Vitrex EYE PROTECTION User Manual

PERSONAL SAFETY GUIDE

EYE PROTECTION

CE 166

EN166:2001

SPECTACLES, GOGGLES AND FACE SHIELDS

INFORMATION FOR USERS:

All Vitrex eye and face protection satisfies the requirements of the European Directive for Personal Protection Equipment

(PPE) 89/686/EEC and has been manufactured in accordance with the requirements of the European Technical Performance

Standard EN166 1995 and in addition carries the European Union CE Mark.

CARE AND CLEANING:

Store at normal room temperature in a box or a locker. Carry in the box, bag or case provided and not unprotected in a

pocket with other items. Clean with warm soapy water, rinse then dry with a clean lint free cloth or tissue. Check daily: hin ge

screws, pivots or other moving parts for tightness and security. Disinfect when required with mild household or medical

disinfectant, then rinse off as in previous clause.

CLASSIFICATION

SPECTACLES:

These meet the requirements of increased robustness or low-energy impact, but do not protect against dust or liquid splash.

GOGGLES:

Designed for low or medium velocity impacts and for goggles with indirect ventilation also against dust and liquid splash. Gas

welding goggles must not be used for electric arc welding.

BROWGUARDS AND SCREENS:

Protect eyes and face against high velocity impacts and also liquid splash but not dust.

LIFE AND PERIOD OF USE:

The shelf life of goods if stored in boxes is indefinite. Products stored in good condition at an even ambient temperature

should be thoroughly inspected before use. If the products show signs of deterioration after storage they should be replaced.

PACKAGING:

Items to be transported should be packaged in the box, bag or case provided and not carried loose with items such as tools

or other metal objects.

PRODUCT CODE MARKINGS:

Refer to tables.

Welding shades will be identified, on the lens by shade density number prior to manufacturers identification mark.

CAUTION:

Should the product cause skin irritation its use should be discontinued and medical advice sought. Broken or damaged

products, scratched lenses and items obviously at the end of their useful life must be immediately replaced. If the symbols S,

F or B are not common to both ocular and the frame, then it is the lower level which shall be assigned to the complete eye

protector. For an eye protector to comply with field of use symbol 9, both the frame and ocular shall be marked together

with one of the symbols F or B.

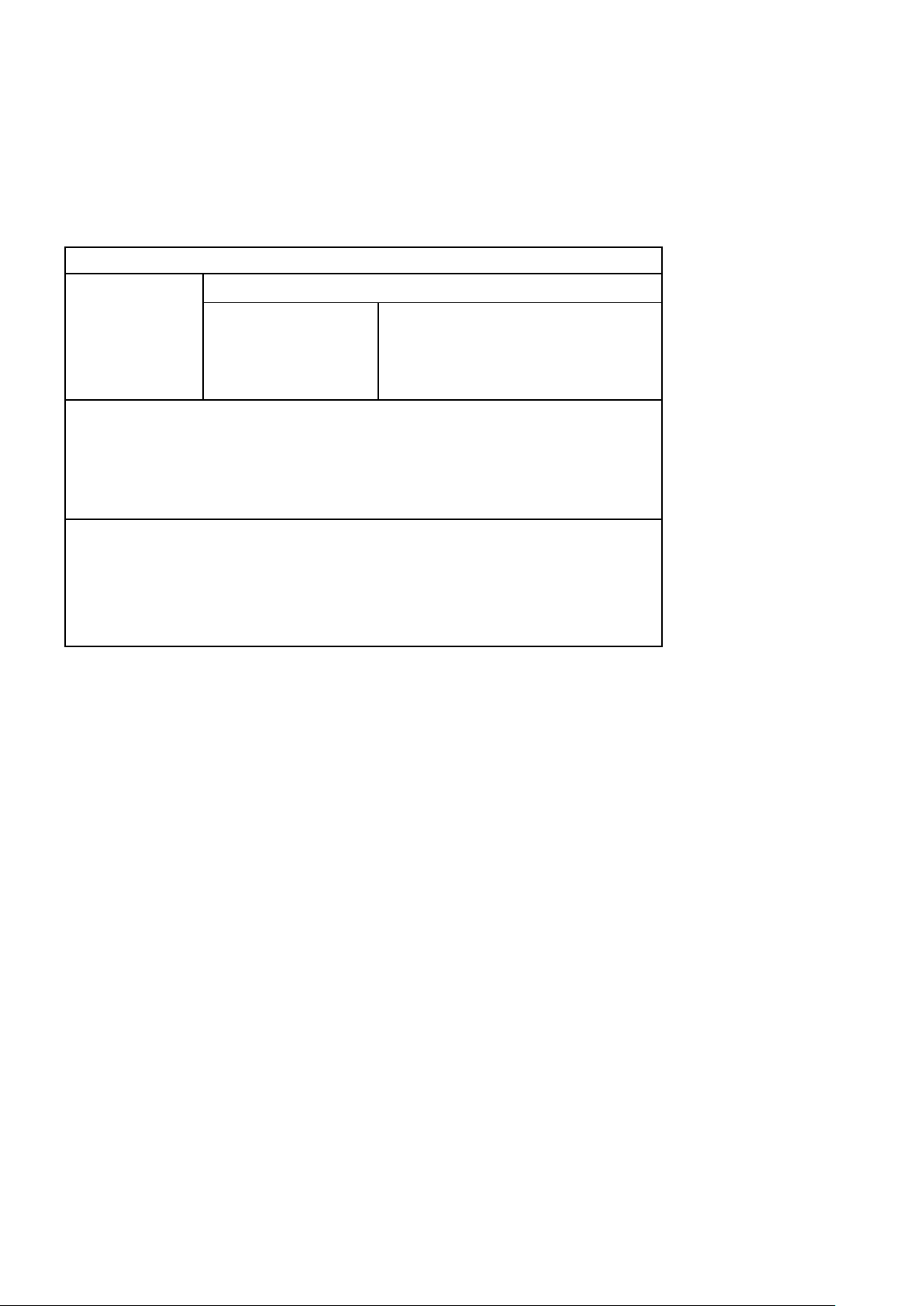

Shade numbers of filters to be used during gas welding & brazing

Flow rate q

of acetylene

Type of operation

Welding &

brazing of heavy

metals

Welding with

emmissive fluxes (notably light alloys)

(L/H)

q<70

4

4F

70<q<200

5

5F

200<q<800

6

6F

800<q

7

7F

Note 1. According to the conditions of use, the next greater or the next smaller

shade number can be used.

Note 2. The term heavy metal applies to steels, alloy steels, copper and its alloys

etc.

Low and medium energy oculars are impact resistant but not unbreakable. Clean and inspect regularity. Pitted or scratched

lenses reduce vision and seriously reduce protection – replace immediately. Some impact resistant eye protectors will

facilitate the wearing of prescription spectacles under them. However in certain cases these eye protectors may transmit

impacts to the eyewear enclosed and therefore may be reduced.

Loading...

Loading...