Page 1

PFW 6854

Display Wall Mount, Rotating

INSTALLATION INSTRUCTIONS

9531-009-Z00-00

Page 2

PFW 6854

Table of Contents

Warning Statements 2

Parts List 3

Installation Tools 3

Thread Depth Indicator 6

Mount Installation 7

Concrete Mounting 8

Universal Mounting Bracket Installation 8

Display Orientation 10

Technical Specications 10

Warranty 11

Warning Statements

PRIOR TO THE INSTALLATION OF THIS PRODUCT, THE INSTALLATION INSTRUCTIONS SHOULD BE READ AND

COMPLETELY UNDERSTOOD. THE INSTALLATION INSTRUCTIONS MUST BE READ TO PREVENT PERSONAL

INJURY AND PROPERTY DAMAGE. KEEP THESE INSTALLATION INSTRUCTIONS IN AN EASILY ACCESSIBLE

LOCATION FOR FUTURE REFERENCE.

VOGEL’S DOES NOT WARRANT AGAINST DAMAGE CAUSED BY THE USE OF ANY VOGEL’S PRODUCT FOR PURPOSES OTHER THAN THOSE FOR WHICH IT WAS DESIGNED OR DAMAGE CAUSED BY

UNAUTHORIZED ATTACHMENTS OR MODIFICATIONS, AND IS NOT RESPONSIBLE FOR ANY DAMAGES, CLAIMS,

DEMANDS, SUITS, ACTIONS OR CAUSES OF ACTION OF WHATEVER KIND RESULTING FROM, ARISING OUT OF OR

IN ANY MANNER RELATING TO ANY SUCH USE, ATTACHMENTS OR MODIFICATIONS.

THE SURFACE MUST BE CAPABLE OF SUPPORTING AT LEAST FIVE TIMES THE WEIGHT OF THE DISPLAY. IF NOT,

THE SURFACE STRUCTURE MUST BE REINFORCED. THE MAXIMUM WEIGHT THAT CAN BE USED WITH THIS

PRODUCT IS 160LBS. PROPER INSTALLATION PROCEDURE BY A QUALIFIED SERVICE TECHNICIAN, AS OUTLINED

IN THE INSTALLATION INSTRUCTIONS, MUST BE ADHERED TO. FAILURE TO DO SO COULD RESULT IN SERIOUS

PERSONAL INJURY, OR EVEN DEATH.

SAFETY MEASURES MUST BE PRACTICED AT ALL TIMES DURING THE ASSEMBLY OF THIS PRODUCT. USE

PROPER SAFETY GEAR AND TOOLS FOR THE ASSEMBLY PROCEDURE TO PREVENT PERSONAL INJURY.

At least two qualied people should perform the assembly procedure. Injury and/or damage can result from dropping or mishandling

the display.

If mounting to studs, make sure that the mounting screws are anchored into the center of the studs. Use of an edge-to- edge stud nder

is recommended.

Be aware of the mounting environment. If drilling and/or cutting into the mounting surface, always make sure that there are no electrical wires in wall. Cutting/drilling into an electrical line may cause serious injury.

Make sure there are no water lines inside the wall where the mount is to be located. Cutting/drilling into a water line may cause

severe water damage to the mounting surface.

This product is intended for indoor use only. Use of this product outdoors could lead to product failure and personal injury.

Do not install near sources of high heat. Do not install on a structure that is prone to vibration, movement or chance of impact

Page 2 Installation Instructions

Page 3

Parts List

PFW 6854

Universal Mounting Brackets (Qty 2)

5/16” x 3” Lag Bolts - wooden studs

This mount is shipped with all installation hardware and components. Make sure that none of these parts are

missing and/or damaged before beginning installation.

only (Qty 6)

PFW 6854 Mounting Bracket (Qty 1)

5/16” Flat Washers

(Qty 6)

M6 Knurl Knob

(Qty 1)

Rotating Universal Bracket Bar (Qty 1)

Griplate™ (Qty 8)

Installation Tools

Phillips Head Screw Driver Soft Material/Blanket 1/2” Socket and Wrench

Pencil Tape Measure Drill Gun

Level (Supplied) M5 Allen Wrench (Supplied) 5/32” Allen Wrench (Supplied)

1/4” Drill Bit (Pilot Holes) Thread Depth Indicator (Supplied)

Masonry Drill Bit (Concrete Applications - Commercially Available)

Installation Instructions Page 3

Page 4

PFW 6854

(Qty 8)

M6 x 20

(Qty 8)

(Qty 4)

(Qty 8)

(Qty 8)

(Qty 8)

(Qty 8)

M6 x 30

M6 x 45

(Qty 8)

M8 x 25

M8 x 20

(Qty 8)

(Qty 8)

(Qty 8)

(Qty 8)

(Qty 8)

M8 x 35

M8 x 30

(Qty 8)

M8 x 70

M8 x 45

(Qty 8)

M4 x 16

M4 x 25

M5 x 12

M5 x 20

M5 x 25

M5 x 16

M5 x 50

M6 x 16

(Qty 8)

(Qty 8)

Page 4 Installation Instructions

Page 5

PFW 6854

The nylon spacers may be stacked to achieve proper spacing.

1/4" Nylon spacer s

(large )

9/16" Nylon spacer s

(Qty 8 )

(Qty 8 )

1/2" Nylon spacer s

(large )

(Qty 12)

Nylon sleeve s

(Qty 8 )

5/16" Flat washers

(metal )

(Qty 8 )

1" Nylon Spacers

(Qty 8 )

1/4" Nylon spacer s

(small )

(Qty 8 )

Installation Instructions Page 5

Page 6

PFW 6854

Thread Depth Indicator

1. Insert the thread depth indicator (supplied) through the thread inserts found on the back of the at panel to make sure the inserts

measure the same full depth and mark it (Figure 1).

2. Locate the correct diameter screw for the thread insert. Compare your marking to the screws (supplied).

3. If your selected screw is longer than the marking on the thread depth indicator, DO NOT USE this screw.

4. The screw length must not bypass the marking. Select another screw size (Figure 2 and 3), until you nd one that comes closest to

your mark without going past.

Inverted Fla t

Panel Displa y

Marking the

Dept h

Figure 1

Scre w

Thread Depth

Indicato r

Figure 2 Figure 3

Marking

Scre w

Thread Depth

Indicato r

Thread Inser t

Thread Depth

Indicato r

Marking

Page 6 Installation Instructions

Page 7

Mount Installation

PFW 6854

Step 1

Determine where the mount location will be. Use a stud nder

to locate the nearest wall stud.

For ease of installation, it is recommended that two people perform the installation. One person should hold the

mount while the other person installs the lag bolt and washer. Making sure that the mount is level, the person not

holding the mount must mark and drill the second mounting hole and secure the second lag bolt and washer.

Step 2 Step 3

Once the stud has been located, use a pencil

to mark the spot.

Using a 1/4” drill bit, drill the upper mounting hole where the mark was made.

Step 4

After the holes have been pre-drilled,

line up the mounting slot openings

with the pre-drilled holes.

Do NOT over-tighten lag bolts when attaching the mount to the wall. Improper installation may result in personal

injury or damage to property.

If the studs are 12” (304.8mm) apart, use three (3) 3” (76.2mm) lag bolts for the top rail and three (3) 3” (76.2mm)

lag bolts for the lower rail. If the studs are 16”(406.4mm), 18” (457.2mm) or 24” (609.6mm) apart, use two (2) 3”

lag bolts for the top rail and two (2) 3” lag bolts for the lower rail.

Step 5

Insert two (2) 5/16” x 3” lag bolts

and washers into the mounting holes

and tighten (see WARNING: below

Place a level (supplied) on the top

rail and make sure that the mount is

level. Once the mount is level, Drill

pilot holes in the lower mounting

slots and install two (2) 5/16” x 3”

lag bolts and washers into the mounting holes and tighten.

Step 6

Installation Instructions Page 7

Page 8

Concrete Mounting

PFW 6854

1. Begin by placing the mount into position against the wall, keeping it level.

2. Mark o four holes to be used for securing the mount.

3. Next, drill holes using a masonry bit for your anchors (recommended masonry bit).

4. Insert a commercially available concrete anchor into each hole (recommended 3/8” wedge anchors).

5. If necessary, a hammer can be used to lightly tap each anchor into place so that they are ush with the wall.

6. Once all of the anchors are in place, move the wall bracket into position.

7. Attach the nut onto the threaded shaft that is protruding from the wall.

8. Do not tighten until all nuts are in place.

Concrete anchors must be used for concrete installation. They can be purchased at your local hardware store. The

mounting surface must be a minimum 6” thick.

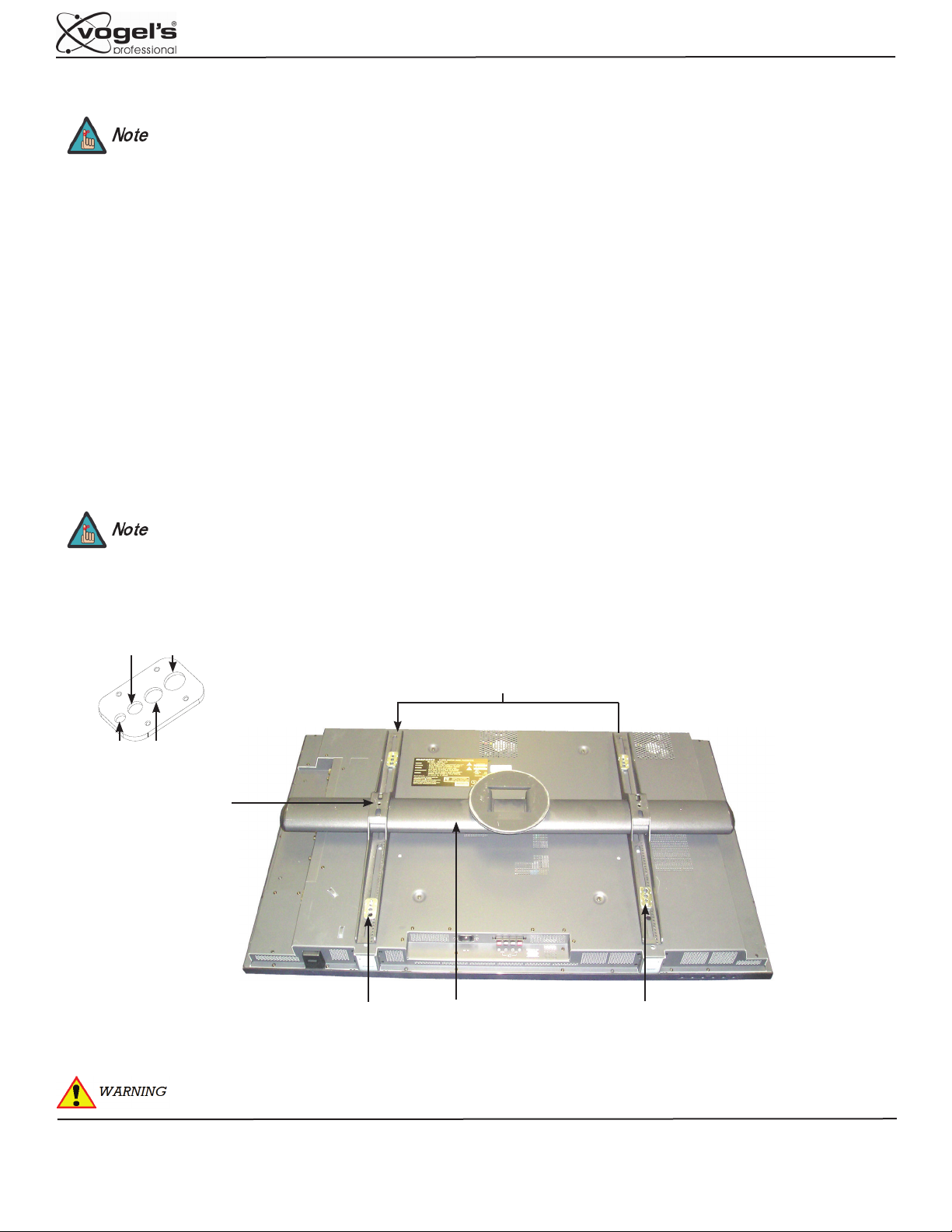

Universal Mounting Bracket Assembly

1. Place the universal bracket bar and the universal brackets on a at surface.

2. Slide the universal brackets onto the universal bracket bar (as shown below) with the set screws facing up. At this

time, do not tighten the set screws that are located on the universal bracket.

3. Place the display on a soft, at surface, face-down. Next, place the universal bracket assembly on the back of the

display, with the universal brackets resting directly over the display mounting points.

4. Once the desired position has been determined, place the Griplate™ washers over each mounting point and secure

them using the appropriate hardware (see Page 5).

5. At this time, center the universal bracket bar and tighten the set screws that are located on the universal brackets.

For the two upper mounting points, the Griplate™ at side must be facing up. For the two lower mounting points, the

Griplate™ at side must be facing down.

M5

M4

M8

Universal Mounting Brackets

M6

Set Screw

Griplate™

IT WILL TAKE TWO PEOPLE TO COMPLETE THE NEXT INSTALLATION STEP.

Universal Bracket Bar

Griplate™

Page 8 Installation Instructions

Page 9

6. Lower the universal bracket bar with attached

display into the cradle (as shown to the left).

Nylon

Sleeve

PFW 6854

After loosening the tension bolts, be sure that the

nose piece is held together tightly before rotating.

Knurl Knob Mounting Point/M6 x 12mm Security Head and

M6 Lock Washer Mounting Point.

7. Insert an M6 Knurl Knob/M6 x 12mm Security

Head and M6 Lock Washer into the knurl knob/

security screw mounting point and tighten.

To access the knurl knob/security screw

location while the display is attached, the

PFW 6854 must be rotated to the “portrait”

position (vertical position

8. Tighten the two (2) Phillips head screws (located

on the side of the mounting block) once the nal

position is attained.

Locking Screws

Installation Instructions Page 9

Page 10

Display Orientation

The PFW 6854 will allow the user to adjust the display a full 360°.

BEFORE ROTATING THE PFW6854, MAKE SURE THAT THE M6 KNURL KNOB IS SECURELY FASTENED

TO THE PFW 6854. ALSO, PLEASE MAKE SURE YOU ALLOW ENOUGH CABLE AND WIRE CLEARANCE FOR FULL ROTATION.

M6 Knurl Knob

1. To adjust the PFW 6854, rotate the display either

clockwise or counter-clockwise.

PFW 6854

Technical Specications

All measurements are in inches (mm).

37.20

944.9

20.00

508

34.30

871.2

19.93

21.00

506.1

533.4

3.73

94.7

9.91

251.6

2. Tighten the two Phillips

head locking screws (see Step 8,

Page 10).

20.00

508

19.00

482.6

16.00

406.4

8.30

210.9

12.00

304.8

.38

9.5

3.15

80

360

ROTATION

1.13

28.8

.41

10.3

Page 10 Installation Instructions

Loading...

Loading...