Vogelzang International TR009 Owner's Manual

THE PERFORMER

HIGH-EFFICIENCY WOODSTOVE

EPA Certified (3.89 grams/hr.)

Model TR009 Owners Manual

(Save These Instructions)

Le manuel de langue français est disponible á www.usstove.com

French language manual is available at www.usstove.com

Certified to comply with 2015 particulate emissions standards.

U.S. Environmental Protection Agency

U.S. Stove Company

227 Industrial Park Road,

P.O. Box 151

South Pittsburg, TN 37380

Phone 1-800-750-2723

www.Vogelzang.com

852171B-1903E

This manual describes the installation and operation of the Vogelzang, TR009 wood heater. This heater meets the 2015

U.S. Environmental Protection Agency's crib wood emission limits for wood heaters sold after May 15, 2015. Under specific test conditions this heater has been shown to deliver heat at rates ranging from 10,889 to 29,421 Btu/hr.

Note: The BTU ratings mentioned above are based on the EPA test protocol burning dimensional Douglas Fir lumber. Our

advertised BTU’s are based on the first hour of operation at high burn rate burning cordwood.

SAFETY INSTRUCTIONS-READ ALL INSTRUCTIONS CAREFULLY

1. The installation of this stove must comply with your local building code rulings. Please observe the clearances to combustibles (see reference figures 10–12). Do not place furniture or other objects within the clearance area.

2. Verify that the stove is properly installed before firing the stove for the first time. After reading these instructions, if you

have any doubt about your ability to complete your installation properly, you must obtain the services of a professional

licensed installer familiar with all aspects of safe and correct installation.

3. DO NOT store wood, flammable liquids or other combustible materials too close to the unit. Refer to certification label

on back of unit and reference figures 10–12 in this manual.

4. DO NOT INSTALL THIS STOVE IN A MOBILE HOME, MANUFACTURED HOME, TRAILER OR TENT NO EXCEPTIONS! (HUD Federal Standard: 24 CFR Ch.XX).

5. DO NOT MODIFY THIS STOVE IN ANY WAY! DO NOT ELEVATE THIS STOVE BY ANY MEANS. (i.e. bricks under

pedestal base, cement blocks) Stove base must set directly upon the solid-surface, non-combustible floor as specified

in this stove instruction manual.

6. DO NOT MODIFY THIS STOVE IN ANY WAY! Stove must be installed with pedestal provided, attached as shown in

the instructions. DO NOT OPERATE WITHOUT BOTTOM HEAT SHIELD – NO EXCEPTIONS. Heat Shield must be

assembled and installed as shown in Assembly Instructions. Assemble only with original parts as supplied and shown

in this manual. DO NOT OPERATE A STOVE THAT IS MISSING ANY PARTS! If any parts are missing or defective,

please notify the dealer or manufacturer immediately. Replace missing, broken or worn parts with factory original or

equivalent parts only.

7. Do not tamper with combustion air control beyond normal adjustment capacities.

8. Always connect this stove to a chimney and vent to the outside. Never vent to another room or inside a building. DO

NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

9. DO NOT CONNECT A WOOD BURNING STOVE TO AN ALUMINIUM TYPE B GAS VENT. This is not safe. Use ap-

proved masonry or an Underwriters Laboratories Listed UL 103 HT / ULC-S629 Residential Type and Building Heating

Appliance Chimney. Use a 6˝/152mm diameter chimney, that is high enough to give a good draft. (See specifics in

Chimney Connections instructions).

10. Be sure that your chimney is safely constructed and in good repair. Have the chimney inspected by the fire department or a qualified inspector. Your insurance company should be able to recommend a qualified inspector. Chimney

connector pipe must be in good condition. Replace if necessary before using stove.

11. Creosote or soot may build up in the chimney connector and chimney and cause a house/building fire. Inspect the

chimney connector and chimney twice monthly during the heating season and clean if necessary. (see Service Hints).

12. In the event of a chimney fire, turn the air control to closed position, leave the building and CALL THE FIRE DEPART-

MENT IMMEDIATELY! Have a clearly understood plan on how to handle a chimney fire by contacting your local fire

authority for information on proper procedures in the event of a chimney fire. After the fire is out, the chimney must be

cleaned and inspected for any stress or cracks before starting another fire. Check the condition of any combustibles

surrounding the chimney.

13. Ashes should not be allowed to accumulate above the top of the lower primary air orifice (LPAO, air vent at front of

firebox, just inside of door).

14. DISPOSAL OF ASHES Ashes should be placed in a steel container with a tight fitting lid and moved outdoors im-

mediately. The closed container of ashes should be placed on a noncombustible floor or on the ground, well away

from all combustible materials, pending final disposal. If the ashes are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container until all cinders have completely cooled. Other waste shall

not be placed in this container.

15. To prevent injury, do not allow anyone to use this stove who is unfamiliar with the correct operation of the stove.

16. Do not operate stove while under the influence of drugs or alcohol.

17. The special paints used on your stove may give off some smoke and an odor while they are curing during the first

12 to 15 fires. Additional smoke and odor may be emitted from the light oils used in construction of the fire box. This

should disappear after a short period of time and not occur again. Persons with lung conditions or owners of susceptible domestic pets (such as birds) should take prudent precautions. Open windows and doors as needed to clear

smoke and/or odor. Paint discoloration will occur if the stove is over fired.

NOTE: A PROFESSIONAL, LICENSED HEATING AND COOLING CONTRACTOR MUST BE CONSULTED IF YOU

HAVE QUESTIONS REGARDING THE INSTALLATION OF THIS SOLID FUEL BURNING APPLIANCE.

2

SAFETY INSTRUCTIONS

18. This stove has a painted surface which is durable but it will not stand rough handling or abuse. When installing your

stove, use care in handling.

19. Clean exterior with soap and warm water when stove is not hot. Do not use any acids or scouring soap, as these

solvents wear and dull the finish.

20. CLEAN STOVE FREQUENTLY as soot, creosote and ash may accumulate.

21. ALERT ALL PERSONS TO THE HAZARDS OF HIGH SURFACE TEMPERATURES while stove is in operation –

especially young children. Keep away from a hot stove to avoid burns or clothing ignition.

22. NEVER LEAVE SMALL CHILDREN UNSUPERVISED WHEN THEY ARE IN THE SAME ROOM AS THE STOVE. If

small children will be in the same room as the stove during operation, provide a sturdy barrier to keep them at a safe

distance from the stove.

23. Keep stove area clear and free from all combustible materials, gasoline, engine oil, naphtha and other flammable

vapors and liquids.

24. WHILE TENDING THE FIRE ALWAYS WEAR PROTECTIVE CLOTHING, fire retardant hearth gloves and eye pro-

tection, to prevent burns.

25. Never operate this stove with the door open except when re-fueling. Such actions can result in very dangerous operating conditions.

26. DO NOT OVER FIRE THE STOVE. Over firing will occur if combustion air is uncontrolled as when feed door is left

open during operation. Such actions can result in very dangerous operating conditions. While in operation, keep the

feed door closed and secured at all times except while tending the fire

27. When adding fuel be careful not to smother the fire. Do not build fires against glass and make sure the coal bed does

not obstruct the air inlet. Do not load fuel to a height or in such a manner that it would be hazardous when opening the

door.

28. NEVER LEAVE THE STOVE UNATTENDED when the door is open. Always close the door after ignition.

29. DO NOT CONNECT TO OR USE IN CONJUNCTION WITH ANY AIR DISTRIBUTION DUCT WORK UNLESS SPECIFICALLY APPROVED FOR SUCH INSTALLATIONS.

30. A WOOD-BURNING STOVE MUST NEVER BE INSTALLED IN A HALLWAY OR NEAR A STAIRCASE, as it may

block egress in the event of a fire.

31. DO NOT INSTALL IN A SLEEPING ROOM. DO NOT INSTALL IN AN ALCOVE OR INSIDE A FIREPLACE.

32. Install at least one smoke detector on each floor of your home. Detectors should be located away from the heating

appliance to avoid false alarms. Detectors should be located close to sleeping areas. Follow the smoke detectors

manufacturer’s placement and installation instructions. Maintain smoke detector per manufacturer’s instructions.

33. CARBON MONOXIDE (CO) HAZARD. A buildup of CO fumes is toxic and can be fatal. Carbon Monoxide is a colorless, odorless gas produced during combustion of wood, coal, oil, gas and by other fuel burning appliances. It is important to have a proper draft and adequate replacement air ventilation so fumes are drawn out the chimney. Installed

as instructed this stove is designed to be as safe as possible yet it is recommended to install a CO detector. Follow

the manufacturer’s recommendations for proper installation and use. It is recommended to be placed at table-top level

(not near the ceiling) to avoid false alarms. Realize that devices other than a stove (i.e. motor exhaust) can trigger CO

alarms.

If alarm sounds:

• Recognize the symptoms of CO poisoning (headaches, nausea & drowsiness).

• Increase ventilation (open windows & doors).

• Make sure stove doors and/or lids are closed and secured.

• Check stove for smoking or puffing (open airflow controls).

• Check chimney & connector pipe for leaks, blockage or down-draft conditions.

• Check CO device for false alarm.

34. Keep power cords, electrical appliances and/or assemblies outside of the clearance area shown in this manual for

combustible materials.

35. Consult your municipal building department or fire officials about restrictions, permits and installation requirements for

your area.

36. For further information on using your stove safely, obtain a copy of the National Fire Protection Association (NFPA)

publication, “Using Coal and Wood Stoves Safely” NFPA No. HS-10- 1978. The address of the NFPA is Batterymarch

Park, Quincy, MA 02269.

3

ASSEMBLY INSTRUCTIONS

NOTICE: Vogelzang International Corp. grants no warranty, stated or implied, for the installation or maintenance of

your wood stove and assumes no responsibility of any incidental or consequential damages.

TOOLS AND MATERIALS REQUIRED FOR

INSTALLATION

Tools:

• Pencil

• 6 ft/2m Folding Rule or Tape Measure

• Tin Snips

• Drill: Hand or Electric

• 1/8”/3mm dia. Drill Bit (for sheet metal screws)

• Screwdrivers (blade and Phillips type)

• 10mm Nut Driver or Ratchet with 10mm Socket

• 11/16” socket or wrench

• Safety Glasses

• Gloves

Materials:

(NOTE: The following items are NOT included with

your stove) Flooring Protection: as specified (see

page 7) Connector Pipe: 6”/152mm dia. minimum

24 MSG black or 26 MSG blue steel straight stove

pipe or elbow(s). 1/2”/13mm Sheet Metal Screws

Chimney: Existing 6”/152mm Code-approved Lined

Masonry Chimney or 6”/152mm Inside Dia. UL/ULC

Listed Type HT manufactured chimney. Furnace Cement (manufacturer recommends Rutland Code 78

or equivalent)

CAUTION:

STOVE IS HEAVY. MAKE SURE YOU HAVE

ADEQUATE HELP AND USE PROPER LIFTING

TECHNIQUES WHENEVER MOVING STOVE.

the side walls of the stove to direct combustion gasses

over the secondary combustion tubes before exiting via

the chimney. DO NOT REMOVE the ceramic blanket or

your stove will not operate properly.

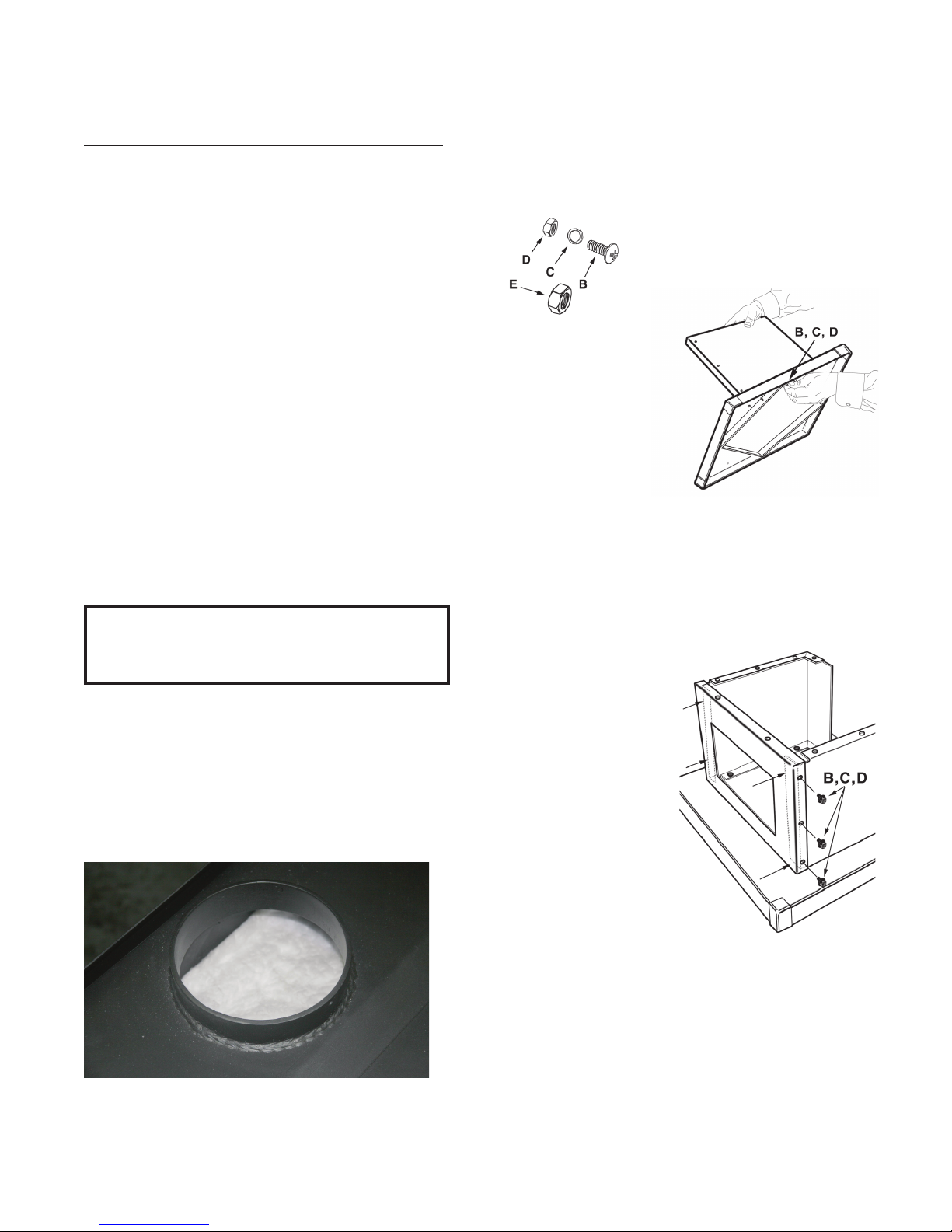

Figure 2 – Pedestal Assembly

Hardware. 1/4-20 machine screws,

lock washers & hex nuts

Figure 3 –

Assemble

sides to base

2. Remove parts and hardware pack located inside

rebox.

3. Align the hole pattern of one of the pedestal sides

to the holes in the base and secure with four (4)

machine screws, lock washers and hex nuts. Assemble the opposite side to the base. (Note: Sides are

interchangeable.)

1. Uncrate the stove and remove all cardboard

and styrofoam packing materials and protective

poly bag. Remove pedestal base, sides, front,

top, ash drawer and ash drawer support from

the carton. (Save packing materials for further

assembly.) NOTICE: DO NOT remove ceramic

blanket material from inside stove pipe opening (Fig. 1). This blanket provides an air seal on

DO NOT

REMOVE!

Figure 1 – DO NOT remove ceramic blanket from

inside stove pipe opening. This is NOT packing

material but an integral component of the stove

combustion system.

Figure 4 – Attach Pedestal

Front Frame to Sides.

(Note– front goes OVER

the side panels.)

4. Attach the pedestal front frame to the sides. e

pedestal front should go over (not inside of) the

side panels. Use three (3) machine screws, lockwashers & hex nuts (provided in the hardware

pack) on each side to attach both pedestal sides

(#31) to the pedestal front (#32).

5. Position ash drawer support into assembled pedestal (Figure 5) and secure from rear with two (2) machine screws, lock washers and hex nuts. Tighten all

pedestal hardware.

4

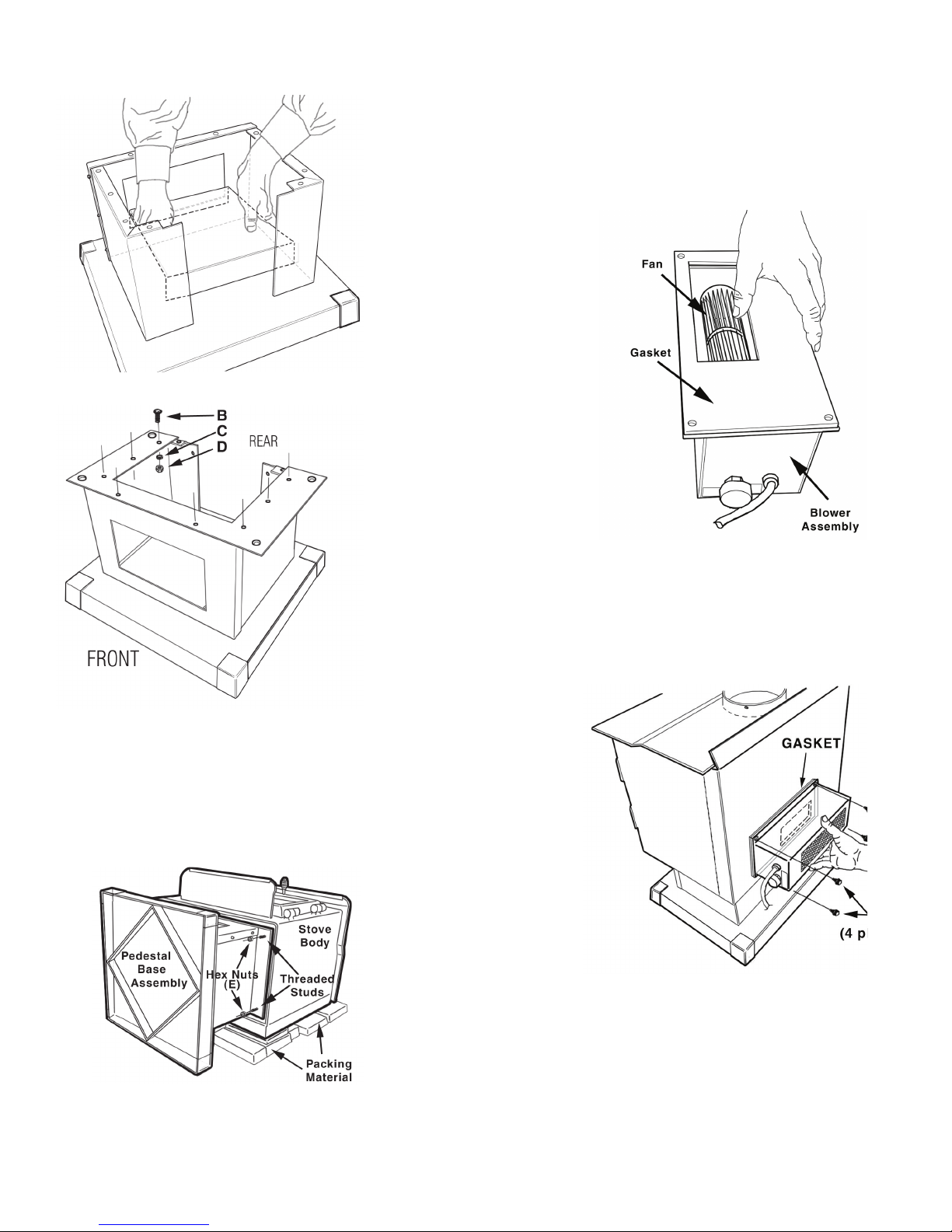

Figure 5 – Insert Ash Drawer Support.

ASSEMBLY INSTRUCTIONS

8. Align four (4) corner mounting studs with holes

in pedestal top (Figure 7). Secure with four (4)

hex nuts (E).

9. Tip the stove assembly upright.

10. Set the ash drawer inside the open box formed

by the pedestal front and sides.

Figure 8

Blower Option

Figure 6 – Attach Pedestal Top.

6. Position the pedestal top and attach with eight

(8) machine screws, lock washers and hex

nuts. (See Figure 6)

7. Place flattened carton/styrofoam packing mate-

rial on floor and carefully tip the stove body onto

it’s back.

11. For Optional Blower Assembly, note the

position of the blower opening in the rear of

the stove.

12. Place blower gasket onto blower assembly

so as not to obstruct the air ow from the

fan (Figure 8)

Figure 9 – Attach Optional Blower to Stove Body

Figure 7 – Attach Pedestal to Stove Body

13. Mount the blower assembly to the back of

the stove aligning the fan opening to the

opening in the back of the stove. Secure

with four sheet metal screws.

14. Aer assembly, check to make sure re

brick are properly positioned and ash clean

out cover is in place.

5

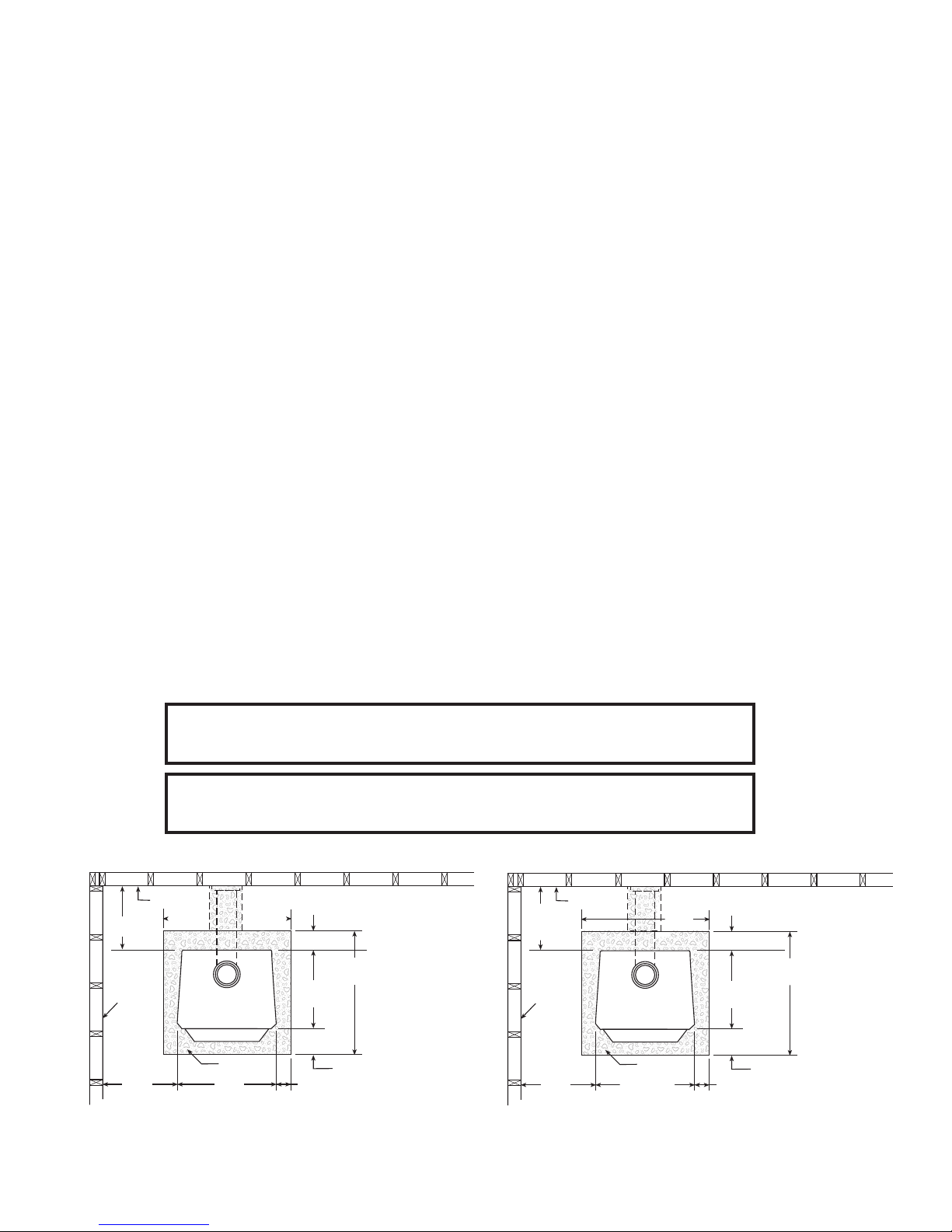

LOCATING STOVE

1. The stove must be placed on solid concrete, solid masonry, or when installed on a combustible floor, on an Underwriters Laboratories Listed Type 2 floor protector listed to UL standard UL 1618, such as Hy-C or Imperial Model

UL3648BK (US) or UL4049BK (CAN). Floor protector must be 1/2˝/13mm minimum thickness (R value = 0.84, see

page 23 for calculation formulas) non-combustible material or equivalent. US Requirements: The floor protector must

extend at least 16˝/41cm beyond the front of the access door, 6˝/15.3cm to the sides, 8˝/21cm beyond the rear and

must extend under and 2˝/50mm beyond either side of the stove pipe connector if it is elbowed towards a wall. (See

figures 10 &11 and consult local building codes and fire protection ordinances.) Canadian Requirements: The floor

protector must extend at least 18˝/46cm beyond the front of the access door, 8˝/21cm to the sides, 8˝/21cm beyond

the rear and must extend under and 2˝/50mm beyond either side of the stove pipe if it is elbowed towards a wall. (See

figures 10 & 12 and consult local building codes and fire protection ordinances.)

2. The room in which the stove is installed must have a minimum floor to ceiling height of 7 ft. (2.2 m).

3. The stove must have its own flue. Do not connect this unit to a chimney flue serving other appliances. DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM. 4.

4. After observing the clearances to combustible materials (figures 10–12), locate your floor protector accordingly (figure

10) and care-fully place the stove in your selected location. Install connector pipe, elbows, and thimble as required,

utilizing either a recently cleaned and inspected 6˝/152mm lined masonry chimney or a 6˝/152mm i.d. UL 103 HT/

ULC-S629 listed manufactured chimney.

5. Use round 6˝/152mm dia., minimum 24 MSG black or 26 MSG blue steel stove pipe to connect the stove to the

chimney. Do not use galvanized stove pipe. Secure connector pipe to the flue collar with three (3) sheet metal screws.

Use three screws in each stove pipe and/or elbow joint to firmly hold the pipe sections together. DO NOT connect this

stove to any air distribution or duct system.

6. Recheck clearances from the stove, connector stove pipe, and corner clearances using the illustrations in figures

10–12 and your local building codes or fire protection ordinances.

7. DO NOT install this stove in a mobile home, Manufactured Home, Tent or trailer – NO EXCEPTIONS! (HUD Federal

Standard: 24 CFR Ch.xx)

8. The clearances provided are minimum dimensions set by UL standard 1482-2010 & ULC-S627-00, tested and applied

by OMNI-Test Laboratories, Inc. the manufacturer’s testing agency. Installation of this stove must comply with the

latest edition of NFPA 211 for reduced clearances and/or your local building code rulings. Use whichever minimum

dimensions are LARGEST. Clearances listed and shown MUST be adhered to for safe operation of this appliance.

CLEARANCES MAY NOT BE REDUCED BY ANY MEANS IN USA OR CANADA.

9. is stove meets U.S. Test Standard: UL 1482-2010& Canadian Standard: ULC-S627-00.

CAUTION: FIRE HAZARD. CARPETING AND OTHER COMBUSTIBLE MATERIAL

SHALL NOT COVER THE FLOOR PROTECTOR. THESE MATERIALS MUST

REMAIN OUTSIDE OF COMBUSTIBLE CLEARANCES, SEE FIG. 10-12

NOTE: ANY WALL CONTAINING COMBUSTIBLE DRYWALL AND FACED WITH

BRICK OR STONE MUST BE CONSIDERED A COMBUSTIBLE SURFACE.

COMBUSTIBLE CONSTRUCTION IN ACCORDANCE WITH US NFPA 211

11"min

SIDEWALL

20"

TOP VIEW | USA CLEARANCES

BA CKWALL

36"

FLOOR

PROTECTOR

DASHED LINES SHOW HORIZONTAL CHIMNEY CONNECTOR

AND ADDITIONAL FLOOR PROTECTOR REQUIRED BENEATH

AND EXTENDING 2” BEYOUND EACH SIDE

min.

Fig. 10 – TOP VIEW Minimum Clearance Dimensions from Combustible Surfaces

8"min.

23"

6"min.24"

47"

16"min.

Minimum

Clearances

according to

UL 1482-2006

COMBUSTIBLE CONSTRUCTION IN ACCORDANCE WITH US NFPA 211

16"/

41cm

min

SIDEWALL

24"/61cm

TOP VIEW | CANADIAN CLEARANCES

BA CKWALL

FLOOR

PROTECTOR

min.

24"/61cm

DASHED LINES SHOW HORIZONTAL CHIMNEY CONNECTOR

AND ADDITIONAL FLOOR PROTECTOR REQUIRED BENEATH

40"/

102cm

8"/21cm min.

23"/58cm

AND EXTENDING 2” BEYOUND EACH SIDE

49"/125cm

Minimum

Clearances

for Canadian

installation

according to

ULC S627

18"/46cm min.

8"/21cm min.

6

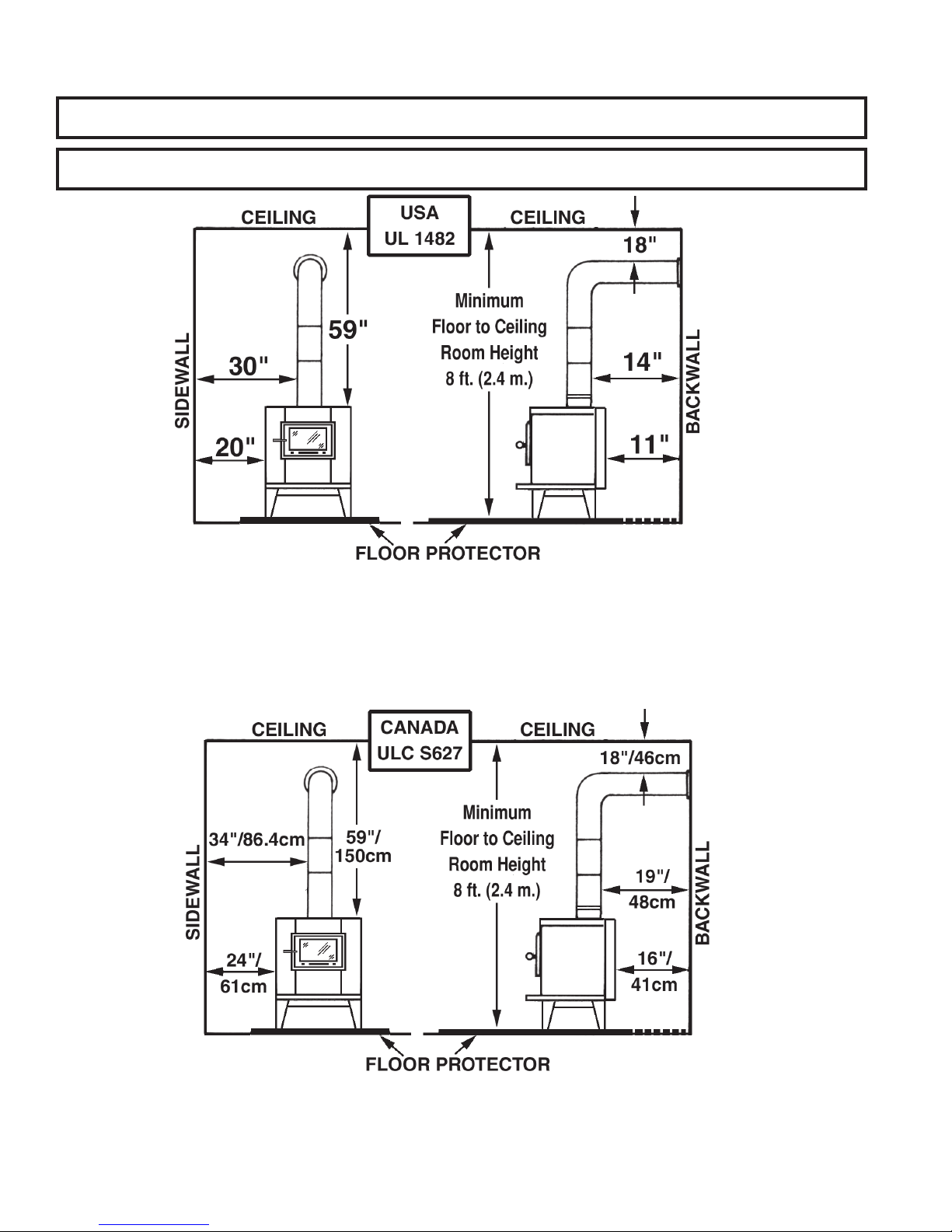

LOCATING STOVE

CAUTION:

KEEP FURNISHINGS AND OTHER COMBUSTIBLE MATERIALS AWAY FROM THE STOVE.

NOTE: BEFORE FIRING WOODSTOVE SLIDE FIREBRICKS TOWARDS THE REAR SO NO GAPS REMAIN

BETWEEN BRICKS.

Figure 11a – Front View

Minimum Clearance Dimensions

from Combustible Surfaces

Figure 11b – Side View

Figure 11c – Front View

Minimum Clearance Dimensions

Figure 11d – Side View

from Combustible Surfaces

7

LOCATING STOVE

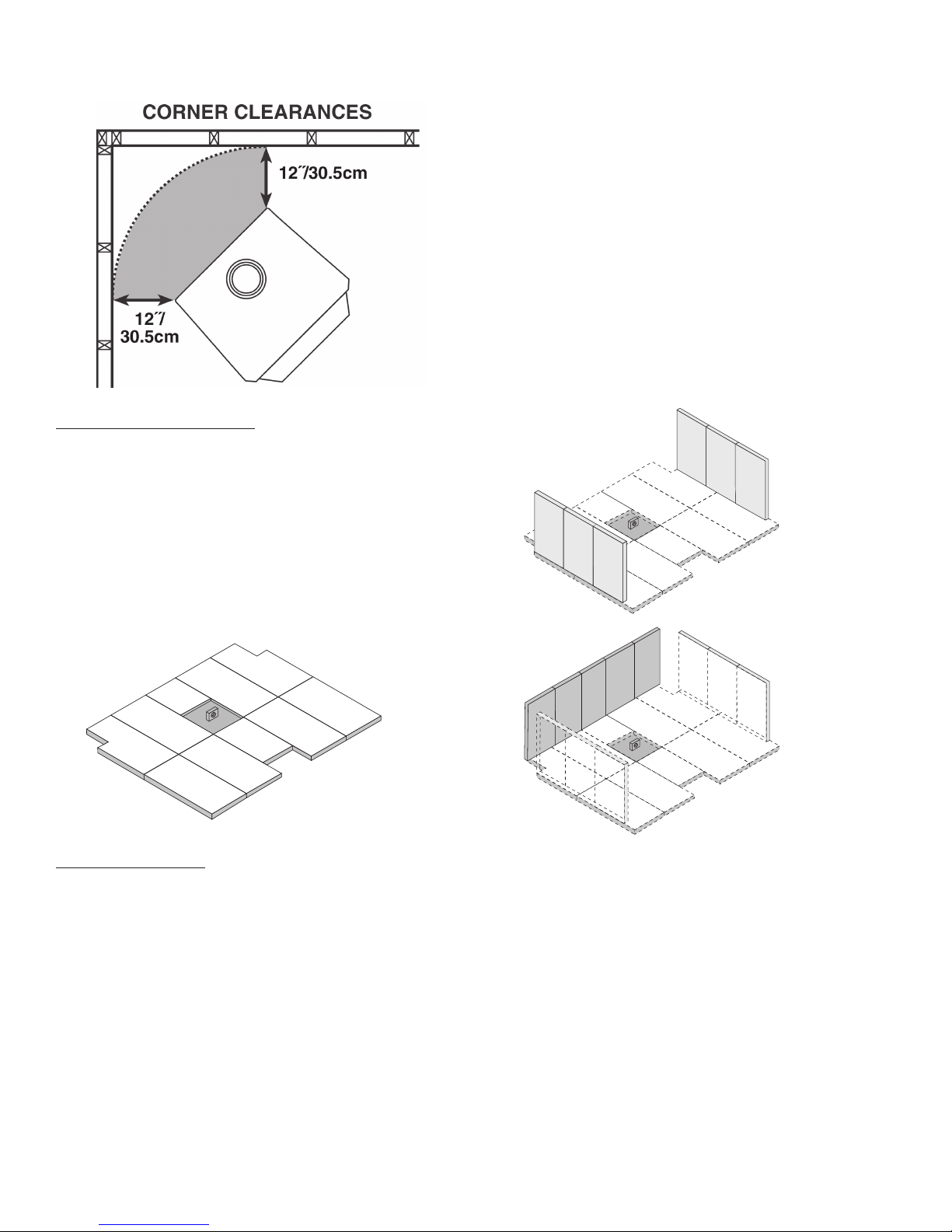

Figure 12 – Top View

Minimum Corner Clearances

from Combustible Surfaces

12˝/30.5cm (US & CDN)

FIREBRICK ASSEMBLY

Firebrick extends the life of your stove and radiates heat more

evenly. Check to see that all firebricks are in their correct positions

and have not become misaligned during shipping or assembly. If

removed for ease of locating stove, firebrick must be replace before firing. See diagrams, fig. 13a – 13c, for proper positioning.

MISSING OR CRACKED FIRE BRICKS!

A

E

A

A

N

A

A

A

A

P

A

A

A

A

O

A

Side Firebrick Arrangement

Fig.13b– Step 2,

Six (6) A-size

Fire Brick Dimensions (inches)

P

A

A

A

A

A

O

Six (6) A-size

One (1) O-size

One (1) N-size

Two (2) P-size

N

A

P

Figure 13a – Step 1, Bottom Firebrick Arrangement

CHIMNEY SIZING

Today’s solid fuel heating appliances are much more efficient than those made in the past. Your heating appliance has

been designed to provide the most efficient transfer of heat possible from the least amount of fuel. Controlled combustion

is the key to optimum heating performance. Controlled combustion requires a flow of fresh air into the appliance, across

the fuel and is finally exhausted up the chimney. Today’s high efficiency stoves transfer more heat into the living area and

less up the chimney. Exhaust gases are typically at a lower temperature than traditional type stoves. With lower exhaust

temperatures, it is important that the chimney is correctly sized to the stove. If the chimney diameter is too large, it will be

difficult to raise the chimney flue temperature to provide for adequate draft. This may result in a poor burn, smoke spillage, and rapid creosote creation. A 6”/152mm diameter chimney is best suited for this stove. Your heating appliance must

have a minimum of a 6” /152mm diameter chimney. Maximum chimney diameter must not exceed 10” /254mm or have a

cross sectional area greater than 85 sq. in. /550cm2. Proper draft for this heating appliance is minimum of 0.05 w.c. (water

column measurement) and is required to prevent back puffing, smoke spillage and prevent safety hazards.

A-size: 9”x4 ½”x1 ¼”

M-size: 9”x2 ¼”x1¼”

N-size: 4 ½”x4 ½”x1 ¼”

O-size: 6 ¾”x4½”x1 ¼”

P-size: 6”x1 ½”x3”x3”x

9”x4 ½”x1 ¼”

A

A

A

P

A

A

M

N

A

A

A

A

A

A

P

A

A

A

A

O

A

Fig.13c– Step 3,

Back Firebrick Arrangement

Four (4) A-size

One (1) M-size

8

CONNECTOR PIPE INSTALLATION

NOTE: CONNECTOR PIPE IS NOT INCLUDED. TO PURCHASE, VISIT YOUR LOCAL HARDWARE, HOME, OR

BUILDING CENTER. SEE “LOCATING STOVE” PAGE 7 FOR ADDITIONAL SPECIFICATIONS.

Connector pipe is used to make the connection from the final positioning of your stove to an approved chimney. Connector pipe is NOT included as part of the stove. Connector pipe must be 6”/152mm diameter minimum of 24 MSG (minimum

standard gauge) black or 26 MSG blue steel stove pipe. Any connector pipe used must be in good condition. Replace

if necessary before using stove. Connector pipe is not rated to provide close contact to combustible materials and must

have proper clearance from combustible materials as shown in the clearance diagrams on the previous pages. Connector pipe should never be used in place of a chimney. If proper clearances are not observed a house fire could result. Take

into account the chimney’s location to insure it is not too close to neighbors or in a valley which may cause unhealthy or

nuisance conditions.

INSTALLATION INSTRUCTIONS

Please Note: Installation of a flue damper is NOT recommended. Combustion control is regulated by the intake of combustion air, not the exhaust.

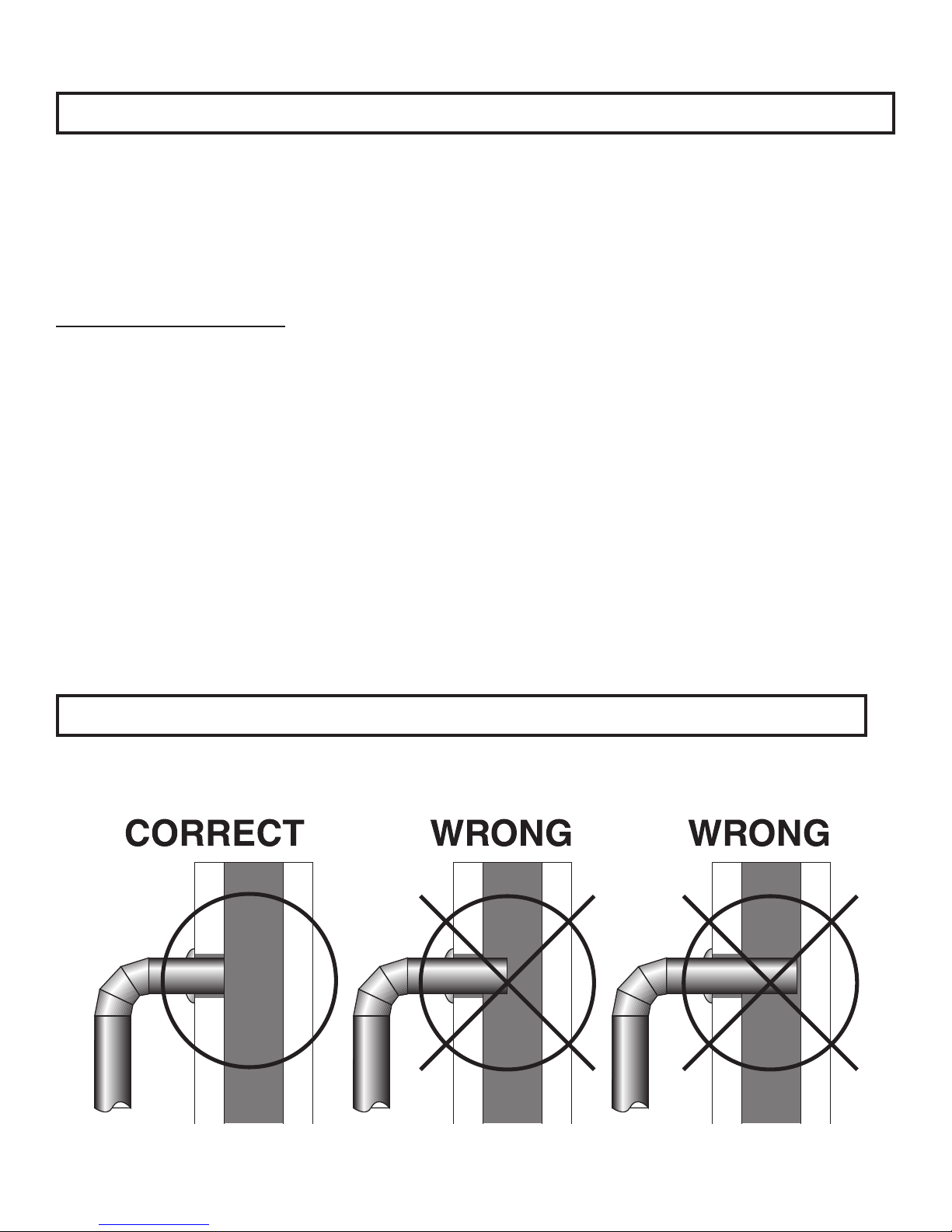

1. The crimped end of the stovepipe fits inside the stove flue collar. Secure with a minimum of three (3) equally spaced

sheet metal screws. The first section of connector pipe must be single walled to properly attach to the stove collar.

Install additional pipe and elbow with the crimped end towards the stove. This will allow any condensation in the flue

to run back into the firebox.

2. Horizontal pipe runs must slope upwards towards the chimney at least 1/4”(6.4mm) per foot of horizontal run.

3. You must have at least 18˝/457mm of clearance between any horizontal piping and the ceiling.

4. The pipe cannot extend into the chimney flue (figure 14).

5. Secure pipe/elbow sections with a minimum of three equally spaced sheet metal screws at each joint to make the piping rigid. DO NOT CONNECT THIS STOVE TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

6. It is recommended that no more than two (2) 90° bends be used in the stovepipe installation. The use of more than

two 90° bends may decrease the amount of draw and possibly cause smoke spillage. Where possible, use only corrugated (non adjustable) elbows. These provide a better seal.

7. The connector pipe must not pass through an attic or roof space, trusses, closet, or any concealed space, floor,

ceiling, wall, or combustible construction. (See Chimney Connector Systems & Clearances, page 14.) A UL 103

HT (USA)/ ULC-S629 (CDN) Listed chimney system must be used from the first penetration of ceiling or wall to the

chimney cap. Where passage through a wall or partition of combustible construction is desired, the installation shall

conform to NFPA 211 (USA) or CAN/CSA-B365 (Canada).

WARNING:

DO NOT USE SINGLE WALL CONNECTOR PIPE AS A CHIMNEY - A HOUSE FIRE COULD RESULT.

Figure 14 – Stovepipe/Flue Connections

9

Loading...

Loading...