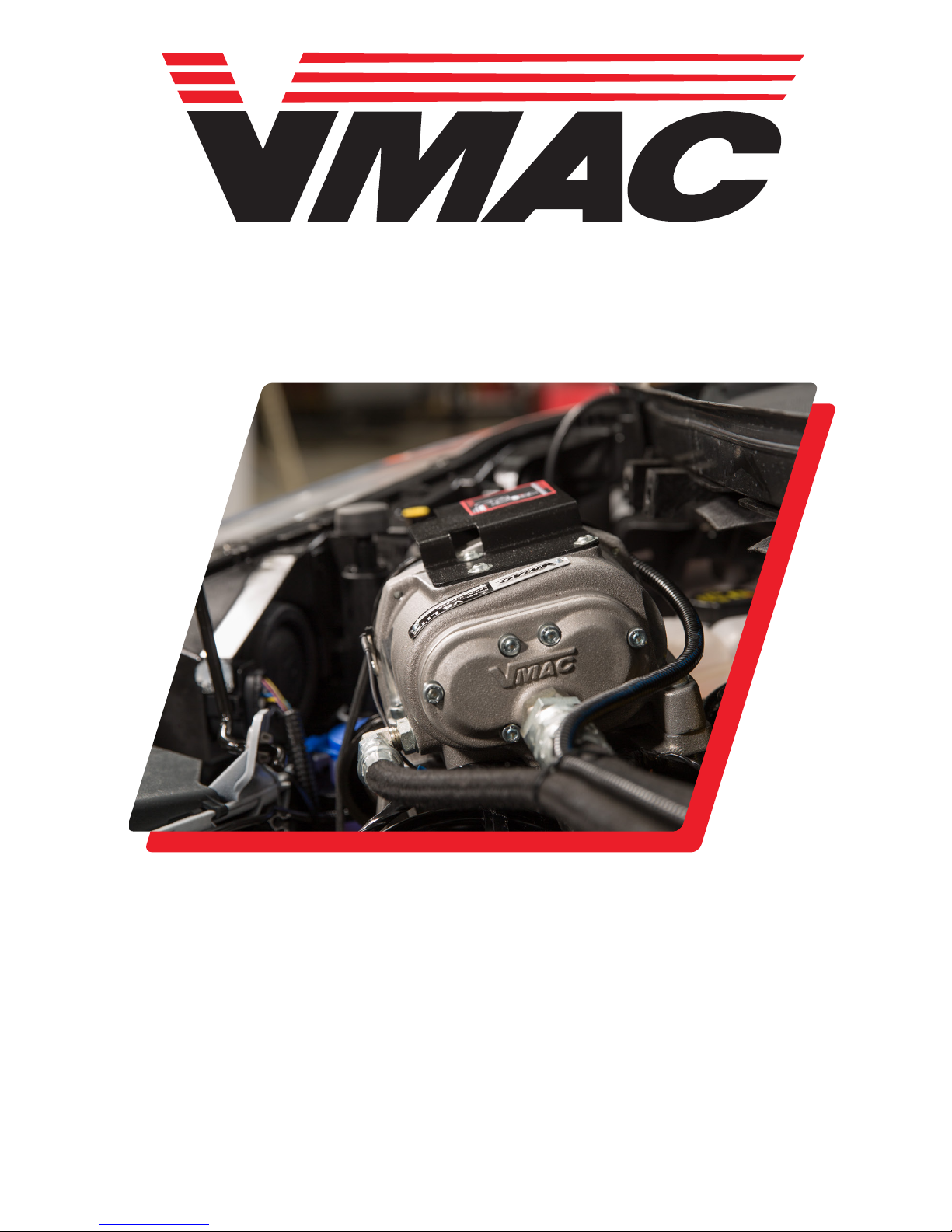

Vmac AIR INNOVATED H400001, AIR INNOVATED H600008, AIR INNOVATED H600004, AIR INNOVATED H400003, AIR INNOVATED H600002 Installation And Owner's Manual

®

AIR INNOVATED

TM

www.vmacair.com

Hydraulic Driven Air Compressor

Installation and Owner’s Manual

(Includes Service Instructions)

®

AIR INNOVATED

TM

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

1

Table of Contents

General Information .................................................3

Safety ..............................................................4

Safety Precautions ..................................................5

Warranty ...........................................................8

Hydraulic Driven Air Compressor Installation Manual ........... 11

Installation Considerations ......................................... 13

Mounting Locations and Ventilation ................................14

Speed Control .....................................................16

Hydraulic Requirements ............................................ 17

Hydraulic Fluid and Line Sizing Recommendations ..................19

Hydraulic Driven Air Compressor Harness Reference ............... 22

Electrical Requirements (12 V dc Systems) ......................... 24

Electrical Requirements (24 V dc Systems) ......................... 26

Installing the Hydraulic Driven Air Compressor System ............. 28

Testing the Installation .............................................31

Performance Testing and System Adjustments ..................... 33

Hydraulic Driven Air Compressor Owner’s Manual ..............35

Identifying Your System ............................................37

System Components and Specifications ........................... 38

System Operation (What to Expect at Start Up) ................... 45

Cold or Hot Weather Operation ................................... 48

Display Box Messages ............................................ 49

System Adjustments (Diagnostics Mode) ...........................51

Limp Mode ....................................................... 53

General Maintenance Information ................................. 54

Maintenance and Repair Safety ................................... 56

Regular Inspection Instructions .................................... 58

500 Hour / 1 Year Service ..........................................62

Diagnostics and Troubleshooting .................................. 69

Hydraulic Testing ..................................................77

Air Receiver Tank...................................................81

Recommended Accessories ....................................... 82

Accessory Products from VMAC ................................... 83

Error and Service Logs ............................................ 86

Warranty Registration ............................................. 88

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

2

Document: 1930366

Changes and Revisions

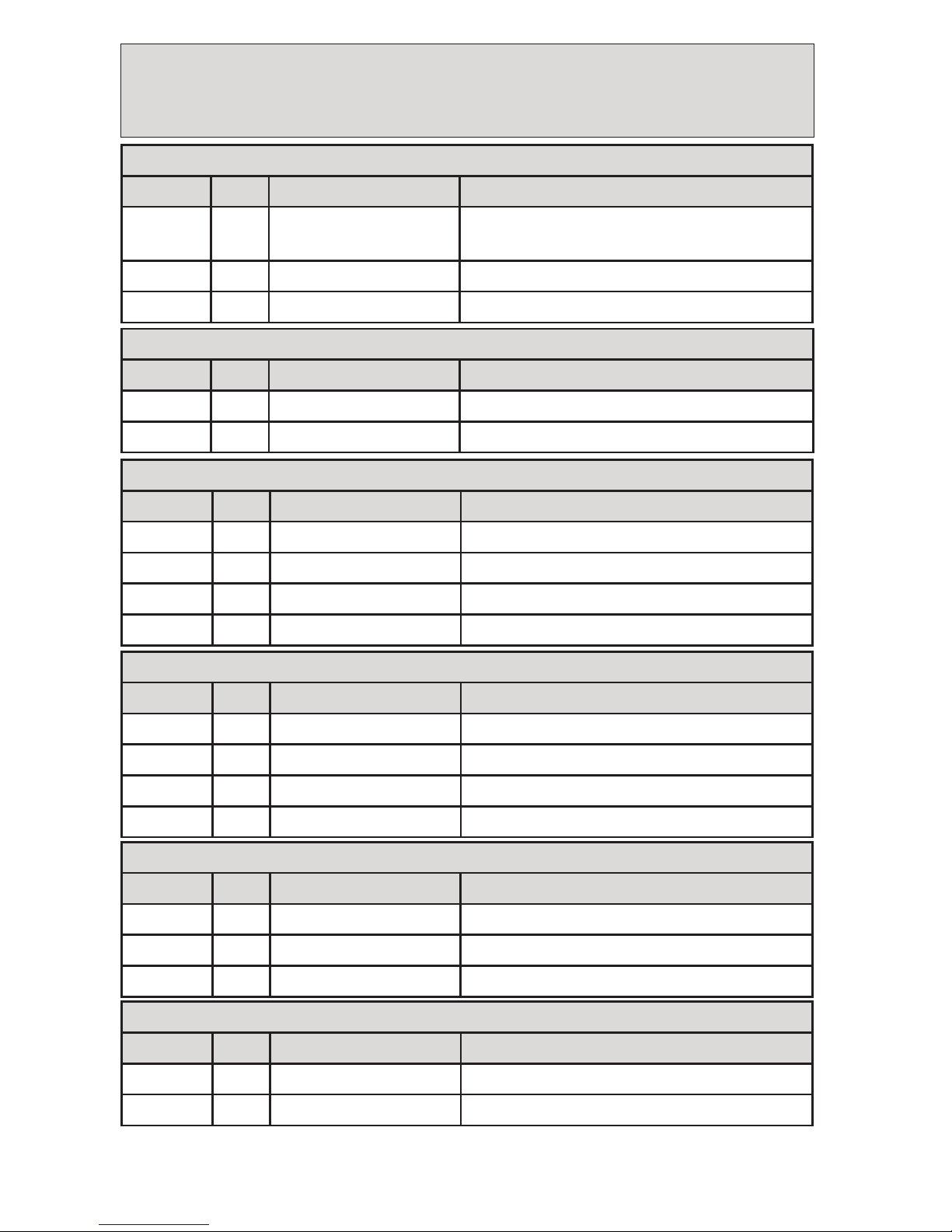

Revision Revision Details Revised by

Checked by

Implemented

Eng.

Tech. Qual.

Mech. Elec.

A Initial Release MSP MRH N/A GB AWM 16 Oct 2018

Additional Application Information

This manual applies to: H400001 / H400003 / H600002 / H600004 / H600008.

•

Not compatible with “load sensing” variable displacement pumps.

•

Requires VMAC Closed Center Manifold if used with “pressure compensated”

variable displacement pumps:

Important Information

The information in the installation section of this manual is intended for certified

VMAC installers who have been trained in installation procedures and/or for

people with mechanical trade certification who have the tools and equipment

to properly and safely perform the installation. Do not attempt this installation

without the appropriate mechanical training, knowledge and experience.

Follow all safety precautions while operating the equipment as well as when

performing any mechanical work. Any fabrication for correct fit in modified vehicles

must follow industry standard “best practices”.

Notice

Copyright © 2018 VMAC Global Technology Inc. All Rights Reserved. These

materials are provided by VMAC for informational purposes only, without

representation or warranty of any kind, and VMAC shall not be liable for errors

or omissions with respect to the materials. The only warranties for VMAC

products and services are those set forth in the express warranty statements

accompanying such products and services, if any, and nothing herein shall be

construed as constituting an additional warranty. Printing or copying of any page

in this document in whole or in part is only permitted for personal use. All other

use, copying or reproduction in both print and electronic form of any part of this

document without the written consent of VMAC is prohibited. The information

contained herein may be changed without prior notice.

Printed in Canada

Registered Trademarks

All trademarks mentioned in this manual are the property of their respective

owners. VMAC’s use of manufacturers’ trademarks in this manual is for

identification of the products only and does not imply any affiliation to, or

endorsement of said companies.

Loctite®, Loctite® 242 and Loctite® 567 are registered trademarks of Henkel AG &

Company KGaA.

Eaton Aeroquip® is a registered trademark of EATON AEROQUIP INC.

Viton® is a registered trademark of The Chemours Company.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

3

Introduction

This manual provides operating instructions, specifications, adjustment,

maintenance and warranty information for the VMAC Hydraulic Driven Air

Compressor systems. Read this manual prior to servicing or operating the

compressor system.

Follow all safety precautions when servicing or operating the VMAC system as

moving fan blades and other rotating components pose an extreme hazard.

Proper service and repair are important to the safety of the operator and the safe,

reliable operation of the equipment. Always use genuine VMAC replacement parts.

The procedures described in this manual are the only approved methods of service

and operation.

Ordering Parts

To order parts, contact a VMAC dealer. The dealer will ask for the VMAC System ID

(see page 37), part number, description and quantity. Locate the nearest dealer

online at www.vmacair.com/dealer-locator or call 1-877-912-6605.

General Information

Additional Support

Additional resources such as installation manuals, illustrated parts lists, the VMAC

Knowledge Base, air tool consumption guides, etc. are available at

https://www.vmacair.com/support/.

VMAC is unable to provide hydraulic circuit designs or consult on

specific hydraulic installations. We recommend working with a local

hydraulic expert to design and/or install the hydraulic circuit that

will power the Hydraulic Driven Air Compressor system.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

4

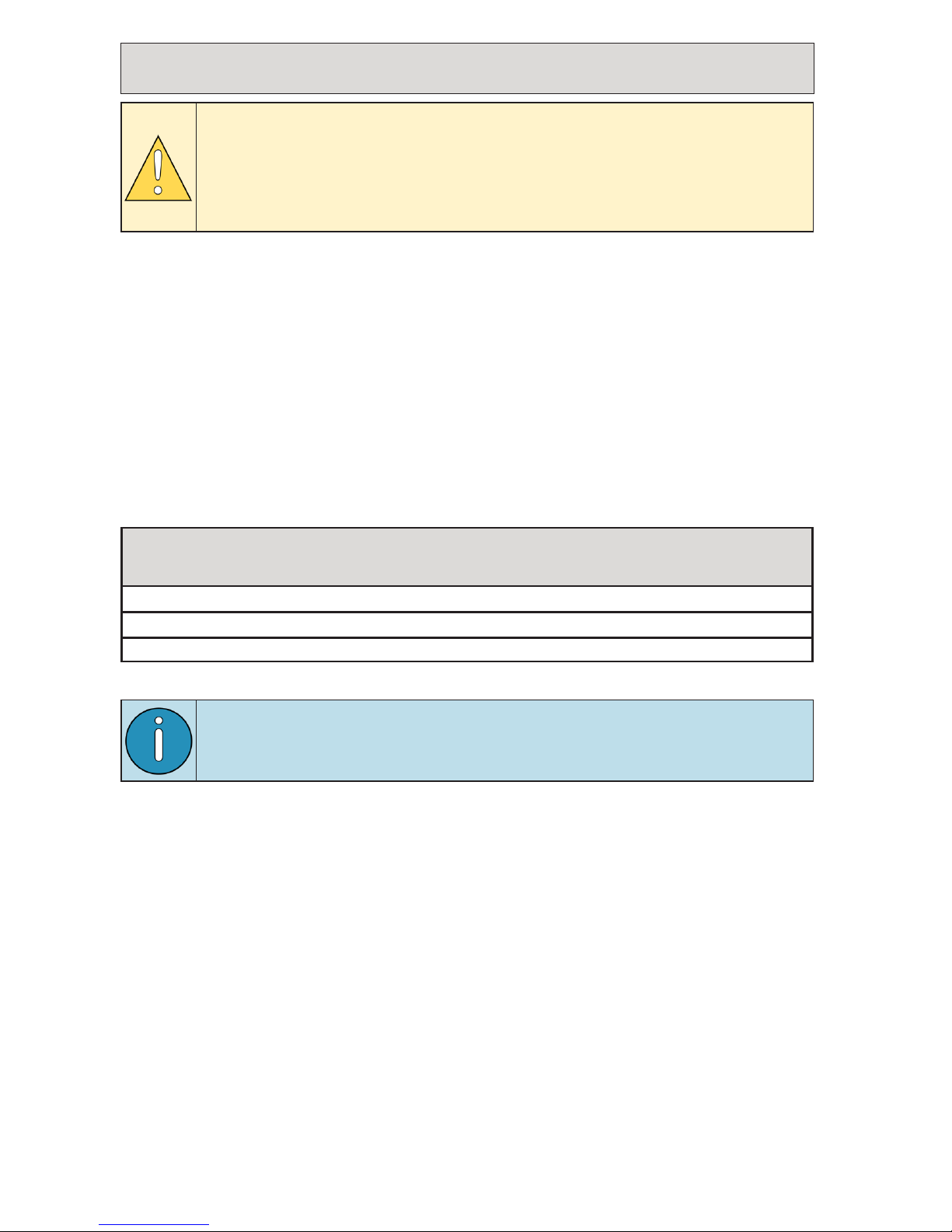

Important Safety Notice

The information contained in this manual is based on sound engineering principles,

research, extensive field experience and technical information. Information

is constantly changing with the addition of new models, assemblies, service

techniques and running OEM changes. If a discrepancy is found in this manual,

contact VMAC prior to initiating or proceeding with installation, service or repair.

Current information may clarify the issue. Any person with knowledge of such

discrepancies, who proceeds to perform service and repair assumes all risks.

Only proven service procedures are recommended. Anyone who departs from the

specific instructions provided in this manual must first assure that their safety and

that of others is not being compromised and that there will be no adverse effects

on the operational safety or performance of the equipment.

VMAC will not be held responsible for any liability, consequential damages, injuries,

loss or damage to individuals or to equipment as a result of the failure of any

person to properly adhere to the procedures set out in this manual or standard

safety practices. Safety should be the first consideration when performing any

service operations. If there are any questions concerning the procedures in this

manual or more information is required, please contact VMAC before beginning

repairs.

Safety Messages

This manual contains various warnings, cautions and notices that must be

observed to reduce the risk of personal injury during installation, service or repair

and the possibility that improper installation, service or repair may damage the

equipment or render it unsafe.

This symbol is used to call attention to instructions concerning

personal safety. Watch for this symbol; it points out important

safety precautions, it means, “Attention, become alert! Your

personal safety is involved”. Read the message that follows and

be aware of the possibility of personal injury or death. As it is

impossible to warn of every conceivable hazard, common sense and

industry standard safety practices must be observed.

This symbol is used to call attention to instructions on a specific

procedure that if not followed may damage or reduce the useful life

of the compressor or other equipment.

This symbol is used to call attention to additional instructions or

special emphasis on a specific procedure.

Safety

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

5

Burn Hazard

•

The compressor system gets very hot during operation, contact

with the components or the oil can cause serious injury. Allow

sufficient time for the system to cool before performing service.

•

Never allow any part of your body to contact the compressor

components.

Personal Safety

•

Do not breathe the compressor air. Vaporized oil is a respiratory

hazard.

•

Always use the appropriate personal protective equipment,

particularly eye and hearing protection when operating air

powered equipment.

As it is impossible to warn of every possible hazard that may result

from operating this system, common sense and industry standard

safety practices must be observed.

Read this information before operating the compressor for the first time. Follow

the information and procedures in this manual for operation, maintenance and

repair. Observe the following items to reduce the chance of personal injury or

equipment damage.

Follow all safety precautions for mechanical work. Moving belts and rotating

components are an extreme hazard. Stay clear of all moving parts when the

system is operating. Only qualified personnel should perform maintenance and

repair on system components and only while the system is properly shut down.

Proper service and repair are important to the safety of the service technician

and the safe, reliable operation of the equipment. Always use genuine VMAC

replacement parts.

The procedures described in this service manual are effective methods of service

and repair. Some procedures may require the use of tools specially designed for a

specific purpose. Anyone using a replacement part, service procedure or tool must

first determine that neither their safety nor the safe operation of the equipment

will be compromised by the replacement part, service procedure or tool selected.

Safety Precautions

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

6

Fire and Explosion Hazard

•

Vaporized oil propelled by high pressure air is an explosive mixture.

•

Fire in the compressor can cause an explosion and flame projection.

Should this occur, there is potential for serious injury or death.

•

Operate the compressor in a well ventilated area free of flammable

vapors, dust, or other combustible materials.

•

Never place objects against or on top of the compressor.

•

Never expose the Air Oil Separator Tank or compressor to extreme

heat.

Compressor Air and Oil Hazard

•

The compressor system is under sufficient pressure that a leak

could force the air/oil mixture through the skin directly into your

bloodstream. This could cause serious injury or death.

•

Ensure the system is completely depressurized before attempting

maintenance or repair.

•

Do not use compressed air to clean off clothing or skin, compressed

air can penetrate the skin causing serious injury or death.

•

Do not move or service the compressor while it is pressurized or

operating.

•

Do not move the compressor by pulling on any hoses.

•

Components and hoses under pressure could separate suddenly, fly

out and cause serious injury or death. If equipped, the air receiver

tank must be drained before servicing any components in the

compressor system.

•

Never adjust or attempt to make any repairs to the system while

the engine is running. Components and hoses under pressure could

fail and cause serious injury or death.

Burst Hazard

•

Serious injury or death may result from an air tank explosion.

•

Never exceed manufacturer’s maximum air pressure rating.

•

Do not repair components, only replace with approved parts.

•

Do not tamper with or disable factory safety equipment.

Moving Parts Hazard

•

Before performing service, disconnect the negative battery cable

and the spark plug wire to prevent unexpected engine start.

•

Do not operate the compressor without guards in place. If the

guards are damaged or missing, replace them before operating the

equipment.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

7

General Warnings

•

Ensure the compressor and hydraulic system are cool and

depressurized prior to servicing.

•

Be attentive for unexplained changes in operation parameters and

record any changes.

•

Check the compressor oil level and condition before starting the

system. Do not add or change oil while the system is running. Use

only approved oil.

•

The compressor may operate anytime the hydraulic circuit is

energized. Avoid contact with the compressor, hoses, or motor

during operation.

•

Keep hoses and wiring away from hot, sharp, or moving

components.

•

Use only approved hoses and replacement parts.

•

Do not modify the equipment.

•

Do not operate the air compressor when fatigued or under the

influence of alcohol or drugs.

•

Know how to operate the compressor, fully read the manual.

•

Check equipment before every use.

•

Never bypass or disable any of the safety equipment.

•

Never adjust or attempt to make any repairs to the compressor

system while the hydraulic circuit is pressurized. Components and

hoses under pressure could fail and cause serious injury or death.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

8

VMAC Standard Warranty (Limited)

For complete warranty information, including both VMAC Standard

Warranty (Limited) and VMAC Lifetime Warranty (Limited)

requirements, please refer to our current published warranty located

at: www.vmacair.com/warranty

If you do not have access to a computer, please contact us and we

will be happy to send you our warranty.

VMAC’s warranty is subject to change without notice.

VMAC Lifetime Warranty (Limited)

A VMAC Lifetime Limited Warranty is offered

on the base air compressor only and only on

UNDERHOOD, Hydraulic Driven, Transmission

Mounted, Gas and Diesel Engine Driven Air

Compressors, Multifunction Power Systems, and

other products as defined by VMAC, provided that

(i) the purchaser fully completes and submits a

warranty registration form within 3 months of purchase, or 200 hours of operation,

whichever occurs first; (ii) services are completed in accordance with the Owner’s

Manual; (iii) proof of purchase of applicable service kits are made available to

VMAC upon request.

The VMAC Lifetime Warranty is applicable to new products shipped on or after

1 October, 2015.

Warranty Registration

The VMAC warranty registration form is located near the back of this manual. This

warranty registration form must be completed and sent to VMAC at the time of

installation for any subsequent warranty claim to be considered valid.

There are 4 ways the warranty can be registered with VMAC:

www.vmacair.com/warranty

warranty@vmacair.com

(877) 740 -3202

VMAC - Vehicle Mounted Air Compressors

1333 Kipp Road, Nanaimo, BC, Canada V9X 1R3

LIFETIME

A

I

R

I

N

N

O

V

A

T

E

D

T

R

U

S

T

S

E

R

V

I

C

E

V

A

L

U

E

WARRANTY

Warranty

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

9

VMAC warranty work must be pre-authorized by VMAC. Claims are

processed via our dealer network. If you are not a VMAC dealer,

please select one to work with via our Dealer Locator:

https://www.vmacair.com/dealer-locator/.

1. Communicate with VMAC Technical Support at 1-888-241-2289 to help diagnose/

troubleshoot the problem prior to repair. VMAC technical support requires the

VMAC System ID, hours on the compressor and mileage on the vehicle.

2. VMAC will provide direction for repair or replacement of the failed components.

3. Failed parts must be held by the dealer for a period of six months, and sent to

VMAC if requested (along with the RMA number) for evaluation, unless otherwise

instructed by VMAC.

4. Dealers may login to the VMAC website to view the VMAC Labour Time Guide

(under “Agreements”) to see the allowable warranty labour times.

5. Warranty invoices must include the Service Ticket (CSR) number, VMAC System

ID#, hours on the compressor, mileage on the vehicle, and a detailed description

of the work performed.

6. VMAC Warranty does not cover consequential damage, overtime charges,

mileage, travel time, towing/recovery, cleaning or shop supplies.

7. Dealers submit warranty claims on behalf of the Vehicle Owner/End User

affected by the defective part(s). The dealer ensures that all warranty credits

are refunded back to the Vehicle Owner/End User who made the initial warranty

claim.

For Standard Warranty (Limited): If the completed warranty

registration form has not been received by VMAC within 6 months

from the date of installation of the Product(s), the warranty period

will be deemed to commence 30 days from the date of shipment

from VMAC.

For Lifetime Warranty (Limited): The completed warranty

registration form must be received by VMAC within 3 months from

the date of purchase or 200 hours of operation of the product(s)

(whichever occurs first).

Failure to follow this procedure may result in denial of the warranty

claim.

VMAC Product Warranty Policies & Warranty Registration can be found on the

VMAC website (see previous page for URL).

VMAC Warranty Claim Process

Hydraulic Driven Air Compressor

Installation Manual

®

AIR INNOVATED

TM

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

13

Installation Considerations

Prior to installing the system, consider the following factors:

•

For proper operation, VMAC’s Hydraulic Driven Air Compressor Systems require

proper hydraulic pressure and flow, ensure the hydraulic circuit is designed

with these requirements in mind (see page 17).

•

See “Hydraulic Fluid and Line Sizing Recommendations” on page 19 for

additional hydraulic circuit recommendations.

•

Special consideration is required for variable rate hydraulic pumps

(see page 17). Is the intended location convenient for electrical, hydraulic,

and air connections?

•

Will the intended location require extensive plumbing for the hydraulic system

or air hoses?

•

Are the wire lengths, and air/hydraulic hose lengths as short as possible, and

with the least amount of 90° fittings possible?

•

Can the oil level at the sight glass be checked easily?

•

Can the unit be serviced easily?

•

Will there be adequate clearance around the unit to provide good air

circulation and effective cooling (see page 14)?

•

Will the unit be protected from excessive exposure to the elements?

•

Will the unit be protected from incidental damage from other operations?

•

Will the unit be mounted away from heat sources such as engines, exhaust, or

other components that can generate heat.

•

Will the unit be mounted where it will be exposed to high contamination levels,

including combustible gases?

•

If the intended mounting location is constructed of thin gauge material,

consider using the VMAC Mounting Brackets (P/N: A700140).

The information in this section is critical to ensure proper operation

of the system. Read these requirements prior to beginning the

installation.

Failure to adhere to these recommendations will cause the

Hydraulic Driven Air Compressor system to operate erratically.

The integrated cooler on the Hydraulic Driven Air Compressor

system is capable of removing all of the heat generated during air

compression from the compressor oil and hydraulic fluid.

Additional hydraulic oil cooling (such as VMAC’s Hydraulic Oil Cooler

(P/N: A850001) may be required for any other hydraulic equipment

installed on the same circuit.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

14

Enclosed mounting is not recommended due to the significant heat

generated by the Hydraulic Driven Air Compressor.

While it is not possible to make absolute recommendations regarding ventilation

due to the widely differing circumstances that are possible, duty cycle, ambient

temperature and enclosure shape are some of the important variables that must

be considered.

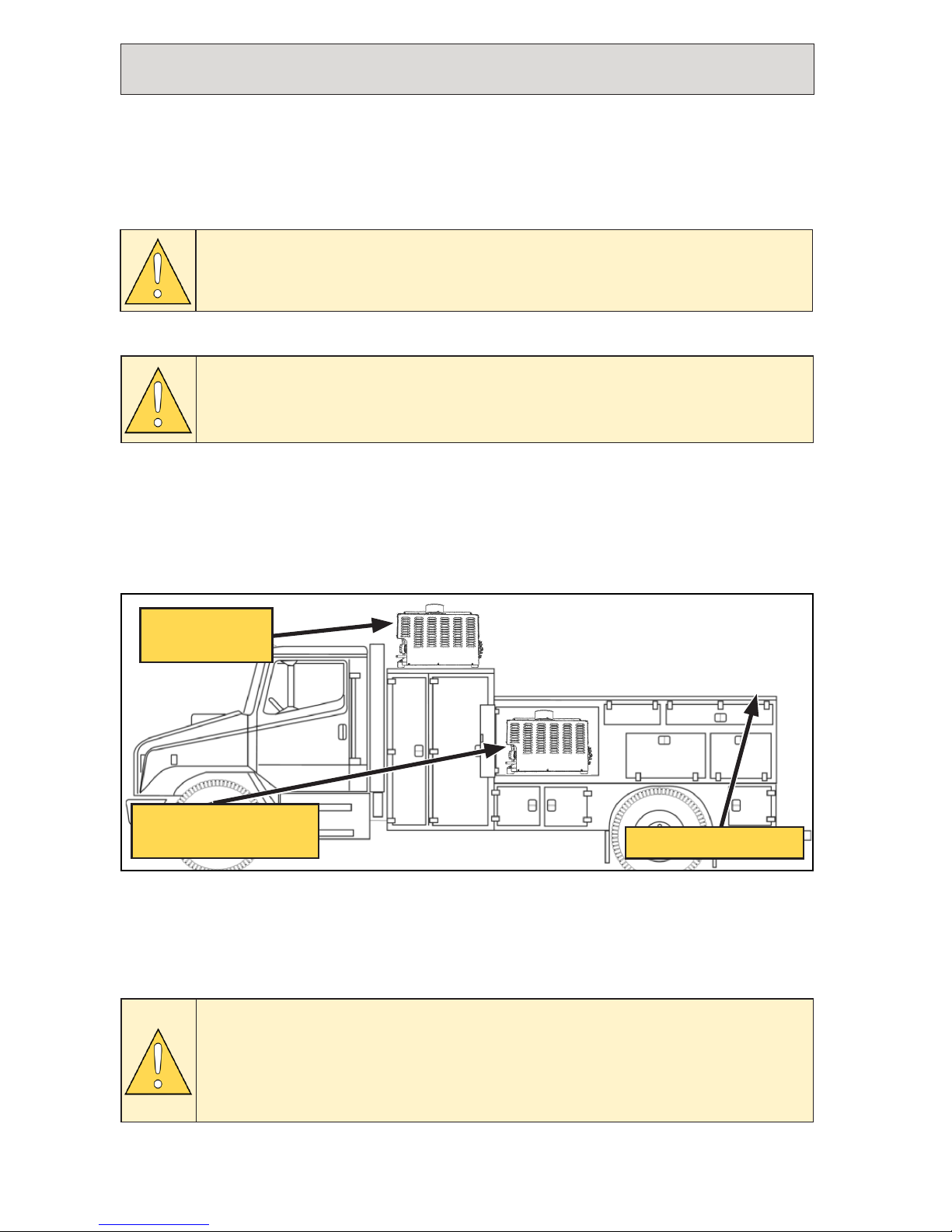

Top Mounting

“Top mounted” is the preferred mounting location for the Hydraulic Driven Air

Compressor. Placing the unit on top of the service body provides the best access to

cool fresh air. Maintain a minimum of 6 in between the sides of the Hydraulic Driven

Air Compressor and all other solid objects (Figure 1).

Mounting Locations and Ventilation

Mounting the Hydraulic Driven Air Compressor in an enclosure will limit access

to cool fresh air, restrict the escape of hot air from around the unit and have an

adverse effect on cooling which may reduce the unit’s duty cycle. Ensure adequate

ventilation is provided for cooling and to evacuate the heat generated by the unit.

If mounting in an enclosure, VMAC strongly recommends mounting the unit on a

pullout drawer and extending the drawer any time the unit is run.

Figure 1 — Mounting locations

Enclosure mounted

(not recommended)

Top mounted

(Preferred)

Not recommended

VMAC does not recommend mounting the unit at the back of the

vehicle as the drag created when the vehicle is moving causes

debris to be deposited (and accumulated) inside the unit.

Significant ventilation and additional cooling will be required if the

Hydraulic Driven Air Compressor is mounted in the same enclosure

as the hydraulic oil reservoir. The heat generated during operation

will continue to heat the hydraulic fluid (even with fresh ambient air

entering the cooler).

Enclosed Mounting

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

15

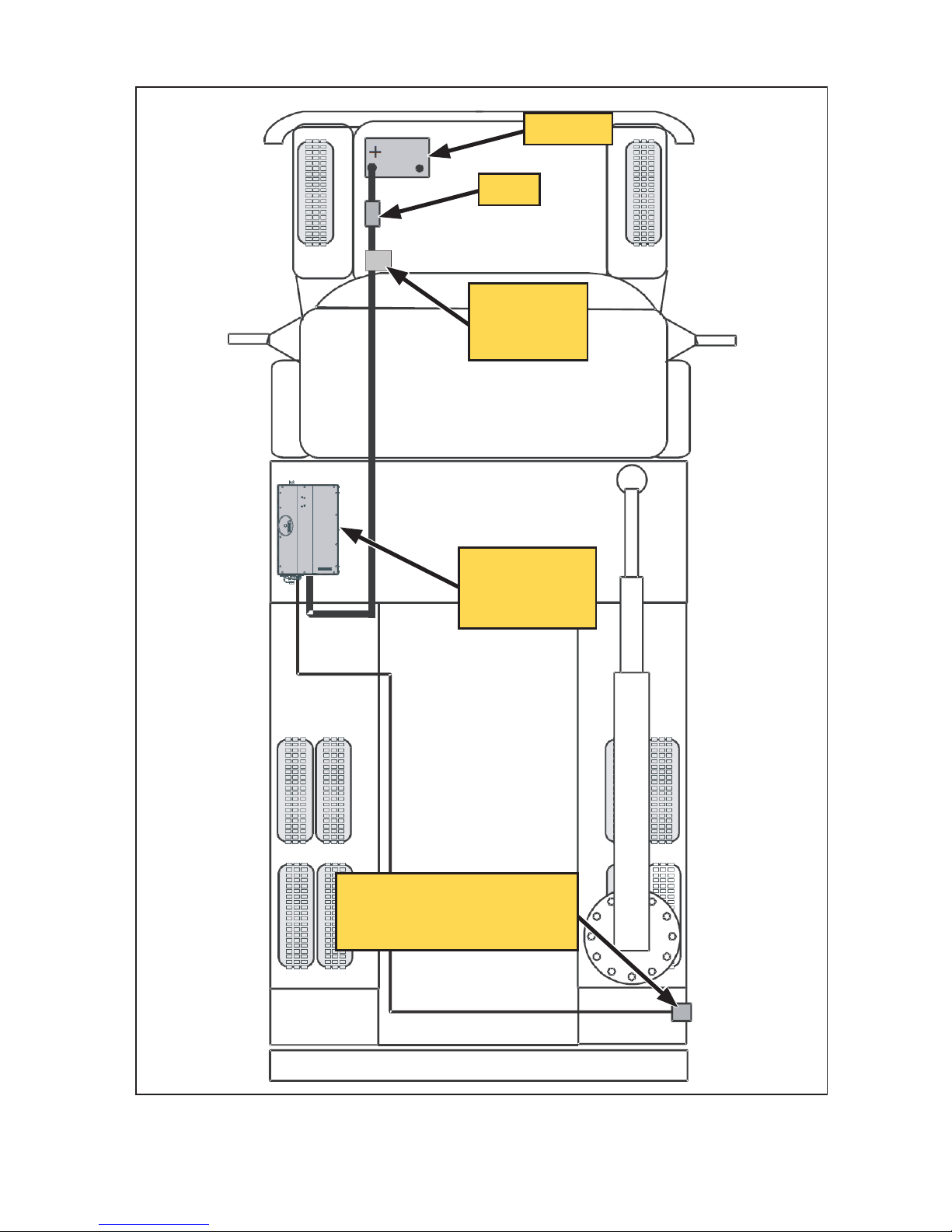

Recommended Component Layout

Figure 2 — Recommended component layout

Battery

Fuse

Ignition

switched

relay

Hydraulic

Driven Air

Compressor

Display Box

(mounted inside weather

proof enclosure)

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

16

Speed Control

The Hydraulic Driven Air Compressor has the ability to signal for a higher engine

speed under high air demand conditions and for a lower engine speed under low

air demand conditions. A built in, electrically activated idle up system or an aftermarket product is required to provide 2 speed operation.

The Hydraulic Driven Air Compressor is capable of constant operation at a

fixed engine speed and hydraulic pump gpm. There are several advantages to

configuring the system for 2 speed operation:

•

Lower fuel consumption.

•

Lower noise when air demand is low.

•

Lower wear rates on the engine, hydraulic pump and compressor.

•

Faster warm up during cold start weather.

The preferred approach for speed control is to restrict the hydraulic flow to the

Hydraulic Driven Air Compressor to the minimum requirement for the system (8 – 9

gpm for the H40, 13 – 14 gpm for the H60 and H60 HHP) this is desirable for cold

climate start-up as it keeps hydraulic pressure low during warm up.

The system must be at, or above, the minimum hydraulic flow before

starting the Hydraulic Driven Air Compressor.

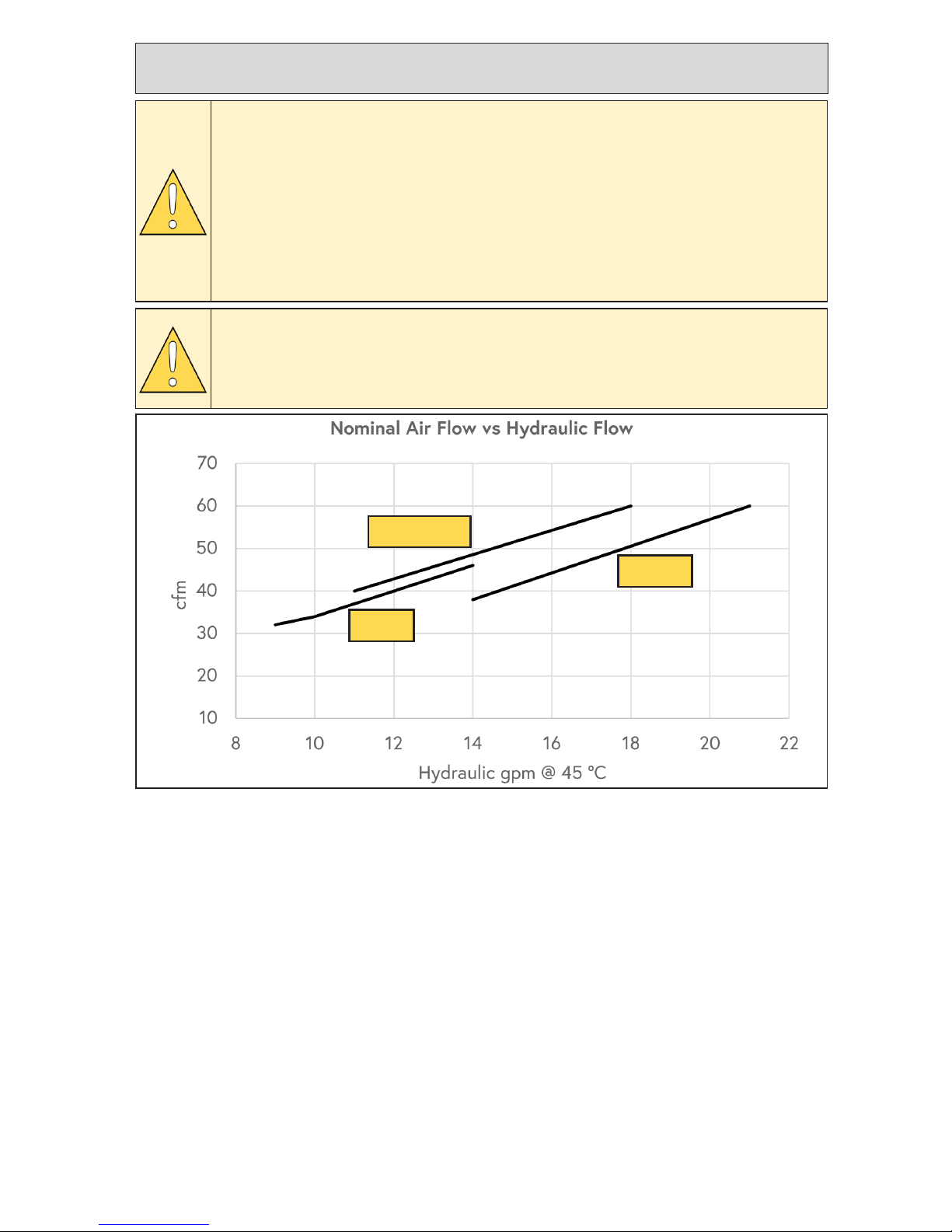

Single Speed Operation (See Figure 3 on page 17 for “gpm vs cfm” chart)

When the “ON” button is pressed, the Control Box in the Hydraulic Driven Air

Compressor will signal the PTO to increase hydraulic flow to provide the desired

cfm.

2 Speed Operation (See Figure 3 on page 17 for “gpm vs cfm” chart)

When the “ON” button is pressed, “Speed 1” is activated and the Control Box in

the Hydraulic Driven Air Compressor will signal the PTO to set hydraulic flow to the

minimum desired cfm.

“Speed 2” is activated to signal the PTO to increase hydraulic flow to provide the

maximum cfm (or speed system warm up).

Remote ON/OFF Control (Optional)

The system can be configured with a remote “ON/OFF” control by connecting the

yellow remote wire on the harness to a switch or relay and connecting the other

side of the switch or relay to ground. The Hydraulic Driven Air Compressor will

turn on when the circuit between the yellow wire and ground is completed via

the switch or relay and will turn off when the switch or relay is used to open the

circuit.

During this time, the Display Box can only be used to view messages as the “ON”

and “OFF” buttons are disabled.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

17

Hydraulic Requirements

H40 / H60

While in operation, the required system pressure will vary between 900 psi and

2,400 psi.

The hydraulic pump must be rated for 2,400 psi (steady state) and 2,800 psi

(intermittent) to allow for an additional 200 psi pressure drop in the pressure lines

(external to the system) during startup with cold hydraulic fluid.

H60 HHP

While in operation, the required system pressure will vary between 900 psi and

2,700 psi.

The hydraulic pump must be rated for 3,200 psi (steady state) and 3,400

psi(intermittent) to allow for an additional 200 psi pressure drop in the pressure

lines (external to the system) during startup with cold hydraulic fluid.

Figure 3 — cfm vs gpm

H60 HHP

H60

H40

VMAC is unable to provide hydraulic circuit designs or consult on

specific hydraulic installations. We recommend working with a local

hydraulic expert to design and/or install the hydraulic circuit that

will power the Hydraulic Driven Air Compressor system.

VMAC’s Hydraulic Driven Air Compressors are designed to be driven

by fixed displacement hydraulic pumps.

Hydraulic circuits using “pressure compensated” variable

displacement pumps must have a Closed Centre Manifold installed

at the Hydraulic Driven Air Compressor (see “Accessory Products

from VMAC” on page 83).

VMAC’s Hydraulic Driven Air Compressors are not compatible with

“load sensing” variable displacement hydraulic pumps.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

18

Hydraulic40

The system must maintain hydraulic flow between 9 gpm and 14 gpm (Figure 3).

Hydraulic60

The system must maintain hydraulic flow between 14 gpm and 21 gpm (Figure 3).

Hydraulic60 HHP

The system must maintain hydraulic flow between 12 gpm and 18 gpm (Figure 3).

The stated hydraulic flow rates are nominal values only and may change due to

variations in hydraulic system efficiency, load, and flow. Tests should be performed to

confirm that the desired cfm has been achieved.

If the Hydraulic Driven Air Compressor system is being installed into an existing

hydraulic circuit, ensure the circuit meets the requirements listed in this chapter.

See “Hydraulic Fluid and Line Sizing Recommendations” on page 19 for additional

information.

An independent hydraulic system is recommended to simplify

installation, operation, and troubleshooting of the Hydraulic Driven

Air Compressor system.

If this system is being installed in a shared hydraulic circuit, the use

of a shut off valve is advised.

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

19

Hydraulic Fluid and Line Sizing

Recommendations

Use only premium quality mineral or synthetic anti wear hydraulic

fluid.

When selecting which hydraulic fluid to use, the decision should be based on the

lowest overnight temperature that the unit will be used in.

Hydraulic Fluid Type

Table 1 — Temperature reference chart

Extreme Cold Climate Cold Climate Temperate Climate

Below -4 °F (-19 °C) -3 °F — 32 °F ( -19 °C — 0 °C) Above 32 °F (0 °)

Cold Climate Temperate Climate

AW22 † AW32

† When possible change to AW32 (e.g. during summer months)

Table 2 — Hydraulic fluid chart

Climate / Temperature Reference Chart

VMAC is unable to provide hydraulic circuit designs or consult on

specific hydraulic installations. We recommend working with a local

hydraulic expert to design and/or install the hydraulic circuit that

will power the Hydraulic Driven Air Compressor system.

The following information is intended as a guideline only.

Mount Location Extreme Cold Climate

Tank and Suction Line Preheat

AW32

No Tank Preheat A seasonal hydraulic fluid change is recommended.

Table 3 — Hydraulic fluid recommendation for extreme cold climates

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

20

Hydraulic Line Sizing

Industrial hydraulic system design guidelines generally call for the following

maximum fluid velocities, which are then used to select line sizes for any particular

gpm:

•

Supply 4 ft/sec.

•

Return 10 ft/sec.

•

Pressure 20 ft/sec.

The above guidelines are not considered comprehensive when working with mobile

hydraulic applications on prebuilt chassis due to the following factors:

•

Extreme start-up temperature variations.

•

Long supply lines.

•

Piggy-backing of motor case drain flow onto the main return line.

Hydraulic pump failure due to cavitation, and/or hydraulic motor

seal failure due to excess return line pressure, may occur if

the above considerations are ignored when line sizes are being

determined.

The following information provides specific line sizing recommendations for mobile

hydraulic system installations intended for use with VMAC’s Hydraulic Driven Air

Compressor systems. The dimensions provided indicate “inside diameter” (ID).

Supply Line Sizing

Failure to use the correct suction line size may result in hydraulic

pump cavitation leading to premature pump failure.

☐

In order to determine the appropriate supply line size, first identify the climate

that the system will be used in (Table 1), then select the corresponding line size

based off of the maximum gpm of the system (Table 4 or Table 5 starting on

page 21).

Special design considerations are required for hydraulic systems

operating in extreme cold climates.

VMAC recommends consulting with hydraulic experts experienced in

the design and installation of hydraulic circuits that will be used in

temperatures below -4 °F (-19 °C).

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

21

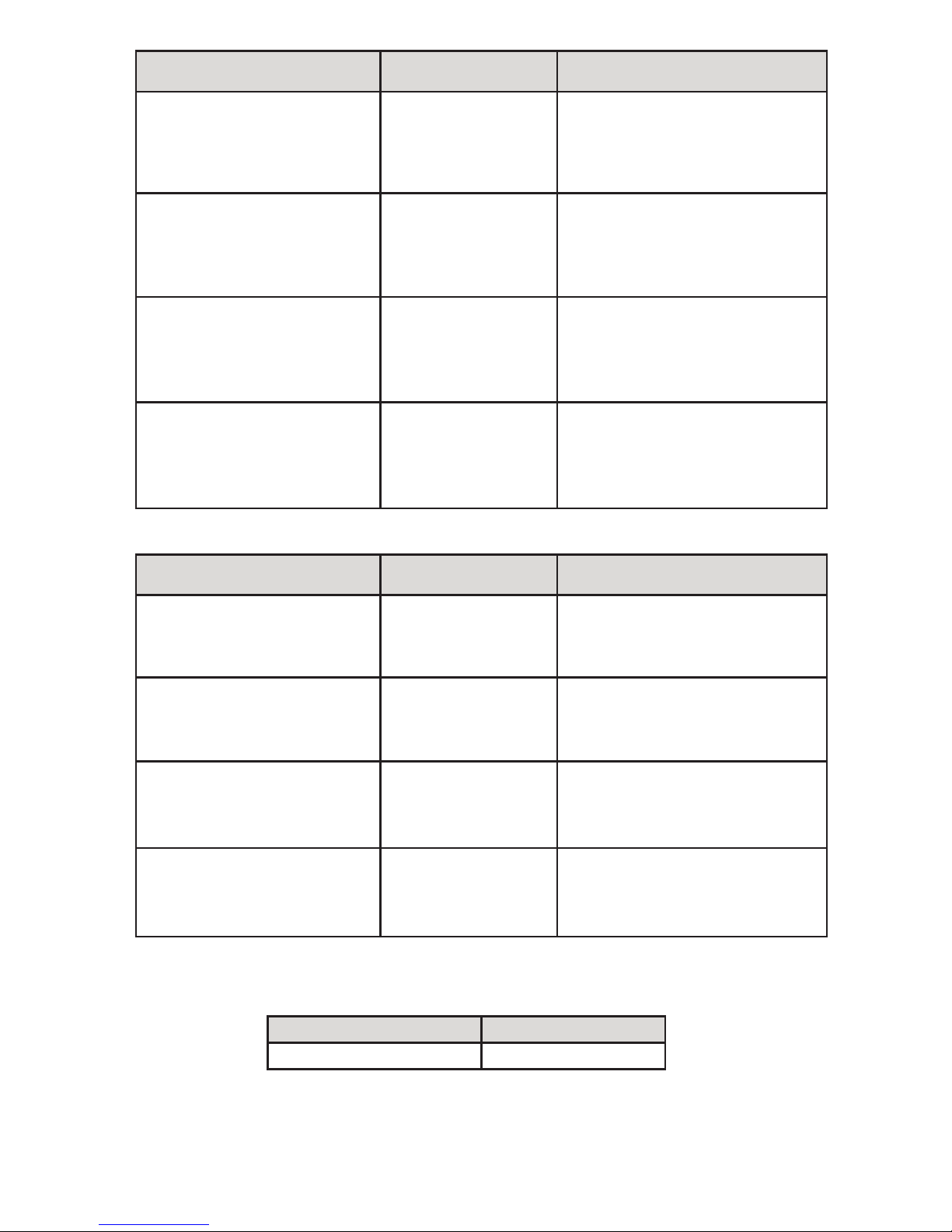

gpm during start up / warm up

Supply Line Size

AW 22

Supply Line Size

AW 32

Up to 8 gpm

1 in (up to 1 ft)

1 1/4 in (up to 2 1/2 ft)

1 1/2 in (up to 6 ft)

1 3/4 in (up to 9 ft)

2 in (above 9 ft)

1 1/4 in (up to 1 ft)

1 1/2 in (up to 2 1/2 ft)

1 3/4 in (up to 3 1/2 ft)

2 in (up to 8 ft)

2 1/2 in (above 8 ft)

12 gpm

1 1/4 in (up to 1 1/2 ft)

1 1/2 in (up to 4 ft)

1 3/4 in (up to 6 ft)

2 in (up to 12 ft)

2 1/2 in (above 12 ft)

1 1/2 in (up to 1 1/2 ft)

1 3/4 in (up to 2 1/2 ft)

2 in (up to 5 ft)

2 1/2 in (up to 13 ft)

3 in (above 13 ft)

16 gpm

1 1/2 in (up to 3 ft)

1 3/4 in (up to 4 1/2 ft)

2 in (up to 9 ft)

2 1/2 in (above 9 ft)

1 1/2 in (up to 1 ft)

1 3/4 in (up to 2 ft)

2 in (up to 4 ft)

2 1/2 in (up to 10 ft)

3 in (above 10 ft)

21 gpm

1 1/2 in (up to 2 ft)

1 3/4 in (up to 3 1/2 ft)

2 in (up to 7 ft)

2 1/2 in (above 7 ft)

1 1/2 in (up to 1 ft)

1 3/4 in (up to 1 1/2 ft)

2 in (up to 3 ft)

2 1/2 in (up to 8 ft)

3 in (above 8 ft)

Table 4 — Cold climate

gpm during start up / warm up

Supply Line Size

AW 22

Supply Line Size

AW 32

Up to 8 gpm

1 in (up to 4 ft)

1 1/4 in (up to 8 ft)

1 1/2 in (above 8 ft)

1 in (up to 1 1/2 ft)

1 1/4 in (up to 4 ft)

1 1/2 in (up to 9 ft)

1 3/4 in (above 9 ft)

12 gpm

1 1/4 in (up to 5 ft)

1 1/2 in (up to 11 ft)

1 3/4 in (above 11 ft)

1 1/4 in (up to 2 1/2 ft)

1 1/2 in (up to 6 ft)

1 3/4 in (up to 9 ft)

2 in (above 9 ft)

16 gpm

1 1/2 in (up to 9 ft)

1 3/4 in (up to 13 ft)

2 in (above 13 ft)

1 1/2 in (up to 4 ft)

1 3/4 in (up to 7 ft)

2 in (up to 14 ft)

2 1/2 in (above 14 ft)

21 gpm

1 1/2 in (up to 7 ft)

1 3/4 in (up to 11 ft)

2 in (above 11 ft)

1 1/2 in (up to 2 1/2 ft)

1 3/4 in (up to 5 ft)

2 in (up to 11 ft)

2 1/2 in (above 11 ft)

Table 5 — Temperate climate

Pressure Line Size Return Line Size

3/4 in 1 in

Table 6 — Pressure and return line size

Pressure and Return Line Sizing

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

22

Hydraulic Driven Air Compressor Harness

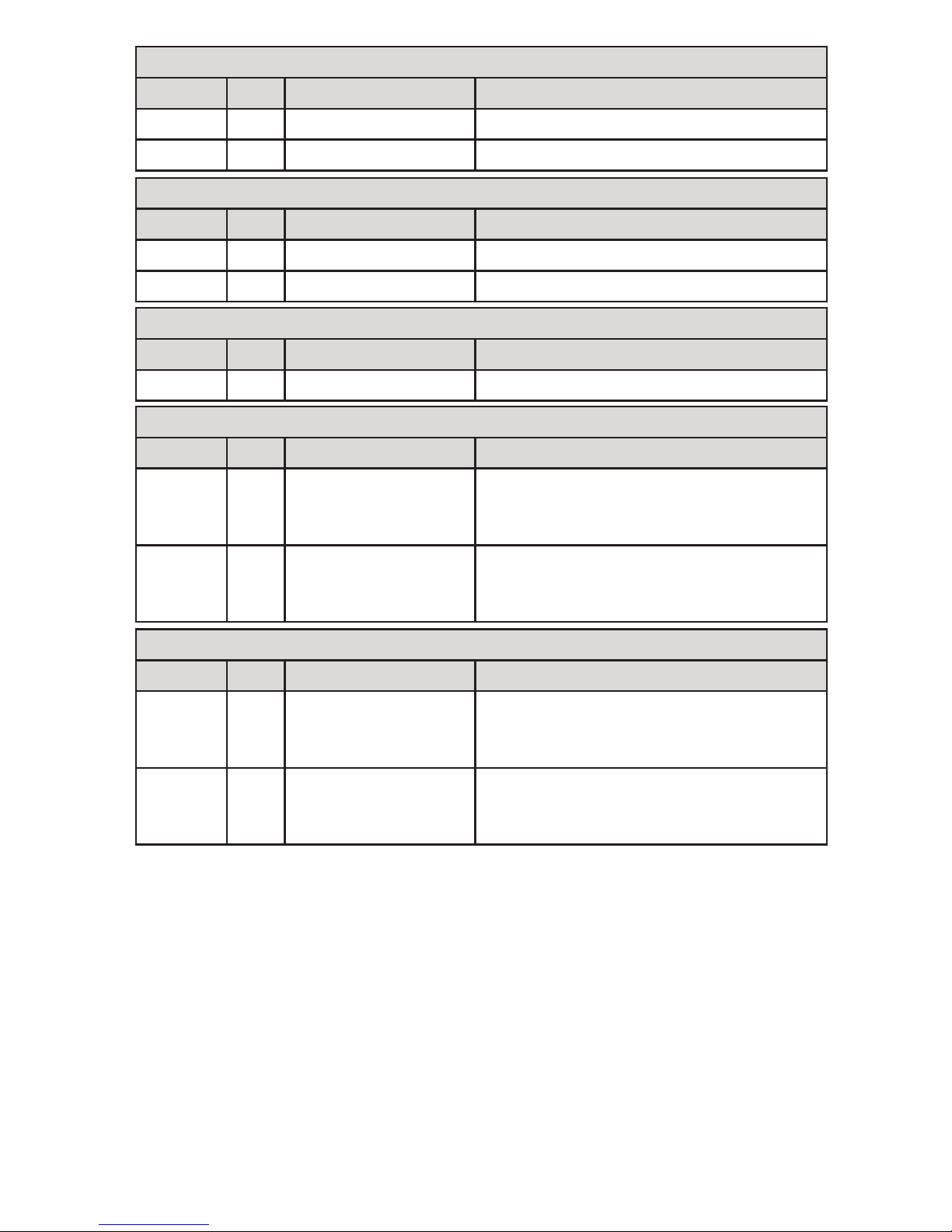

Reference

Installer Interface

Colour Pin Function Notes

Purple A High Idle Output

Ground switching signal, use to supply

ground to relay or equivalent

Green B System Ground 0 Ω

Red C System Power

+

12 V (H400003: +24 V)

Fan Motor

Colour Pin Function Notes

Red A Relay Switched +12 V+12 V (H400003: +24 V)

Green B System Ground 0 Ω

Fan Relay

Colour Pin Function Notes

Red 85 System Power

+

12 V

Orange 86 Switched Ground Switched

Red 87 Relay Switched +12 V (To fan motor) +12 V (H400003: +24 V)

Red 30 System Power

+

12 V (H400003: +24 V)

Display Box

Colour Pin Function Notes

Red A Display +12 V

+

12 V

Green B Display Ground 0 Ω

White C CAN Hi CAN bus signal

Black D CAN Low CAN bus signal

System Pressure Sensor

Colour Pin Function Notes

Red –

+

5 V

+

5 V

Green – Pressure Signal

+

0.5 V – +4.5 V, 0 – 150 psi (ratiometric)

Black – Ground 0 Ω

Air Solenoid

Colour Pin Function Notes

Red 1

+

12 V Supply

+

12 V

Black 2 Switched Ground Switched

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

23

Remote Switch Wire

Colour Pin Function Notes

Yellow – Remote Enable Wire Ground wire to run compressor

Hydraulic Solenoid

Colour Pin Function Notes

Red A Switched Ground Switched

Red B

+

12 V Supply

+

12 V

Heater Solenoid (Cold Climate Kit P/N: A800070)

Colour Pin Function Notes

Blue A Switched Ground Switched

Blue B

+

12 V Supply

+

12 V

Compressor Temperature Probe

Colour Pin Function Notes

White A

Thermistor Signal

Voltage

Varies with temperature - see

thermistor resistance tables for further

diagnosis.

White B

Thermistor Signal

Voltage

Varies with temperature - see

thermistor resistance tables for further

diagnosis.

Hydraulic Temperature Probe

Colour Pin Function Notes

White A

Thermistor Signal

Voltage

Varies with temperature - see

thermistor resistance tables for further

diagnosis.

White B

Thermistor Signal

Voltage

Varies with temperature - see

thermistor resistance tables for further

diagnosis.

Table 7 — Harness reference chart

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

24

Electrical Requirements (12 V dc Systems)

VMAC’s Hydraulic Driven Air Compressor systems require steady a 20 A at 12 V dc

(nominal) to operate. A 30 A fuse or circuit breaker is recommended.

To ensure an uninterrupted supply of power, the ground wire should be routed

either to the negative terminal of the battery or to a substantial, fully grounded

point on the vehicle chassis. Confirm the selected ground is good by using an

ohm meter to measure the resistance between the ground point and the negative

battery terminal. Resistance should be less than 1 Ω.

The power supplied to the unit should be ignition switched through a relay to

reduce the risk of battery drain when the engine is off. The main power should be

supplied directly from the positive terminal of the battery via a relay. Using a relay

allows the heavy gauge power wire to be routed directly and permits the use of a

light gauge wire (e.g. 18 AWG) between the relay and the control switch.

The information in this section is critical to ensure proper operation

of the system. Read these requirements prior to beginning the

installation.

Failure to adhere to these recommendations will cause the

Hydraulic Driven Air Compressor system to operate erratically.

Wire Sizing Guide 12 V Systems

Combined length of power and ground wires Recommended wire gauge

Less than 10 ft (3 m) 12 AWG

Between 10 ft (3 m) and 18 ft (5.5 m) 10 AWG

18 ft (5.5 m) to a maximum of 35 ft (10.5 m) 8 AWG

Table 8 — Wire size table

VMAC does not recommend installing the system in a location that

would require a combined wire length greater than 35 ft (10.5 m).

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

25

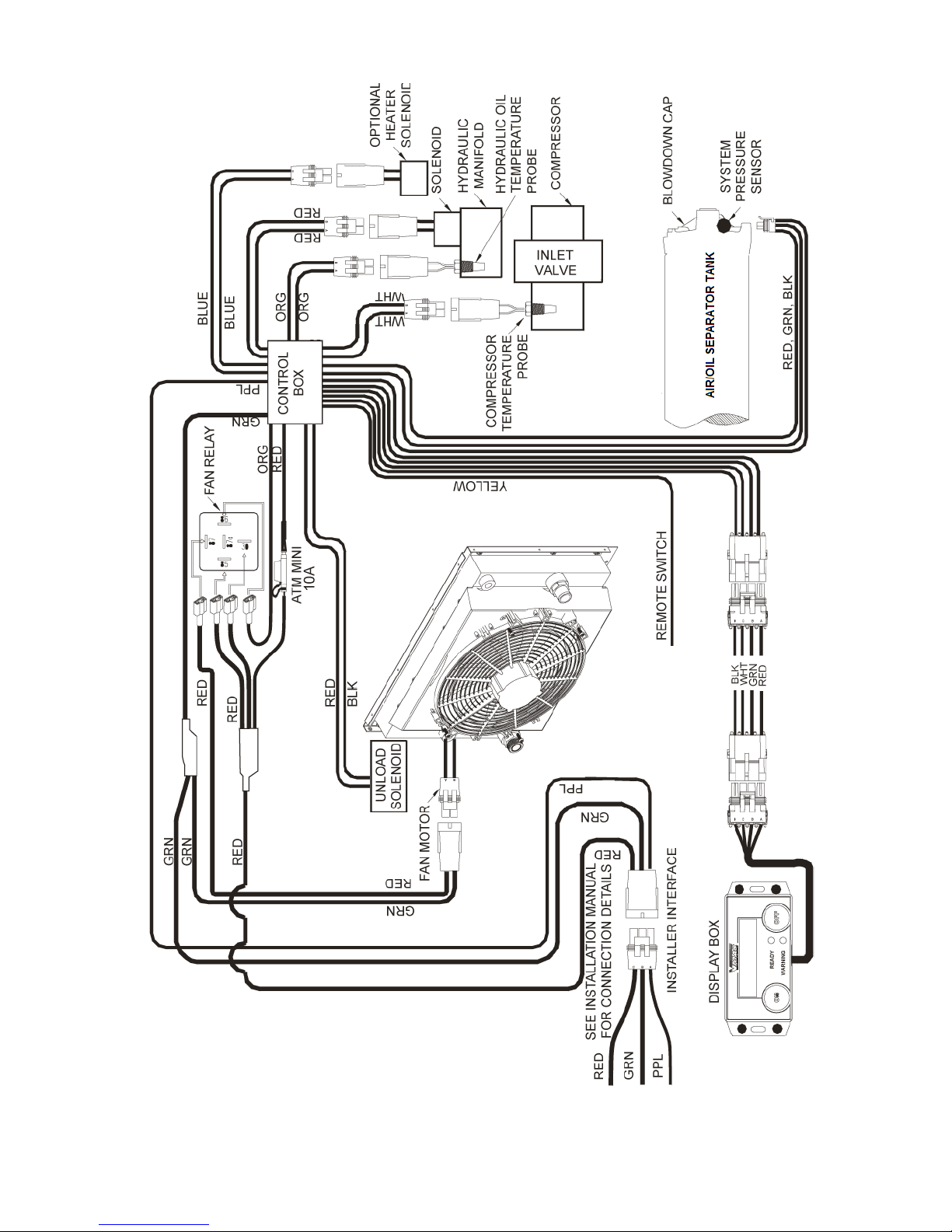

Electrical Schematic 12 V dc

Figure 4 — Electrical schematic 12 V dc

VMAC - Vehicle Mounted Air Compressors

VMAC Technical Support: 888-241-2289

VMAC Knowledge Base: www.kb.vmacair.com

26

Electrical Requirements (24 V dc Systems)

The information in this section is critical to ensure proper operation

of the system. Read these requirements prior to beginning the

installation.

Failure to adhere to these recommendations will cause the

Hydraulic Driven Air Compressor system to operate erratically.

Wire Sizing Guide 24 V Systems

Combined length of power and ground wires Recommended wire gauge

Less than 10 ft (3 m) 14 AWG

Between 10 ft (3 m) and 18 ft (5.5 m) 12 AWG

18 ft (5.5 m) to a maximum of 35 ft (10.5 m) 10 AWG

Table 9 — Wire size table

VMAC’s Hydraulic Driven Air Compressor systems require steady a 15 A at 24 V dc

(nominal) to operate. A 25 A fuse or circuit breaker is recommended.

To ensure an uninterrupted supply of power, the ground wire should be routed

either to the negative terminal of the battery or to a substantial, fully grounded

point on the vehicle chassis. Confirm the selected ground is good by using an

ohm meter to measure the resistance between the ground point and the negative

battery terminal. Resistance should be less than 1 Ω.

The power supplied to the unit should be ignition switched through a relay to

reduce the risk of battery drain when the engine is off. The main power should be

supplied directly from the positive terminal of the battery via a relay. Using a relay

allows the heavy gauge power wire to be routed directly and permits the use of a

light gauge wire (e.g. 18 AWG) between the relay and the control switch.

VMAC does not recommend installing the system in a location that

would require a combined wire length greater than 35 ft (10.5 m).

Loading...

Loading...