Vogelzang 2500 User Manual

NORSEMAN

WARM AiR FuRNAcE

Models 1500/2500 Owners Manual

(save this manual for future reference)

™

SOlid FuEl

READ ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING

THIS FURNACE.

FAILURE TO FOLLOW INSTRUCTIONS

MAY RESULT IN PROPERTY DAMAGE,

BODILY INJURY, OR EVEN DEATH.

REFER TO MARKINGS ON

FURNACE LABELS FOR

ADDITIONAL INFORMATION.

VGZ-018 / 051809.0 NORSEMAN™ 1500/2500 FURNACE / Page 1

NOTE: INSTALLATION MUST BE

COMPLETED BY A QUALIFIED

HEATING EQUIPMENT INSTALLER!

DO NOT USE THIS FURNACE IN A

MOBILE HOME, MANUFACTURED HOME,

TENT OR TRAILER – NO EXCEPTIONS!

Vogelzang International Corporation

400 West 17th Street

Holland, Michigan 49423

www.vogelzang.com

Phone: 1-616-396-1911

Fax: 1-616-396-1971

This furnace meets

U.S. Test Standard:

UL 391-06

SAFETY INSTRUCTIONS

SAFETY NOTICE: IF THIS FURNACE IS NOT PROPERLY INSTALLED, A HOUSE/BUILDING FIRE

MAY RESULT. FOR YOUR SAFETY, CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT

PERMITS, RESTRICTIONS, AND INSTALLATION REQUIREMENTS FOR YOUR AREA.

READ ALL INSTRUCTIONS CAREFULLY.

Refer to instru ctio n panel s, ca utio n and

warnin g plates on furnac e for ad dit iona l

information.

1. This furnace is designed to burn coal or wood fuels

only and is for INDOOR INSTALLATION ONLY.

DANGER: RISK OF FIRE OR EXPLOSION. Do

not burn garbage, gasoline, drain oil or other

flammable liquids.

2. DO NOT attempt to retrofit this unit with any type

of water coil or water jacket.

3. The installation of this furnace MUST comply

with your local building code rulings. Please

observe the clearances to combustibles (see

reference figures 1–3). Do not place furniture

or other objects within the clearance area.

4. Verify that the furnace is properly installed before firing for the first time. Obtain the services

of a professional licensed installer familiar with

all aspects of safe and correct installation. DO

NOT use temporary or makeshift compromises

during installation.

5. WARNING: Risk of Fire. DO NOT store fuel,

flammable liquids or other combustible materials too close to the unit. Refer to the certification

label on back of unit and reference clearance

instructions in this manual.

6. DO NOT INSTALL THIS FURNACE IN A MO-

BILE HOME, MANUFACTURED HOME, TENT

OR TRAILER – NO EXCEPTIONS! (HUD Fed-

eral Standard: 24 CFR Ch.XX)

7. If any parts are missing or defective, please notify the manufacturer or dealer immediately. DO

NOT OPERATE A STOVE THAT IS MISSING

ANY PARTS

8. Always connect this furnace to a chimney and

vent to the outside. NEVER vent to another

room or inside a building. DO NOT CONNECT

THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

9. DO NOT CONNECT this furnace to an aluminum

Type B gas vent. This is not safe. Use approved

masonry or a UL 103 HT Listed Residential

Type and Building Heating Appliance Chimney.

Use a 6” diameter chimney or larger, that is high

enough to provide required draft. (See specifics in

installation instructions).

WARNING: Risk of Fire. Do not operate with flue draft

exceeding

10. Inspect flue pipes, pipe joints, and flue pipe seals

regularly to ensure that smoke and flue gases are

not drawn into, and circulated by the air circulation

system.

11. Cleaning of this furnace, is especially important at

the end of the heating season. Accumulated ash

attracts moisture and may cause corrosion during

the summer months.

12. B e s u re t h a t yo u r c h i m ne y is s afe l y

constructed and in good repair. Have the chimney

inspected by the fire department or a qualified

inspector. Your insurance company may be able to

recommend a qualified inspector.

13. Creosote or soot may build up in the chimney

connector and/or chimney and cause a house,

building or chimney fire. Inspect the chimney

connector and chimney twice monthly during the

heating season and clean if necessary. (See Chimney Maintenance, page 18).

14. To prevent injury, do not allow anyone to use this

furnace who is unfamiliar with the correct operation

of the furnace.

15. D o n ot operate furnace while under the

influence of drugs or alcohol.

16. Ashes should not be allowed to accumulate higher

than the ash pan. Dispose of ashes in a metal container with a tight fitting lid. Keep the closed container on a noncombustible floor or on the ground,

well away from all combustible materials. Keep the

ashes in the closed container until all cinders have

thoroughly cooled. The ashes may be buried in the

ground or picked up by a refuse collector.

17. Build several small fires on first use. This will help

to “season” the cast iron parts and avoid cracking.

Allow furnace to cool between firings.

18. The special paints used on your furnace may

give off some smoke and an odor while they

are curing during the first 12 to 15 fires.

Additional smoke and odor may be emitted from

the light oils used in construction of the fire box.

This should disappear after a short period of time

continued on next page

Page 2 / NORSEMAN™ 1500/2500 FURNACE VGZ-018 / 051809.0

SAFETY INSTRUCTIONS continued…

and not occur again. Persons with lung conditions

or owners of susceptible domestic pets (such as

birds) should take prudent precautions. Open windows and doors as needed to clear smoke and/or

odor. Paint discoloration will occur if the furnace

is over fired.

19. This fur nace has a painted surface which is

durable but it will not stand rough handling or

abuse. When installing your furnace, use care

in handling. Clean with soap and warm water

when furnace is not hot. Do not use any acids

or sco uring so ap, as these we ar and dul l

the finish.

20. CAUTION: HOT SURFACES. Keep children

away. Do not touch while in operation. While in

operation, all persons, especially young children,

should be alerted to the hazards from high surface

temperatures and should be kept away to avoid

burns or clothing ignition.

21. If small children will be in the same room as the

furnace during operation, provide a sturdy barrier

to keep them at a safe distance from the stove.

NEVER LEAVE SMALL CHILDREN UNSUPERVISED when they are in the same room as the

stove.

22. Keep furnace area clear and free from all combustible materials, gasoline, and other flammable

vapors and liquids.

23. To prevent burns, always wear protective clothing,

leather hearth gloves and eye protection while

tending the fire.

24. WARNING: Risk of Fire. While in operation, keep

the feed door and ash door closed at all times except while tending the fire.

25. WARNING: Risk of Fire. Do not over fire the furnace. Over firing will happen if the feed door or ash

door is left open during operation. Over firing may

occur if flue draft is too great. Do not operate with

a flue draft exceeding 0.05˝ water column (0.1 Pa).

Such actions can result in very dangerous operating

conditions and risk of structure fire.

26. WARNING: Risk of Fire. Inspect and clean flues

and chimney regularly. See Chimney Maintenance

section (pg 18).

27. For fu r t her informa tion on us ing yo ur furnace safely, obtain a copy of the National Fire

Protection Association (NFPA) publication, Using

Coal and Wood Stoves Safely, NFPA No. HS-10-

1978. The address of the NFPA is Batterymarch

Park, Quincy, MA 02269.

NOTE: INSTALLATION SHOULD BE COMPLETED BY A PROFESSIONAL, LICENSED

HEATING AND COOLING CONTRACTOR ONLY.

VGZ-018 / 051809.0 NORSEMAN™ 1500/2500 FURNACE / Page 3

TABLE OF CONTENTS

SAFETY PRECAUTIONS ..................................................................................... 2

FURNACE DESCRIPTION & INSTALLATION OPTIONS .................................... 5

LOCATING THE FURNACE ................................................................................. 6

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION ............................ 7

ASSEMBLY INSTRUCTIONS ............................................................................... 8

FURNACE INSTALLATION .................................................................................. 9

WIRING DIAGRAM ............................................................................................. 10

FURNACE DIMENSIONS ................................................................................... 11

CHIMNEY CONNECTIONS ................................................................................ 12

CONNECTOR PIPE INSTALLATION ................................................................. 13

OPERATING INSTRUCTIONS ........................................................................... 15

COAL BURNING TIPS ........................................................................................ 16

BLOWER LIMIT CONTROL SETTINGS ............................................................ 17

AIR FILTER INSTRUCTIONS ............................................................................. 17

POWER FAILURE INSTRUCTIONS................................................................... 17

BLOWER FAN AND MOTOR CARE .................................................................. 17

CHIMNEY MAINTENANCE ................................................................................ 18

END OF SEASON (ASH REMOVAL) MAINTENANCE ..................................... 18

INSTALLATION ARRANGEMENT DIAGRAMS ......................................... 19 – 22

PARTS NORSEMAN™ 1500 ...................................................................... 24 – 25

PARTS NORSEMAN™ 2500 ...................................................................... 26 – 27

Page 4 / NORSEMAN™ 1500/2500 FURNACE VGZ-018 / 051809.0

FURNACE DESCRIPTION & INSTALLATION OPTIONS

Your NORSEMAN™ Solid Fuel Warm Air Furnace

is designed to provide supplemental or central heating

for your home. This solid fuel furnace may be installed

in conjunction with a central furnace that is in proper

operating condition and meets all national and/or

local building codes, safety standards, required controls

and has been installed in accordance with appropriate

standards of the National Fire Protection Association

and in accordance with the clearances specified on the

furnace nameplate.

Installation of NORSEMAN™ Furnaces must

be accomplished by a qualified heating contractor

(one who is engaged in, and is responsible for, or is

thoroughly familiar with the installation and operation

of gas, oil, and solid fuel burning heating appliances,

who is experienced in such work and familiar with all

the requirements of the authority having jurisdiction.)

The installation shall be in strict accordance with the

manufacturer’s installation instructions furnished with

the solid fuel furnace.

The chimney connector of the furnace is to be

installed to provide clearances to combustible materials not less than specified in the individual classifications and marked on the furnace. The chimney must

be suitable for use with residential type or building

heating appliances which burn solid fuel. DO NOT

CONNECT THIS UNIT TO A CH IMN EY FLUE

SERVING ANOTHER APPLIANCE.

The furnace is designed to operate in either parallel air flow arrangement with a central

furnace as shown in the diagrams or as a stand alone

central furnace. (See connection option diagrams,

figures 17 – 23, on pages 19 – 22.)

CENTRAL FURNACE INSTALLATION

As a ce n t r al furnace, t h e u nit functi o n s

independently of any other heating system. The

blower(s) will come on when the plenum temperature

reaches the setting on the blower control.

ate simultaneously. For the most efficient use of your

NORSEMAN™ Warm Air Furnace, it is recommended

that it be fired as much as possible in order to reduce

the demand on the central heating system. An optional

forced draft kit (Model DK-50) is available that operates

from a wall thermostat. When the temperature falls

below the setting on the wall thermostat, the forced

draft will come on.

T h e w ar m a i r s u p p l y ou t l et o f t h e

NORSEMAN™ Furnace MUST NOT BE CON-

NECTED TO THE COLD AIR RETURN of th e

central heating furnace because of the possibility of

overheating components of the central furnace and

causing it to operate outside the specifications for which

it was designed.

The operating external static pressure and air

temperature rise of existing furnace must be within ratings marked on the central furnace nameplate. Test for

proper operation of the central furnace after installation

of the supplementary furnace.

FURNACE SIZING

When using a NORSEMAN™ furnace in parallel

with an existing central heating furnace it is important

to select a size that is compatible with the existing unit.

For best results, the BTU rating of the NORSEMAN™

furnace should be equal to or less than the rating of

your existing furnace.

NOTICE: Installing an add-on furnace that

exceeds the listed BTU rating of the existing heating appliance may create an unsafe operating

condition.

Seek the services of a professional HVAC contractor if you have questions regarding your duct supply

system.

PARALLEL INSTALLATION

When the NORSEMAN™ Warm Air Furnace is installed in parallel with an existing central heating furnace, it is designed to turn on the

central unit blower whenever the Warm Air Furnace blower turns on. The NORSEMAN™ blower

will only come on when the temperature in the

plenum has reached the setting on the blower

control. This insures there will be sufficient warm air

in the system to provide for efficient operation. When

the central system thermostat calls for heat, the central

system will operate by igniting the burner and turning

on the blower. It is possible that both systems will oper-

VGZ-018 / 051809.0 NORSEMAN™ 1500/2500 FURNACE / Page 5

LOCATING FURNACE

NOTICE: Installation of this furnace must be done

by a qualified heating equipment installer.

C A U T I O N : F U R N AC E U N I T S A R E

HEAVY - APPROXIMATELY 450-550 LBS.

MAKE SURE YOU HAVE PROPER EQUIPMENT AND OR SUFFICIENT MANPOWER TO

PREVENT INJURY WHEN DELIVERING AND

LOCATING FURNACE UNITS.

1. The furnace must be placed on solid concrete or

masonry floor. NOTE: To reduce weight during in-

stallation remove parts from inside the firebox.

Additional weight reductions can be obtained

by removing the fire brick. Make note of position

so they are returned to the same positions.

CAUTION: DO NOT OPERATE THIS APPLIANCE

WITH CRACKED OR MISSING FIREBRICKS.

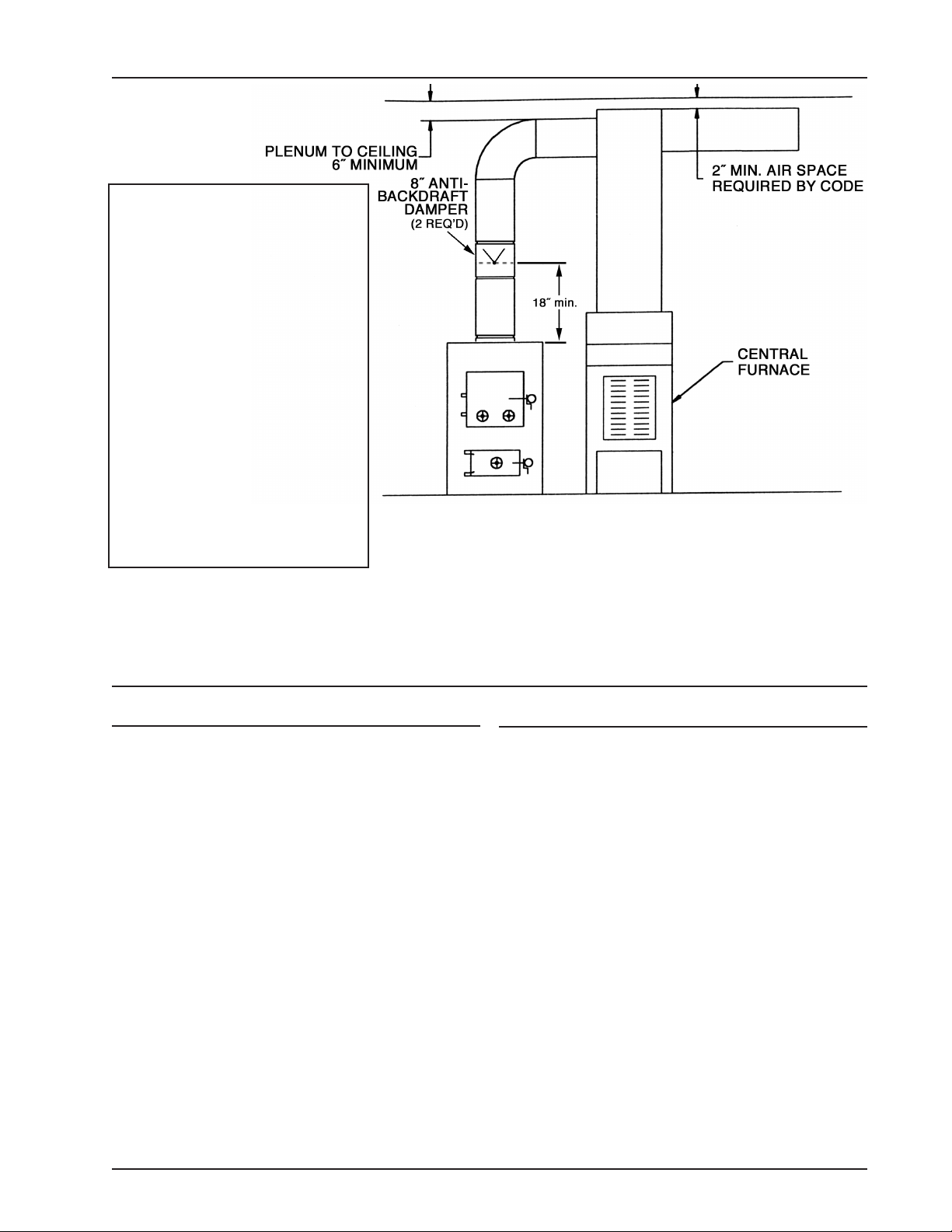

2. The furnace should be located in the same

room as the central heating system, as close as

possible but no closer than 6˝ to the central system. (See figures 16 – 23). Make sure to allow for

maintenance clearances of the central heating

system.

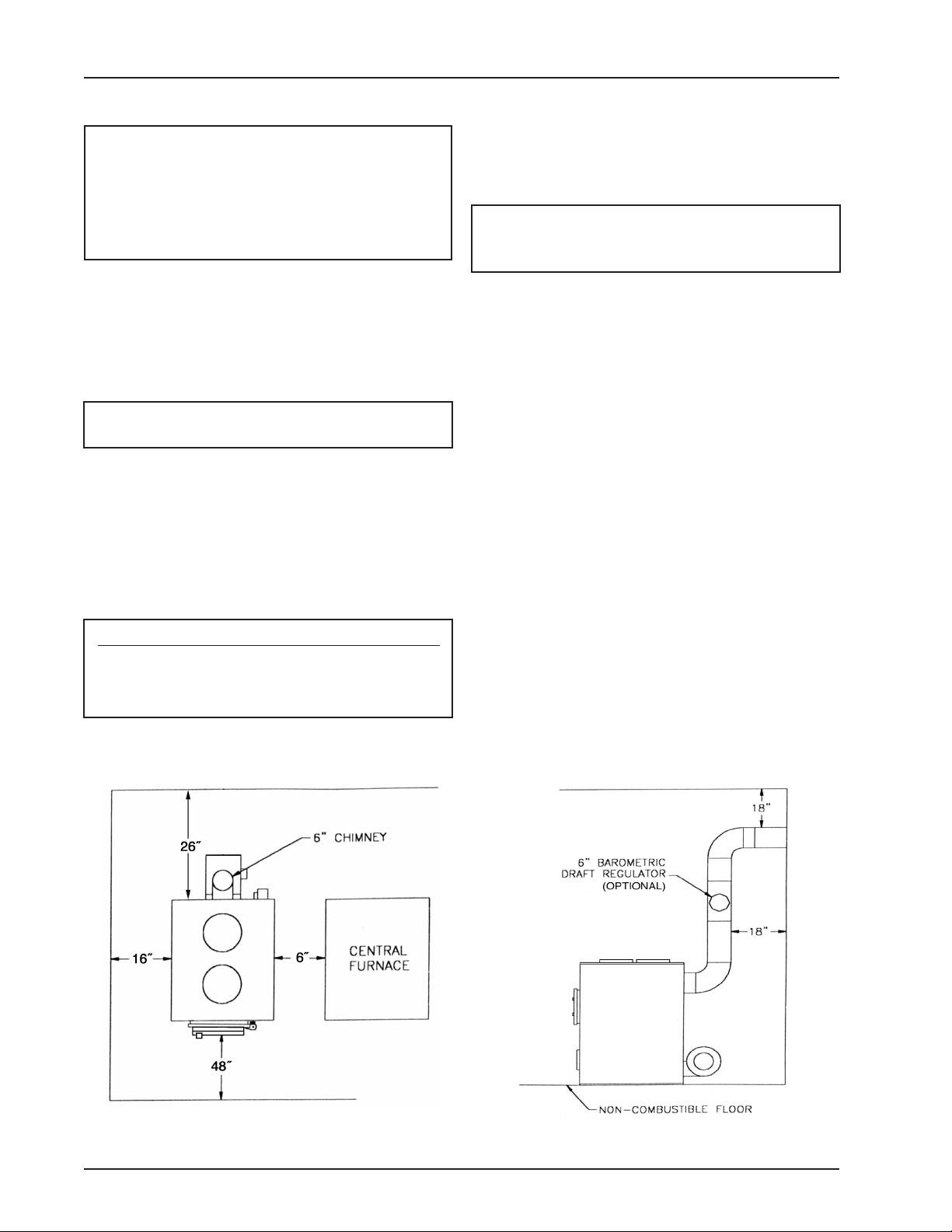

3. Obser ve the clearances to c o m bustible

materials as listed and shown in figures 1, 2 & 3.

Minimum Clearances to Combustible Surfaces

Front: 48 in. Side: 16 in. Back: 26 in.

Chimney Connectors: 18 in. Plenum to wall-

studs, joists or finished wall or ceiling: 2 in.

4. The furnace MUST have its own flue. DO NOT

CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING OTHER APPLIANCES.

5. Install furnace pipe, elbows, and thimble as

required, utilizing either a recently cleaned and

inspected 6˝ masonry chimney or a 6˝ i.d. listed UL

103 HT chimney. NOTE: A barometric draft regulator may be necessary if the chimney draft is found

to be excessive.

WARNING: RISK OF FIRE. DO NOT OPERATE

WITH FLUE DRAFT EXCEEDING 0.05˝ WATER

COLUMN (0.1 Pa).

6. Use 6˝ diameter minimum 24 MSG black or 26 MSG

blue steel furnace pipe to connect to the chimney.

DO NOT use galvanized furnace pipe. Secure pipe

sections with three (3) sheet metal screws in each

furnace pipe and/or elbow joint to firmly hold the

pipe sections together.

7. Re c h eck c l e aran c e s f rom t h e f ur n a ce,

connector furnace pipe, and corner clearances using the illustrations in figures 1 – 3 and

your local bui lding codes or fire protection

ordinances.

NOTE: A studded wall faced with brick or stone

must be considered a combustible surface.

8. DO NOT INSTALL THIS FURNACE IN A MOBILE

HOME, MANUFACTURED HOME, TENT OR TRAILER.

NO EXCEPTIONS! (HUD Federal Standard: 24 CFR Ch.XX)

9. The clearances provided are minimum dimensions determined by the manufacturer’s testing

facility in accordance with U.S. Test Standard

UL 391-06. Installation of this fur nace must

comply with the latest edition of NFPA 211 for reduced clearances and/or your local building code

rulings (use whichever minimum dimensions are

LARGEST).

Fig. 1 – TOP VIEW

Minimum Clearances from Combustible Surfaces

Minimum Clearances from Combustible Surfaces

Fig. 2 – SIDE VIEW

Page 6 / NORSEMAN™ 1500/2500 FURNACE VGZ-018 / 051809.0

LOCATING FURNACE continued…

WARNING: RISK OF FIRE

• DO NOT STORE FUEL, FLAMMABLE LIQUIDS OR OTHER

CO MBU STI BLE MATE RIALS

TOO CLOSE TO THE UNIT.

• Keep furni shi ngs and

OTHER COMBUSTIBLE MATERIALS OUTSIDE OF CLEARANCE

DIMEN S I ONS MAR K E D ON

FURNACE.

• Before firing furnace,

SLIDE FIREBRICKS TOWARDS

REAR SO NO GAPS REMAIN

BETWEEN BRICKS. DO NOT

OPERATE FURNAC E WI T H

CRACKED OR MISSING FIRE

BRICKS.

Fig. 3 – Minimum Plenum Clearances from Combustible Materials

TOOLS & MATERIALS REQUIRED FOR ASSEMBLY

AND INSTALLATION

TOOLS REQUIRED

Safety Glasses

Gloves

Pencil

6 ft. Tape Measure

Tin Snips

Sabre Saw

Drill

1/8” dia. Drill Bit (for sheet metal screws)

Screwdrivers (Phillips & slotted)

6mm Socket with Driver

10mm Socket with Driver

10mm open end box wrench

7/16” box wrench

NOTE: The following items are NOT included with

your furnace:

Chimney Connection:

6” da. minimum 24 MSG black or 26 MSG blue steel

straight furnace pipe, elbow(s), collar and thimble (as

required).

6˝ Barometric Draft Regulator (optional)

8˝ Round Butterfly Anti-Backdraft Damper

(2 required – for parallel installation only)

Plenum & Duct Work with min. temperature rating of

250° F (as required).

Chimney: Existi ng 6” Lined Masonry Ch imney

or 6” Inside Dia. Listed Type HT chimney.

1/2” Sheet Metal Screws

Electrical Wiring: 16 ga. AWG copper with 90° C min.

DO NOT use aluminum wire or connectors.

1/2˝ Conduit & Connectors

Furnace Cement (manufacturer recommends Rutland

Code 78 or equivalent)

MATERIALS REQUIRED

VGZ-018 / 051809.0 NORSEMAN™ 1500/2500 FURNACE / Page 7

ASSEMBLY INSTRUCTIONS

Your N ORS E M AN™ W a r m A i r F ur n a ce

requires the following items to be assembled or installed

by the furnace installer:

Feed Door Pull Handle/Thermostat Assembly

Feed Door Locking Handle

Blower(s) and Blower Control

Electrical Connections

1. Remove all parts from inside the furnace and

inspect for damage, including the firebrick as

some breakage could occur during shipment.

Do not operate furnace with broken or miss-

ing fire box bricks. Replace damaged bricks

before operating furnace.

2. Assemble the feed door pull handle as shown in

figure 4. Install thermostat assembly and cover as

shown.

3. Align thermostat control knob with flat on thermostat

control shaft and press onto shaft (figure 4).

4. Attach feed door locking handle as shown in

figure 5 with screws and nuts provided.

Note: Slotted holes are for adjustment of handle.

Adjust handle until pressure is required to lock feed

door.

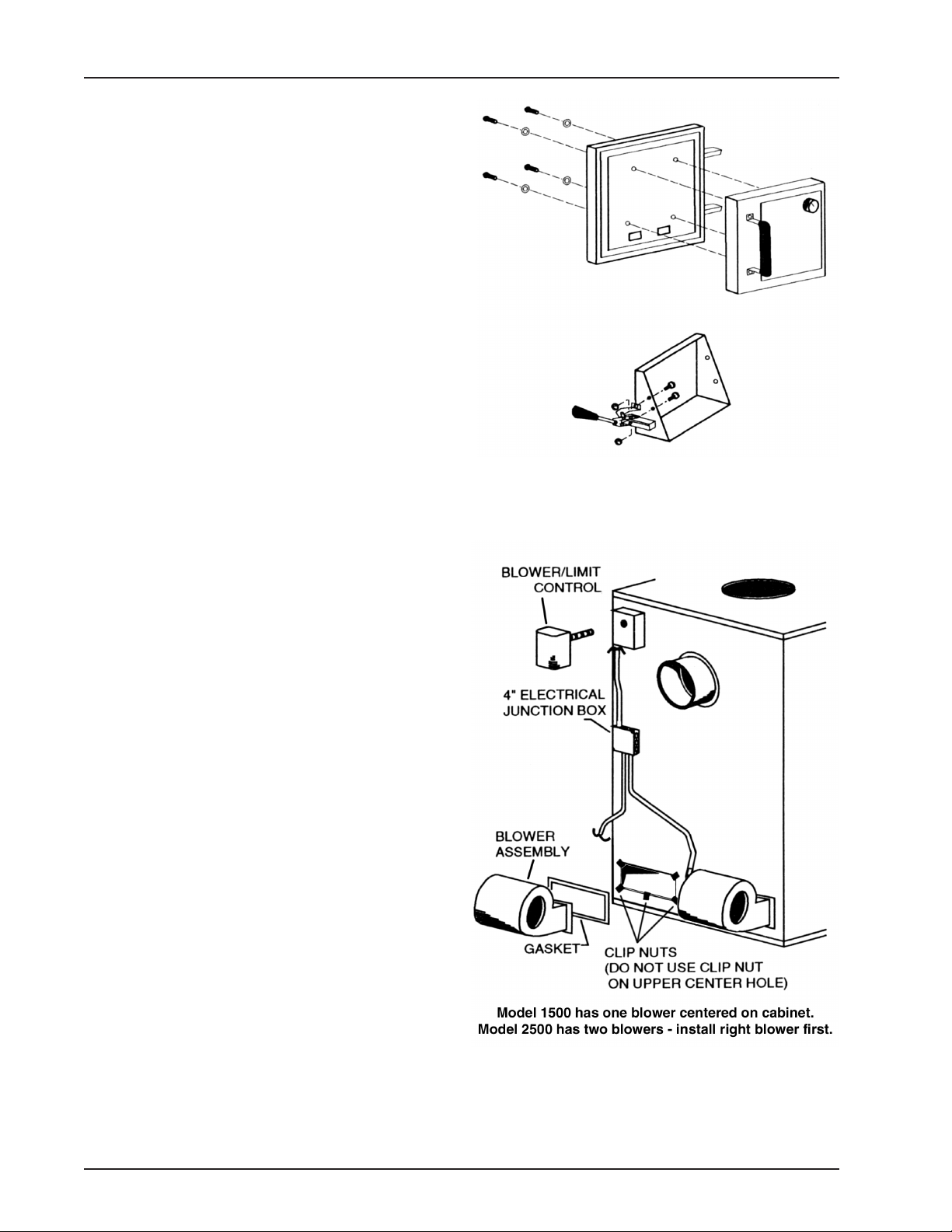

5. Install Blower/Limit Control on rear of furnace

cabinet as shown in figure 6 using three (3) sheet

metal screws.

6. Remove blower(s) from carton(s). Attach the flex-

ible conduit/wire assembly to the blower(s) before

mounting.

7. Remove junction box cover and take out the mount-

ing hardware package. Position clip nuts to furnace

housing around blower opening as shown in figure

6. On Model #2500, install the right (when facing

rear of furnace) blower first. Install the blower(s)

with gasket using 1/4-20 x 3/4˝ bolts.

8. Secure the 4 inch square electrical junction box to

the black bracket on the rear of the stove using two

(2) sheet metal screws.

9. Wire blower according to the wiring diagram shown

in figure 7/8. On model 2500, wire right side blower

first (see figure 7). Replace junction box cover when

complete. Use 16 ga. AWG rated for 90° C min.

10. Check operation of shaker grates with grate handle

before loading fuel in furnace.

Fig. 4 – Door/Handle/Thermostat Assembly

Fig. 5 – Feed Door Handle Assembly

Fig. 6 – Blower Assembly

Page 8 / NORSEMAN™ 1500/2500 FURNACE VGZ-018 / 051809.0

FURNACE INSTALLATION

NOTE: INSTALLATION MUST BE MADE BY A

QUALIFIED HEATING EQUIPMENT INSTALLER

(one who is engaged in, and is responsible for, or is

thoroughly familiar with the installation and operation

of gas, oil, and solid fuel burning heating appliances,

who is experienced in such work and familiar with all the

building requirements and/or fire codes of the authority

having local jurisdiction.)

This is a furnace, not a stove. Heated air must be

directed away from the furnace or it will not operate

properly.

1. Th e i nst a l l ati o n i s to b e c o mple t e d i n

acco r dance with Nationa l Fire Prote c t ion

Association (NFPA) installation standards No.

89M, 90B, 211, 70 (National Electrical Code) and

Uniform Mechanical Code 913, 6-4 in states where

applicable (where code offers making flue pipe

connections into an existing chimney with other

fuel burning appliances).

2. Wood /coal burning appliance s need air for

combustion and circulation to the house.

Provision must be made to provide make up

ai r so as not to st arve th e central heat ing

system of combustion air. Have the local regu-

lating authority determine that make up air

supply is adequate. Reference NFPA standards

No. 30 & 54, Code for Installation of Gas and Oil

Equipment.

3. H a ve t he l o cal r e gul a t ing a uth o r ity o r

qua l ifie d expert inspe ct all chimneys and

ins talla tions for adequa te vent ing and fo r

compli anc e with stan dar d local co des and

regulations regarding installation of wood/coal

burning appliances. (Also see Pipe Installation on

following pages.)

4. Po s i t i on the furnace according t o c l e a r -

ances shown in figures 1–3 and to maintain

chimney connections as short as possible. Avoid

unnecessary turns and installation of devices that

would create excessive resistance to the flow of

flue gases.

5. Make flue pipe connections to the chimney

with 6” dia. minimum 24 MSG black or 26 MSG

blue steel pipe and elbows (not included with

furnace) maintaining proper clearances. DO

NOT use galvanized pipe for chimney connec-

tions. Seal the flue pipe in the chimney with

furnace cement. (Chimney connections must be

securely supported and connections fastened with

3 sheet metal screws at each joint.)

6. For parallel installations, install (two) 8˝ anti-backdraft butterfly dampers (Vogelzang Model AD-8, not

included with the furnace) in the heat (duct) pipes

a minimum of 18 inches above the furnace

plenum. Anti-backdraft butterfly dampers may be

obtained where you purchased your appliance or

from a local HVAC distributor.

7. Install 8˝ diameter 26-gauge heat (duct) pipe

and connectors (not included with furnace) to

make connection to the plenum of the central

heating system. The heat pipe, plenum, and

connections must be constructed of metal with

a minimum temperature rating of 250° F. If

cen tral air co nditi onin g is in stall ed in the

plenum, i n s t a l l h e a t p ip e above t h e a i r

condi t i o n i n g u n i t . S e c u r e th e h e at p i p e

connec tion with su ppor t s and sheet meta l

screws.

8. Make ele ctric al sup ply con nect ions in th e

ele ctri cal jun ction box and con nect powe r

supply wires to designated wires using wire nuts

(see wiring diagram figure 7 & 8). The power cord

supplied may be used for installation if local codes

and regulations permit. If not permitted, power

supply wiring must be minimum of 16 ga. AWG

copper and rated for 90° Centigrade installed in a

metal cable or conduit. Power connections should

be made by a qualified installer to comply with

NFPA Standard No. 70 and all local codes and

regulations.

VGZ-018 / 051809.0 NORSEMAN™ 1500/2500 FURNACE / Page 9

Loading...

Loading...