green for >2s, the

PAViX records the reference.

The user must hold the spindle in position while the

reference is being recorded.

NOTE: If the force becomes too great or too weak when

the reference is being recorded, the process is

interrupted.

Reference recorded.

Page 25

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 25 / 48

5.6.5 User type change

The PAViX manages two types of users: Operator and Locked.

In Operator mode, the user can correct hand fitting heights. In Locked mode, this operation is not possible.

Figure 38: User mode selection

“Operator” mode is the same as the checked “Ht correction” radio button in the HIM (refer to § 4.2.5

Authorisation to correct hand fitting heights, page 14). A change of user type in the staking-tool overwrites the

setting selected when creating the programs in the HMI.

5.6.6 Buzzer

The PAViX provides a sound signal option during operations. These signals are configured from the “Buzzer”

menu.

Figure 39: Sound signals on force(a) / on stop(b)

Depending on the selected settings, a sound is released:

- When the min force is reached and when the maximum force is exceeded

- When the maximum force is exceeded

- When the stop is reached

5.6.7 LED

The PAViX also provides the option to indicate the hand fitting status in three different colours: orange if the

force is below tolerance, green if the force is within the tolerance range and red if the maximum force is

exceeded.

The intensity of these light signals can be configured from the “LED” menu. It is possible to configure the

intensity or disable the signal with the barrel.

Figure 40: Light intensity adjustment

5.6.8 Screen contrast

The PAViX provides the option to adjust the screen’s contrast so as to adapt to various light environments.

Figure 41: Screen contrast adjustment

Page 26

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 26 / 48

5.6.9 Sleep timer

As the PAViX is self-sufficient in energy, a timer enables the Standby mode when the device is not being used.

This timer can be set from the “Sleep timer” menu to: 10 minutes, 30 minutes or Disabled (no automatic

activation of the Standby mode).

Figure 42: Setting the time before standby

5.6.10 Bluetooth

The PAViX is equipped with a Bluetooth function. It can be configured so as to be used in different ways:

- Off

- Used with a scanner

- Used with a PC/tablet.

Figure 43: Bluetooth adjustment options

5.6.11 Use of a bar code reader (Bluetooth scanner)

If the user wishes to use a bar code scanner, he/she must first connect it to the PAViX. This operation can be

done using the “Scanner” menu.

Before starting the staking-tool, ensure the scanner is in Bluetooth® SPP mode. To this end, start the scanner

using the switch located at the back and scan the bar codes below in order (that can also be found on the user

guide supplied with the scanner)

Figure 44: Bar code for SPP mode configuration

Page 27

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 27 / 48

Once the scanner is in SPP mode, it flashes blue for as long as it is not connected to the staking-tool. The

procedure described below can then be performed. Once the scanner is connected and switched on, the

staking-tool automatically detects its presence at less than 1m away.

PAViX screen

Comment(s)

When the “Scanner” menu is selected, the

PAViX performs a search of the scanners in its

range. The scanners are then classified

depending on their distance to the PAViX.

NOTE: If no scanner is detected, an error

message is displayed.

The user then selects the scanner’s

corresponding MAC address he/she wishes to

pair up.

The PAViX then establishes the connection

with the scanner and informs the user on the

outcome of the operation (success or not).

NOTE: The scanner emits a sound when the

connection is established.

The PAViX can only pair with one bar code reader (Item no.: 26.01001.SP.09).

Figure 45: Bluetooth scanner (Item no.: 26.01001.SP.09)

Scanner operation: § 4.3.3 Scanner, page 10.

5.6.12 Information

The Information menu displays all the information relating to the staking-tool:

- Staking-tool SN

- Staking-tool software version

- Force sensor SN

Page 28

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 28 / 48

5.6.13 Language

The PAViX provides the option to select the language from the “Language” menu.

Figure 46: Configuration of the PAViX language

5.6.14 Traceability

The PAViX offers extended traceability options. Traceability rules are configured from the “Traceability” menu.

Traceability can be enabled on the users (USER), manufacturing orders (MO) and continuous ID traceability by

entering the administrator password (1234). Movement serial number traceability is enabled in each program

(via the PAViX HMI)

Figure 47: Traceability summary

NOTE: Traceability settings can also be managed from the PAViX HMI (Refer to § 4.4 Strategic management of

traceability, page 14).

Note: Continuous ID traceability allows the scanned ID to be stored in the memory when moving to the next

movement (Refer to § 6.3.2 Hand-setting, page 37).

If this setting is disabled (OFF), a new ID scan is requested after each movement.

Page 29

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 29 / 48

5.7 Program and data management

The PAViX “ADMIN” menu allows for the following actions:

- Recovery of hand fitting results

- Program updates

5.7.1 Access to the ADMIN menu

The Administrator mode (ADMIN) is used to update programs, export results of hand-setting operations saved

by the staking-tool as well as reset the device’s memory. Resetting the memory erases all hand-setting

programs as well as traceability data contained in the device. Access to the Admin mode is done using the

following password: 1234

PAViX screen

Comment(s)

PAViX

The ADMIN menu is accessible via one of the

configuration pages: press and hold the PAViX left-hand

side button to enter the setting mode.

Then, by rotating the barrel to the left, the ADMIN menu

will appear.

Confirm access with the right-hand side button.

The barrel allows the user to select the number to display,

the right-hand side button is used to confirm the choice.

See below for use of the ADMIN mode.

Page 30

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 30 / 48

5.7.2 Program updates

The programs contain the fitting parameters required for hand setting operations.

In order to use the PAViX, it must contain hand-setting programs that are transferred using a SD card according

to the following procedure:

PAViX screen

Comment(s)

PAViX

To transfer programs, insert the SD card and select .

NOTE: When updating, the information contained on the

SD card has priority

When the user validates the action with the right-hand

side button, the programs contained in the device’s

memory are updated and hand fitting data is automatically

transferred to the SD card.

The PAViX memory can contain up to 1,000 programs. The PAViX memory can be erased using the Trash icon

from the ADMIN menu. When updating the programs, movement holder height references are erased.

The SD cards used must be formatted to FAT32, allocation unit size 1024 for full formatting.

5.7.3 Recovery of hand fitting results

The PAViX is equipped with a system that traces hand-setting operations. The PAViX can store up to 9,000

operations.

We therefore recommend saving the device’s memory on a regular basis. Data export is carried out as follows:

PAViX screen

Comment(s)

PAViX

To retrieve stored data, insert the SD card and select (

).

NOTE: The data stored in the PAViX memory is erased

after the transfer.

Page 31

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 31 / 48

When the user validates the action with the right-hand

side button, the data contained in the device’s memory is

transferred to the SD card.

- The results are exported in a “.csv” format that can be opened in an Excel-type spreadsheet.

- Results are sorted by staking-tool and by program

- If a program is already present, data is added at the end of the file

Below is an overview of a PAViX export opened on a Windows PC:

Figure 48: SD on PC and SD tree structure

Figure 49: Example of a .csv file content exported from the PAViX

Page 32

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 32 / 48

5.8 Software update

If an update is available, the administrator will receive an e-mail from VOH SA containing a ZIP file called

“PAViX_potence_vx_xx”. In order to update the staking-tool, open the ZIP file containing a folder called “BL”.

Move this folder to an empty SD card then insert this SD card to the staking-tool (turned off). The update starts

when the staking-tool is turned on.

Figure 50: Staking-tool software version

Do turn off or remove the SD card during programming!

Once the update complete, the PAViX automatically displays the home screen.

Various error screens may be displayed:

PAViX screen

Comment(s)

PAViX

The staking-tool is not programmed, please

insert a SD card with the corresponding BL

folder

The SD card was removed during the

programming process. Replace the card in its

holder.

The battery is not sufficient to program the

staking-tool. Replace the battery

The program contained on the SD card is not

valid. Copy the appropriate program to the SD

card.

Page 33

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 33 / 48

6 Hand-setting

In order to have all the information required for traceability purposes, the user may be required to scan a certain

number of information before starting hand-setting operations.

6.1 User identification

When starting the PAViX, the user is prompted to identify from the home screen. Identification is carried out with

the bar code scanner.

Figure 51: Home screen without a scanner then in User or Expert mode with a connected scanner

The graph located above the “ON/OFF” icon ( ) represents the memory used by the traceability data. The

graph is divided into 8 sections. Each section therefore equates to 12.5% of the total memory. When traceability

data occupies less than 12.5% of the total memory, the graph is empty ( ). When the staking-tool is used and

the traceability data is stored, the graph gradually fills out. When the memory is full ( ), the oldest data is

replaced by the newest data.

NOTE: Users can identify themselves as guests using the right-hand side button ( / ). In this case, user

traceability will be replaced by “GUEST”.

6.2 Selection of the hand-setting program

Starting a hand-setting program can be done two different ways.

- Manual selection

- Automatic selection by bar code (when the scanner is connected)

6.2.1 Manual selection

When manually selecting the corresponding program, the user uses the barrel and the buttons to perform the

selection.

PAViX screen

Comment(s)

After identifying himself/herself, the user

presses the right-hand side button ( ) to

enable the manual selection of a program.

The family is then selected using the barrel

and validated with the right-hand side button.

The left-hand side button takes you back to the

previous page.

The program is then selected using the same

method.

Page 34

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 34 / 48

6.2.2 Automatic loading of the bar code program

For automatic selection by bar code, the user uses the bar code scanner to select a program.

The link between a bar code and a program is done in the PAViX HMI (Refer to § 4.3 Management of the bar

code database, page 10).

PAViX screen

Comment(s)

After identifying himself/herself, the user scans

a bar code corresponding to the program

he/she wishes to call.

NOTE: The bar code can contain up to 20

characters maximum.

NOTE: If the bar code read by the scanner matches a program, the program is automatically called.

Page 35

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 35 / 48

6.3 Performing a hand-setting operation

When the program is selected (via a scanned bar code or a manual selection from the list of programs), the

system needs to know the movement holder height before starting a hand-setting program.

The system will request taking of this “0” reference each time a program starts or will offer to scan a bar code

present on the movement holder.

6.3.1.1 Taking a reference without an active scanner

PAViX screen

Comment(s)

When the program has started and no scanner

is active, the user is invited to use the 0

reference.

Start by placing the part-holder, then validate

with the button located on the right-hand side

of the staking-tool.

Select the requested barrel position, here no.1.

Confirm selection with the right-hand side

button

The system automatically tares the force once

placement of the movement holder is

validated.

Press the spindle down so the cleat comes into

contact with the movement and the light turns

green (meaning the force has been reached).

When it is green for >2s, the PAViX records

the reference.

Page 36

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 36 / 48

6.3.1.2 Taking movement holder reference with the scanner

Using the bar code reader streamlines taking of reference 0. The PAViX provides the option to store the heights

of the part-holder so as to avoid recording this reference when starting the program. To do this, the part-holders

must have bar codes. Starting a program is then done as follows.

PAViX screen

Comment(s)

Once the program is started, the user is

prompted to:

1) Record the reference in accordance

with standard procedure (Refer to

6.3.1.1, page 35)

2) Scan a part-holder bar code

NOTE: If the bar code is known, the PAViX

places itself directly in Hand-setting mode.

By pressing and holding the left-hand side

button, it is possible to change the height of a

part-holder whose bar code is already known.

Once the button is pressed down, simply follow

the information on the screen.

If the bar code of the scanned part-holder is

not known, the user is prompted to create a

new part-holder. To do this, simply press the

right-hand side button.

The PAViX then guides the user through the

standard reference recording procedure

Once the reference is recorded, simply

validate for the part-holder to be stored and for

the program to start

NOTE: Part-holder bar codes must contain 5 characters (alphanumeric).

Page 37

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 37 / 48

6.3.2 Hand-setting

When selecting a program, if the staking-tool is not connected to a scanner, the user is prompted to record the

working reference in accordance with the procedure presented in Paragraph 4.2.2 , page 35. Once the

reference is recorded, the hand-setting program can start.

Figure 52: Hand-setting screen

Figure 53: Hand-setting screen (barrel position turns black when it matches the one defined in the program)

Figure 54: Hand fitting result screen

When the user selects an active cleat (by turning the barrel), the PAViX automatically adjusts the stop height as

well as the information displayed on the screen. During the adjustment of the height, the luminous surface

flashes blue.

Figure 55: Flashing luminous surface during height adjustment and other automatic operations

The user performs the hand fitting operation by lowering the spindle that, when passing through the barrel,

takes the selected cleat. During the operation, light and sound signals indicate the change in force.

Figure 56: Force change indication during the hand-setting operation

Page 38

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 38 / 48

The operator is guided by the PAViX during the hand-setting operations, as shown in the diagram below.

PAViX screen

Comment(s)

If ID traceability is enabled and a scanner is

connected, the PAViX prompts the operator to

enter a movement identification bar code.

At the start of the program, the PAViX prompts

the operator to select the required barrel

position (position 7)

Once the position is selected, the number 7

goes to a black box and the staking-tool moves

to the appropriate height. The operator can

then place the hand

When the hand fitting operation is complete, its

result is displayed. Of everything is OK, the

result is automatically validated after 3

seconds and the following instruction is

displayed.

In the event of a KO, the operator will need to

validate the operation with the right-hand side

button, then a simple short impulse on the lefthand side button will repeat the operation with

a compliant hand.

The PAViX then prompts the operator to move

to barrel position no.1 in order to mount the

next hand

Once the position is selected, the number 1

goes to a black box and so forth until the end

of the program

After the last hand fitting operation (barrel

position no.3 in the program opposite), the

operator may move to the next movement

(right-hand side button) or start a new MO by

exiting the program (left-hand side button)

Page 39

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 39 / 48

6.3.3 Hand-setting operation results

The PAViX is used to carry out hand-setting operations on an industrial scale. Productivity is critical while

maintaining operation traceability and control.

The result of a hand-setting operation is determined based on the force applied to the hand when the spindle

comes into contact with the stop. The force saved for traceability purposes is the force measured at the moment

the stop comes into contact with the spindle.

Figure 57: Indication of the result (force at stop contact within the tolerance range, without exceeding the max. tolerance)

The following situations may also occur:

Figure 58: KO operation (F > max. tol)

If, during the operation, the max. tolerance is exceeded, the operator is supposed to stop what he/she is doing.

The result of the operation is then KO (F > max. tol and stop not reached). The light signal is fixed red. If the

operator continues to the stop, the result will be considered KO and the force saved for traceability purposes

shall be the maximum force observed during the operation.

Figure 59: KO operation (F < min. tol)

If the force measured when the stop contact is detected is below the min tolerance, the result will be considered

KO. The force saved for traceability purposes is the force measured at the moment the stop comes into contact

with the spindle.

Page 40

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 40 / 48

In order to manage cases very close to the upper limit, the PAViX is equipped with an intelligent system that

takes into account human reaction time (0.1s). If the measured force exceeds the max tolerance by less than

10% in a time interval smaller than 0.1s before stop detection, the operation is considered successful.

Furthermore, as the displacement potentially applied during the 0.1s is low, the movement will not be damaged.

The force saved for traceability purposes is the force measured at the moment the stop comes into contact with

the spindle.

Figure 60: Smart detection, OK operation and details

The results for the setting operation are indicated as soon as the stop is reached or the max force is exceeded.

F < Fmin

Fmin<F<=Fmax

F > Fmax

Stop reached

Stop not reached

N/A

N/A

The results in red must be acknowledged by the operator using the right-hand side button. OK operations are

automatically validated after a period of 1.5 seconds.

6.3.4 Height corrections

If the “Ht correction” option has been enabled in the HMI when creating the programs or when the “Operator”

mode is selected in the staking-tool, it is possible to correct hand fitting heights by pressing and holding the

right-hand side button (as long as the current barrel position matches the current operation):

Figure 61: Hand fitting in “Operator” mode (equivalent of the “Ht correction” option of the HMI)

When the button has been pressed and held down, the following page is displayed:

Figure 62: Height correction page

Simply turn the height setting wheel to perform the correction. The correction is displayed on the screen in mm.

Note: Height correction is available in this program on a temporary basis. It is lost when the user leaves the

program.

Page 41

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 41 / 48

7 Exclusion of liability/guarantee

Damages caused by conditions of use, transport or storage non-compliant with the conditions described in this

manual are not supported by the manufacturer. Changes to the device and opening of the casing are forbidden

and lead to exclusion of liability. Guarantee rights expire when it is proven that the detected faults are not from

origin.

8 Maintenance and service

8.1 Cleaning of the spindle

Frequency: Once a week (depending on use)

Equipment required:

- Light Benzine

- Clean cloth

Stage

Description

1

Remove the spindle

2

Dampen the cloth with light Benzine

3

Clean the entire length of the spindle

4

Let the spindle dry before putting back into

place

Page 42

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 42 / 48

8.2 Cleaning of spindle smooth bearings

Frequency: Once a week (depending on use)

Equipment required:

- Light Benzine

- Cotton buds

Stage

Description

1

Remove the spindle

2

Dampen a cotton bud

3

Clean the upper bearing

4

Clean the lower bearing

5

Let the spindle dry before putting back into

place

8.3 Replacement of the backup battery (CR2032)

Frequency: Once a year (depending on the staking-tool’s signals)

Equipment required:

- CR2032 battery

- Watchmaker's screwdriver - 140

- Spindle height standard

Stage

Description

1

Turn the staking-tool off

2

Remove the main battery

3

Unscrew the two retaining screws of the

CR2032 holder

4

Remove the battery holder

5

Replace the used battery with a new one

6

Insert the battery holder in its housing et

secure using the screws provided for this

purpose

7

Set staking-tool time as described in the user

guider

8

Record a spindle reference as per the user

guide

Page 43

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 43 / 48

8.4 Sensor inspection

8.4.1 Access to the Maintenance menu

The Maintenance mode is used to inspect distance and force sensors.

This is done by a validating the force or distance measurement by using a weight or a gauge block. Access to

the Maintenance mode is done using the following password: 7426

PAViX screen

Comment(s)

PAViX

The Maintenance menu is accessible via one of the

configuration pages: press and hold the PAViX left-hand

side button to enter the Setting mode.

Then, by rotating the barrel twice to the left, the

Maintenance menu will appear.

Confirm access using the right-hand side button.

The barrel allows the user to select the number to display,

the right-hand side button is used to confirm the choice.

The barrel is used to select the validation to perform:

- Distance : “Position[um]”

- Force: “Valid[N]”

Page 44

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 44 / 48

8.4.2 Verifying force measurement accuracy

Verification of force measurement accuracy requires a quiet environment as well as a rigid and stable work

surface.

Equipment required:

- Force measurement accuracy verification kit VOH 26.01001.SP11

- Standard spindle VOH 26.01001.SP04

Fitting procedure

PAViX screen

Comment(s)

PAViX

Remove the spindle and cleat in position under the

spindle.

To facilitate cleat removal, the spindle automatically

moves to a high position during initialisation.

Start by placing the standard spindle (SP.04 “EB”) on

the plate. Confirm with the right-hand side button.

Then place the calibration plate in place of the spindle,

resting on the standard spindle. Validate using the righthand side button

The PAViX automatically tares the force: do not

touch the calibration plate of the PAViX plate.

Page 45

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 45 / 48

Validation procedure:

PAViX screen

Comment(s)

PAViX

…

1) Delicately place the required mass on the plate.

Confirm placement using the right-hand side

button.

2) Once the measurement is stable, confirm using

the right-hand side button.

These 2 operations must be performed with 1, 2 and 5kg

masses.

If the measures are correct, the screen displays “OK”.

Upon the first measure with an out-of-machinetolerance value, the operator is invited to recalibrate

the force.

(Refer to § 8.4.3 Force calibration, page 46)

Page 46

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 46 / 48

8.4.3 Force calibration

Force calibration requires a quiet environment as well as a rigid and stable work surface.

Equipment required:

- Calibration plate VOH 26.01003.SP49

- Set of standard weights for calibration VOH 26.01003.SP50

- Standard spindle VOH 26.01001.SP04

Validation procedure:

PAViX screen

Comment(s)

PAViX

If force validation gives an out-of-machine-specification

result, you are prompted to calibrate the force

measurement system.

Remove the spindle and cleat in position under the

spindle.

Then place the calibration plate in place of the spindle,

resting on the standard spindle. Confirm with the righthand side button.

Once the measure is stable, the “check mark” button

appears.

It allows the operator to move to the next step.

Like on the image

below, with no weight.

Repeat the operations opposite for 1, 2, 5 and 10kg

masses.

Once calibration is complete, the error relating to the

extent of measurement is displayed (<= 2.0).

If the error on the extent of measurement is >2.0, it is not

possible to save the calibration.

3 consecutive calibrations can be carried out with a result

>2.0; after which, VOH SA must be contacted.

Page 47

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 47 / 48

8.4.4 Distance validation

Equipment required:

- Position accuracy verification kit VOH 26.01001.SP.10

Fitting procedure

PAViX screen

Comment(s)

PAViX

Remove the cleat in position under the spindle.

Place two 20mm wedges next to one another on the

plate

On top, in the centre of the plate and

perpendicularly: a 4.5mm wedge

Follow staking-tool instructions, identical to that of

taking a spindle reference.

(Apply minimum force and wait for contact with the

stop)

Repeat the height reference taking operation for a

10mm wedge, as subsequently specified by the

staking-tool.

Page 48

VOH SA

GU-04-06-01

PAViX - User Guide

Version 3.2

Created 10.2017

Page 48 / 48

If the measures are correct, the screen displays

“OK”.

When the measures do not meet machine

specifications, please contact VOH SA.

9 Representation/distribution

Loading...

Loading...