Vmac VR70, VR150 Owner's Manual

VR70 & VR150 UNDERHOOD

AIR COMPRESSOR

OWNERS MANUAL

Keep with vehicle

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

1

Table of Contents

Accessory Products from VMAC ............................................... 3

Introduction .................................................................................. 4

Ordering Parts .............................................................................. 4

Important Safety Notice .............................................................. 4

Safety Messages .......................................................................... 5

Safety Precautions ...................................................................... 6

Installation Instructions .............................................................. 8

System Specifications ................................................................ 9

Operating Principles.................................................................... 10

Oil Separation and Cooling ....................................................... 10

Filtration ..................................................................................... 10

Belt Alignment and Tensioning ................................................. 11

Pressure Regulation and Engine Speed Control ...................... 11

Safety Devices .......................................................................... 11

Line Protection .......................................................................... 12

Special Installation Notes .......................................................... 12

System Operation ........................................................................ 13

Cold Climate Operation ............................................................. 14

Control Box Features and Operation ........................................ 15

Automatic Shutdown ................................................................. 19

Adding Oil to the System ........................................................... 19

Adjusting the System .................................................................. 20

Adjusting the Pressure Regulator ............................................. 22

Electronic Throttle Control Adjustment ..................................... 23

Routine Maintenance................................................................... 25

Maintenance Schedule .............................................................. 25

Inspect the Drive Belt ................................................................ 26

Inspect the Muffler ..................................................................... 26

Inspect the Pressure Relief Valve ............................................. 27

Replacing the Air Filter .............................................................. 27

Replacing the Oil Filter .............................................................. 28

Changing Compressor Oil ......................................................... 29

Changing the Coalescing Filter ................................................. 31

Problem Diagnostics / Troubleshooting ................................... 34

VMAC Warranty ............................................................................ 39

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

2

Owner Manual - Document #1930060

VR70 and VR150 Systems

Changes and Revisions

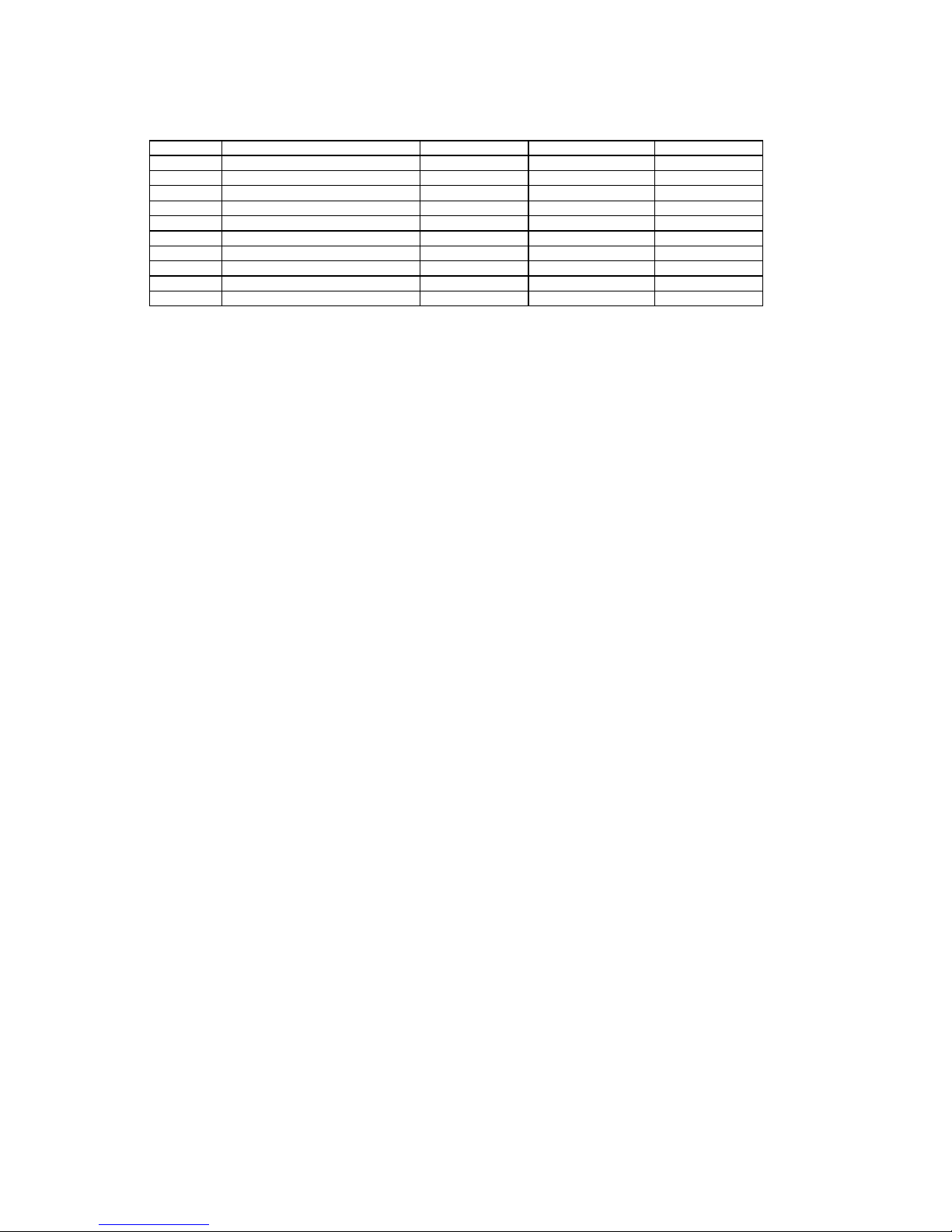

Version

Revision Detai

ls Revised

Approved

Implemented

00 Initial draft, revised to completion IB 27 Jan 2004 SC 16 Mar 2004 16 Mar 2004

a Added coalescing information IB 19 Apr 2005 SM 27 Apr 2005 29 Apr 2005

b Warranty information change IB 18 Apr 2006 SM 19 Apr 2006 20 Apr 2006

c ECN 06-220 Coalescing spring IB 25 Oct 2006 SM 28 Oct 2006 30 Oct 2006

d ECN 07-009 phone & general IB 10 Jan 2007 RD 26 Jan 2007 29 Jan 2007

e ECN 07-099 lack of use failure IB 18 Jun 2007 SC 18 Jun 2007 24 Jun 2007

f ECN 08-242 General updates SL 15 Oct 2009 SC/SM 22Sep2010 22 Sep 2010

g ECN 12-003 General updates SR 06 Jan 2012 SJC 17 JAN 2012 19 JAN 2012

h ECN 12-169 PRV and muffler RK 10Dec 2012 MH 12 Dec 2012 17 Dec 2012

h Cor: warranty info & card MP 23Sep 2016 N/A 26 Sept 2016

Manuals are subject to change without notice.

Registered Trademarks

All trademarks used in this manual are the property of the respective copyright

holder.

Copyright 2017

The contents of this manual may not be reproduced in any form

without the express written permission of VMAC.

Printed in Canada

1333 Kipp Road, Nanaimo, BC V9X 1R3

1-800-738-8622

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

3

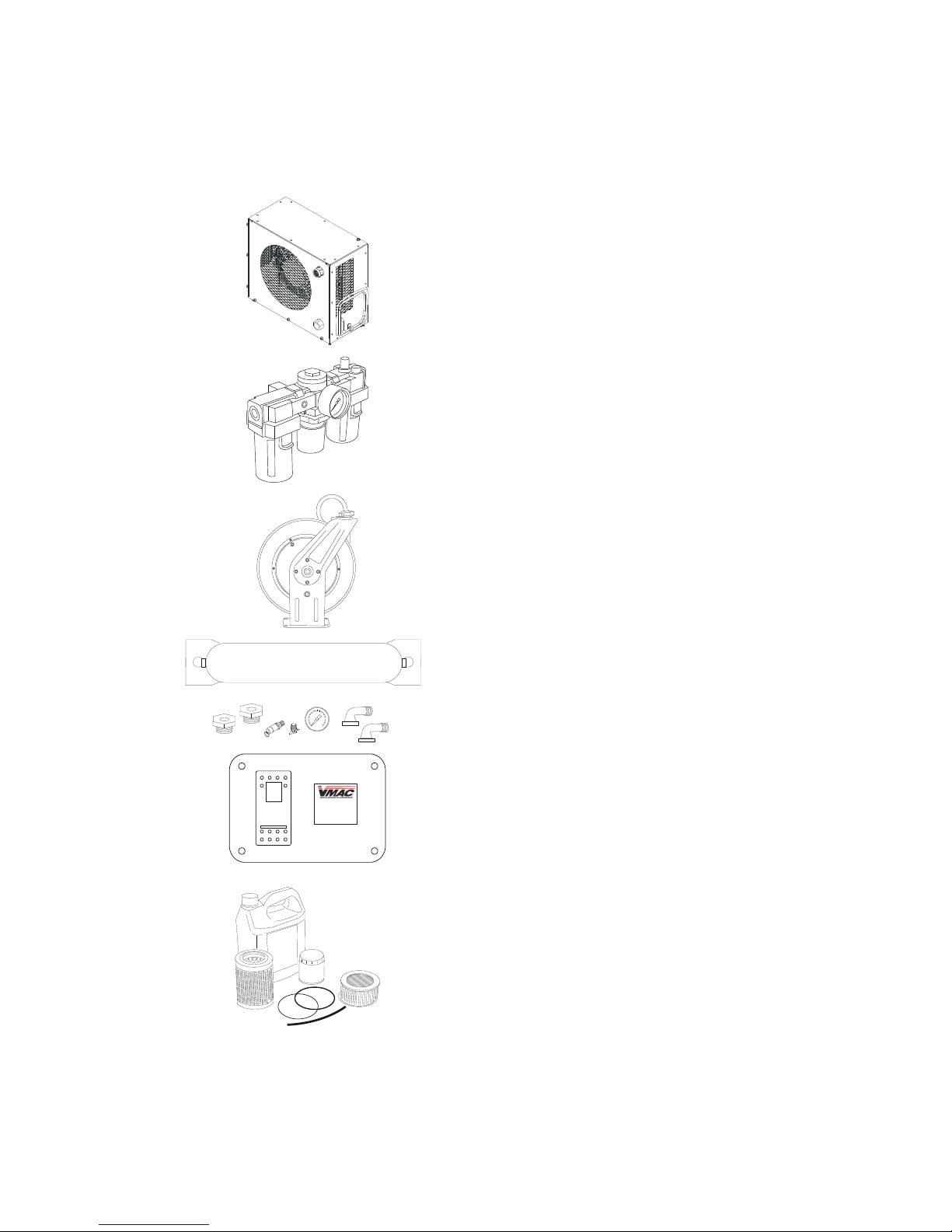

Accessory Products from VMAC

The following accessory products for your VR compressor system

are available from VMAC. For more information or to order these

products, call toll free 1-800-738-8622 or local 250-740-3200.

Eliminator Aftercooler

Part Number A800070

Removes up to 80% of moisture from

compressed air. Quick installation, automatic

drain and compact design

Filter Regulator Lubricator

Part Number A700151

Removes lubricants, water and dirt from the air

stream. Adds atomized tool oil to lubricate tools.

Reduces pressure for longer tool life.

Hose Reel

Part Number A700007

Secure, compact, retractable hose storage in a

sturdy reel.

Air Receiver Tank

Part Number A300010

Thirty-five gallon capacity in a compact tank,

complete with fittings and a gauge.

DE-ICING

HEATER

De-icer Kit

Part Number A700031

Insulated rope heater prevents freezing of lines

and regulator in freezing conditions.

Service Kits

VR150 200 hour Part Number A700059

VR150 400 hour Part Number A700060

VR70 200 hour Part Number A700019

VR70 400 hour Part Number A700020

Using OEM service products will extend the life

of your system. Includes oil, filters, seals and Orings. 200 hour and 400 hour service interval kits

are available

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

4

Introduction

This manual provides operation instructions, specifications,

adjustment, maintenance, and warranty information for the VMAC

VR70 and VR150 underhood air compressor, and VMAC Electronic

Throttle Controller.

Ordering Parts

To order parts, contact your VMAC dealer. Your dealer will ask for

the VMAC serial number, part number, a description of the part and

the quantity. To locate your nearest dealer, call 1-800-738-8622.

Important Safety Notice

The information contained within this manual is based on sound

engineering principles, research, extensive field experience and

technical information. Information is constantly changing with the

addition of new models, assemblies and service techniques. If a

discrepancy is noted in this manual, contact VMAC prior to initiating

or proceeding with service. Current information may clarify the

matter. Any person with knowledge of such discrepancies who

performs any work on the system, service and repair assumes all

risks.

Only proven service procedures are recommended. Anyone who

departs from the specific instructions provided in this manual must

first assure that their safety and that of others is not being

compromised and that there will be no adverse effects on the

performance or the operational safety of the equipment.

VMAC will not be held responsible for any liability, injuries, loss or

damage to individuals or to equipment as a result of the failure of any

person to properly adhere to the procedures set out in this manual or

standard safety practices. Safety should be your first consideration in

performing service operations. If you have any questions concerning

the procedures set out in this manual or require any more

information on details that are not included in this manual, please

contact VMAC before beginning any work.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

5

Safety Messages

This symbol is used to call your attention to instructions

concerning your personal safety. Watch for this symbol;

it points out important safety precautions, it means

“attention, become alert!” Your personal safety is

involved. Read the message that follows and be alert to

the possibility of personal injury or death. Be alert; your

safety is involved. While it is impossible to warn about

every conceivable hazard, let good common sense be

your guide.

This symbol is used to call your attention to instructions

on a specific procedure that if not followed may damage

or reduce the useful life of the compressor.

This symbol is used to call your attention to additional

instructions involving fire hazards.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

6

Safety Precautions

Observe the following general safety rules:

Pay attention to operations; do not leave the vehicle

unattended.

Follow safe work practices and wear the appropriate safety

equipment when operating air-powered equipment,

particularly eye and hearing protection.

Avoid all contact with pressurized air, because if it

penetrates your skin it can enter your bloodstream and

cause serious bodily harm or even death.

To prevent compressor explosion or fire, make sure that

the air entering the compressor is free of flammable

vapors.

To prevent compressor explosion or fire, make sure that

correct servicing procedures and intervals are

observed.

Vaporized oil propelled by high-pressure air is an

explosive mixture.

Do not breathe the compressor air. Vaporized oil is a

severe respiratory hazard.

Avoid contact with drive belts and stay clear of all

moving parts when the system is operating.

Follow all safety precautions for underhood mechanical

work.

Follow safety procedures for the type of work being

completed.

Observe these rules when operating the compressor:

Do not bypass or disable the oil temperature sensor.

Do not expose the tank or compressor to extreme heat.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

7

Do not perform any service until the system has been

completely blown-down and you have verified that all air has

been discharged.

Do not try to repair or service a pressurized system

Maintenance and repair on system components should only

be performed by qualified personnel

The vehicle must be in park (for automatic transmissions) or

neutral (for manual transmissions) with the park brake or air

spring brake fully applied before starting the compressor and

at all times during compressor operation

Use a regulator in the output line to precisely control the final

air delivery pressure

Run the system at idle speed under no-load conditions for 1

minute before turning the system off to allow system cooling

and lubrication

Do not bypass the park brake or DDC connections

Do not operate the compressor while driving

Do not tamper with the pressure relief valve

Do not attempt to repair or modify any component

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

8

Installation Instructions

Detailed information provided in a separate publication, Installation

Manual for the Underhood Air Compressor, which provides specific

information for each different application.

This information includes torque tables, recommendations and other

important information for correct installation. The information in the

installation manual is intended for use by trained, professional

technicians with the knowledge, tools, and equipment to do the job

properly and safely. Installation should not be performed by persons

without the appropriate skills.

Do not attempt to install any of these systems without

the appropriate installation manual.

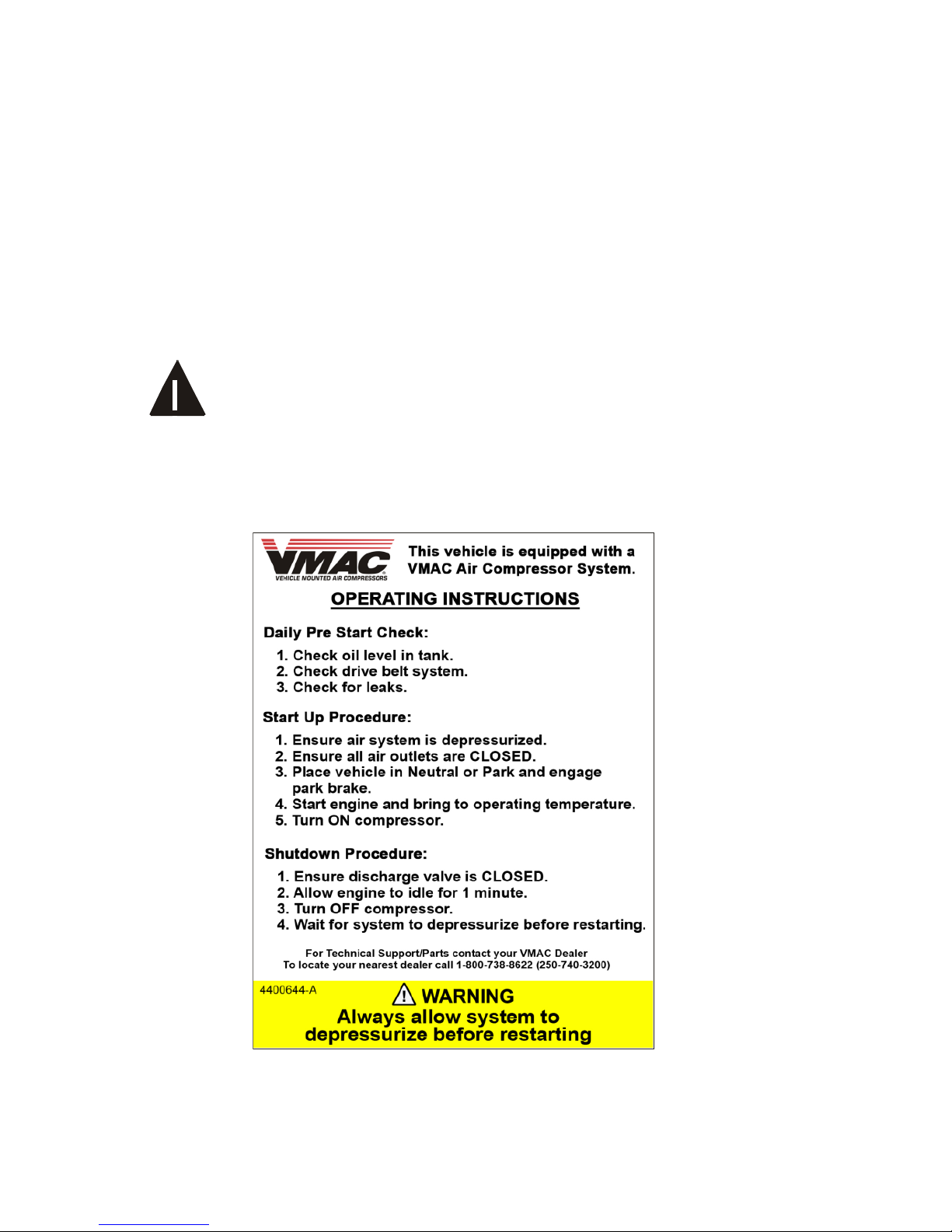

Ensure that the safety and operational instruction decal is affixed in

an obvious location so that vehicle operators can easily see it.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

9

System Specifications

Model: VR70 and VR150 Underhood Air Compressor

Type: rotary screw

Drive System: front end auxiliary drive

Control: electric on/off 12V clutch control

Maximum Air Delivery:

VR70 70 CFM and 175 PSI / 1207 KPA

VR150 150 CFM and 175 PSI / 1207 KPA

Pressure Regulation: mechanical inlet control valve modulates flow

in response to demand

Engine Controls: throttle control to modulate between idle and upper

limit RPM to maintain air requirements

NOTE: Some trucks have onboard computers that must

be programmed by the OEM dealer to permit operation

of the electronic throttle control.

Safety Features:

200 PSI / 1379 KPA relief valve in oil/air tank

temperature safety sensor in compressor

rapid blow-down valve to discharge system pressure on

shutdown (10-15 seconds)

drive disable circuit (DDC)

Lubrication: VMAC certified and approved synthetic oil

Filters:

paper-type replaceable air filter

spin-on type high pressure oil filter

coalescing separator element

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

10

Operating Principles

These systems use a flooded-lobe, rotary screw compressor. The

oil-filled compressor housing contains two rotors.

Compression occurs when inlet air (at normal atmospheric pressure)

enters a chamber where it is trapped between the rotating rotor

lobes.

A lubricated pitch line provides sealing. As the lobes mesh, they

reduce the volume of the air, compressing it to the desired pressure.

Oil Separation and Cooling

The system has a two-stage air/oil separator. The first separation

stage consists of baffles, which perform mechanical separation. The

second stage uses an integral serviceable coalescing element.

A liquid-to-liquid cooler connected to the engine cooling system cools

the oil. This maintains the oil temperature in an optimal performance

range that increases system durability and reduces the temperature

of the compressed air.

Filtration

The rotary screw compressor is designed and machined to exacting

tolerances. Foreign particles entering the system will drastically

damage or shorten the life expectancy of the compressor and will

result in damage to bearings, gears, rotors and the inside of the

housing.

The system is equipped with a replaceable paper element air inlet

filter, spin on cartridge type high pressure capable oil filter and a

scavenge screen filter.

These system filters enhance performance and extend component

life by reducing damage from dust and other debris. Proper filter

maintenance is the key to long compressor life.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

11

Belt Alignment and Tensioning

This system is equipped with automatic belt tensioning and does not

require manual adjustment. Always check pulley alignment to ensure

proper belt operation. All components are designed and machined

for precision, some variation in mounting holes may still occur.

Pressure Regulation and Engine Speed Control

The system uses two control systems; an inlet control valve

incorporating a mechanical pressure regulator and an engine speed

control that automatically adjusts engine RPM to respond to air

consumption demand. These control devices provide the following

benefits:

instant response to air flow demands

reduction of standby noise

reduction of cooling system load

fuel conservation when not using air

For information an adjustment, please refer to the section titled

“Adjusting the System”

An external regulator is recommended for operation at pressures

lower than 145 PSI / 999.7 KPA.

Safety Devices

A 200 PSI / 1379 KPA pressure relief valve in the tank to prevent

system over pressure. The system is also equipped with an

automatic rapid blow-down system to discharge system pressure on

shutdown.

There is a switch which only permits operation when the mechanical

or air park brake is applied. Vehicles with automatic transmission are

fitted with a “Drive Disable Circuit”, (DDC) which disables the throttle

control and prevents engine speed increase when the vehicle is in

gear.

The compressor is equipped with an oil temperature sensor which

stops system operation should the temperature become excessive.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

12

A fuse protects the system. If the fuse blows

continuously, there is an electrical problem that will not

be solved by a higher fuse rating. Exceeding the rating

can cause component damage.

Do not disable or bypass the over-temperature

shutdown circuit. Failure of the shutdown system could

result in equipment damage, injury or death.

Line Protection

To prevent damage to the lines, observe the following:

Always ensure that the hoses are secure, do not allow the

hoses to dangle under the vehicle

Always ensure that the hoses do not get pinched in steering

or suspension components

Make sure to keep the hoses away from hot surfaces, such

as turbocharger housings or exhaust system components

Hoses should not be bent tightly around sharp metal edges

Ensure that hoses are kept away from fan blades or belts

If the hoses are secured in a bundle, protect them from

abrasion by insulating them from each other using rubber

padding or plastic loom

Special Installation Notes

If you intend to use an auxiliary air tank with this system you must

observe the following installation procedure. Failure to observe this

procedure may result in damage to the system.

The line from the VMAC tank to the auxiliary air tank must have a

check valve installed to prevent VR tank blow-down from draining the

auxiliary tank and to prevent moisture from entering the VMAC tank.

The line to the auxiliary tank must not be installed in the bottom of

the tank, but must be installed as high as possible to prevent water

from clogging the line.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

13

System Operation

Diesel Particulate Filter Warning (DPF)

When engine driven or PTO driven equipment is run on vehicles with

DPF for extended periods of time, particulate may build up in the

filter. All vehicles with a DPF have a warning light (or message) on

the instrument panel or message center. Run time until filter build up

depends on many variables and is the responsibility of the operator

to monitor. It is suggested that if equipment is run for extended

periods of time (over 1 hour) without driving, the vehicle DPF

warning system must be checked after 1 hour and every 15 min

thereafter. If the DPF warning light or message appears, see the

vehicle owner’s manual for methods of cleaning or regenerating.

Operating Instructions

The vehicle must not be parked on grades exceeding 15 º in slope

as this may affect lubrication and air/oil separation.

1. Place the manual transmission in neutral or the automatic

transmission in park and fully apply the park brake.

2. Start and run the vehicle long enough for the engine to stabilize

at base idle and reach normal operating temperature.

3. Close the hood (if open).

4. Close all compressor air system outlets.

Loading...

Loading...