Page 1

V.07.17

OPERATING INSTRUCTIONS USER MANUAL

MANUAL DE INSTRUCCIONES

TL-A150

LINE ARRAY

GBE

USA

D

TOWERLIFT

TORRE ELEVADORA

TRAVERSENLIFT

Page 2

LIFTING TOWER TL-A150

TORRE ELEVADORA TL-A150

TRAVERSENLIFT TL-A150

PRO LIFTS S.L.

C/ Ciudad de Barcelona Nº19

Pol.Ind. Fuente del Jarro

46988 Paterna (Valencia)

Tlf Export: +34 96 171 81 86

Tlf Nacional: 96 171 81 83

info@prolifts.es - www.prolifts.es

Manufacturer - Fabricante

Este manual de usuario y catálogo anexo de piezas de repuesto es propiedad de PRO LIFTS S.L.

Queda prohibida su reproducción total o parcial por cualquier medio que la tecnología actual permita.

Deposito legal y copyright 2014. Todos los derechos reservados.

MADE IN SPAIN (EU)

BGV-C1

BGG-912

EC Conformity Declaration pursuant to the EC Machinery Directives 89/392/CE and

98/37/CE: Manual lifters

Find a copy of the certications at the end of this booklet.

Puede ver una copia de las certicaciones al nal del manual.

CONTENTS / ÍNDICE

Features of the TL-A150 Towerlift / Características TL-A150............. 3 - 4

English Quick operation guide.................................................................... 5 - 11

Manual de usuario Español.......................................................................... 12 - 18

Bedienungsanleitung Deutsch.................................................................... 19 - 25

Sketches / Planos piezas................................................................................ 26 - 33

Spare part list / Lista de repuestos.............................................................. 34 - 36

Certifications / Certificaciones...................................................................... 37

Page 3

Depósito legal y copyright 2014. Todos los derechos reservados. 3PRO LIFTS S.L.

T

V

V

S

T

TL-A150

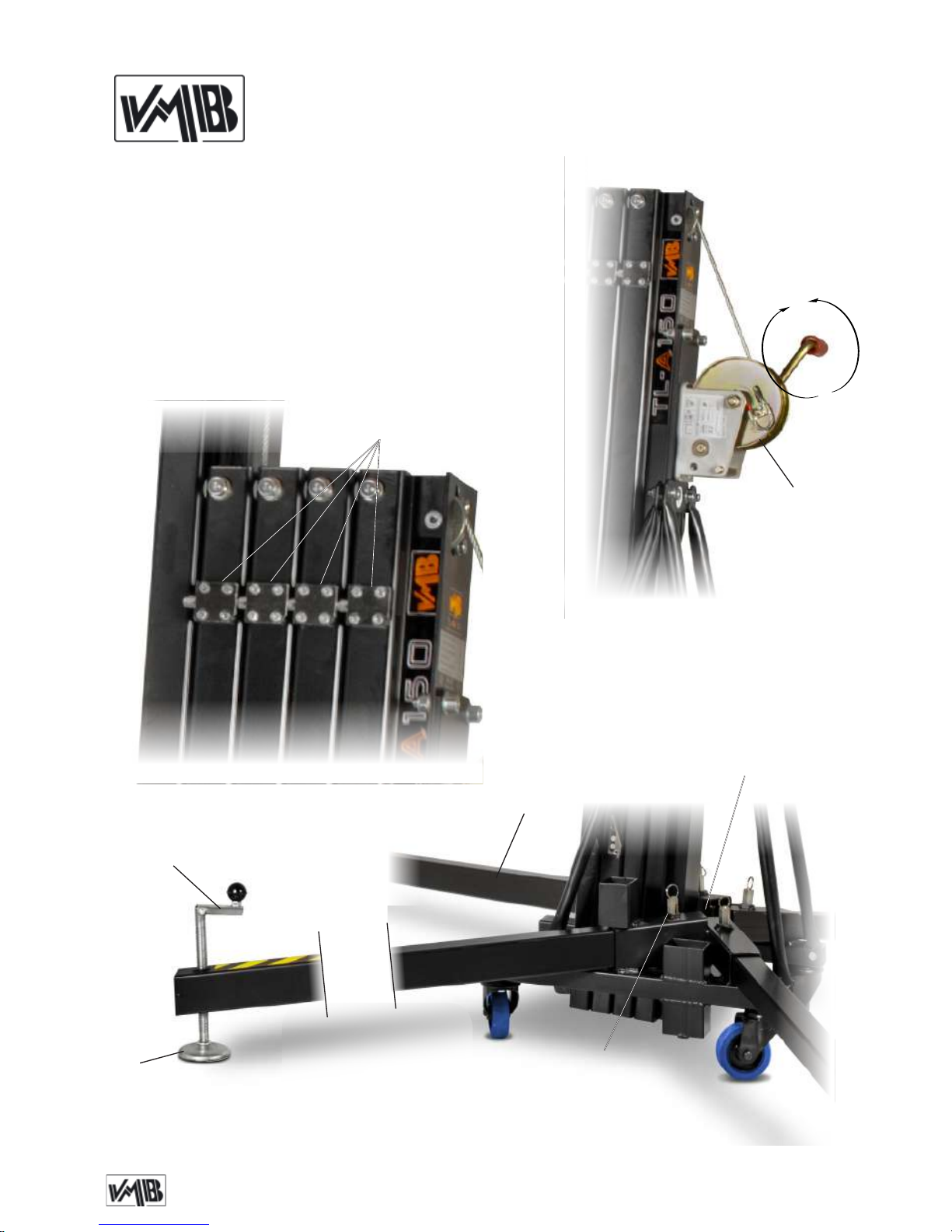

F: Forks / Brazos de carga

S: Transport compartment / Alojamiento de transporte

T: Transport wheels / Ruedas de transporte

V: Working compartment / Alojamiento de trabajo

F

Page 4

Depósito legal y copyright 2014. Todos los derechos reservados. 4PRO LIFTS S.L.

W

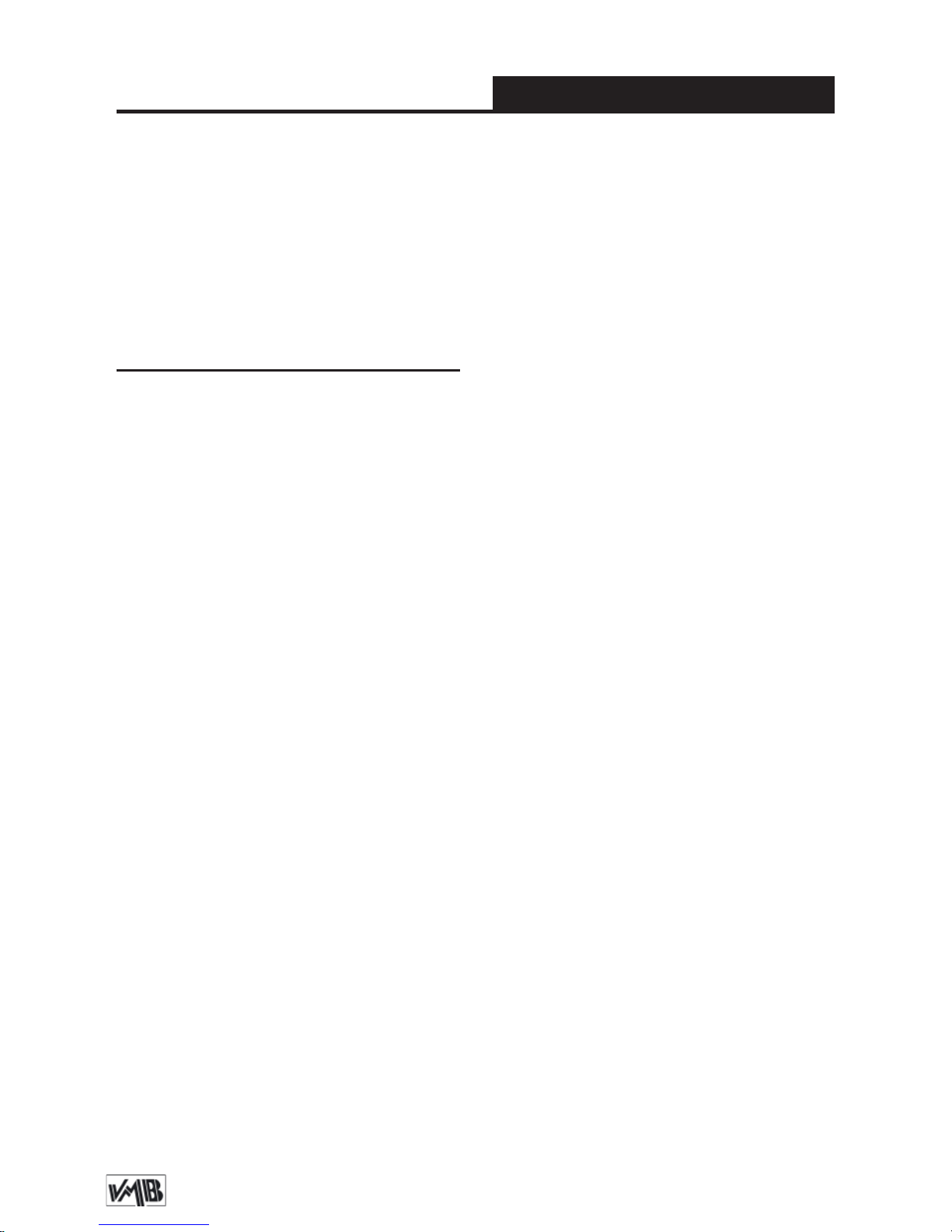

H: Handle / Manivela

L: Spirit level

N: Force on hand crank / Fuerza sobre manivela

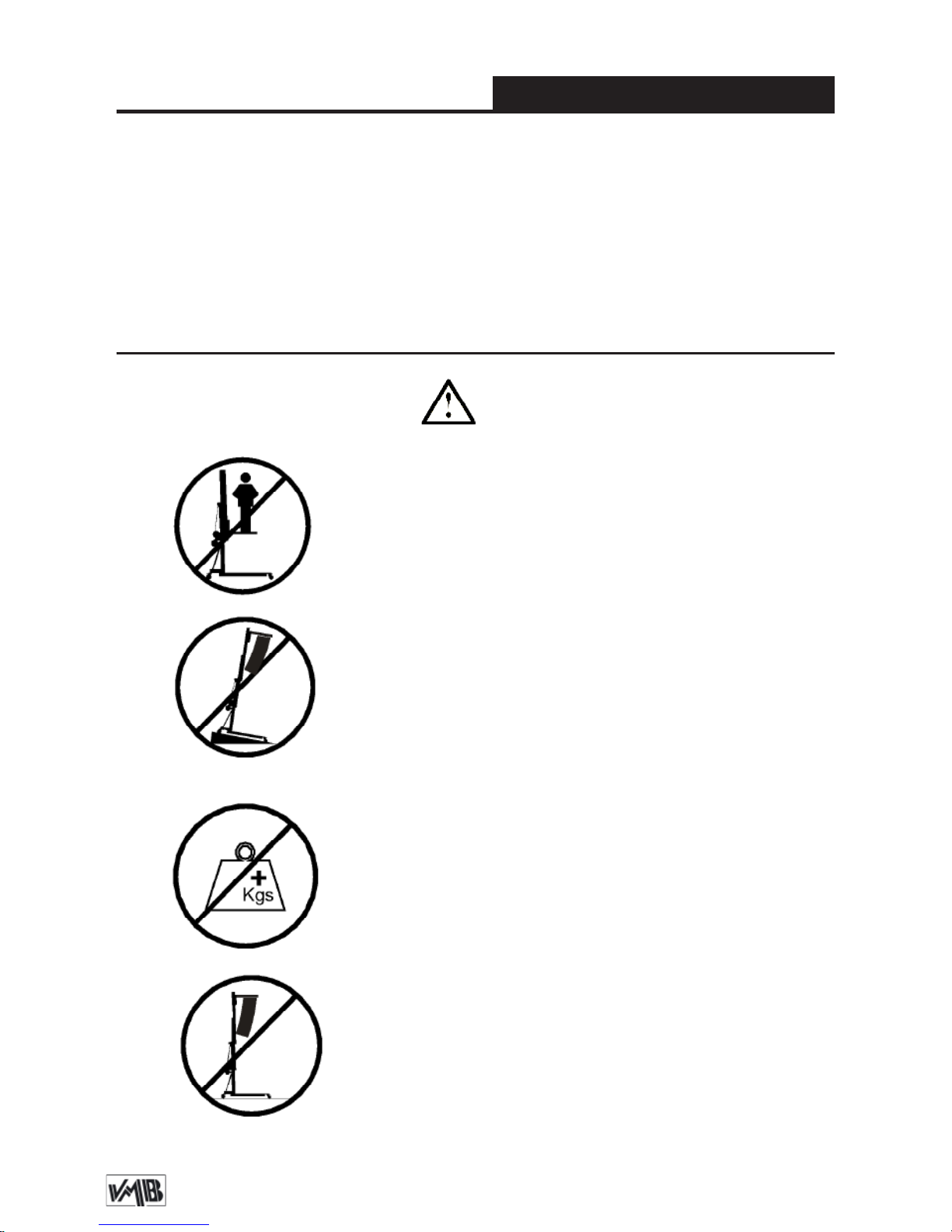

P: Leg / Pata

Q: Stabilizer / Estabilizador

R: Catch pawl / Gatillo bloqueo patas

SRS: Sequence Retainer System

W: Winch / Cabrestante

N

1

N

2

TL-A150

SRS

P

R

Q

L

H

Page 5

Depósito legal y copyright 2014. Todos los derechos reservados. 5PRO LIFTS S.L.

Quick operation guide

ENGLISH

CONTENTS

1. Introduction.

2. Technical information.

3. Safety precautions.

4. Operation.

5. Maintenance.

6. Guarantee.

1. INTRODUCTION

Dear customer, in order to ensure a safe

and reliable operation of the TL-A150

towerlift please follow the instructions in

this booklet carefully. Before operating the

lift, read the instructions completely and

please note the technical information contained within this manual.

All VMB products undergo very rigorous

testing, under strict conditions and they

are monitored continuously during the manufacturing process.

In order to guarantee the lifts function and

safety, only original parts from the manufacturer must be used. If any parts other

than those of the manufacturer are used,

or the product is modied in any way, the

user forfeits all warranty rights to claim.

VMB reserves the right to modify the pro-

duct specications without prior notice.

The model type, production year and serial number must be quoted in any queries

or orders for spare parts.

2. TECHNICAL INFORMATION

2.1 - TL-A150 Towerlift.

2.2 - Designed to lift audio systems, such

as PA systems or Line Array, up to different heights.

2.3 - Maximum load : 150 kg (331 lb).

2.4 - Minimum load: 25 Kg (55 lb).

2.5 - Security : ILS (Inertial Lock Security).

2.6 - Maximum height : 5.30 m (17.4’).

2.7 - Folded height : 1.54 m (5’).

2.8 - Transport surface:

0,6x0,42x1,54m (1.97x1.38x5’)

2.9 - Shipping dimension:

0,62x0,44x1,56m (2.03x1.44x5,12’)

2.10 - Work surface :

1.7 x 1.85 m (5.6’ x 6.1’).

2.11 - Unit weight : 107 Kg (236 lb).

2.12 - Load support:

Long forks (54.5 cm).

2.13 - Construction material : 6082-T6 alluminium for the main body, comprised of 5

proles and a lifting carriage. Base and legs

are made of steel prole according to DIN

2394. Catches and pulleys of ST-37 steel.

2.14 - Winch: 450 Kg. maximum load with

automatic brake. Certication CE and GS

TÜV.

2.15 - Cable : Steel DIN 3060. Quality 180

Kg/mm

2

twist resistant. Cable diameter: Ø

5 mm.

Page 6

Depósito legal y copyright 2014. Todos los derechos reservados. 6PRO LIFTS S.L.

Quick operation guide

ENGLISH

3. SAFETY PRECAUTIONS.

2.16 - Adjustable stabilizing feet with rub-

ber non-slip supports.

2.17 - Safety catches to anchor the legs.

2.18 - Antirust protection, primed paint

with cured polyester dust cover. The tower

can be supplied with natural aluminium

nish or black (version B).

2.17 - Spirit level to adjust the tower vertically.

2.18 - Swivel wheels to transport the lift

when folded.

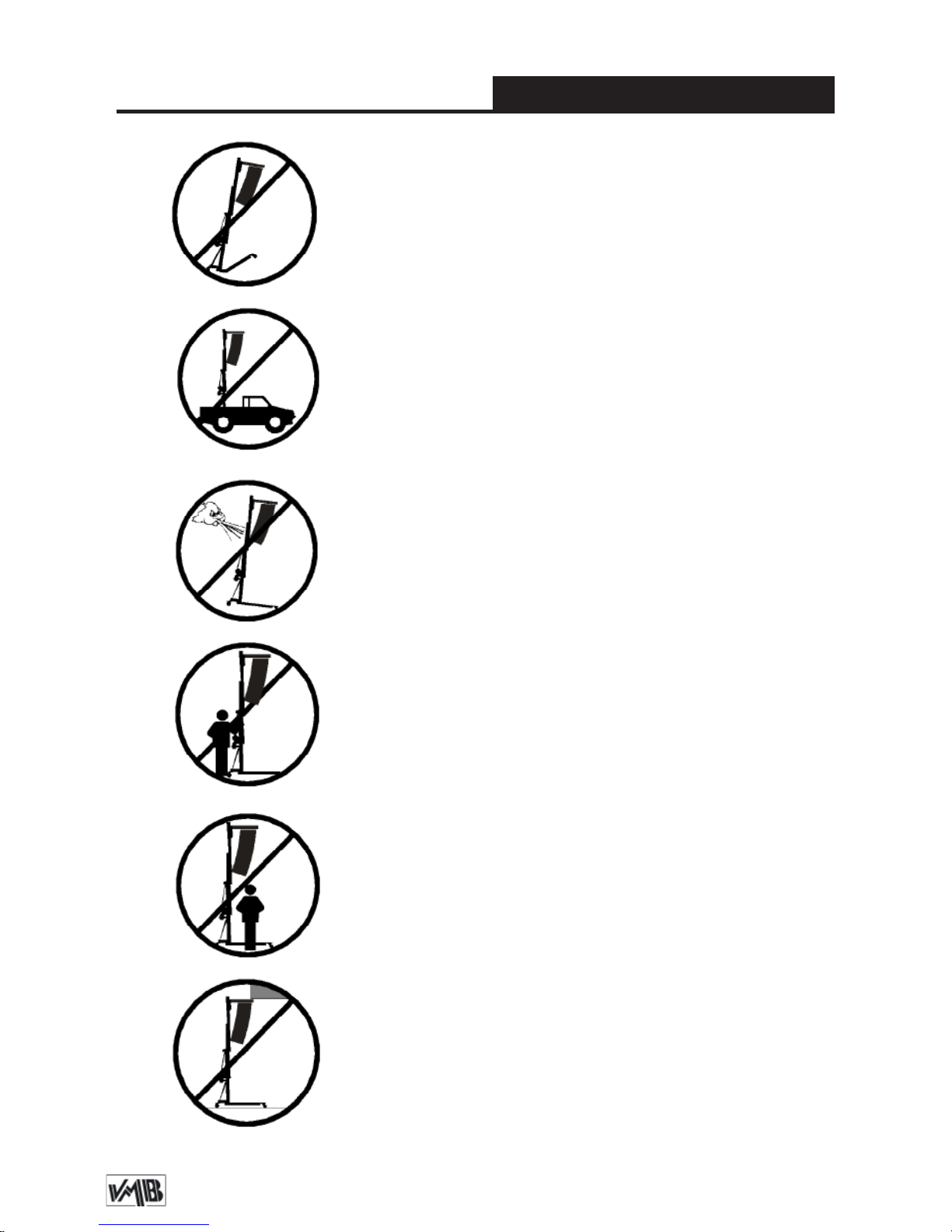

3.1 - The TL-A150 is a machine designed to elevate

loads upwards in a vertical direction, It should NEVER

be used as a platform to elevate people.

3.3 - The maximum load indicated on the characteristics

label and the instructions manual should not be exceeded.

3.4 - This lift should NEVER be used to elevate a load

that has not been properly checked. It is necessary to

verify that the load is correctly supported and centred

on the appropriate lift support so that the weight of the

load will only elevate in a vertical direction.

3.2 - Only place the lift on hard, at surfaces always

checking that it is in a vertical position by using the bub-

ble level indicator (L) found on the base. Adjust the leg

stabilizers (Q) by turning the handles (H) to level if necessary. NEVER use wedges or other foreign objects to

balance the lift.

Page 7

Depósito legal y copyright 2014. Todos los derechos reservados. 7PRO LIFTS S.L.

Quick operation guide

ENGLISH

3.6 - NEVER use the lift on a vehicle or any other mobile

surface.

3.7 - If there is a possibility of strong winds or gusts,

place the lift on the ground rmly and secure it with the

use of straps. NEVER attach a strap to a vehicle or any

other object that can possibly be moved.

3.8 - NEVER move the lift whilst it is carrying a load. It

is not advisable to carry out any type of horizontal movement even small positional adjustments.

3.9 - NEVER allow any team member below the load or

anybody else in the lifts operating zone.

3.10 - Take care with all obstacles above the lift and

its extension zone such as cornices, balconies, and

luminous signboards. It is very important to avoid the

presence of all types of cables below the extended lift.

3.5 - Check that the legs (P) are placed and set-up correctly with their safety pins (R) inserted and locked.

Page 8

Depósito legal y copyright 2014. Todos los derechos reservados. 8PRO LIFTS S.L.

Quick operation guide

ENGLISH

3.11 - Do not use stepladders on the lift or use it as a

support for them.

3.12 - Before using the lift, check the condition of the

cable. The cable should not have broken threads or

show any signs of crushed/attened areas. NEVER use

faulty cables, always change them if there is any doubt.

Only use VMB steel cables; reference: DIN 3060.

Quality: 180KG/mm and torsion resistant.

3.14 - Do not grease or lubricate the winch’s braking

mechanism. The brake disks have been greased with

a special heat and pressure resistant solution. Other

products should not be used to avoid negative effects

regarding the braking mechanism.

3.15 - The minimum load to avoid problems regarding

the braking mechanism is 25Kg. Without this load the

brake will not work.

3.16 - NEVER take apart the crank of the winch when

the lift is carrying a load or extended.

3.13 - All sections must be lowered rst, and the legs

placed in its transport position, before transportation.

Page 9

Depósito legal y copyright 2014. Todos los derechos reservados. 9PRO LIFTS S.L.

Quick operation guide

ENGLISH

3.17 - Only original replacement parts should be used.

ORIGINAL

4. USER INSTRUCTIONS.

4.1 - Place the lift on a rm, at surface

in the area it is to be used with the help of

the transport wheels (T).

4.2 - Remove the legs (P) from their trans-

port compartment (S) and fully insert them

into their working positions (V) checking

that they are xed by the pins (R).

4.3 - Check that the lift is in vertical posi-

tion using the spirit level (L) at the base of

the tower, adjust the stabilizer (Q), turning

the handle (H) if necesary.

4.4 - Release the forks (F) and place them

in its working horizontal position ready to

take the load on them. Insert the pins to

block the forks.

4.5 - DO NOT OVERLOAD THE LIFT.

MAXIMUM LOAD IS 150 kg (331 lb)

The lift should NEVER be overloaded.

Safety at work is the most important issue. Place the load onto the lift using an

adequate VMB support according to the

need, use so that the weight of the load

will only be elevated in a vertical direction.

The minimum load is 25 Kg.

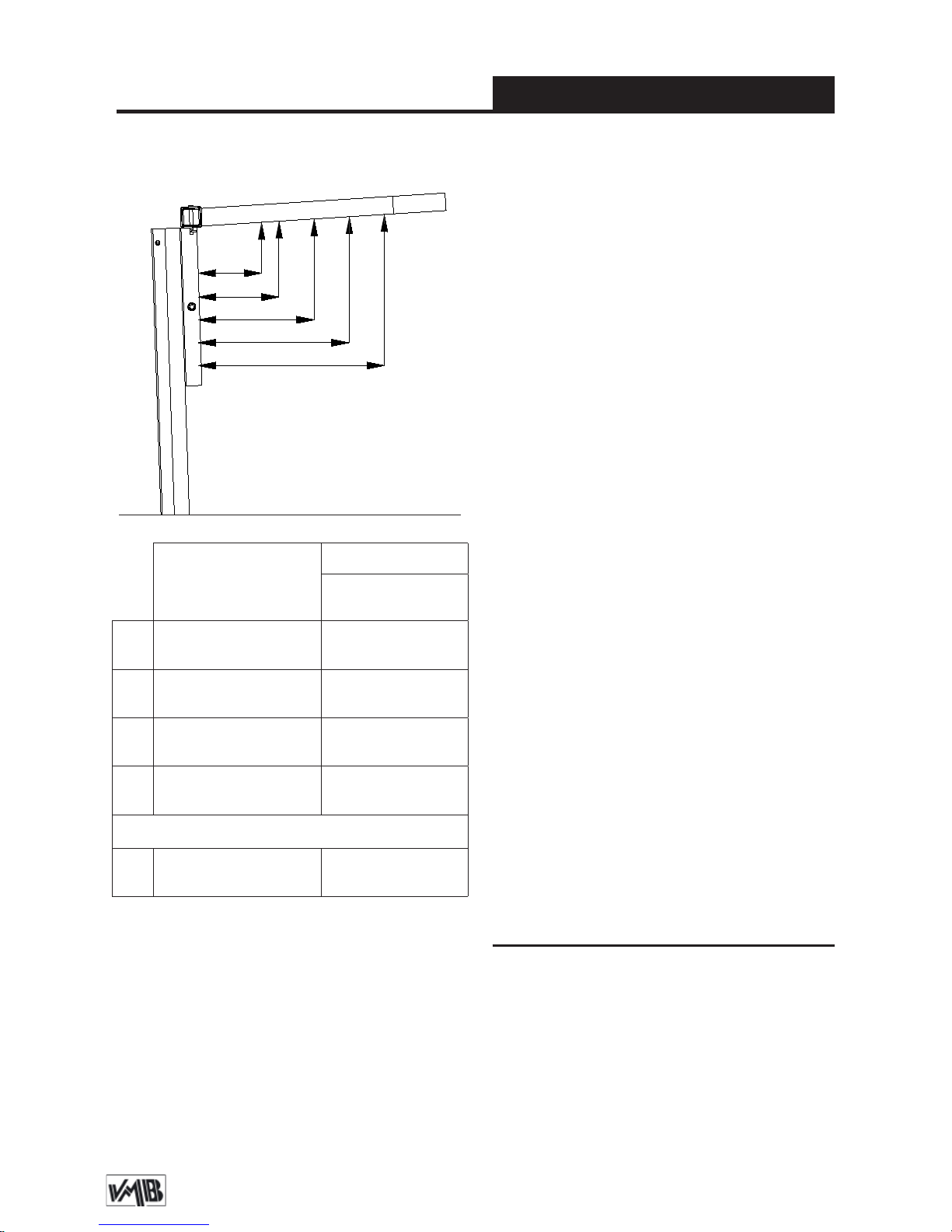

4.6 - How to place the load:

Always load

as close to the tower as possible.

The maximum load diminishes according

to the distance from the body of the tower

as illustrated in the diagram 4.6.1, which

shows the load on the gravity centre with

distances to the lifting carriage at a maximum lifting. Use a VMB adaptor if necessary.

CAUTION

When two towers are used to elevate a

truss bridge, or many towers to elevate a

structure of any type, it is almost impossible that two or more people co-ordinate

the winches elevating or lowering the

loads, at exactly the same pace. At a certain point each tower will be extended to

different height. For this reason it is necessary that the structure does not stretch

and allows for these differences.

With a rigid xation and if the level difference is signicant, the force generated

from the handle of the winch will deform

the structure and apply a lateral force to

the lifts causing them to break and block.

Page 10

Depósito legal y copyright 2014. Todos los derechos reservados. 10PRO LIFTS S.L.

Quick operation guide

ENGLISH

B

C

D

E

A

4.7 - Elevation:

Turn the winch crank clockwise (N

1

) to

lift the carriage. The unique SRS system

(Sequence Retainer System) will ensure

that the proles rise in sequence, one after the other.

4.8 - Hold:

The tower can be left in any intermediate

position if it is necessary. Just stop turning

the handle of the winch and leave it. The

automatic brake of the winch will block it

and hold the load.

4.9 - Lowering:

To bring the lift down you need to rst turn

the winch handle gently clockwise (N

1

) to

release the clutch of the winch. Then turn

the handle anti clockwise (N

2

) until all pro-

les have been completely lowered.

4.10 - Transport:

For the transport of the tower is necessary

to fold the machine lowering every prole

completely. Once the towerlift is completely folded, place the legs in their transport compartment (S) and the lift will be

ready to be transported.

5. MAINTENANCE.

5.1 - Regularly check the state of the ca-

ble. If the cable has broken threads, or if

it shows any signs of crushed/attened

areas, it should be changed and replaced

Security system ILS

The TL-A150 incorporates the ILS secu-

rity system (Inertial Lock Security). This

VMB system automatically blocks each

prole and the lifting carriage in the unlikely event of cable breaking.

Diagram 4.6.1

Distance from the

load’s center to the

lifting carriage

Maximum load

TL-A150

A

25 cm

(0.82’)

150 kg

(331 lb)

B

30 cm

(0.98’)

135 kg

(298 lb)

C

40 cm

(1.31’)

112 kg

(247 lb)

D

50 cm

(1.64’)

96 kg

(212 lb)

For large forks:

E

60 cm

(1.97’)

84 kg

(185 lb)

Page 11

Depósito legal y copyright 2014. Todos los derechos reservados. 11PRO LIFTS S.L.

Quick operation guide

ENGLISH

PRO LIFTS S.L. promises, that from the

date of purchase and during the warranty

period to resolve any faults that may occur, produced through defect material or

fabrication. Damage caused by improper

use, product modication, third party manipulation or accidental re are not cove-

red by this warranty.

immediately with a new one. Do not use

the lift if the cables are in bad condition.

Only use VMB steel cables reference: DIN

3060 torsion resistant.

5.2 - The lift is supplied from the factory

completely greased. However, it is recommended to periodically grease according

to use, the gearing, the axis bearings, the

spiral of the crank, and the sections.

5.3 - All lifts should undergo an annual

technical inspection carried out by an

authorized VMB dealer to check the certications and general condition of all the

lift’s elements and security systems involved in the lift’s use.

5.4 - Only use original spare parts to guarantee a continued security level. The

user loses all rights to warranty if any spare parts other than originals are used or

carries out any modication or alteration

to the towerlift.

5.5 - To request a spare part please indicate the corresponding code which can

be found in this manual together with the

lift’s serial number and year of manufacture.

6. GUARANTEE.

The warranty period for this lift is 2 years

from the date of purchase.

Page 12

Depósito legal y copyright 2014. Todos los derechos reservados. 12PRO LIFTS S.L.

Manual de usuario

ESPAÑOL

CONTENIDO

1. Introducción.

2. Información técnica.

3. Precauciones de seguridad.

4. Instrucciones de uso.

5. Mantenimiento.

6. Garantía.

1. INTRODUCCIÓN

Estimado cliente: Con el n de garantizar

un funcionamiento seguro y able de la

torre elevadora TL-A150 por favor, siga

cuidadosamente las instrucciones de este

manual.

Antes de manipular la torre elevadora,

lea las instrucciones completas y tenga

en cuenta la información técnica contenida en este manual. Todos los productos de VMB se someten a pruebas muy

rigurosas, en condiciones estrictas y son

monitorizados continuamente durante el

proceso de fabricación. Con el n de garantizar el correcto funcionamiento y seguridad de los elevadores, sólo deben ser

utilizadas piezas originales del fabricante.

Si se utilizan piezas que no sean las originales del fabricante, o el producto se mo-

dica de alguna manera, el usuario pierde

todos los derechos de garantía.

VMB se reserva el derecho de modicar

las especicaciones y las piezas del pro-

ducto sin previo aviso. El tipo de modelo,

año de producción y el número de serie

deben ser citadas en cualquier consulta o

pedido de piezas de recambio.

2. INFORMACIÓN TÉCNICA

2.1 - Torre elevadora TL-A150.

2.2 - Diseñada para levantar sistemas de

audio, como sistemas de Line Array o PA,

en sentido vertical a diferentes alturas.

2.3 - Carga máxima: 150 kg (331 lb).

2.4 - Carga mínima: 25 Kg (55 lb).

2.5 - Seguridad: ILS

(Sistema de seguridad de inercia).

2.6 - Altura máxima: 5.3 m (17.4’).

2.7 - Altura plegada: 1,54 m (5’).

2.8 - Dimensiones de la torre plegada:

0,6x0,42x1,54m (1.97x1.38x5’)

2.9 - Dimensiones de la caja transporte:

0,62x0,44x1,56m (2.03x1.44x5,12’)

2.10 - Área de trabajo de la torre:

1.7 x 1.85 m (5.6’ x 6.1’).

2.11 - Peso de la torre: 107 kg (236 lb).

2.12 - Soporte de carga: Brazos de carga

cortos (54.5cm).

2.13 - Material de construcción: Cuerpo

principal de cinco tramos más carro ele-

vador en perl de aluminio extrusionado

6082-T6. Base, patas y soportes varios,

en perleria de acero según DIN 2394.

Gatillos de seguridad y poleas acanaladas en acero ST-37.

Page 13

Depósito legal y copyright 2014. Todos los derechos reservados. 13PRO LIFTS S.L.

Manual de usuario

ESPAÑOL

3. PRECAUCIONES DE SEGURIDAD

2.14 - Cabestrante: 450 kg de carga máxi-

ma con freno automático de retención de

la carga. Certicación CE y GS TÜV.

2.15 - Cable: Acero DIN 3060. Calidad de

resistencia a la torsión 180 kg/mm

2

.

Diámetro del cable: Ø 5 mm.

2.16 - Patas estabilizadoras ajustables

con soportes de goma antideslizante.

2.17 - Gatillos de seguirdad para anclar

las patas.

2.18 - Protección anti-óxido, imprimación

con pintura de polvo poliester al horno. La

torre puede ser suministrada con acabado natural de aluminio o negro (versión

B).

2.19 - Nivel de burbuja para ajustar la verticalidad de la torre.

2.20 - Ruedas direccionales para el transporte de la torre cuando este plegada.

3.1 - La torre elevadora TL-A150 es una máquna diseñada para la elevación de cargas en dirección vertical.

NUNCA se debe utilizar como plataforma eleavadora

de personas.

3.3 - La carga máxima indicada en las características

técnicas mostradas en la etiqueta de la torre o en este

manual NO deben ser excedidas.

3.2 - Colocar el elevador sólo en supercies rmes y

planas, vericando que está en posición vertical, utili-

zando el indicador de nivel de burbuja (L) que se encuentra en la base. Ajuste los estabilizadores (Q) girando las manivelas (H) hasta nivelar, si es necesario.

Nunca utilice cuñas u otros objetos extraños para equilibrar el elevador.

Page 14

Depósito legal y copyright 2014. Todos los derechos reservados. 14PRO LIFTS S.L.

Manual de usuario

ESPAÑOL

3.6 - NUNCA use el elevador sobre un vehículo o cualquier

supercie móvil.

3.7 - Si existe la posibilidad de vientos fuertes o ráfagas,

coloque el elevador en el suelo con rmeza y jelo mediante

tirantes tensores. Nunca je un tirante a un vehículo o cual-

quier otro objeto que se pueda mover.

3.8 - NUNCA mueva el elevador mientras esté cargado. No

es aconsejable llevar a cabo cualquier tipo de movimiento

horizontal, ni tan sólo pequeños ajustes de posición.

3.9 - NUNCA permita que ningún miembro del equipo o

cualquier otra persona se sitúe debajo de la carga en la

zona de operación de las torres elevadoras.

3.5 - Comprobar que las patas (P) estén situadas correctamente, y jadas con los gatillos de seguridad (R) los cuales

deben estar introducidos y bloqueados.

3.4 - Este elevador NUNCA debe utilizarse para elevar una

carga que no ha sido correctamente revisada. Es necesario

vericar que la carga está correctamente apoyada y centrada en el soporte de elevación apropiado para que el peso de

la carga sólo actúe en una dirección vertical.

Page 15

Depósito legal y copyright 2014. Todos los derechos reservados. 15PRO LIFTS S.L.

Manual de usuario

ESPAÑOL

3.12 - Antes de utilizar el elevador, compruebe el estado

del cable. El cable no debe contener hilos rotos o mostrar

signos de áreas aplastadas/aplanadas.

NUNCA use cables defectuosos, siempre debe cambiarlos

si hay alguna duda. Utilice solamente cable de acero VMB

referencia: DIN 3060. Calidad: 180kg/mm y resistente a la

torsión.

3.13 - Antes de transportar la torre, todos los tramos deben

ser bajados, y las patas deben extraerse y colocarse en su

posición de transporte.

3.14 - No engrasar ni lubricar el mecanismo de freno del

cabestrante. Los discos de freno vienen engrasados con

una solución especial resistente a la presión y al calor. No

deben utilizarse otros productos, para evitar los efectos

negativos sobre el mecanismo de frenado.

3.15 - La carga mínima para evitar problemas relaciona-

dos con el mecanismo de rotura es 25 kg. Sin esta carga

mínima el freno no funcionará.

3.11 - No usar escaleras encima del elevador ni utilizarlo

como un apoyo para éstas.

3.10 - Tenga cuidado con todos los obstáculos por encima

de la elevación y su zona de extensión, como cornisas,

balcones, letreros luminosos, etc. Es muy importante evitar la presencia de todo tipo de cables por debajo de la

torre extendida.

Page 16

Depósito legal y copyright 2014. Todos los derechos reservados. 16PRO LIFTS S.L.

Manual de usuario

ESPAÑOL

4. INSTRUCCIONES DE USO.

4.1 - Coloque el elevador sobre una su-

percie rme y plana de la zona de trabajo sirviendose de las ruedas direccionales

de transporte (T).

4.2 - Extraiga las patas (P) de su aloja-

miento para transporte (S) e insertelas

totalmente en su posición de trabajo (V),

comprobando que los gatillos de seguridad (R) se insertan y jan la pata.

4.3 - Compruebe que la torre esta en

posición vertical sirviendose del nivel de

burbuja (L) situado en el perl base, si es

necesario ajuste la vertical de la torre con

los estabilizadores (Q) de las patas, girando las manivelas (H).

4.4 - Libere los brazos de carga (F) y co-

loquelos en posición horizontal e inserte

los pasadores de seguridad con sus clips.

4.5 - LA CARGA MÁXIMA PARA TLA150 ES 150 kg (331 lb).

La torre elevadora NUNCA debe ser sobrecargada. La Seguridad en el Trabajo

es el elemento más importante. Coloque

la carga en el elevador mediante un soporte adecuado según la necesidad de

modo que el peso de la carga sólo actúe

en dirección vertical. La carga mínima

son 25 kg.

4.6 - Como colocar la carga:

Cargue siempre tan cerca de la torre

como pueda. La capacidad de carga de

la torre decrece cuanto más lejos este la

carga separada de la torre, como se ilustra en el esquema (4.6.1) de la siguiente

página. El cual muestra la carga en su

centro de gravedad con distancias al carro elevador que sostiene los brazos y a

máxima altura.

3.17 - Sólo deben ser utilizadas piezas de repuesto

originales de VMB PRO LIFTS S.L.

ORIGINAL

3.16 - NUNCA desmontar la manivela del cabrestante

cuando el elevador está soportando una carga o extendido.

Page 17

Depósito legal y copyright 2014. Todos los derechos reservados. 17PRO LIFTS S.L.

Manual de usuario

ESPAÑOL

B

C

D

E

A

re y permita estas diferencias. Con una

jación rígida y si la diferencia de nivel es

importante, la fuerza generada a partir de

la manivela del cabrestante deformará la

estructura y aplicará una fuerza lateral a

los elevadores provocando su bloqueo y

ruptura.

Sistema de seguridad ILS

La torre elevadora TL-A150 incorpora el

sistema de seguridad ILS (Bloqueo de

inercia). Este sistema de VMB bloquea

automáticamente la torre en el caso inprobable de rotura del cable de acero.

4.7 - Elevación:

Gire la manivela del cabestrante en sentido horario (N

1

) para elevar el carro. El

sistema retentor SRS asegurará que los

perles se elevan de forma secuencial,

uno detrás de otro.

4.8 - Bloqueo:

La torre puede dejarse en cualquier posición intermedia si se requiere. Una vez el

sistema esta elevado hasta la altura deseada tan solo deje de girar la manivela

y el freno automático del cabrestante bloqueará y sujetará la carga.

4.9 - Descenso:

Para descender la torre es necesario,

primero girar la manivela del cabrestante

ligeramente en sentido horario (N

1

) para

liberar el embrague del cabrestante y a

continuación, girar la manivela en sentido

anti-horario (N

2

) hasta que todos los per-

les estén completamente bajados.

PRECAUCIÓN

Cuando se utilizan dos torres para elevar

un puente, descender truss o varias torres

para elevar una estructura de cualquier

tipo, es casi imposible que dos o más personas coordinen los cabrestantes exactamente a la misma velocidad al elevar o

bajar las cargas. En un momento determinado cada torre se elevará a una altura

diferente a la de las demás. Por ello, es

necesario que la estructura no se esti-

Esquema 4.6.1

Distancia del

centro de la carga

al carro elevador

Carga máxima

TL-A150

A

25 cm

(0.82’)

150 kg

(331 lb)

B

30 cm

(0.98’)

135 kg

(298 lb)

C

40 cm

(1.31’)

112 kg

(247 lb)

D

50 cm

(1.64’)

96 kg

(212 lb)

Para brazos de carga largos:

E

60 cm

(1.97’)

84 kg

(185 lb)

Page 18

Depósito legal y copyright 2014. Todos los derechos reservados. 18PRO LIFTS S.L.

Manual de usuario

ESPAÑOL

a una inspección técnica anual llevada a

cabo por un distribuidor autorizado VMB

para comprobar las certicaciones y el

estado general de todos los elementos de

elevación y sistemas de seguridad que intervienen en el uso del elevador.

5.4 - Utilice únicamente piezas de repuesto originales para garantizar el nivel de

seguridad de forma continuada. El usuario pierde todos los derechos de garantía

si las piezas de repuesto utilizadas no son

originales o se utilizan o se lleva a cabo

cualquier modicación o alteración de la

torre elevadora.

5.5 - Para solicitar una pieza de recambio indique el código correspondiente que

se encuentra en este manual junto con el

número de serie de la torre y el año de

fabricación.

6. GARANTÍA

El período de garantía para este elevador

es de 2 años a partir de la fecha de compra.

PRO LIFTS S.L. se compromete, que a

partir de la fecha de compra y durante el

período de garantía, a resolver los fallos

que puedan producirse, debidos a material defectuoso o fabricación. Los daños

causados por un uso inadecuado, modi-

cación del producto, la manipulación de

terceros o incendio accidental no están

cubiertos por esta garantía.

4.7 - Transporte:

Para el transporte de la torre es necesario bajar completamente todos los tramos.

Una vez la torre haya sido plegada, coloque las patas en su alojamiento para

transporte (S) y la torre ya estará lista

para su transporte.

5. MANTENIMIENTO

5.1 - Comprobar periódicamente el esta-

do del cable. Si en el cable existen hilos

rotos, o si muestra signos de zonas aplastadas/aplanadas, debe ser sustituido inmediatamente por uno nuevo. No use el

elevador si los cables están en mal estado. Utilice solamente cable de acero DIN

3060 resistente a la torsión.

5.2 - La torre elevadora es suministrada

de fábrica completamente engrasada.

Sin embargo, se recomienda un engrase

periódico, según el uso, de las ruedas de

fricción, los cojinetes de eje, la espiral de

la manivela, y los tramos.

RECUERDE: NUNCA engrasar ni lubricar

el mecanismo de freno. No es necesario

engrasar los discos de freno. Los discos

de freno vienen engrasados con una solución especial resistente a la presión y

al calor. No deben utilizarse otros productos, para evitar los efectos negativos sobre el mecanismo de frenado.

5.3 - Todos los elevadores se someten

Page 19

Depósito legal y copyright 2014. Todos los derechos reservados. 19PRO LIFTS S.L.

Bedienungsanleitung

DEUTSCH

INHALTSVERZEICHNIS

1. Einführung.

2. Technische Daten.

3. Sicherheitsmaßnahmen.

4. Bedienungsanleitung.

5. Wartung.

6. Garantie.

7. Zertikat.

1. EINFÜHRUNG

Sehr geehrte Damen und Herren,

die vorliegende Betriebsanleitung wurde

mit dem Zweck erstellt, eine zuverlässige

Bedienung des TL-A150 Hebeturms zu

ermöglichen. Lesen Sie bitte die Betriebsanleitung vor der Inbetriebnahme sor-

gfältig durch. Bitte beachten Sie auch die

technische Daten.

Unsere Produkte unterliegen strengsten

Prüfungen und Kontrollen bei der Fertigung.

Es sind ausschließlich Original-Ersatzteile

zu verwenden. Für den Anwender werden

alle Gewährleistungsansprüche aufgehoben, wenn er Nicht-Original-Ersatzeile

verwendet bzw. änderungen am Produkt

selbst vormimmt.

2. TECHNISCHE DATEN.

2.1 - Hebeturm, Typ TL-A150.

2.2 - Das Gerät ist zum senkrechten Heben

von Lasten, wie Beleuchtungskörper auf

verschiede Höhen, konzipiert worden.

2.3 - Zulässige Hubkraft: 150 kg (331 lb)

2.4 - Mindesthublast : 25 Kg.

2.5 - Zulässige Hubhöhe: 5.3 m (17.4’)

2.6 - Mindesthöhe: 1.54 m (5’)

2.7 - Gefaltete Dimensionen:

0,6x0,42x1,54m (1.97x1.38x5’)

2.8 - Abmessungen Box:

0,62x0,44x1,56m (2.03x1.44x5,12’)

2.9 - Grundplattenäche :

1.7 x 1.85 m (5.6’ x 6.1’).

2.10 - Transportgewicht: 107 kg (236 lb)

2.11 - Werkstoffe: Aluminium 6082-T6 Prol.

Basisplatte und Ausleger aus Stahlprol

DIN 2349. Verschlüsse aus ST-37 Stahl.

2.12 - Exklusive ALS System

( Pat. Pen. 200501056)

2.13 - Die Winde: 900/1000 kg.

2.14 - Seildurchmesser: Steel DIN 3060.

Qualität 180 kg/ mm

2

Durchmesser: Ø5 mm

2.15 - Ausleger mit verstellbaren Spindeln

und rutschfesten Gummifüßen.

2.16 - Verankerung der Ausleger über

Sicherheitsrastbolzen.

2.17 - Wasserwaage zum Einstellen der

senkrechten Turmlage.

2.18 - Korrosionsschutz und Veredelung

durch elektrolytische Cadmierung oder

(Version B) Satinpolyester. Erhältlich in

Natur Aluminium oder.

2.19 - Transportrollen zum Bewegen des

Turms bei senkrechter und eingefahrener

Stellung zur Arbeitsstelle.

(optional TL-A150)

Page 20

Depósito legal y copyright 2014. Todos los derechos reservados. 20PRO LIFTS S.L.

Bedienungsanleitung

DEUTSCH

3. SICHERHEITSMAßNAHMEN.

3.1 - Der TL-A150 wurde konzipiert zum Heben und Senken

von vertikalen Lasten. Nutzen Sie Ihn niemals zur Beförderung von Personen.

3.4 - Niemals sollten Sie eine ungesicherte Ladung heben.

Vergewissern Sie sich immer, das die Ladung zentriert auf

der Gabel auiegt und nur in vertikaler Richtung hebt!

3.2 - Achten Sie darauf, das der TL-A150 Tower auf festem,

geraden Untergrund steht. Und vergewissern Sie sich mit Hilfe

der Wasserwaage (F), dass er eine vertikale Position zum

Boden eingenommen hat.Bei Bedarf mittels des Stelltellers

(Q) durch Drehen der Spindelkurbel (H) die entsprechende

Tunlage einstellen.

3.3 - Die zulässige Höchstlast, die Sie auf den Typenschild,

welche sie in der Bedienungsanleitung nden, darf niemals

überschritten werden

3.5 - Vergewissern Sie sich, dass die Ausleger richtig ein-

gesteckt sind und nutzen Sie die Rastbolzen zum feststellen!

Page 21

Depósito legal y copyright 2014. Todos los derechos reservados. 21PRO LIFTS S.L.

Bedienungsanleitung

DEUTSCH

3.10 - Achten Sie auf alle Gegenstände im oberen Hubbe-

reich des Liftes. Achten Sie auf Balkone, Leuchtschriften

und besonders auf stromführende Kabel.

3.8 - Bewegen Sie den Lift niemals unter Belastung.

3.9 - Halten Sie sich niemals während des Hebens und

Senkens in Gefahrenbereich auf.

3.7 - Bei Freiluftanwendungen den Turm auf festen Boden

stellen und mittels Seilanker gegen Windbelastung sichern.

Niemals an Fahrzeugen die Abspannungen befestigen oder

an Gegenständen, die ausweichen könnten.

3.11 - Stellen Sie niemals Leitern an den Tower.

3.6 - Es ist nicht gestattet den Lift auf einem Fahrzeug mit

einen mobilen Unterbau zu installieren!

Page 22

Depósito legal y copyright 2014. Todos los derechos reservados. 22PRO LIFTS S.L.

Bedienungsanleitung

DEUTSCH

3.14- Ölen oder Fetten der Fallbremsen ist zu unterlassen,

da diese mit einem Druck und Hitzebeständigen Material

bearbeitet wurden. Andere Werkstoffe führen in der Handhabung zu negativen Effekten.

3.15 - Die maximale Belastung zur Überprüfung der Si-

cherungen ist 50 kg. Ohne Belastung ist die Überprüfung

nicht möglich.

3.16 - Niemals die Winde, oder Teile der Winde unter Belastung demontieren.

3.13 - Alle Angebauten Teile sind für den Transport einzufahren.

3.17 - Es sind ausschließlich Original Ersatzteile zu verwenden. Für den Anwender werden alle Gewährleistungsansprüche aufgehoben, wenn nicht Original Ersatzteile verendet

bzw.Änderungen an Produkten vorgenommen werden.

ORIGINAL

3.12 - Vor Gebrauch Seilzustand kontrollieren. Das Seil

darf keine Seilbrüche oder Quetschungen aufweisen. Es

dürfen auf keinem Fall Seile in einem schlechten Zustand

verwendet werden.

Page 23

Depósito legal y copyright 2014. Todos los derechos reservados. 23PRO LIFTS S.L.

Bedienungsanleitung

DEUTSCH

4. Bedienungsanleitung.

4.1 - Den Hebeturm auf den Transportrollen

( T ) abgestützt auf eine ebene und feste

Fläche an der Arbeitsstelle aufstellen.

4.2 - Die Ausleger (P) aus der Transporhalterung (S) herausnehmen und in deren

Arbeitsaufnahmen (V) voll einschieben.

Dabei achten Sie bitte darauf, daß sie mittels

der Sicherheitsbolzen (R) befestigt sind.

4.3 - Die senkrechte Turmlage über die

verstellbaren Stellteller ( Q ) durch Drehen

der Kurbel ( H ) in entsprechender Richtung

zum Zentrieren der Wasserwaagenblase (

F ) an der Kreismitte einstellen.

4.4 - Die Sicherheitsbolzen ( L ) der Lastau-

fnahmeausleger entfernen, die Ausleger zur

Lastaufnahme ( U ) in einer waagerechten

Position bringen und die Sicherheitsbolzen

wieder anbringen.

4.5 - Die zu hebende Last auf dem Turm

mittels eines geeigneten Trägers so aufstellen, dass das Lastgewicht nur senkrecht

wirkt. Die maximale Last von 240 kg darf

nie überschritten werden.

4.6 - Plazieren der Ladung:

Plazieren Sie die Ladung so nah wie

möglich in Richtung des Towers. Die Maxi-

malbelastung reduziert sich, gemäß dem

nebenstehenden Diagramm.

Achtung!

Werden zweit Stative dazu benutzt, eine

Traverse oder mehrere Stative dazu be-

nutzt, eine Konstruktion jedweden Typs

anzuheben, ist es fast unmöglich, dass

zwei oder mehrere Bediener in der Lage

sind, die Winde in der exakt gleichen

B

C

D

E

A

Diagram 4.6.1

Distance from the

load’s center to the

lifting carriage

Maximum load

TL-A150

A

25 cm

(0.82’)

150 kg

(331 lb)

B

30 cm

(0.98’)

135 kg

(298 lb)

C

40 cm

(1.31’)

112 kg

(247 lb)

D

50 cm

(1.64’)

96 kg

(212 lb)

For large forks:

E

60 cm

(1.97’)

84 kg

(185 lb)

Page 24

Depósito legal y copyright 2014. Todos los derechos reservados. 24PRO LIFTS S.L.

Bedienungsanleitung

DEUTSCH

Geschwindigkeit zu bedienen, um die Last

anzuheben oder abzusenken.

Ab einem bestimmten Punkt wird sich

jeder Tower in einer anderen Höhe als der

andere benden.

Aus diesem Grund ist es notwendig, dass

die Konstruktion in der Lage ist, diese

Differenz auszuhalten. Bei einer starren

Fixierung und wenn der Höhenunterschied

sehr groß ist, wir die Kraft, die von der

Winde erzeugt wird, die Konstruktion deformieren und dazu führen, dass die Lifte,

ausgelöst durch seitlich wirkende Kräfte,

brechen oder blockieren.

Die Tower können in jeder notwendigen

Zwischenposition belassen werden. Beenden Sie einfach das Drehen der Winde. Die

automatische Bremse wird die Position der

Last halten.

4.7 - Heben:

Die Transportsicherung ( O ) entriegeln.

Den Lift mittels Drehen der Winde ( W )

in Uhrzeigersinn ( N1 ) in die gewünschte

Höhe kurbeln.

4.8 - Halten:

Die Last kann in jeder Position ehalten

werden. Stoppen Sie dazu lediglich das

drehen der Kurbel. Die Automatic in der

Winde und die Fallbremse sichern die

Ladung. Für den Transport des Turmes ist

dieser durch Senken der Einzelabschnitte

herunterzufahren. Es ist sehr wichtig den

Schlitten in seiner Parkposition wieder zu

verriegeln ( B ). Die Ausleger entsperren und

diese in ihre Transportstellung ( S ) bringen.

Die Befestigungsschraube anziehen.

4.9 - Senken:

Zum Transport die Sicherung ( O ) weder

einrasten die Handkurbel der Winde gegen

den Uhrzeigersinn drehen, bis der Lift in

einer Endposition ist. Der Lift kann in jeder

beiliegenden Zwischenstellung angehalten

werden. Durch kurzes anheben der Ladung

mittels der Winde lässt sich ALS - Lock

entriegeln ( rot ). Drücken Sie diese und

lassen Sie die Last mittels Winde ab. Sollte

der ALS – Lock blockieren heben Sie die

Last erneut an und wiederholen Sie den

Vorgang.

5. Wartung.

5.1 - Regelmäßig den Seilzustand kontro-

llieren. Weist ein Seil Drahtbrüche bzw.

Quetschungen auf, ist es sofort durch ein

meues zu ersetzen. Unter keinen Umständen den Hebeturm mit Seilen in schlechtem

Zustand verwenden.

Nur verwindungssteifes Stahlseil nach DIN

3060 verwenden.

5.2 - Der Hebeturm wird werkseitig kom-

plett geschmiert geliefert. Es wird jedoch

Page 25

Depósito legal y copyright 2014. Todos los derechos reservados. 25PRO LIFTS S.L.

Bedienungsanleitung

DEUTSCH

empfohlen, regelmäßig ( je nach Bedarf

) das Zahnrad des Winde, die Wälzlager

der Antriebswelle und Hülse, das Kurbelgewinde und die Abschnitte zu schmieren.

Achtung: Die Bremsscheiben nicht

einölen oder fetten !!!

5.3 - Der Hebeturm TL-A150 sollte von

einer Fachkraft mindestens einmal jährlich

geprüft werden.

5.4 - Für eine kontinuierliche Betriebs-

sicherheit sind ausschließlich Original

– Ersatzteile zu verwenden. Alle Gewährleistungsansprüche sind für den Anwender

aufgehoben, wenn er Nicht- Original – Ersatzteile verwendet bzw. änderungen am

Produkt selbst vornimmt.

5.5 - Für die Bestellung von Ersatzteilen ist

stets dessen Bestellnummer anzugeben,

welche den Stücklisten-Blättern dieser

Anleitung zu entnehmen ist.

VMB Service Deutschland:

Tel : 04442 - 92900

Fax: 04442 - 929090

6. Garantie.

Ab Kaufdatum und innerhalb der Garantie-

zeit beim Händler beseitigt die PRO LIFTS

S.L. alle material-order herstellungsbe-

dingten Mängel durch Reparatur order

Austausch.

In Europa gilt eine Garantiezeit von mindestens 24 Monaten.

Von der garantie ausgenommen sind

Schäden aufgrund von unsachgemäBen

Gebrauch, VerschleiB oder Eingriffen

Dritter. Die Garantie umfasst keine Verbrauchsmaterialien und Mängel, die dedn

Wert oder die Gebrauchstaugllichkeit nur

unerheblich beeinträchtigen.

7. Zertikat

BGV-C1

BGG-912

EC Conformity Declaration pursuant to the

EC Machinery Directives 89/392/CE and

98/37/CE: Manual lifters

Page 26

Depósito legal y copyright 2014. Todos los derechos reservados. 26PRO LIFTS S.L.

TL-A150 SPARE PARTS SKETCHES /

CROQUIS DE LAS PIEZAS DE REPUESTO DE TL-A150

A

B

C

D

E

Proles / Barras.............................................................................................28

TL-A150 Proles / Barras TL-A150

A.1 SRS System / Sistema retentor SRS

A.2 Cable xation / Prisionero cable

A.3 Base prole lower area / Zona inferior perl Base

A.4 Prole upper area / Zona superior barras

A.5 Alluminium stop piece / Pieza de aluminio tope barras

Base / Base....................................................................................................30

B.1 Wheels / ruedas

B.2 Screws for the base / Tornillería de la Base

B.3 Reinforcing struts / Tirantes de refuerzo

B.4 Leg locks / Gatillos patas

B.5 Pin and “R” clip / Pasadores y clips “R”

Winch / Cabrestante......................................................................................31

Forks / Brazos de carga

Fork support / Soporte brazos de carga

Lifting carriage / Carro elevador..................................................................32

D.1 Fixation screw for fork support /

Tornillo jador soporte brazos de carga

D.2 Nylon roller / Rodillos

D.3 Inertial break / Freno de inercia

D.4 Prole stop piece / Taco tope barra

D.5 Pulley system of the carriage lower area /

Sistema de rodillos y poleas inferior carro

Legs / Patas....................................................................................................33

E.1 Complete legs and legs prole / Patas completas, y perles patas

E.2 Complete stabilizer kit and stabilizer exploded /

Estabilizador completo y despiece estabilizador

Page 27

Depósito legal y copyright 2014. Todos los derechos reservados. 27PRO LIFTS S.L.

TL-A150

7040

1520C

C

D

1512

1513

1514

1515

1511

B

A.1

A.1

7209

7209D

2026

Page 28

Depósito legal y copyright 2014. Todos los derechos reservados. 28PRO LIFTS S.L.

TL-A150

A

1511

1512

1513

1514

1515

5414

A.4

A.4

A.4

A.4

A.4

D.3

D.4

D.3

D.4

D.3

D.4

D.3

D.4

D.5

D.5

D.5

D.5

A.3

A.5

A.5

A.5

A.5

A.5

D.2

D.2

D.2

D.2

A.2

1511

1512

1513

1514

1515

5414

Page 29

Depósito legal y copyright 2014. Todos los derechos reservados. 29PRO LIFTS S.L.

TL-A150

A

6 mm

3 mm 3 mm

1531

1540

A.1

3233

3233

2244

2244

1540

3253

3253

3252

3251

3251

1531 /

1532

Profile 1514

(TL-A150)

6 mm

3 mm 3 mm

1532

3 mm

3 mm

Profile 1513

(TL-A150)

1532

3 mm

3 mm

Profile 1512

(TL-A150)

1532

3 mm

3 mm

Profile 1511

(TL-A150)

A.2

8025 (x2)

8025 (x2)

8025 (x2)

5434R

A.3

A.4

5432 (x2)

5418

5419

72467246

5433

5415

54165432

1520C

A.5

5421

72467246

8019

7234

7234

2152 (x2) Solo en tramo 1515

2152

2152

5465

7234

7234

Page 30

Depósito legal y copyright 2014. Todos los derechos reservados. 30PRO LIFTS S.L.

TL-A150

B

B.2

20377061 (x2)2044

6409

2026

7209

(x2)

7209D

(x2)

B.3

B.4

1508

B.2

B.2

B.4

PAT-02

MR-PAS

B.5

2141

2152 (x2)

7078

5429

7962

2047

B.1

2140

Page 31

Depósito legal y copyright 2014. Todos los derechos reservados. 31PRO LIFTS S.L.

TL-A150

C

7040

5401

7160-AC

1507N

7061

2044

7061

70782152

70782152

72407061

72407061

2044

7246

7246

Page 32

Depósito legal y copyright 2014. Todos los derechos reservados. 32PRO LIFTS S.L.

TL-A150

D

D.3

D.5

D.2

D.4

D.1

D.1

D.2

D.3

D.4

D.5

7246

7246

5421

7247

3250

7248

7244

A

7245

72467246

5419

7222N

7223

7061F

7223

7222N

2050 (x2)

5420

2047

5415

5478

5414

7223N

7222N7061F

2044

7061F

7061F 7061F

7061F

5430N 7242 7242 7243

Solo en tramos intermedios

NO EN CARRO 5414

Page 33

Depósito legal y copyright 2014. Todos los derechos reservados. 33PRO LIFTS S.L.

TL-A150

E

2029

2051

2161

2037

2050

2046

7048

2047

2030

2048

2049

Stabilizer kit

TL-A150

Ref: 7039

E.2

1504

1502

1505

1503

E.1

Page 34

Depósito legal y copyright 2014. Todos los derechos reservados. 34PRO LIFTS S.L.

SPARE PARTS LIST / LISTA DE REPUESTOS

TL-A150

Code Description GB / USA Descripción ES

1502 (B) Complete long leg (B Black) Pata larga completa (B Negro)

1503 (B)

Long leg prole (50x70x1465mm) (B Black) Perl pata larga (50x70x1465mm) (B Negro)

1504 (B) Complete short leg (B Black) Pata corta completa (B Negro)

1505 (B)

Short leg prole (50x50x995mm) (B Black) Perl pata corta (50x50x995mm) (B Negro)

1507N (B) Winch xation plate (B Black) Placa portacabrestante (B Negro)

1508 (B) TL-A150 Base (B Black) Base TL-A150 (B Negro)

1511

Base prole 1 (B Black) TL-A150 (1495mm) Tramo 1 Base (B Negro) TL-A150 (1495mm)

1512 Prole 2 (B Black) TL-A150 (1495mm) Tramo 2 (B Negro) TL-A150 (1495mm)

1513 Prole 3 (B Black) TL-A150 (1495mm) Tramo 3 (B Negro) TL-A150 (1495mm)

1514 Prole 4 (B Black) TL-A150 (1495mm) Tramo 4 (B Negro) TL-A150 (1495mm)

1515 Prole 5 (B Black) TL-A150 (1495mm) Tramo 5 (B Negro) TL-A150 (1495mm)

1520C Steel cable Ø5mm x 16 m Cable de acero Ø5mm x 16 m

1531 (B) SRS Unit Prole 4 (B black) Pieza Retentor tramo 3 (B Negro)

1532 (B) SRS Unit Prole 1, 2 & 3 (B black) Pieza Retentor tramo 1, 2 y 3 (B Negro)

1540 (B) SRS Unlock (B black) Desbloqueador sistema SRS (B Negro)

2026 Safety catch Gatillo de seguridad

2029 Crank nob Ø34 Pomo baquelita estabilizador patas Ø34

2030 Stabilizer round plate Platillo de apoyo estabilizador patas Ø84

2037 M10x30 Allen screw Tornillo allen M10x30

2044 M10 Auto-block nut Tuerca autoblocante M10

2046 M5 Auto-block nut Tuerca autoblocante M5

2047 M12 Washer Arandela M12

2048 M6 Washer Arandela M6

2049 M6x10 Allen screw Tornillo allen M6x10

2050 M5x25 Allen screw Tornillo allen M5x25

2051 M10 Nut Tuerca M10

2140 M12 Auto-block nut Tuerca autoblocante M12

2141 M8x25 Allen screw Tornillo allen M8x25

2152 M8 Washer Arandela M8

2161 Steel hand crank Manivela estabilizador patas

Page 35

Depósito legal y copyright 2014. Todos los derechos reservados. 35PRO LIFTS S.L.

Code Description GB / USA Descripción ES

2244 M6 Auto-block nut Tuerca autoblocante M6

3233 Conic screw M6x16 Tornillo cabeza cónica M6x16

3250 M8x20 Conic screw Tornillo cabeza cónica M8x20

3251 M6x16 Allen screw Tornillo allen M6x16

3252 SRS screwed plate Pletina roscada Retentor

3253 M6x10 Headless allen bolt Tornillo allen sin cabeza M6x10

5401 (B) Fork support (B Black) Soporte brazos de carga (B Negro)

5414 Lifting carriage (B black) Carro elevador (B Negro)

5415 Special pulley Ø55 Polea especial Ø55

5416 Steel axe Ø12x58 Eje de acero Ø12x58

5418 Alluminium stop holding piece Pieza de aluminio sujeta tope

5419 Alluminium stop piece Tope de aluminio

5420 Alluminium stop holding piece Pieza de aluminio sujeta tope

5421 Alluminium stop piece Tope de aluminio

5429 Wheel Ø100 Rueda Ø100

5430N M14x150 Allen screw Tornillo allen M14x150

5432 M8x20 Conic screw Tornillo cabeza cónica M8x20

5433 M6x15 Conic screw Tornillo cabeza cónica M6x15

5434R Cable grip (6 screws) Pieza jación cable (6 Tornillos)

5465 Alluminium M12 axel support Pieza de aluminio soporte eje M12

5478 Special thin head screw M12x30 Tornillo especial cabeza na M12x30

6409 Spirit level Ø30mm Nivel de burbuja Ø30mm

7039 Complete stabilizer Estabilizador completo

7040

Short load support fork (B Black) (54.5cm)

Brazo de carga corto (B Negro) (54.5cm)

7048 M18 Threaded bolt Perno roscado M18

7061 M10 Washer Arandela M10

7061F M10 Thin washer for adjustments Arandela na de ajuste M10

7078 M8 Auto-block nut Tuerca autoblocante M8

7160-AC 450kg Winch (Short crank) Cabrestante 450kg (Short crank)

7209 (B) Left reinforcement strut (B Black) Tirante de refuerzo izquierdo (B Negro)

7209D (B) Right reinforcement strut (B Black) Tirante de refuerzo derecho (B Negro)

7222N Special screw for black nylon roller Tornillo especial para rodillo nylon negro

Page 36

Depósito legal y copyright 2014. Todos los derechos reservados. 36PRO LIFTS S.L.

Code Description GB / USA Descripción ES

7223N Black nylon roller Rodillo nylon negro

7234 M8x16 Screw Tornillo M8x16

7240 M10x35 Allen screw Tornillo allen M10x35

7242 M14 Washer Arandela M14

7243 M14 Auto-block nut Tuerca autoblocante M14

7244A Inertial brake lock (Ø21mm disk) Varilla freno de inercia (Disco Ø21mm)

7245 Brake lock support Soporte varilla freno de inercia

7246 M8x25 Conic screw Tornillo cabeza cónica M8x25

7247 M5x10 Conic screw Tornillo cabeza cónica M5x10

7248 Brake spring Muelle freno de inercia

7962 M12x40 Allen screw Tornillo allen M12x40

8019 Threaded alluminium piece inner stop Pletina roscada tope interior de aluminio

8025 M8x10 Headless allen bolt Tornillo allen sin cabeza M8x10

MR-PAS ‘R’ Clip Clip de seguridad ‘R’

PAT-02 Fastener steel pin Ø10 x 88.5mm Pasador de acero Ø10 x 88.5mm

REMEBER TO QUOTE THE TYPE, PRODUCTION YEAR

AND SERIAL NUMBER OF THE TOWERLIFT.

RECUERDE CITAR EL MODELO, EL AÑO DE PRODUCCIÓN

Y EL NÚMERO DE SERIE DE LA TORRE ELEVADORA.

Page 37

Depósito legal y copyright 2014. Todos los derechos reservados. 37PRO LIFTS S.L.

Page 38

Page 39

Page 40

PRO LIFTS S.L.

C/ Ciudad de Barcelona Nº19

Pol. Ind. Fuente del Jarro

46988 Paterna (Valencia) Spain

Tlf Export: +34 96 171 81 86

Tlf Nacional: 96 171 81 83

email: info@prolifts.es web: www.prolifts.es

facebook / vmblifts

Canal VMBLifts

Para más información consulte con nuestros técnicos en:

For further information follow the advise of our technicians:

Loading...

Loading...