Vmar J3.PIPER GUB, L4-GRASSHOPPER Assembly & Operation Manual

ALMOST

READY

TO FLY MODEL

J3.PIPER

GUB

L4-GRASSHOPPER

ASSEMBLY

& OPERATIONS

MANUAL

Please review

this

manual

thoroughly

before assembling or

operating this model.

Proceeding with

assembly

and use of this

product

indicates

A Remote

Gontrol Model Aircraft is not

a

toy.

lt is

a flying

model

that functions

much like

a

full

size

airplane. lf

you

do not

assemble

and operate this

product properly

you

can cause injury

to

yourself

and others and

damage

prop-

erty. DO

NOT FLY this model

if

you

are not

qualified.

You

are entirely responsible

for

the mechanical,

aeronautical and electrical integrity

of this model

and it's

structure,

control

surfaces, hinges, linkages,

covering,

engine, radio, wiring,

battery

and all other

components.

Gheck all components

before and after

each flight.

Don't

fly until it's

right!

POLYCOTE*EGS

ENHANCED

COVERING

SYSTEM

w

Agreement With

&

Acceptance

of the

following

Liability Disclaimer.

Model

airplanes, model

engines, model

engine

fuel,

propellers

and

related

accessories,

tools and equipment

can be haz-

ardous if improperly

used. Be cautious

and

follow

all

safety

recommendations

when using

your

VMAR

model

airplane.

Keep hands,

tools, clothing

and all

foreign

objects well

clear of

engines when

they are

operating.

Take

particular

care to safe-

guard

and

protect

your

eyes and

fingers

and the

eyes and

fin-

gers

of other

persons

who

may be nearby.

Use only a

good

quality propeller

that has no

cracks or flaws.

Stay clear of the

propeller

and

stay clear of the

plane

of rotation defined

by

the

propeller.

The Manufacturer,

Distributor,

Retailer and/or

other

suppliers of this

product

expressly

disclaim any warranties

or

representations,

either expressed or implied,

including

but

not

limited

to implied warranties

of

fitness

for the

purposes

of

achieving and sustaining remotely

controlled flight. ln no

event

will the Manufacturer, Distributor,

Retailer

and/or other suppli-

ers of this

product

have any obligation

arising from

contract or

toft, or for loss

of

revenue

or

profit,

or for indirect,

special, inci-

dental, consequential

or other damages

arising

from

the use

of

this

product.

ln

purchasing

and/or

using this

product,

the

user

accepts

all

responsibility

for its use

and accepts all liability

associated with such use.

The

Graphics

and Detailing

are

inside

the POLYCOTE ECS/

WING ASSEMBLY

Parts

needed

-

Roll of

wing

joiner

tape

-

Right and

left wing

panels

-

Wing

joiner

(also

called dihedral

brace)

Step

1.1 Locate

the wing

joiner

(also

called

Dihedral

brace). Using

a

ruler, determine

the center

of the wing

join-

er and

mark it with a

pencil

as illustrated

in 1B.

Step

1.2 Trial fit the

wing

joiner

into the

wing

panels.

lt

should

insert

smoothly

up

to the center

line as

illustrated

in

SIIETSN

1A-

Left

and

right

wing

panels

Step

1.3 Apply

plenty

of 30

minute

Epoxy to one end

of the

wing

joiner

using

a stir stick

or epoxy

brush as

illustrated

in

1D.

Carefully

insert

the epoxy

coated

half

of

the wing

join-

er

into one

wing

panel

as

illustrated

in

'lE.

See

1F and use a cloth

or

tissue to wipe away

any excess

epoxy

that squeezes

out of

the

joint.

Repeat this

process

rL

UP

1C- Trial

fit

the

wing

joi

UP

Center

line

pointing

up

1E-

Carefully

insed the

joiner

all the

way to the center

line

2

.

JOINING

THE

WING HALVES

Tools and

Adhesives

needed

-

30

minute epoxy

-

Epoxy brush

or stir sticks

-

Disposable

mixing dish

for the epoxy

-

Sandpaper

(Coarse

240

grit

recommended)

-

Low tack

masking tape

-

Pencil,

knife, ruler

-

Paper

towels

1C. Now slide

the other

wing

panel

onto

the wing

joiner

until the

wing

panels

meet. lf the

fit is overly

tight, sand

the

wing

joiner

slightly and

try again.

Mark the

joiner

to

indicate

which

way is UP

as illustrated

in 18.

UP

1B-

Preparation of

wing

joiner

several

times

to ensure

the

wing

joiner

and cavity

are

well

coated

with 30 minute

epoxy.

When the

wing

joiner

& cavity

are

well coated

with 30

minute epoxy,

inserl the

joiner

to the center

line,

wipe away

any excess

epoxy

and let dry.

(Note:

Do

not

use

5

minute

epoxy

or CA to

join

the wings).

1D- Apply

plenty

of 30 minute epoxy

to the

wing

joiner

n

1F

-

Wipe off the excess

epoxy then allow

to cure

WING

ASSEMBLY - JOINING THE WING HALVES

(Gont.)

2A- Apply

plenty

of30 minuta epory 2B-Align the two wing

panels

and 2C- Use low tack masking tape to

hold

gluetoall

surfac6 slowly close the

gap

until the tightly together

:ilg",'iil

"11f"."31"

rirmr' in

Step 2.4 Once the epoxy has cured completely

(allow

sev- supplied.Starting on

the bottom side of the wing, stick the

eral

hours

at

least), the

tape can

be carefully removed from tape centrally over the

joint

ensuring that it is

pressed

down

the

wing

panels.

Peel the tape back on

itself...

do

not

pull

firmly

as

you

work around the wing. Wrap the tape all the

upright away from the wing.

To

seal and

finish

the

joint

in way

around

the wing

joint

in one

piece,

starting and finish-

the wings, a roll of wing

joiner

tape has been

ing

on the bottom.

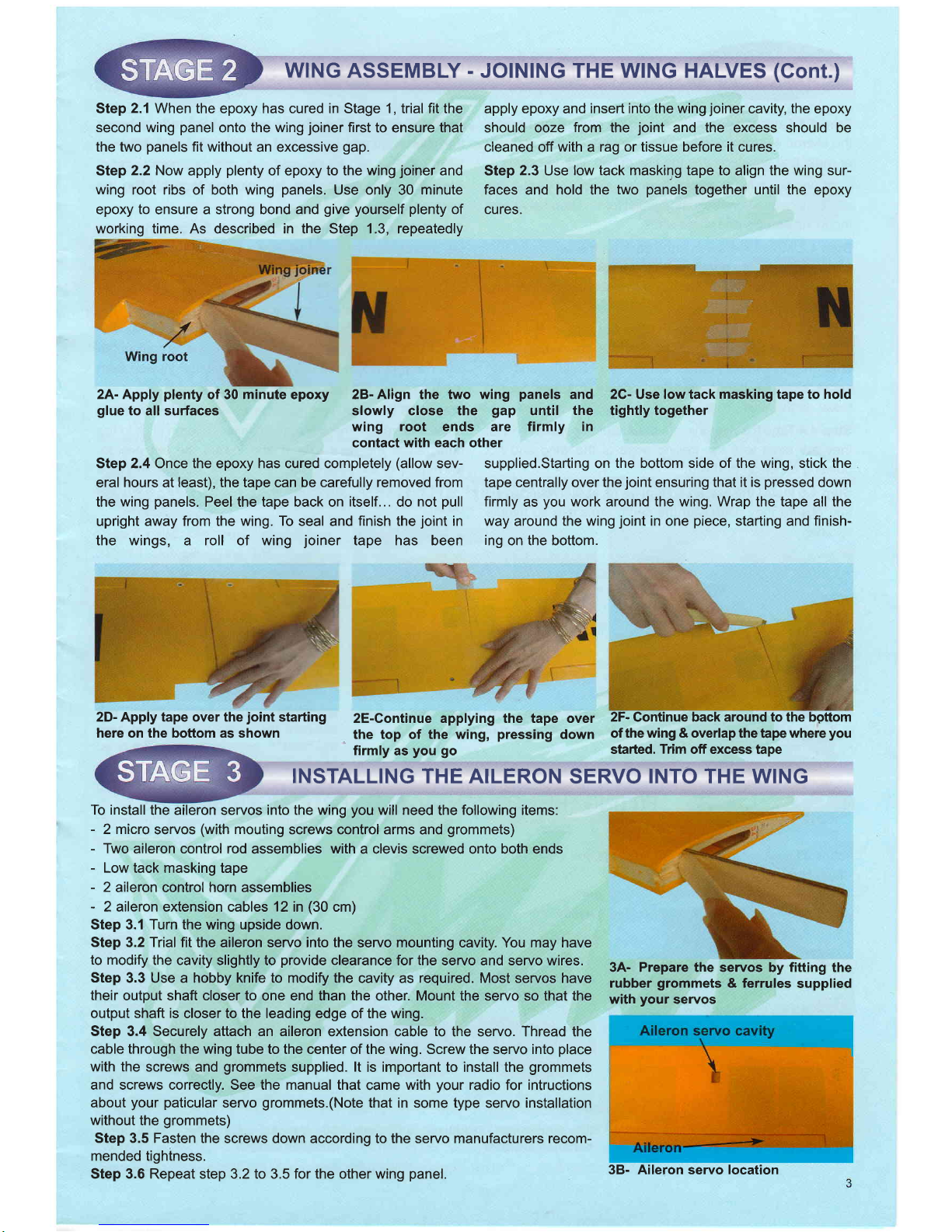

Step

2.1

When the epoxy has cured in Stage 1, trial fit the

second wing

panel

onto the

wing

joiner

first

to ensure that

the two

panels

fit without

an excessive

gap.

Step

2.2 Now

apply

plenty

of epoxy to the wing

joiner

and

wing

root ribs of both wing

panels.

Use only

30

minute

epoxy

to

ensure a strong bond

and

give yourself plenty

of

working time. As described in the Step 1.3, repeatedly

apply epoxy

and

insert into the wing

joiner

cavity,

the

epoxy

should ooze

from

the

joint

and the excess should be

cleaned off

with

a

rag or tissue before it cures.

Step

2.3

Use

low tack maskilg tape to

align

the wing sur-

faces and hold the

two

panels

together until

the

epoxy

cures.

3A- Prepare the servos

by

fitting

the

rubber

grommets

&

ferrules

supplied

with

your

seryos

2D- Apply tape over the

joint

starting

here on the boftom as shown

To install

the aileron servos into the wing

you

will need

the

following

items:

-

2 micro

servos

(with

mouting

screws control arms

and

grommets)

-

Two

aileron control rod

assemblies

with

a clevis screwed onto both ends

-

Low

tack masking tape

-

2

aileron

control

horn assemblies

-

2 aileron

extension cables

12

in

(30

cm)

Step 3.1 Turn the wing upside down.

Step

3.2

Trial

fit the aileron servo into the

servo

mounting

cavity. You may have

to modify

the cavity

slightly to

provide

clearance

for

the

servo and servo wires.

Step

3.3 Use a hobby knife to modify the

cavity as

required.

Most servos have

their

output shaft closer to

one end than

the

other. Mount the servo so that the

output shaft is

closer to the leading edge of the wing.

Step 3.4 Securely attach an aileron

extension cable

to

the servo. Thread the

cable through the wing tube

to the center of the wing. Screw the servo into

place

with the

screws

and

grommets

supplied.

lt

is important to install the

grommets

and screws correctly. See the manual that

came

with

your

radio

for

intructions

about

your paticular

servo

grommets.(Note

that in some type

servo

installation

without

the

grommets)

Step 3.5 Fasten

the screws down according to the seryo manufacturers recom-

mended

tightness.

Step 3.6 Repeat step 3.2 to 3.5 for the other wing

panel.

2E-Continue applying the tape over

2F-

Gontinue

back around to the bgttom

the top of the wing,

pressing

down

of

the wing & overlap

the tape

where

you

firmly

as

you go

stafted.

Trim

off excess tape

INSTALLING THE AILERON

SERVO

INTO THE WING

38- Aileron servo location

INSTALLING

THE AILERON

CONTROL

SYSTEM

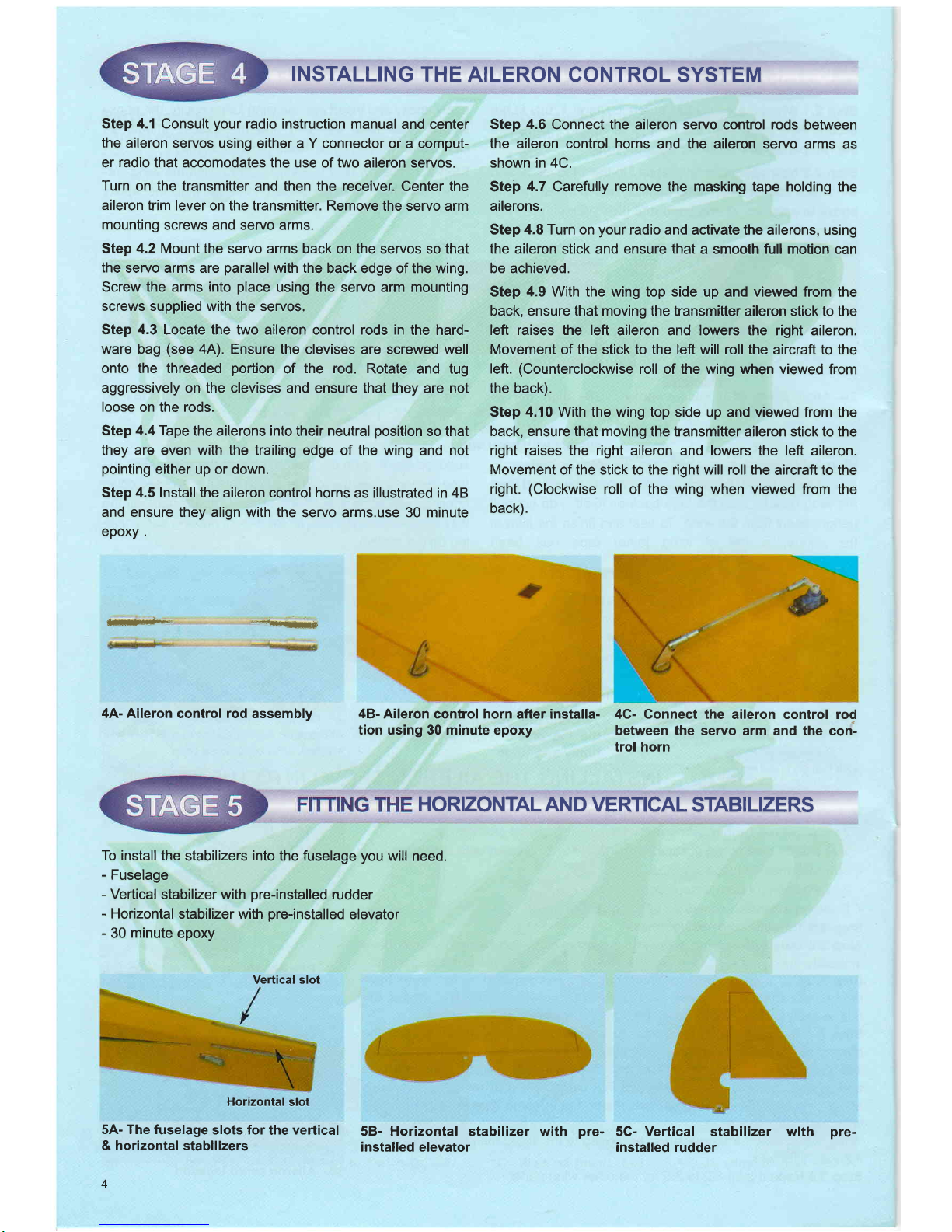

Step 4.1

Consult

your

radio instruction manual

and center

the

aileron

servos using either a Y connector

or a comput-

er

radio

that accomodates the use

of

two

aileron servos.

Turn on the

transmitter and then the receiver.

Center the

aileron trim

lever on the transmitter. Remove

the servo arm

mounting

screws and servo arms.

Step

4.2 Mount

the servo arms

back on the servos so that

the

seruo arms are

parallel

with the

back edge of the wing.

Screw the arms into

place

using the servo arm mounting

screws supplied with the servos.

Step

4.3

Locate the two aileron

control

rods in

the hard-

ware

bag

(see

4A). Ensure the

clevises are screwed well

onto the threaded

portion

of

the rod.

Rotate

and tug

aggressively

on

the

clevises and ensure that

they are not

loose

on the

rods.

Step 4,4Tape

the ailerons into

their

neutral

position

so that

they are

even with the trailing

edge of

the wing

and not

pointing

either up or down.

Step

4.5

Install the aileron control horns

as illustrated in 48

and ensure they align with the

servo arms.use 30 minute

epoxy .

dr*lfl**rd

4A- Aileron

control

rod

assembly

Step 4.6

Connect the aileron servo

control

rods

between

the aileron control horns

and the aileron seryo

arms as

shown in 4C.

Step

4.7

Carefully remove the masking tape holding

the

ailerons.

Step 4,8 Turn on

your

radio and

activate the ailerons, using

the aileron

stick and

ensure that

a smooth full motion can

be achieved.

Step

4.9

With the wing top side up

and

viewed from the

back,

ensure that

moving

the transmitter aileron

stick

to the

left raises the left

aileron and lowers the right aileron.

Movement

of the stick to the left will roll the aircraft to the

left.

(Counterclockwise

roll of the wing when viewed

fr:om

the back).

Step 4.10 With the wing

top side up and viewed from the

back, ensure that moving

the transmitter aileron stick to the

right raises the right

aileron and lowers the left aileron.

Movement

of the stick to the right will roll the

aircraft to the

right.

(Clockwise

roll of the wing when viewed from

the

back).

48-

Aileron control horn

after installa-

tion using

30

minute

epoxy

4G- Connect the

aileron control rod

between

the servo arm and the con'-

trol horn

HORIZONTAL

AN D

VERTICAL

STABI

LIZERS

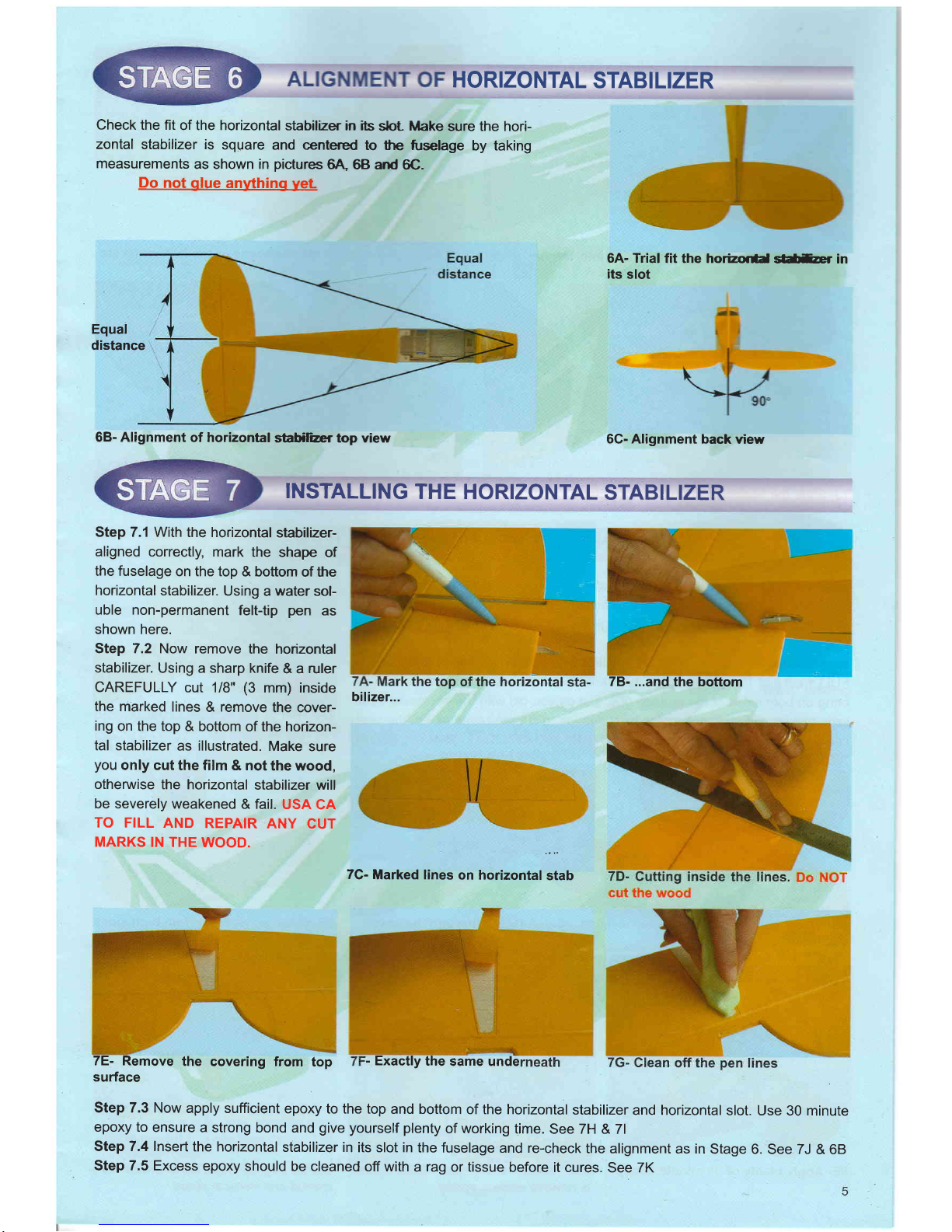

To

install the

stabilizers

into

the fuselage

you

will need.

-

Fuselage

-

Veftical

stabilizer with

pre-installed

rudder

-

Horizontal

stabilizer with

pre-installed

elevator

-

30

minute

epoxy

Horizontal

slot

5A- The fuselage

slots for

the

vertical

&

horizontal

stabilizers

4

58- Horizontal stabilizer with

installed elevator

pre-

5C- Vertical stabilizer

with

installed rudder

Vertical slot

pre-

HORIZONTAL

STABILIZER

Check

the fit

of the horizontal

stabilZer in ibs

sbt Make

sure the hori-

zontal

stabilizer is

square

and centered

to the

fuselage

by taking

measurements

as shown in

pictures

6A,

68 and

6C.

Do

not

glue

anything

yet

6A- Trial

fit the horizor*d

sl*tur in

its

slot

Equal

distance

68- Alignment

of horizontal

stabiliar top view

6G- Alignment back

view

INSTALLING

THE HORIZONTAL

STABILIZER

Step 7.1 With

the horizontal

stabil2er-

aligned

correctly,

mark the

shape

of

the fuselage

on the top

& bottom

of the

horizontal

stabilizer.

Using

a

water

sol-

uble non-permanent

felt-tip

pen

as

shown here.

Step 7.2 Now

remove

the horizontal

stabilizer.

Using a sharp knife

& a ruler

CAREFULLY

cut 1/B'

(3

mm) inside

the marked

lines & remove

the cover-

ing

on the top

& bottom

of the horizon-

tal stabilizer

as illustrated.

Make

sure

you

only cut

the film & not

the wood,

otherwise

the horizontal

stabilizer will

be severely

weakened

& fail.

USA

CA

TO FILL

AND

REPAIR

ANY

CUT

MARKS

IN THE

WOOD.

7C-

Marked lines

on horizontal

stab

7E- Remove

the

covering from

top

surface

Step 7.3 Now

apply sufficient

epoxy to the top

and bottom of the horizontal

stabilizer

and horizontal

slot. Use 30 minute

epoxy to

ensure a strong

bond and

give

yourself plenty

of working

time. See ZH & 7l

Step 7.4 Insert

the horizontal

stabilizer in its slot in

the fuselage and re-check

the alignment

as in Stage

6. See 7J & 68

Step 7.5 Excess

epoxy should

be cleaned off with a rag

or tissue

before it cures. See 7K

78- ...and

the bottom

bilizer...

-

Exactly

the

same unde

Loading...

Loading...