Vivax ACP-24COFM70GEI, ACP-28COFM80GEI Service Manual

ACP-24COFM70GEI

ACP-28COFM80GEI

RoHS

Service

manual

ENG

Note: The above data is subject to change without notice. Please refer to the nameplate of the unit.

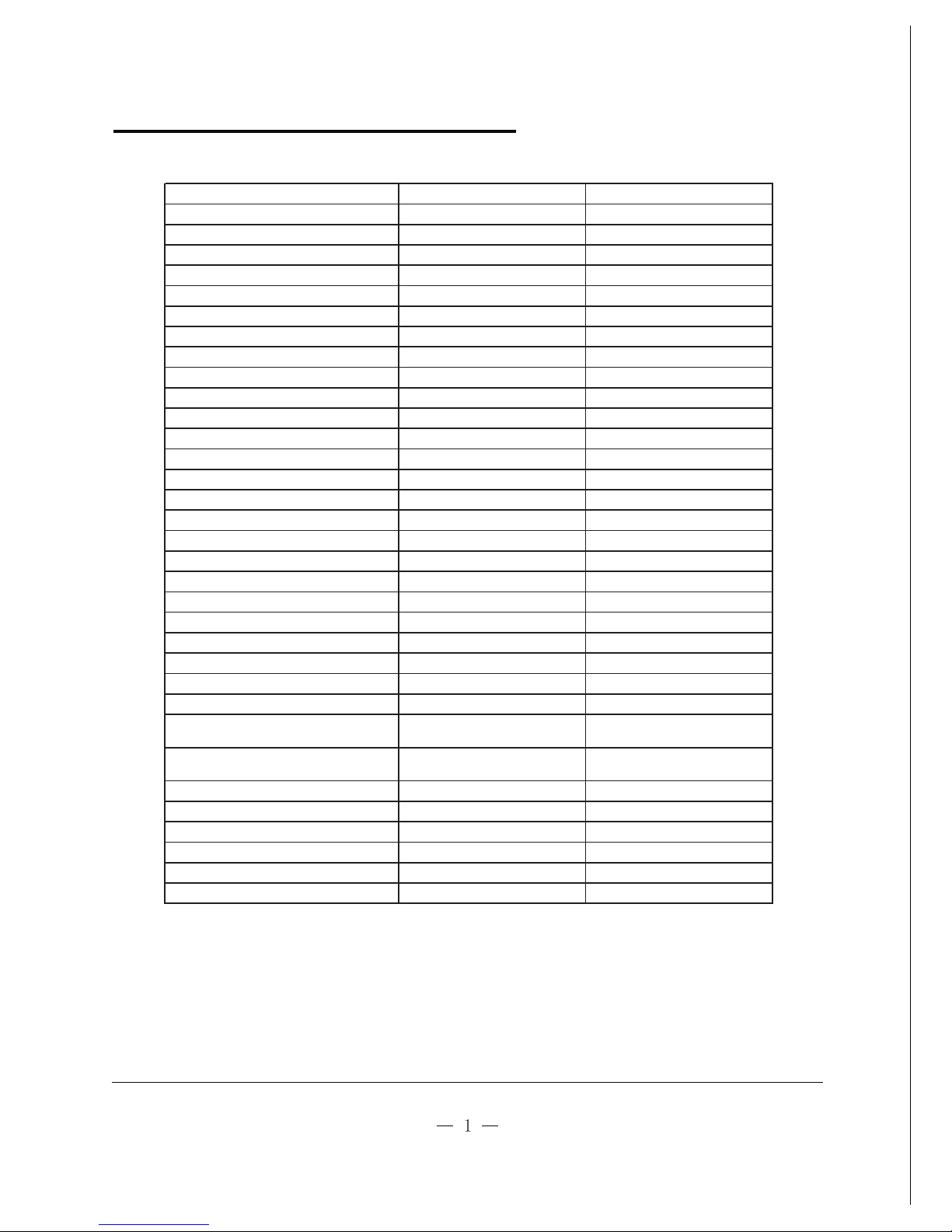

1.Technical specifications

1.Technical specifications

ACP-24COFM70GEI ACP-28 COFM80GEI

Shenyang SANYO /SA NYO Shenyang SANY O / SANY O

C-7RZ233H1A C-7RZ233H1A

Rotary Rotary

34 34

8.2 8.2

1760 1760

1NT11L-3979 1NT11L-3979

Electronic E xpansion Valve Electronic E xpansion Valve

Tr ansducer st ar ting Transducer star ting

-10°C ≤ T ≤ 43°C

-10°C ≤ T ≤ 43°C

Aluminum fin- copper t ube Aluminum fin- c o ppe r tube

Φ9.52 Φ9.52

2-1.4 2-1.4

806X813X44 806X813X44

860/760/540 860/760/540

60 60

0.3 0.3

33

//

Ax ia l fan 1Axial fan 1

460 460

A u t o defrost A uto defr ost

T1 T1

II

IP24 IP24

3.8 3.8

1.2 1.2

60/54 60/54

69/68 69/68

950X840X420 950X84 0X420

1100X450X905 1100X450X905

75/80 75/80

R410a/3.3 R410a/3.3Refrigerant Charge (kg)

Compressor Manufacturer/ trademark

Compressor Model

Compressor Type

Moisture Protection

Permissible Excessive O per atin

g

Pressure for the Discharge Side(MPa)

Permissible Excessive Operatin

g

Pressure for the Suction Side(MPa)

Sound Pressure Level dB (A) (H/M/L)

Fan Diameter (mm)

Defrosting Method

Climate Type

Isolation

Mo de l

L.R.A. (A)

Com pres s or RLA(A)

Com pres s or Power Input(W)

Overload Protector

Throttling Method

Fan Type-Piece

Rows-Fin Gap(mm)

Sound Power Level dB (A) (H/M/L)

Dimension (W/H/D) (mm)

Dimension of Package (L/W/H)(mm)

Net Weight /Gross Weight (kg)

Fan Motor RLA(A)

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit

Starting Method

Working Temp Range (ć)

Condenser

Pipe Diameter (mm)

Coil length(l) x height(H) x coil width(L)

Fan Motor Speed (rpm) (H/M/L)

Output of Fan Motor (W)

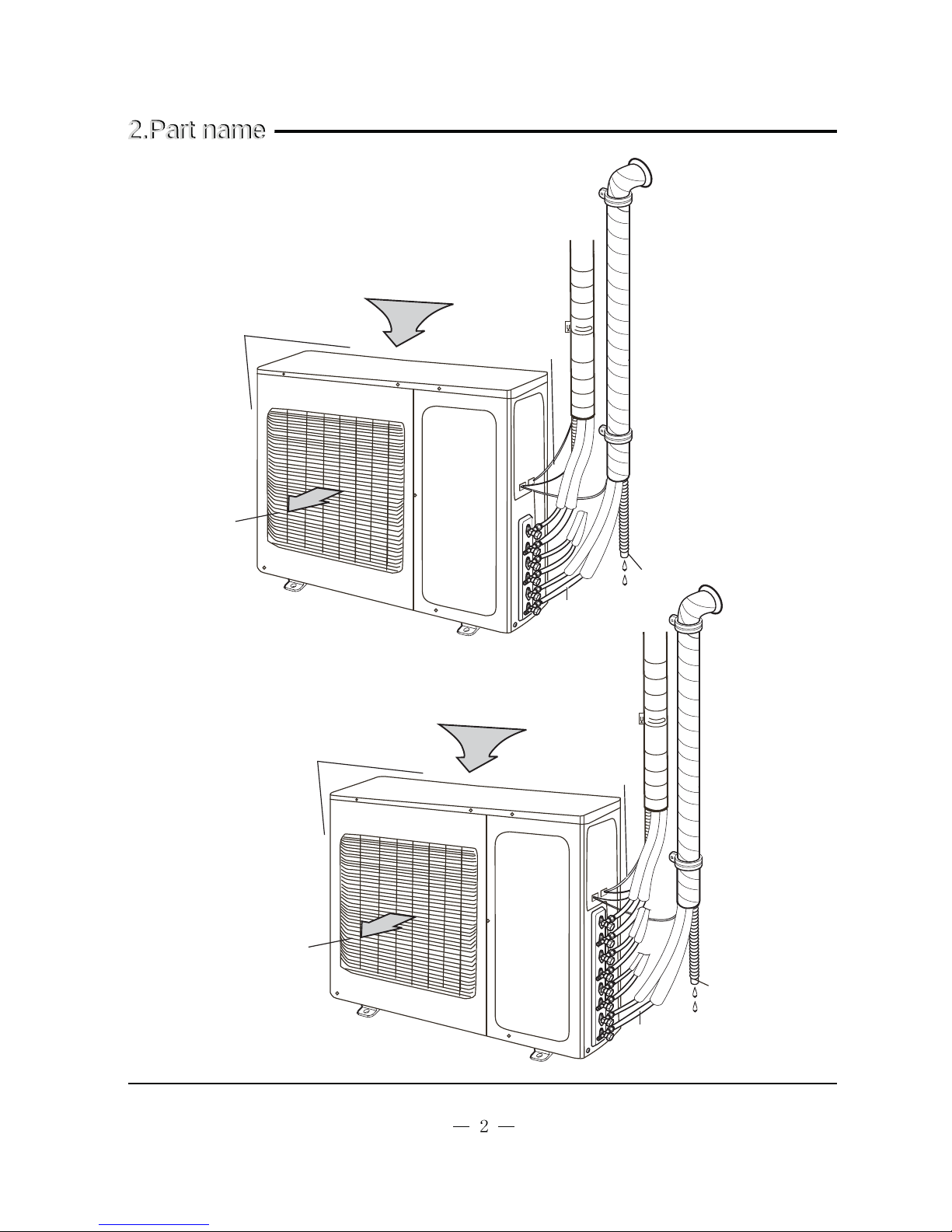

Air intake

Air outlet

Connection pipe

Drainage hose

Connection wire

Air intake

Air outlet

Drainage hose

Connection wire

Connection pipe

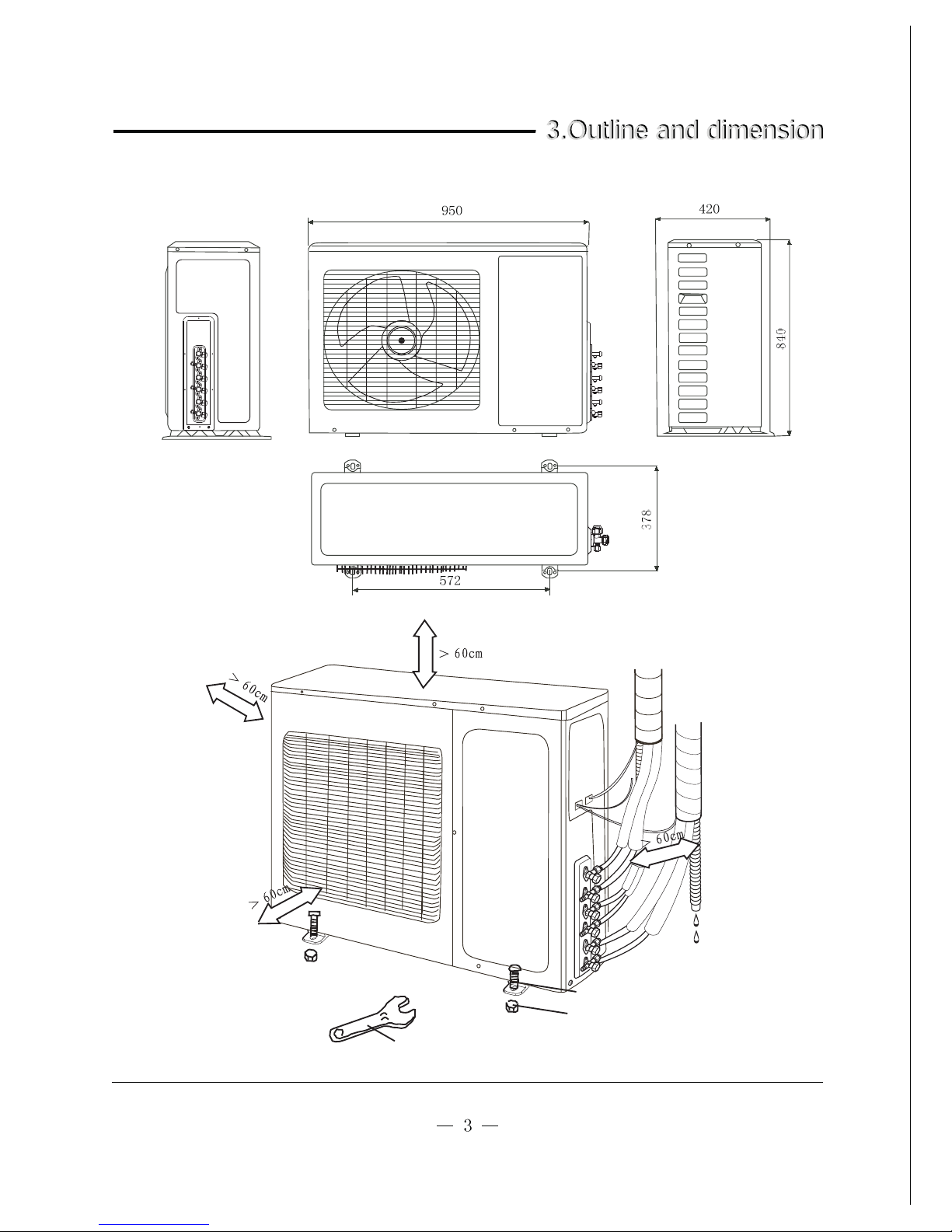

Model: ACP-24COFM70GEI

Model: ACP-28COFM80GEI

Wrench

Bolt

Nut

Unit: mm

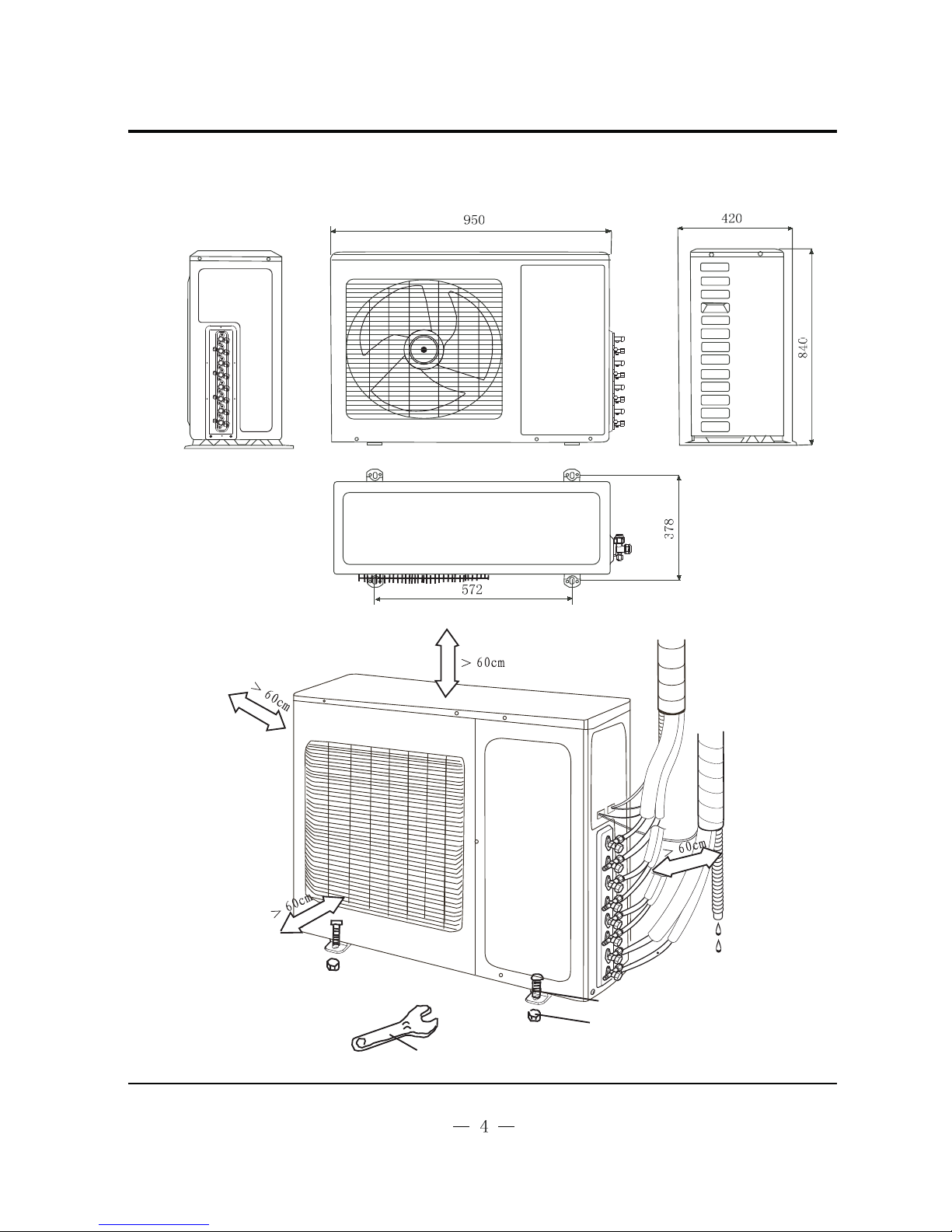

Model: ACP-24COFM70GEI

Wrench

Bolt

Nut

Unit: mm

Model: ACP-28COFM80GEI

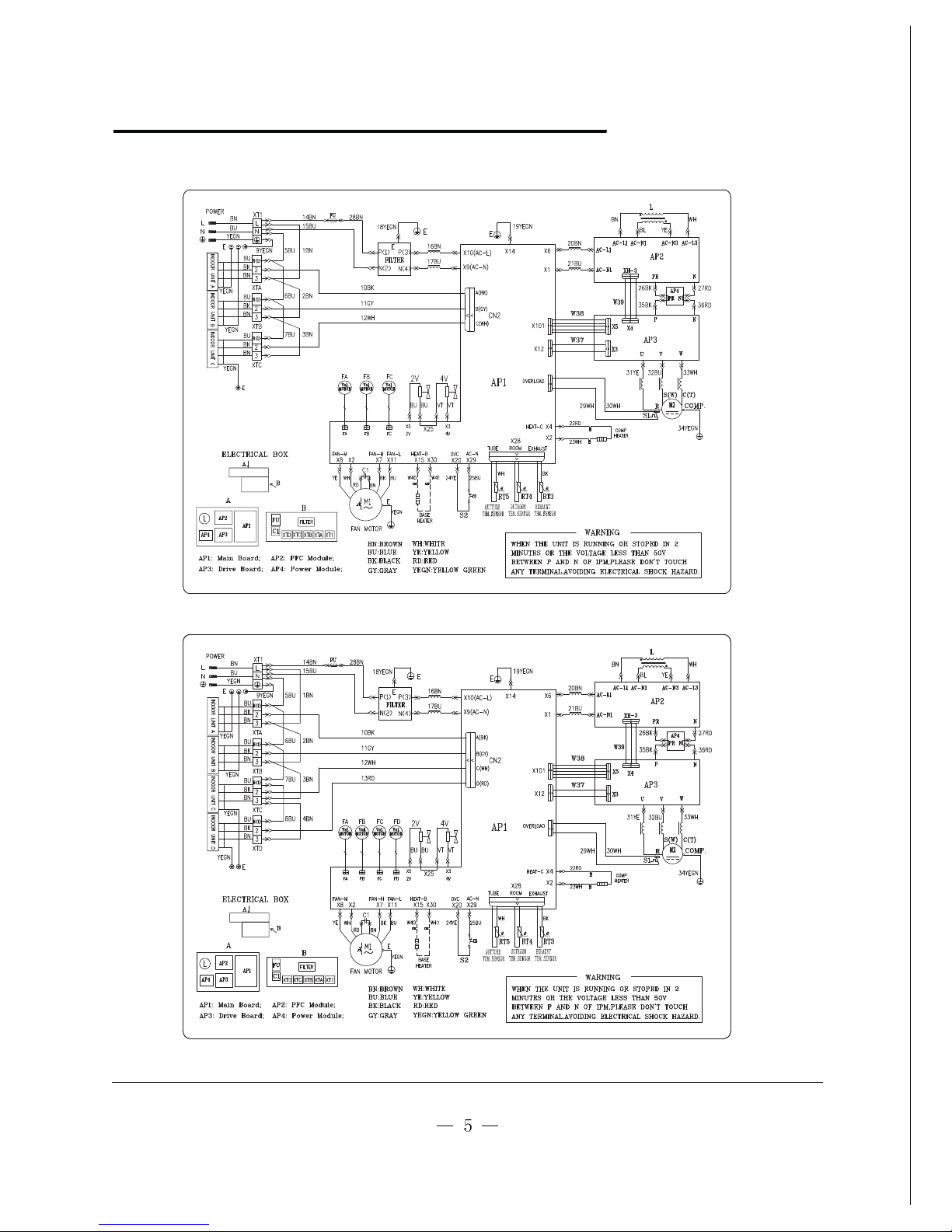

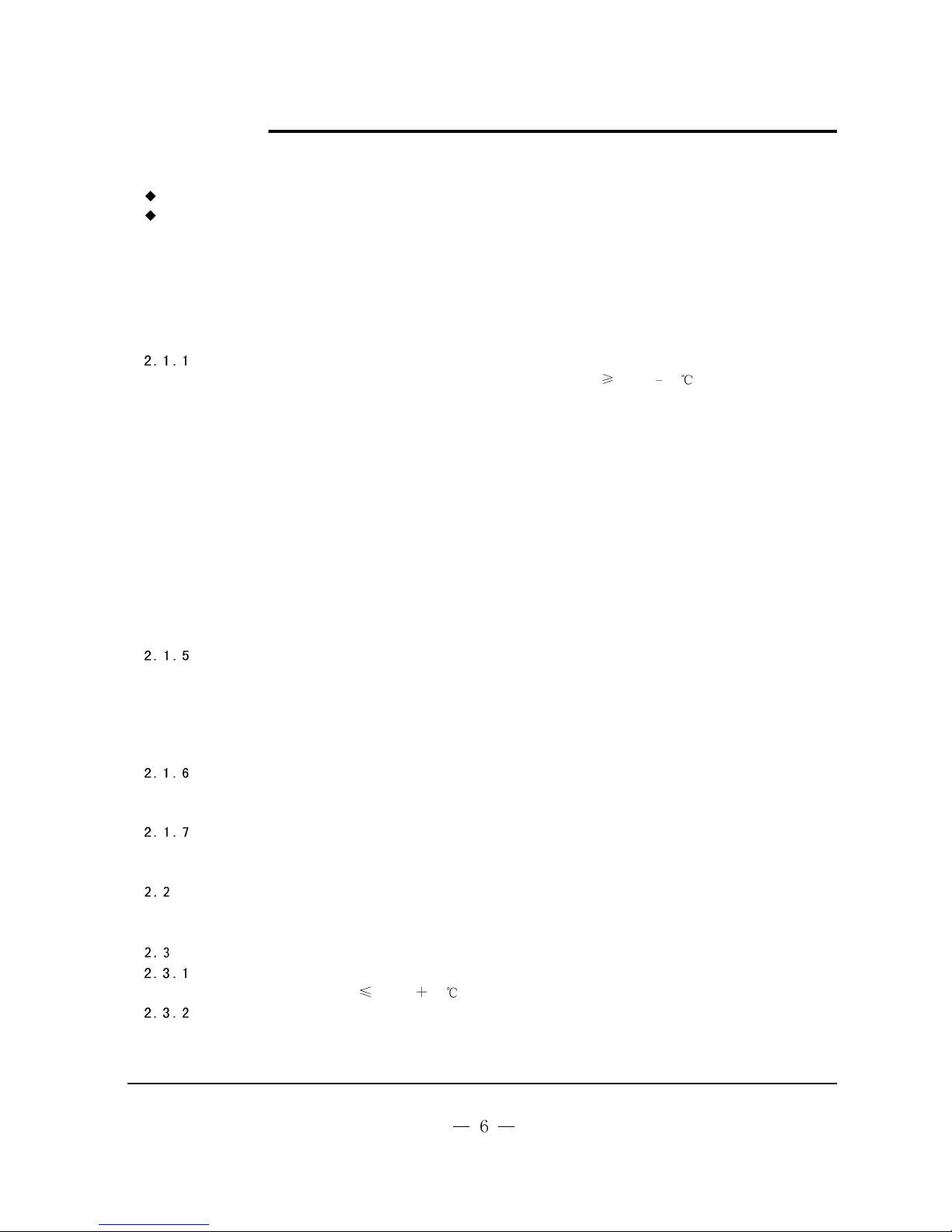

4.Wiring Diagram

4.Wiring Diagram

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

Model: ACP-24COFM70GEI

Model: ACP-28COFM80GEI

2SHUDWLRQ

2SHUDWLRQ

1.Temperature parameters

Indoor ambient temperature (Tinner ambient)

Indoor setting temperature (Tset)

2.System first power on

2.1 Cooling mode

2.1.2 Unit will stop for cooling

(1) Compressor will stop running

2.1.4 4-way valve control

Under this mode, 4-way valve will close (that is not electrified).

2.1.3 Switching from cooling mode to heating mode

Anti-freezing protection

Dehumidify mode

Heating mode

Unit will stop for heating

Working condition and procedure of cooling running

Cooling oil return condition

Outdoor unit fan motor control under cooling mode

Working condition and procedure of heating running

(2) Part of indoor unit arrive at unit stop running condition (Compressor will not stop)

When any one of indoor unit Tindoor amb Tpreset 2.5 , will start heating mode (turns on the heating and arrive at the unit on temperature)

Working condition and procedure of dehumidifying: the same with Cool mode; Protection function: the same with Cool mode. Close up 4-way

valve. The single unit capacity requirement percent of dehumidifying mode max. value is the cooling mode 90%, outdoor fan motor, compressor

start up condition is the same with that in Cool mode.

All indoor units arrived at unit off or unit stop condition: compressor will stop, outdoor fan unit will delay 1min will stop, all the elctrictron expansion

valve will start to work, when all valves turn to OP adjustment, the side valve will electrified, when turn the valve to 480P, the side valve will not

electrified.

After electrified, the side valve will be powered on, each electron expansion valve will be turned off orderly, then side valve will be powered off,

all the electron expansion valve should be turned to a certain angle, the unit on is standby.

Under each modes, once the compressor starts up, at least running for 7mins the unit will stop (not including

malfunction protection, modes switch the compressor needed to stop running);

Once compressor stopped, the unit will start up after 3mins delay (Heating oil return or defrosting except).

When cooling oil return, after compressor frequency rise up to 70Hz, it will stayabily run; Outdoor fan motor will accord to indoor unit will run at current

fan speed and after 1min delay to stop.

rating capacity total capacity and temperature automatically adjust the fan speed.

The oil return lasting time of cooling will be 5min. (including frequency rising time), oil return will be completed.

Compressor will stop running right away, outdoor fan motor will delay 1min and will stop running, all the electron expansion valve starts to work, when

turns off all valves at OP, the side valve will be electrified, the valve fully turns to 480P, the side valve will turn off.

When turning to heating mode, after compressor stopped, 4-way valve will electrify after 2mins delay, the others are the same with cooling.

If compressor stopped and turn on the unit for cooling, if any one indoor unit (T

indoor amb. Tpreset) 0.5 , that the cooling will run;

at this time, the outdoor fan motor, compressor starts to run, the compressor frequency will run at the capacity requirement calculated.

When it is satisfied with anti-freezing protection, the system will enter into anti-freezing protection, at this time only some of the indoor unit anti-freezing

protection, indoor capacity will be set as 0; when all running indoor unit act the anti-freezing protection, the unit will process as Cool mode. When it is

satisfied with the anti-freezing protection finished, the anti-freezing protection will be finished.

Compressor will run according to capacity requirement calculated frequency, when capacity requirement is 0 indoor unit corresponding electron

expansion valve 5s turns off, compressor frequency variable start meanwhile running indoor unit (no matter it is newly opened or indoor unit

has been run) the corresponding electron expansion valve resumes to the original value.

NOTE: Unit off, Fan, Protection as the same with Cool mode;

Before compressor start 5s start cooling, after outdoor fan motor start up and run in high speed for 3min, then according to the indoor unit rated capacit

y

total amount and outdoor ambient temperature, automatically select High, Mid, Low three fan speeds.

Other control: When the newly opened indoor unit is running, outdoor fan motor will run at high fan speed for 40s, then according to control logic to

adjust. Fan motor each grade at least run 80s (when indoor unit running quantities change and calculate indoor unit rated capacity total amount

and according to temperature to adjust the fan speed.) When compressor stops running, outdoor fan will run at

2.4 System protection function

2.4.1 Indoor unit modes confliction protection

2.4.3 Air exhaust temperature protection

2.4.4 Communication malfunction

2.4.5 Module protection

Communication malfunction: when continuously 3mins hasn’t received the correct signal of all the installed indoor unit or

within 10s, cannot receive the correct signal from the drive board that are communication malfunction, the outdoor unit

will stop running.

Communication malfunction happened during defrosting, will process as following: multi unit heating, defrosting break off start part of

indoor unit communication wire, go on defrosting, until defrosting finished then make response to indoor unit communication malfunction.

2.4.2 Overload protection (Anti-high temperature protection)

2.3.5 Defrosting

2.3.4 Outdoor fan control

2.3.3 Turns to Cooling (dehumidifying), Fan modes

2.3.6 Heating oil return control

Indoor unit installation quantities test: after powered on, within 3mins, outdoor unit hasn’t received the communication data from some indoor unit,

that outdoor unit wiill judge this indoor unit haven’t installed. Outdoor unit will not communicate with indoor unit.

Compressor will stop when module protect, when indoor temperature arrive at presetting temperature, the unit will stop running, compressor

has stopped 3mins, it will automatically resume to running status.(If in defrosting procedure, after 180s later that will resume); If the continuous

protection times excess 6 times ( if compressor running time excess 7min, that the protection times will clean to 0), the system will turn off the

unit and sent wrong signal to outdoor unit, it cannot resume to running status; It is need to resume after powered on.

Compressor stop running; four-way valve will delay 2min and powered off; outdoor fan will delay 1min and stop running; 4-way valve will

electrified. All the expansion valve will turn to OP for adjustment, the side valve will electrify, the valve will fully turn to 480P, the side valve

will power off.

If the preset of indoor unit is different, according to the following for running:

a. Consider the first running indoor unit mode as the standard mode, other indoor units modes compared to this mode and judge whether

there is conflict happened. Cool mode (Dehumidifying) conflicts with Heat mode.

b. Fan mode conflicts with Heat mode, consider heating as the basic mode, no matter the sequence of units turns on, indoor units conflict,

will run in heating mode.

When satisfied with defrosting condition, the system will enter into defrosting,at this time the compressor will stop running; All electron expansion

valve will turn to 480P; after compressor stop 40s later, outdoor fan will stop, meanwhile the four-way valve will reversal; after 4-way valve reversed

all electron expansion valve will turn to 150p, after expansion valve turned to preset positio, compressor starts up and frequenctly run (frequency limit,

frequency droop will be effective). When defrosting condition finished has been satisfied, defrosting will finish.

When Ttube temperature is tested very low, compressor will run rise frequency; when the temperature is tested very high, the compressor

will run at frequency limit or frequency drop; if Ttube is very high, compressor will stop running.

If the tube temperature overload protection 6 times continuously happened that the compressor cannot resume to run, it needs to power

on then it can resume. During the operation, if compressor running time exceed 7mins, the overload protection times will clear to 0.

When detected the Tair exhaust is very high,frequency rise is forbidden; If detected the Tair exhaust is very high, compressor will run at drop

frequency; If detected the Tair exhaust is too high and excessive, compressor will stop for 3mins, if Tair exhaust resume to normal that the

compressor, outdoor fan will resume to run.

If the Tair exhaust temperature protection has continuously happened for 6 times that the compressor cannot resume.

it needs to power on then can resume. (If compressor running time exceed 7mins, the protection times will clear to 0).

Heating start up and compressor start up before 5s running, after outdoor fan start up and run in high speed 80s, then according to indoor

unit rated capacity total amount and outdoor ambient temperature will automatically select Hig, Mid, Low three fan speed.

When heating running and produce oil return condition, then send the oil return signal to indoor unit, indoor unit will execute as oil return

operation; Compressor will stop running, all electron expansion valve of indoor valve will turn to 480P (all electron expansion valve turns

to 480P then side valve will turn on); Compressor stops 40s later, 4-way valve will reversed. Outdoor fan: Firstly run at high speed 40s

(Before this, if low fan speed rotate to high fan speed 40s; At this time, if it run at high fan speed that will maintain high fan speed runs

for 40s), 4-way valve reversed, all electron expansion valve will turn to 150P; Expansion valve will turn to preset position, the compressor

will start up and runs at high frequency in a certain frequency.

When oil return maintain time arrives 5mins, will finish.

Other control: newly open indoor unit for running, outdoor fan motor will run at high speed for 40s right away, then adjust according to

control logic. Fan motor each speed runs 80s at least (Indoor unit running quqntity changed, will calculate the total amount of indoor unit

rated capacity and according to the temperature to adjust the fan speed.) When compressor stop running, outdoor fan motor will stop

after 1min delay. When tout ambient 15 and indoor unit stop running or unit off, meanwhile the outdoor unit will stop running, 30s

later, restart again.

2.4.6 Compressor high pressure protection

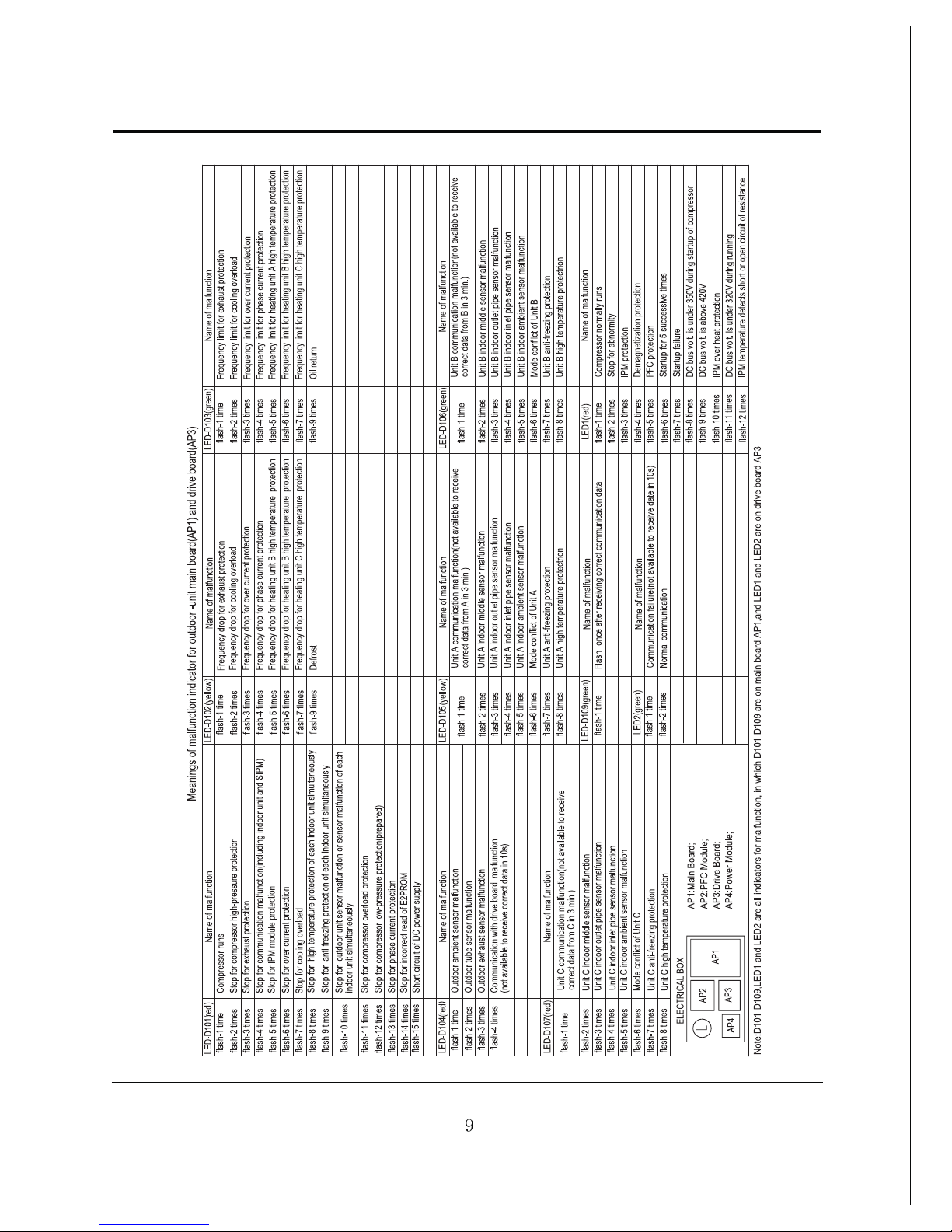

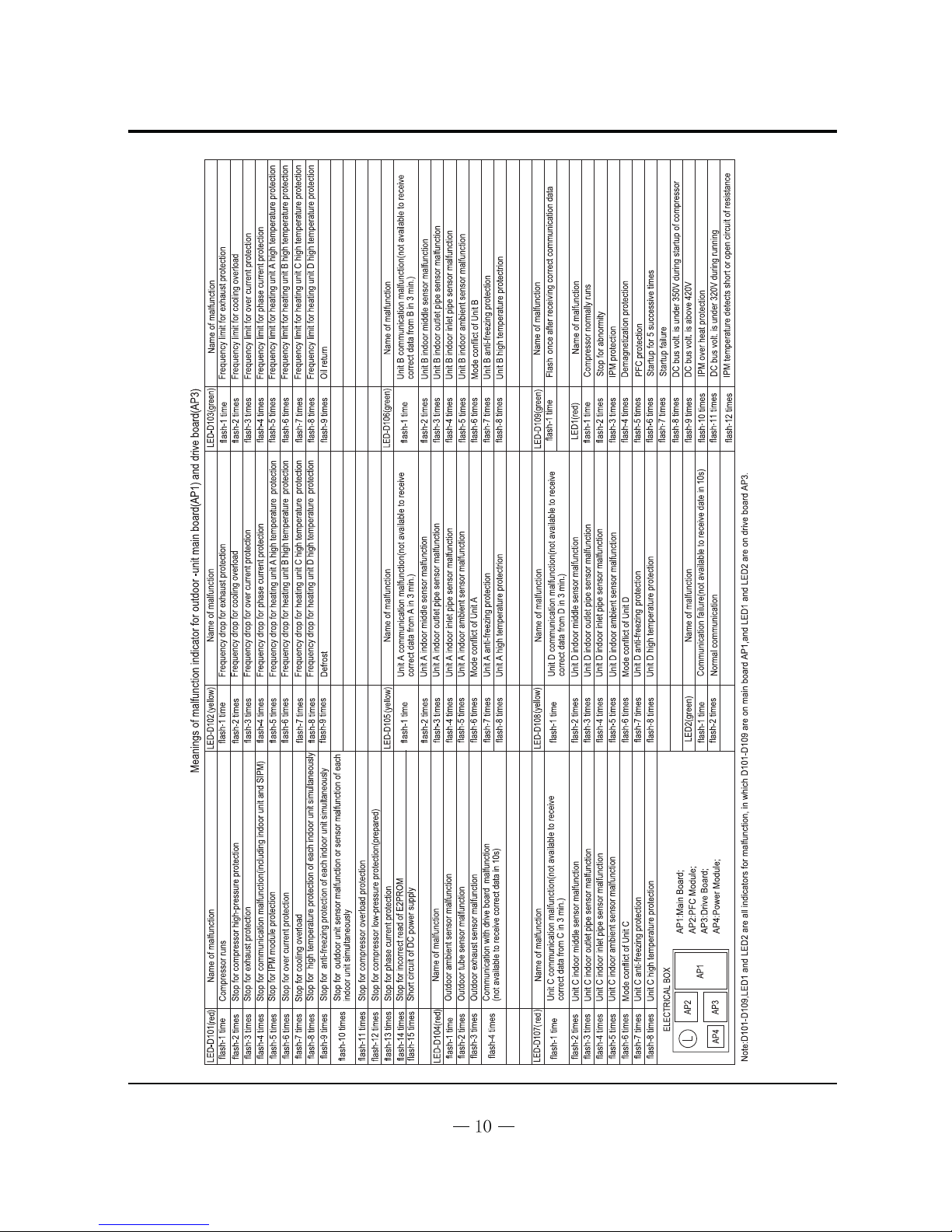

2.5 Malfunction indicator

2.4.10 Sensor malfunction testing

(1) At unit standby do not test the malfunction of outdoor tube sensor, ambient sensor;

(2) Under Heat mode, compressor continuously run 3mins later, start to test the air

exhaust sensor malfunction, under other modes for testing all along;

(3) Under Heating mode, compressor start up within 10mins, after Defrosting, Heating

oil return later within 10mins, do not test outdoor tube sensor malfunction;

(4) After other outdoor sensor turned on, test the malfunction right away, outdoor each

sensor continuously test 30s;

(5) After the sensor malfunction has been tested, stop the unit right away.

2.4.7 Compressor overload protection

2.4.8 Compressor electric heating control

If continuously 3s detected the high pressure switch break off, will treat as arrive at preset temperature point, unit will stop,

meanwhile send the “High-pressure protection” signal to indoor unit; After the high-pressure malfunction happened,

if onditnuously 6s detected the high pressure switch off, should turn power off and repower on, the whole unit can resume

to work.

If tested the compressor overload switch, according to indoor temperature arrive at preset temperature condition, unit will stop

and display the corresponding malfunction, compressor has stopped 3mins above and the compressor overload switch reset,

it will automatically resume to the running status. If protection times more than 6 times (if compressor continuously running

time more than 7 mins, that the protection times will clear to 0) that cannot automatically resume, it should to turn the power

off and repower again.

If outdoor ambient temperature is detected very low and compressor dosen’t start up, the compressor electric heating start to work;

If compressor start up or compressor doesn’t start up, but the outdoor temperature is very high, then the electric heating will not to work.

Chassis electric heating (this function is optional, it could be added according to the customer required)

When outdoor ambient temperature is very low, condenser electric heating will start to work;when outdoor ambient temperature is very high,

the condenser electric heating will not work. When entering into Defrosting, untile defrosting finished, after compressor started up 3mins

later, the indoor chassis electric heating will start to work, after compressor run 3mins and outdoor ambient temperature is very high, the

electric heating will stop to work.

Model: ACP-24COFM70GEI

Model: ACP-28COFM80GEI

Loading...

Loading...