Page 1

Instruction Sheet For:

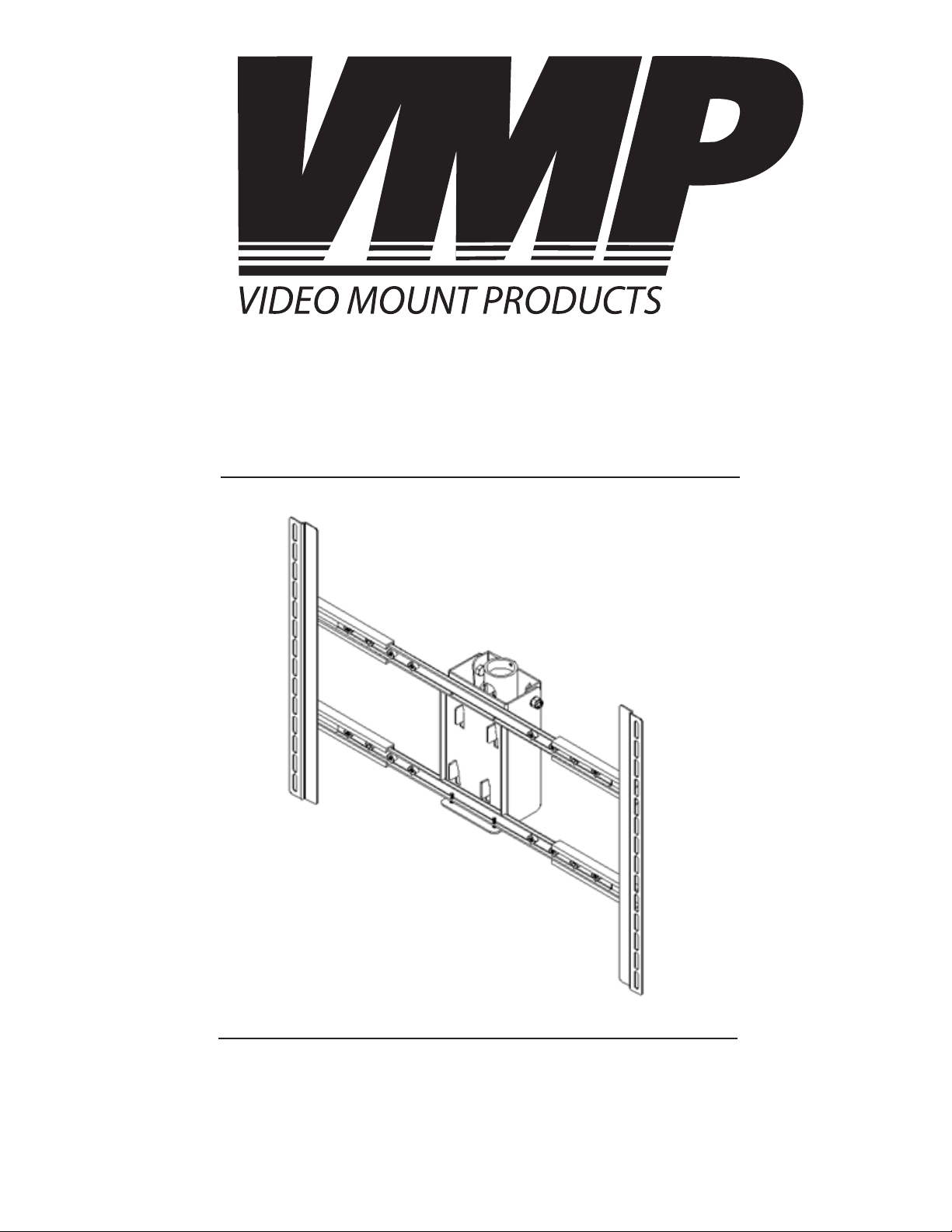

PDS-LCHB

For more information, please contact us at:

345 Log Canoe Circle, Stevensville, Maryland 21666

Toll Free: 877.281.2169 Phone: 410.643.6390 Fax: 410.643.6615

www.videomount.com

Page 2

14 10 717 34

6

913

2

12

1

11

35

8

32

31

30

29

28

1

QTY.

16

15

PDS-LCHB

4

4

4

2

2

1

1

1

2

2

55.6*T0.7

1

1

55.6*T3.0

1

4

2

18*T1.6

2

1

4

16*T1.6

5

3

4

4

4

4

4

4

4

4

4

4

4

33

4

4

18*T2.0

18

19

20

21

22

4

1

1

2

2726

25

23

24

H Bracket

Tilt Bracket

Tilt Support

DESCRIPTION

1

NO.

ITEM

Mounting Rail

2

3

4

16.5*

17*

Cotter Pin

Pipe Couple

Nylon Nut M16*P2.0

Nylon Nut M10*P1.5

Security Screw M5*P0.8*L20

5

Washer

PVC Washer

6

Adjusting Screw M12*P1.75*L100

7

8

9

10

11

12

8*

10.5*

Washer

Hex Screw M10*P1.5*L25

Washer

Hex Screw 5/16"-18UNC*L5/8"

16

14

15

13

Brake Screw 1/4"-20UNC*L3/8"

17

5.5*

Spacer M6

Lock Washer M4

Lock Washer M5

Lock Washer M6

Lock Washer M8

28

29

Washer

31

30

Cross Screw M4*P0.7*L12

Cross Screw M5*P0.8*L12

Cross Screw M6*P1.0*L12

Cross Screw M4*P0.7*L30

Cross Screw M5*P0.8*L30

Cross Screw M6*P1.0*L35

Cross Screw M8*P1.25*L40

23

24

25

26

27

18

Cross Screw M8*P1.25*L16.5

19

20

21

22

Spacer M8

M3 Allen Key

Mounting Rail B

Long Allen Key M4

32

33

34

35

Page 3

Step 1

Before starting, lay out all parts to your mount and match them to

the parts list provided. Verify that you have all your parts before

attempting to assemble the mount.

Step 2

Attach the Tilt Support (#1) to the Pipe Couple (#10) using the

Large Washers (#7), PVC Washers (#6) and M16 Nylon Nut (#11).

7

Once the Nylon Nut (#11) is tight, slide the Cotter Pin (#8) through

1

6

11

10

11

8

the small hole near the bottom of the screw coming out of the

Pipe Couple (#10). Note: Be sure to tighten down the nylon nut

11

(#11) as far as possible to prevent sag or list in the mount.

10

Step 3

Attach the Tilt Bracket (#2) to the Tilt Support (#1) using the M10

Screws (#14), Washers (#13) and Nylon Nut (#12). Insert the Adjustable Screw (#9) into the back of the Tilt Support (#1).

14

9

2 1

13

12

1

Step 2: Attaching the tilt

support to the pipe couple

SStep 3: Attaching the tilt

bracket to the tilt support

Step 4

Determine which Mounting Rails (#4 or #35) are most appropriate

4

35

for the size hole pattern that you have. Place those rails onto the H

Bracket (#3) and center the rails on the H Bracket. Determine the

3

correct screw size and if you need to use washers, lock washers, or

spacers. Secure the display to the Mounting Rail (#4 or #35) using

the appropriate hardware (#18 through #32).

18

32

4

35

Step 4A: Attaching the at panel to the

mounting rails (spacers not needed)

Step 4B: Attaching the at panel to the

mounting rails (spacers used for recessed

hole pattern)

Page 4

Step 5: Securing the mounting

rails to the H bracket

Step 5

Secure the Mounting Rails (#4 or #35) to the H Bracket (#3) using

4

the 5/16” Screws (#16) and Washers (#15).

35

1516

3

Step 6

Screw the 1.5” NPT into the Pipe Couple (#10) as tight as possible. Once the Pipe Couple (#10) is securely tighten screw the

10

10

¼”-20UNC brake screw in the threaded hole in the side of the Pipe

Couple (#4) as tight as possible.

4

Step 7

Lift the H Bracket (#3) onto the tabs of the Tilt Bracket (#2).

Once the H Bracket (#3) is set onto the Tilt Bracket (#2), secure

3

the two together using the M5 Security Screws (#5) in the holes

2

5

23

at the bottom of the H Bracket and Tilt Bracket.

Please verify that all nuts and screws are securely tightened.

Step 6: Attaching the pipe

couple to the 1.5” NPT mast

(mast not provided)

Step 7: Attaching the H bracket

onto the tilt bracket

Enjoy Your Mount!

WARNING: The installer of these products must verify that the mount surface, ceiling or wall, will safely

support the combined weight of all attached equipment and hardware. Video Mount Products will not

be held liable for the improper use or installation of its products.

Loading...

Loading...