Page 1

1

ARROW-Tiger

40-52 ARF ECS

SPORT TRAINER MODEL

WITH POLYCOTE ECS ENHANCED GRAPHICS SYSTEM

TM

ASSEMBLY & OPERATIONS MANUAL

Please review this manual thoroughly before assembling or operating this model.

Proceeding with assembly and use of this product indicates

Agreement With & Acceptance of the following Liability Disclaimer.

Model airplanes, model engines, model engine fuel, propellers and related accessories, tools and equipment can be

hazardous if improperly used. Be cautious and follow all safety recommendations when using your VMAR model airplane. Keep hands, tools, clothing and all foreign objects well clear of engines when they are operating. Take particular

care to safeguard and protect your eyes and fingers and the eyes and fingers of other persons who may be nearby.

Use only a good quality propeller that has no cracks or flaws. Stay clear of the propeller and stay clear of the plane of

rotation defined by the propeller.

The Manufacturer, Distributor, Retailer and/or other suppliers of this product expressly disclaim any warranties or representations, either expressed or implied, including but not limited to implied warranties of fitness for the purposes of

achieving and sustaining remotely controlled flight.

In no event will the Manufacturer, Distributor, Retailer and/or other suppliers of this product have any obligation arising

from contract or tort, or for loss of revenue or profit, or for indirect, special, incidental, consequential or other damages

arising from the use of this product.

In purchasing and/or using this product, the user accepts all responsibility for its use and accepts all liability associated

with such use.

CAUTION

A Remote Control Model Aircraft is not a toy. It is a flying model that functions much like a full size airplane. If

you do not assemble and operate this product properly you can cause injury to yourself and others and dam-

age property. DO NOT FLY this model if you are not qualified.

You are ultimately responsible for the mechanical, aeronautical and electrical integrity of this model and it's

structure, control surfaces, hinges, linkages, covering, engine, radio, wiring, battery and all other components.

Check all components before and after each flight.

Don't fly until it's right!

The Graphics and Detailing are inside the POLYCOTE ECS!

Page 2

2

- Roll of wing joiner tape (supplied with kit) - 30 minute epoxy

- Right and left wing panels - Epoxy brush or stir sticks

- Wing joiner (also called dihedral brace) - Disposable mixing dish for the epoxy

- Two short dowel guides - Sandpaper (Coarse 240 grit recommended)

- Low tack masking tape

- Pencil

- Knife

- Ruler

- Paper towels.

Parts needed T

ools and

Adhesives needed

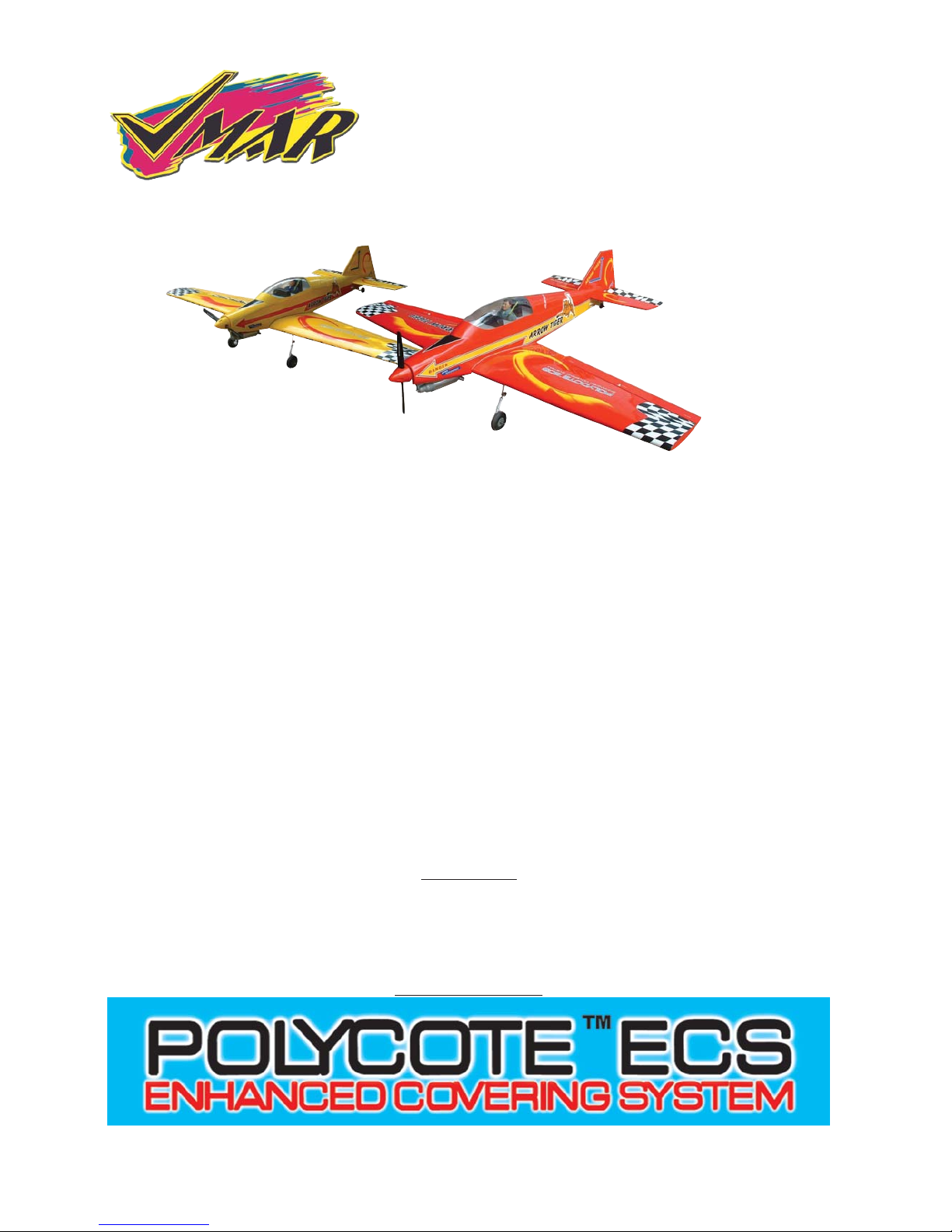

STAGE 1

– WING ASSEMBLY.

JOINING THE WING HALVES

1.1 Locate the wing joiner (also called Dihedral brace). Using the ruler, determine the center of the wing joiner and

mark it with a pencil as illustrated in 1A. Also mark a center line on each of the dowel guides.

1A- Preparation of wing joiner and dowel guides. 1B- Trial fit the wing joiner and dowel guides

1.4 Apply plenty of 30 minute epoxy to one end of the wing joiner, using a stir stick or epoxy brush. Carefully insert

the joiner into the first wing panel as illustrated in 1D, 1E and 1F, then wipe off the excess epoxy that squeezes

out of the joint with a cloth or tissue. Repeat this process several times to ensure that the wing joiner and cavity

are well coated in epoxy. When the wing joiner & cavity are well coated with 30 minute epoxy, insert the joiner to

the center line, wipe away any excess epoxy and let dry. (Note: Do not use 5 minute epoxy or CA to join the wings)

1.2 Trial fit the wing joiner into the wing panels. It should insert smoothly up to the center line as illustrated in 1B.

Now slide the other wing panel onto the wing joiner until the wing panels meet. If the fit is overly tight, sand the wing

joiner slightly and try again.

1.3 Insert the dowel guides into one of the wing panels all the way to the center lines. Apply CA glue to secure the

dowels into their places as illustrated in 1B and 1C. Do not apply CA glue to the wing joiner.

1C- Apply CA glue to secure dowels into their places 1D- Apply plenty of epoxy glue to the wing

joiner.

wing joiner

dowel guides

Center line

Wing guide

Wing guide cavity

Page 3

3

2.1 When the epoxy has cured in Stage 1, trial fit the second wing

panel onto the wing joiner first to ensure that the two panels fit

without an excessive gap.

2.2 Now apply plenty of epoxy to the wing joiner and wing root ribs of

both wing panels. Use only 30 minute epoxy to ensure a strong bond

and give yourself plenty of working time. As described in the Step 1.4,

repeatedly apply epoxy and insert into the wing joiner cavity, the

epoxy should ooze from the joint and the excess should be cleaned

off with a rag or tissue before it cures.

2.3 Use low tack masking tape to hold the two panels together until

the glue cures.

1E- Carefully insert the joiner all the way to the cen-

ter line

2A- Apply plenty of 30 minute epoxy

glue to all surfaces.

2C- Use low tack masking tape to hold tightly

together.

3.1 Once the epoxy has cured completely (allow several hours at least), the tape can be carefully removed from

the wing panels. Peel the tape back on itself… do not pull upright away from the wing. To seal and finish the joint

in the wings, a roll of wing joiner tape has been supplied.Starting on the bottom side of the wing, stick the tape centrally over the joint ensuring that it is pressed down firmly as you work around the wing. Wrap the tape all the way

around the wing joint in one piece, starting and finishing at the wiring harness cavities at the bottom of the wing.

Center line pointing up

1F - Wipe off the excess epoxy then allow to cure.

2B- Align the two wing panels and slowly close the

gap until the wing root ends are firmly in contact

with each other

3C- Trim off the excess tape.

3B- Continue applying the tape

over the bottom of the wing,

pressing down firmly as you go.

3A- Apply tape over the joint,

starting here

STAGE 2 - WING ASSEMBLY - JOINING THE WING HALVES CONTINUED.

STAGE 3 - WING ASSEMBLY - JOINING THE WING HALVES CONTINUED.

UP

Wing root

Page 4

4

Aileron servo cavity

4B- Aileron servo location

4A- The servo componemts

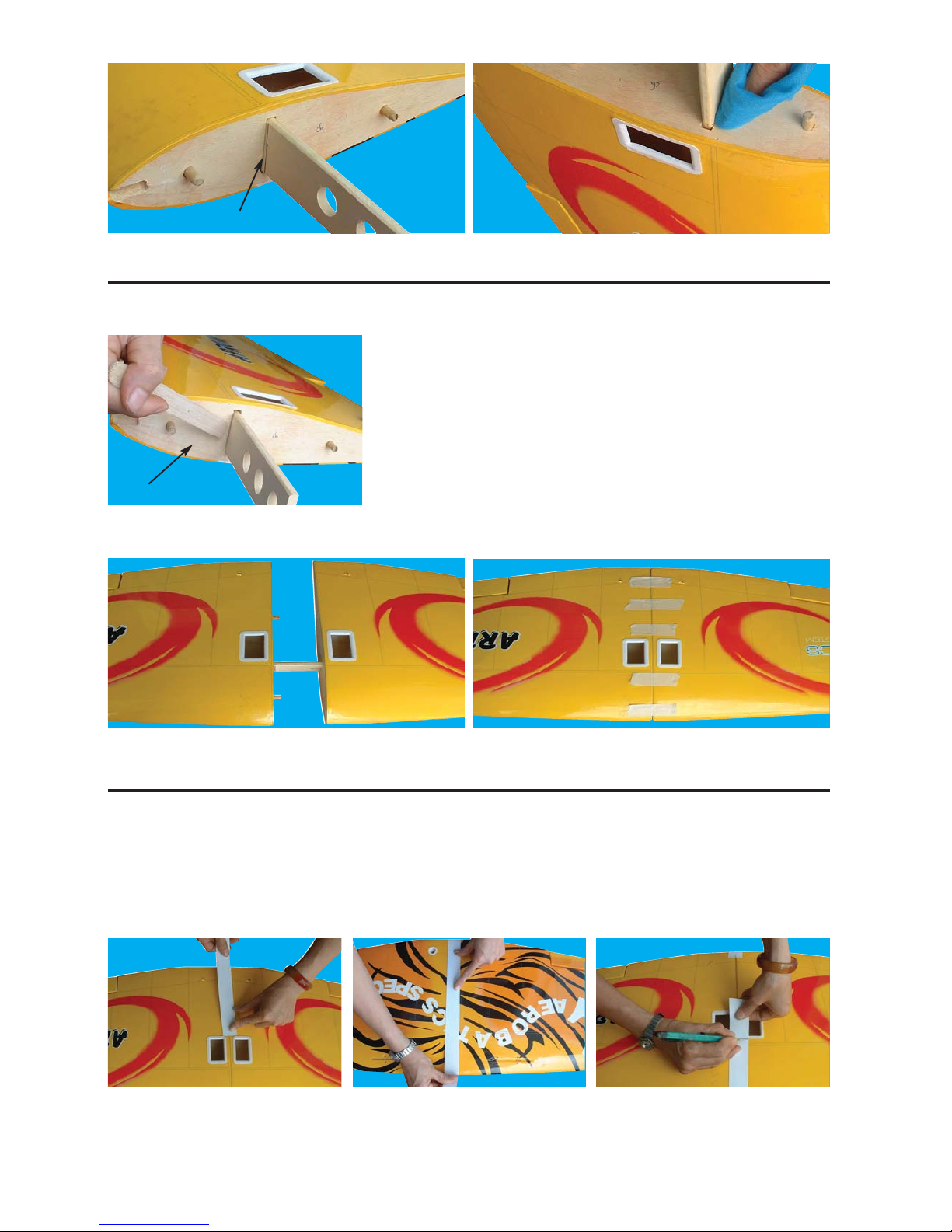

STAGE 4

- INSTALLING THE AILERON SERVO INTO THE WING.

To install the aileron servo into the wing you will need the following items :

- 2 servos

- Servos mounting screws and grommets as supplied with servos.

- Servo control arms as supplied with the servos.

- Two aileron control rod assemblies supplied with the kit. The

assemblies consist of a metal rod with clevis screwed onto both

ends.

- Low tack masking tape.

- 2 aileron control horn assemblies

- 1 servo wire connection wire

STAGE 5 - INSTALLING AILERON CONTROL SYSTEM

5A- Aileron control rod assembly 5B- Aileron control horn assembly 5C- Aileron control installed

5.1 Consult your radio instruction manual and center the aileron servo by plugging it into the aileron channel in the

receiver. Turn on the transmitter and then the receiver. Center the aileron trim lever on the transmitter. Remove the

servo arm mounting screw and the servo arm.

5.2 Mount the servo arm back on the servo so that the arm is parallel with the back edge of the wing. Screw the

arm into place with the servo arm mounting screw supplied with the servo.

5.3 Locate the two aileron control rods in the hardware bag (see 5A). Ensure the clevises are screwed well onto

the threaded portion of the rod. Rotate and tug aggressively on the clevises and ensure that they are not loose on

the rods.

5.5 Ensure that the aileron control horns are screwed onto the threaded aileron control horn bolts and that both

control horns are in approximately the same place on their respective bolts.

Aileron

Aileron

Aileron

4.1 Carefully remove the white cover plates from the aileron

servo cavities. Ensure you know which cover plate is for the

right wing and which is for the left. Notice that there are wooden servo rails pre-installed into each servo cavity end.

4.2 Locate the wiring harness tubes that are protruding slightly

into each aileron servo cavity. The tube can be moved slightly

at this point. Check out the other end of each tube for a clean

position and then using C/A glue secure the wiring harness

tubes at the aileron servo cavity end.

4.3 Install a servo in each aileron servo cavity and connect the

servo wire to the servo extension wires and run the extension

wires through wiring harness tubes to the centre of the wing

Install the aileron control horns

4C- Aileron servos mount

4D- Screw servo in position

4E- Install aileron control horn

Aileron

Page 5

5

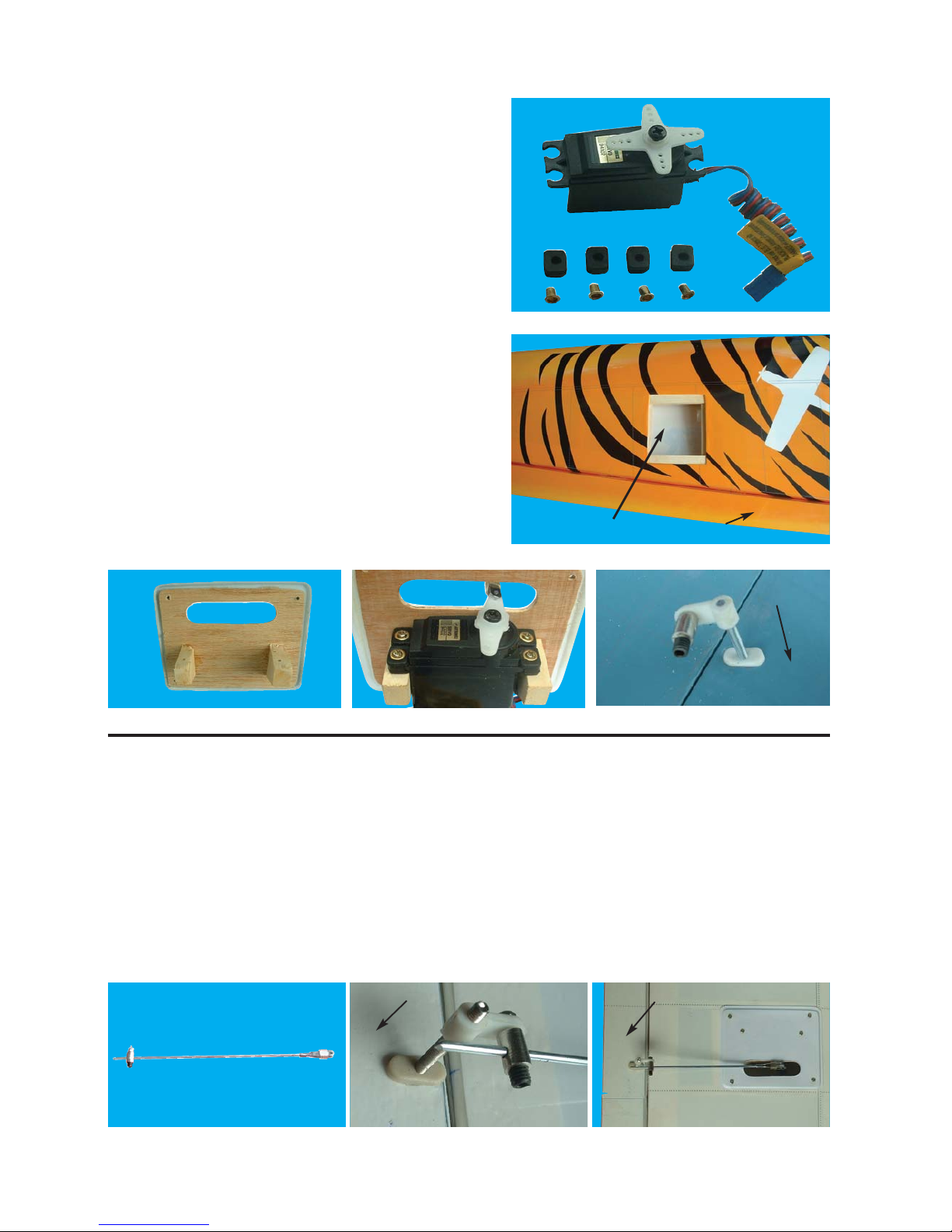

STAGE 6 - FITTING THE

HORIZONTAL AND VERTICAL

STABILIZERS

To install the stabilizers into the fuselage you will need.

- Fuselage

- Vertical stabilizer with pre-installed

rudder

- Horizontal stabilizer with preinstalled elevator

6A- The fuselage slots for the vertical & horizontal stabilizers

6B- Horizontal stabilizer with pre-installed elevator 6C- Vertical stabilizer with pre-installed rudder

Vertical slot

Horizontal slot

STAGE 7 - ALIGNMENT OF HORIZONTAL STABILIZER

7.1 Check the fit of the horizontal stabilizer in its slot. Make sure the

tail is square and centered to the fuselage by taking measurements

as shown in pictures 7A, 7B and 7C. Do not glue anything yet.

Equal

distance

Equal distance

90

0

7A- Trial fit the horizontal stabilizer in its

slot

7B- Alignment of horizontal stabilizer top view. 7C- Alignment back view

5.6 Connect the aileron servo rods to the aileron control horns.The one end with clevis will be attached to the servo

output arm.

5.7 Connect the other end of the rod to the control horn pre-installed with an EZ connector

5.8 Remove the masking tape holding the ailerons.

In the case of computer radios the servos together by connecting them to the appropriate receiver channel. In the

case of analog radios couple the servos together using a Y harness

5.10 Turn on your radio and activate the ailerons, using the aileron stick and ensure a smooth full motion can be

achieved.

5.11 With the wing top side up and viewed from the back, ensure that moving the transmitter aileron stick to the left

raises the left aileron and lowers the right aileron. Movement of the stick to the left will roll the aircraft to the left.

(Counterclockwise roll of the wing when viewed from the back ).

5.12 With the wing top side up and viewed from the back, ensure that moving the transmitter aileron stick to the

right raises the right aileron and lowers the left aileron. Movement of the stick to the right will roll the aircraft to the

right. (Clockwise roll of the wing when viewed from the back).

Page 6

6

8.1 With the horizontal stabilizer

aligned correctly, mark the shape of

the fuselage on the top & bottom of

the horizontal stabilizer using a

water soluble non-permanent felt-tip

pen as shown here

8A- Mark the top of the horizontal

stabilizer...

8B- ...and the bottom

STAGE 8

- INSTALLING

THE HORIZONTAL STABILIZER

9.1 Now remove the horizontal stabilizer & using a sharp

knife & a ruler CAREFULLY cut 1/8" (3 mm) inside the

marked lines & remove the covering on the top & bottom

of the horizontal stabilizer as illustrated. Make sure you

only cut the film & not the wood, otherwise the horizontal stabilizer will be severely weakened & fail.

9A- Marked lines on horizontal stab

9B- Cutting inside the lines

9C- Remove the covering from top surface.

9D- Exactly the same underneath 9E- Clean off the pen lines.

10A- Apply plenty of epoxy

10.1 Now apply sufficient epoxy to the top and bottom of

the horizontal stabilizer and horizontal slot. Use 30

minute epoxy to ensure a strong bond and give yourself

plenty of working time (see 10A & 10B).

10.2 Insert the horizontal stabilizer in its slot in the fuse-

lage and re-check the alignment as in Stage 7 (see 10C).

10.3 Excess epoxy should be cleaned off with a rag or

tissue before it cures (see 10D).

STAGE 9 - INSTALLING THE HORIZONTAL

STABILIZER CONTINUED

STAGE 10 - INSTALLING THE HORIZON-

TAL STABILIZER CONTINUED

Page 7

7

10B- Apply plenty of epoxy 10C- Slide the horizontal stabiliz-

er in place

10D- Wipe off excess epoxy

STAGE 11

- FITTING THE VERTICAL

STABILIZER

11.1 Check the fit of the vertical stabilizer in its slot.

Make sure that it is square to the horizontal stabilizer

and fuselage (see 11A)

11.2 Mark the shape of the fuselage on the left & right

sides of the vertical stabilizer using a felt-tip pen (11B)

11.3 Now remove the vertical stabilizer, using a sharp

knife & ruler, CAREFULLY cut just 1/8" (3mm) inside

the marked lines (see 11C) and remove the covering

on both sides of the fin (see 11D), just as you did with

the horizontal stabilizer, making sure you only press

hard enough to cut the covering, not the vertical stabi-

lizer. Do not cut the wood.

11A- Trial fit the vertical stabilizer into fuselage slot.

11B- Mark both sides of the verti-

cal stabilizer

11C- Carefully cut through the

covering

11D- Remove covering from both

sides

12.1 Now apply sufficient epoxy to both sides & the bot-

tom of the vertical stabilizer as illustrated in 12A. Use 30

minute epoxy to ensure a strong bond and give yourself

plenty of working time.

12.2 Insert the vertical stabilizer in its slot in the fuse-

lage and re-check the alignment. Excess adhesive

should be cleaned off with a rag or tissue before it

cures.

12A- Apply plenty of epoxy 12B- Slide the stab into place &

remove excess epoxy

12C- 90 degrees angle between

the horizontal and vertical stabs.

90

0

STAGE 12 - FITTING THE VERTICAL STABILIZER CONTINUED

Page 8

8

Identify the main landing gear components shown below

- 2 main landing gear esemblies

- 2 main wheels 2-7/16” ( 60mm)

- 8 sheet metal screws and 4 straps

- 2 wheel collars

13A- Main landing gear components

13B- Turn over the wing to locate

the pre-drilled main landing gear

mounting holes.

13C- Main landing gear assembly

13D- Use 4 sheet metal screws

and 2 traps to mount the main

landing gear into the wing

Pre-made main-landing

gear mounts

STAGE 13

- FITTING THE MAIN LANDING GEAR

2 main landing

gear esemblies

Wheels

Wheel collars

Landing gear straps

Metal screws

Wheel collars

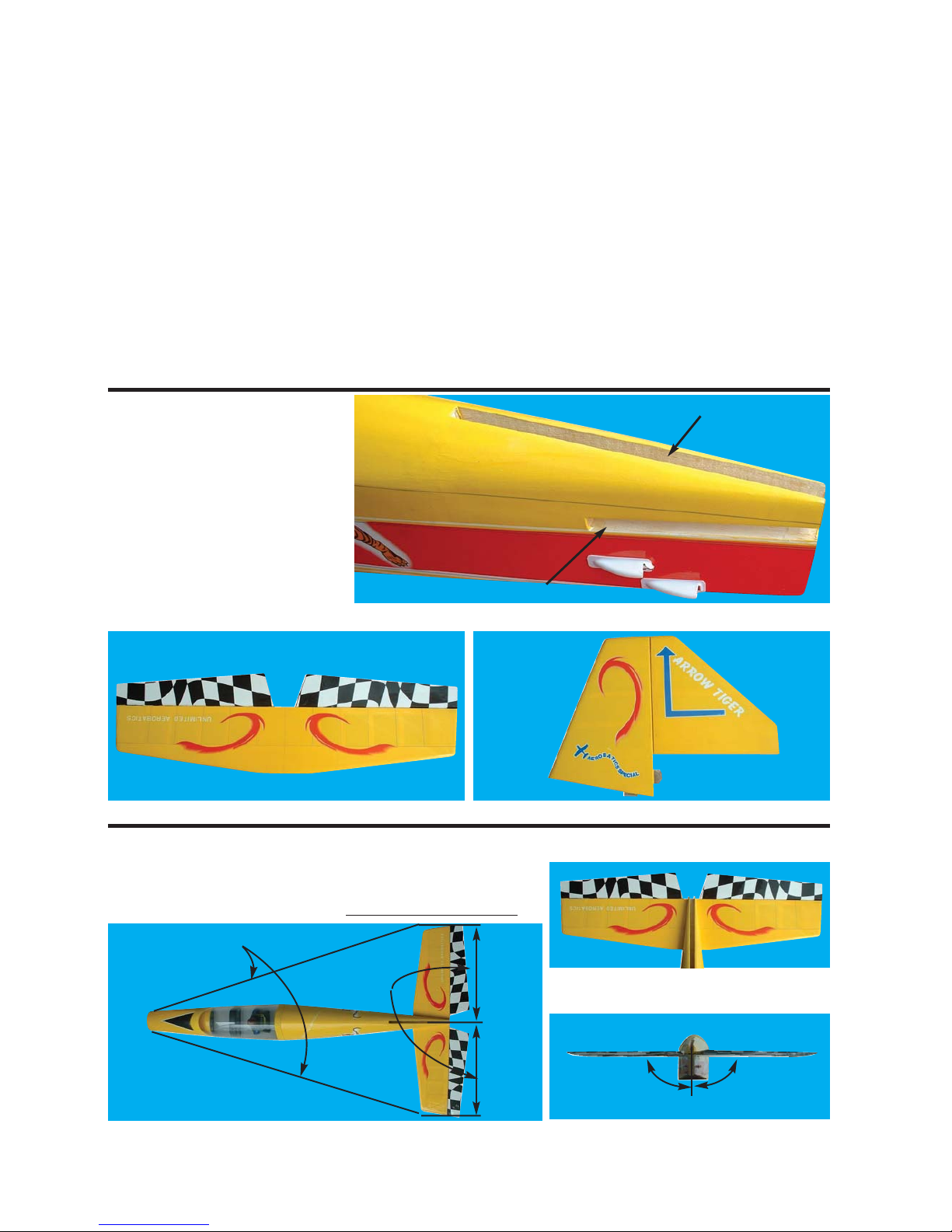

STAGE 14 - FITTING THE TAIL WHEEL

14A- Tail wheel components

14B- Slide the tail wheel asembly

into the pre-installed sleeve tube

14C- Screw the tail wheel assem-

bly to the fuselage

14D- Trim off the excess tail

steering wire

Identify the tail wheel components

- 1 tail gear esembly

- 2 (3 x 15 mm) sheet metal screw

14.1 Slide the loose wire end on the tail wheel asembly

into the sleeve tube that has been installed into bottom

of the rudder.

14.2 Position the plastic bracket on the bottom of the

fuselage. Mark the location of the screw holes. Tap the

holes with the screws and then fasten the plastic bracket to the fuselage. See 14C & 14D

Page 9

9

Engines vary quite a bit in sizes, styles and brands but

most have mounting lugs, a carburetor with a throttle

(speed) control arm, a prop washer, a prop nut and a

muffler.

The procedure we describe here assumes that you are

mounting a 2-stroke engine that has a side exhaust on

the right (when viewed from behind looking forward)

and a throttle control arm on the right.

To assemble the fuel tank you will need the following

items:

- The fuel tank and fuel stopper assembly (supplied)

- The clunk (supplied)

- About 7” (20 cm) of medium ID silicone fuel line (DUB

197 or DUB-222 or similar)

- Cross head Phillips screw driver

15C - Illustration of fuel line positioning inside cutaway of the tank

15D - Fuel tank installed into the

fuselage

fuel line

pressure line

fuel line

pressure line

15B - Use 4" (100 mm) for fuel line

and 2" (50mm) for pressure line

4” (100mm) for fuel line

2” (50mm) for pressure line

16A- VMAX 46PRO 2 cycle engine recommended

16C- Remove the muffler, position the engine on

the engine mount and confirm that the fuel tank

metal tubes clear the back of the engine. Trial fit

the engine temporarily into place. Tighten the

screws only enough to tack the engine into place

16B- Use a 4mm socket ball wrench or Allen Key

to remove the 4 black machine screws that work

with the clamping plates on the metal engine

mount that has been pre-installed into your

Hornet

STAGE 15

- FITTING THE FUEL TANK

15A - Fuel tank & stopper assembly.

STAGE 16

- INSTALLING THE ENGINE

Connect to the fuel line

fuel line

Connect to the

presure line

pressure line

throttle control rod

Clamping plates

Machine screws

fuel line pressure line

Page 10

10

17B- Throttle control rod connected to the engine throttle arm

and to the servo arm

17A- Clevis attached to engine

throttle arm

18A- Fuel line connected to the car-

buretor and pressure line connect-

ed to the muffler.

STAGE 18

- CONNECTING THE FUEL & PRESSURE LINES

18.1 Install the muffler then connect the fuel tubing from the

tank metal pressure lines to the muffler

18.2 Connect the fuel tubing from the tank metal fuel line to the

carburetor

18.3 Double check that you have the metal fuel line from the

tank connected to the carburetor and that the metal pressure

line from the tank to the muffler.

STAGE 19 - INSTALL THE PROPELLER AND THE SPINNER

19.1 Consult your engine manual and select a suitable propeller.

19.2 Install the thrust washer, the spinner backing plate, the pro-

peller, the prop washer, and the prop nut. Ensure that they are all

firmly attached.

19.3 Trial fit the spinner cone and spinner cone retaining screws. If

necessary enlarge the cutouts in the spinner cone to allow adequate clearance for the propeller. The spinner should not touch the

edges of the propeller.

19.4 Double check that the spinner cone retaining screws are firmly attached.

19A- The spinner and propeller

attached to the engine.

STAGE 20 - FITTING ELEVATOR AND RUDDER CONTROL HORN

20.1 The elevator control horn

is installed through the elevator and protrudes from the bottom of the elevator as shown in

20A and 20B. Pierce the covering over the pre-drilled hole

and install the control horns as

shown.

20A- Control horn assembly

20B- Typical control horn mounted

to the surface control

STAGE 17

- CONNECTING THE THROTTLE CONTROL ROD TO THE ENGINE.

Page 11

11

21.1 Install the rubber servo grommets & brass ferrules supplied

with your radio equipment. The three servos that control the elevator, rudder and throttle are to be installed in the servo tray mounted

in the fuselage. Remove the servo tray from the fuselage, mounting

the servos to the servo tray as shown.

21A- Universal servo tray

20C- Elevator control horn location

20D- Rudder control horn location

Elevator

control

horn

location

Rudder

control

horn

location

21B- Note the orientation and positions of the three

servos in the servo tray

21C- Throttle, rudder and elevator servos connected to their push rods as referenced left to right.

22.1 Consult illustrations 21C & 22A-C showing how the throttle, rudder and elevator servos are positioned and connected to the

pushrods.

STAGE 21

- INSTALLING THE SERVOS

STAGE 22 - CONNECTING THE PUSHRODS

TO THE THROTTLE, RUDDER AND ELEVATOR SERVOS

22A- Throttle (left), elevator (upper) & rudder (lower)

servos connected to their respective push rods.

Throttle

servo

Elevator

servo

Rudder

servo

NOSE TAIL

NOSE TAIL

Page 12

12

23.1 Connect the elevator servo to the receiver and turn on your transmitter. Confirm that

the neutral positions of the elevator servo are sustained as per illustration 22C

22B- Pre-installed elevator, throttle and rudder

pushrod

22C- Center the servos, control surfaces & throttle

(carb) then connect the control rods to the servos.

23A- elevator control horns

shown in position

23B-

Loosen the set screws to connect the elevator pushrods to the elevator control horns, align the elevator surfaces so that it is level with the

plane of the horizontal stabilizer, then tighten set screws securely.

24.1 Connect the rudder servo to the

receiver & turn on your transmitter.

Confirm that the neutral position of

rudder servo is sustained as per illustration 22C

24A - The rudder pushrod is connected to the rudder control horn

25.1 With the throttle control arm clevis connected to the engine throttle

arm, move the throttle arm to roughly half throttle. Look into the throat of

the engine carburetor as you rotate the throttle arm and select a position

where the throttle opening is about haft what it is when fully open.

25A- Throttle control rod connected to the engine throttle arm and

to the servo arm

Connected to the engine throttle arm

engine throttle arm

25B- Throttle control rod connected to the engine throttle arm

Elevator pushrod

Throttle pushrod

Rudder pushrod

STAGE 23

- CONNECTING THE PUSHRODS TO THE ELEVATOR

STAGE 24 - CONNECTING THE PUSHRODS TO THE RUDDER

STAGE 25

- CONNECTING THE THROTTLE CONTROL

NOSE TAIL

NOSE TAIL

Page 13

13

26.1 Adjust the deflection of the control surfaces to match the specifications on page 15

You can reduce the amount of throw by doing either or both of the following:

- From the servo end, move the clevis or EZ connector to a hole in the servo arm that is closer to the servo output

shaft.

- From the control horn end, move the horn out further on the threaded bolts. Always confirm that the horn is still

thoroughly engaged with the threaded bolt after you have adjusted it.

Before starting the final

set-up of the model,

switch on the radio and

ensure that all trims are

in their neutral positions. Check that the

ailerons, elevator and

rudder are centered. If

any adjustments are

needed, do these by

uncoupling the relevant

clevis and turning it

clockwise to shorten

the linkage or counter clockwise to lengthen it.

Only when each control

surface has been centered mechanically in

this way should you

begin adjusting the surface movement (or

throw)

Now confirm

that the control surfaces

are moving

in the correct

direction.

Use the

servo reversing switches

on your

transmitter to

reverse the

direction of a

servo if necessary. The

most popular

transmitter

mode (with

the throttle

on the left,

with ailerons

and elevator

on the right)

is shown

here.

STAGE 28

ELEVATOR

UP

ELEVATOR

DOWN

AILERON

UP

AILERON

DOWN

AILERON

DOWN

AILERON

UP

RUDDER

RIGHT

RUDDER

LEFT

STAGE 26

- ADJUST CONTROL SURFACE THROW LIMITS

STAGE 27

FINAL RC SET-UP

Page 14

14

STAGE 29

- INSTALLING THE RECEIVER BATTERY

STAGE 30 - INSTALLING THE RECEIVER

29.1 Consult your radio manual for instructions about hooking up your receiver battery, receiver and switch har-

ness.

29.2 Wrap the battery pack securely in foam suitable for RC equipment and wrap the foam insulated pack in a

plastic bag or cling wrap. Position the battery pack under the fuel tank or nearby.

29.3 Thread the battery pack connector back through from beneath the fuel tank to the radio compartment by

passing the battery connector through an opening beside or beneath the fuel tank.

29.4 Connect the battery connector to your radio system according to the radio manual.

30.1 Consult your radio manual for instructions about hooking up your receiver.

30.2 Plan where you are going to put the receiver with consideration for routing the antenna safely.

30.3 Wrap the receiver securely in foam suitable for RC equipment and wrap the foam insulated receiver in a

plastic bag or cling wrap.

30.4 Generally in the absence of specific instructions from the radio manufacturer, it is recommended that the

receiver should be placed where it is least likely to have impact during a crash. Keep the battery pack and other

heavy loose items ahead of the receiver.

STAGE 31 - CONFIRM RADIO OPERATION

STAGE 32 - BALANCING THE AIRCRAFT

31.1 Consult your radio manual for instructions about testing and operating your radio system.

31.2 Pay particular attention to charging your radio system batteries and range testing the system before and

after each flight.

31.3 Check that all controls are working correctly before and after each flight.

32.1 The CG for your HORNET is located at 3-1/8“ to 3-3/8" (80 - 85 mm) back from the leading edge of the wing

when the wing has been attached to the fuselage as per illustration 34A.

32.2 For the initial flight, the CG should be located at 3 1/8” (80mm) back from the leading edge of the wing

when the wing has been attached to the fuselage.

32.3 The CG is measured with the engine, radio gear and all other components installed but WITH NO FUEL IN

THE TANK.

32.4 Set up the CG as it will be when you fly it BUT WITH NO FUEL IN THE TANK.

32.5 It is very important to have the CG correct. Flying your model with the CG too far will likely lead to loss of

control and a crash.

If you discover that after you have assembled your model and installed your radio and engine that the CG of your

model is incorrect you must bring the CG to the correct location by doing the following BEFORE FLYING :

- Move the battery pack fore or aft.

- Move other components fore or aft.

- Change engine to a lighter or heavier model.

- Add weight to the nose or tail. If adding it to the nose, try to make it useful by going to a heavier duty engine

or adding a spinner with a heavy metal backing plate. As a last resort, add stick on “dead” weight where appropriate.

Page 15

15

33.1 Once you have confirmed that the CG is correct,

you should do a thorough review of the entire model

before your first flight. Check everything twice! Every

hook up, every coupling, everything! Do it twice!!

33.2 Before your first flight, have an experienced flyer

review your work. Do not fly your model until it has

been checked out by a third party who knows how to

fly and how to set up a model aircraft. Do not fly alone.

Seek experienced help.

33.3 Once you have completed your first flight, get in

the habit of checking your model over before and after

each flight! Don’t fly if you find something that is not

right!

80 - 85 mm

3 1/8 - 3 3/8”

Elevator

Aileron Rudder

CG

STAGE 33

- CONFIRM MECHANICAL INTEGRITY

33A- CG location

CONTROL SURFACE THROW SPECIFICATIONS: The throws are measured at the widest part of the control

surface. Adjust the position of the pushrods at the control and/or servo horns to control the amount of throw.

You may also use ATV's if you radio has them but the mechanical linkages should still be set so that the ATV's

are near 100% for best servo resolution.

5/8”-1”

16mm - 25mm

1/4”-3/8”

6mm - 9mm

1/3”-1/2”

8mm - 12mm

Low rate High rate

ELEVATOR 1/3 “ (8mm) up 1/2” (12 mm) up

1/3 “ (8mm) down 1/2” (12 mm) down

AILERON 1/4” (6 mm) right 3/8” (9 mm) right

1/4” (6 mm) left 3/8” (9 mm) left

RUDDER 5/8 “ (16 mm) up 1” (25 mm) up

5/8 “ (16 mm) down 1” (25 mm) down

5/8”-1”

16mm - 25mm

1/4”-3/8”

6mm - 9mm

1/3”-1/2”

8mm - 12mm

Page 16

16

Parts for this VMAR Model

In the event that you require replacement parts for your ARROW TIGER 40-52 ARF, you can order parts from

your retailer or from the VMAR On - line store at www.richmondrc.com/support.htm.

For aftermarket parts and other information related to this model see the VMAR On - Line store at

www.richmondrc.com/support.htm

VMAR, POLYCOTE and VMAX are Trademarks of VMAR Manufacturing Inc. and appointed VMAR agents worldwide.

Copyright VMAR Manufacturing Inc - 20032809

The Graphics and Detailing are inside the POLYCOTE ECS!

TM

ARROW-Tiger

Loading...

Loading...