Page 1

PFW6855

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

9531-060-Z00-01

www.vogels.com

Page 2

Refer to

Step:

PFW6855

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

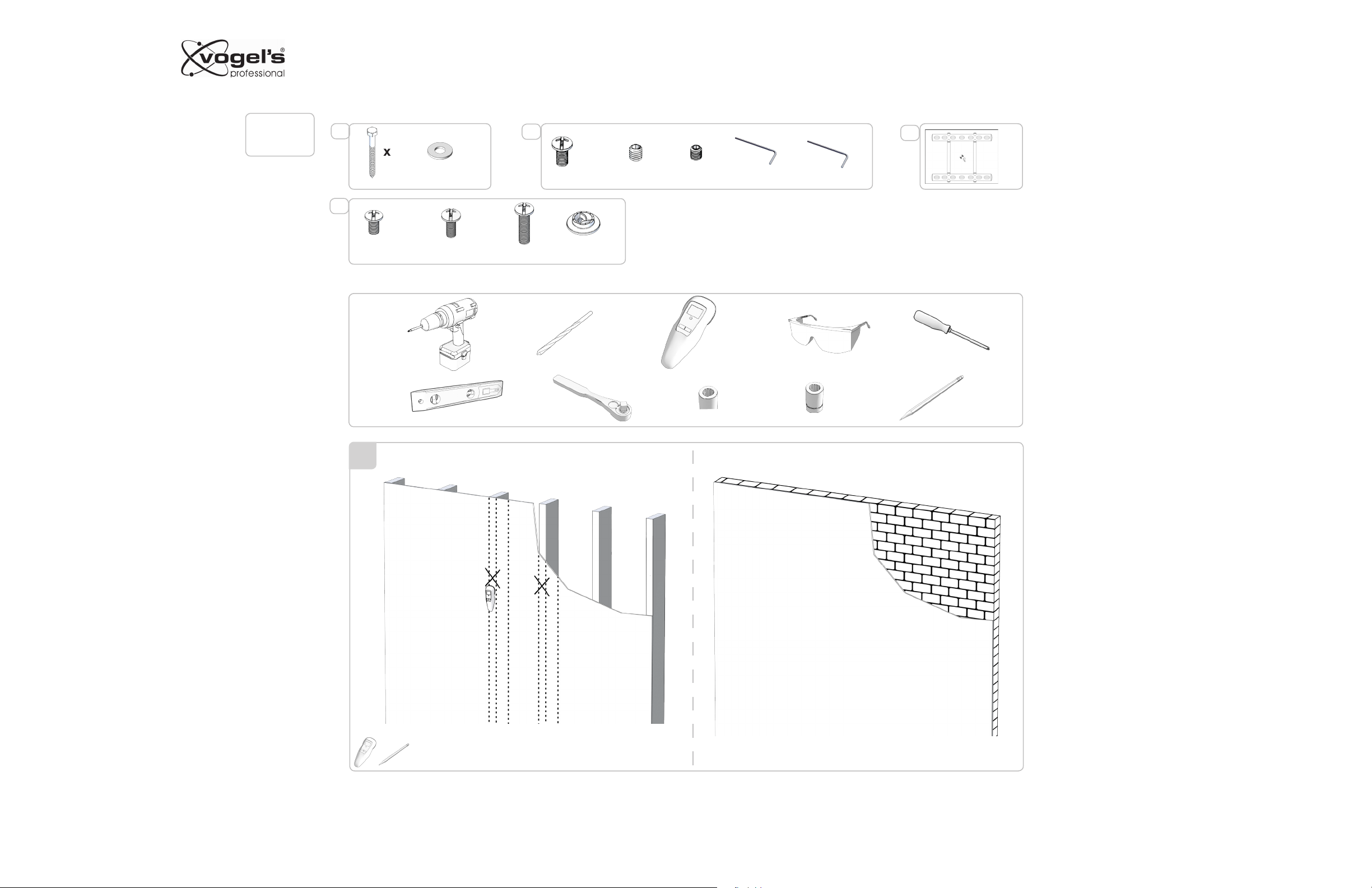

Included components

3

x6

x6 x2

10

x4

x2

x1

x1

3

x1

5/16” x 3”

10

5/16” M6 x 12mm M8 x 10mm

x4 x4 x4

M8 x 16mm M8 x 20mm M8 x 30mm

Required for installation

1

1

1/4” / 6.5mm

x8

M5 x 6mm

Stud Finder

M10 1/2 ”/13mm

5/32”

2.5mm

Drill Template

Note: It is extremely important that this installation be

carried out by well qualified installation personal and the

mounting surface capable of supported the weight of the

display mount together through out the articulating range of

the PFW6855 series mount.

9531-060-Z00-01

www.vogels.com

Page 3

PFW6855

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

1

3

2

4

2 3

Take the mounting template supplied insure the template

is centered and level at the desired height on the mounting

surface. Mark the mounting hole (six recommended) three

on top and three on bottom.

Note: drill mounting pilot holes to a proper depth to insure

the lag or wedge anchor bolts are fully engaged into the

hole.

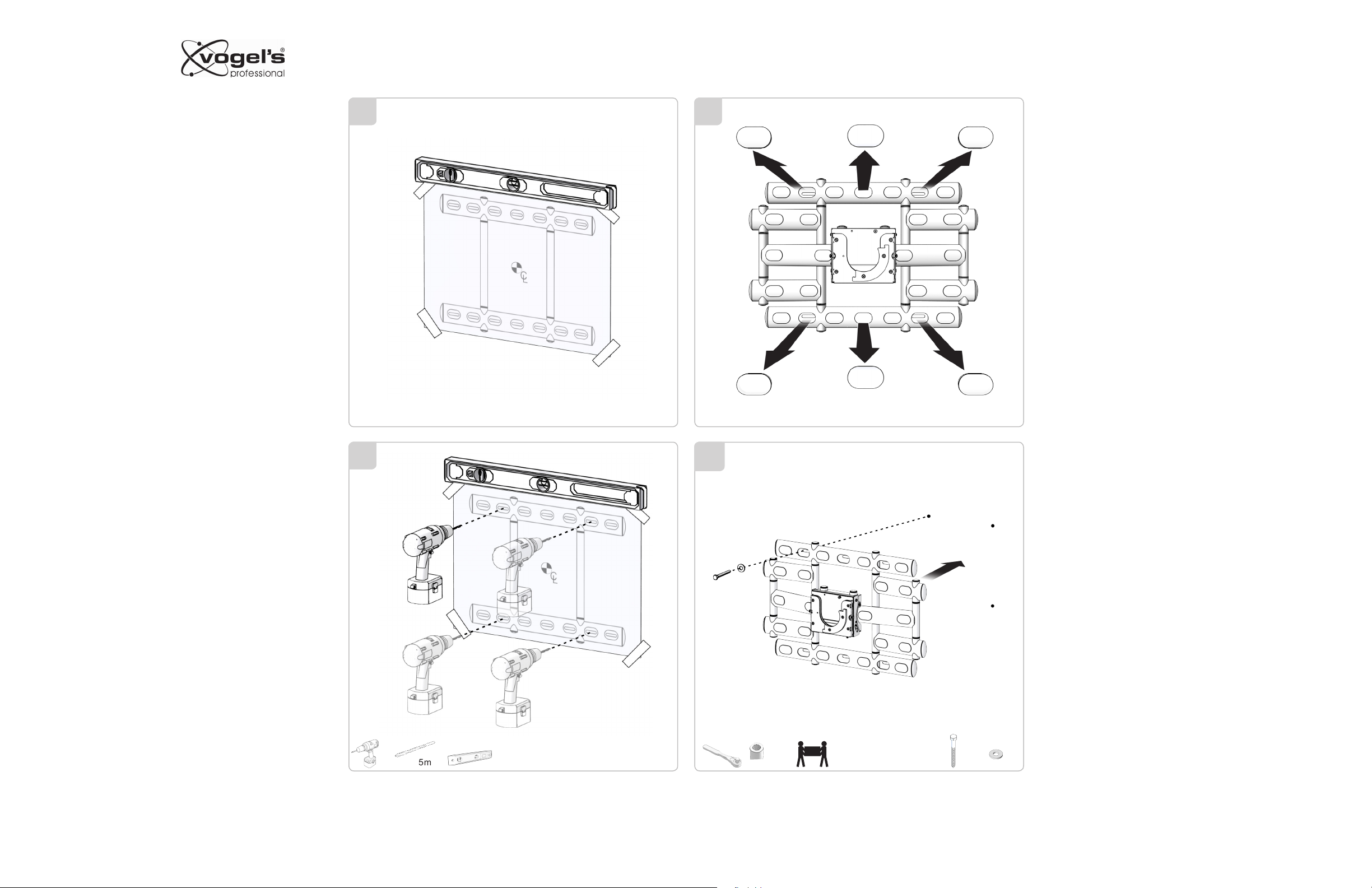

3

5

1/4” / 6.5mm

4

6A

4 5

1/2 ”/13 mm

x1

With minimum two people place the PFW6855 wall plate

assembly and secure to the wall using the top center hole of

the wall plate.

With a spirit level place on top of the wall plate level the

mounts than secure the remaining bolts through the wall

plate to the wall.

x1

9531-060-Z00-01

www.vogels.com

Page 4

6

PFW6855

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

6B 7

1

2

7

Remove the two security screws from the right and left side

of the mounting bracket crossbar and slide the two mounting

brackets inside the left and right side security screw hole

and reinstall the two security screws.

Remove the two security screws from the right and left side

of the mounting bracket crossbar and slide the two mounting

brackets inside the left and right side security screw hole

and reinstall the two security screws.

8 9

3

8

1/2 ”/13mm

x4

x4

9A

4

Make sure to keep space between

the bracket and display.

9531-060-Z00-01

www.vogels.com

5/32”

x4

M8 x 16 mm

or

x4

M8 x 20 mm

or

M8 x 30 mm

x4

Page 5

PFW6855

C

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

9B

1

5/32”

Make sure to keep space between

the bracket and display.

2

10

5/32”

Invert the flat panel display and place it on a smooth flat

surface so the back of the display panel is facing up.

Align the two mounting bracket to the four mounting points

on the rear of the display and secure them bracket to the

display with the proper “pitch” supplied hardware. Check the

owners manual to determine correct pitch hardware recommended.

Once the mounting brackets are secured to the rear of the

display, align the round portion of the cross bar so it is on

dead center of the display from left to right side.

Secure the cross bar to the bracket using the four Allen

head screws supplied.

L

x4

3

11A

411B

9531-060-Z00-01

www.vogels.com

Page 6

PFW6855

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

Remove the 6mm knurl knob safety screw and set it aside.

1

12

2

13

Note: appropriate number of personal and possible installation lift aids lift and insert the round portion of the crossbar

with display attached and safely insert the round portion of

the cross bar into the open round receiver por tion on the

wall mount.

With the cross bar fully seating

into the receiver reinstall the

6mm safety knurl knob.

3

Once all mounting points and level of the display have been

41514

confirmed, remove the plastic covers to route cable from the

wall to the display.

9531-060-Z00-01

www.vogels.com

Page 7

PFW6855

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

Power and signal cables may be conveniently run through

the arms of the mount between the display and the power

and signal source to assist in the clean look of the cable

installed.

Note: Once cables have been installed carefully check the

movement of the mount and cables together to insure their is

no “pinching of the cables” when the mount is ar ticulated.

1

16

2

17

The two side mounted screws in the receiver head of the

mount can be adjusted to add or subtract tension in the rotation of the display in the mount.

The PFW6855 has a unique “load offset adjustment” feature

that allow for the heavier weight displays to be tilt corrected

past base center back to level from top to bottom. With

personal lifting gently “out “ on the bottom of the display a

9/16” (14mm) socket may be used to increase or decrease

the tilt feature of the mount.

3

=14mm wrenc h socket

M10

41918

M2.5

With the 2.5mm Allen head wrench supplied, install the two

each M5 x 6mm mini adjustment Allen head screws supplied

to both sides of the “rotation” stop bar. Slowly turn the display

to the level position in each direction and adjust the two adjust

screw to set max rotation in each direction to level.

x2

M5 x 6 mm

9531-060-Z00-01

www.vogels.com

Page 8

4

1

3

2

6

5

3

2

1

6

4

5

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

3106-000-037-XX

MOUNTING BRACKET ASSEMBLY LARGE

(ELLIPTICAL)

2

2

3106-000-035-XX

SWIVEL TUBE ASSEMBLY (LARGE)

1

3

6095-PSD-E-E

PLASTIC CAP (ELLIPTICAL TUBE 3.149 X

1.574 )

2

4

0474-061-104-6X

SCREW PAN PHILLIPS COMB (M6X1.0 X 12)

2

5

1658-079-091-6X

SET SCREW CUP POINT ( M8 X 1.25 X 10 )

4

6

1658-052-061-6X

SET SCREW CUP POINT ( M5 X 0.8 X 6 )

2

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

3106-000-035-XX

SWIVEL TUBE ASSEMBLY (LARGE)

1

2

6095-PSD-E-E

PLASTIC CAP (ELLIPTICAL TUBE 3.149 X 1.574 )

2

3

0474-061-104-6X

SCREW PAN PHILLIPS COMB (M6X1.0 X 12)

2

4

3106-000-038-XX

MOUNTING BRACKET ASSEMBLY XLARGE (ELLIPTICAL)

2

5

1658-079-091-6X

SET SCREW CUP POINT ( M8 X 1.25 X 10 )

4

6

1658-052-061-6X

SET SCREW CUP POINT ( M5 X 0.8 X 6 )

2

PFW6855

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

9

1

108 6

5

6

21

20

18

3

22

12

14

ITEM NO.

17

2

19

13

7

16

11

QTY.

PART NO.

1 2

2 2

3 2

4 2

5 2 2482-22-AM3 01

6 26 2482-23-AM3 00

7 10

8 8

9 12

10 20 2482-36-AM3 01

11 10

12 2

13 12

14 1

15 2

16 10

17 10

18 2

19 8

20 1

21 2

22 1

3106-000-032-XX

3106-000-031-XX

3106-000-033-XX

2482-21-AM3 01

0700-205-226-XX

6095-PSD-E-E

0477-087-147-6X

204X-57A-L00-69

204X-578-502-10

204X-86B-N00-28

3106-000-022-XX

3106-000-013-XX

2270-45A-E01-45

0548-061-077-6X

3106-000-003-XX

1658-061-077-6X

3106-000-024-XX

0422-061-104-6X

0562-061-077-6X

REV

DESCRIPTION

00

WALL BRACKET TUBE WELDED ASSEMBLY (ELLIPTICAL)

01

DOUBLE ARM TUBE WELDED ASSEMBLY

00 SHORT ARM WELDED ASSEMBLY (ELLIPTICAL)

SHAFT .75 X 12" LONG

SHAFT .75 X 20" LONG

COVER,OBLONG HOLE COVER (PLASTIC)

00

TUBE/PIPE END CAP COVER 1.181 X 1.375 X .616

00

PLASTIC CAP (ELLIPTICAL TUBE 3.149 X 1.574 )

HEX FULLY THREADED 3/8"-16 x 3/4"

BUSHING FLANGE DIE CAST .750 ID X 1.180 OD X 1.395 FLANGE .

3/8" WASHER NON-STD (.405 ID) X (1.062 OD) X (.098 THK)

3/8" WASHER NON-STD (.406 ID) X (.748 OD) X (.066 THK)

WASHER DELRIN (.765 ID) X (1.400 OD) X (.020 THK)

03

ROTATIONAL MOUNT ASSEMBLY

00

SHAFT .75 X 6.67" LONG

00

1" X .3 VINYL FEET

SCREW TRUSS HEAD COMBO PHILLIPS (M6X1.0X8)

00

INTERNAL ROTATION TUBE

SET SCREW CUP POINT ( M6 X 1.0 x 8 )

00

ROTATIONAL STOP

SCREW FLAT 90 DEGREES PHILLIPS (M6 x 1.0 x 12)

00

SCREW KNURL KNOB PHILLIPS (M6X1.0 X 8)

1

ITEM NO.

1

2

3

4

5

6

3

PART NUMBER

3106-000-036-XX

6095-PSD-E-E

3106-000-034-XX

0474-061-104-6X

1658-079-091-6X

1658-052-061-6X

MOUNTING BRACKET WELD ASSEMBLY

PLASTIC CAP (ELLIPTICAL TUBE 3.149 X

SCREW PAN PHILLIPS COMB (M6X1.0 X 12)

SET SCREW CUP POINT ( M8 X 1.25 X 10 )

SET SCREW CUP POINT ( M5 X 0.8 X 6 )

4

DESCRIPTION

(ELLIPTICAL)

1.574 )

SWIVEL TUBE ASSEMBLY

5

2

QTY.

2

2

1

2

4

2

415

9531-060-Z00-01

www.vogels.com

Loading...

Loading...