VMI VIBER X2 Pro User Manual

VIBER X2 Pro™

An instrument for analysing and trending

Manual Ver. 1.0

English

2

Index

1.0 Important information 4

2.0 Introduction 4

2.1 Scope of supply 5

2.2 Menu and funktions 6

2.3 Menu for vibration 7

3.0 Warning messages 9

4.0 Battery status bar 10

4.1 Changing Battery 10

5.0 How to interpret vibration levels 10

6.0 ISO standard 10816-312 11

7.0 Vibration analysis 12

8.0 Recommended bearing condition levels 13

9.0 Trend View 14

9.1 Create a measurement project 15

9.2 Create a “Route Plan” and edit a project 38

9.3 Trend measurements 40

9.4 Transfer of data to Trend View 42

9.5 General description and viewing trends 51

10.0 Technical data 52

3

1 Important information

Safety precautions

Vibration measurement involves measurement on rotating machines. Keep a safe distance to rotating parts and

secure transducers and transducer cables from rotating parts. Always follow internal, local and national

security regulations! When working with weights on the rotor always secure the start switch with a locker and

also use the emergency switch for double safety. This is especially important when the machine is remote

controlled.

VMI takes no responsibility for any accidents on people and machines.

VMI and our authorized dealers will take no responsibility for damages on machines and plants as the result

of the use of VIBER X2 ProTM measurements.

VMI has the aim to improve and develop our work, why surely an upgraded version of this manual will be

distributed in the future. As a result of this, we might change and correct these items in later issues without

further notice. Also changes in the VIBER X2 ProTM equipment may take place that affects this information.

2 Introduction

VIBER X2 Pro™ is designed for maintenance/repairer personnel. It is an excellent tool, for basic condition

monitoring checks, easy to use and reliable for status analyse. The VIBER X2 Pro™ instrument has the

following features:

Accurate measurements for 4 selectable frequency ranges. Gives high reliability.

Real-time measurement of the total vibration level and the Bearing Condition (BC) measures and

displayed simultaneously, facilitates analysis of bearing faults.

Fast and easy fault analysis screen displaying the five highest peaks with amplitude and frequency one

by one.

Measurement quantities and their units and presentation can be selected by the user from the

following list:

o g-value = Acceleration (RMS, Peak or Peak-Peak)

o a = Acceleration (m/s2) (RMS, Peak or Peak-Peak)

o V = Velocity (mm/sec) (RMS, Peak or Peak-Peak)

o V = Velocity (inch/sec) (RMS, Peak or Peak-Peak)

o D = Displacement (mils) (RMS, Peak or Peak-Peak)

o D = Displacement (μm) (RMS, Peak or Peak-Peak)

Bar indicator shows measurement stability.

Bearing Condition measurements in the frequency range (0,5 – 16 kHz).

Fast and easy fault analysis displaying the five highest peaks frequency in Hz or RPM in main screen

display.

Large dynamic range of the vibration signal (up to 50g).

Low power consumption.

High performance accelerometer.

Vibration, danger alarms by red and yellow colour LED’s.

Fast battery charging capacity using an external charger, provided in the delivery.

Display with backlight.

4

LED’s

idicato

A complete delivery is:

VIBER X2 Pro™, machine

condition analyzer

Accelerometer, magnet

included

1 m transducer cable

Cable for transfer between

“VIBER X2 Pro” and

computer

Battery charger

VMI “Trend View” software

Manual for instrument and

software

Shoulder bag

Calibration certificate

2.1 Scope of supply

The VIBER X2 PRO™ keypad

* ON/OFF Orange key *MENU and ACCEPT Green key *SAVE key for Route measurement

*Arrow white keys *LED:s

Green LED lights, when any key is pressed.

Yellow LED lights, when the measurement is above the warning set level.

Red LED lights when the measurement is above the danger set level.

5

6

Frequency range

Frequency of the highest peak

2-400 Hz

2 - 400 Hz

6 – 1600

6 – 1600* Hz

11-3200 Hz

11 to 2000* Hz

10-1000 Hz

10 to 1000 Hz

Frequency

Vibration

Theoretically

Measured

Deviation

Velocity

Displacement

Displacement

Hz

mm/s (RMS)

µm (RMS)

µm (RMS)

%

2

10

795,8

203

-74,5

2,5

10

636,6

540

-15,2 3 10

530,5

549

3,5

5

10

318,3

321

0,85

10

10

159,16

160

0,53

80

10

19,89

20

0,55

The frequency appears as follows:

The Frequency range of the highest peak in relation to the frequency range setting is described in the below

table, the limit of the maximum frequency* of the peak is 1000 Hz.

Reliability is reduced when measuring Displacement with accelerometer and double integration.

7

Calibration

lost!

Battery

too low

Shut-off

in 5 sec

Missing

transducer

3 Warning messages

The following message may appear in normal operation:

This message may appear if the calibration data is lost from the permanent FRAM memory

or if the calibration data are corrupted. In such cases, the instrument must be re-calibrated;

otherwise it will measure incorrectly. The message appears only once, and then

default calibration data is used.

When this message appears, the battery voltage is too low to ensure a correct running

condition. The measurements may be invalid! The instrument battery pack must be charged

immediately, using the external charger. In order to temporarily decrease the power

consumption, the backlight will be switched OFF. The instrument can still work, but only

for a short while. If even in this condition the voltage remains low, the instrument will shut

off in 20 sec.

This message appears only if the Auto-shut off setting is enabled. The user may cancel the

shut-off condition, pressing any key except ON/OFF. If no key is pressed the instrument

will shut off in 5 seconds.

This message appears only if the Transducer power setting is enabled and indicates that the

transducer is missing or is out of order.

When the Transducer power setting is disabled, the user has the possibility to use another external source for

the vibration input (a signal generator or a buffered output from another device).

When the instrument starts, the Transducer power is always ENABLED. When this message appears, it will

remain on the screen, even if the transducer is plugged-in. To continue the normal running mode in such a

condition, switch the screen temporarily to another menu. When you come back, the message disappears.

8

4 Battery status bar

When the measurement window is activated, a battery symbol appears on the top of

the screen (see page 7) which shows approximately how much battery capacity is left.

If the battery voltage drops below approximately: 3.3 V then the instrument turns off.

When the battery charger is connected, a moving staple moves back and forth, and a

green LED lights up until the battery is fully charged.

4.1 Changing Battery

The unit has an embedded Lithium battery and after a number of years when the

battery is exhausted we recommend that a VMI reseller or service centre makes the

replacement.

5 How to interpret vibration levels

User with no previous experience, we recommend to use the ISO 10816-3 standard.

The standard normally calls for a measure in velocity based on mm/s RMS. To better

understand what this measure means, consider the reading as a mean or average value

of the back and forward motion of the machine. This measure gives a good

understanding of the amount of "break down energy", causing mainly wear and fatigue

in the machine, or the structure.

The instrument measuring the total RMS-value of the vibration in the frequency range.

This RMS value is the square average sum of all the measured vibrations, in the actual

frequency range.

CALCULATION:

If the simultaneous vibration caused by unbalance is (4mm/s), by misalignment (2

mm/s) and by the gear mesh (5 mm/s), then the total vibration measured on the

VIBER X2 Pro is 6.7 mm/s.

Total vibration (RMS) =

9

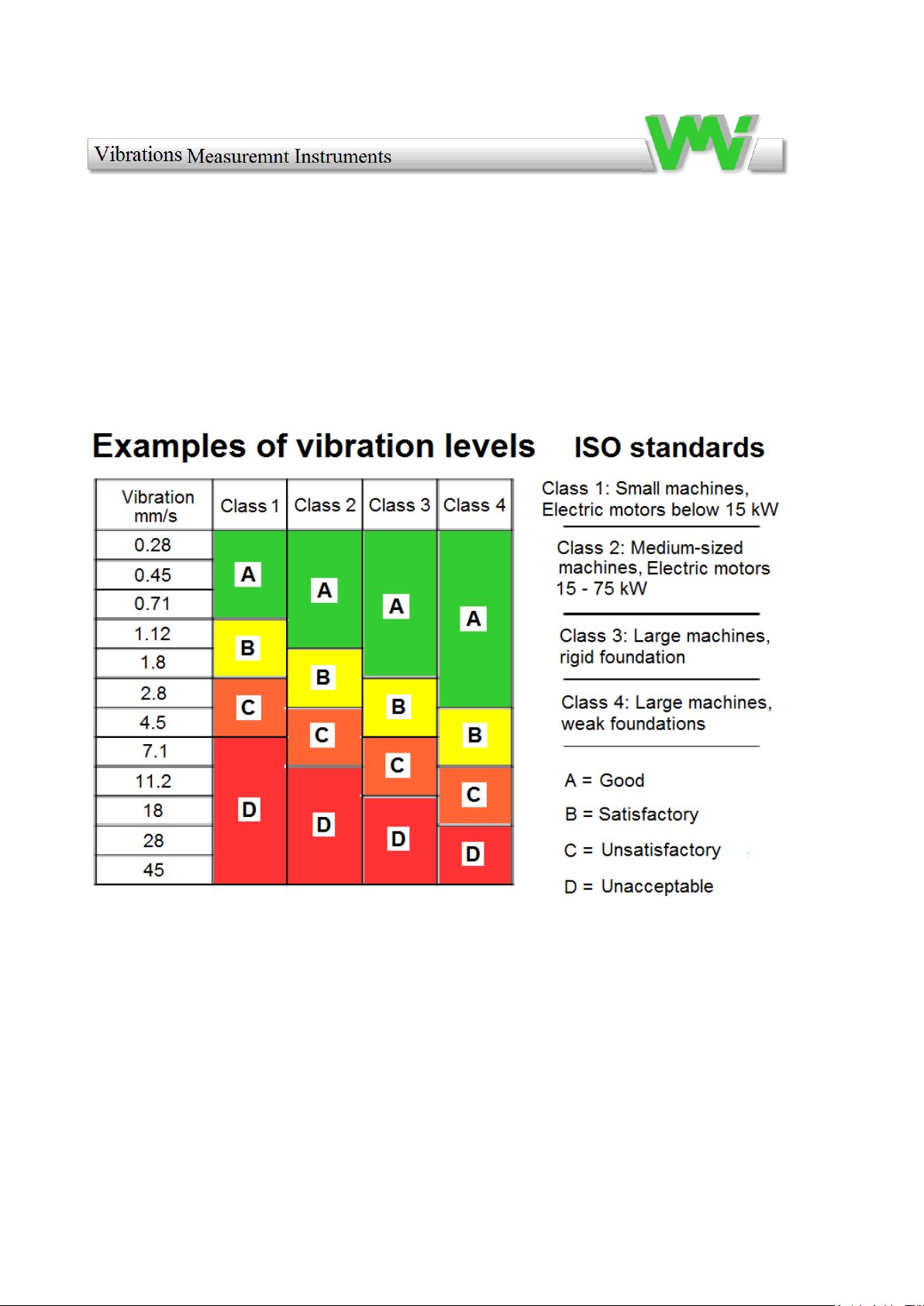

6.0 Excerpt from ISO standard

Iso Standard 10816-3 classifies machines differently depending on whether they are

flexible or rigid (fixed) mounted. This reflects the location of the machine's "rigid

resonances" related to the machine's operating speed.

10

7 Vibration analysis

7.1 Recommended vibration levels

The following is an extraction of part of the old standard ISO 2372 class 4, large

machines on flexible foundations, with some common findings added. Use this

simplified list as a first indication, when approaching a newly commissioned machine

or after some time in operation. Investigate the reason for any machine that vibrates

above 3 mm/s RMS.

0 – 3 mm/s 0 – 0,12 in/s

Small vibrations – None or very small bearing wear. Rather low noise level.

3 – 7 mm/s 0,12 – 0,28 in/s

Noticeable vibration levels are often concentrated to some specific part as well as

direction of the machine. Noticeable bearing wear. Seal problems occur in pumps

etc. Increased nois level; try to investigate the reason. Plan an action during next

regular stop. Keep the machine under observation and measure at shorter time

intervals than before to detect a deterioration trend if any. Compare vibrations to

other operating variables.

7 – 11 mm/s 0,28 – 0,43 in/s

Large vibrations and high noise levels. This is detrimental to the safe operation of

the machine. Stop operation if technically or economically possible. Few machines

can withstand this levels without internal or external damage. Reduce any further

running time to an absolute minimum.

≥ 11 mm/s - ≥ 0,43 in/s –

Very large vibrations and high noise levels. This is detrimental to the safe

operation of the machine. Stop operation if technically or economically possible.

Few machines can withstand this level without internal or external damage. Reduce

any further running time to an absolute minimum.

11

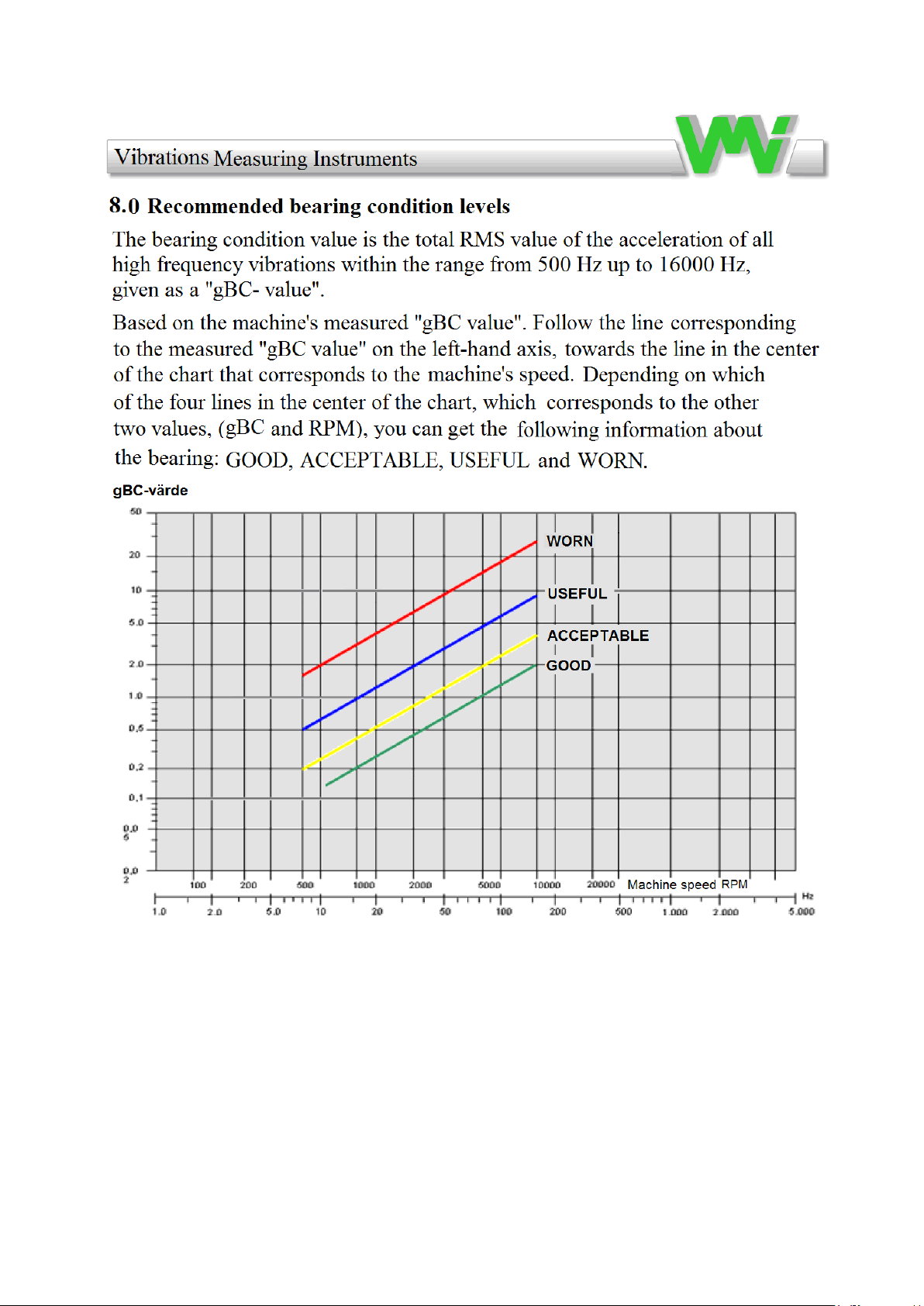

The diagram above is a help to translate bearing condition values. About, for example, the measured

gBC value is 2.0g. It shows that if a machine has a speed of approximately: 10000 RPM, the bearing

may still be good while a machine with a speed of about 550 RPM with the same gBC value can be

considered as consumed. If vibrations of other causes occur (eg flow, pressure shock, gears) and

within the frequency range, it may also give high "gBC values" without damage to the bearings. A

high "gBC value" can also be expected if the bearing is poorly lubricated or overloaded (eg in case of

poor alignment or hard tension drive belt). Compare this value with the bearing temperature. If both

the "gBC value" and the temperature are high or increase in a trend measurement, then there is

probably a bearing problem.

12

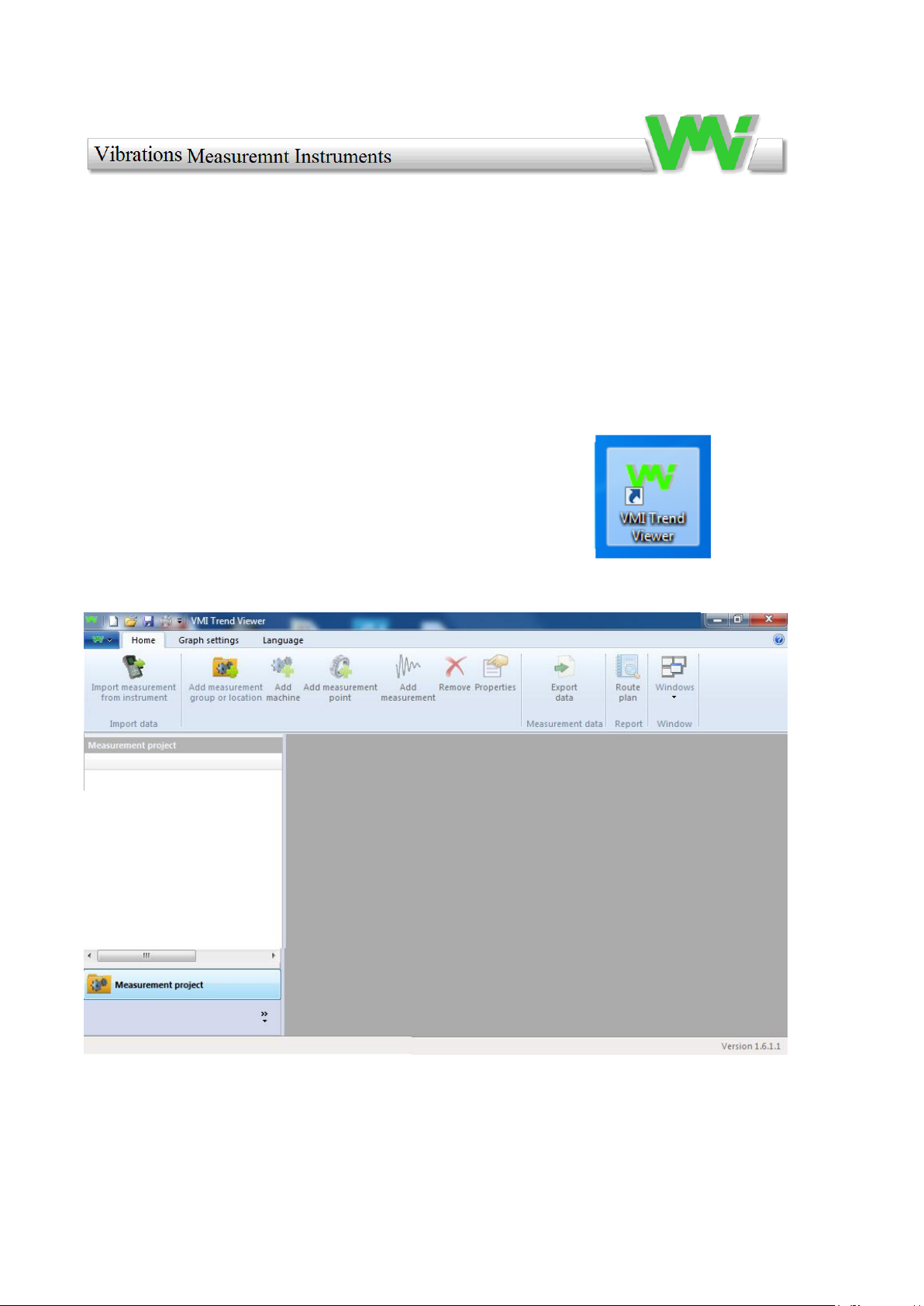

9 Trend View software use for trends and route

This software is designed to trend measurement and this enables the users to monitor

the condition in machines.

Trends are one method to perform condition monitoring (CM). TREND VIEW™ is

designed for use only with VIBER X2 Pro™ and VIBER X3™.

For every plant or building, you can create a database and a rout with up to 100

measurements. If there are need for several measurement points, you can create

several projects with 100 new storage locations. Each measurement store vibration

amplitude and bearing condition. This covers normally 5 – 20 machines / project,

depending on how many directions are measured on every bearing* and the number of

bearings. That amount is equivalent to number of measuring points in a route.

If only one direction is measured at each measuring point, choose the direction with

the highest vibration. After the measurement, the data can be uploaded to the

computer. In the computer you can store almost an unlimited number of machines.

You can choose what unit you want to display in TREND VIEW™.

Analyzing this information, periodically, you can act proactively and avoid failures.

Regarding installation of the software, see the installation guide.

* Bearing condition is stored in horizontal direction on each bearing. If you not

measures this direction you must choose one of the direction you measure. Change

direction in properties.

13

9.1 Create a measurement project

You start by creating a "measurement project" to store measurement values.

In this manual, we show an example of how to build a "measurement project" or

"database" with two grinding machines. Grinding machine 1 and Grinding machine 2.

For both machines we measure : Vibration, Bearing condition (BC) The machines

belong to the "Grinding department".

Start the "Trend View" program by clicking on the icon: on the

desk.

14

You can also click on the symbol that shows a "white sheet of paper" to create a new

project.

15

Here is the new project. You can not measure temperature or perform balancing with

VIBER X2 Pro.

You can build a hierarchical tree, from a plant or department down to a single

measuring point, or just set up a single machine. In this example, we select

"Department" (Grinding Department). We also add two machines,

(Grinding machine 1) and (Grinding machine 2). Next step is to click on the icon:

If you click on the icon "Add Group or Location" before you create a

project, you will receive the following prompt:

16

Assign the project a name by clicking on the green "W"

17

Loading...

Loading...