Vivax ACP-12CT35GECI, ACP-18CT50GECI Service Manual

ACP-12CT35GECI

ACP-18CT50GECI

Service

manual

ENG

RoHS

NNO-1/09

Summary and Features...............................................................................

Part 1 Safety Precautions

.......................................................................................

Part 2 Specifications

..................................................................................................

2.1 Unit Specifications...............................................................................................

2.3 Capacity Variation Ratio According toTemperature............................................

2.4 Operation Data....................................................................................................

Part 3 Construction Views

.....................................................................................

3.1 Indoor Unit ..........................................................................................................

3.2 Outdoor Unit .......................................................................................................

Part 4 Refrigerant System Diagram

..................................................................

5.1 Electrical Data......................................................................................................

5.2 Electrical Wiring....................................................................................................

Part 5 Schematic Diagram

......................................................................................

6.1 Remote Control Operations.................................................................................

6.2 Description of Each Control Operation................................................................

Part 6 Function and Control

..................................................................................

Part 7 Installation Manual

.......................................................................................

Table of Contents

5.3 Printed Circuit Board............................................................................................

7.1

Choosing an Installation Site

..............................................................................

7.2

Indoor Unit Installation Drawings

........................................................................

7.3 Installation Tips .................................................................................................

7.4 Indoor unit Installation.........................................................................................

2.2 Operation Characteristic Curve............................................................................

2.5 Noise Criteria Curve Tables for Both Models......................................................

1

2

3

3

7

7

8

9

11

12

13

13

13

15

18

18

22

24

24

24

26

27

10

10

Part 8 Exploded Views and Parts List

..............................................................34

Part 9 Troubleshooting

...............................................................................................40

9.1

Precautions Before Performing Inspection or Repair

...........................................40

9.2

Confirmation

.........................................................................................................40

9.3

Flashing LED of Indoor/Outdoor Unit and Primary Judgement

...........................40

9.4

How to Check Simply the Main Part

.....................................................................43

8.1 Indoor Unit............................................................................................................34

8.2 Outdoor Unit.........................................................................................................36

Part10 Removal Procedure

.......................................................................................48

10.1

Removal Procedure of Indoor Unit

.....................................................................48

10.2

Removal Procedure of Outdoor Unit(09K/12K)

..................................................53

10.3

Removal Procedure of Outdoor Unit(18K)

.........................................................57

Table of Contents

Summary and features

1

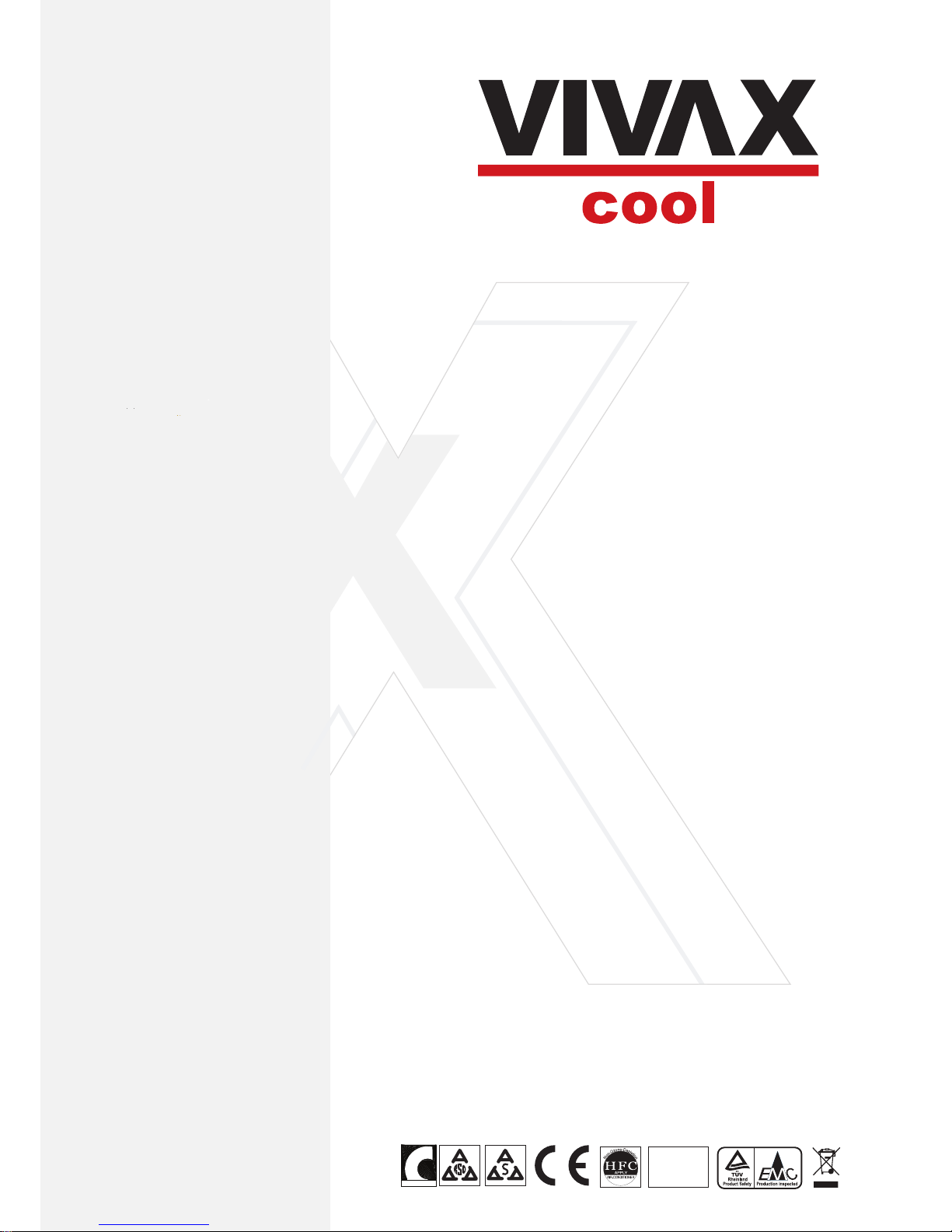

Summary and Features

Indoor Unit

ACP-12CT35GECI

ACP-18CT50GECI

Outdoor Unit

ACP-12CT35GECI

Remote control

ACP-18CT50GECI

2

Safety Precautions

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components,

and equipment location, etc.

Only trained, qualified installers and service personnel are

allowed to install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should

be performed by trained service personnel.

When handling the equipment, observe precautions in the

manual and on tags, stickers, and labels attached to the

equipment. Follow all safety codes. Wear safety glasses

andwork gloves. Keep quenching cloth and fire extinguisher

nearby when brazing.

Read the instructions thoroughly and follow all warnings or

cautions in literature and attached to the unit. Consult local

building codes and current editions of national as well as

local electrical codes.

Recognize the following safety information:

Incorrect handling could result in

personal injury or death.

Incorrect handling may result in

minor injury,or damage to product

or property.

Warning

Caution

Caution

Warning

All electric work must be performed by a licensed technician

according to local regulations and the instructions given in

this manual.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out

and tag switch with a suitable warning label.

Never supply power to the unit unless all wiring and tubing are completed, reconnected and checked.

This system adopts highly dangerous electrical voltage.

Incorrect connection or inadequate grounding can cause

personal injury or death. Stick to the wiring diagram and

all the instructions when wiring.

Have the unit adequately grounded in accordance with

local electrical codes.

All installation or repair work shall be performed by your dealer or a specialized subcontractor as there is the risk of fire,

electric shock, explosion or injury.

Have all wiring connected tightly. Loose connection may

lead to overheating and a possible fire hazard.

Make sure the outdoor unit is installed on a stable, level

surface with no accumulation of snow, leaves, or trash

beside.

Make sure the ceiling/wall is strong enough to bear the

weight of the unit.

Make sure the noise of the outdoor unit does not disturb

neighbors.

Follow all the installation instructions to minimize the risk

of damage from earthquakes, typhoons or strong winds.

Avoid contact between refrigerant and fire as it generates

poisonous gas.

Apply specified refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the

refrigerant line as it may lead to rupture and other hazards.

Make sure no refrigerant gas is leaking out when installation is completed.

Should there be refrigerant leakage, the density of refrigerant in the air shall in no way exceed its limited value,

or it may lead to explosion.

Keep your fingers and clothing away from any moving

parts.

Clear the site after installation. Make sure no foreign objects are left in the unit.

Always ensure effective grounding for the unit.

Never install the unit in a place where a combustible gas

might leak, or it may lead to fire or explosion.

Properly insulate any tubing running inside the room to

prevent the water from damaging the wall.

1.Safety Precautions

Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

Provide an electric leak breaker when it is installed in a

watery place.

Never wash the unit with water.

Should any emergency occur, stop the unit and disconnect the power immediately.

Handle unit transportation with care. The unit should not

be carried by only one person if it is more than 20kg.

Never touch the heat exchanger fins with bare hands.

Never touch the compressor or refrigerant piping without

wearing glove.

Do not have the unit operate without air filter.

3

Specifications

2.Specifications

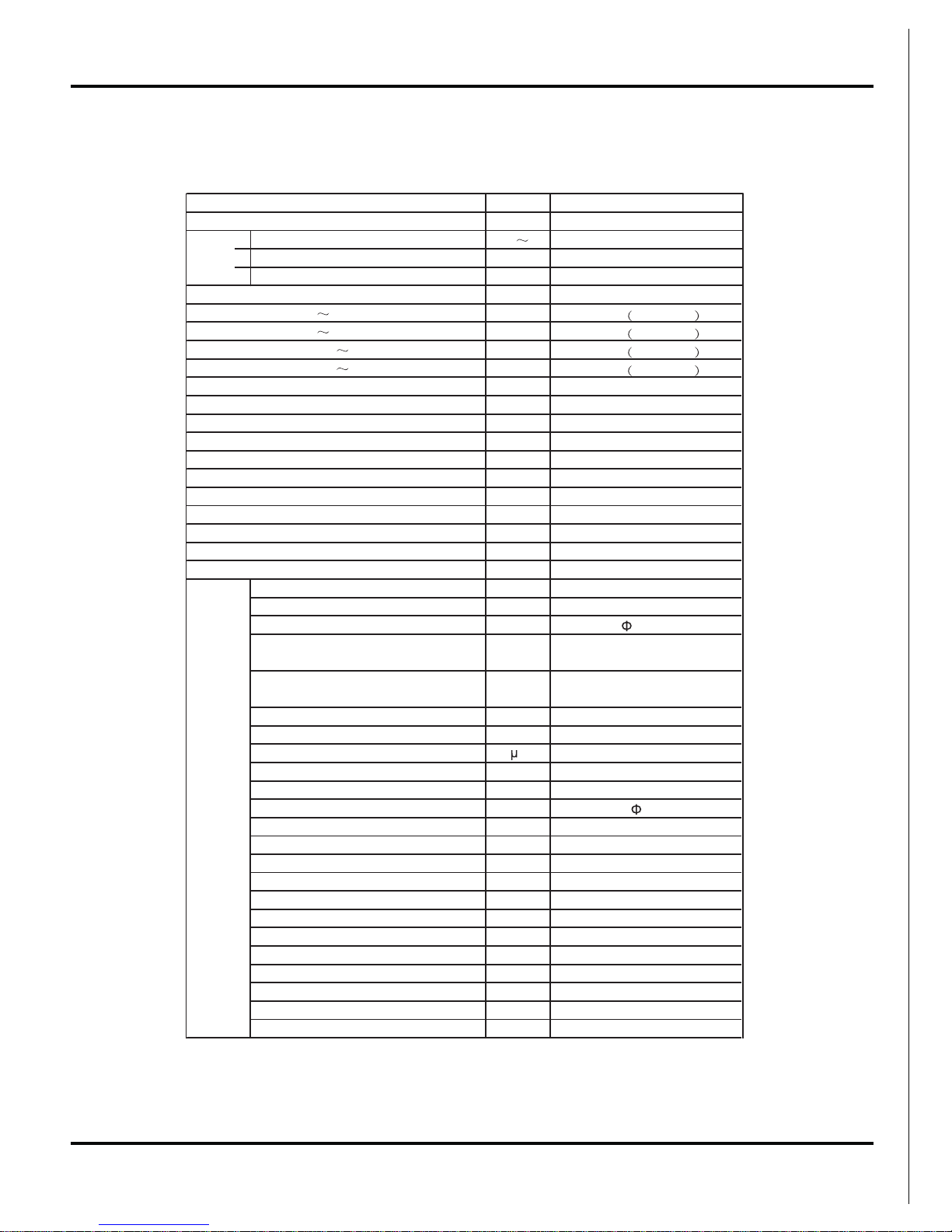

2.1 Unit Specifications

ACP-18CT50GECI

CV01000020

Rated Voltage V

220-240

Rated Frequency Hz

50

Phases

1

Indoor

W

3520

600~3950

W

4000

600~4700

W

1080

220~1700

W

1108

220~1500

A

4.70

A

4.82

W

1700

A

7.39

m

3

/h

600/520/-/440/-/360/280

2.1

h/L

62.3

W/W

16.3

W/W

-

W/W

-

W/W

m

2

16-24

Model of indoor unit

ACP-18CT50GECI

Fan Type

Centrifugal

Diameter Length(DXL) mm

370X80

Fan Motor Cooling Speed

(SH/H/HM/M//LM/L/S)

r/min 750/650/600/550/500/450/350

Fan Motor Heating Speed

(SH/H/HM/M//LM/L/S)

r/min 750/650/600/550/500/450/350

Output of Fan Motor W

20

Fan Motor RLA A

0.34

Fan Motor Capacitor

F

-

Input of Heater W

-

Evaporator Form Aluminum Fin-copper Tube

Pipe Diameter mm

6.35

Row-fin Gap mm

2-1.2

Coil Length (LXDXW) mm

511X24X396

Swi n g Mot o r Mod el

MP24AE

Output of Swing Motor W

2.0

Fus e A

PCB 3.15A

Sound Pressure Level (SH/H/M/L/SL) dB (A) 42/40/38/37/35/32/26

Sound Power Level (SH/H/M/L/SL) dB (A) 52/50/48/47/45/42/36

Dimension (WXHXD) mm

700X600X215

Dimension of Carton Box (L/W/H) mm

785X680X280

Dimension of Package (L/W/H) mm

788X695X283

Net Weight kg

15

Gross Weight kg

18

Mo d e l

Product Code

Power

Supply

Power Supply Mode

Cooling Capacity (Min

Ma x)

Heating Capacity (Min

Ma x)

Cooling Power Input (Min

Ma x)

Heating Power Input (Min

Ma x)

Cooling Power Current

Heating Power Current

Rated Input

Rated Current

Air Flow Volume(SH/H/M/L/SL)

Dehumidifying Volume

EER

COP

SEER

HSPF

Application Area

Indoor

Unit

4

Specifications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Model of Outdoor Unit

ACP-12CT35GECI

Compressor Manufacturer/Trademark

DIT/daikin

Compressor Model

1YC23AEXD

Compress or Oil

DAPHNE FVC50K

Compressor Type

Rotary

L.R.A. A

20

Compressor RLA A

4.00

Compressor Power Input W

600

Overload Protector

CS-7SA

Throttling Method

Capillary

Operation temp

16 30

Ambient temp (cooling)

10 48

Ambient temp (heating)

-15 24

Condenser Form

Pipe Diameter mm

7

Rows-fin Gap mm

2-1.4

Coil Length (LXWXD) mm

7 24 X5 08 X3 8. 1

Fan Motor Speed rpm

820

Output of Fan Motor W

30

Fan Motor RLA A

0.42

Fan Motor Capacitor

2

F

Ai r Fl ow Volum e o f Ou tdoor Uni t

m

3

/h

0061

wolf-laixA

epyT naF

mmretemaiD naF

400

gnitsorfeD citamotuA

dohteM gnitsorfeD

1T

epyT etamilC

I

noitalosI

42PI

noitcetorP erutsioM

Permissible Excessive Operating

Pressure for the Discharge Side

8.3

aPM

Permissible Excessive Operating

Pres sure for the Suction Si de

2.1

aPM

-/-/25

)A( Bd)L/M/H( leveL erusserP dnuoS

-/-/26

)A( Bd)L/M/H( leveL rewoP dnuoS

D

imension (WXHXD) mm 848X540X320

Dimension of Carton Box (L/W/H) mm 878X360X580

Dimension of Package (L/W/H) mm 881X363X595

33

gkthgieW teN

73

gkthgieW ssorG

A014R

tnaregirfeR

50.1

gkegrahC tnaregirfeR

5

mhtgneL

02

m/gegrahC lanoitiddA saG

O

uter Diameter Liquid Pipe mm

6

Outer Diameter Gas Pipe mm

9.52

01

mthgieH ecnatsiD xaM

51

mhtgneL ecnatsiD xaM

Outdoor

Unit

Connecti

on Pipe

5

Specifications

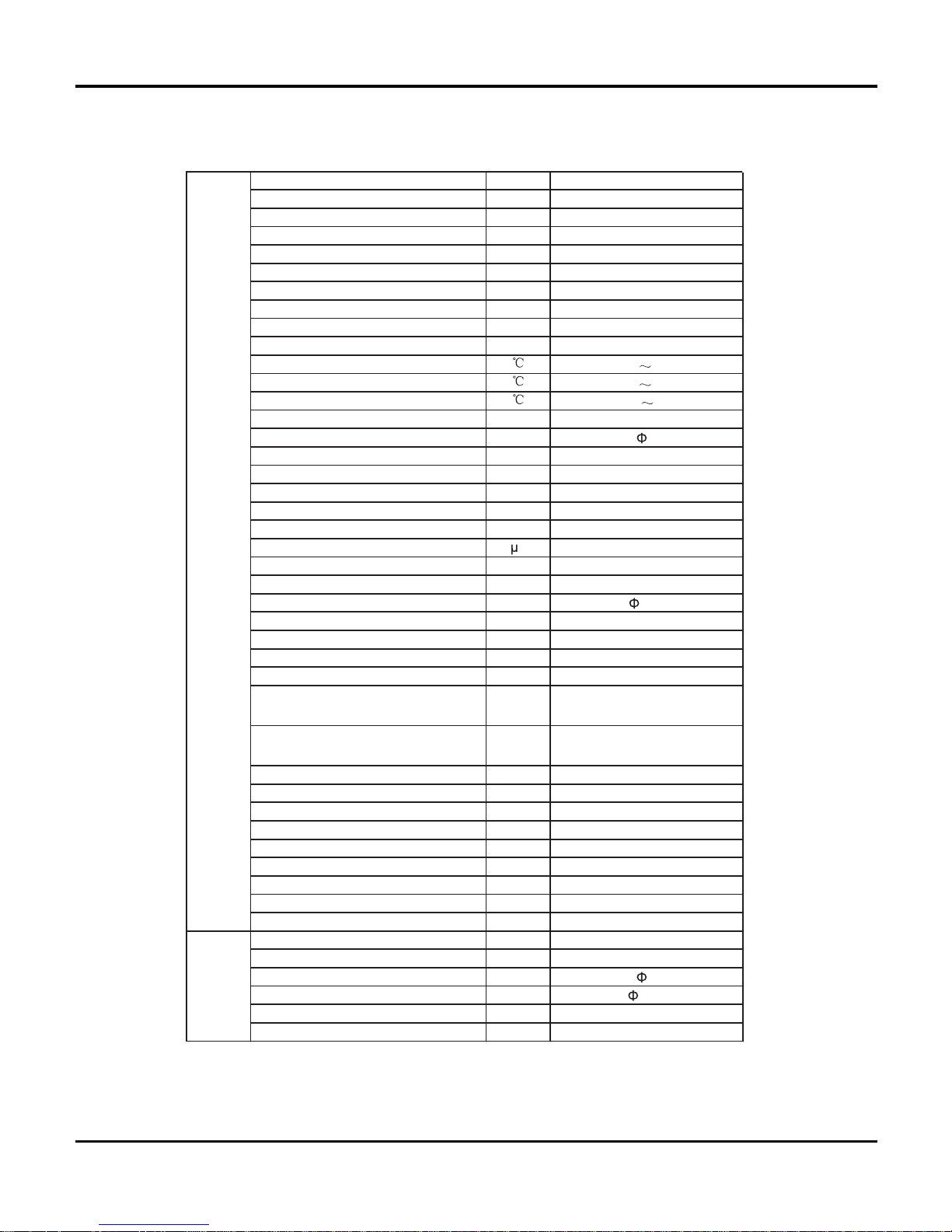

CV01000030

Rated Voltage V

220-240

Rated Frequency Hz 50

Phas es 1

Indoor

W 5270˄900~5600

˅

W 5500˄900~6600

˅

W 1630˄360~2500

˅

W 1520˄350~2500

˅

A7.09

A6.61

W 2500

A10.87

m

3

/h

650/620/-/500/-/410/320

L/h 2

W/W 3.23

W/W 3.62

W/W -

W/W -

m

2

23-34

Model of indoor unit

Fan Type Centrifugal

Diameter Length(DXL) mm ĭ370X80

Fan Motor Cooling Speed (SH/H/HM/M/LM/L/S) r/min 840/800/720/650/580/530/410

Fan Motor Heating Speed (SH/H/HM/M/LM/L/S) r/min 900/840/760/690/620/570/450

Output of Fan Motor W 20

Fan Motor RLA A 0.34

Fan Motor Capacitor ȝF-

Input of Heater W -

Evaporator Form Aluminum Fin-copper Tube

Pipe Diameter mm ĭ6.35

Row-fin Gap mm 2-1.2

Coil Length (LXDXW) mm 511X24X396

Swin g Mo tor Mo de l MP24AE

Output of Swing Motor W 2.0

Fuse A PCB 3.15A

Sound Pressure Level (SH/H/M/L/SL) dB (A) 48/46/44/41/37/35/32

Sound Power Level (SH/H/M/L/SL) dB (A) 58/56/54/51/47/45/42

Dimension (WXHXD) mm 700X600X215

Dimension of Carton Box (L/W/H) mm 785X680X280

Dimension of Package (L/W/H) mm 788X695X283

Net Weight kg 15

Gross Weight kg 18

Mo de l

Product Code

Power

Supply

Power Supply Mode

Cooling Capacity (MinMa x)

Heating Capacity (MinMa x)

Cooling Power Input (MinMa x)

Heating Power Input (MinMa x)

Cooling Power Current

Heating Power Current

Rated Input

Rated Current

Air Flow Volume(SH/H/M/L/SL)

Dehumidifying Volume

EER

COP

SEER

HSPF

Application Area

Indoor

Unit

6

Specifications

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Model of Outdoor Unit

Compressor Manufacturer/Trademark

China Resources (Shenyang) Sanyo

CO.,LTD/Sanyo

Compress or Model C-6RZ146H1A

Compressor Oil FV50S

Compress or Type Rotary

L.R.A. A 41

Compress or RLA A 8.40

Compressor Power Input W 1640

Overload Protector 1NT11L-3979

Throttling Method Capillary

Operation temp

ć

1630

Ambient temp (cooling)

ć

1048

Ambient temp (heating)

ć

-1524

Condenser Form Aluminum Fin-copper Tube

Pipe Diameter mm ĭ7

Rows-fin Gap mm 2-1.4

Coil Length (LXWXD) mm 853X660X38.1

Fan Motor Speed rpm 690

Output of Fan Motor W 60

Fan Motor RLA A 0.58

Fan Motor Capacitor ȝFAi r Fl ow Volum e o f Ou td oor Uni t

m

3

/h

3200

Fan Type Axial-flow

Fan Diameter mm ĭ520

Defrosting Method Autom atic Defrosting

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating Pressure for

the Discharge Side

MP a 3 . 8

Permissible Excessive Operating Pressure for

the Suction Side

MP a 1 . 2

Sound Pressure Level (H/M/L) dB (A) 54/-/Sound Power Level (H/M/L) dB (A) 64/-/Dimension (WXHXD) mm 955X700X396

Dimension of Carton Box (L/W/H) mm 1026X455X735

Dimension of Package (L/W/H) mm 1029X458X750

Net Weight kg 49

Gross Weight kg 54

Refrigerant R410A

Refrigerant Charge kg 1.23

Length m 5

Gas Additional Charge g/m 20

Outer Diameter Liquid Pipe mm ĭ6

Outer Diameter Gas Pipe mm ĭ12

Max Distance Height m 10

Max Distance Length m 25

Outdoor

Unit

Connecti

on Pipe

7

Specifications

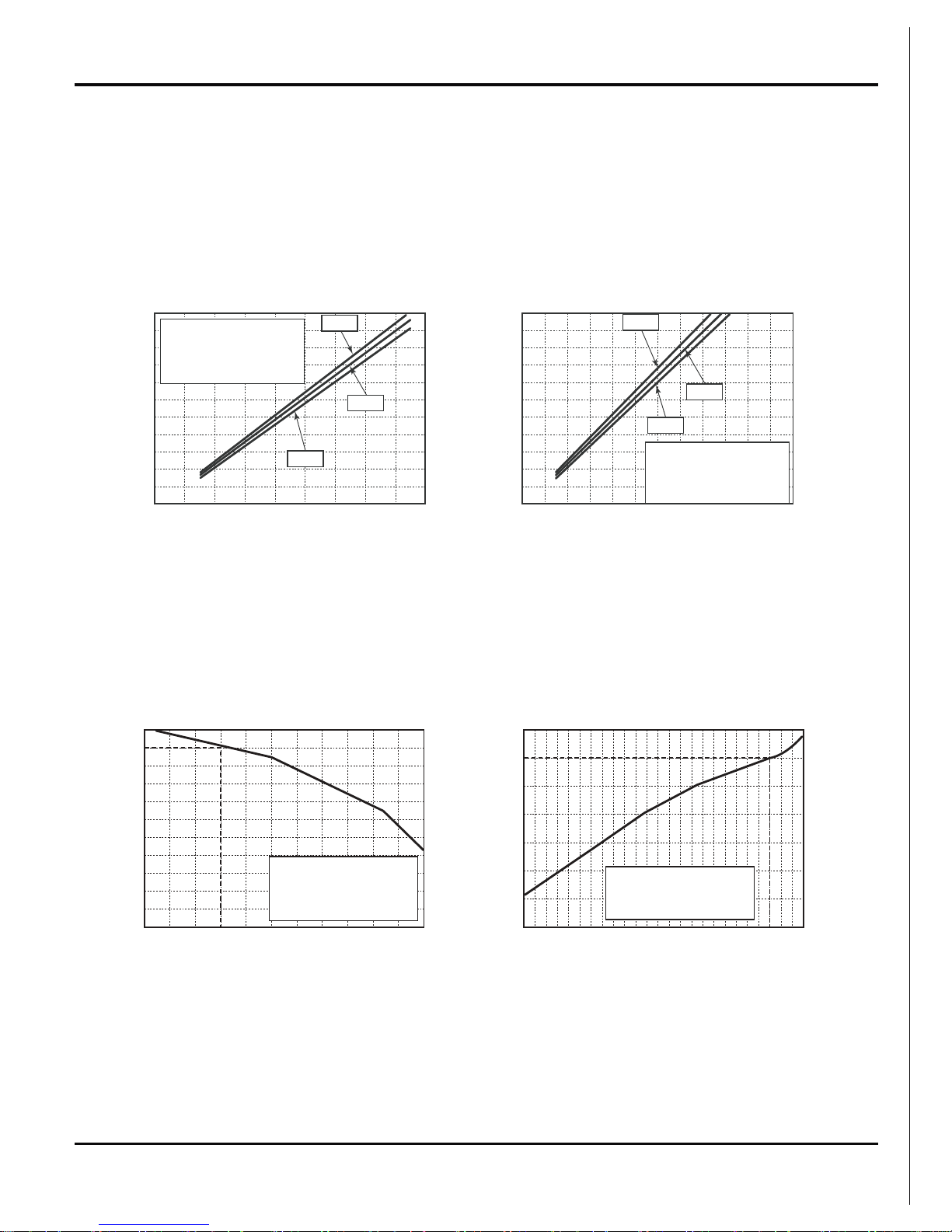

2.2 Operation Characteristic Curve

gnitaehgnilooc

2.3 Capacity Variation Ratio According to Temperature

gnitaehgnilooc

32 33 34 35 36 37 38 39 43 –15 –10 –5 0 5 7 10

40 41 42

100

105

95

90

85

80

75

70

65

60

55

50

Outdoor temp.Û&

%(oitaryticapa&

110

100

90

80

70

60

50

40

Outdoor temp.Û&

%(oitaryticapa&

&RQGLWLRQV

Indoor :'%Û&:%Û&

Indoor air flow : High

Pipe length : 5m

&RQGLWLRQV

Indoor :'%Û&:%Û&

Indoor air flow : High

Pipe length : 5m

009070605040302010 110210010908070605040302010

80

11

10

9

8

7

6

5

4

3

2

1

0

A(tnerru&

11

10

9

8

7

6

5

4

3

2

1

0

A(tnerru&

&RQGLWLRQV

Indoor :'%Û&:%Û&

Outdoor :'%Û&:%Û&

Indoor air flow : High

Pipe length : 5m

&RQGLWLRQV

Indoor :'%Û&:%Û&

Outdoor :'%Û&:%Û&

Indoor air flow : High

Pipe length : 5m

220V

230V

240V

220V

230V

240V

zH(ycneuqerfrosserpmo&zH(ycneuqerfrosserpmo&

8

Specifications

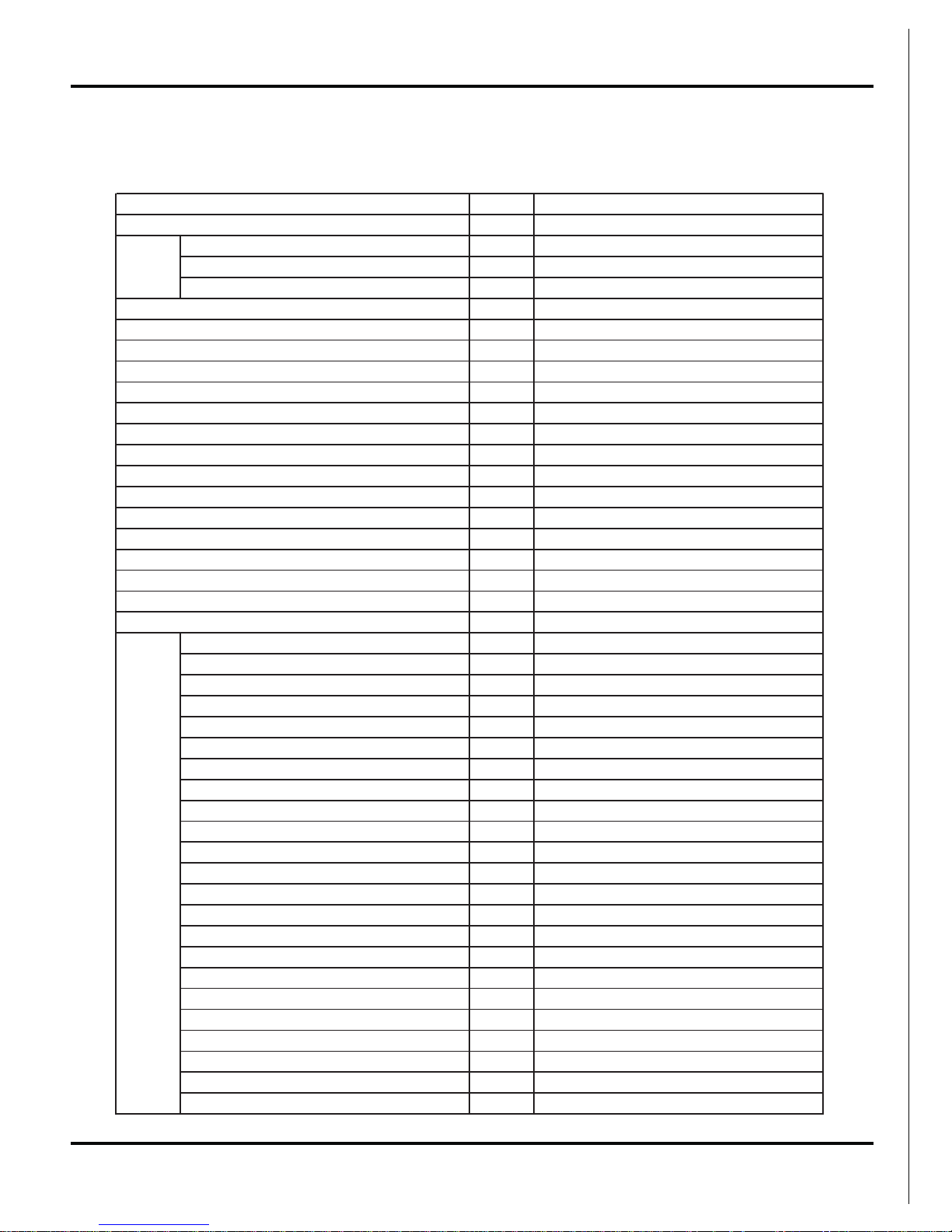

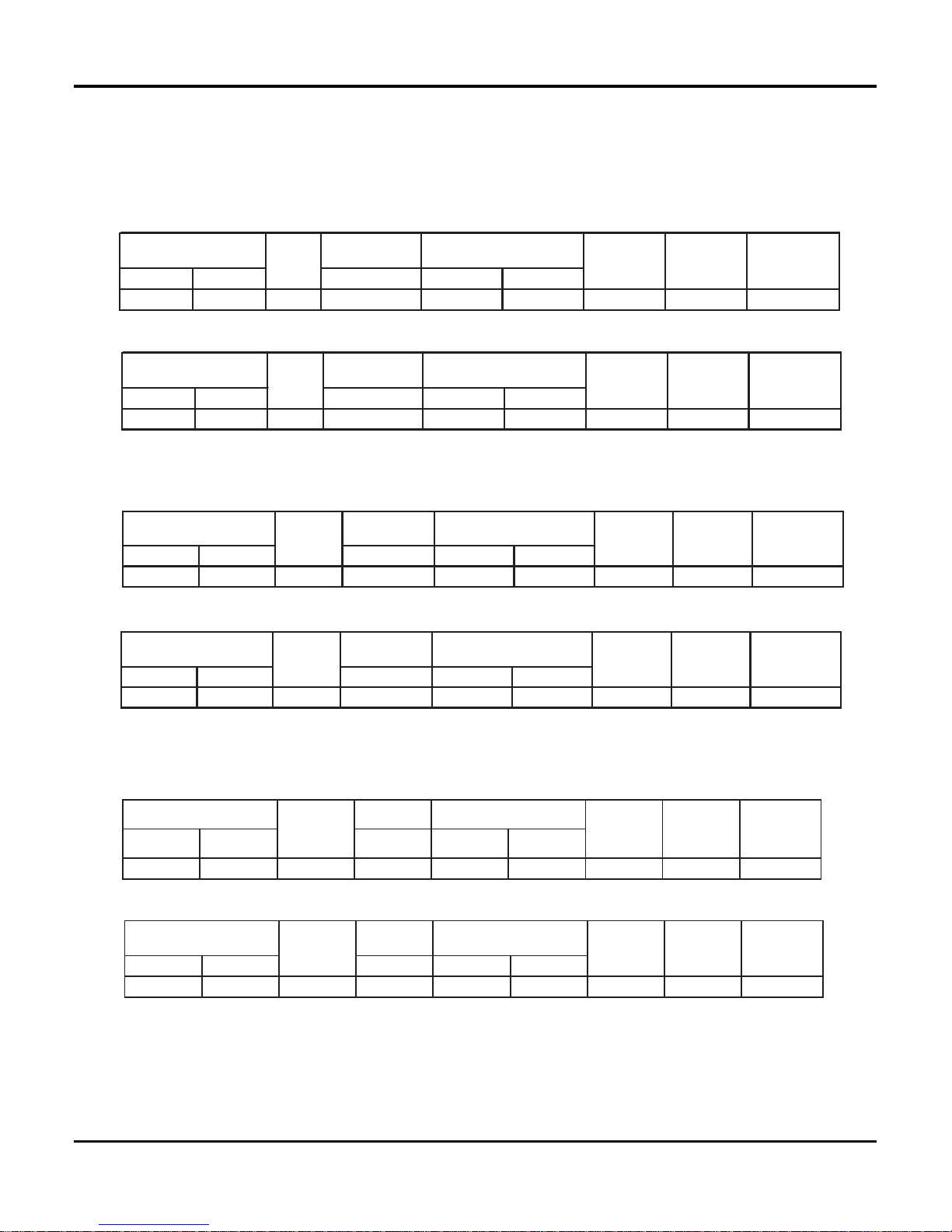

2.4 Operation Data

Cooling

Heating

09K

Standard

pressure

Indoor Outdoor P(MPa)

T1(ć)T2(ć)

27/19 35/24 09k 0.9 to 1.1 12 to 14 70 to 40 Super High High 52

Heat exchanger pipe temp

Indoor fan

mode

Outdoor fan

mode

Compressor

revolution(rps)

Temperature condition

(ć)

Model

name

Standard

pressure

Indoor Outdoor P(MPa)

T1(ć)T2(ć)

20/- 7/6 09k 2.2 to 2.4 70 to 35 2 to 4 Super High High 65

Temperature condition

(ć)

Model

name

Heat exchanger pipe temp

Indoor fan

mode

Outdoor fan

mode

Compressor

revolution(rps)

12K

Cooling

Heating

Standard

pressure

Indoor Outdoor P(MPa)

T1(ć)T2(ć)

27/19 35/24 12k 0.9 to 1.1 12 to 14 70 to 40 Super High High 72

Heat exchanger pipe temp

Indoor fan

mode

Outdoor fan

mode

Compressor

revolution(rps)

Temperature condition

(ć)

Model

name

Standard

pressure

Indoor Outdoor P(MPa)

T1(ć) T2(ć)

20/- 7/6 12k 2.2 to 2.4 70 to 35 2 to 4 Super High High 77

Temperature condition

(ć)

Model

name

Heat exchanger pipe temp

Indoor fan

mode

Outdoor fan

mode

Compressor

revolution(rps)

Standard

p

ressure

Indoor Outdoor P(MPa) T1(ć)T2(ć)

27/19 35/24 18k 0.9 to 1.1 12 to 14 70 to 40 Super High High 70

T

emperature con

diti

on

(ć)

Heat

exchanger pipe

tem

p

Indoor fan

mode

Outdo or fan

mode

Compressor

revolution(rp

s)

Model

name

Standard

press ure

Indoor Outdoor P(MPa) T1(ć)T2(ć)

20/- 7/6 18k 2.2 to 2.4 70 to 35 2 to 4 Super High High 64

Outdo or fan

mode

Compressor

revolution(rp

s)

Temperature condition

(ć)

Model

name

Heat exchanger pipe

tem p

Indoor fan

mode

18K

NOTES :

T1: Inlet and outlet pipe temperature of evaporator.

T2: Inlet and outlet pipe temperature of condenser.

P: Pressure of air pipe connecting indoor and outdoor units.

Cooling

Heating

9

Specifications

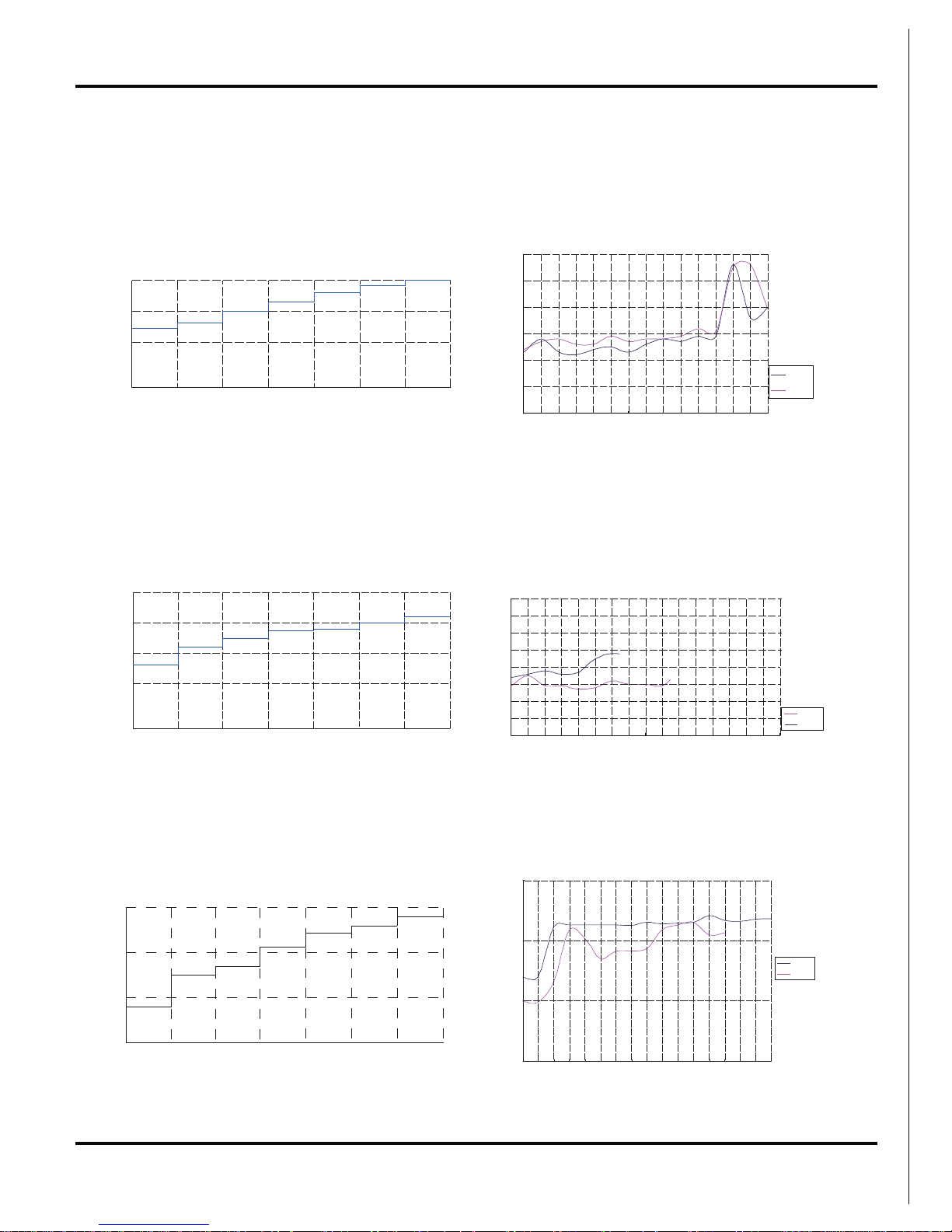

2.5 Noise criteria curve tables for both models

09K

12K

18K

Indoor fan motor rotating speed

Indoor side noise when blowing

s L LM M HM H SH

20

30

40

50

20

30

40

Indoor side noise when blowing

Indoor fan motor rotating speed

SH

H

HM M LM L S

L

46

47

48

49

50

51

52

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85

Compress or frequency

˄Hz˅

Noise dB(A)

Cooling

Heating

30.0

40.0

50.0

60.0

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 94

Compress or frequency

˄Hz˅

Noise/dB(A)

Cooling

Heating

45

46

47

48

49

50

51

52

53

1234567891011121314151617

Compres sor frequency(Hz)

Noise dB(A)

Cooling

Heating

Indoor side noise when blowing

Indoor fan motor rotating speed

SH HHMMLM L S

L

20

30

40

50

10

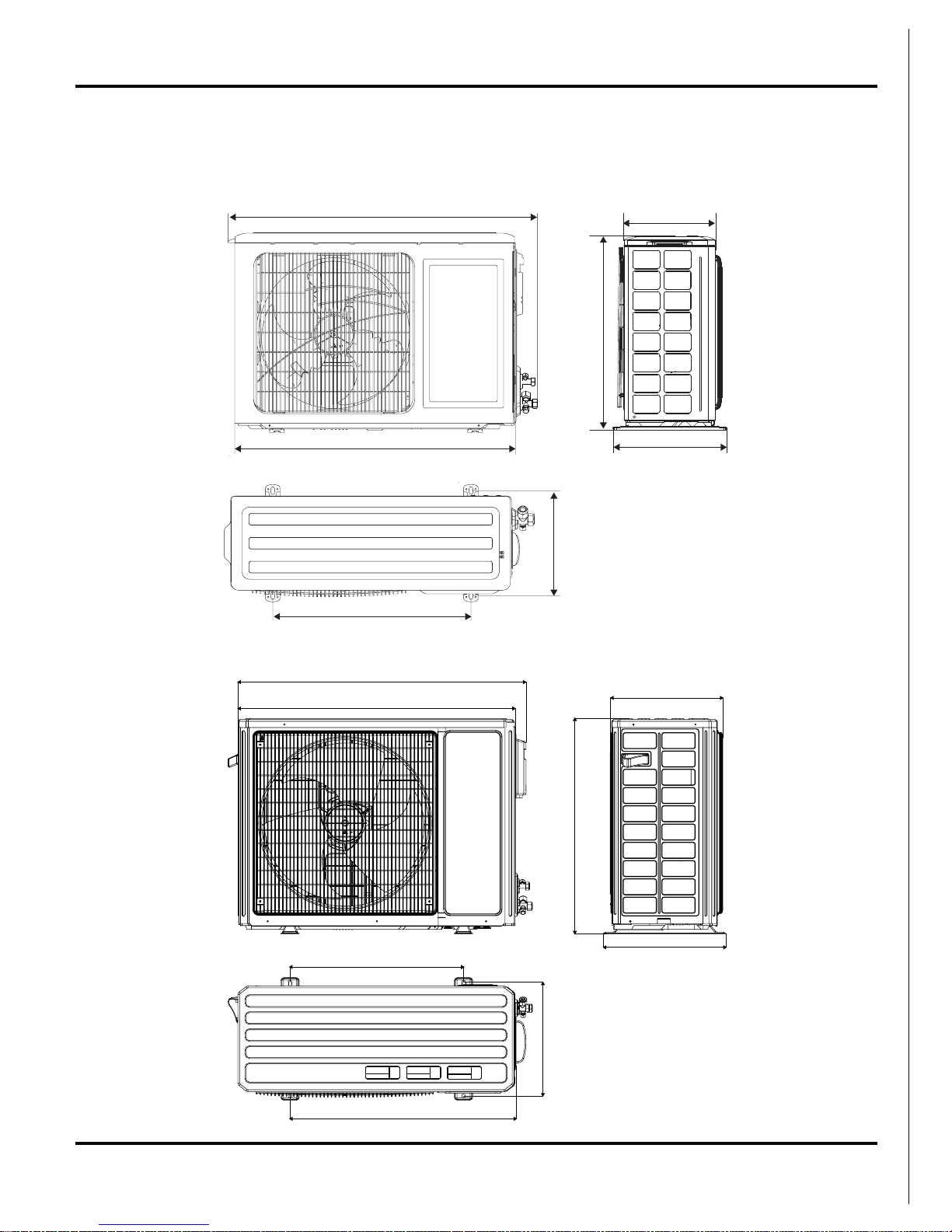

Constrction views

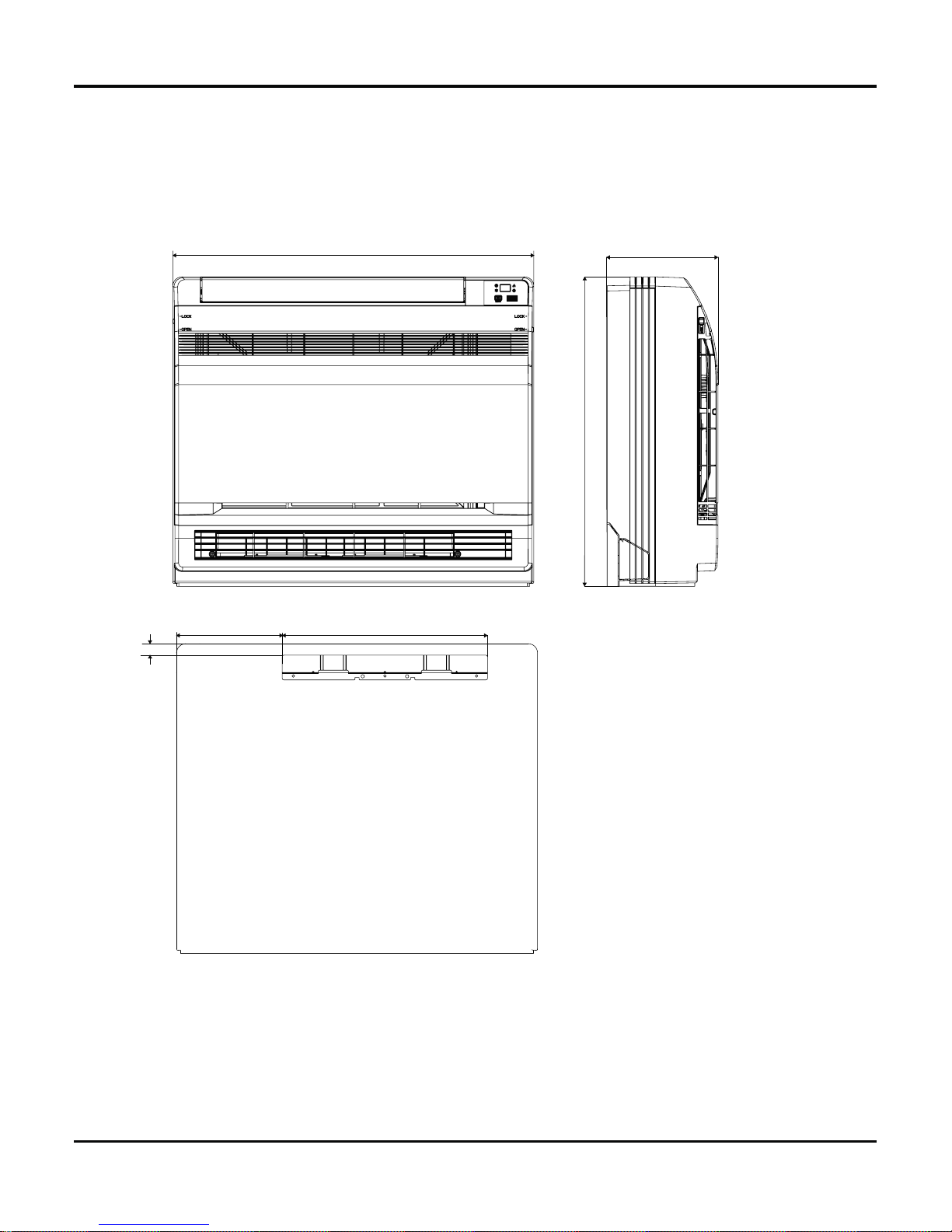

3. Construction Views

3.1 Indoor Unit

Unit:mm

700

215

600

398

205

22

11

Constrction views

364

930

896

695

396

560

368

730

3.2 Outdoor Unit

09K 12K

Unit:mm

18K

Unit:mm

848

320

540

540

766

276

286

12

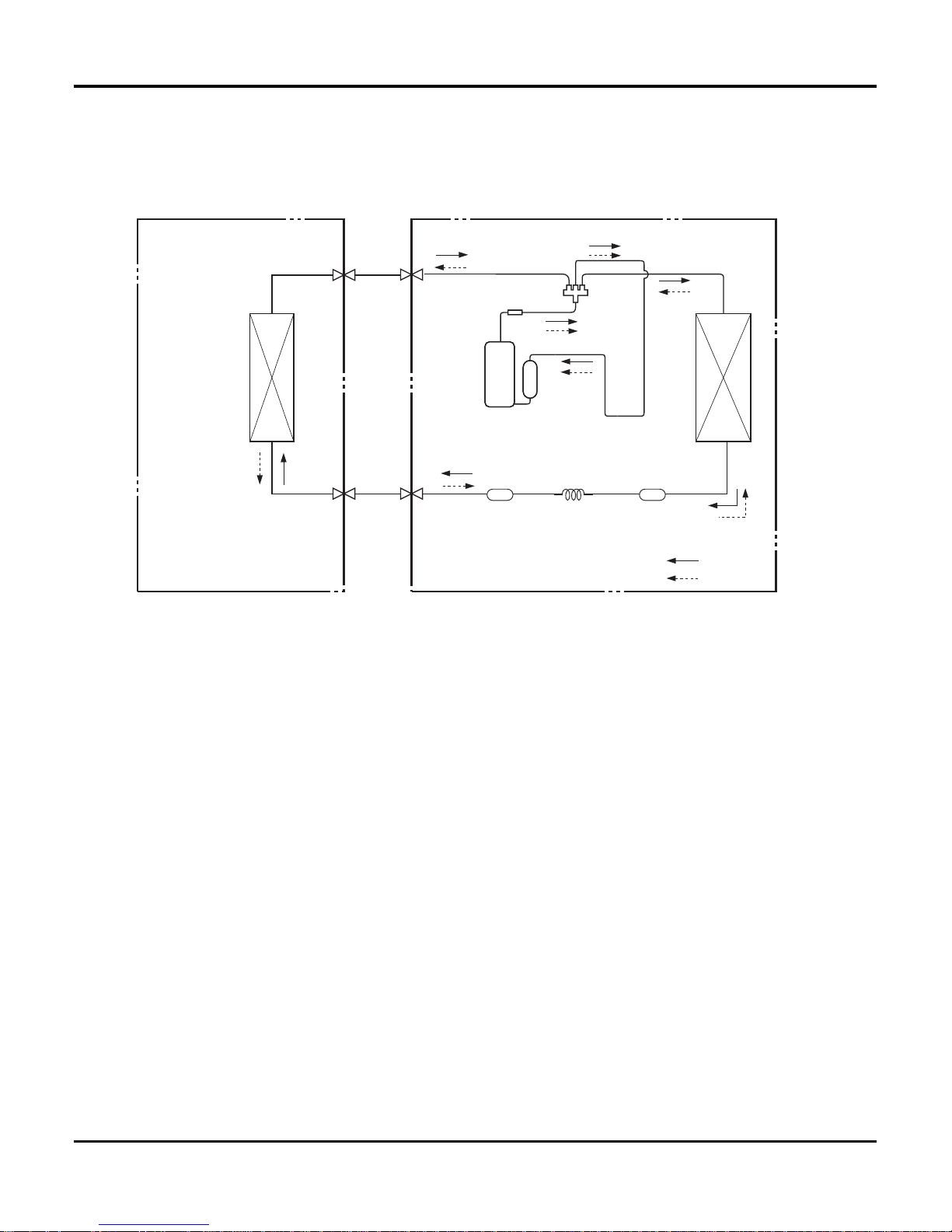

Refrigerant System Diagram

4. Refrigerant System Diagram

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

HEATING

Accumlator

Discharge

Suction

Muffler

4-Way valve

CapillaryStrainer Strainer

Refrigerant pipe diameter

18K

Liquid : 1/4" (6 mm)

Gas : 1/2" (12 mm)

Refrigerant pipe diameter

09K 12K

Liquid : 1/4" (6 mm)

Gas : 3/8" (9.52 mm)

13

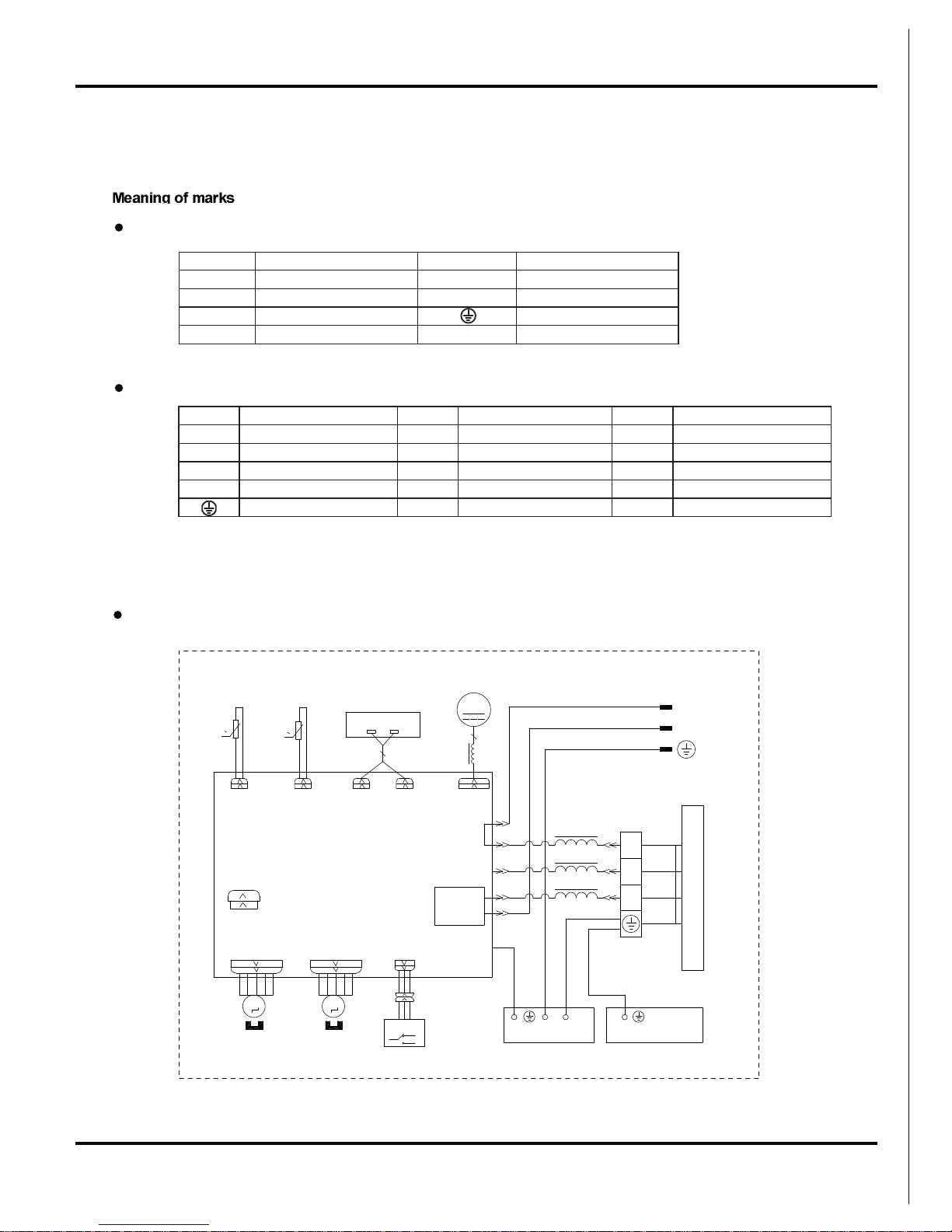

Schematic Diagram

5. Schematic Diagram

5.1 Electrical Data

5.2 Electrical wiring

Outdoor Unit

Indoor Unit

Indoor Unit

Symbol Color symbol Symbol Color symbol

NWORBNBEULBUB

YE YELLOW

RD RED

BK BLACK

YEGN YELLOW GREEN

PROTECTIVE EARTH

Symbol Parts name Symbol Color symbol Symbol Color symbol

C1 CBB61 BN BROWN WH WHITE

C2 CBB65 BU BLUE YE YELLOW

SAT OVERLOAD BK BLACK RD RED

COMP COMPRESSOR OG ORANGE YEGN YELLOW GREEN

PROTECTIVE EARTH WH WHITE

YEGN

BK

BU

M1

SWING-DOWN

OUTDOOR UNIT

CAP

JUMP

AP1 PRINTED CIRCUIT BOARD

ROOM

RT2

RT1

TUBE

SENSOR

SENSOR

ROOM

TUBE

POWER

BU(WH)

N

DISPLAY

RECEIVER AND

DISPLAY BOARD

DISP2

AP2

DISP1

FAN

DC-MOTOR

MOTOR

TEMP.

TEMP.

STEPPING

SWING-UP

M2

AP3

S

CN8

SELECT

SWITCH

MOTOR

STEPPING

MOTOR

BN(BK)

YEGN(GN)

N(1)

2

XT

3

BN

COM-OUT

L-OUT

AC-L

BU

BK

BN

PE

EVAPORATOR

YEGN

K7

TERMINAL

BLOCK

MAGNETIC

RING

L1

L1

L1

E

ELECTRIC BOX

PE

YEGN

YEGN

5

L2

MAGNETIC

RING

0

0

L

N

M3

14

Schematic Diagram

Outdoor Unit

09K 12K

18k

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

BKWH

0

0

0

R(U)

S(V)

CN2

YEGN

AC-L1

N1

YEGN

BU

E

BN

BK

C(W)

PE

PE

PE

COMU

RT1

RT2

RT3

BU

YE RD

OVC-COMP

RD

RD

SAT

YEGN

COMP

BK

BN

BU

N3N2

TERMINAL

COMP.

COMP-U

COMP-V

COMP-W

LX-2

OG

WH

LX-1

L

OUTTUBE

TEMP. SENSOR

OUTROOM

TEMP. SENSOR

EXHAUST

TEMP. SENSOR

4YV

4V

FAN MOTOR

PE

BLOCK

4-WAY

VALVE

PE

PE

YEGN

REACTOR

L1

L1

L2

L2

L2

AC-L2

OFAN

OFAN-BRW OFAN-RED

BU

L3

L3

BU

(BK)

BN

RD

PROTECTOR

OVERLOAD

INDOOR UNIT

XT

AP1 PRINTED CIRCUIT BOARD

N(1)

2

3

VT

VT

M

BKWH

0

0

0

R(U)

S(V)

T-SENSOR

YEGN

AC-L

N

YEGN

BU

PE

BN

BK

BU

YE

RD

C(W)

PE

PE

PE

COM-INNER

RT1

RT2

RT3

YE

BU RD

OVC-COMP

WHWH

SAT

YEGN

M

BK

BN

BU

PFCC2

YE

PFCC1

CAP.

X1

TERMINAL

YE

COMP.

COMP-U

COMP-V

COMP-W

INDC2

OG

WH

INDC1

L

OUTTUBE

TEMP. SENSOR

OUTROOM

TEMP. SENSOR

EXHAUST

TEMP. SENSOR

FAN

M

HALL OFAN

4YV

4V

MOTOR

PE

BLOCK

4-WAY

VALVE

PE

PE

YEGN

REACTOR

OVERLOAD

PROTECTOR

INDOOR UNIT

XT

AP1 PRINTED CIRCUIT BOARD

N(1)

2

3

15

Schematic Diagram

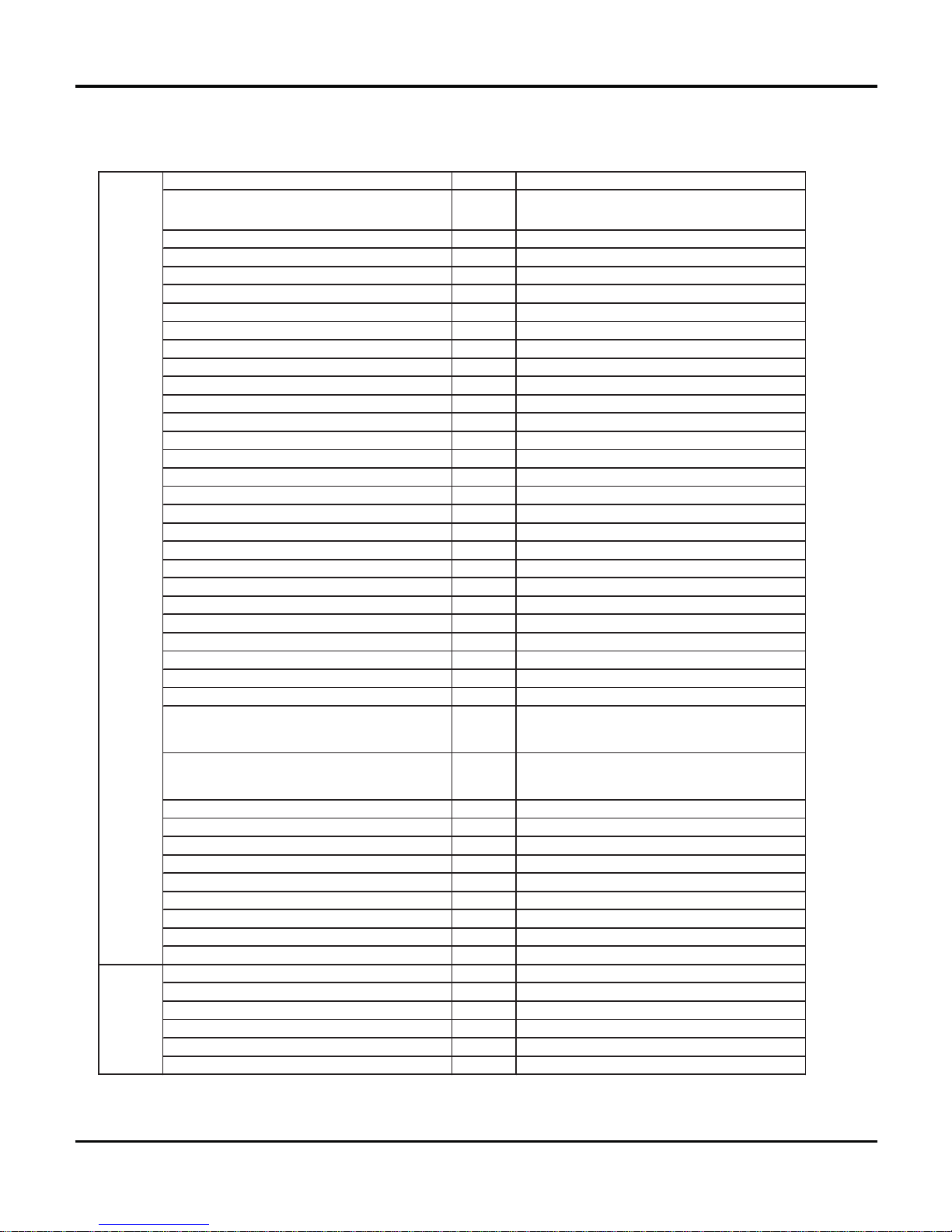

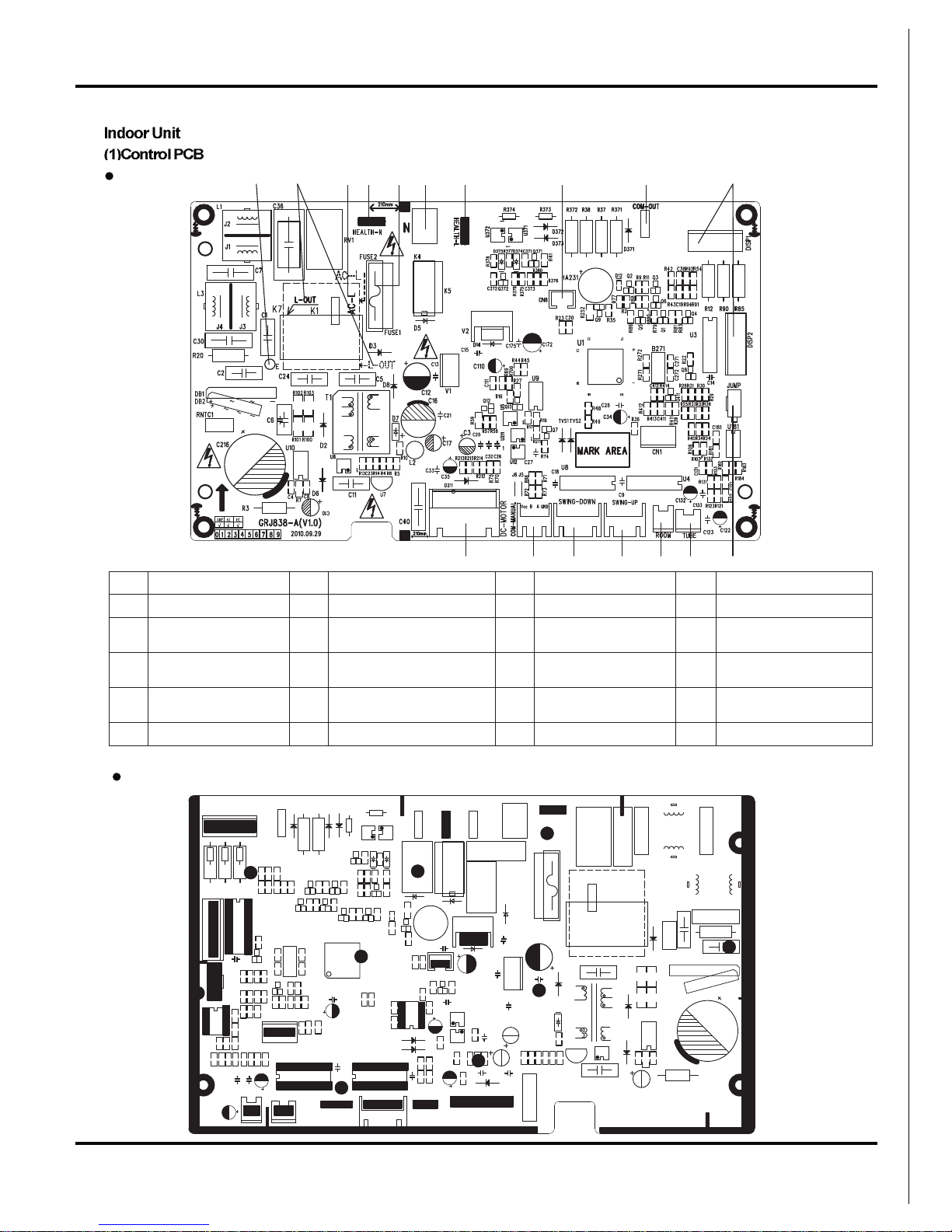

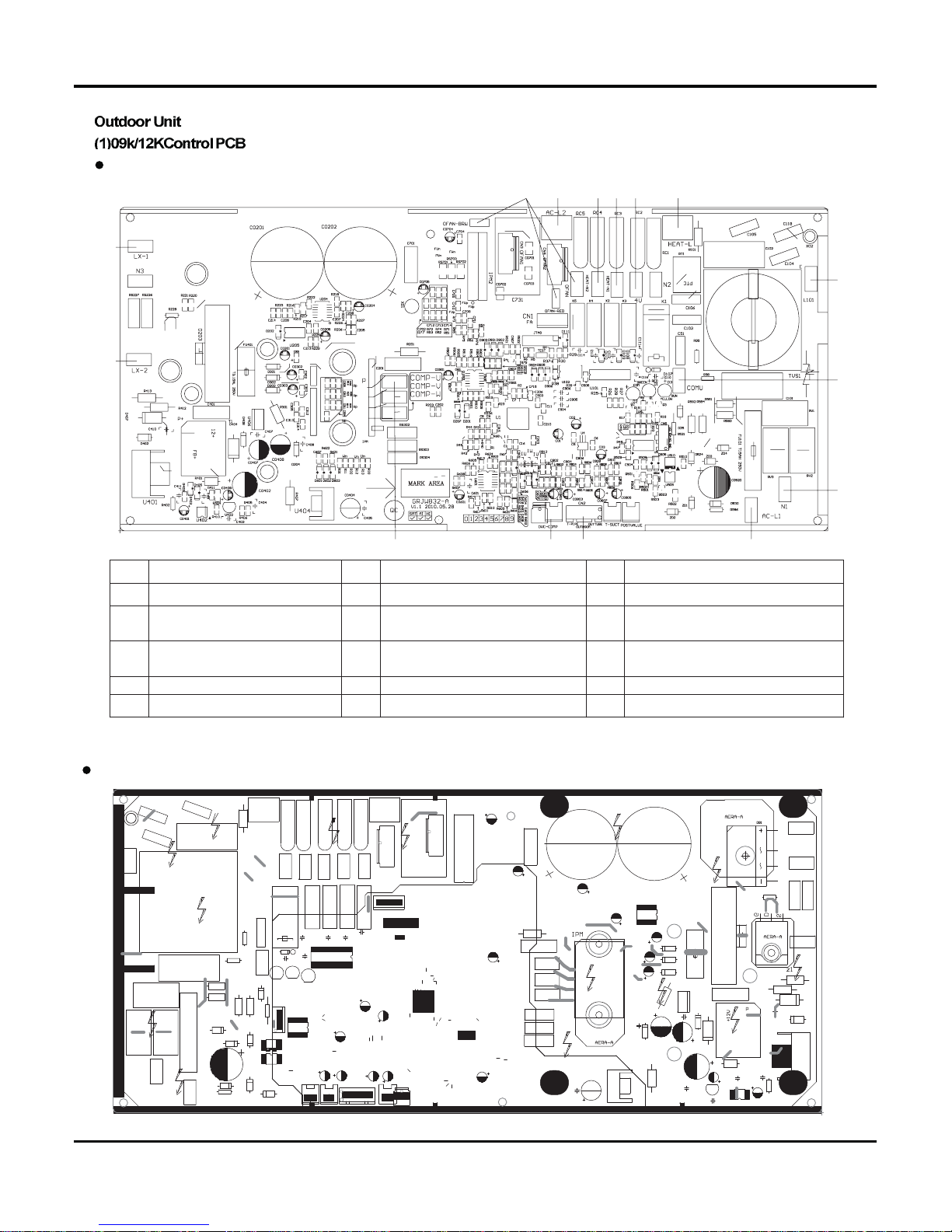

5.3 Printed Circuit Board

TOP VIEW

12 34567 8 9 10

11121314151617

BOTTOM VIEW

No. Name No. Name No. Name No. Name

1 Earthing wire 6 Neutral wire input 11 Jumper cap interface 16 Wire controller interface

2

Outdoor power supply

interface

7

Health function live wire

interface

12

Indoor tube

temperature sensor

17 DC fan interface

3

Live wire input

interface

8

Lower swing control

interface

13

Indoor ambient

temperature sensor

18 /

4

Health function

neutral wire interface

9

Communication interface

of indoor and outdoor unit

14 Upper swing interface 19 /

5 Fuse 10 Display board interface 15 Lower swing interface 20 /

16

Schematic Diagram

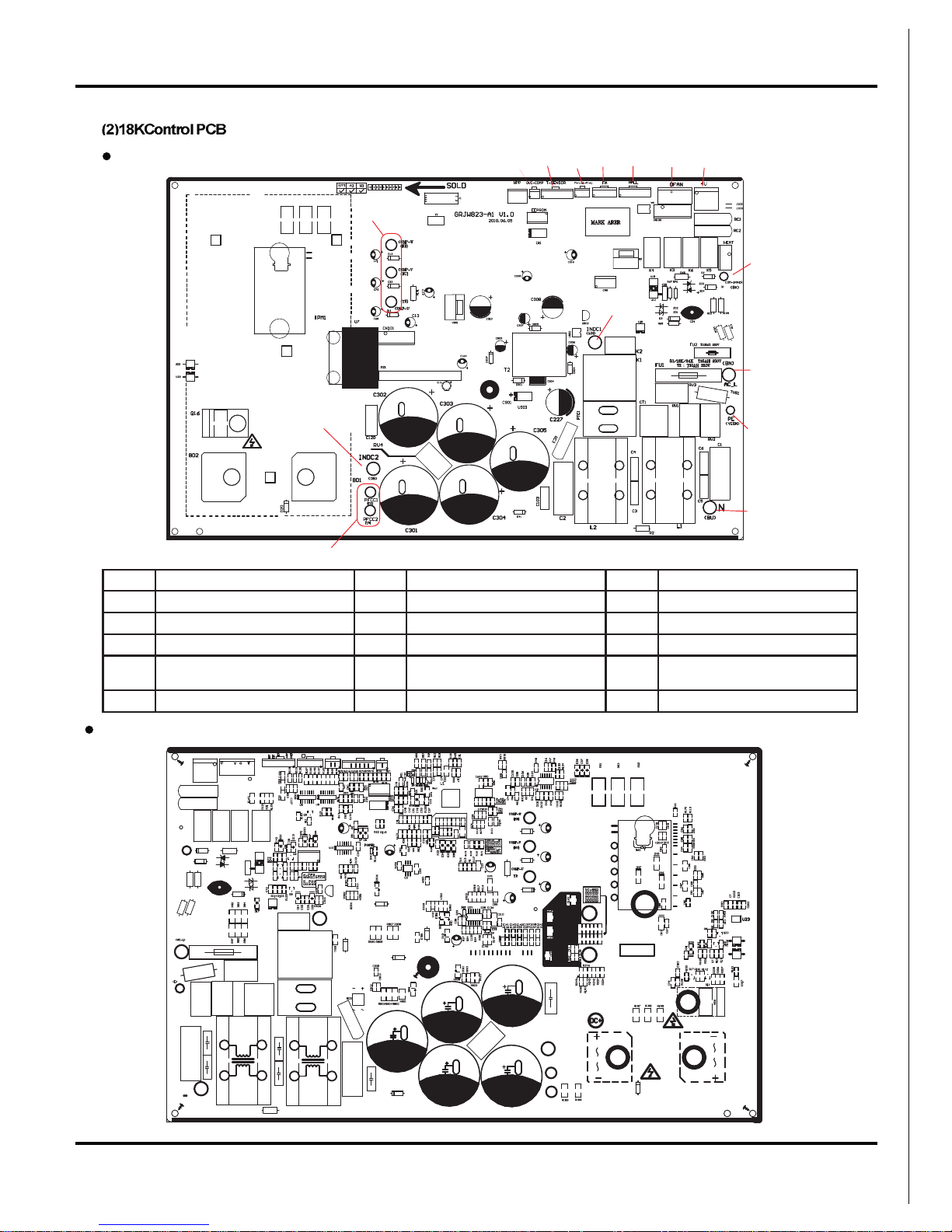

TOP VIEW

1

2

3

4

5

6

78 9

10

11

14 12 13

15

BOTTOM VIEW

No. Name No. Name No. Name

1 Power supply neutral wire input 6 Fan interface 11 Electric heating belt live wire

2 Power supply live wire input 7

Chassis electric heating belt

neutral wire

12 Overload input

3 Communication interface 8

Compressor electric heating belt

neutral wire

13 Temperature sensor

4 Reactor interface 1 9 4-way valve neutral wire 14 Compressor three phases U, V, W

5 Reactor interface 2 10

4-way valve live wire

15 Power supply earthing wire input

17

Schematic Diagram

BOTTOM VIEW

15

13

14

1

2345678

9

10

11

12

NO. Interface name NO. Interface name NO. Interface name

1 Interface of compressor 6 Fan HALL interfzce

11

Earthing wire

2 Overload protector of compressor 7 Outdoor fam 12 Neutral wire

3 Temperature sensor 8 Four-way valve 13 Interface 1 of reactor

49

Communication interface for indoor

unit

14 PFC capacitor interface

5 Electron expansion valve 10 Live wire 15 Interface 2 of reactor

TOP VIEW

Outdoor tube temperature sensor

Loading...

Loading...