Vivax cool ACP-12CC35GECI, ACP-18CF50GECI, ACP-36CC100GECI, ACP-24CF70GECI, ACP-36CF100GECI Service Manual

...

ACP-12CC35GECI

ACP-18CC50GECI

ACP-24CC70GECI

ACP-36CC100GECI

ACP-18CF50GECI

ACP-24CF70GECI

ACP-36CF100GECI

Service

manual

ENG

RoHS

NNO-1/09

GREE COMMERCIAL AIR CONDITION A/A DC INVERTER U-MATCH AIR CONDITIONERS

1

PRODUCT

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

2

PRODUCT

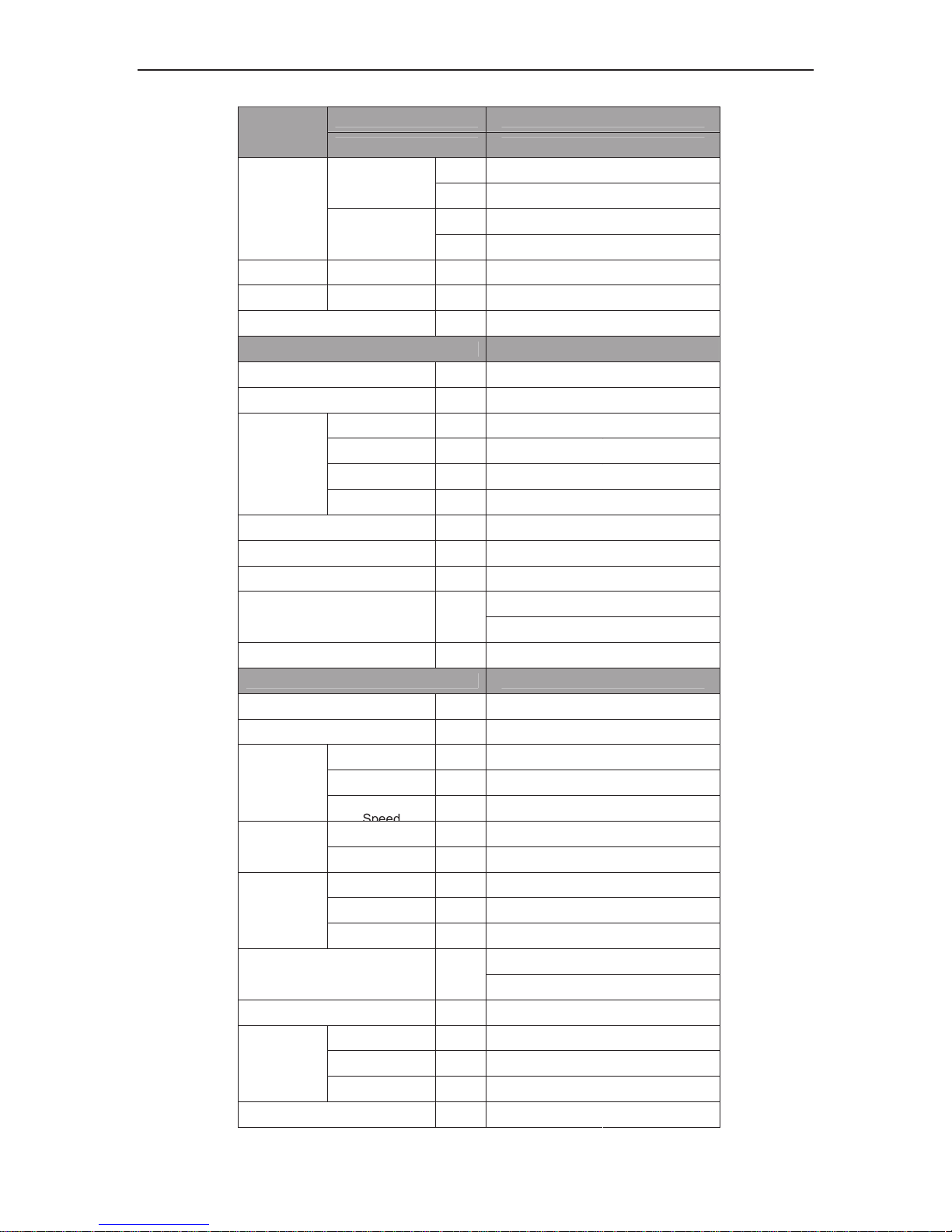

1 MODELS LIST

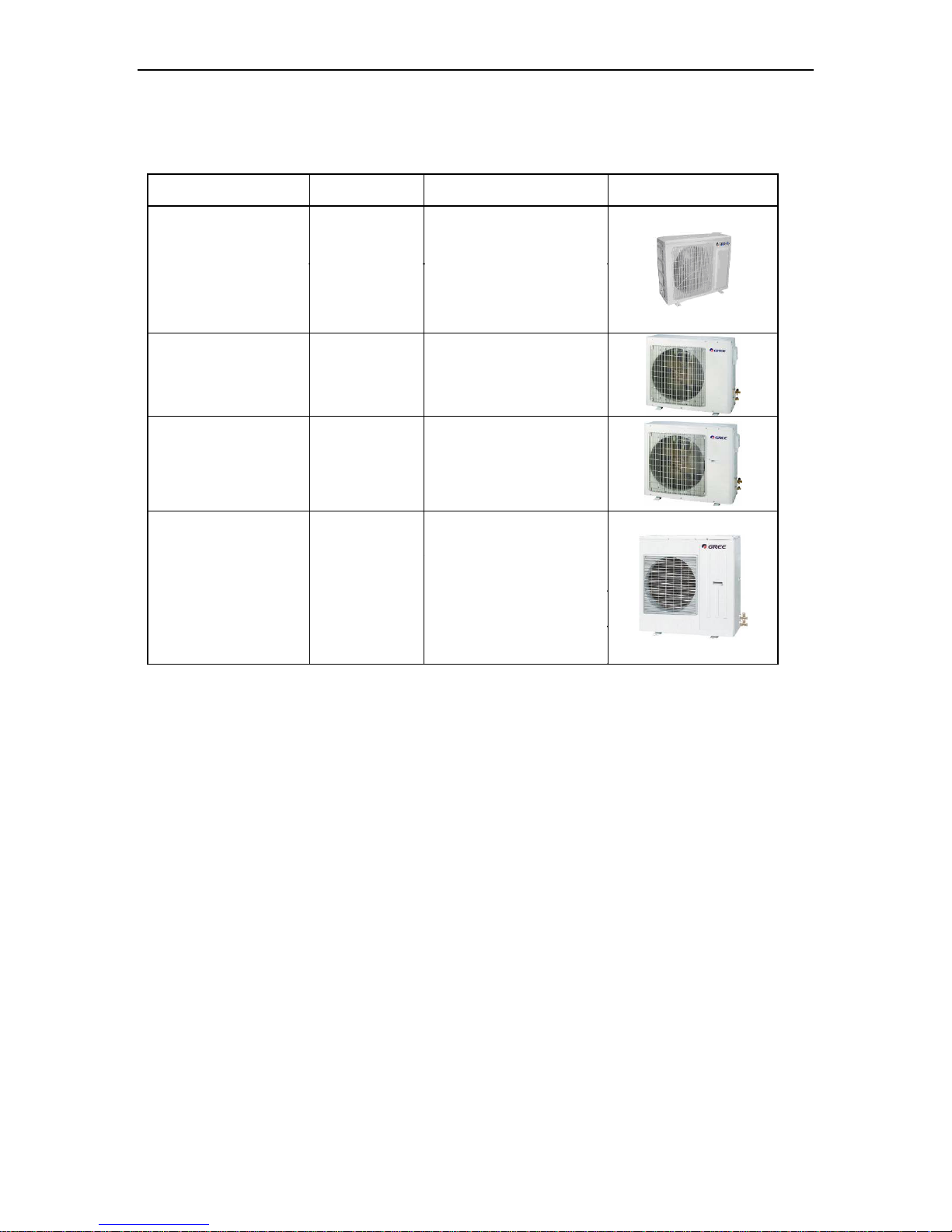

1.1 Outdoor Unit

Model Name Ref.

Power supply

(V, Ph, Hz)

Appearance

ACP-12CC35GECI R410A 220-240 V 1 Ph ~ 50 Hz

R410A 220-240 V 1 Ph ~ 50 Hz

R410A

220-240 V 1 Ph~ 50 Hz

R410A 220-240 V 1 Ph~ 50 Hz

ACP-18CC50GECI

ACP-18CF50GECI

ACP-24CC70GECI

ACP-24CF70GECI

ACP-36CC100GECI

ACP-36CF100GECI

Note:1 Ton =12000Btu/h = 3.517kW

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

3

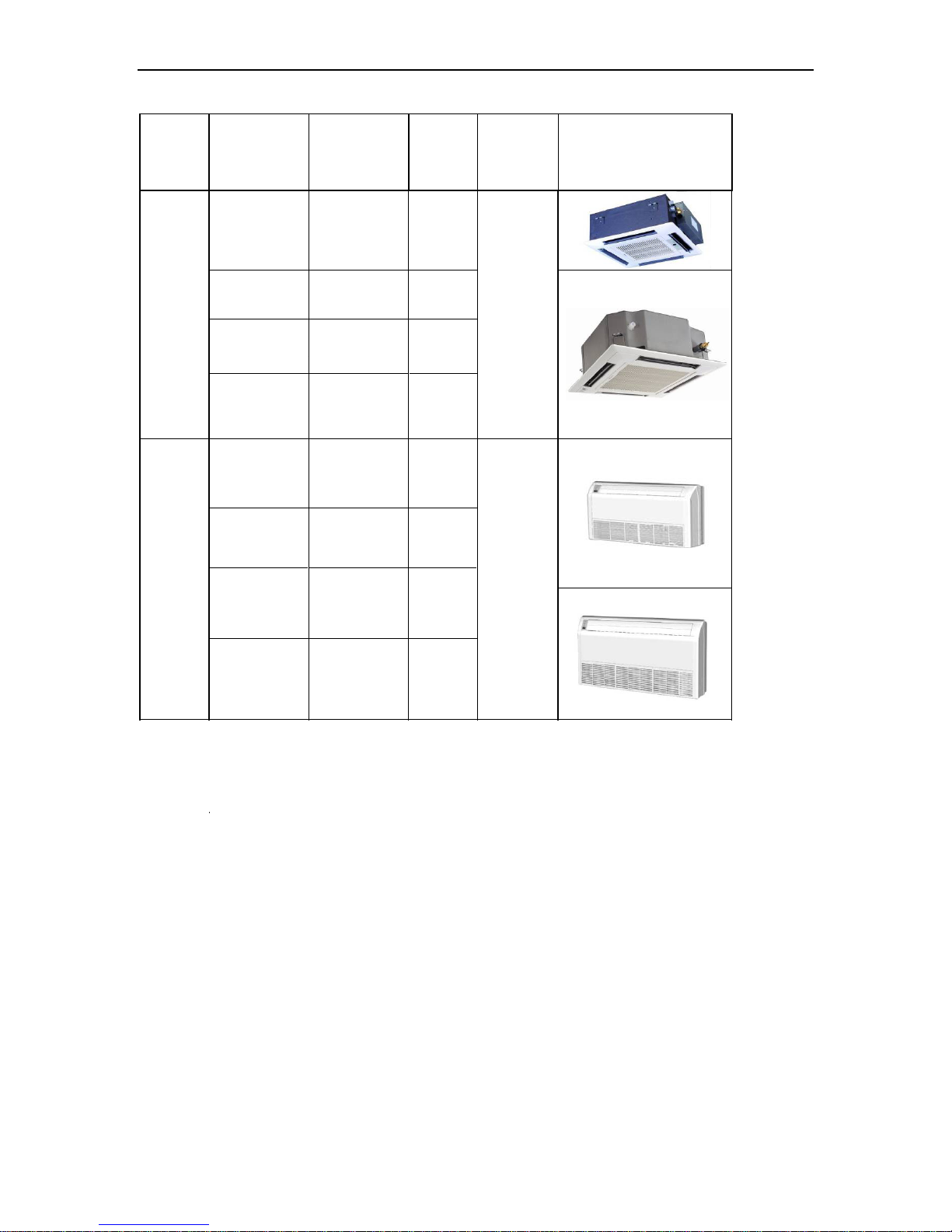

1.2 Indoor Unit

Type Model Name

Nominal

Capacity

Cooling/Heati

ng

(Btu/h)

Ref.

Power

supply

(V, Ph, Hz)

Appearance

ACP-12CC35GECI 12000/12600 R410A

18000/21000 R410A

24000/29500 R410A

35140/38210 R410A

Cassette

Type

220-240 V

1Ph~

50Hz

12000/13000 R410A

18000/21000 R410A

24000/27000 R410A

36167/40944 R410A

220-240 V

1Ph~

50Hz

Ceiling

Type

ACP-18CC50GECI

ACP-18CF50GECI

ACP-24CC70GECI

ACP-24CF70GECI

ACP-18CC50GECI

ACP-18CF50GECI

ACP-24CC70GECI

ACP-24CF70GECI

ACP-12CC35GECI

ACP-36CC100GECI

ACP-36CF100GECI

ACP-36CC100GECI

ACP-36CF100GECI

Note:1 Ton =12000Btu/h = 3.517kW

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

4

NOTES:

The universal outdoor units means that the customer can choose any of three kind of indoor unit to match the

outdoor unit without any change with it.

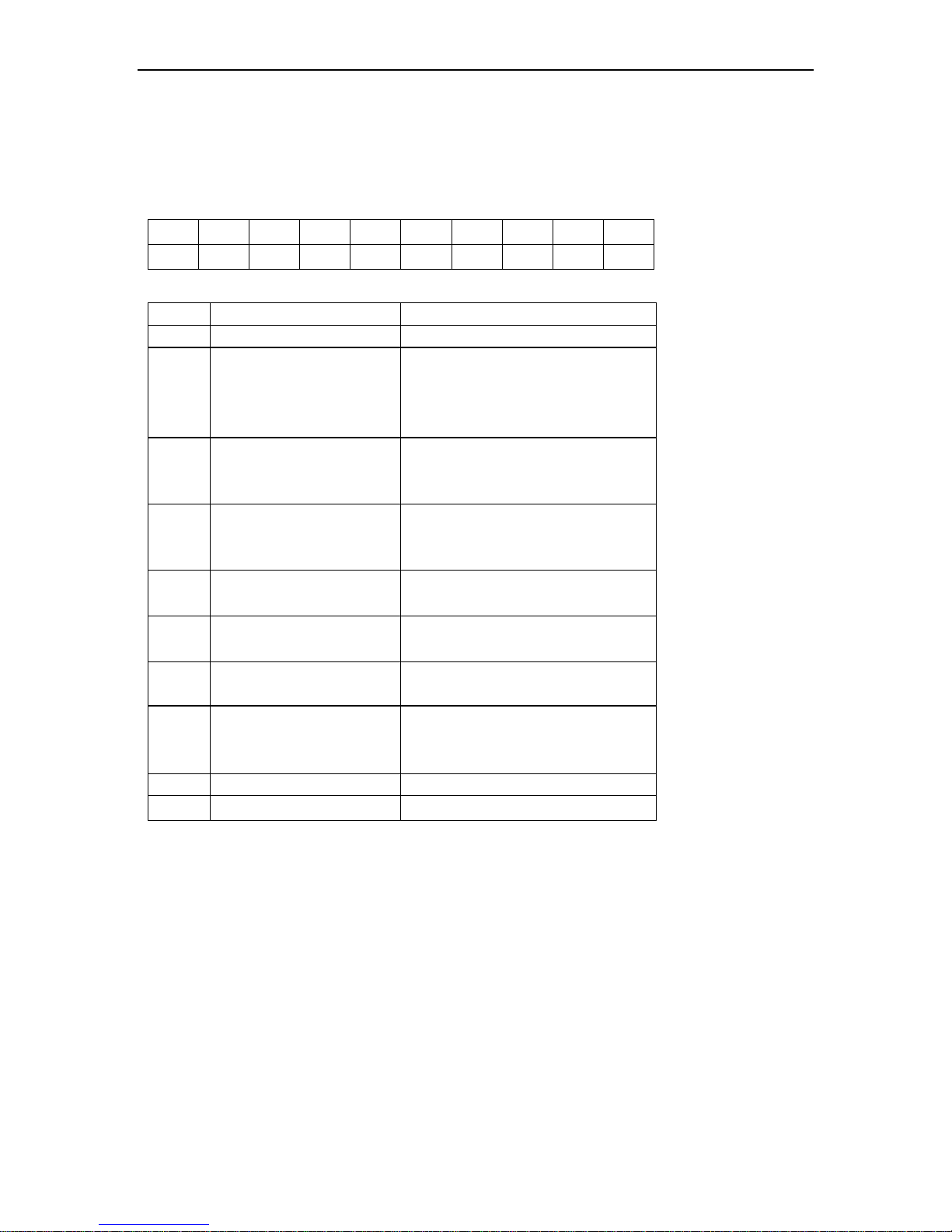

2 NOMENCLATURE

G U H D 09 N K 3 A O

1 2 3 4 5 6 7 8 9 10

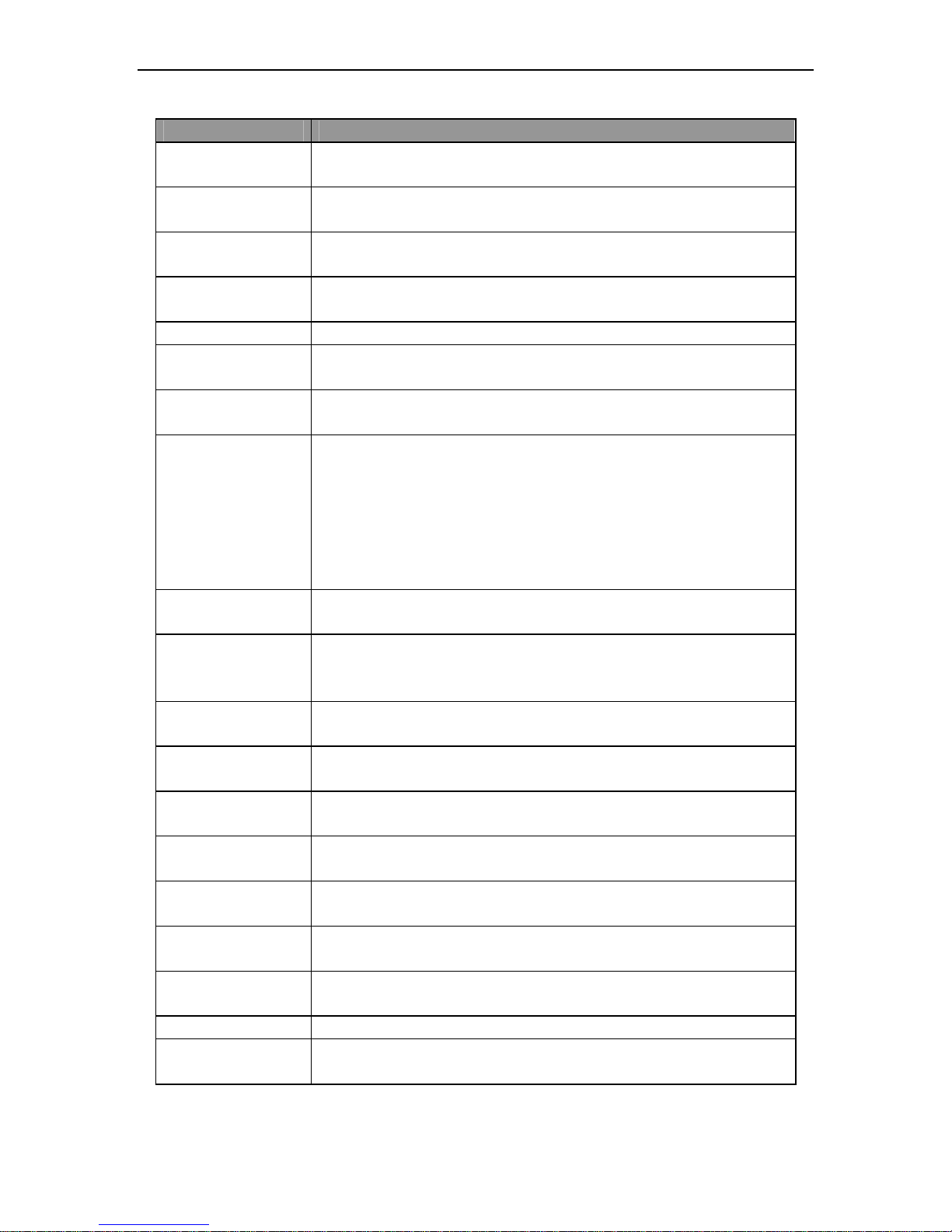

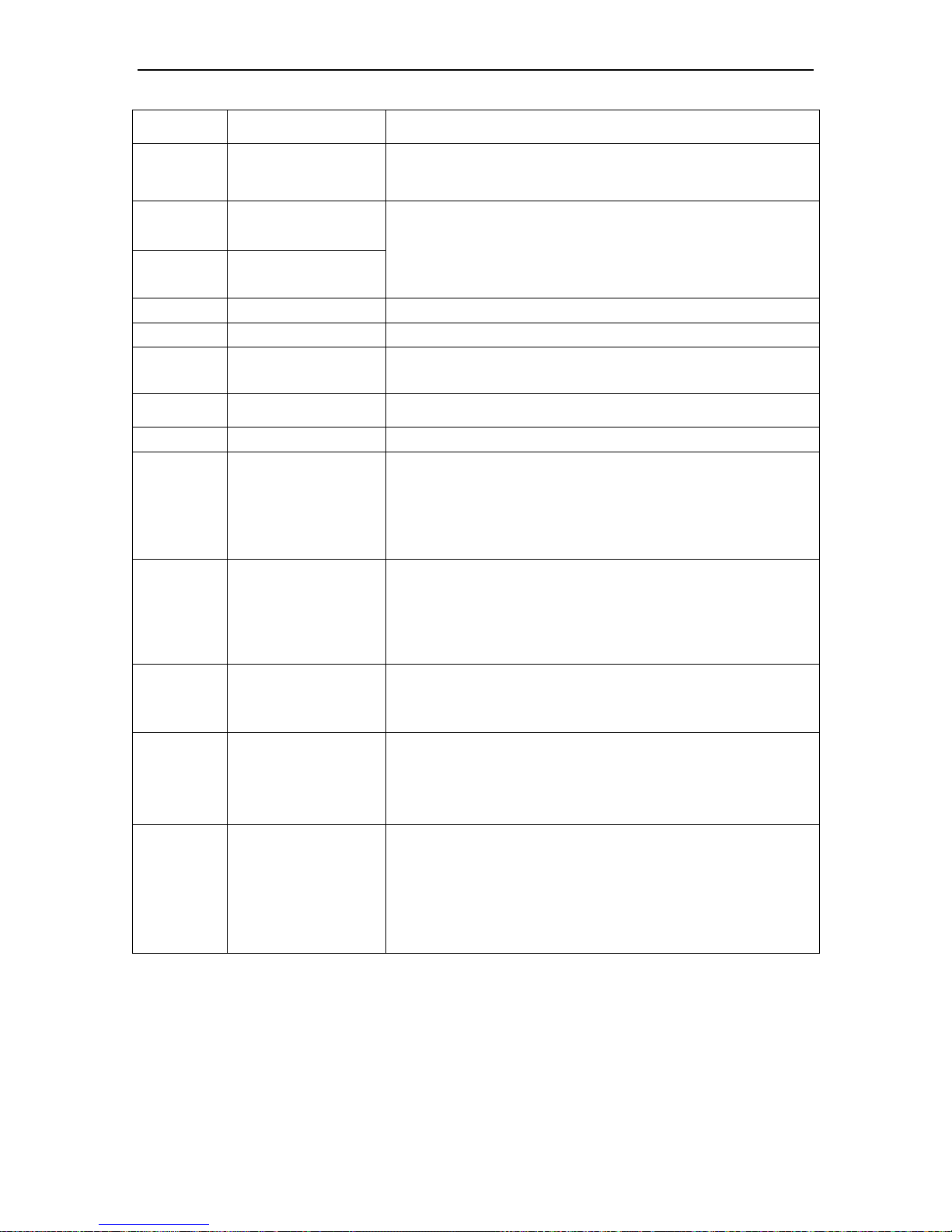

NO. Description Options

1 Gree Electric Appliances Inc Capital Letter :G

2 Unit Type

U=Match Outdoor Unit

F=Duct Type

K=Cassette Type

T= Floor-ceiling Type

3 Product Type

C=Cool Only

H=Heat Pump without Aux Electric

Heaters

4

Compressor Power Supply

Type Code

N=Constant Frequency

D=DC Inverter

A=AC Inverter

5 Nominal Cooling Capacity

Nominal Cooling Capacity

=Number×1000Btu/h

6 Climate Type

N=Climate T1 Condition

T= Climate T3 Condition

7 Power Supply Code

K=1Ph 220~240V 50HZ

M=3Ph 380~415V 50HZ

8 Refrigerant

1 =R22

2=R407C

3=R410A

9 Design Code Design Code: A, B, C, D……

10 Unit Code I=indoor unite O=Outdoor unit

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

5

3 FUNCTION

Function Description

Memory function

when unit restarts after power off, it will run on former status, the mode and

parameter are kept the same

Remote control function

wireless controller and remote controller can be selected, and the maximum

control distance of remote controller is 10m.

Timing function

it can timing ON/ OFF separately, meanwhile, it can also timing on circularly

Self-diagnosis with

alarm function

Once the unit has malfunction, the malfunction code will be indicated and alarm

rings immediately

Sleep function it can self control for saving energy in energy saving mode.

Automatic function

the fan of indoor unit can adjust fan speed automatically based on actual

demand when cooling or heating under automatic mode

Cool air proof function

the fan starts only when the temperature of indoor unit heat exchanger is higher

than indoor temperature under heating mode

Weekly Time

Centralized Control and Weekly Timer Functions: The centralized controller and

the weekly timer are integrated in the same wire controller. The system has both

the centralized control and the week timing functions. Up to 16 sets of units can

be controlled simultaneously by the centralized controller (weekly timer). The

weekly timer has the function of invalidating the lower unit. The weekly timing

function is able to realized four timing ON/OFF periods for any unit every day, so

as to achieve fully automatic operation. No timing control can be set for holidays.

High/low pressure

protection

when suction pressure is too low or discharge pressure is too high, compressor

will stop and unit display malfunction code

Overload protection

compressor has its own overheat protection.Once the temperature of

compressor is higher than allowable level, compressor will stop and only when

temperature recovery, compressor restart

Over current protection

once the current of compressor is higher than normal level, compressor will stop

and unit display malfunction code

Discharge high

temperature protection

once the discharge temperature of compressor is higher than allowable value,

compressor will stop and unit display malfunction code

Reverse (open) phase

protection

once the phase sequence of power supply is incongruent or the phase is absent,

unit can’t work.

Anti-high temperature

protection

once the heat exchanger temperature of indoor unit is too high, the outdoor fan

motor will stop.

Timing ON/OFF display

display and timing turn ON/OFF time( only with wired controller have this

function)

Fan speed display

display the speed (high,medium,low) of fan(only with wired controller have this

function)

Function model display

cooling mode,dry mode,heating mode,fan mode(only with wired controller have

this function)

Testing display display testing mode(only with wired controller have this function)

Temperature display

display room temperature and set temperature(only with wired controller and

remoter board have this function)

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

11

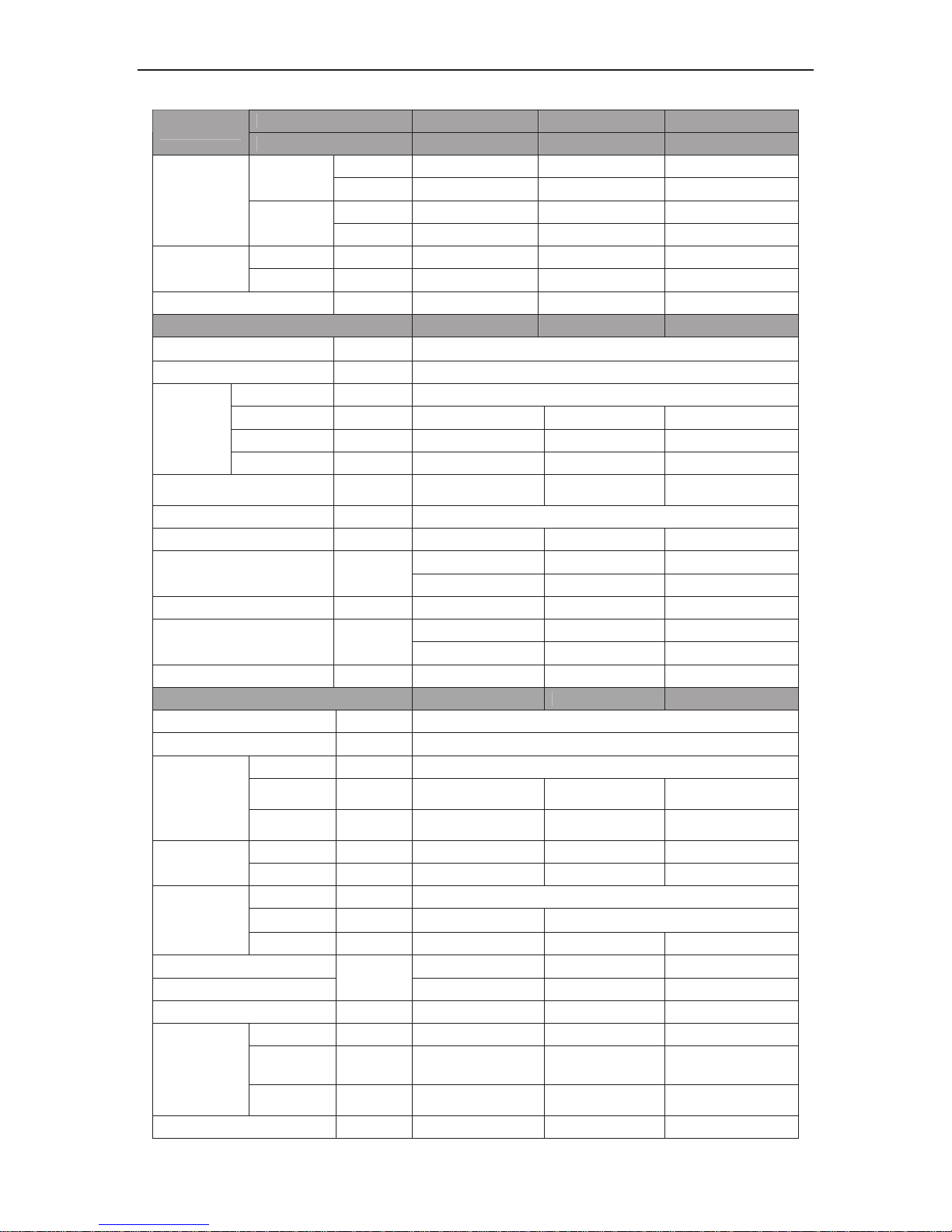

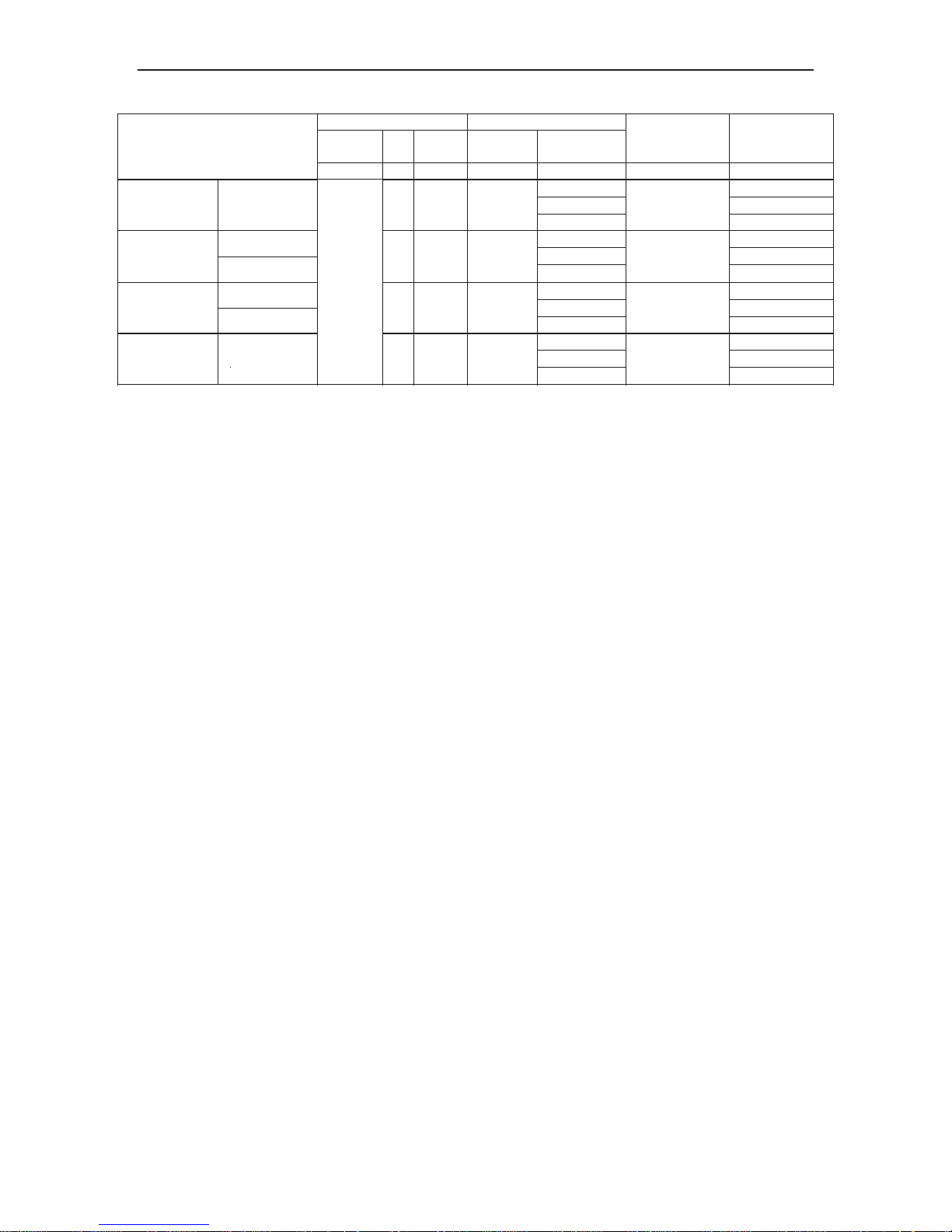

4.1.2 Cassette Type

Indoor unit ACP-12CC35GECI

ACP-18CC50GECI

ACP-24CC70GECI

Model

Outdoor unit ACP-12CC35GECI

ACP-18CC50GECI

ACP-24CC70GECI

kW

3.4

5.3 7

Cooling

Btu/h

11600

18000 24000

kW

3.7

6.15 8.65

Nominal

Capacity

Heating

Btu/h

12600

21000 29500

Cooling kW

1.03

1.65 2.19

Power Input

Heating kW

1.025

1.7 2.4

EER/COP

W/W

3.2/3.61 3.21/3.61 3.20/3.61

Indoor Unit

ACP-12CC35GECI

ACP-18CC50GECI ACP-24CC70GECI

Power Supply

-

220-240V-50Hz-1Ph

Heat Exchange - Cross Fin Coil

Type - Centrifugal fan

Drive - direct direct direct

Motor Output kW 0.011x1 0.035×1 0.040×1

Fan

Air Flow

m3/h

550 1180 1400

Sound Pressure

Level(H/M/L)

dB(A) 47/45/43 47/45/43 51/49/48

Air Filter - Standard washable synthetic

Drain Piping mm Φ32×3 Φ32×3 Φ32×3

600×230×600 840×240×840 840×240×840

Indoor Unit Dimensions

(Outline/Package) (W×H×D)

mm

848×310×678 960×310×960 960×310×960

Weight(Net/Gross) kg 20/27 27/36 27/36

650 x50x650 950×60×950 950×60×950

Panel Dimensions

(Outline/Package) (W×H×D)

mm

670 x102x730 1025×115×1040 1025×115×1040

Panel Weight(Net/Gross) kg 2.5/3.5 6.5/10 6.5/10

Outdoor Unit ACP-12CC35GECI

ACP-18CC50GECI

ACP-24CC70GECI

Power Supply - 220-240V-50Hz-1Ph

Heat Exchange - Cross Fin Coil

Type - Axial fan

Motor

Output

kW 0.75x1 0.06×1 0.09×1

Fan

Fan Motor

Speed

rpm 1070 690±15 780±20

Type - ROTARY ROTARY ROTARY

Compressor

Power Input W 850 1630 2200

Type - R410A

Control

-

Caplllary Tube Electronic Expansion Valve

Refrigerant

Charge kg 1.35 1.4 2.4

Dimensions (W×H×D) 776×320×540 955×700×396 980×790×427

(Outline/Package)

mm

848×360 ×580 1026× 735×455 1080×840×485

Weight(Net/Gross) kg 30/34 48/53 65/70

Liquid Inch Φ1/4" Φ1/4" Φ3/8"

Gas Inch Φ3/8" Φ1/2" Φ5/8"

Piping

Connections

Max.

Length

m 20 20 30

Max. Height Difference m 15 15 15

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

12

Continued

1

Indoor unit

ACP-36CC100GECI

Model

Outdoor unit ACP-36CC100GECI

kW 10.3

Cooling

Btu/h 35140

kW 11.2

Nominal

Capacity

Heating

Btu/h

38210

Power Cooling kW 3.2

EER/COP

W/W

3.22/3.73

Indoor Unit

ACP-36CC100GECI

Power Supply

-

220-240V-50Hz-1Ph

Heat Exchange

-

Cross Fin Coil

Type

-

Centrifugal fan

Drive

-

direct

Motor Output kW

0.06

Fan

Air Flow

m3/h

1660

Sound Pressure Level(H/M/L) dB(A) 53/51/48

Air Filter

-

Standard washable synthetic

Drain Piping mm

Φ32×3

Indoor Unit Dimensions

840×320×840

(Outline/Package) (W×H×D)

mm

960×394×960

Weight(Net/Gross) kg 32/43

Panel Dimensions 950×60×950/

(Outline/Package) (W×H×D)

mm

1025×115×1040

Panel Weight(Net/Gross) kg 6.5/10

Outdoor Unit ACP-36CC100GECI

Power Supply

-

220-240V-50Hz-1Ph

Heat Exchange

-

Cross Fin Coil

Type

-

Axial fan

Motor Output kW

0.75×1

Fan

02±028

mpr deepS rotoM naF

Type

-

ROTARY

Compress

or

Power Input W 3010±7.5%

Type

-

R410A

Control

-

Electronic Expansion Valve

Refrigera

nt

Charge kg 3.5

1107×1100×440

Dimensions (W×H×D)

(Outline/Package)

mm

1155×1220×490

Weight(Net/Gross) kg 86/97

Liquid Inch

Φ3/8"

Gas Inch

Φ5/8"

Piping

Connectio

ns

Max. Length m 30

Max. Height Difference m

15

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

15

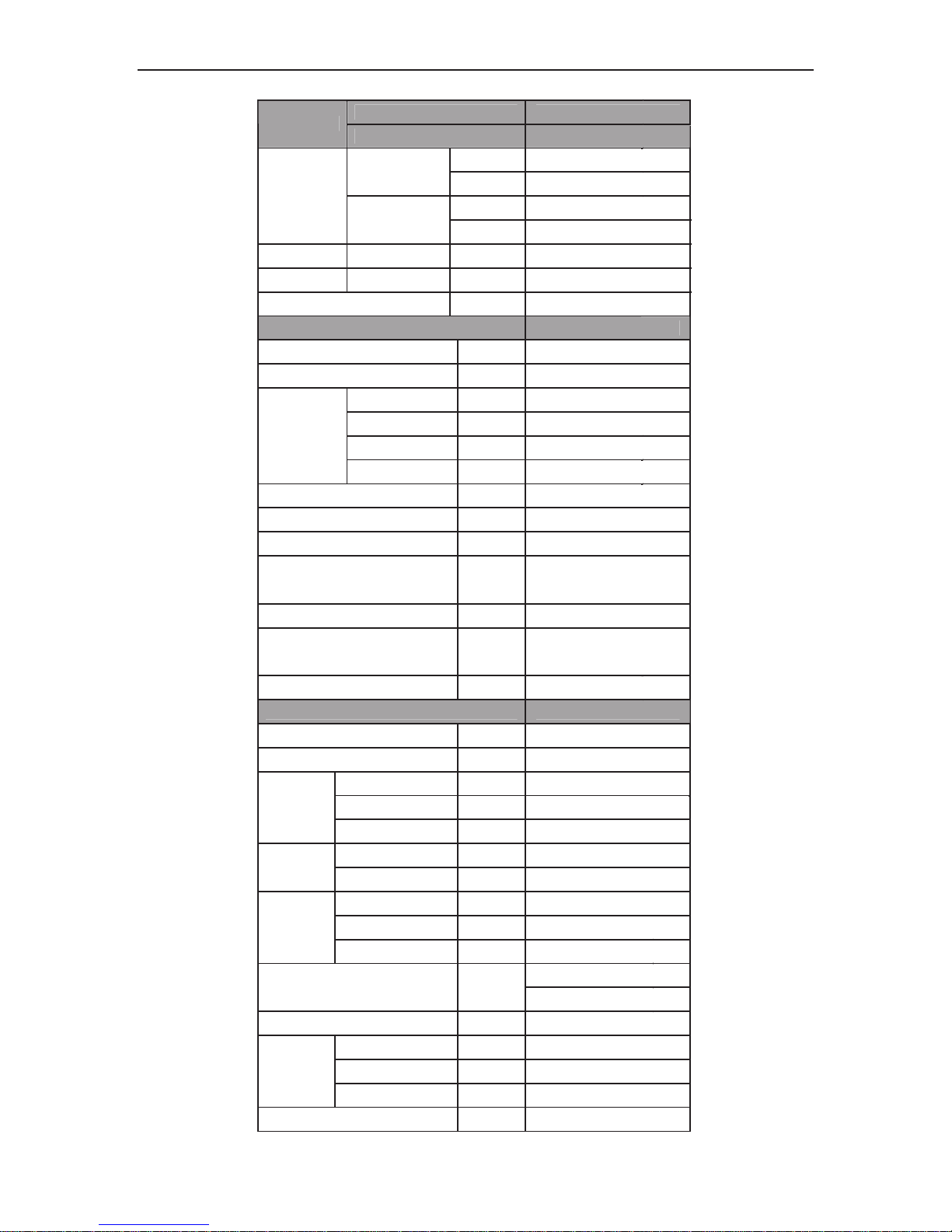

Continued

Indoor unit ACP-18CF50GECI ACP-24CF70GECI

Model

Outdoor unit ACP-18CF50GECI ACP-24CF70GECI

kW 5.3 7

Cooling

Btu/h 18000 24000

kW 6.15 8

Nominal

Capacity

Heating

Btu/h

21000 27000

Cooling kW 1.65 2.19

Power

Input

Heating kW 1.7 2.22

EER/COP

W/W

3.21/3.61 3.20/3.60

Indoor Unit

ACP-18CF50GECI ACP-24CF70GECI

Power Supply

-

220-240V-50Hz-1Ph

Heat Exchange

-

Cross Fin Coil

Type

-

Centrifugal fan

Drive

-

Direct Direct

Motor Output kW 0.02×1 0.05×1

Fan

Air Flow

m3/h

900 1200

Sound Pressure Level(H/M/L) dB(A) 45/42/39 52/49/46

Air Filter

-

Standard washable synthetic

Drain Piping mm Φ17×1.75 Φ17×1.75

1220×225×700 1220×225×700

Dimensions (W×H×D)

(Outline/Package)

mm

1345×310×825 1345×310×825

Weight(Net/Gross) kg 42/51 43/52

Outdoor Unit ACP-18CF50GECI ACP-24CF70GECI

Power Supply

-

220-240V-50Hz-1Ph

Heat Exchange

-

Cross Fin Coil

Type

-

Axial fan

Motor Output kW 0.06×1 0.09×1

Fan

Fan Motor Speed rpm 690±15 780±20

Type

-

ROTARY ROTARY

Compressor

Power Input W 1630 2200

Type

-

R410A

Control

-

Electronic Expansion Valve

Refrigerant

Charge kg 1.4 2.4

955×700×396 980×790×427

Dimensions (W×H×D)

(Outline/Package)

mm

1026× 735×455 1080×840×485

Weight(Net/Gross) kg 48/53 65/70

Liquid Inch Φ1/4" Φ3/8"

Gas Inch Φ1/2" Φ5/8"

Piping

Connections

Max. Length m 20 30

Max. Height Difference m 15 15

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

16

Continued:2

Indoor unit

ACP-36CF100GECI

Model

Outdoor unit

ACP-36CF100GECI

kW 10.6

Cooling

Btu/h 36160

kW 12

Nominal

Capacity

Heating

Btu/h

40940

Power Cooling kW 3.26

Input Heating kW 3.16

EER/COP

W/W

3.25/3.8

Indoor Unit

ACP-36CF100GECI

Power Supply - 220-240V-50Hz-1Ph

Heat Exchange - Cross Fin Coil

Type - Centrifugal fan

Drive -

Direct

Motor Output kW 0.15

Fan

Air Flow

m3/h

2000

Sound Pressure Level(H/M/L) dB(A) 54/51/48

Air Filter -

Standard washable synthetic

Drain Piping mm Φ17×2.5

1420×245×700

Dimensions (W×H×D)

(Outline/Package)

mm

1545×330×825

Weight(Net/Gross) kg 53/61

Outdoor Unit ACP-36CF100GECI

Power Supply - 220-240V-50Hz-1Ph

Heat Exchange - Cross Fin Coil

Type - Axial fan

Motor Output kW 0.75×1

Fan

Fan Motor

02±028 mpr

Type - YRATOR

Compressor

Power Input W 3010±7.5%

Type - A014R

Control - Electronic Expansion Valve

Refrigerant

Charge kg 3.5

1107×1100×440

Dimensions (W×H×D)

(Outline/Package)

mm

1155×1220×490

Weight(Net/Gross) kg

86/97

Liquid Inch Φ3/8"

Gas Inch Φ5/8"

Piping

Connections

Max. Length m 30

Max. Height Difference m 15

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

19

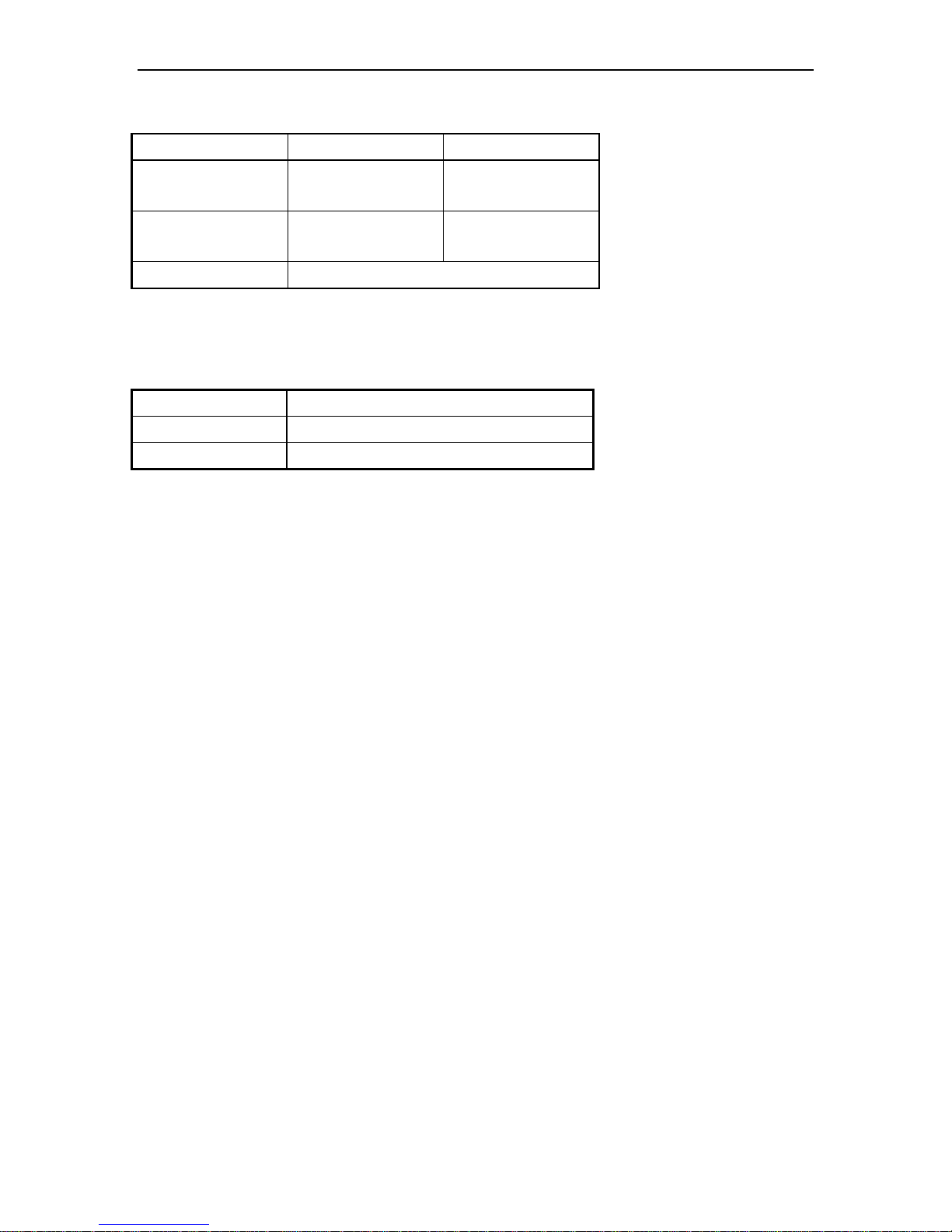

Note:

① Nominal capacities are based on the follow conditions.

Mode Indoor Outdoor

Cooling

DB:27 (80.6 )

WB:19 (66.2 )

DB:35 (95 )

WB:24 (75.2 )

Heating

DB:20 (68 )

WB:-- ( -- )

DB:7(44.6)

WB:6(42.8)

Piping Length 5m

② The air volume is measured at the relevant standard external static pressure.

③ Noise is tested in the Semianechoic room, so it should be slightly higher in the actual operation due to

environmental change.

4.2 Operation Range

Mode Range of Outdoor Temperature ( )

Cooling 18-48

Heating -7-24

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

20

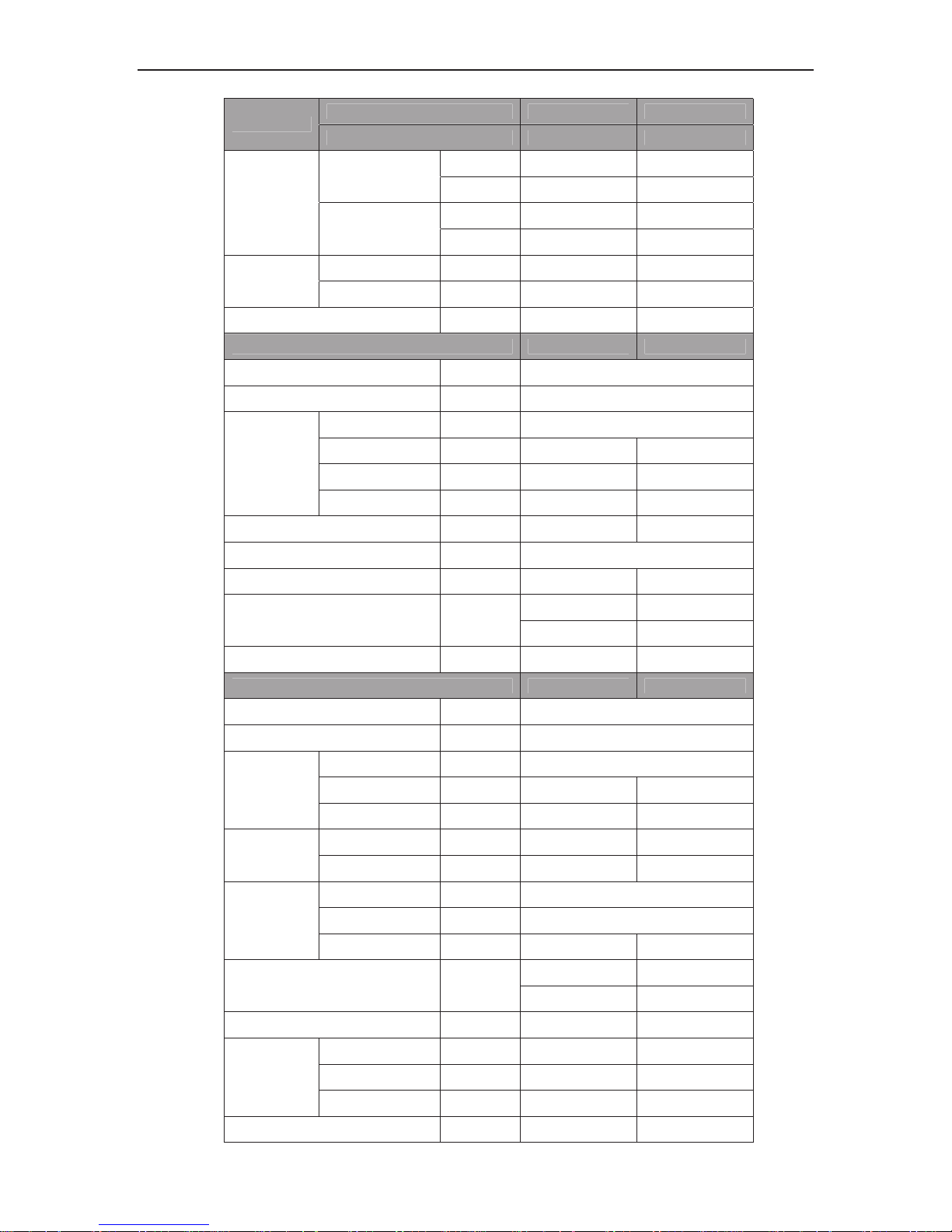

4.3 Electrical Data

Compressor Fan Motor

Power

Supply

Qty. RLA

Condenser

Fan Motors

Supply Blower

Motor

Max. Fuse

Breaker Size

(Indoor/Outdoor)

Min.

Disconnect Size

(Indoor/Outdoor)

Model

V,Ph,Hz — Each FLA Each FLA Each Amperes Amperes

5.2/0.1 A14.0

5.2/0.1 A01.0

ACP-12CC35GECI 1 4.8 0.35

0.2A

6/16

1.0/2.5

0.4/0.1 A17.0

0.4/0.1 A12.0

ACP-18CC50GECI

ACP-18CF50GECI

1

8.38/7.07

0.58

0.35A

6/20

1.0/4.0

0.4/5.1 A25.1

0.4/5.1 A15.0

ACP-24CC70GECI

ACP-24CF70GECI

1 9.7

0.85

0.40A

10/20

1.5/4.0

0.6/5.1 A50.5

0.6/5.1 A25.1

ACP-36CF100GECI

1 13.5

1.1

0.61A

10/32

1.5/6.0

220-240

1,

50

Notes:

RLA:Rated load amperes

LRA:Locked rotor amperes

FLA:Full load current

ACP-18CC50GECI

ACP-18CF50GECI

ACP-24CC70GECI

ACP-24CF70GECI

ACP-36CF100GECI

A/A DC INVERTER U-MATCH AIR CONDITIONERS PRODUCT

21

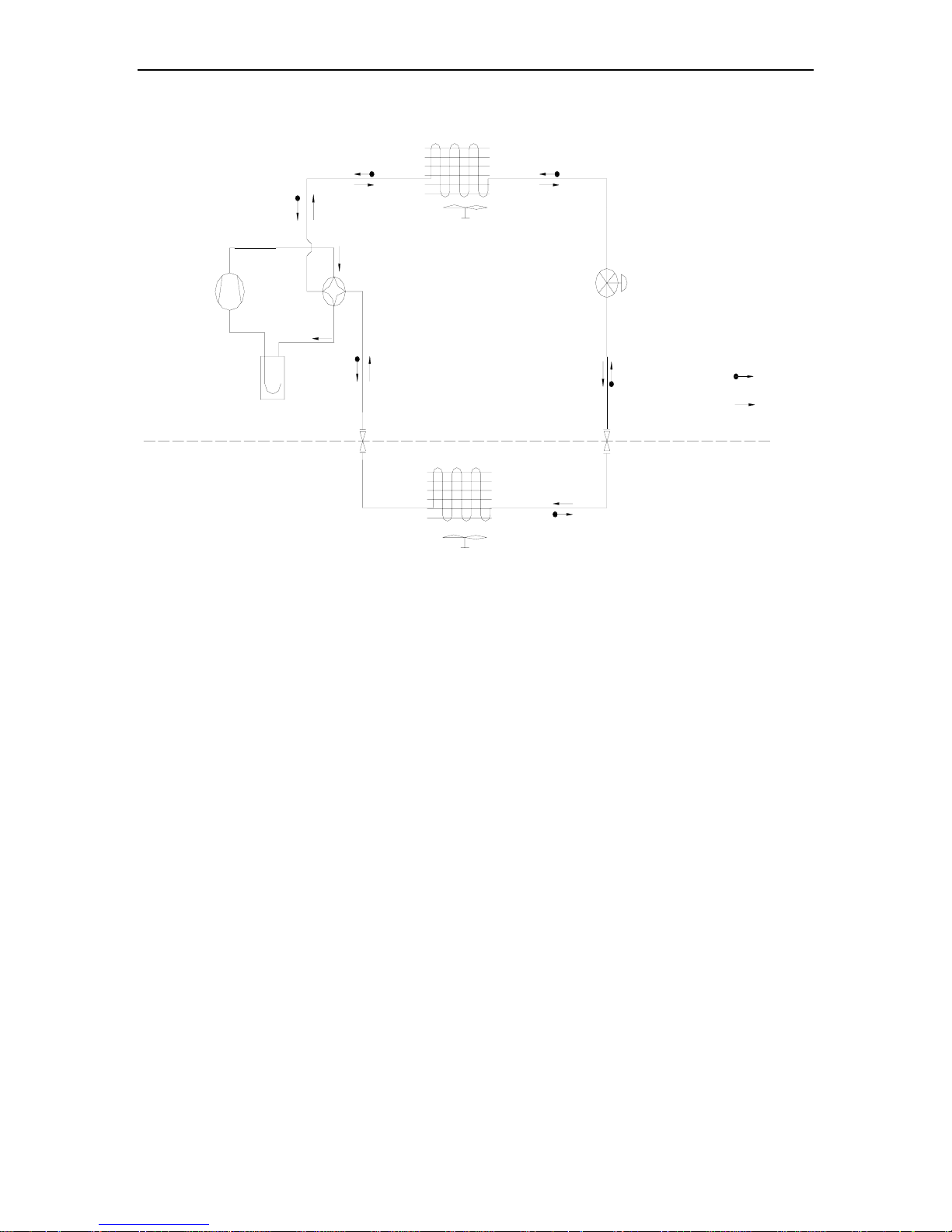

5 PIPING DIAGRAM

Indoor

Outdoor

Cool i ng

Heati ng

Throt tl e

Compr ess or

Vapour Liquid Separator

4-way Valve

Outdoor Heat Exchange

Indoor Heat Exchange

Throttling Method:

ACP-12CC35GECI:Capillary Tube

ACP-24CC70GECI, ACP-36CC100GECI,

ACP-18CF50GECI, ACP-24CF70GECI

ACP-36CF100GECI

:Electronic expansion valve

GREE COMMERCIAL AIR CONDITION A/A DC INVERTER U-MATCH AIR CONDITIONERS

22

CONTROL

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

23

CONTROL

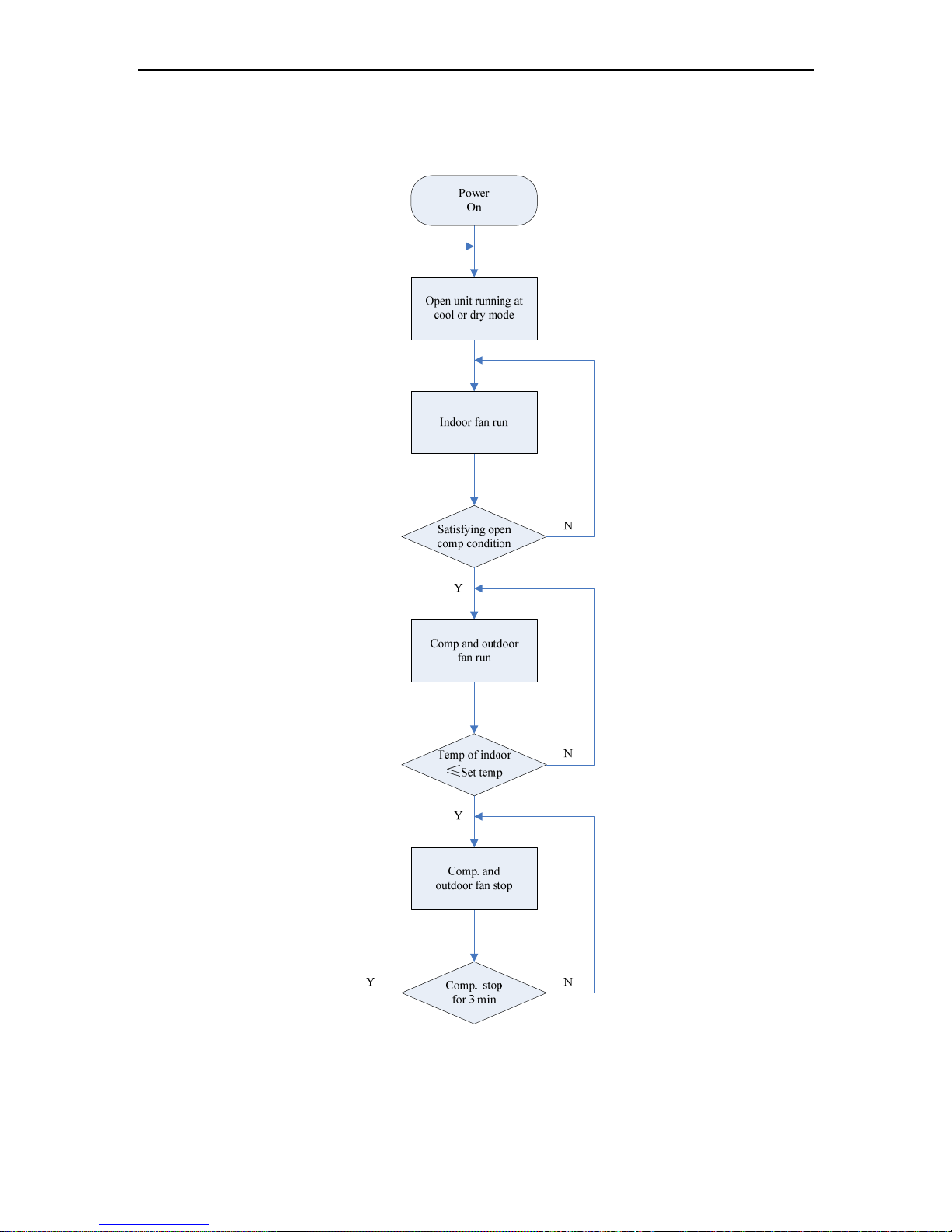

1 OPERATION FLOWCHART

1.1Cooling/Dry Operation

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

24

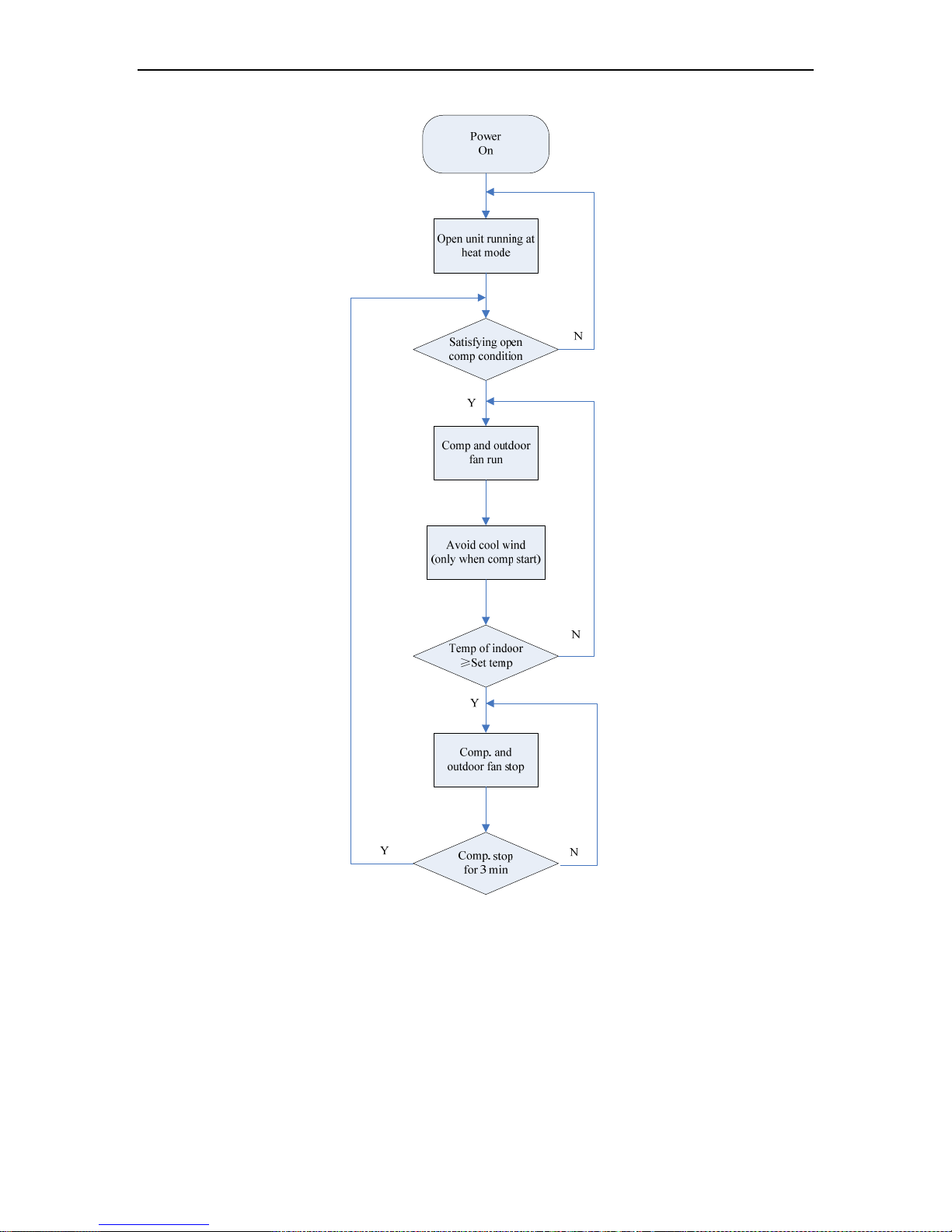

1.2 Heating Operation

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

25

2 MAIN LOGIC

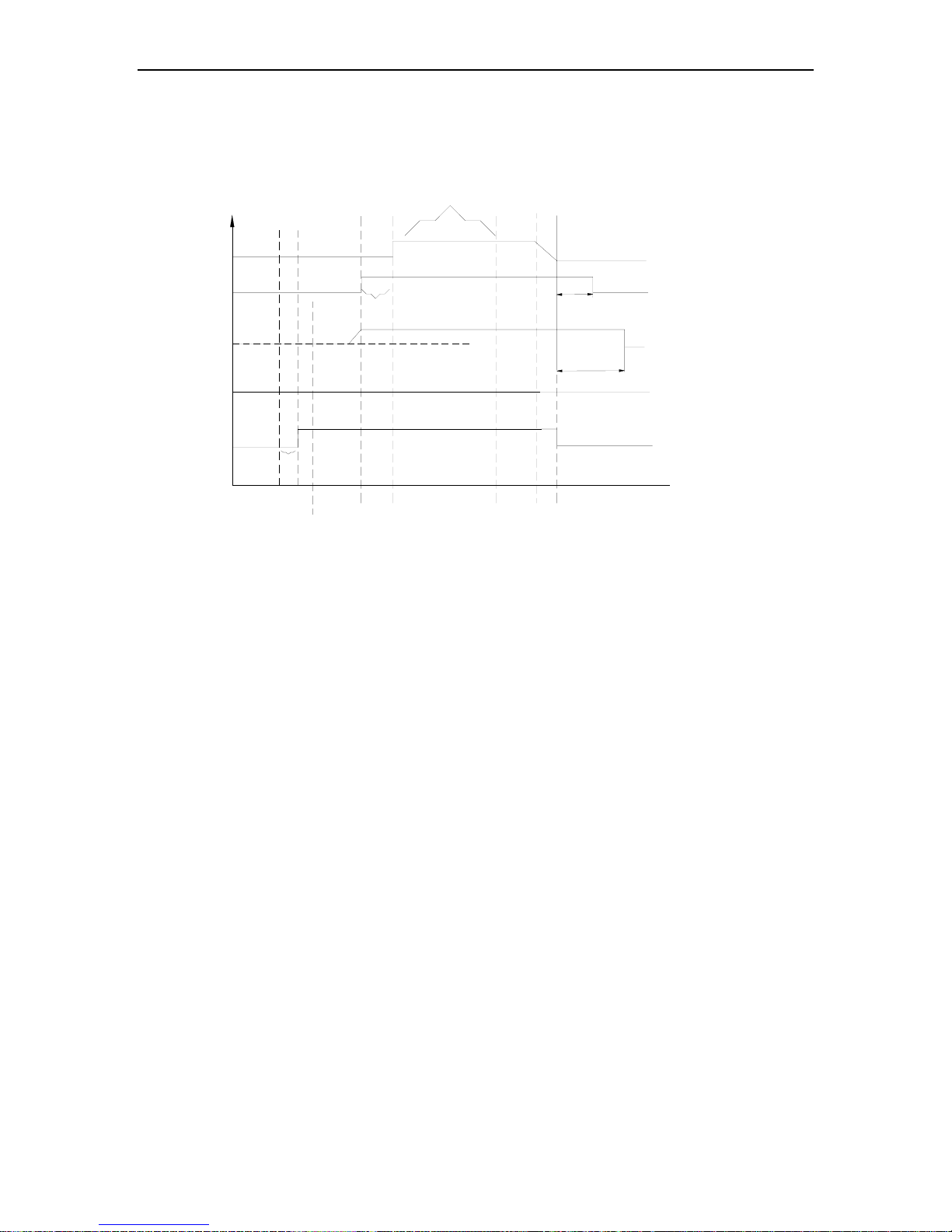

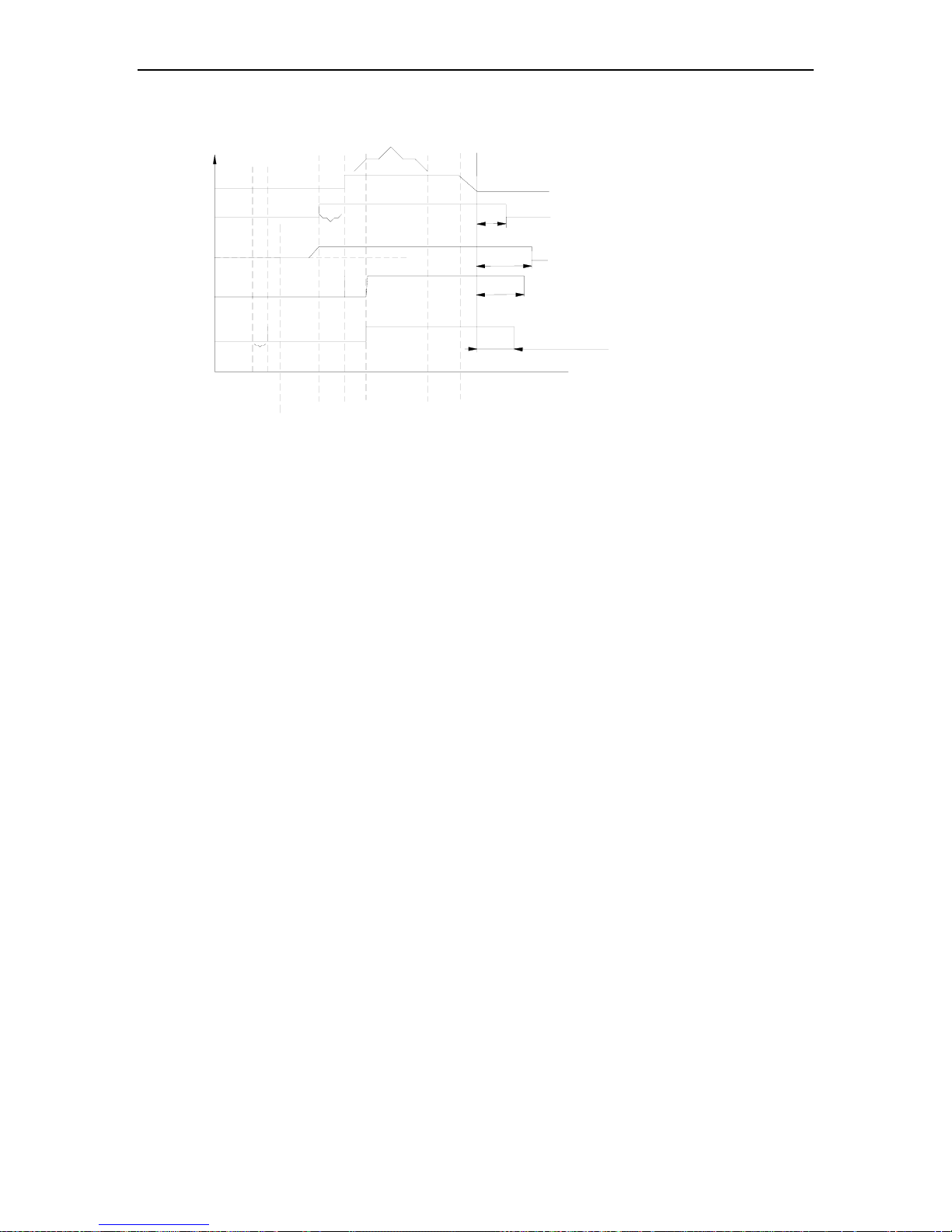

2.1 Cooling

Acc.to control

logic

Cooling mode

3min

Firstly switch off to step 0 and

then switch off step 60

150s atfer the compressor is stoped

180steps

Send out switch-off command

Acc.to control

logic

capacity demand>0

send out cooling

command

Indoor fan

(cooling)

4-way valve

3s

Xsteps

30s

ON

ON

ON

OFF

OFF

OFF

Outdoor fan

EXV

compressor

OFF

60s

60s

After the cooling command is sent out, the indoor fan will run at high speed for 5 seconds before it is put into

operation according to the setting. Then, it is started to calculate the system load demand value. If the load is 0, the

other loads except the indoor fan will not be put into operation (The water pump will run according to the pump

control logic behind). If the load is >0, the EXV will be firstly opened to step X; then the indoor fan is started. After 30

seconds, the compressor is started at initial frequency 40Hz and will be maintained for 3 minutes. After that, the

compressor, EXV and outdoor fan will adjust according to logic.

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

26

2.2 Dry Mode

Max.capacity out put:A×90%

3min

Firstly switch off to step 0

and then switch off step 60

150s atfer the compressor is stoped

180steps

Send out switch-off command

Acc.to controll

logic

capacity

demand

>0

send out dry

command

Indoor fan

(cooling)

4-way valve

3s

Xsteps

30s

ON

ON

ON

OFF

OFF

OFF

Outdoor fan

EXV

Compressor

OFF

Dry Mode

Acc.to controll

logic

60s

150s

The dry mode is basically same as cooling mode. The difference is that:

The indoor fan is fixed at low speed.

Max. capacity output: A×90%

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

27

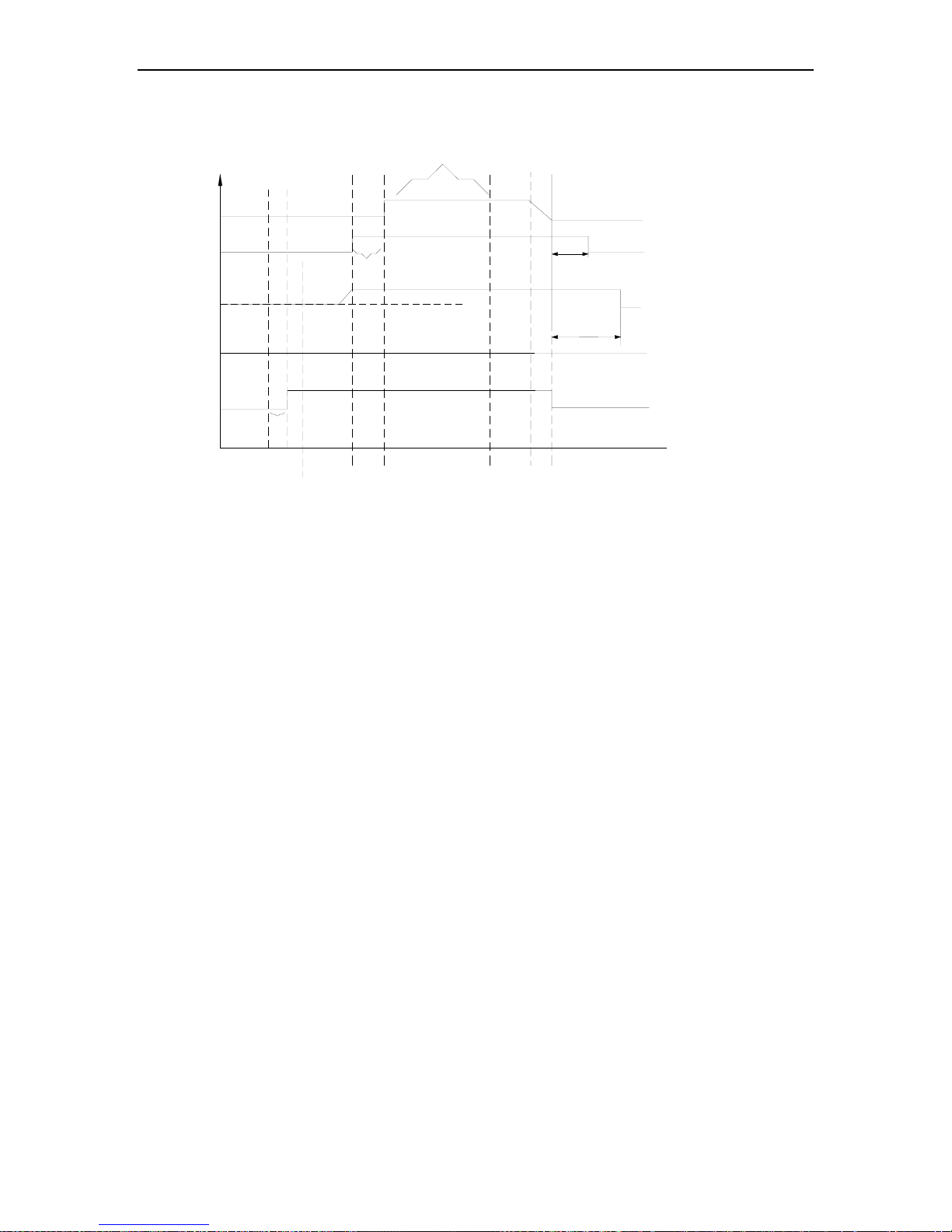

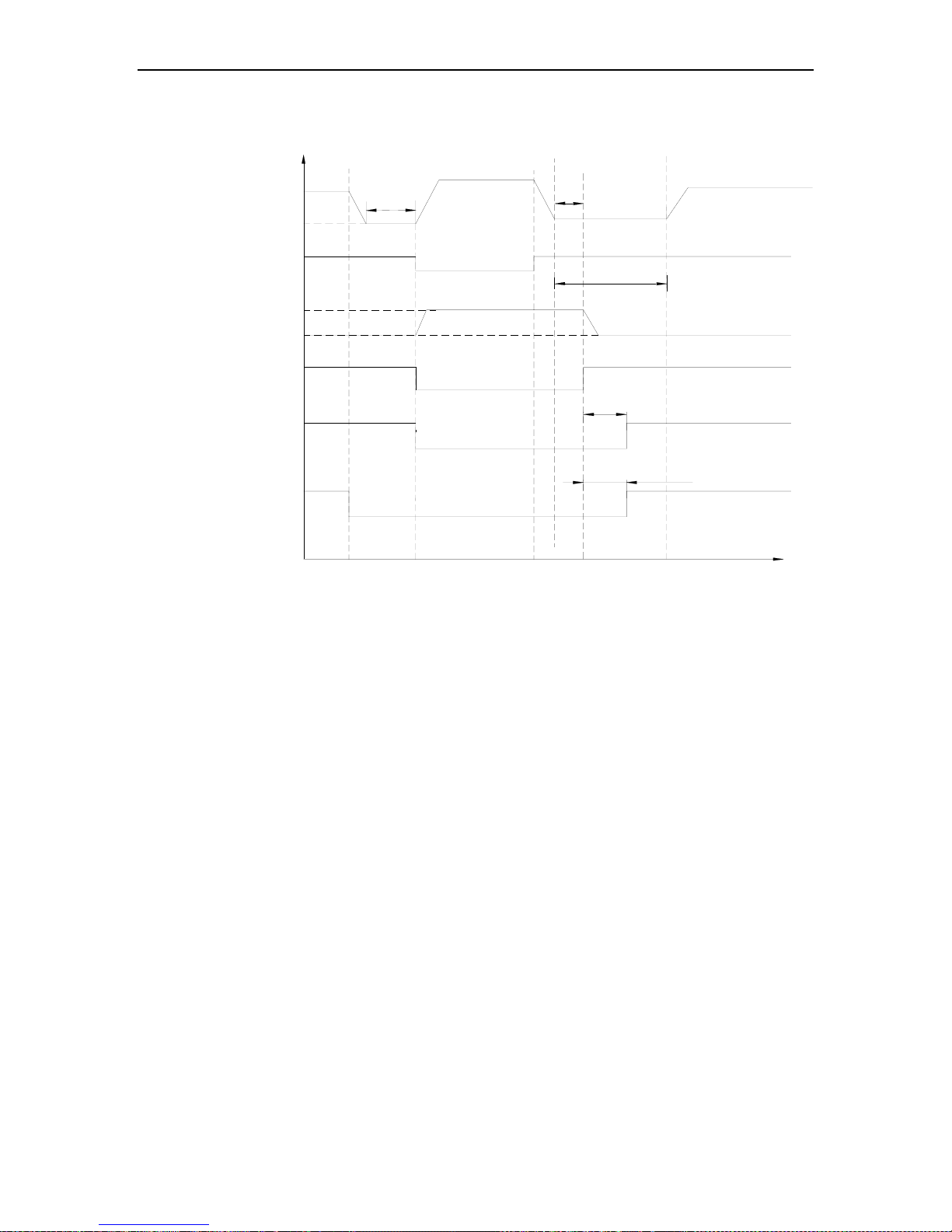

2.3 Heating Mode

150s atfer the compressor is stoped

Firstly switch off to step 0 and

then switch off step 60

Send out switch-off command

Acc.to controll

logic

Acc.to controll

logic

Xsteps

ON

ON

ON

OFF

Heating mode

3min

3s

OFF

OFF

OFF

compressor

EXV

outdoor fan

4-way valve

Indoor fan

(cooling)

send out heating

command

capacity

demand

>0

10s

Run as per cold air

prevention mode

30s

60s

150s

120s

Blow residual heats

When the heating command is sent out, it is started to calculate the system load demand value. If the load is 0,

all the loads will not be put into operation. If the load is >0, the EXV will be firstly opened to step Y; then the outdoor

fan is started. After 30 seconds, the compressor will increase its frequency to the required initial frequency 40Hz

before it started. It is started to count the time when the compressor frequency is increased to 20Hz. After 10

seconds, the 4-way valve is energized and then the indoor fan will run as per cold air prevention mode. The

compressor will keep running at initial frequency for 3 minutes. After that, the compressor, EXV and outdoor fan will

adjust according to logic.

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

28

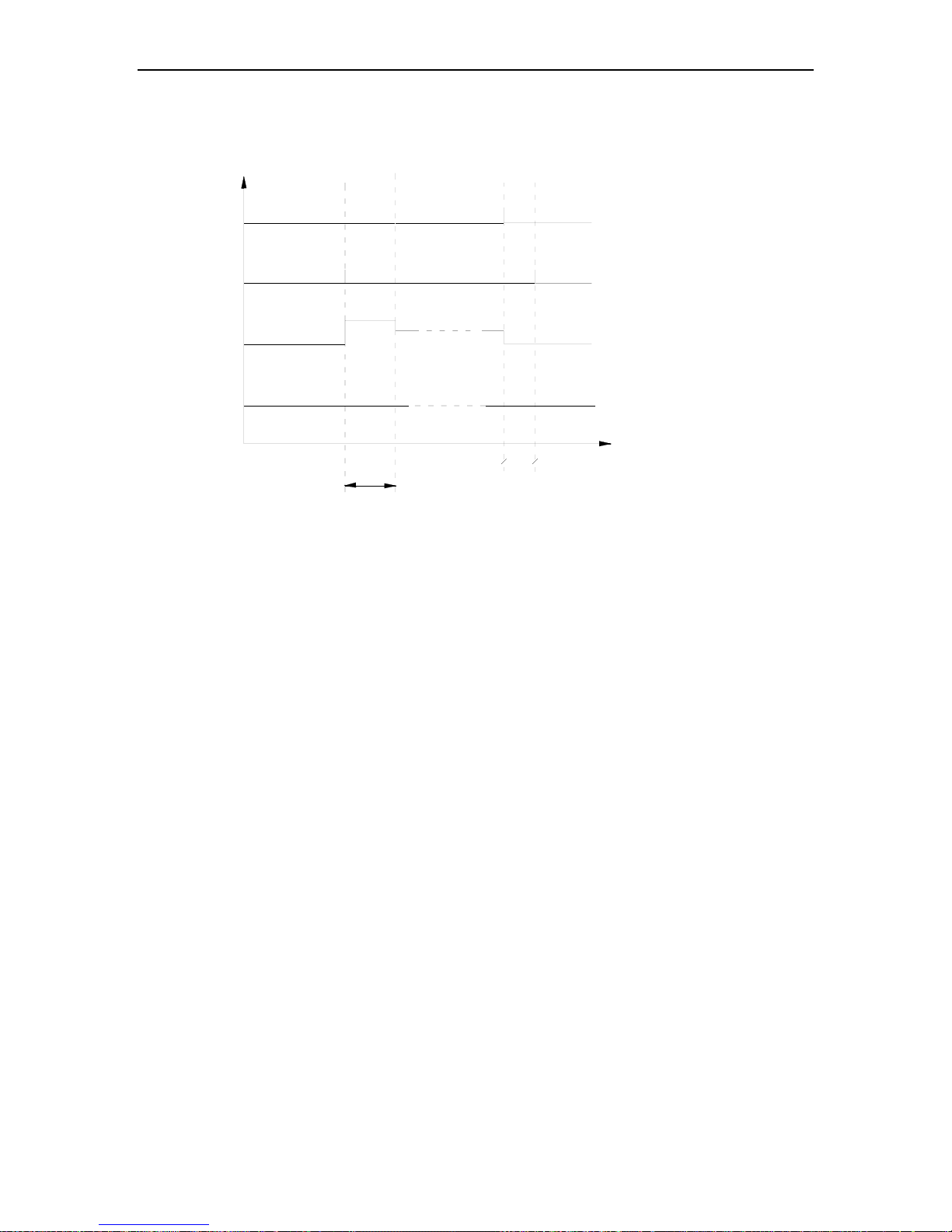

2.4 Defrosting

ON

ON

OFF

ON

Z

Heating/Defrosting Time sequence chart

Defrosting

marking

Defrosting frequency

Compressor

35Hz

Outd oor fa n

Energized

De-energized

Indoor fan

Auxilary power

Defr ostin g

end s

Condition for ending

the defro st

OFF

OFF

Time

Meet the conditions for

ending the defrost

Acc.to the conditions for

starting the auxiliary power

Cold air prevention

Fixed step Y

Adjust according to control logic

High fan

35Hz

Adjust per PI

Acc . to o utdo or fa n co ntro l logic

EXV

4-way valve

10s

3 min

10s

The conditions for starting the defrosting are as follows:

The defrosting is started when one of the following three conditions is satisfied:

The total time for outdoor defrost sensor to run below 3 is longer than 40 minutes and this temperature is kept

lower than -6 for over 3 minutes.

The outdoor temperature sensor keeps lower than 3 ℃ for at least 80 minutes and keeps lower than -4 ℃ for at

least 3 minutes.

The outdoor temperature sensor keeps lower than 3 ℃ for at least 120 minutes and keeps lowers than -3 ℃ for

at least 3 minutes

The conditions for ending the defrosting are as follows:

The defrosting is ended when one of the following three conditions is satisfied:

When the temperature of outdoor heat exchanger rises to higher than 10 .

When the temperature of outdoor heat exchanger rises to higher than 8 and this lasts for over 80 seconds.

When the defrosting keeps for 10 minu tes.

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

29

2.5 Fan Mode

Fan Mode

Compressor

Outdoor

fan

4-way valve

Start

Time

Indoor fan

5s

Run at present

speed

Manual speed

OFF

OFF

OFF

OFF

OFF

OFF

High fan

The indoor fan will run at high speed for 5 seconds before running at preset speed

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

30

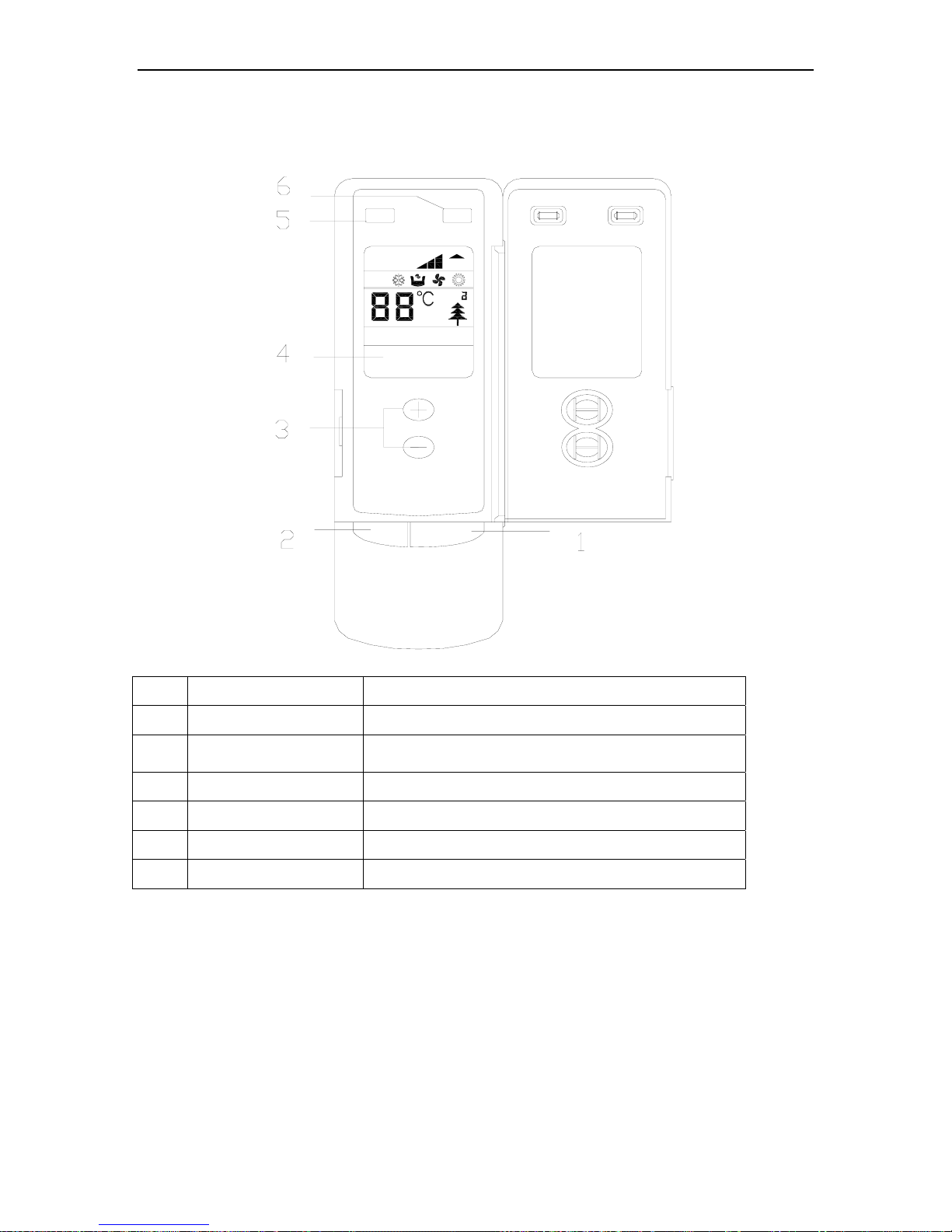

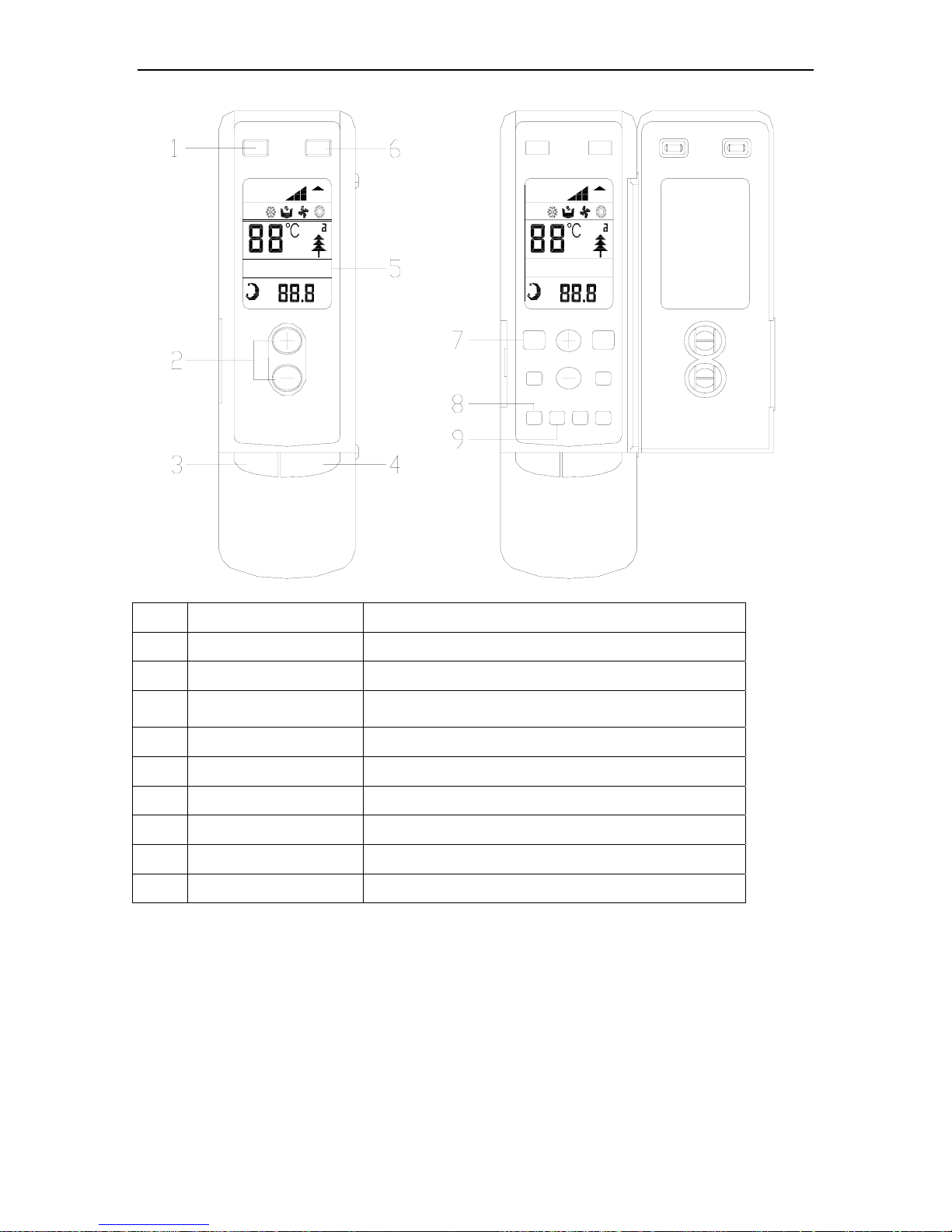

3 WIRELESS REMOTE CONTROLLER

3.1 Operation View

3.1.1 Controller-Duct Type

ON/OFF

MODE

AUTO FAN

SWING

AUTO

SWING

OPER

AIR

FAN

NO. Name Function description

1 ON/OFF button Press the button to set turning on/off the unit

2 Mode button

Press the button to select the mode,

cooling , heating , fan or auto mode.

3 Increase/Decrease button Press this button to increase/decrase the setup temp

4 LCD Screen Display the status of remote information

5 Swing button Press this button set swing function

6 Fan speed button Press this button to set fan speed

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

31

3.1.2 Controller-Cassette Type and Ceiling Type

ON/OFF

MODE

LIGHT

AUTO

TIMER

ON/OFF

SWING HUMID

SWING

Auto Fan

SAVE

HR

AIR

FAN

OPER

TIMER

ON/OFF

ON/OFF

ANION

TIME OFFTIME ON

MODE

LIGHT

SLEEP

SAVE

HUMID

AIR

HR

LIGHT

AUTO FAN

SWING

HUMID

AUTO

SWING

SAVE

OPER

AIR

FAN

NO. Name Function description

1 Swing button Press this button to set swing function

2 Increase/Decrease button Press this button to increase/decrase the setup temp

3 Mode button

Press the button to select the mode,

cooling , heating , fan or auto mode.

4 ON/OFF button Press the button to set start or close unit

5 LCD Screen Display the status of remote information

6 Fan speed button Press this button to set fan speed

7 Sleep button Press the button to set sleep function

8 Time on Press the button to set time on function

9 Time off Press the button to set time off function

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

32

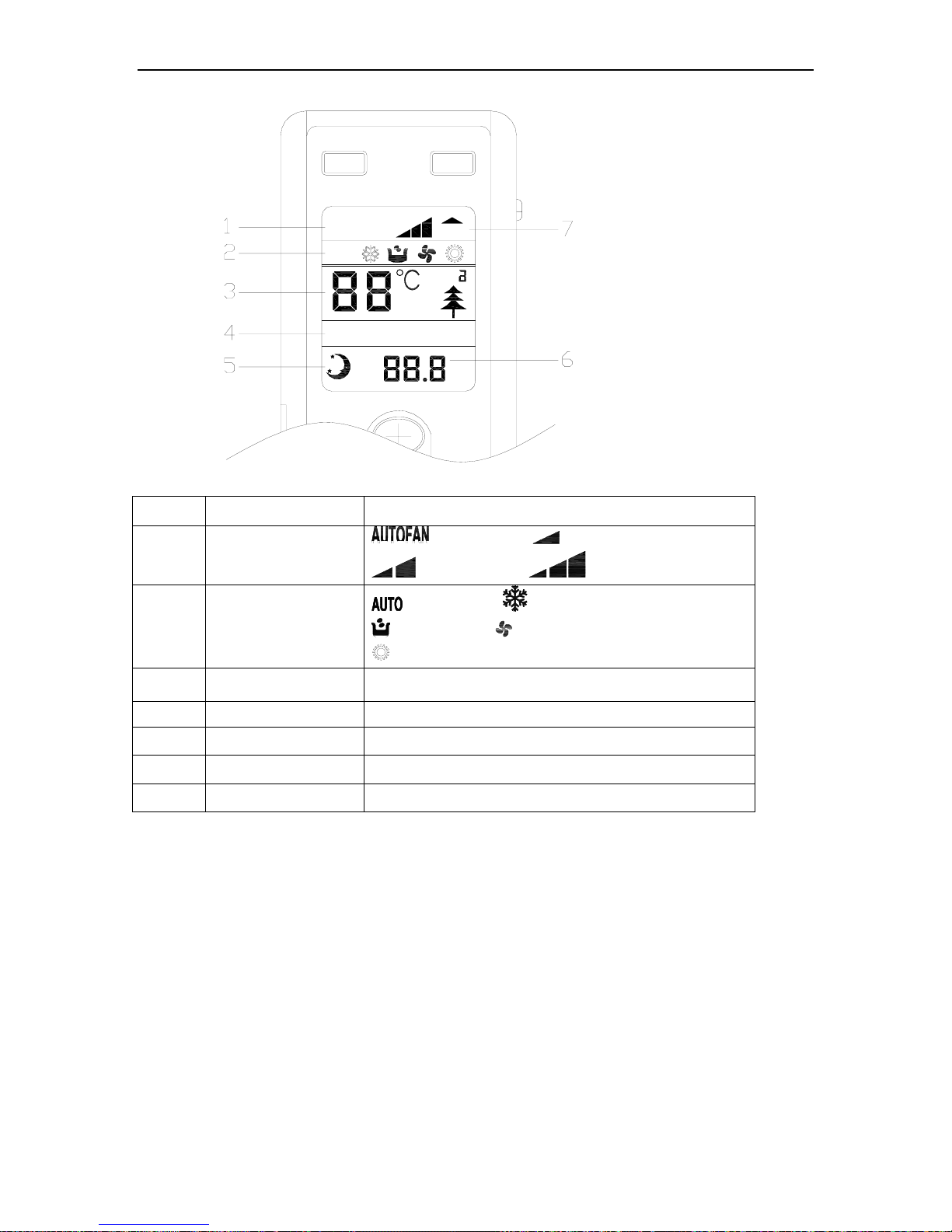

3.2 Display View

LIGHT

AUTO

TIMER

ONOFF

SWING

HUMID

SWING

AUTO FAN

SAVE

HR

AIR

FAN

OPER

No. Display Function description

1 Fan Speed

:auto fan speed, :low fan speed,

:middle fan speed :high fan speed,

2 Run Mode

:Auto running; :Cool running;

:Dry Running; :Fan Running;

:Heat running (Heat and Cool unit only)

3 Setup temp Temperature value of setting

4 Swing function Swing is on

5 Sleep mode Sleep mode is on

6 Time value Timing value of setting

7 OPER The controller is on

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

33

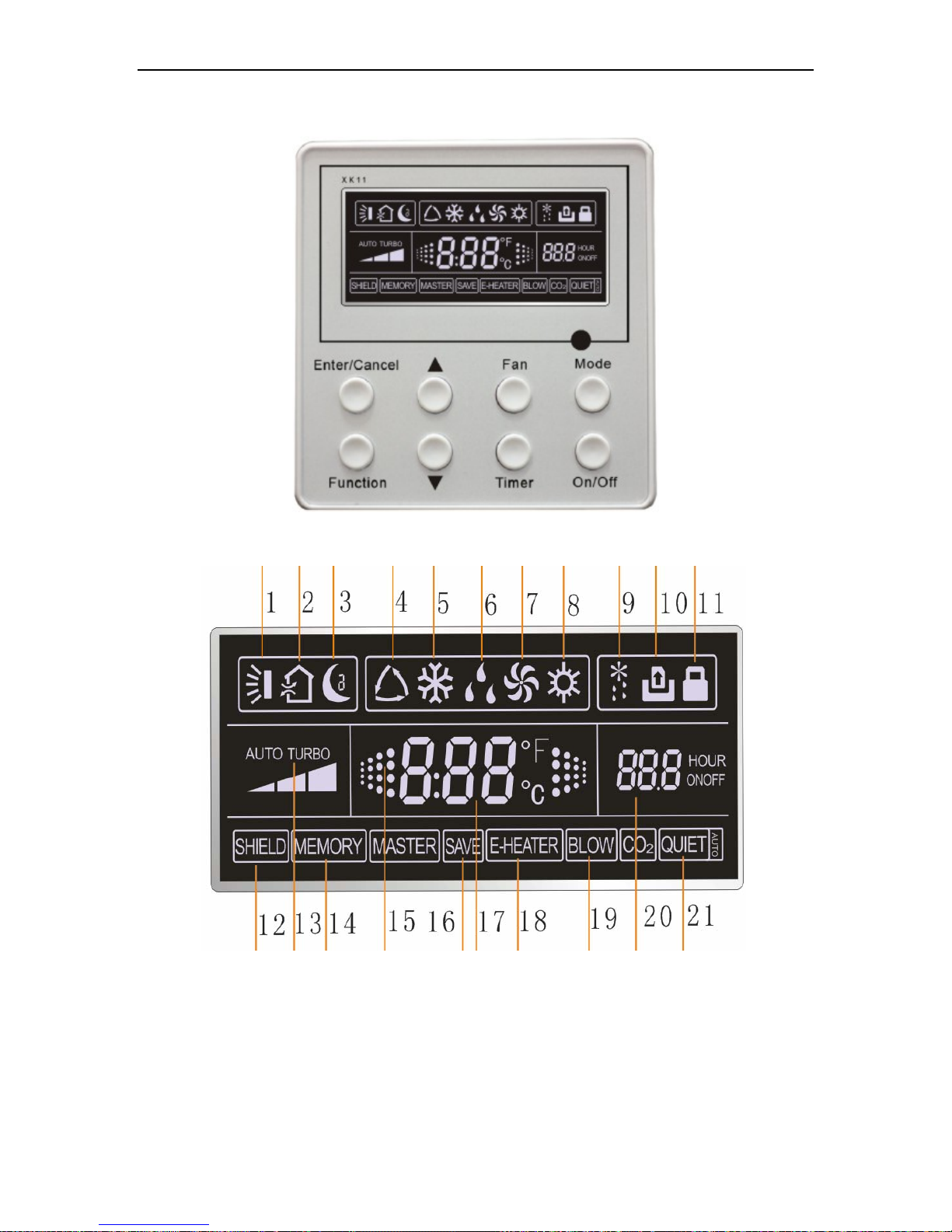

4 WIRED REMOTE CONTROLLER

4.1 Operation View

4.1.1 LCD Display of Wired Controller

.

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

34

4.1.2 Instruction to LCD Display

No. Description Instruction to Displaying Contents

1 Swing Swing function

2

Air

*

Air exchange function

3 Sleep Sleeping states

4 Running mode Each kind of running mode of indoor unit (auto mode)

5 Cooling Cooling mode

6 Dry Dry mode

7 Fan Fan mode

8 Heating Heating mode

9 Defrost Defrosting state

10

Gate-control

card

*

Gate control

11 Lock Lock state

12 Shield

Shielding state (buttons, temperature, on/off, mode or save is shielded by

long-distance monitoring

13 Turbo Turbo function state

14 Memory

Memory state (Indoor unit resumes original setting state after power failure and then

power recovery)

15 Twinkle Flicking when unit is on without operation of buttons

16 Save Energy-saving state

17 Temperature Ambient/setting temperature value

18

E-Heater

*

Mark that E-heater is allowed to turned on

19 Blow Blow mark

20 Timer Timer-displayed location

21 Quiet Quiet state(two types: quiet and auto quiet)

Notes: The functions with * are reserved for other models and are not applicable for the models

listed in this manual.

Table 4.1

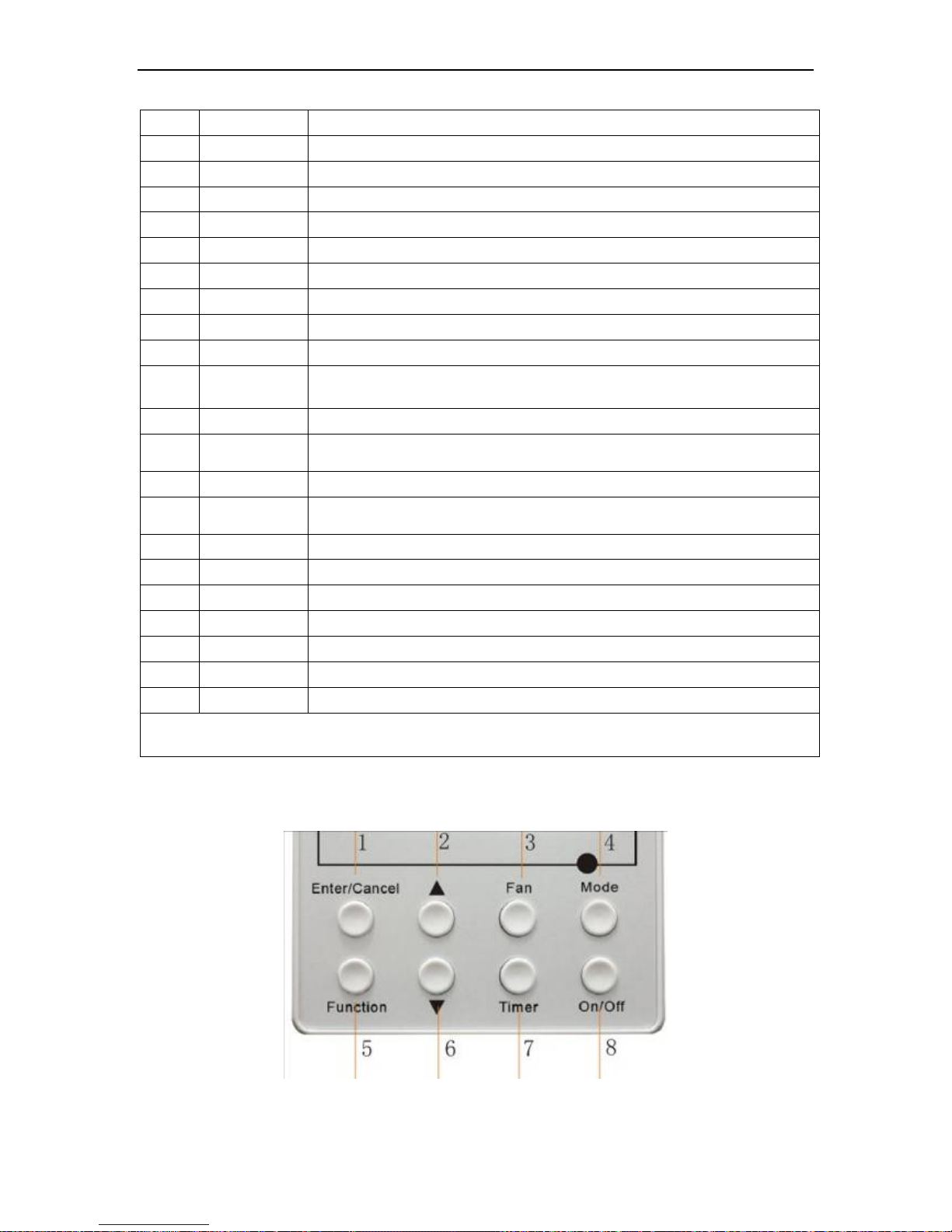

4.2 Buttons

4.2.1 Silk Screen of Buttons

Fig. 4-2-1 Silk screen of butto

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

35

4.2.2 Instruction to Function of Buttons

No. Description Function of Button

1 Enter/cancel

(1)Function selection and canceling;

(2)Press it for 5s to enquiry the outdoor ambient temperature.

2 ▲

6 ▼

(1)Running temperature setting of indoor unit, range :16~30℃

(2)Timer setting, range:0.5-24hr

(3)Switchover between quiet/auto quiet

3 Fan Setting of high/middle/low/auto fan speed

4 Mode Setting of cooling/heating/fan/dry mode of indoor unit

5 Function

Switch over among these functions of

air/sleep/turbo/save/e-heater/blow /quiet

7 Timer Timer setting

8 On/off Turn on/off indoor unit

4 Mode

and

2 ▲

Memory function

Press Mode and ▲for 5s under off state of the unit to enter/cancel key

memory function (If memory is set, indoor unit will resume original

setting state after power failure and then power recovery. If not, indoor

unit is defaulted to be off after power recovery. Memory function is

defaulted to be off before outgoing.)

2 ▲

and

6 ▼

Lock

Upon startup of the unit without malfunction or under off state of the unit,

press ▲ ▼ key at the same time for 5s in to lock state. In this case, any

other buttons won’t respond the press. Repress ▲ ▼ key for 5s to quit

lock state.

4 Mode

and

5 Function

Enquiry and setting of

address of wired

controller

Under the off-state of the unit, press Mode/Function button for 5

seconds to set the address.

5 Function

And

7Timer

Setting Ambient

Temperature Sensor

and three Grades of

Speed for Indoor Fan

Under off state of the unit, press Function and Timer buttons

continuously for 5s to go to the debugging menu. Press Mode button to

adjust the setting items and ▲ or ▼ button to set the actual value.

5 Function

and

6▼

Enquiry of Historical

Errors

Continuously press Function and ▼ buttons for 5s to go to the enquiry

state. In this state, press Enter/Cancel button to quit, or it will

automatically quit after there is not any operation of button in 30min

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

36

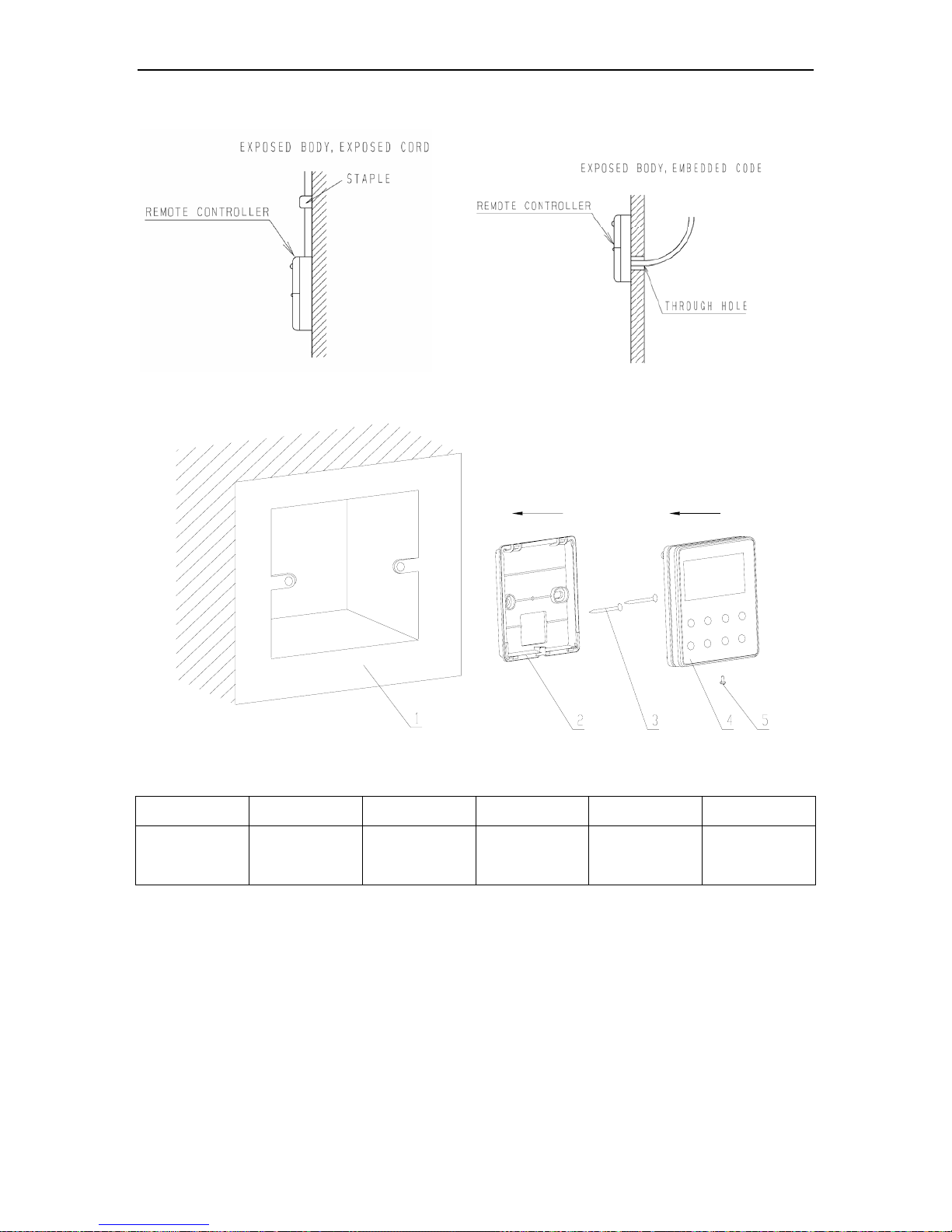

4.3 Installation of Wired Controller and Project Debugging

4.3.1 Installation of Wired Controller

Fig.4.3.1: Fig.1

Surface mounting of Cable Fig.4.3.2: Fig.2 Concealed mounting of Cable

Fig.4.3.3: Sketch for Installation of Wired Controller

No. 1 2 3 4 5

Description

Socket’s base

box installed in

the wall

Soleplate of

controller

Screw M4X25

Front panel of

controller

Screw ST2.2X6.5

Fig.4.3.3: Sketch for Installation of Wired Controller. Pay attention to the following items during installation of wired

controller:

1. Cut off power supply of heavy-current wire embedded in mounting hole in the wall before installation. It is

prohibited to perform the whole procedure with electricity.

2. Pull out 4-core twisted pair line in mounting hole and then make it through the rectangle hole at the back of

controller’s soleplate.

3. Joint the controller’s soleplate on wall face and then fix it in mounting hole with screws M4X25.

4. Insert the 4-core twisted pair line through rectangle hole into controller’s slot and buckle the front panel and

soleplate of controller together.

5. At last, fix the controller’s front panel and soleplate with screws ST2.2X6.5.

A/A DC INVERTER U-MATCH AIR CONDITIONERS CONTROL

37

Caution:

During connection of wirings, pay special attention to the following items to avoid interference of electromagnetism

to unit and even failure of it.

1. To ensure normal communication of the unit, signal line and wiring (communication) of wired controller should be

separate from power cord and indoor/outdoor connection lines. The distance between them should be kept 20cm

in min.

2. If the unit is installed at the place where there is interference of electromagnetism, signal line and wiring

(communication) of wired controller must be shielded by twisted pair lines.

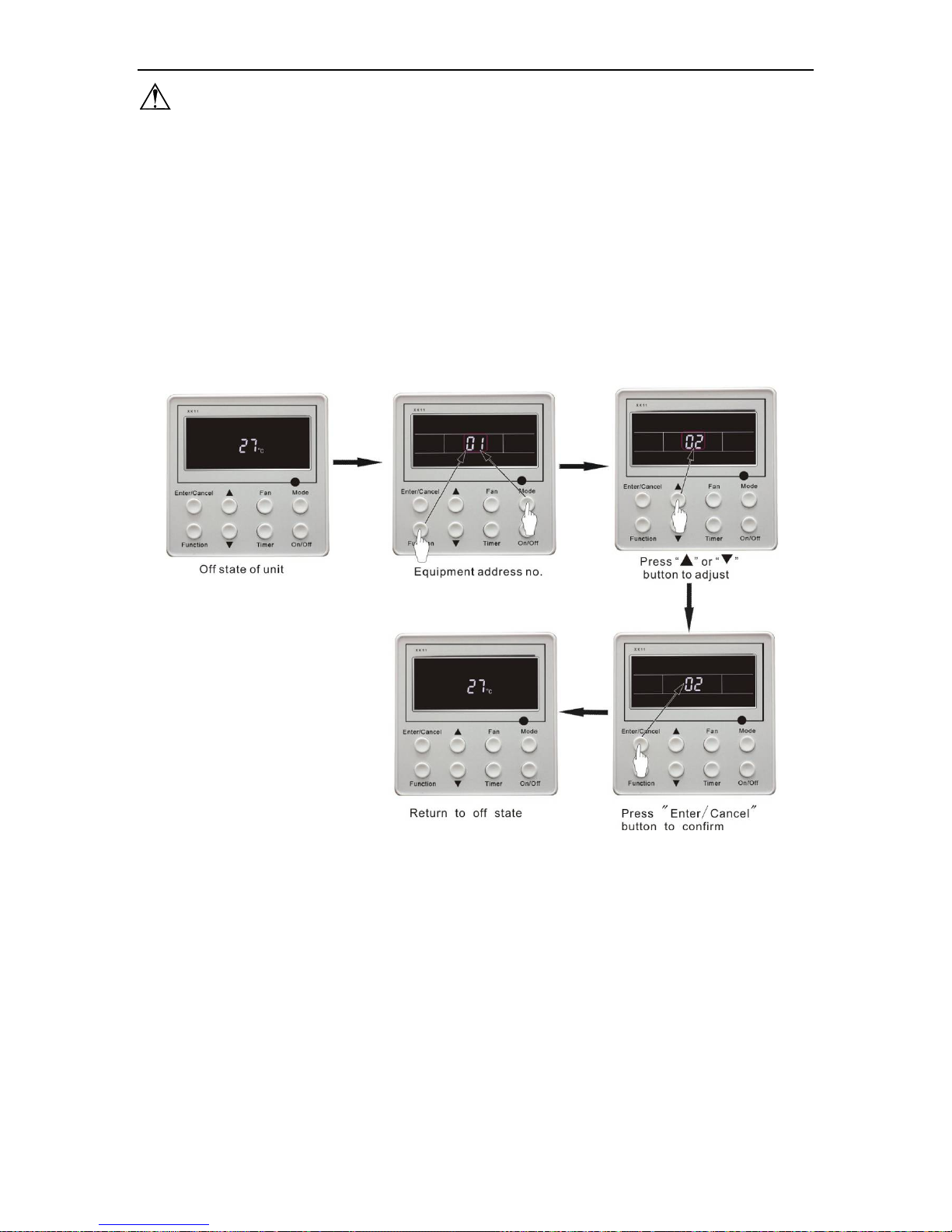

4.3.2 Project Debugging

Enquiry of wired controller’s address: Press Function and Mode buttons at the same time for 5s under off state

of the unit, and then LCD displays wired controller’s address number.

Setting of wired controller’s address: Press Function and Mode buttons at the same time for 5s.In this case,

LCD displays address number. Then press ▲ or ▼ button to adjust address (address no.:1-16) .After that, press

Enter/cancel button to confirm.

Addresses of the wired controller are used for centralized control of wired controller. Enquiry and setting of

wired controller’s address is shown as Fig.4.3.4 below:

Fig.4.3.4: Enquiry and Setting of Wired Controller’s Address

Loading...

Loading...