Page 1

Page 2

VIVID AUDIO

USER GUIDE

This manual applies to the following models:

K1, B1, C1, V1.5, and the V series.

TABLE OF CONTENTS

Page number

1 2 4 5 7 8 9

10

15

16

23

Content

Important information on unpacking and use

Introduction and positioning

Multi channel use

V1w wall mount

Connecting up

Spikes

Disclaimer

Specifications

Installation notes

Early loudspeaker history.

Contacting Vivid Audio

Page 3

Important Notes

The silver aluminium domed/coned drive units

are extremely sensitive. They must never be

subjected to probing fingers or other sharp

objects! If so, certain damage will result and a

replacement driver will have to be fitted.

This replacement will not be performed under

guarantee conditions.

Unpacking Instructions

Read these instructions that contain important

information about the safe use, installation and

maintenance of this loudspeaker.

• Unpack the loudspeaker following the instruction

sheet attached to the shipping crate. The method is also

described below. Check for damage. Keep potentially

hazardous packaging (plastic bags, polystyrene etc.) out

of reach of children.

• Dispose of packaging in compliance with current waste

disposal requirements.

1

Page 4

Introduction

We’re obviously very happy that you chose Vivid Audio Loudspeakers so please

spend a little time reading this manual to help ensure that you are equally happy

with your purchase.

These loudspeakers are the culmination of many years of research by our design

engineer Laurence Dickie and the R&D team in Durban. They feature a range of

unique drive units and enclosures which deliver an unprecedented purity of reproduced

sound. All our drivers include novel features, many of which have been patented.

A fundamental design philosophy has always been to keep resonances and the effects

of reflection well out of band and this applies just as much to our mid-range units

as to our tweeters so we don’t take a basically floppy cone and treat it until the

resonances are acceptable, we make jolly sure they are not there in the first place.

Similarly you may have noticed that the enclosures used in all Vivid Audio products

share a very rounded form. This not done for pure aesthetics but is there to completely

remove the effects of reflection from the edge of the cabinet.

Having perfected a driver and enclosure combination that deliver totally smooth

responses, the crossover designs are quite straightforward with no extra elements

required to make up for the deficiencies of the basic acoustic designs.

We follow the conventional rules for system design quite closely and find there is

no need to deviate from the path because we do not have to compensate for

driver idiosyncrasies.

So having taken all this trouble to develop the loudspeakers we feel it would be only

fair that you take the time to read these notes to help squeeze out as much of that

performance as possible into your listening space.

Positioning

Vivid Audio loudspeakers are designed with both home theatre and two channel

stereo application in mind and, because of the intrinsically shielded magnet structure,

all our products can be placed near to conventional tube televisions or computer

monitors if necessary.

For two-channel installations we recommend as a starting point that you position

the loudspeakers at least 0.5m from the rear wall and, if anything, a little further

from the side walls if possible. Hving two different distances here will help to smooth

out the effects of the boundaries on the low frequencies and improve the sense of

space and scale of the performance.

As a general rule, the closer the speakers are to a wall the more the upper bass will

be accentuated. Conversely, if you move them away from the walls only the lower

bass will be reinforced. If the walls are of a light construction these reinforcement

effects will be reduced accordingly.

Furthermore, all rooms have resonances at a number of single frequencies that will

tend to be emphasised when the speakers are placed nearer the corners which can

cause ‘boominess’. So again, if these are problematic, try moving the speakers away

from the corners.

2

Page 5

Remember that all the rules which apply to the loudspeaker position also apply to

the listening position so if you find that the low frequencies are a little light because

you have placed your sofa in the middle of the room to be equidistant from the

surround speakers then you may recover some of this low end by moving the speakers

back towards the walls. Similarly, if you are in two channel mode with the listening

position close to the back wall and you have excessive bass, try moving away from

the wall.

One technique for finding the best speaker position which exploits this reciprocity

is to place a speaker at the listening position and to move around the room to find

places with an even bottom end. Then you can swap the speaker and listener and

find the same result. This only works for one speaker at a time and the results with

both speakers in position may not be quite as you expect so be prepared to try again.

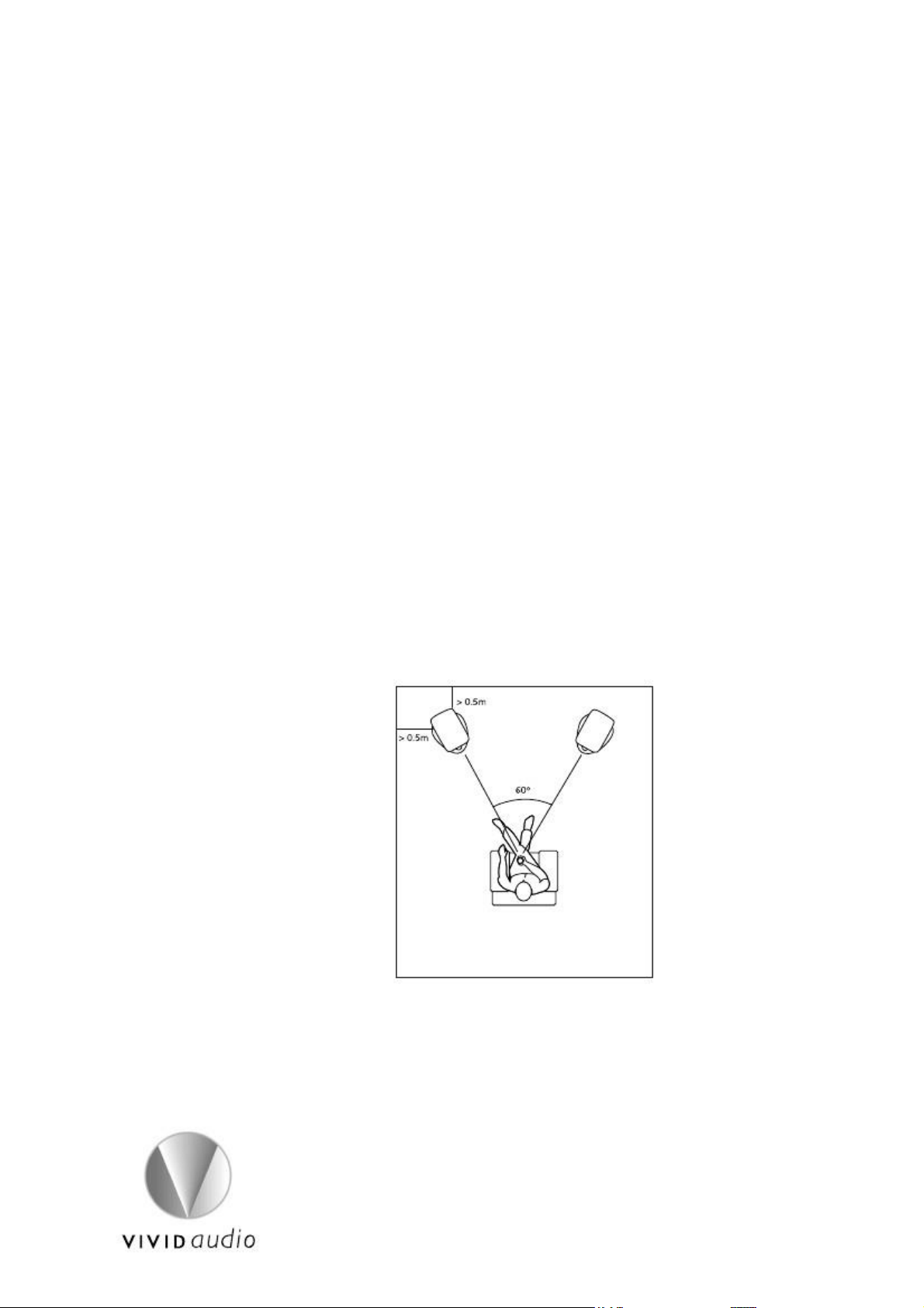

A good listening position will often be found at the point where the loudspeakers

are about 60˚ apart, fig.1. Much closer together than this and the apparent image

width will suffer, much wider and you may find a ‘hole’ in the centre of the image,

particularly when seated off to one side.

There is no appreciable beam from any of the Vivid Audio loudspeaker drivers, that

is to say; the tonal balance is consistent across a wide angle as opposed to some

designs where the high frequencies in particular quickly fall in level as you move

away from a point directly in front of the speaker as if they were shining out from

a flashlight. It is our experience that, because of the very smooth wide sound field

produced by our designs, angling the loudspeakers so that they both face a position

just ahead of the listeners can help to widen the useful area where stereo sound may

be enjoyed.

Fig.1

An absence of beaming is also a feature in the vertical plane, so being absolutely at

the same level as the loudspeakers is not important. In fact a perfectly enjoyable

sound balance may be found when lying on the floor more or less anywhere between

the loudspeakers!

Because of the infinite number of combinations of wall materials dimensions and

furnishings in the room it is impossible to give more precise positioning advice than

that above. In the end we strongly recommend that you experiment, so if you are

going to fit the spikes to the bases then we suggest that you leave this until the

positions have been determined.

3

Page 6

Small Studio Monitoring

All Vivid Audio speakers make excellent small-scale studio monitors giving pin-point

imaging and incredible detail which are both indispensable qualities in such an

applications. B1 and K1 are balanced for flat response in a free field acoustic and

are thus best suited to very dry acoustics such as heavily damped studios or where

the desk and monitors are fairly well removed from the walls. In smaller rooms where

the desk is close to the walls, the V1 range or C1 may give a more natural balance.

In either case, you should really measure the response of the system at the listening

position and EQ accordingly.

Centre Speaker

With the introduction of a third, central channel, the sound stage tends to fill out

in the middle and the two main speakers may be positioned a little further apart,

or the listener a little closer, without suffering from holes in the image. If you are

positioning the speakers around a TV or monitor, it’s worth bearing in mind that the

sound stage is best kept in proportion to the size of the picture, so if you have a

35cm screen it might seem a bit disconcerting if the sound stage is as big as a house.

The C1 centre channel model is tonally balanced in such a way that it can be

positioned closer to the walls than either B1 or K1. Because of the broad vertical

dispersion, even through crossover, it is not too important whether the loudspeaker

is sited above or below the screen. If you are using an acoustically transparent screen

you can arrange for the tweeter to be at the same height as that of the main speakers.

Surround Speakers

Cinema sound tracks are provided with not just the front three channels but also a

variable number of side and rear channels. As these tracks are not really intended

to give precise imaging but a more general ambience, it is not so critical that they

be accurately positioned.

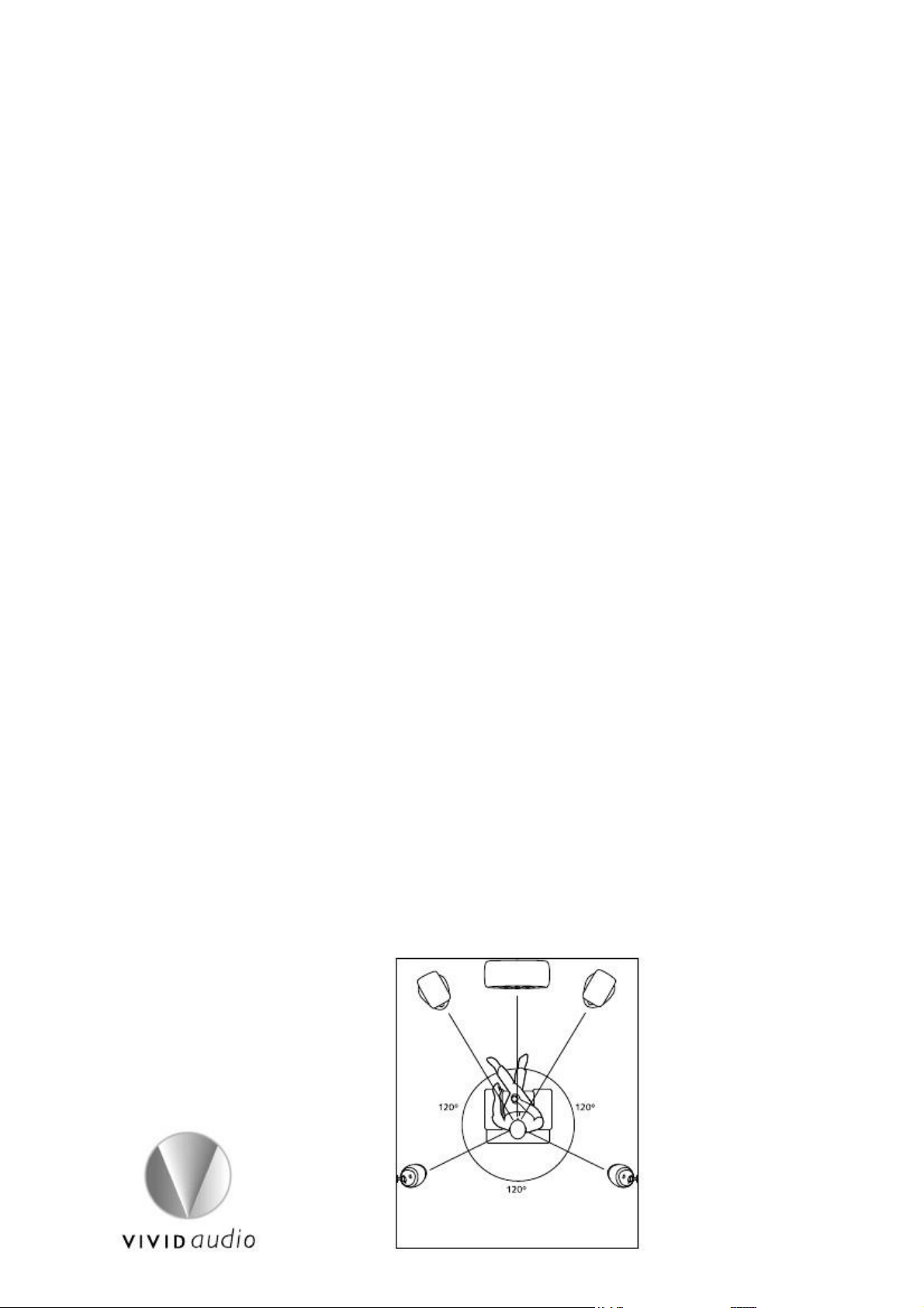

When using two surround speakers for the 5.1 rear position them at around 60˚

either side of a point directly to the rear of the listening position, fig.2. With uneven

rooms such as L-shapes, aim to have a general symmetry to their locations so the

angle of the speakers, as seen from the main listening position, is similar on both left

and right. Level differences due to the differing distances can be compensated for

during the set-up of the decoder.

Fig.2

4

Page 7

If the speakers are the wall mounted V1w, they should be mounted a good 50cm

above ear height, fig. 3, and, while mounting in the very corners of the room is not

to be recommended, try to get them as far away as reasonable. Again experiment

with the relative position of the seating, the screen and the speakers. You could

mount speakers on the back wall facing outward so the main sound is bounced off

the side walls to give a greater feeling of space.

Fig.3

With 6.1 and 7.1 installations, the side channels should be further forward, on a line

just behind the seating or around 80˚ either side of a point directly to the rear of the

listening position. A 6.1 system has a single rear speaker which should be directly

behind the listeners while a 7.1 system uses two rear speakers which should be placed

around 25˚ either side of the rear centre point, fig.4..

Fig.4

Installing V1 wall mount

V1w is designed for wall mounting through the use of a de-mountable ball and

socket arrangement. A hemispherical cage with cruciform cut-out is fitted to the

enclosure while the corresponding skeletal ball is fitted to a stem which can be

threaded directly onto an M8 wall anchor into a masonry wall, or bolted to a wall

plate which should be screwed to stud or timber walls using appropriate fixings.

5

Page 8

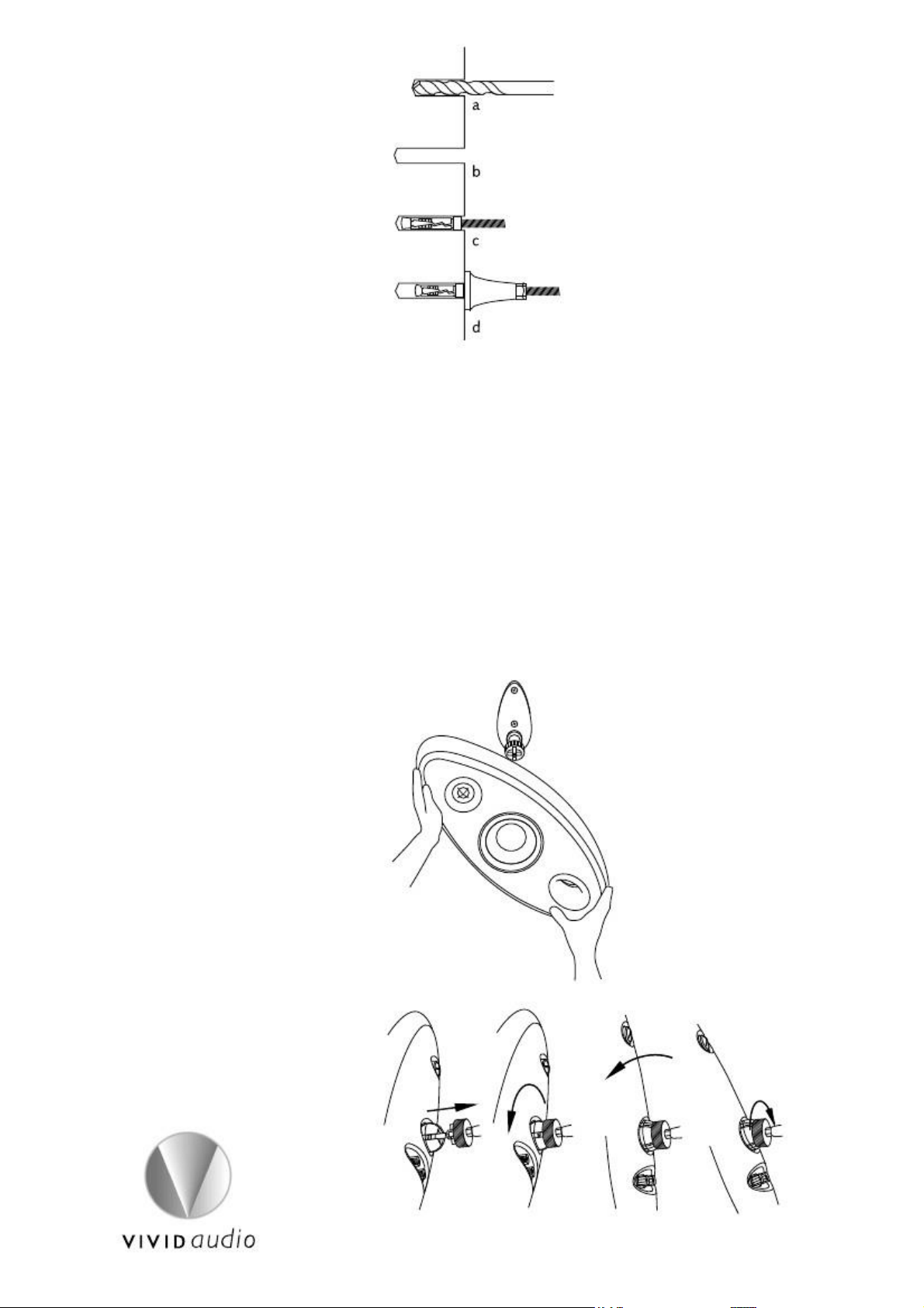

Fig.5

In the case of a masonry wall (fig. 5), first drill a 13mm hole to the depth of 60mm

using a suitable carbide tipped drill bit. Insert the wall anchor to the full depth and

hand wind the bracket stem onto the projecting M8 thread. Using a 13mm spanner,

tighten the stem until secure. Release the M8 Nylock nut on the end of the stem to

free the cross shaped ball and adjust its position a few degrees to the right or left

until the cross is square to the vertical. Tighten the lock nut.

With hollow walls you will need to use the wall plate. First mark the wall using the

plate as a guide and drill the appropriate holes. Then bolt the stem to the plate using

the M8 countersunk bolt. The assembly can then be fixed to the wall with a pair of

expanding or toggle bolts or, if fixing into the wooden studs, a pair of 5mm

countersunk woodscrews. Then align the cross–shaped ball to the vertical as before.

Now you can attach the loudspeaker.

Fig.6 a b c d

Fig.7 6 Facing the wall, turn the large knurled nut clockwise until it is right the way back

Page 9

against the end of the stem. Hold the loudspeaker at 45 degrees to the vertical (fig.6)

and offer up the cruciform hole in the socket to the corresponding cross on the end

of the stem and slide into place (fig.7a). Rotate the speaker until it is vertical (fig.7b)

then adjust the overall position to suit, fig.7c. The knurled nut should then be

tightened to lock the speaker into position, fig.7d.

Cabling and connections

We recommend that you make and secure all connections before turning on any

power to avoid short-circuiting the amplifiers.

In order to discourage folks from trying to stick speaker wires into mains outlets the

use of 4mm plugs is not encouraged which is a shame really because they tend to

be the most convenient. To this end the holes in the WBT connectors have small

rubber bungs fitted to make their use awkward but these can be removed.

To the sides of the WBT terminals are rectangular apertures into which you may

insert spade connectors. Vivid Audio speakers are supplied with these angled to the

opposite sides in the left and right speakers. This is just to help get the wires pointing

in the right direction but just use whichever suits your installation.

We don’t try to recommend any particular cable because it is an ever-changing field

but we would advise that you get something reasonably thick, say 2.5 mm2 for less

than 10m lengths and 4 mm for up to 20m.

K1, B1, C1 and V1.5 are provided with four terminals to permit the use of bi-wiring

or bi-amping shown in fig.8. The mid and high frequency crossover is connected

to the right hand pair of terminals (as view from the back) and the low frequency

to the other allowing the user to have separate wires feeding each section connected

to a single amplifier output, in the case of bi-wiring, or two independent amplifiers

in the case of bi-amping. This latter case even gives rise to the possibility of mixing

different types of amplifier for the two ranges but be careful to match the gain

and polarity of the two if you are to avoid messing up the basic frequency response

of the loudspeaker. If you are in any doubt about this you really should talk to

your dealer.

2

L.F.

Mid & H.F.

Fig.8

For many folks the use of extra wires will seem quite pointless in which case a single

pair of good quality conductors will be all you require and the two pairs of terminals

must be linked at the speaker using the links provided. In the accessories pack you

will find two 10cm lengths each of red and black wire each terminated with a 4mm

plug and spade. Link the hi-mid section to the low section as shown in Fig.10.

7

Page 10

Supplied non bi-wired links. Fig 9.

This arrangement will allow you to use amplifier leads terminated with either spade

connectors (as shown) or 4mm plugs.

L.F.

Mid & H.F.

Fig.10

Spikes

One of the innovative design features of certain Vivid Audio designs is the use of

reaction cancelling drivers and ports, the purpose of which is to cancel out any

reaction forces on the enclosure and hence the dependency of the overall acoustic

delivery on the way in which the loudspeaker is supported on the ground.

Nevertheless we do provide five M8 threaded holes in the bottom surface of the

base and five corresponding spikes to fit into these points if required for stability on

soft carpets. Some have also reported sonic benefits as a result.

We recommend that you have two fairly strong people available for this operation

particularly for our larger models. First lie the cabinet down on its side on a soft towel

and screw the five spikes all the way into their holes. Next, unscrew the two rear and

single front spike by two or thee turns and stand the speaker up. Ensure that the

speaker is vertical as seen from the front. Adjust the two rear spikes accordingly if

not. From the side you will have to verify that the base is horizontal since some of

the models have a slightly angled baffle. Don’t worry too much about this since it

is purely a visual issue so if it looks OK leave it there. If it needs a tweak then use the

front spike to make that adjustment. Once aligned tighten the lock nuts on these

three spikes. Then unscrew the two side spikes by hand until they touch the ground,

at which point it will become difficult to turn them further. Tighten the two

corresponding lock nuts and the operation is complete. Only hand tighten these

spikes - DO NOT USE A WRENCH.

Running in

8

Page 11

It is now fairly well accepted that, despite the protestations of the engineering teams

who design loudspeakers and who have difficulty accounting for it, there is a definite

period of time during which the sound of the equipment improves subtly. There are

definite and measurable changes which occur, particularly for the compliant

suspensions, as the various materials used soften up and gradually approach their

design values but it really does seem that some other improvements occur.

Some well respected authorities have even referred to it as a ‘learning’ phase.

There is also the far more earthly explanation that what is happening is that our

brain/ear combination is becoming accustomed to the new sound balance from the

loudspeakers. Certainly, the great clarity delivered by the Vivid Audio approach can

be a little disconcerting at first if you have been used to the sound of mid-range

cone break-up and the first reaction is that something is missing. Bit by bit you realise

that something is missing and you are really hearing through to the original recording

in a way that you never experienced before. This can in itself be rather revealing of

poorly edited work but then the original recording engineers may not have had the

benefit of monitoring on Vivid Audio loudspeakers so give them a break!

It is not really for us to get involved here with the philosophy or metaphysics of what

might be happening but suffice to say that you shouldn’t be too surprised if, after

owning you speakers for a few weeks, you really get very excited about what you’re

hearing.

Important

• The manufacturer warrants that these loudspeakers supplied will at the time

of delivery correspond to the description given by the manufacturer.

• The manufacturer declines all responsibility for damage resulting from improper,

incorrect or negligent use.

• Repairs must only be carried out by a service centre authorised by the manufacturer.

• All other warranties, conditions or terms relating to fitness for purpose, quality

or condition of the Goods, whether express or implied by statute or common law

or otherwise are excluded to the fullest extent.

9

Page 12

K1

K1 SPECIFICATION

Configuration :

3 & 1⁄2 way vented cabinet

Cabinet material :

Complex loaded carbon fibre filled polymer

Finish :

High gloss automotive

Drive units :

26mm metal dome hf unit

50mm metal dome mf unit

158mm metal coned lf unit (two pairs coupled)

Sensitivity :

89dB/1w @1m

Nominal Impedance (

6

):

Frequency range (hz) :

- 6dB points 35 – 44,000

Frequency response (hz) :

39 – 41,000 +/- 2dB on reference axis

Harmonic distortion (2nd and 3rd harmonics) :

< .0.5% over frequency range

Cross over frequencies (hz) :

100, 900, 4000

Power handling (music program) watts rms :

600

Loudspeaker dimensions (H, W, D cabinet, D base) mm :

1300, 280, 450, 488

Net mass (kg) :

56

Shipping dimensions (H, W, D) mm :

1420, 450, 560

Shipping mass (kg) :

70

10

Page 13

B1

B1 SPECIFICATION

Configuration :

3 & 1⁄2 way vented cabinet

Cabinet material :

Complex loaded carbon fibre filled polymer

Finish :

High gloss automotive

Drive units :

26mm metal dome hf unit

50mm metal dome mf unit

158mm metal coned lf unit (two of coupled)

Sensitivity :

89dB/1w @1m

Nominal Impedance (

4

):

Frequency range (hz) :

- 6dB points 35 – 44,000

Frequency response (hz) :

39 – 41,000 +/- 2dB on reference axis

Harmonic distortion (2nd and 3rd harmonics) :

< .0.5% over frequency range

Cross over frequencies (hz) :

100, 900, 4000

Power handling (music program) watts rms :

300

Loudspeaker dimensions (H, W, D cabinet, D base) mm :

1095, 265, 375, 420

Net mass (kg) :

38

Shipping dimensions (H, W, D) mm :

1220, 410, 510

Shipping mass (kg) :

50

11

Page 14

C1

C1 SPECIFICATION

Configuration :

3 way vented cabinet

Cabinet material :

Complex loaded carbon fibre filled polymer

Finish :

High gloss automotive

Drive units :

26mm metal dome hf unit

50mm metal dome mf unit

158mm metal coned lf unit (two of)

Sensitivity :

90dB/1w @1m

Nominal Impedance ( ) :

8

Frequency range (hz) :

- 6dB points 35 – 44,000

Frequency response (hz) :

39 – 41,000 +/- 2dB on reference axis

Harmonic distortion (2nd and 3rd harmonics) :

< .0.5% over frequency range

Cross over frequencies (hz) :

100, 900, 4000

Power handling (music program) watts rms :

300

Loudspeaker dimensions (H, W, D cabinet, D base) mm :

268, 755, 330

Net mass (kg) :

23

Shipping dimensions (H, W, D) mm :

370, 945, 450

Shipping mass (kg) :

35

C1 STAND

Material :

Complex loaded carbon fibre filled polymer

Finish :

High gloss automotive

Dimensions (H, W, D) :

440, 535, 380

Net mass (kg) :

13

Shipping dimensions (H, W, D) mm :

350, 448, 292

Shipping mass (kg) :

20

12

Page 15

V1.5

V1.5 SPECIFICATION

Configuration :

2 way vented cabinet

Cabinet material :

Complex loaded carbon fibre filled polymer

Finish :

High gloss automotive

Drive units :

26mm metal dome hf unit

158mm metal coned lf unit

Sensitivity :

89dB/1w @1m

Nominal Impedance (

8

Frequency range (hz) :

- 6dB points 40 - 28,000

Frequency response (hz) :

42 - 24,000 +/- 2dB on reference axis

Harmonic distortion (2nd and 3rd harmonics) :

< .0.5% over frequency range

Cross over frequency (hz) :

3000

Power handling (music program) watts rms :

150

Loudspeaker dimensions (H, W, D) mm :

1130, 255, 240

Net mass (kg) :

23

Shipping dimensions (H, W, D) mm :

1300, 430, 460

Shipping mass (kg) :

37 (unit)

):

13

Page 16

V1

V1s

V1 s,w & h SPECIFICATION

V1h

Configuration :

2 way vented cabinet

Cabinet material :

Complex loaded carbon fibre filled polymer

Finish :

High gloss automotive

Drive units :

26mm metal dome hf unit

158mm metal coned lf unit

Sensitivity :

89dB/1w @1m

Nominal Impedance (

8

Frequency range (hz) :

- 6dB points 42 - 28,000

Frequency response (hz) :

45 - 24,000 +/- 2dB on reference axis

Harmonic distortion (2nd and 3rd harmonics) :

< .0.5% over frequency range

Cross over frequency (hz) :

3000

Power handling (music program) watts rms :

150

Loudspeaker dimensions (H, W, D) mm :

635, 255, 195

Net mass (kg) :

V1s = 17 V1w = 13, V1h = 15

Shipping dimensions per pair (H, W, D) mm :

1420, 450, 560

Shipping mass (kg) :

V1s = 47 (pair), V1w = 39 (pair), V1h = 22 (unit)

):

The V1w suitable for both dry and masonry type

walling. As above without the moulded foot.

14

Page 17

Installation Notes:

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________

15

Page 18

Some loudspeaker history

1874 - Ernst W. Siemens was the first to describe the "dynamic" or moving-coil

transducer, with a circular coil of wire in a magnetic field and supported so that it

could move axially. He filed his U. S. patent application for a "magneto-electric

apparatus" for "obtaining the mechanical movement of an electrical coil from electrical

currents transmitted through it" on Jan. 20, 1874, and was granted patent No.

149,797 Apr. 14, 1874. However, he did not use his device for audible transmission,

as did Alexander G. Bell who patented the telephone in 1876. After Bell's patent was

granted, Siemens applied for German patent No. 2355, filed Dec. 14, 1877, for a

nonmagnetic parchment diaphragm as the sound radiator of a moving-coil transducer.

The diaphragm could take the form of a cone, with an exponentially flaring "morning

glory" trumpet form. This is the first patent for the loudspeaker horn that would be

used on most phonographs players in the acoustic era. His German patent was

granted July 30, 1878 and his British patent No. 4685 was granted Feb. 1, 1878.

Oliver Lodge

from Das Fotoarchiv

1898 - Oliver Lodge filed for British patent No. 9712 on Apr. 27, 1898, for an

improved loudspeaker with nonmagnetic spacers to keep the air gap between the

inner and outer poles of a moving coil transducer. This was the same year he applied

for a patent on his famous radio tuner. A model of his loudspeaker is in the British

Science Museum in South Kensington, and a photo was published in Wireless World

Dec. 21, 1927. This improvement was later claimed by Pridham and Jensen in the

Magnavox application for patent No. 1,448,279 filed Apr. 28, 1920, and granted

Mar. 13, 1923.

1901 - John Stroh first described the conical paper diaphragm that terminated at

the rim of the speaker in a section that was flat except for corrugations, filed for the

British patent No. 3393 on Feb. 16, 1901, granted Dec. 14, 1901.

1908 - Anton Pollak improved the moving-coil loudspeaker with a voice-coil centering

spider, filed for U.S. patent No. 939,625 on Aug. 7, 1908, granted Nov. 9, 1909.

1911 - Edwin S. Pridham and Peter L. Jensen in Napa, California, invented a moving-

coil loudspeaker they called the "Magnavox" that was used by Woodrow Wilson in

San Diego in 1919.

16

Page 19

Early Bell loudspeakers

1915 - Harold Arnold began program at Bell Labs to improve phonographic sound

recording. The first priority was the electronic amplifier using the new vacuum tube,

second was the microphone, and third was the loudspeaker that would improve the

"balanced armature" units developed for public address. After WWI, J. P. Maxfield

led this project that produced E. C. Wente's moving coil speaker by 1925, the

Orthophonic phonographic player by 1925, and Vitaphone talking motion pictures

by 1926.

1918 - Henry Egerton on 1918/01/08 filed patent for balanced-armature loudspeaker,

used in the Bell Labs No. 540AW speakers developed by N. H. Ricker Oct. 6, 1922,

that became the 540 commercial speaker by 1924; was based on the balanced

armature telephone patent of Thomas Watson granted Oct. 24, 1882, similar to

devices also developed by Siemens and Frank Capps.

1925 Grebe radio receiver and 1924 Western Electric 540 speaker (NMAH)

1921 - The Phonetron based on patent No. 1,847,935 filed Apr. 23, 1921, by C. L.

Farrand, was the first coil-driven direct-radiator loudspeaker to be sold in the U.S.

and was well-received, competing with the horns used by table radios

1923 - The Thorophone was a gooseneck loudspeaker with a voice-coil driver

1925 - The research paper of Chester W. Rice and Edward W. Kellogg at General

Electric was important in establishing the basic principle of the direct-radiator

loudspeaker with a small coil-driven mass-controlled diaphragm in a baffle with a

broad midfrequency range of uniform response. Edward Wente at Bell Labs had

independently discovered this same principle, filed patent No. 1,812,389 Apr. 1,

1925, granted June 30, 1931. The Rice-Kellogg paper also published an amplifier

design that was important in boosting the power transmitted to loudspeakers. In

1926, RCA used this design in the Radiola line of a.c. powered radios.

1925 - Victor Orthophonic acoustic phonograph player had a folded exponential

horn that was later used as model for the Klipsch speaker of the hi-fi era. Within a

year, the Orthophonic faced competition from all-electric phonographs with an

electromechanical pickup, vacuum-tube amplifier, and moving-coil loudspeaker, such

as the Brunswick Panatrope sold by the Brunswick-Balke-Collender Company.

17

Page 20

Vitaphone 555-W, from AT&T Archives

1926 - Vitaphone sound system for motion pictures used a new speaker developed

at Bell Labs. Wente and Thuras designed the Western Electric 555-W speaker driver

that was coupled with a horn having a 1-in. throat and a 40-sq. ft. mouth; it was

capable of 100-5000 hz freq. range with an efficiency of 25% (compared to 1%

today) needed due to low amp power of 10 watts. The power amps were 205-D.

Older loudspeakers were balanced armature type, but the newer 555-W speakers of

the Vitaphone were moving coil type.

1928 - Herman J. Fanger filed patent No. 1,895,071 on Sep. 25, 1928, granted Jan.

24, 1933, that described what came to be known as the coaxial speaker, composed

of a small high frequency horn with its own diaphragm nested inside or in front of

a large cone loudspeaker, based on the variable-area principle that made the center

cone light and stiff for high frequencies and the outer cone flexible and highly

damped for lower frequencies.

1929 - E. W. Kellogg filed patent No. 1,983,377 on September 17, 1929, granted

December 4, 1934, that described an electrostatic speaker composed of many small

sections able to radiate sound with out magnets or cones or baffles. This patent, as

well as the 1932 British patents of Hans Vogt, influenced Peter Walker to build the

Quad ESL flat panel speaker in 1957.

1929 - J. D. Seabert of Westinghouse developed a horn-type loudspeaker that directed

the sounds of human speech toward the audience better than cone speakers that

were intended for the over-all sound including music to fill the entire . These

"directional baffle" horns had an opening 3 ft. by 4 ft. and were different from small-

throat horns.

18

Page 21

Thuras bass-reflex patent

1930 - Albert L. Thuras filed patent No. 1,869,178 on Aug. 15, 1930, granted July

26, 1932, for the bass-reflex principle while working at Bell Labs. Early cabinets used

a passive baffle to direct sound to the front, allowing the back of the cabinet to be

open for the low sounds. The bass-reflex enclosure kept the low-frequency sounds

from being lost from the rear of the diaphragm.

1931 - Bell Labs developed the two-way loudspeaker, called "divided range" for the

demonstration by H. A. Frederick in December of vertically cut records. The high

frequencies were reproduced by a small horn with a frequency response of 3000-

13,000 hz, and the low frequencies by a 12-inch dynamic cone direct-radiator unit

with a frequency response within 5db from 50-10,000 hz. By 1933, a triple-range

speaker had been developed for the Constitution Hall demo in April, adding Western

Electric No. 555 driver units as the mid-range speaker. For the low frequency range

40-300 hz, a large moving coil-driven cone diaphragm in a large baffle expanding

from a 12-in throat to a 60-inch mouth over a total length of 10 ft. This 3-way system

was introduced in motion picture s as "Wide Range" reproduction.

1932 - RCA demonstrated a dual-range speaker of its own design for s, using three

6-inch cone diaphragms with aluminium voice coils in divergent directions, with a

response of 125-8000 hz, and 10-ft. horns 40-125 hz.

1933 - "Progress was such that a demonstration of the new system - called

"stereophonic" because of its ability to give a spatial sense corresponding to stereoscopic

vision - was given before the National Academy of Sciences and many invited guests

at Constitution Hall, Washington in the spring of 1933. Transmission was

Thuras theatre speaker 1933, from AT&T Archives

over wire lines from the Academy of Music in Philadelphia and three channels were

used with microphones respectively at left, centre and right of the orchestra stage

and loud speakers in similar positions in Constitution Hall." This transmission of music

"was carried out with special loud speakers developed for the purpose by Dr. Wente

and the late A. L. Thuras. The objectives in the design of these loudspeakers were

uniform response over the whole tonal range of the orchestra, an enhanced sound

power output capacity without noticeable non-linear distortion and uniform distribution

of the emitted sound at all frequencies throughout a wide solid angle.

19

Page 22

For the receiving unit and the multicellular horn which were developed for this

demonstration, Dr. Wente, jointly with the Bell Telephone Laboratories, was awarded

a gold plaque by the Academy of Motion Picture Arts and Sciences in 1936." (Bell

Labs, 1953)

1935 - Douglas Shearer and John Hilliard at MGM developed a standard speaker

system, starting with the Loews 5000-seat Capitol on Broadway. James Lansing and

Dr. John F. Blackburn of Cal Tech designed a 2-way speaker system; the high frequency

driver had a 3-inch aluminium diaphragm and throat size of 1.4 inches; the low

frequency baffled cone unit was 15 inches. ERPI provided speakers from Fletcher's

hi-fi experimental equipment to help design the speakers. The low frequency horn

used four 15-in. Lansing cone drivers and Lansing 284 drivers for multicell horns of

different sizes. The system was installed in 12 s for the opening of "Romeo and Juliet"

with Norma Shearer, sister of Douglas,

Aztec A-7 Voice of the , from Audio, Dec. 1961

then installed in all Loews s, then became the standard established by the Academy.

1940 - Paul W. Klipsch filed patent No. 2,310,243 on Feb. 5, 1940, granted Feb. 9,

1943, for the corner horn speaker.

1941 - Altec Lansing Corp. was formed when Altec bought Lansing; Altec Service

Corp. (from "all technical") had been formed in 1938 by M. Conroe and George

Carrington to manage ERPI installations after ERPI was dissolved. John Hilliard worked

at Altec Lansing in 1943 on magnetic airborne sub detection and in 1945 put on

the market the 2-way "Voice of the Theater" speaker system with improved horns

and magnet drivers. See Lansing Heritage for images and a detailed history.

Avery Fisher with 9-tube amp and coaxial speaker, from Fortune, Oct. 1946

1949 - W. E. Kock and F. K. Harvey at Bell Labs developed the acoustical lens, and

reported findings in 1949 JAES. These lenses are used in James B. Lansing theater

speakers and home hi-fi speakers

1953 - Arthur Janszen was granted patent No. 2,631,196 on March 10, 1953, for

an electrostatic high-frequency speaker

20

Page 23

1954 - Acoustic Research introduced the small AR-1 bookshelf loudspeaker that used

the acoustic suspension principle developed by company co-founder Edgar Villchur.

This was soon followed by the $89 AR-2 and by the AR-3 with improved domed

tweeters in 1958.

Walker's ESL, from Quad

1957 - Quad ESL marketed as the first full-range electrostatic loudspeaker, designed

by Peter Walker and David Williamson, based on Edward W. Kellogg's patent No.

1,983,377 filed September 17, 1929 and granted December 4, 1934.

1974 - Earthquake premiered Nov. 15 in the Chinese in Hollywood with Universal

Picture's Sensurround process developed by W. O. Watson and Richard Stumpf at

Universal. Four large low-frequency horns were located behind the screen, two in

each corner. The Model W horn in each corner was 8 ft. long, 4 ft. wide, 4 ft. high.

The Model C horn in each corner was a modular unit 1 ft. wide and 5 ft. high. Two

additional horns were located on a platform in the rear of the . Each horn was driven

by a 1000-watt amplifier controlled by inaudible tones on a special optical control

track along with the normal 4-track magnetic soundtrack of the 35mm Panavision

filmstrip.

1994 Sees the introduction of what was quite possibly the world’s least coloured

loudspeaker system – the Nautilus. Conceived and designed by Laurence Dickie the

loudspeaker has been highly acclaimed for over a decade and has a pride of place

in the Millennium Dome in London. Ten years later Laurence had honed these

technologies from Nautilus to new heights for a range of products from Vivid Audio,

to similar levels of acclaim and excitement from the world’s specialist press.

21

Page 24

To quote from Laurence’s Vivid Audio Ethos “Through aeons of evolution, the hearing

of animals like ourselves has developed an incredibly high sensitivity to resonance

and reflection as a matter of survival. Much crucial information can be deduced

about the surrounding environment and the presence of imminent danger by listening

for subtle changes in these effects.

At Vivid Audio, we believe that the subjective transparency of a loudspeaker system

is closely related the reduction of these two aberrations and have made every effort

to keep them to a minimum.

Each driver is designed to be pistonic within their working bandwidth with resonant

break-up occurring well above the range of audibility or at a frequency at least five

times that of the upper band limit. At the rear of the diaphragm, any cavities which

might lead to in-band resonances have been comprehensively vented or coupled to

matched absorbers, both actions which completely remove them.

Reflected energy from the rearward wave-front is also controlled by minimising the

area of any obstruction, such as the struts of the low frequency driver chassis or the

dome driver pole pieces, and ensuring that the wave then passes through an adequate

volume of absorbent material before meeting any boundaries.

A similar attention to detail is applied to the external surface which dictates that it

be free of any sharp features which might give rise to distinct reflections. The gently

swept spline curve, which defines the cabinet shape, ensures that the emerging

wave-front encounters no perturbation. All aspects of the enclosure design were

created using solid modelling to produce the seamless curves and precision features.

Such a smooth form and compact enclosure results in an extremely wide mid-band

dispersion which gradually narrows with ascending frequency. This natural sounding

polar performance integrates with a wide variety of listening environments to give

a gently falling power response which quality is widely acclaimed as being highly

desirable. Having a well-controlled off-axis response also widens the usable listening

area to include much of the room.

22

Page 25

Radial magnet technology permits the mounting of drivers with a minimal separation

ensuring the widest vertical beam at crossover while also having an intrinsically low

stray magnetic field which allows placement close to CRT monitors.

Having such a flowing line, the natural choice of enclosure material is a moulded

polymer. We selected a synthetic resin filled with a blend of graded mineral particles

and medium length carbon fibres. The moulds were cast from patterns cut from

solid using multi-axis mills driven directly from the 3D models created in the design

process.

The doubly curved form of the cabinet walls possesses a high degree of intrinsic

rigidity further enhanced by moulded lateral bracing which two factors ensure that

the resonant modes are sufficiently high in frequency. Direct mechanical excitation

of the enclosure is, in any case, avoided by rigorous use of compliant mounts for

every driver and reaction cancelling between the two low frequency drivers which

ensures that there is no net movement of the chassis below 100Hz. Reaction cancelling

is further applied to the design of the low frequency venting where a pair of ovoid

ports, with streamlined profile to minimise air turbulence, are positioned on the front

and back of the cabinet. The result is an extremely stable low frequency performance

with a rather novel appearance.

* Many of the above technologies are patented and are protected by international

law. Perceived infringements will be actively pursued.

VIVID AUDIO (PTY) LTD., P. O. BOX 343, KLOOF, 3640 KWAZULU NATAL, SOUTH

AFRICA

Telephone: +27 31 705 4168, Facsimile: +27 31 705 4167

VIVID AUDIO and the VIVID AUDIO logo are registered trade marks.

Patents exist on D26,D50 and C125 drivers.

All VIVID AUDIO products are in conformity with the EMC directive and the low

voltage directive.

Availability of models may vary from country to country.

Please visit our web site for the details of your nearest authorised dealer and to learn

more about us and our technology.

VIVID AUDIO reserves the right to change the design and or specifications of VIVID

AUDIO products without prior notice.

© 2003/4/5/6/7 VIVID AUDIO (PTY) Ltd. All rights

23

Loading...

Loading...