Vmac PREDATAIR60 Installation Manual

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

1

Installation Manual

PREDATAIR60

Hydraulic Compressor

1.0 General Information ...................................................................3

1.1 Specifications and Components ...............................................3

2.0 Installation Requirements..........................................................6

2.1 Ventilation Requirements..........................................................6

2.2 Hydraulic Requirements..........................................................11

2.3 Electrical Requirements ..........................................................12

2.4 Air Receiver Requirements .....................................................13

3.0 Installing the PREDATAIR60 ...................................................15

3.1 Mounting the Compressor.......................................................15

3.2 Connecting the Wiring.............................................................15

3.3 Speed Control .........................................................................20

4.0 Completing the Installation .....................................................23

4.1 Before Operation Checklist .....................................................23

4.2 After Engaging the Hydraulics Checklist.................................23

4.3 Setup, Performance Testing and Adjustments .......................24

5.0 Testing Ventilation ...................................................................26

5.1 Calculating Duty Cycle............................................................26

5.2 Testing the Installation ............................................................28

5.3 Analyzing the Test Results .....................................................31

6.0 Hydraulic System Data.............................................................34

6.1 Hydraulic Oil Type...................................................................34

6.2 Hydraulic Line Sizing ..............................................................35

6.3 Hydraulic System Filtration .....................................................40

6.4 Hydraulic Oil Reservoir ...........................................................40

6.5 Avoiding Cavitation .................................................................44

Ordering Parts.................................................................................44

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

2

Document #1930125

Installation Manual for VMAC System H600001

PREDATAIR60 Hydraulic Compressor

Changes and Revisions

Version Revision Details Revised by/date Approved Implemented

00 Original manual IB June 16 2006 SM 25 Aug 2006 28 Aug 2006

Important Information

The information in this manual is intended for certified VMAC

installers who have been trained in installation procedures and for

people with mechanical trade certification who have the tools and

equipment to properly and safely perform the installation. Do not

attempt this installation if you do not have the appropriate

mechanical training, knowledge and experience.

Follow all safety precautions for mechanical work. If you have

difficulty with the installation, contact VMAC.

The VMAC warranty form is located at the back of this manual. This

warranty form must be completed and mailed or faxed to VMAC at

the time of installation for any subsequent warranty claim to be

considered valid.

To order parts, contact your VMAC dealer. Your dealer will ask for

the VMAC serial number, part number, description and quantity. To

locate your nearest dealer, call 1-800-738-8622.

Copyright 2006

All trademarks used in this manual are the property of the respective copyright holder.

The contents of this manual may not be reproduced in any form without the express

written permission of VMAC, 1333 Kipp Road, Nanaimo, BC V9X 1R3.

Printed in Canada

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

3

1.0 General Information

Read this manual before beginning the installation so that you can

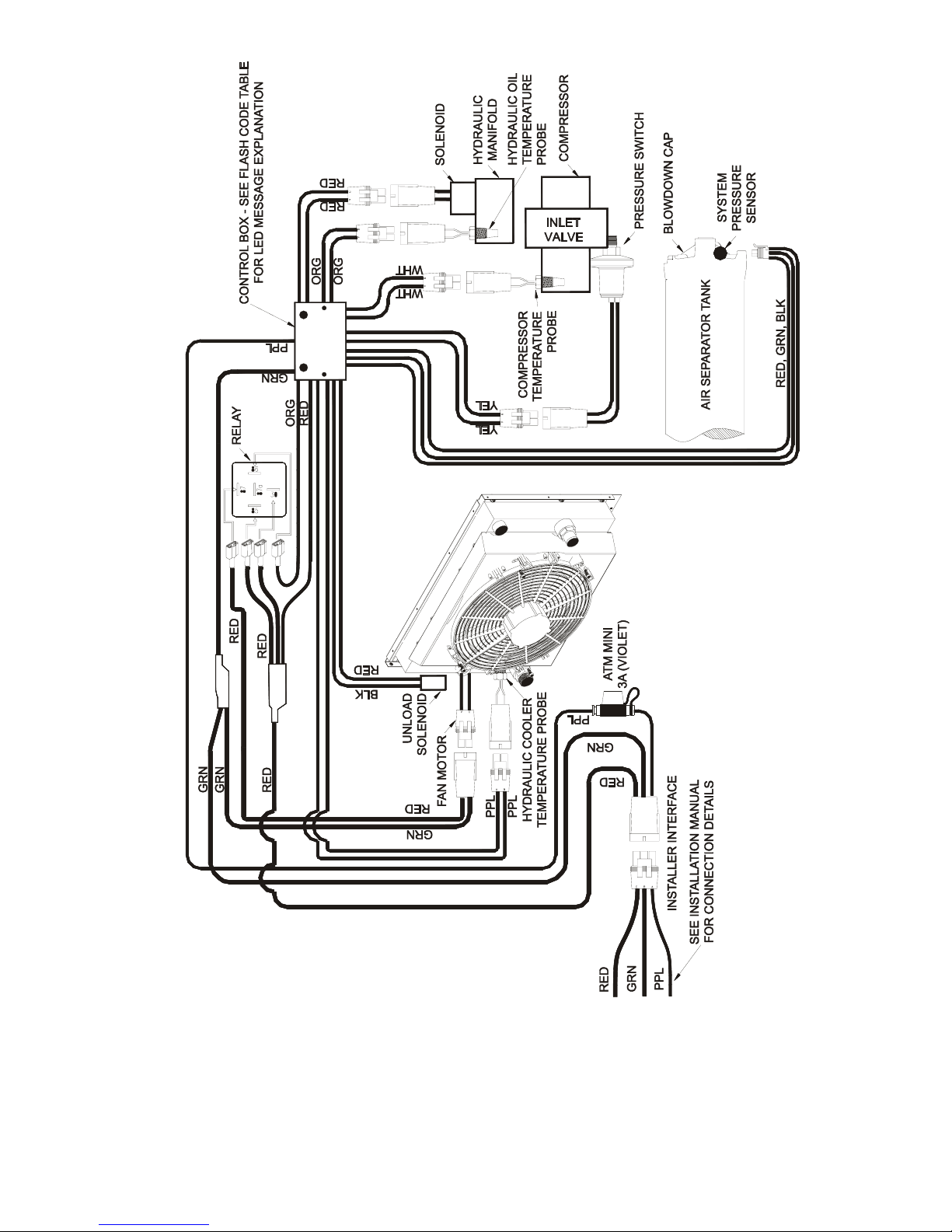

understand the hydraulic, electric (Figure 2) and ventilation

requirements. This will ensure a successful installation and effective

operation of the PREDATAIR60 (Figure 1).

1.1 Specifications and Components

This is a flooded-lobe, rotary screw compressor (filled with VMAC

certified and approved synthetic oil) driven by a hydraulic motor.

Compression occurs when inlet air (at normal atmospheric pressure)

enters a chamber where it is trapped between the rotating rotor

lobes. A lubricated pitch line provides sealing. As the lobes mesh,

they reduce the volume of the air, compressing it to the desired

pressure.

The system has a two-stage air/oil separator. The first separation

stage consists of baffles, which perform mechanical separation. The

second stage uses a special separation element, which delivers dry

air to the outlet.

Pressure regulation is achieved with a mechanical inlet control valve

and an adjustable pressure regulator.

The compressor is protected by a paper-type replaceable air filter

and a spin-on type oil filter. Oil is removed from the delivered service

air by a coalescing separator element.

Safety features include:

• 2,650 psi hydraulic pressure relief valve

• 200 PSI relief valve in oil/air tank

• blow-down valve to discharge system pressure on shutdown

• temperature safety sensor in compressor

Do not disable or bypass the over-temperature

shutdown circuit. Failure of the shutdown system could

result in equipment damage, injury or death.

A liquid-to-air cooler maintains operating temperatures in an optimal

performance range which increases system durability and reduces

the temperature of the compressed air.

The system pressure is pre-set at 150 psi. Do not increase this

pressure setting as it will also increase the hydraulic operating

pressure. To reduce the pressure, use a Filter Regulator Lubricator

(FRL).

!

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

4

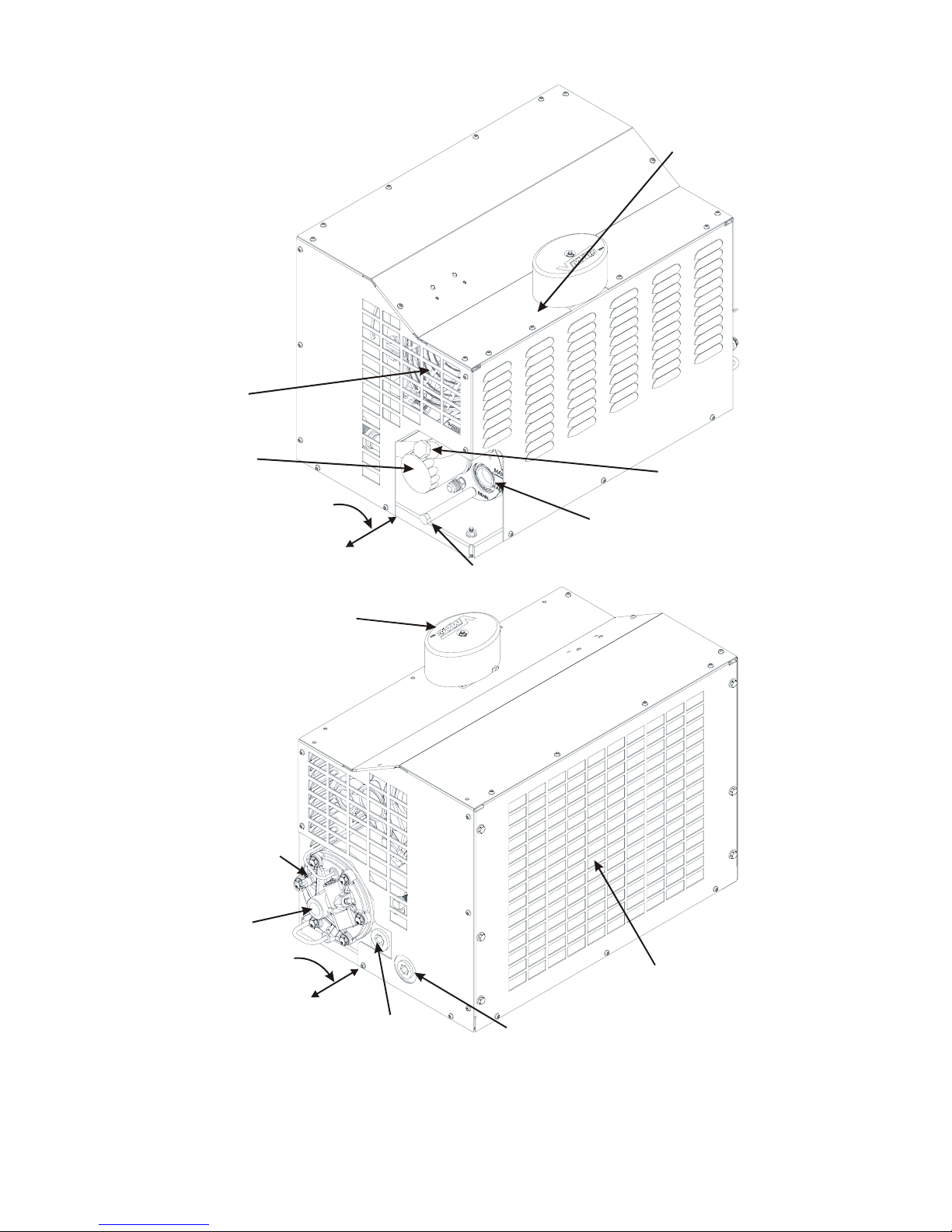

Compressor air filter

(must have proper ventilation)

Oil cooler (inside cover,

must have proper ventilation

)

Air discharge port

with check valve

Hydraulic fluid inlet

Hydraulic fluid return

Blowdown cap with

internal coalescing filter

Minimum clearance

for servicing - 6 inches

Compressor oil fill

(shipped full from

the factory)

Oil level sight glass

(make sure this can be easily

accessed for daily inspection)

Compressor oil drain

Oil filter

Cooling fan

Regulator on

inlet valve

(inside cover)

Minimum clearance

for servicing - 6 inches

Figure 1 – System components

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

5

Figure 2 – System wiring

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

6

2.0 Installation Requirements

The information in this section is very important for

proper operation of the compressor. Read these

requirements before beginning installation.

Before installing the compressor, examine the possible locations and

consider the following factors when selecting a location:

• it is convenient for making electrical, hydraulic and air

connections and does not require extensive plumbing

• hose and wire lengths will be the shortest possible and a

minimum number of 90 degree fittings will be used

• the oil level at the sight glass can be checked easily

• there will be sufficient clearance around the unit for good air

circulation and effective cooling

• it can be serviced easily without having to disconnect lines or

remove and reposition the unit

• it will be protected from excessive exposure to the elements

and possible incidental damage from other operations

• it is away from heat sources such as engines, exhaust

systems or other components that generate heat

• it is not in a location where it will be exposed to high

contamination levels, including combustible gases

2.1 Ventilation Requirements

During operation, the PREDATAIR60 can develop

considerable heat, as much as a house furnace.

Proper ventilation is vital for proper operation and to

avoid damage to components.

If you are installing the compressor into a new

configuration, refer to section 5.0 Testing Ventilation for

information.

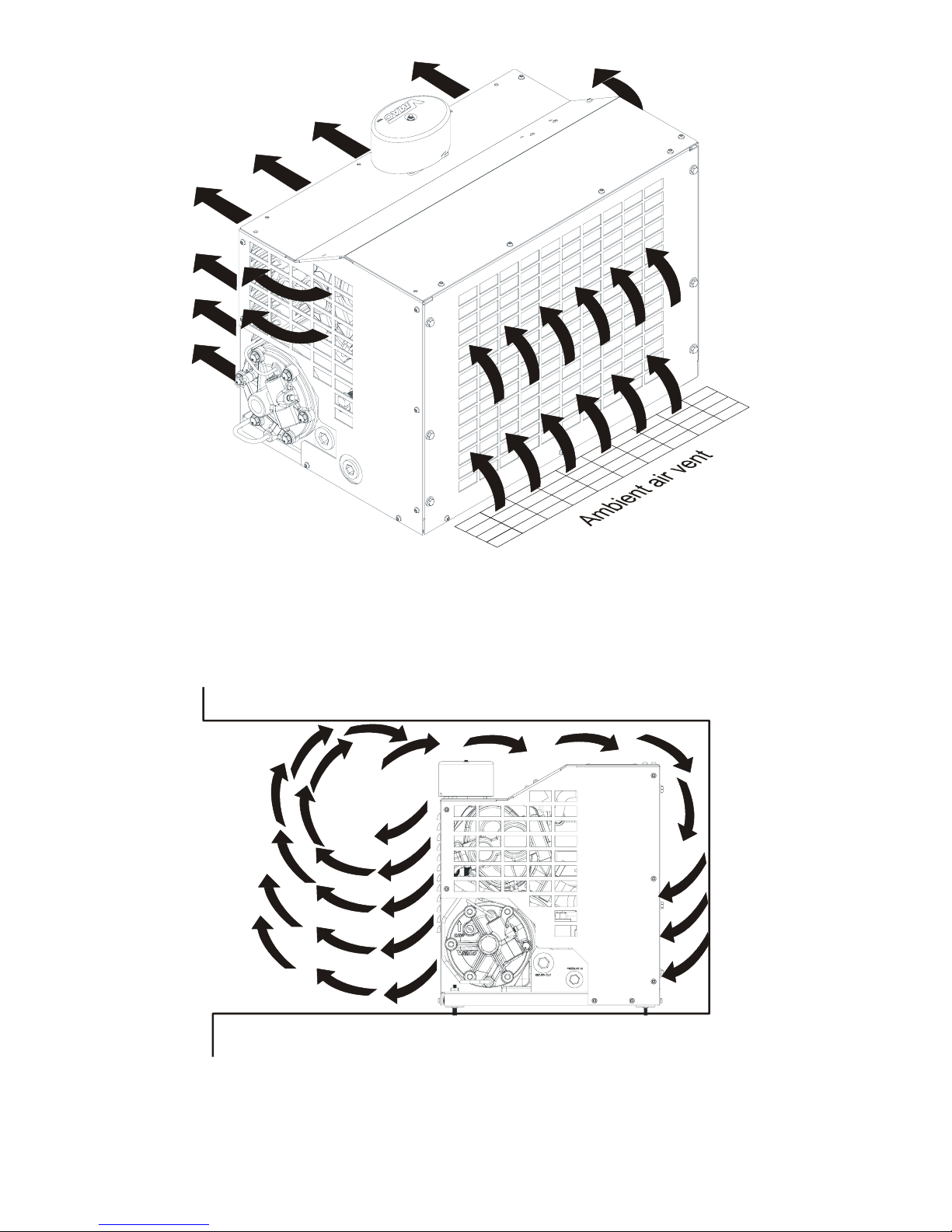

2.1.1 Top Mounting

This is the preferred mounting location. Placing the unit on top of

the service body (Figure 3) provides the best access to ambient

air and provides the best cooling. Maintain a minimum of 6”

between the sides of the compressor housing and all other solid

objects

!

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

7

2.1.2 Enclosed Mounting

Mounting the PREDATAIR60 in an enclosure (Figure 3) will limit

the access to ambient air, restrict the escape of hot air from

around the unit and have an adverse effect on cooling. Make sure

that adequate ventilation is provided so the cooling system will

function properly.

Top mount

Enclosed mount

Figure 3 – Mounting locations

It is not possible to make absolute recommendations regarding

ventilation because of the widely differing circumstances that are

possible. Duty cycle, ambient temperature and enclosure shape

are some of the important variables.

Significant ventilation and additional cooling will be

required if the PREDATAIR60 is mounted in the

same enclosure as the hydraulic oil reservoir. The

heat generated during operation will continue to

heat the hydraulic oil, even with fresh, ambient air

entering the cooler

Ideal ventilation will provide good airflow through the unit with no

restrictions (Figure 4). Cool ambient air ducted to the cooler and

exhaust fan are recommended.

!

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

8

Figure 4 – Ideal ventilation with ambient air vent of a suitable

size for the application

Avoid installing deep into enclosures that will not permit adequate air

circulation (Figure 5).

Enclosure

Enclosure

Figure 5 – Avoid deep installation

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

9

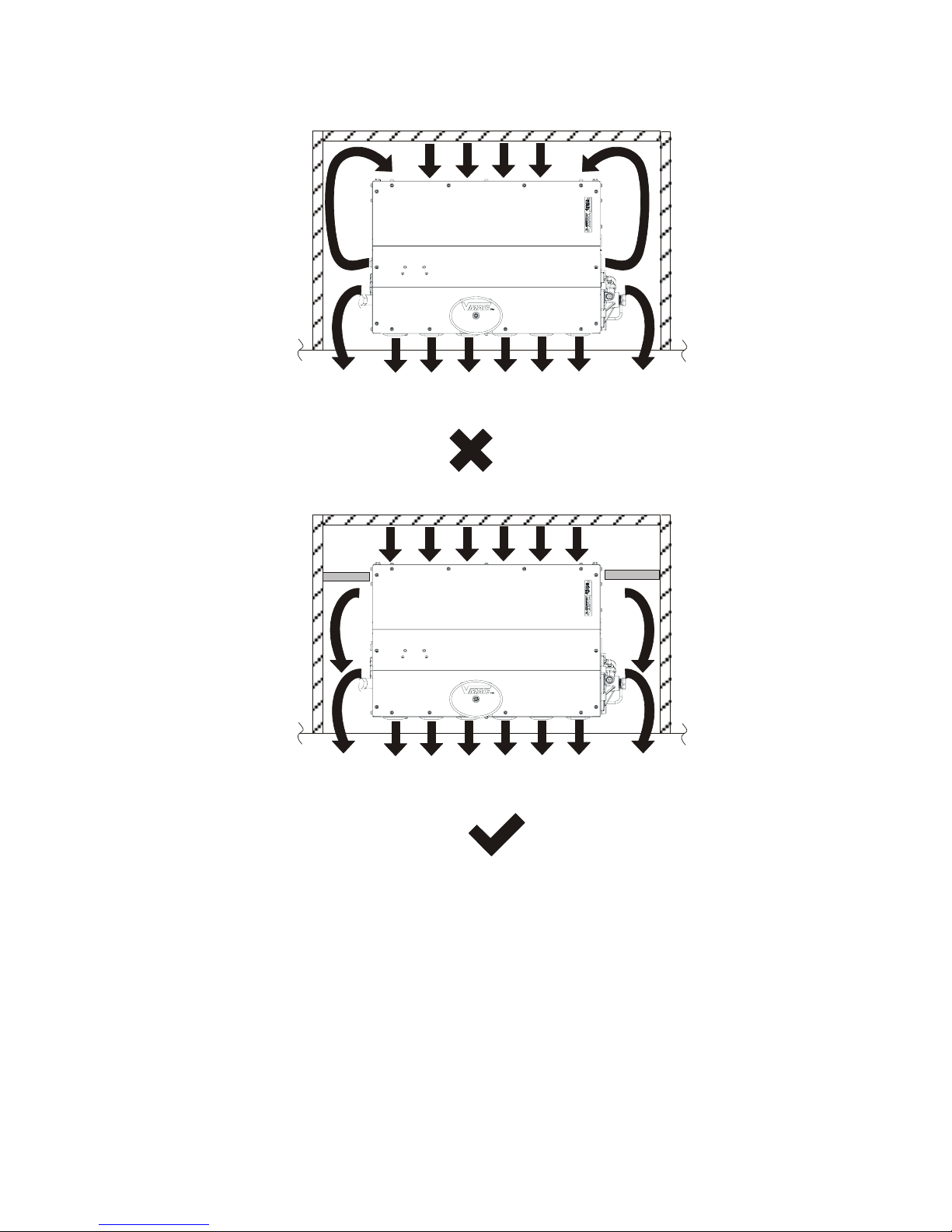

The effects of hot air recirculation drastically reduce cooling but

those effects can be reduced by using air dams (Figure 6).

Top view

Hot air recirculating

Top v ie w

Dams installed to block recirculation

Figure 6 – Reducing hot air recirculation

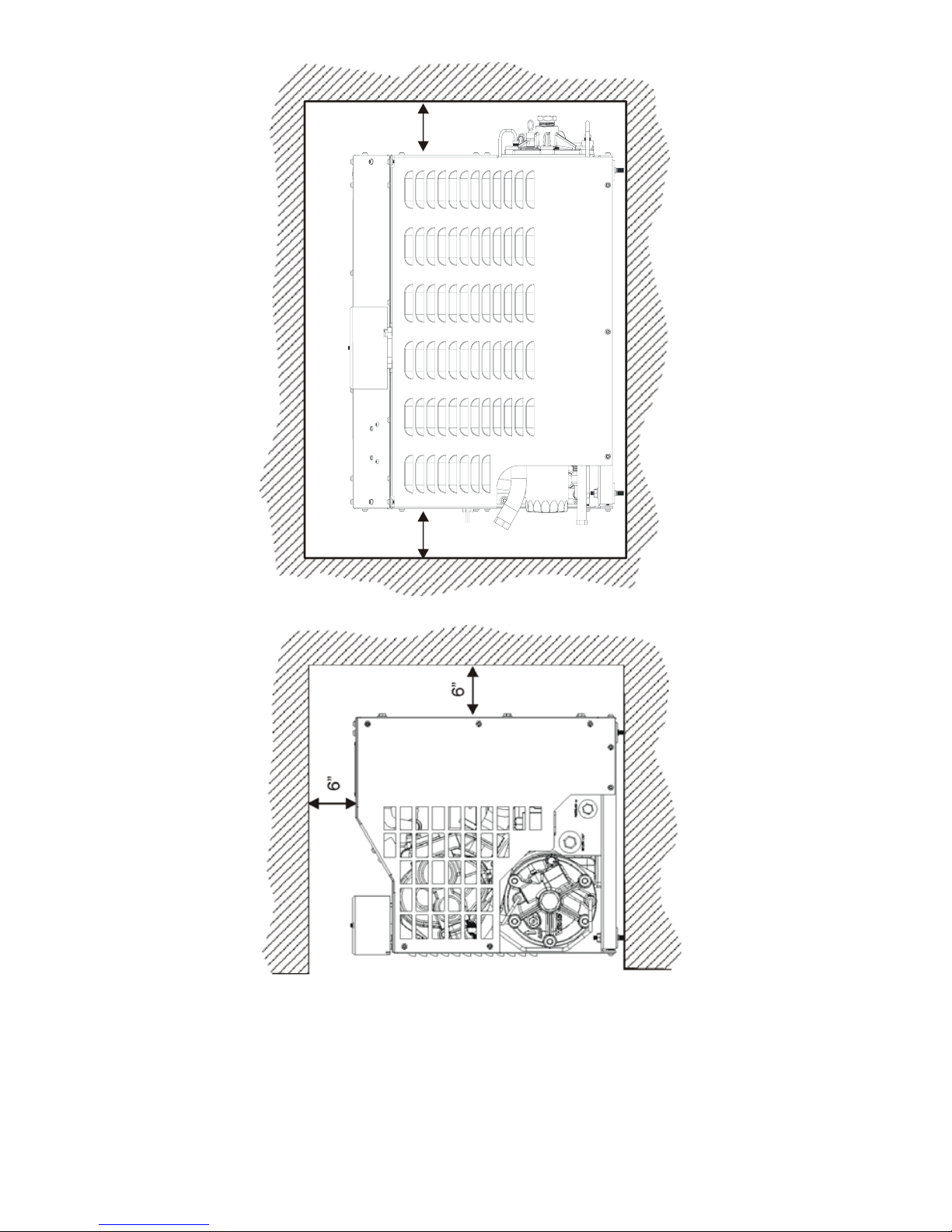

Recommended minimum clearances if no back ventilation is possible

are very important (Figure 7) but are not adequate for 100%

operational capacity (see section 5.0 Testing Ventilation).

Enclosure sizes (Figure 8) should meet minimum requirements for

optimum operation (see section 5.0 Testing Ventilation).

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

10

6”

6”

6”

6”

Figure 7 – Minimum clearances

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

11

22”

24”

With back ventilation Without back ventilation

Figure 8 – Recommended enclosure size

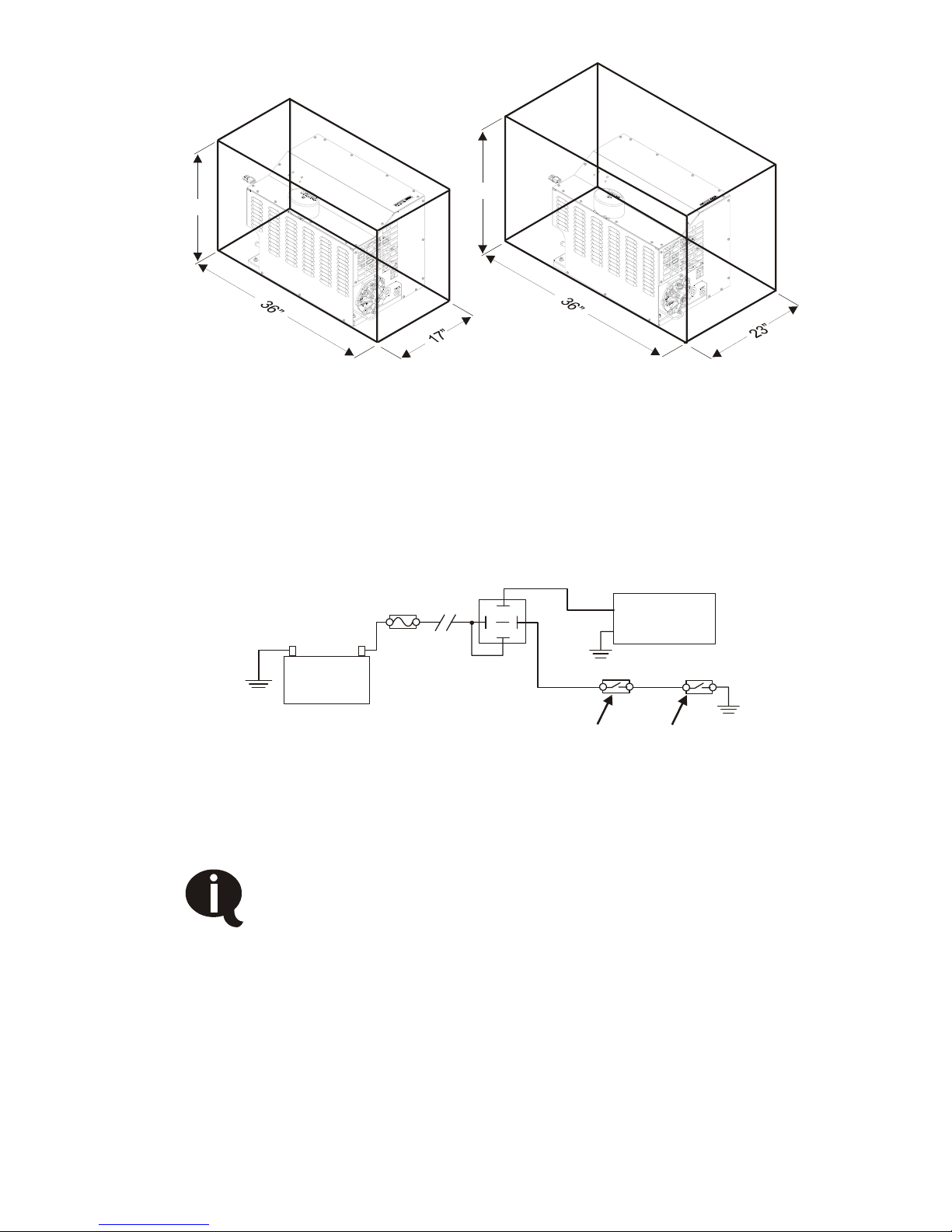

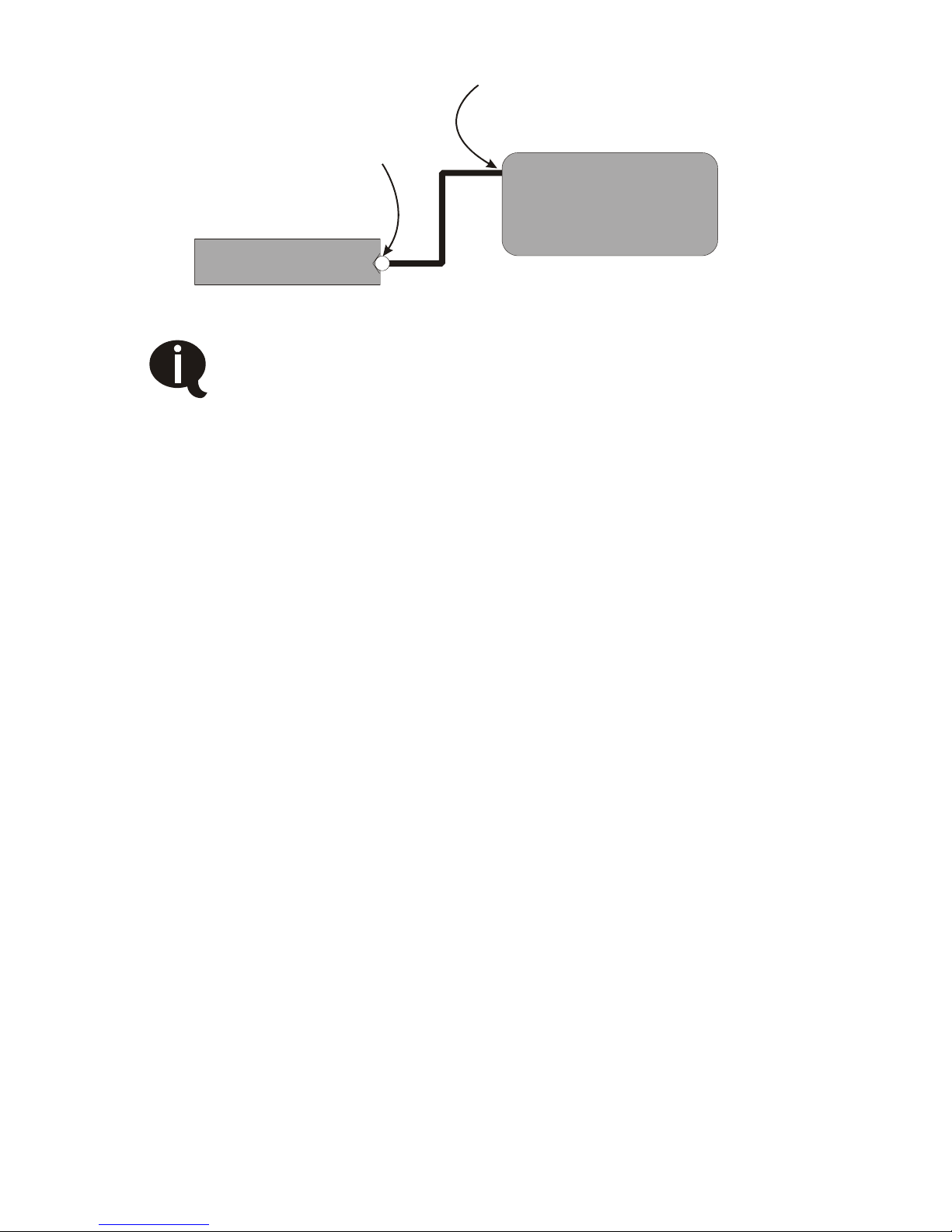

If the PREDATAIR60 is mounted inside a service body with a door

that needs to be manually opened to provide ventilation, install a

switch on the door so that the compressor will only operate when the

door is open (Figure 9).

Battery

Relay

PREDATAIR60

R

emote s

witch

Door switch

Figure 9 – Door switch

2.2 Hydraulic Requirements

If the compressor is being installed on a truck that does

not have a hydraulic system, you will find information

on selecting and installing hydraulic components in

section 6.0 Hydraulic System Data.

Compressor capacity depends on hydraulic flow. For single speed

operation a minimum of 14 GPM and a maximum of 20 GPM

hydraulic oil flow is required. For two speed operation, a minimum of

12 GPM and a maximum of 22 GPM hydraulic oil flow is required.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

12

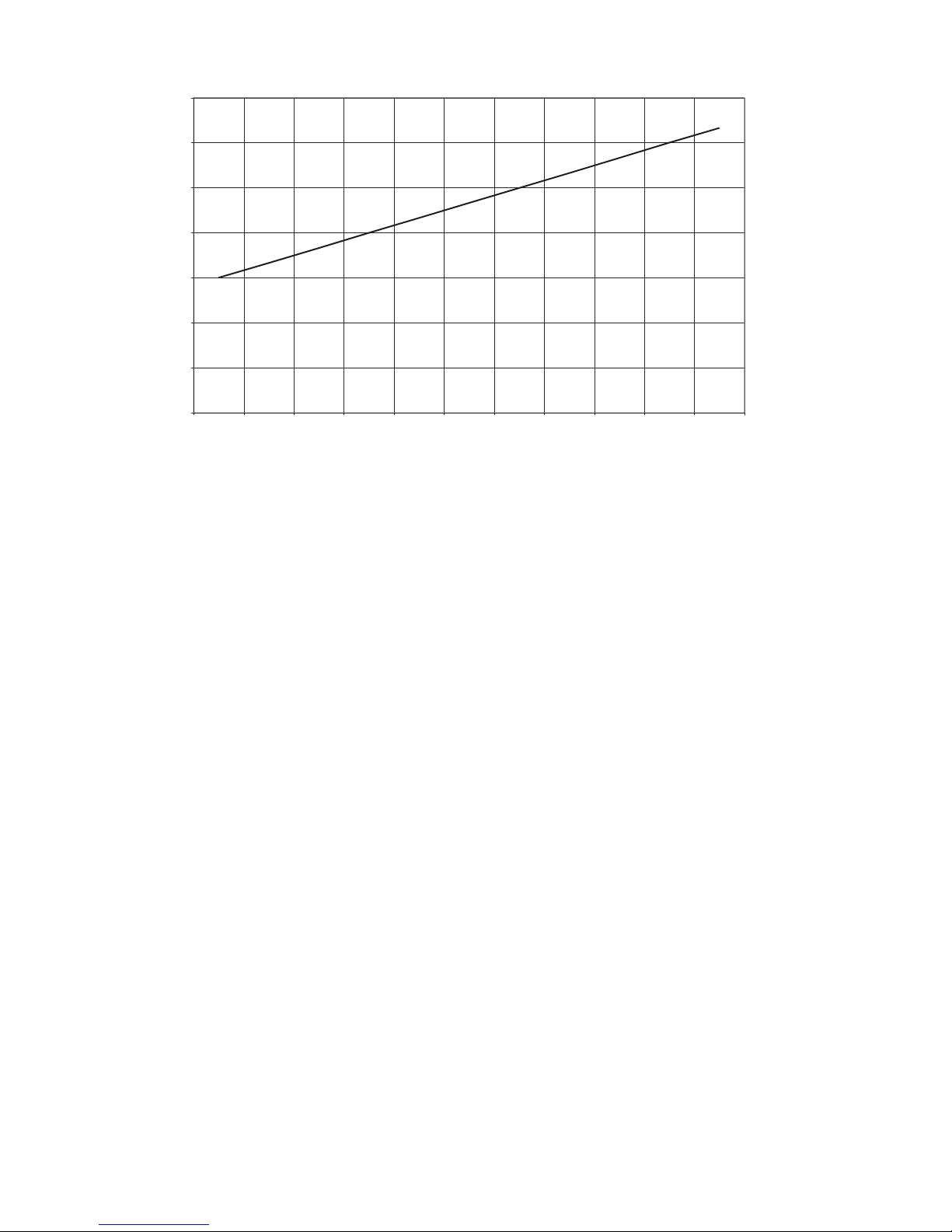

Nominal Air Flow vs Hydraulic Flow

0

10

20

30

40

50

60

70

12 13 14 15 16 17 18 19 20 21 22

Hydraulic Flow (GPM

)

A

i

r

F

l

o

w

(

C

F

M

)

These are nominal values only. Due to variations in hydraulic system

efficiency, load and flow tests should be performed to confirm that

the desired CFM has been achieved.

If the compressor is being installed on a truck that already has a

functioning hydraulic system, check the specifications for that system

to ensure that it meets minimum requirements.

The information in this manual is based on a fixed displacement

pump. Special considerations may be required for a variable

displacement pump.

2.3 Electrical Requirements

The PREDATAIR60 requires a steady 17 Amps @ 12 VDC to

operate. A 30 Amp fuse or circuit breaker is recommended.

To assure an un-interrupted supply of power, the ground wire should

be routed either to the negative terminal of the battery or to a

substantial, fully grounded point on the vehicle chassis, located in an

area which will provide a good ground at all times.

Power should be tapped directly from the positive terminal of the

battery through a relay with a contact rating of at least 20 Amps.

Using a relay allows the heavy gauge power wire to be routed

directly and permits the use of a light (18 AWG) wire between the

relay and the control switch.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

13

2.3.1 Wire Size Selection

Selecting the correct wire size is vital for proper operation. If the wire

size is too small, voltage drop will be excessive and the compressor

will operate erratically. Measure the length required for both the

power wire and the ground wire, add them together and select the

correct wire size from Table 1.

Total length of Power wire PLUS Ground wire Recommended Wire Gauge

Less than 10 ft. 12AWG

10 ft. to 15 ft. 10AWG

More than 15 ft. 8AWG

Table 1 – Wire gauge size

Never connect the PREDATAIR60 so that it switches on

at the same time as the PTO is engaged. This can cause

sudden, excessive hydraulic pressure which can

damage components.

2.4 Air Receiver Requirements

The PREDATAIR60 uses an unloader system which minimizes fuel

burn, equipment wear, cooling load, enclosure temperature,

hydraulic temperature and noise, when compressed air is not being

used. For this unloader system to work most efficiently, and to avoid

having the compressor loading and unloading too frequently, some

air receiver volume is very beneficial.

If the plumbing downstream from the PREDATAIR60 is tight, a 5

gallon air receiver is adequate. If a receiver tank is not possible,

then consider using the existing welded tubular structure within the

service body as an air receiver. For reference, 21’ of 3/16” wall 2-1/2”

x 2-1/2” square tube has a volume of 5 gallons.

If you use an auxiliary air tank with this system, the line to the

auxiliary tank must be installed as high as possible (not in the bottom

of the tank) to prevent water from clogging the line (Figure 10).

Failure to observe these requirements will result in damage to the

system.

!

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

14

PREDATAIR60 Tank

Auxiliary Tank

One-way check valve

built into PREDATAIR60

tank

Install this line high on the

tank, not at the bottom

Figure 10 – Auxiliary tank connection

A one-way check valve is built into the PREDATAIR60

tank. Do not install an additional check valve as this

may cause undesirable operations.

Loading...

Loading...