Page 1

PFT8857

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

9531-060-Z05-00

www.vogels.com

Page 2

PFT8857

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

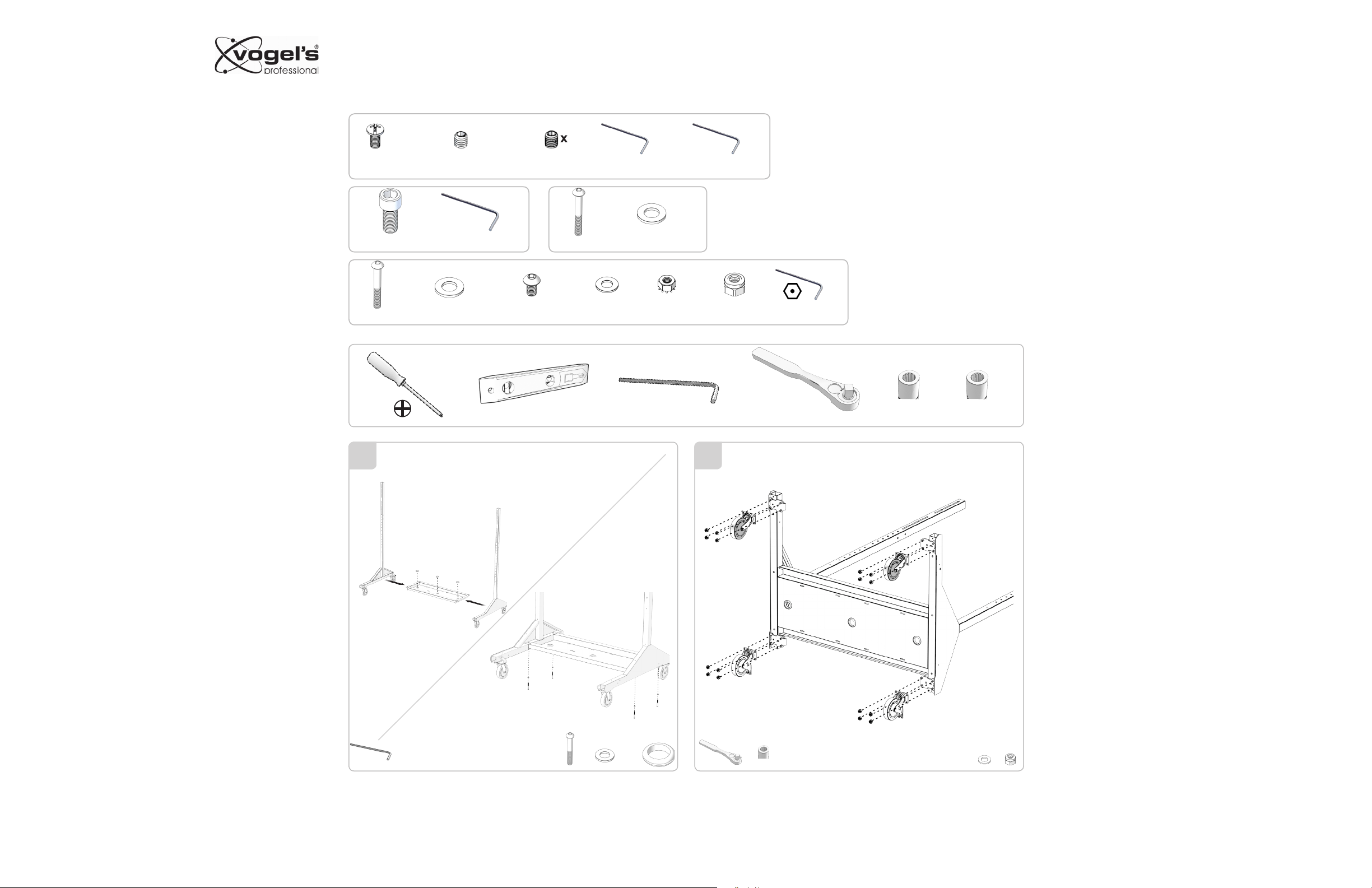

Included components

If this is a “one man” installation find a “friendly” clear flat

wall to place one leg assembly along side. Place the lower

pan panel on top of the legs channel between the “upright”.

Next place the second leg over the lower pan panel so all

four through holes line up and loosely secure the lower pan

to the legs with the four M8 x 1.25 x 60mm “button head Allen head screws and M8 flat washers supplied.

x2

M6 x 12mm

x4

M8 x 60mm

x4

M8 x 10mm

x1x4

14mmM16 x 35mm

x2

M5 x 6mm

x4

M8 x 60mm

x20 x20 x4

M8 M6 x 10mm M4 M4 M8

x1

5/32”

x4

M8

x4 x4

Required for installation

31 2

1 2

x1

2.5mm

x1

5mm

Laying the paired leg assembly first on its back and then on

its front securely install the four casters on the front and rear

of the leg assemblies using the M8 flat washers and M8 self

locking nuts supplied. Then securely install the four casters.

We recommend the two rear caster be the “locking pair”

5mm

9531-060-Z05-00

4x

4x

3x

www.vogels.com

13mm

16x

16x

Page 3

PFT8857

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

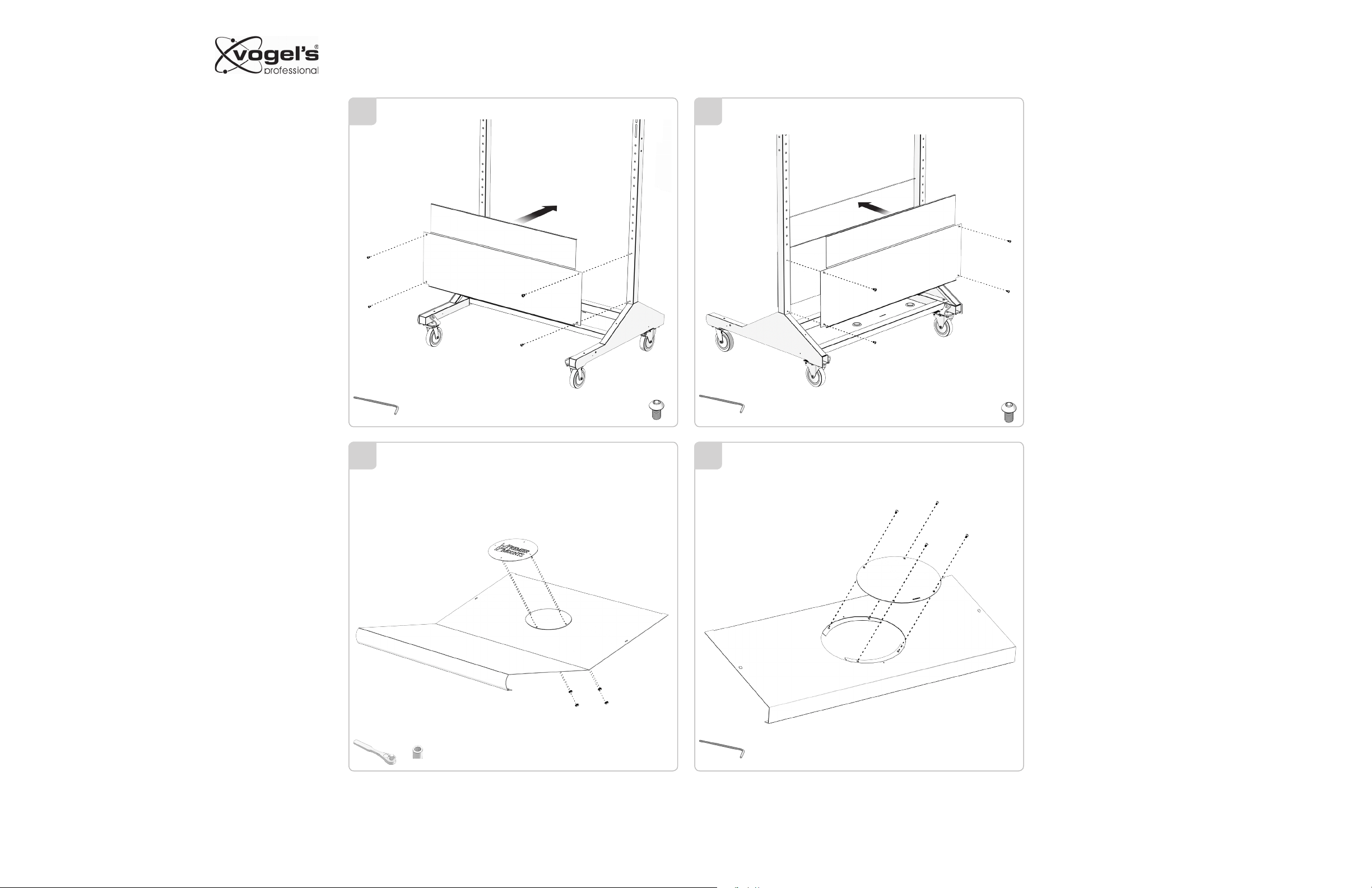

Loosely install the front upper cover to the front of the cart

with the four M6 x 1.0 x 10mm”button head” Allen screws

supplied.

1

3

4mm

4x

2

4

3 4

4mm

4x

Repeat the same procedure with the upper rear panel to the

leg assembly with the four each “button head” Allen screws

supplied.

Now secure firmly the four lower pan “button head” screws

to the leg assembly and tighten firmly. Repeat the same process with the front and rear upper cover panels but “don’t”

over-tighten these.

Install the front “logo” plate to the lower panel cover with the

four each 10/32 x 1/2” “kep” nuts and flat washers supplied.

3

3

5 6

13mm

6

4

The rear oval panel cover can be installed before or after

final assembly of the cart with the four each M6 button head

Allen head screws supplied.

5mm

9531-060-Z05-00

www.vogels.com

Page 4

PFT8857

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

Install the lower front panel cover to the frame front and

secure to the frame assembly with the four each M6 x 1.0 x

10mm “button head” Allen head screws supplied

1

7

4mm

4x

2

8

With the rear of the lower pan exposed now would be the

time to place and wire any powered suppor t products feeding the display with the power and signal cable being fed

between the front and rear upper cover panels. Power and

signal cable can also be run up through the three rubber

grommet hole in the base ob the pan as well.

Once housed the rear cover panel may now be installed

with the four “button head” Allen screws supplied. Access to

the inner pan is still available through the rear oval access

cover.

4x

4mm

Two people recommended for this portion of the “mega” cart

assembly process. Raise the receiver cross bar assembly

to the desired “centerline” height and secure to the uprights

firmly with the four “button head Allen screws and flat washers supplied.

3

5mm

4x

4x

The 90 degree rotation stop can be installed to allow for left

4109

or right rotation of the arm only. Simply remove the two M6

flat head screw to reposition the 9 0 degree stop plate and

reinstall

9531-060-Z05-00

www.vogels.com

Page 5

PFT8857

C

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

1

11

2

12

Slide the left and right display mounting brackets over the

cross bar and install the left and right M6 x 1.0 x 12mm security Phillips head screws supplied into the cross bar.

With the display safely positioned “face down” on a smooth

flat surface place the cross bar with brackets loosely attached so the center of the round receiver is center on the

display left to right and top to bottom.

Slide the left and right mounting bracket over the lef t and

right mounting holes (normally four each) and firmly install

the brackets to the display with the correct length M8 x 1.25

Phillips head screw supplied. Note: measure the depth of

the threaded mounting hole to confirm the correct length of

the M8 screws from the three lengths supplied Confirm the

crossbar is still centered left to right on the rear of the display and firmly secure the bracket to the cross bar with the

four M6 x 1.0 x 10mm Allen head set screws supplied.

Eight optional use M4 - M8 plastic spacer are included in

the hardware kit if needed to create clearance between the

mounting g bracket and the display. These

spacers easily joined together for additional height is

needed as well.

3

5/32”

413 13

L

5/32”

9531-060-Z05-00

www.vogels.com

Page 6

PFT8857

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

Remove the M6 security holding screw from the receiver and

set to the side for re-install after the crossbar and display

are installed into the received slots.

1

14

2

15

Depending on the size and weight of the display use appropriate number or personal and lift assistance device to

raise and slowly install the round center of the cross bar into

the round receiver chassis and insure it is fully seated in the

receiver chassis.

Re-install the M6 security screw.

3

41716

Friction of the rotation can be adjusted by increasing or

decreasing the friction screw on either side of the receiver

assembly penetration of the two installed friction screw with

a Phillips head screwdriver.

9531-060-Z05-00

www.vogels.com

Page 7

PFT8857

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

Vertical flatness of the installed display can be adjusted using an M10 socket and ratchet on the lower “head assembly.

IT helps if someone is gently lifting “out” on the lower display

as the “tilt in” adjustment is made.

1

18

M10

219

M2.5

With the 2.5mm Allen head wrench supplied install the two

each M5 x 6mm mini adjustment Allen head screws supplied

to both sides of the “rotation” stop bar. slowly turn the display to the level position in each direction and adjust the two

adjust screw to set max rotation in each direction to level.

9531-060-Z05-00

www.vogels.com

Page 8

11

PFT8857

Installation Guide

Installationsanleitung, Guía de Instalacíon, Guida de Installazione, Guide d’Installation, Installatie gids

ITEM NO.

QTY.

8 3

1

147

9

10

1 1

2 1

3 2

4 4

5 20

6 20

7 1

8 3

9 1

10 1

11 1

12 4

13 4

14 2

15 1

16 16

17 2

18 2

19 1

PART NO.

3201-000-010-XX

3201-000-020-XX

0725-DCG-W02-13

0411-079-320-6X

198X-507-600-50

0398-061-091-6X

3201-000-001-XX

1558-BUD-P00-86

3201-000-005-XX

3201-000-060-XX

3201-000-006-XX

198X-265-100-35

1200-034-007-5X

3201-000-015-XX

3201-000-003-XX

1070-079-015-0X

0031-000-001-07

0031-000-001-08

3201-000-008-XX

REV

02

02

03

00

02

02 SIGN PANEL

01

05

N/A

00

PLUG PUSH-IN RIBBED SQUARE CAP 2 X 2"

WASHER M8 ( .335 ID ) X ( .621 OD ) X ( .063 THK )

GROMMET BUNA-N RUBBER (1.50I.D) X (2.13 OD) X (.5"THK)

WASHER M4 ( .172 ID ) X ( .347 OD ) X ( .031 THK )

NUT LOCK NYLON INSERT M8X1.25 X 8

DURABLE SUPERIOR CASTERS (SWIVEL)

DURABLE SUPERIOR CASTER (LOCKING)

DESCRIPTION

VERTICAL LEFT LEG ASSEMBLY 2X2

VERTICAL RIGHT LEG ASSEMBLY 2X2

SCREW BUTTON HEX (M8 x 1.25 x 60)

SCREW BUTTON HEX (M6 x 1.0 x 10)

LOWER TRAY

ACCESS PANEL

REAR PANNEL WELDED ASSY

NUT KEP (6/32"X .109)

UPPER COVER

FRONT COVER

SIGN PANEL BACKING PLATE

15

5

2

4

1213

17

1

3

5

2

7

6

4

ITEM NO.

18 616

QTY.

PART NO.

1 4

0411-079-320-6X

2 4

201X-50A-B00-55

3 1

3201-000-070-XX0285"- 103" FLAT PANEL ROLLING CART BACK PLATE

4 1

3106-000-035-XX02SWIVEL TUBE ASSEMBLY (LARGE)

5 4

1658-079-091-6X

6 2

1658-052-061-6X

7 2

6095-PSD-E-E

8 2

0474-061-104-6X

9 2

3106-000-038-XX01MOUNTING BRACKET ASSEMBLY XLARGE (ELLIPTICAL)

REV

DESCRIPTION

SCREW BUTTON HEX (M8 x 1.25 x 60)

WASHER LG O.D M8 (.335 ID) X (.934 O.D) X (.079)

SET SCREW CUP POINT ( M8 X 1.25 X 10 )

SET SCREW CUP POINT ( M5 X 0.8 X 6 )

00

PLASTIC CAP (ELLIPTICAL TUBE 3.149 X 1.574 )

SCREW PAN PHILLIPS COMB (M6X1.0 X 12)

8

13

3

4

2

9

12

ITEM NO.

QTY.

1 1

2 1

3 1

4 1

5 4

6 2

7 4

8 2

9 2

10 1

11 1

12 1

13 1

14 1

7

15 2

6

16 1

17 1

18 2

19 1

PART NO.

0477-061-320-9X

3106-000-019-XX02FRONT COVER ( ROTATION BEARING)

3106-000-018-XX03ROTAIONAL MOUNT BRACKET

6441-10-RUM-RFC01RUM FRONT COVER

0422-061-182-6X

0474-079-153-6X

198X-507-600-50

1070-079-015-0X

0474-061-153-6X

199X-447-700-50

198X-396-200-50

1070-061-012-9X

3201-000-080-XX0285"- 103" FLAT PANEL ROLLING CART BACK PLATE

3106-000-024-XX00ROTATIONAL STOP

0422-061-104-6X

180X-063-117-70

3106-000-040-XX001/2" TILT ROD WELDED ASSY

2303-657-601-60

0562-061-077-6X

REV

DESCRIPTION

HEX FULLY THREADED M6x1.0x60

SCREW FLAT 90 DEGREES PHILLIPS (M6 x 1.0 x 25)

SCREW PAN PHILLIPS COMB (M8X1.25 X 20)

WASHER M8 ( .335 ID ) X ( .621 OD ) X ( .063 THK )

N/A

NUT LOCK NYLON INSERT M8X1.25 X 8

SCREW PAN PHILLIPS COMB (M6X1.0 X 20)

1/4" WASHER SAE (.286 ID) X (.630 OD) X (.065 THK)

WASHER M6 ( .256 ID ) X ( .464 OD ) X ( .060 THK )

NYLON INSERT HEX LOCK NUT (M6x1.0x.236) DIN 985

SCREW FLAT 90 DEGREES PHILLIPS (M6 x 1.0 x 12)

SPACER NYLON 6/6 (.250 ID) X (.555 OD) X (.551 THK)

FLG BUSH.BRONZE,SAE 863 (.500 ID X .625 O.D X .375 LG X .8

00

SCREW KNURL KNOB PHILLIPS (M6X1.0 X 8)

18

11

98

9531-060-Z05-00

www.vogels.com

5

1

Loading...

Loading...