Vogelzang International VG1500, VG2500 Owner's Manual

Models VG1500/VG2500

OWNER'S MANUAL

SOLID FUEL

WARM AIR FURNACE

FOR PARALLEL INSTALLATION WITH EXISTING FORCED AIR-GAS OR OIL

FIRED FURNACE (U.S. ONLY)

FOR INSTALLATION AS A CENTRAL FURNACE

THE VG2500 FURNACE HAS BEEN APPROVED FOR U.S. INSTALLATIONS

ONLY.

ALL MODELS CERTIFIED UNDER UL 391-2010

MODELS VG1500 IS ALSO CERTIFIED UNDER CSA-B366.1-11

SAVE THESE INSTRUCTIONS

CAUTION:

READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING THE

INSTALLATION OR OPERATING

THE FURNACE

IMPROPER INSTALLATION MAY

VOID YOUR WARRANTY

DO NOT USE THIS FURNACE

IN A MOBILE HOME OR TRAILER

UNITED STATES STOVE COMPANY

227 Industrial Park Road

South PIttsburg, TN 37380

PH.: (800) 750-2723 • www.Vogelzang.com

LISTED BY LISTED BY

OMNI-Test Laboratories, Inc.

Report Number 215-S-07c-4

VG2500 (Certied for US only)

PORTLAND,

OREGON, USA

PORTLAND,

OREGON, USA

OMNI-Test Laboratories, Inc.

Report Number 215-S-07c-4

VG1500 (Certied for US and Canada)

852057

CONGRATULATIONS!

You've purchased one of America's Finest Wood and Coal

Burning Furnaces. By heating with wood and coal you're

helping CONSERVE AMERICA'S ENERGY! Wood is our

Renewable Energy Resource. Please do your part to preserve our wood supply. Plant at least one tree each year.

Future generations will thank you.

NOTE: YOUR UNIT MUST BE INSTALLED BY A

QUALIFIED FURNACE INSTALLER.

TOOLS AND MATERIALS NEEDED

TOOLS

Pencil

6 Foot Folding Rule or Tape

Tin Snips

Drill, Hand or Electric

Drill Bit- 1/8" Dia.

(For Sheet Metal Screws)

Screw Driver (Blade-Type)

Gloves

Sabre Saw

5/16" Nut Driver or

5/16" Socket w/Ratchet

Safety Glasses

6" Pipe, 6" Elbow, Collar and Thimble;

as required (24 gauge min.)

1/2" Sheet Metal Screws

6" Inside diameter Listed Residential

Type or Building Heating Appliance

Chimney or existing masonry chimney

Electrical Wiring

6" Draft Regulator

1/2" Conduit (Conduit Connectors)

Furnace Cement (Manufacturer

Recommends: Rutland Black-Code 78

or Equivalent)

Plenum and Duct work as required.

MATERIAL

2

Caution Labels

Your Furnace has the following labels. Read and Obey all labels.

DANGER: RISK OF FIRE OR EXPLOSION.

DO NOT burn garbage, gasoline, drain oil, or other ammable liquids.

WARNING: FIRE HAZARD.

DO NOT operate with re draft exceeding .06 inches w.c.

DO NOT operate with fuel loading or ash removal doors open.

DO NOT store fuels, paints, thinners, ammable liquids, or other highly volatile sub-

stances in the furnace room.

CAUTION:

HOT SURFACES! Keep children away. Do not touch during operation.

CAUTION!

INSPECT FLUE PIPES, FLUE PIPE JOINTS AND FLUE PIPE SEALS

REGULARLY TO ENSURE THAT SMOKE AND FLUE GASES ARE NOT

DRAWN INTO, AND CIRCULATED BY, THE AIR CIRCULATION SYSTEM.

CAUTION!

CLEANOUT OF THE HEAT EXCHANGER, FLUE PIPE, CHIMNEY, AND

DRAFT INDUCER (IF USED), IS ESPECIALLY IMPORTANT AT THE END

OF THE HEATING SEASON TO MINIMIZE CORROSION DURING THE

SUMMER MONTHS, CAUSED BY ACCUMULATED ASH.

SAFETY NOTICE:

If this heater is not properly installed, a house re may result. For your

safety, follow the installation directions. Contact local building or re ofcials about restrictions and installation inspection requirements in your

area. If not already installed, we recommend that smoke detectors be

installed.

3

Rules for safe installation and operation

Read these rules and the instructions carefully. Failure to follow them will cause a

hazard that could result in death, serious bodily injury, and/or property damage.

1. Check your local codes. The installation must comply

with their rulings.

2. Do not install this furnace in a mobile home or trailer.

3. Always connect this furnace to a chimney and vent

to the outside. Never vent to another room or inside

a building.

4. Do not connect this furnace to an aluminum Type

B gas vent. This is not safe and is prohibited by

the National Fire Protection Association Code. This

furnace requires a masonry or Listed Factory Built

Chimney for residential type or Building Heating

Appliance Chimney. Use a 6" diameter chimney or

larger, that is high enough to give a good draft.

5. Be sure that if a masonry chimney is used, it is safely

constructed and in good repair. Have the chimney

inspected by the Fire Department or an inspector.

6. Inspect chimney connector and chimney before and

frequently during the heating season for any deposit

of creosote or soot which must be removed.

7. Provide air for combustion into the room where the

furnace is located. If the intake is not in the same

room, air must have free access to the room.

8. CAST IRON PARTS MUST BE "SEASONED" TO

AVOID CRACKING, BUILD ONLY SMALL FIRES

ON FIRST USE.

9. To prevent injury, do not allow anyone to use this

furnace who is unfamiliar with the correct operation

of the furnace.

10. For further information on using your furnace safely,

obtain a copy of the National Fire Protection Association (NFPA) publication "Chimney's, Fireplaces

and Solid Fuel Burning Appliances" NFPA 211. The

address of the NFPA is Batterymarch Park, Quincy,

MA 02269.

11. Keep the ashpit section free of excess ashes. Do

not allow ashes to stack higher than the sides of the

ash pan.

12. Disposal of Ashes – Ashes should be placed in a steel

container with a tight tting lid and moved outdoors

immediately. The closed container of ashes should be

placed on a noncombustible oor or on the ground,

well away from combustible materials, pending nal

disposal. If the ashes are disposed of by burial in

soil or otherwise locally dispersed, they should be

retained in the closed container until all cinders have

thoroughly cooled. Other waste shall not be placed

in this container.

13. CAUTION- The special paints used on your furnace

may give off some smoke while they are curing during

rst few res., Build small res at rst. The metal

used in construction of the furnace and duct work has

a light coating of oil. This could give off smoke and/

or odor from registers when furnace is used for the

rst time. This should disappear after a short period

of time. Once this burn-off has occurred, it should

not reoccur.

14. CARING FOR PAINTED PARTS- This furnace has

a painted outside jacket, which is durable, but it will

not stand rough handling or abuse. When installing

your furnace, use care in handling. Clean with soap

and warm water when furnace in not hot. DO NOT

use any acids or scouring soap, as these wear and

dull the nish. DISCOLORATION WILL OCCUR

IF THE FURNACE IS OVERHEATED. FOLLOW

OPERATING INSTRUCTIONS CAREFULLY.

15. Keep the feed and ash doors closed at all times

except while tending the furnace.

16. WARNING: RISK OF FIRE - Inspect and clean ues

and chimney regularly

CAUTION: Hot surfaces

CAUTION: Keep children away

CAUTION: Do not touch during operation

CAUTION: Maximum draft marked on nameplate

CAUTION

GASES THAT ARE DRIVEN FROM FRESH COAL MUST

BE BURNED OR THEY WILL ACCUMULATE AND EX-

PLODE. NEVER SMOTHER A FIRE WHEN ADDING

FRESH COAL.

CAUTION

DO NOT OPERATE WITH THE FEED AND/OR ASH DOOR

OPEN. THIS FURNACE IS DESIGNED FOR THERMOSTATIC OPERATION. OPERATION WITH ANY OF THESE

DOORS OPEN WILL OVERHEAT AND DAMAGE THE

FURNACE.

CAUTION

NEVER USE GASOLINE, GASOLINE-TYPE LANTERN

FUEL, KEROSENE, CHARCOAL LIGHTER FLUID, OR

FLAMMABLE LIQUIDS TO START OR "FRESHEN UP"

A FIRE IN THE FURNACE.

WARNING

NEVER STORE FLAMMABLE LIQUIDS, ESPECIALLY

GASOLINE, IN THE VICINITY OF THE FURNACE.

Your Furnace is designed to be installed in a parallel air ow arrangement with a gas or oil-

red forced air upow-type central furnace, or it may be installed as a central furnace.

4

HOW THE FURNACE FUNCTIONS

Your furnace is designed to be a supplemental

or central heating source for your home. This

Solid Fuel Furnace may be installed in conjunction with a properly operating central furnace that

is listed or certied in accordance with nationally

recognized safety standards and equipped with

the required controls and other safety features and

which has been installed in accordance with appropriate standards of the National Fire Protection

Association with installation clearances specied

in the furnace nameplate marking. The installa-

tion must be accomplished by a qualied agency

(one who is engaged in, and is responsible for,

or is thoroughly familiar with the installation and

operation of the gas, oil, and solid fuel burning

heating appliances, who is experienced in such

work, familiar with all the requirements of the authority having jurisdiction.) The installation shall

be in strict accordance with the manufacturer's

installation instructions furnished with the solid

fuel furnace.

The chimney connector of the furnace is to be

installed to provide clearances to combustible

material not less than specied in the individual

classications and marked on the furnace. The

chimney connector must be connected to a chimney suitable for use with residential type or building

heating appliances which burn solid fuel.

The Furnace is designed to operate in either paral-

lel or series air ow arrangement with the central

furnace or as a central furnace.

CENTRAL FURNACE INSTALLATION:

As a central furnace, the unit functions independently of any other system. The blower will come

on when the plenum temperature reaches the

setting on the blower control.

PARALLEL INSTALLATION: (U.S. ONLY)

The design is such that when the blower comes

on, the blower on the central system also comes

on. The blower will only come on when the temperature in the plenum has reached the setting

on the blower control. This is to insure that there

is sufcient warm air in the system to make it efcient for the unit to operate. When the central

system thermostat calls for heat, the central system

will operate by the burner igniting and the blower

coming on. It is possible that both systems will

operate simultaneously. It is recommended that

for the most efcient use of your furnace, that it

be red as much as possible in order to reduce

the demand on your existing central heating

system. This unit has an optional forced draft kit

that operates from a wall thermostat. When the

temperature falls below the setting on the wall

thermostat, the forced draft will come on (U.S.

Stove Option 11/DIKL)

The warm air supply outlet of the furnace shall

not be connected to the cold air return of the

central furnace, because the possibility exists of

components of the central furnace overheating

and causing the central furnace to operate other

than is intended.

SERIES INSTALLATION:

This type of installation uses only the blowers of

the existing central furnace. The solid fuel fan/

limit control must also control the functions of the

existing furnace. All electrical power must come

from a single branch circuit.

5

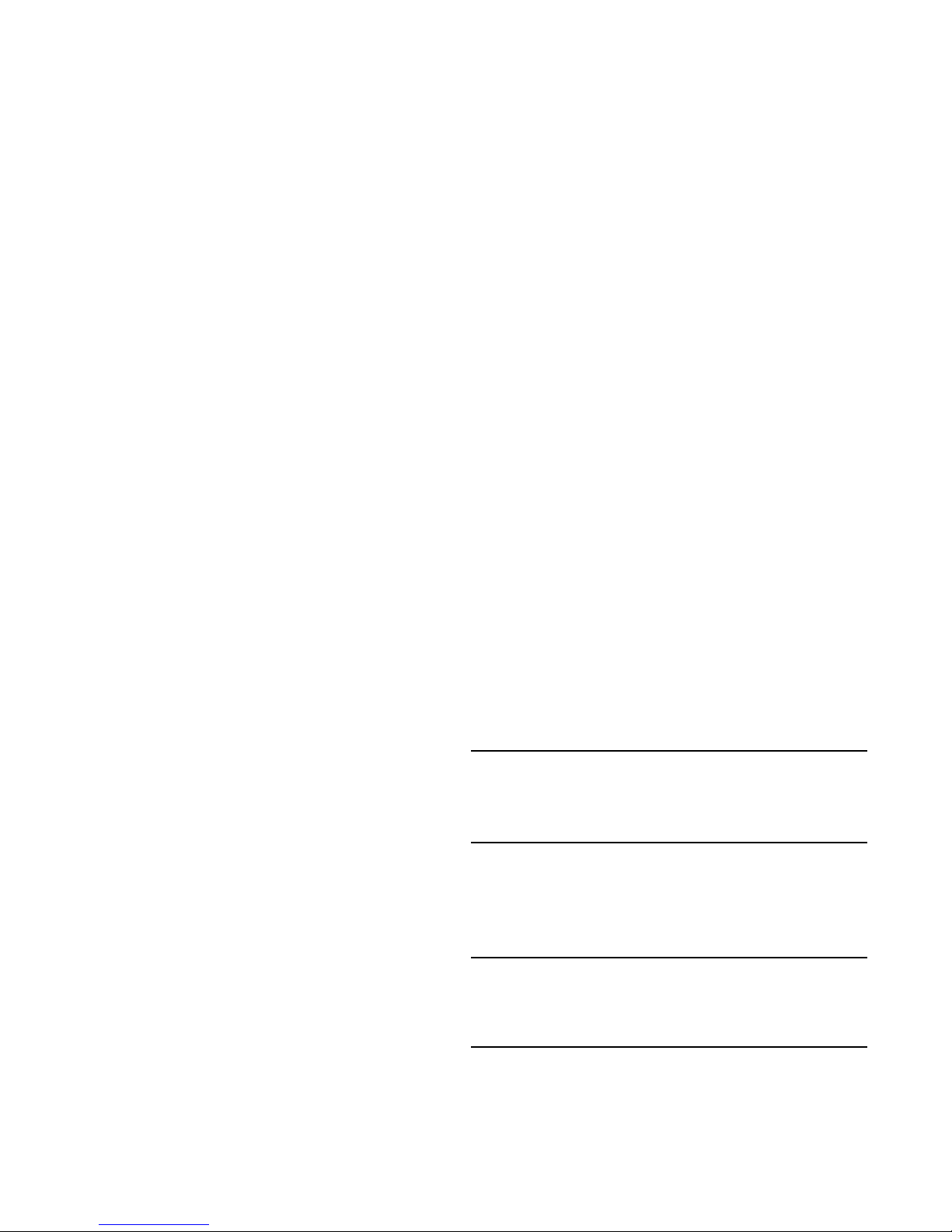

DIMENSIONS OF FURNACE

Figure 1

Model VG1500

Figure 2

Models VG2500

6

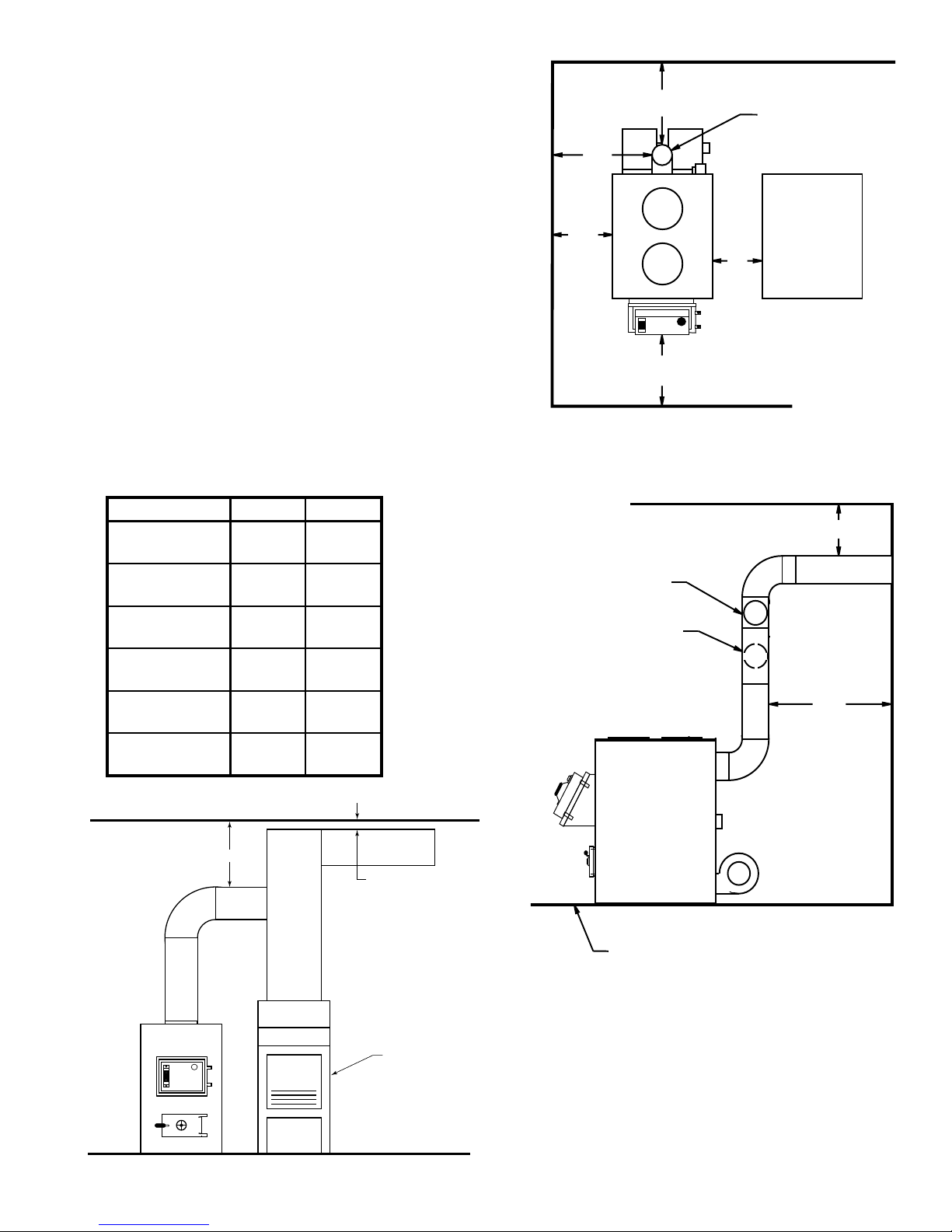

Locating the Furnace

18"

18"

6" SOLID DAMPER

6" BAROMETRIC

DRAFT REGULATOR

NON-COMBUSTIBLE FLOOR

12"

9"

48"

18"

CENTRAL

FURNACE

6" CHIMNEY

21"

1. The furnace should be located in the same

room as the central system and as close as

possible, but not closer than 9". There should

be no wall between the furnace and the warm

air outlet duct that is connected directly to the

warm air outlet plenum of the central furnace.

(See Fig. 4)

2. Place the furnace on a noncombustible oor.

3. Check gures 3 through 5. Be sure you have

the clearances shown below from the furnace

and the connector pipe to combustible surfaces. If you have a solid brick or stone wall

behind your furnace, you can place the furnace

as close as you wish to the wall. If the wall

is only faced with brick or stone, treat it as a

combustible wall.

Unit to Sidewall

Unit to Backwall

Front of Unit to

Combustible

Chimney Pipe

to Sidewall

Chimney Pipe

to Backwall

Plenum to

Combustibles6"(150mm)6"(150mm)

VG1500 VG2500

12"

(305mm)

30"

(760mm)

48"

(1.22m)

18"

(460mm)

18"

(460mm)

12"

(305mm)

30"

(760mm)

48"

(1.22m)

21"

(530mm)

18"

(460mm)

Figure 4

PLENUM

TO

CEILING

6" MIN.

2" MIN. AIR SPACE

REQUIRED BY CODE

Figure 5

CENTRAL

FURNACE

Figure 3

7

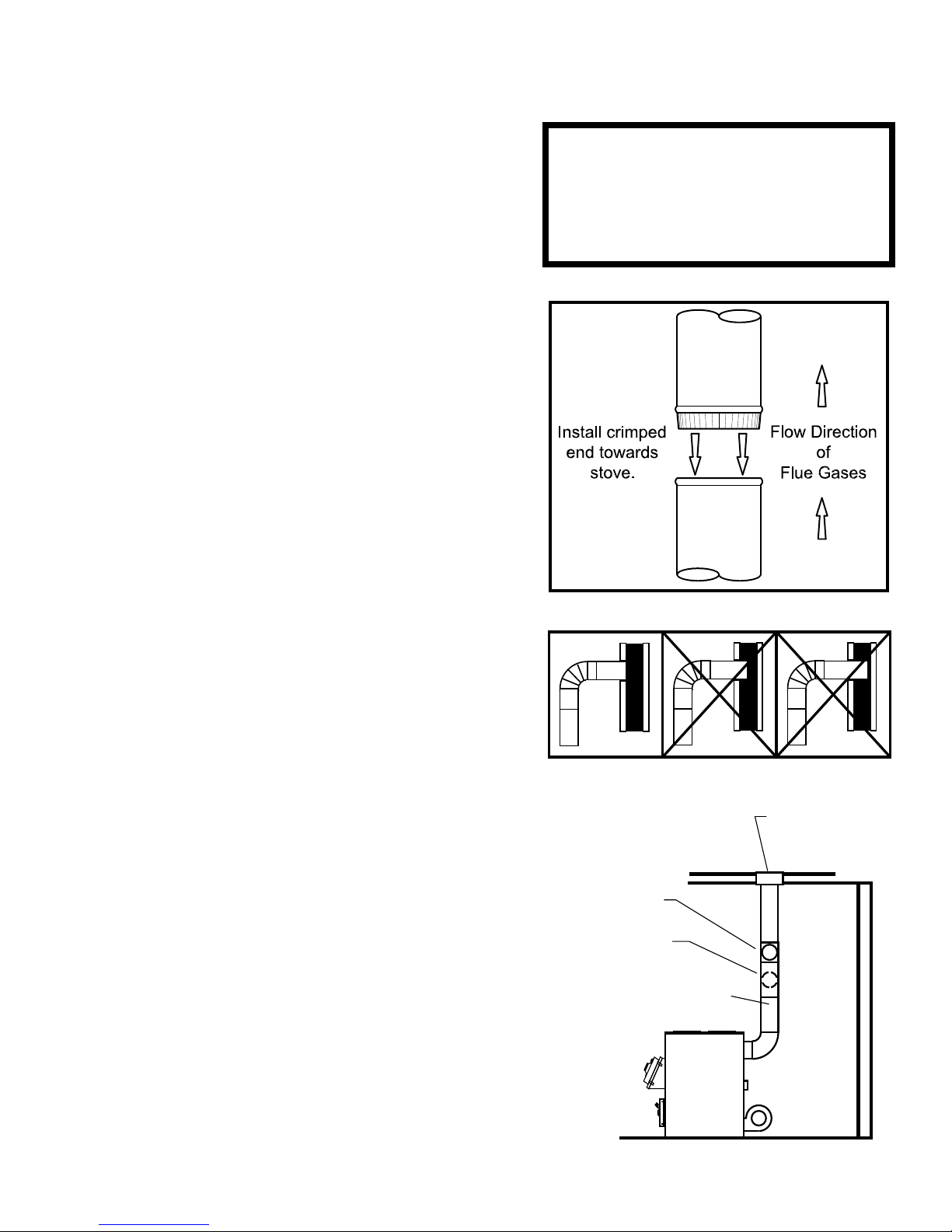

10'

2' MIN.

3' MIN.

6" CHIMNEY CONNECTOR

6" ELBOW

6" SOLID DAMPER

6" BAROMETRIC

DRAFT REGULATOR

REFER TO CHIMNEY

MANUFACTURER'S

INSTRUCTIONS AND

PARTS.

Chimney Connection

6" SOLID DAMPER

6" BAROMETRIC

DRAFT REGULATOR

THIMBLE

6" ELBOW

6" CHIMNEY

CONNECTOR

6" ELBOW

NON-COMBUSTIBLE WALL

MASONRY CHIMNEY

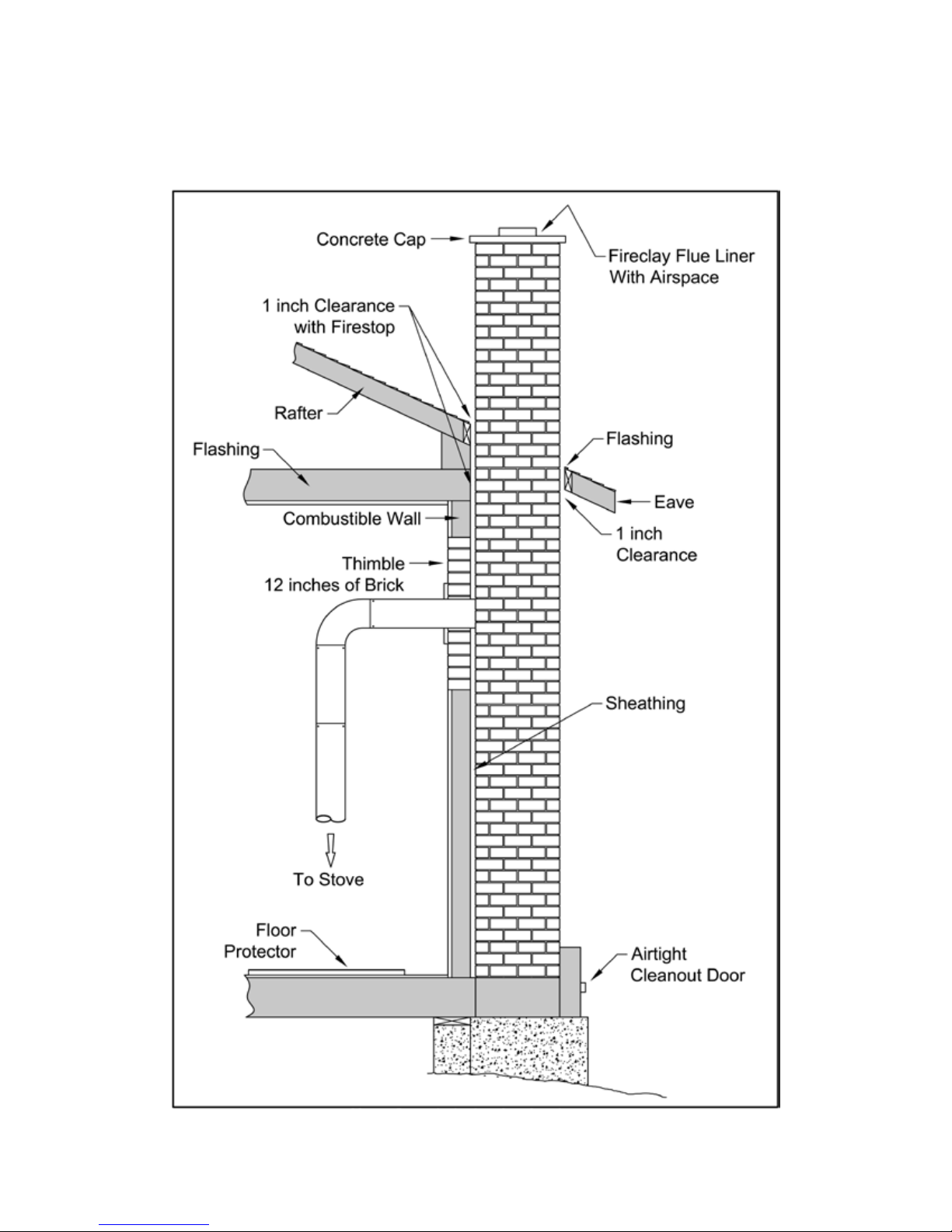

Before using an existing masonry chimney, clean

the chimney and inspect the ue liner to be sure

it is safe to use. Make repairs before attaching

the furnace. The connector pipe and ttings

you will need to connect directly to a masonry

chimney are shown.

The chimney connection should be as short as

possible.

If the connector pipe must go through a combustible wall before entering the masonry chimney,

consult a qualied mason or chimney dealer.

The installation must conform to local re codes,

and N.F.P.A. 211.

DO NOT CONNECT THIS FURNACE TO

A CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

The chimney used for a furnace must not be used

to ventilate the cellar or basement. If there is

a cleanout opening at the base of the chimney,

close it tightly.

Figure 6

LISTED FACTORY BUILT CHIMNEY

Carefully follow chimney manufacturer's instructions. Use only a Listed Residential Type or

Building Heating Appliance Chimney. If your

chimney starts at the ceiling (Fig. 7), you will

need enough 6" pipe to reach the ceiling.

The top of the chimney must be at least 3 feet

above the roof and be at least 2 feet higher than

any point of the roof within 10 feet (Fig. 7).

Figure 7

8

6" SOLID DAMPER

6" BAROMETRIC

DRAFT REGULATOR

NON COMBUSTIBLE

INSTALLATION PER

NFPA 211

MEASURE FLUE DRAFT HERE

Rules for Connector Pipe Installation

1. The crimped end of the chimney connector ts inside

the furnace ue collar. Install additional chimney con-

nectors and elbow with the CRIMPED END TOWARD

THE FURNACE. This will allow any condensation

in the ue to run back into the furnace. Use 6" dia.

steel pipe and elbows for connection to chimney.

Never use less than 24 gauge and although blued

steel is satisfactory, high temp painted black is much

more desirable. (See Figure 8)

2. Slope any horizontal pipe upward toward the chimney

at least 1/4 inch for each foot of horizontal run.

3. You must have at least 18 inches of clearance be-

tween any horizontal piping and the ceiling.(See Fig.

5)

4. The chimney connector must not extend into the

chimney ue. (See Fig. 9)

5. Seal each chimney connector pipe joint with furnace

cement. Also seal the pipe at the chimney.

6. Use 3 sheet metal screws at each chimney pipe joint

to make the piping rigid.

7. The chimney connector may include a section for a

barometric draft regulator between the furnace and

the chimney (Fig. 6, 7, & 10). The barometric draft

regulator must be installed in the same room (same

pressure zone) as the furnace.

A ue pipe shall not pass through an attic, roof

space, closet or similar concealed space, a oor

or ceiling of combustible construction. Where

passage through a wall or partition is desired,

installation must conform with UL standards.

Figure 8

NOTE:

8. Install the barometric draft regulator strictly in ac-

cordance with the instructions that are provided with

the barometric draft regulator.

9. A solid damper must be used in the chimney connect-

ing pipes between the ue collar and the chimney.

When used in conjunction with a barometric draft

regulator, the solid damper must be placed between

the barometric and the chimney. (See Fig. 6, 7, & 10)

Adjusting the Barometric Draft Regulator

1. Drill a hole in the chimney connector within 18" of

the ue collar below the barometric draft regulator

just large enough for the tube of the manometer.

2. Build a re after all chimney connections have been

made.

3. Use a manometer to measure the draft in the ue.

4. Adjust the Barometric Draft Regulator to obtain a

draft of 0.05 - 0.06" W.C. under stable re conditions.

RIGHT WRONG WRONG

Figure 9

Figure 10

9

CONNECTION OF CHIMNEY CONNECTOR TO A MASONRY CHIMNEY THROUGH A COMBUSTIBLE WALL

Figure 8 shows how to connect the chimney connector of a heater to a masonry chimney through a combustible wall.

There are ve allowable ways that a chimney connector can be connected to a masonry chimney by passing through a

combustible wall. NFPA Standard 211 allows the following wall pass-through systems.

Figure 11

10

Loading...

Loading...