USER’S GUIDE

6000-2 & 6000-3

Phase Angle Voltmeters

Warranty

This Vitrek instrument is warranted against defects in material and workmanship for

a period of two years after the date of purchase. Vitrek agrees to repair or replace

any assembly or component (except batteries) found to be defective, under normal

use, during the warranty period. Vitrek's obligation under this warranty is limited

solely to repairing any such instrument, which in Vitrek's sole opinion proves to be

defective within the scope of the warranty, when returned to the factory or to an

authorized service center. Transportation to the factory or service center is to be

prepaid by the purchaser. Shipment should not be made without prior authorization

by Vitrek.

This warranty does not apply to any products repaired or altered by persons not

authorized by Vitrek or not in accordance with instructions provided by Vitrek. If

the instrument is defective as a result of misuse, improper repair, or abnormal

conditions or operations, repairs will be billed at cost.

Warranty 3

Vitrek assumes no responsibility for its product being used in a hazardous or

dangerous manner, either alone or in conjunction with other equipment. Special

disclaimers apply to this instrument. Vitrek assumes no liability for secondary

charges or consequential damages, and, in any event, Vitrek's liability for breach of

warranty under any contract or otherwise, shall not exceed the original purchase

price of the specific instrument shipped and against which a claim is made.

Any recommendations made by Vitrek or its representatives, for use of its products

are based upon tests believed to be reliable, but Vitrek makes no warranties of the

results to be obtained. This warranty is in lieu of all other warranties, expressed or

implied and no representative or person is authorized to represent or assume for

Vitrek any liability in connection with the sale of our products other than set forth

herein.

Instrument Serial Number: _________________________________________

4 6000-2 & -3 User Guide, Rev E

Document Part Number MO-6000-M Revision E

Copyright

Copyright© 1995–2005 Vitrek. All rights reserved.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form

with prior written consent from Vitrek. This product manual is copyrighted and

contains proprietary information, which is subject to change without notice. The

product displays and manual text may be used or copied only in accordance with the

terms of the license agreement.

Vitrek

is a trademark of Vitrek. All other trademarks or

registered trademarks are acknowledged as the exclusive property of their respective

owners.

In the interest of continued product development, Vitrek reserves the right to make

changes in this guide and the product it describes at any time, without notice or

obligation.

Manufacturers of Engineering & Production Test Equipment

12169 Kirkham Road

Poway, CA 92064

(858) 689-2755

E-Mail: info@vitrek.com

Contents 5

Contents

Warranty_________________________________________________ 3

Introduction _____________________________________________ 11

Features _________________________________________________11

Principles of Operation _____________________________________12

Central Processor _______________________________________ 12

Signal Conditioning and DSP Sections ______________________ 13

Input Scaling___________________________________________ 14

Amplitude Measurement Circuitry and DSP __________________ 14

Frequency Measurement _________________________________ 15

Range/Mode Control ____________________________________ 15

Sample Clock Generation _____________________________ 15

Filter Clock Generation _______________________________ 16

Front Panel Operation _____________________________________ 17

Front Panel Operational Features______________________________17

Power Switch __________________________________________ 17

The Display ___________________________________________ 17

Display Select Keys _____________________________________ 18

The Up and Down Arrow Keys ____________________________ 19

The Left and Right Arrow Keys____________________________ 19

Total & Harms Keys_____________________________________ 19

Numeric Entry Keys_____________________________________ 20

Clear & Enter Keys _____________________________________ 20

Store & Recall Keys_____________________________________ 20

Setup Key_____________________________________________ 21

Local Key & Indicator ___________________________________ 21

Calibration Key ________________________________________ 22

Print Key______________________________________________ 22

The Nullmeter _________________________________________ 22

Input Connector Keys & Indicators _________________________ 23

6 6000-2 & -3 User Guide, Rev E

Making Input Connections___________________________________24

Guard Connections______________________________________ 24

Input Cables ___________________________________________ 25

Using the Operational Keys __________________________________25

Changing Displayed Information or Settings__________________ 25

Setting Defaults ________________________________________ 27

Entering New or Changed Information ______________________ 30

Setting/Formatting Time & Date ___________________________ 31

Storing & Retrieving Configurations___________________________32

Store & Recall Memory Menus ____________________________ 33

Storage Area Maintenance ________________________________ 34

Repacking of the Storage Areas____________________________ 35

Rear Panel ______________________________________________ 37

Connectors & Controls _____________________________________37

Power Connection ______________________________________ 38

Configuration Control Switch _____________________________ 38

Parallel Printer Interface__________________________________ 38

RS232 Connectors ______________________________________ 38

IEEE488 Connector _____________________________________ 38

Configuration Setup_______________________________________ 39

Setup Guidelines __________________________________________39

Input Configuration Menu ___________________________________43

Input Scaling___________________________________________ 43

Guard ________________________________________________ 43

Measurement Configuration Menu ____________________________44

Fundamental Frequency__________________________________ 44

Fundamental Frequency Range ____________________________ 45

Fundamental Source_____________________________________ 45

Nominal Amplitude Measurement Period ____________________ 46

Filter Frequency ________________________________________ 47

Maximum Harmonics____________________________________ 47

Fundamental÷Bandwidth _________________________________ 48

Analysis ______________________________________________ 48

Fundamental Frequency Averaging _________________________ 49

Fundamental Frequency Measurement Period_________________ 49

Nullmeter Display Menu ____________________________________49

Nullmeter Parameter Types _______________________________ 49

Contents 7

Parameter Display Menus ___________________________________50

Parameter (p) __________________________________________ 50

Reference Parameter (r) __________________________________ 54

Reference Parameter Type ________________________________ 54

Data Result Units _______________________________________ 54

Comparison Limit_______________________________________ 55

Filter Time Constant_____________________________________ 56

Some Useful Hints ______________________________________ 56

Showing Percentages & dB Changes_____________________ 56

Unstable Displayed Results ____________________________ 57

Display Line Format _______________________________________57

Nullmeter Scale Menu ______________________________________58

Scale Factor ___________________________________________ 58

Type _________________________________________________ 59

Additional Application Examples _____________________________60

Interface Operation _______________________________________ 63

RS232 Data Format Selection ________________________________63

IEEE488 Interface Setup ____________________________________64

Configuring the Controller Card ___________________________ 65

Configuring the Controller Software ________________________ 66

Interrogating the Data ______________________________________67

Reading Data __________________________________________ 67

Sending Data __________________________________________ 68

RS232 Interfacing_______________________________________ 69

IEEE488 Interfacing_____________________________________ 69

Bus Timing_________________________________________ 69

Bus Commands _____________________________________ 69

Application for the Lower Case Portions of Commands______ 70

Command Set_____________________________________________71

Interface Commands_____________________________________ 71

Available Parameter Strings_______________________________ 74

Retrieving Parameters ________________________________ 75

Source and Bandwidth Strings__________________________ 79

Sub-Definition Strings ________________________________ 80

Special Parameter Strings _____________________________ 81

ID Data Format _____________________________________ 82

UNITS=String Format ________________________________ 82

Full-Parameter Definition Format _______________________ 84

8 6000-2 & -3 User Guide, Rev E

High Speed Operation ______________________________________85

Measurement Periods____________________________________ 85

Frequency Measurement _________________________________ 85

Harmonic Measurement__________________________________ 85

Interrogating Results ____________________________________ 85

Maintenance & Calibration _________________________________ 87

Daily Maintenance_________________________________________87

Low Level DC Measurements _____________________________ 87

Procedure without Equipment __________________________ 87

Procedure with Equipment_____________________________ 88

External Calibration________________________________________89

Preparation for Calibration________________________________ 90

Required Equipment_____________________________________ 91

Calibration Procedure____________________________________ 91

Performing a Partial Calibration ______________________________93

Performing a Calibration Check Only __________________________93

Appendix A: AIO Option___________________________________ 95

AIO Option Features _______________________________________95

AIO Option Commands_____________________________________95

Appendix B: Specifications _________________________________ 97

Voltage Input _____________________________________________97

Current Input _____________________________________________98

Input Filtering ____________________________________________98

Phase ___________________________________________________98

Fundamental Frequency Measurement _________________________99

Harmonic Analysis_________________________________________99

Peak Parameters__________________________________________100

Date and Time ___________________________________________100

General_________________________________________________100

Contents 9

Figures

Figure 1. System Block Diagram _______________________________________ 12

Figure 2. Digital Signal Processing Block Diagram_________________________13

Figure 3. Sample Clock_______________________________________________ 16

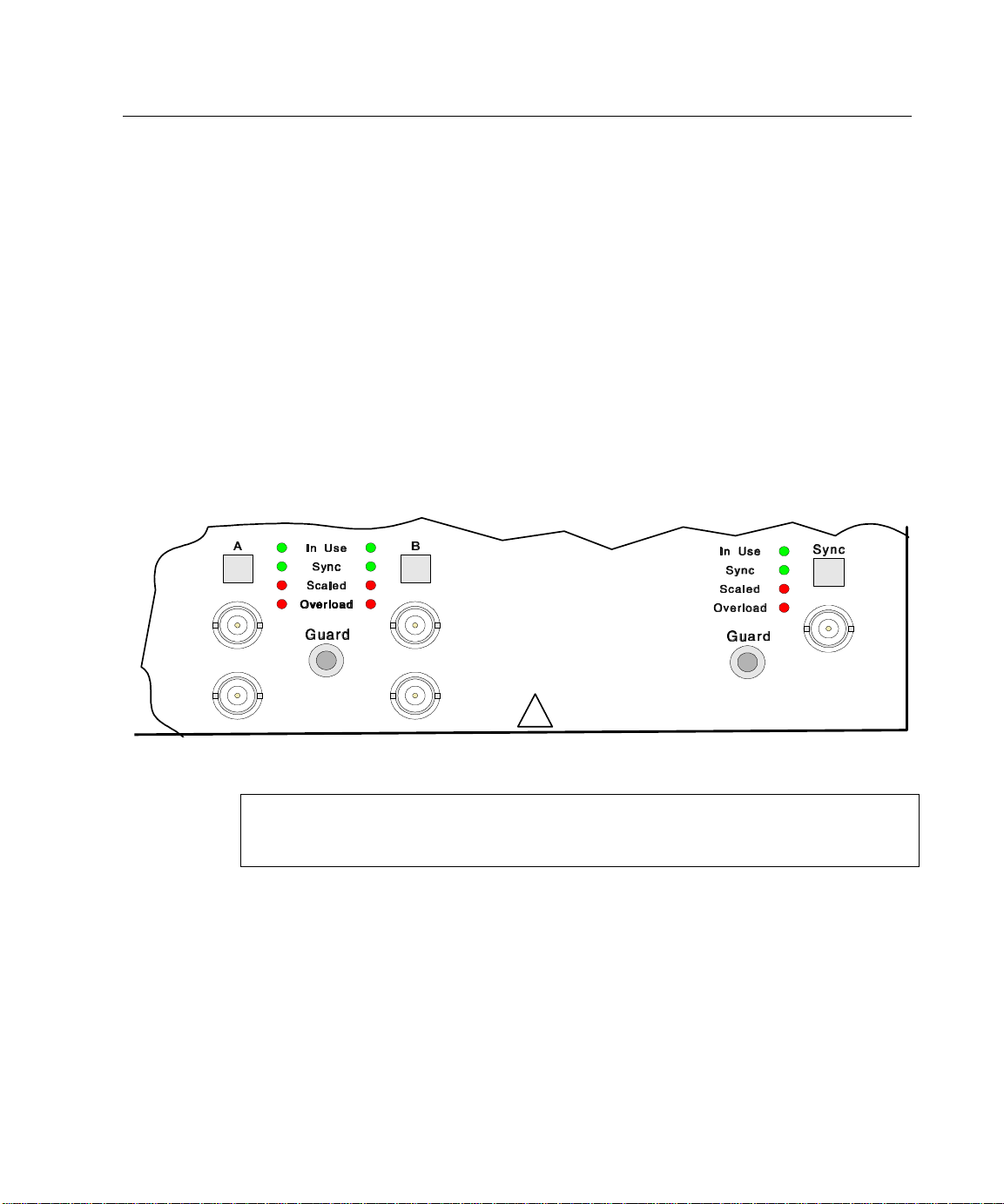

Figure 4. The 6000-3 Voltmeter Front Panel ______________________________17

Figure 5. Display Showing Results Data _________________________________18

Figure 6. The Nullmeter ______________________________________________22

Figure 7. Input Terminals _____________________________________________ 23

Figure 8. Display Line Configuration Data _______________________________ 26

Figure 9. Rear Panel Partial View_______________________________________ 37

Figure 10. Initial Setup Display ________________________________________ 39

Figure 11. Setup Measurements Display__________________________________40

Figure 12. Input Configure Display _____________________________________41

Figure 13. Nullmeter Sample Display____________________________________42

Configuration Examples

ØTo change a display line of Results Data: _______________________________ 26

ØTo select an option: ________________________________________________ 26

ØTo set defaults:____________________________________________________27

ØTo abort a displayed menu and discard any changes: ______________________ 28

ØTo change a display line: ____________________________________________28

ØTo adjust a “noisy” measurement (to a given value): ______________________29

ØTo provide a “fast/medium/slow” style of adjustment capability: ____________ 29

ØTo add display lines (up to 50 lines possible): ___________________________ 30

ØTo delete a display line:_____________________________________________30

ØTo add dashes in a display line as a separator: ___________________________ 30

ØTo “enter” data and changes into the menu—when the cursor is flashing:______ 30

ØTo “enter” data and changes into the menu—when no cursor is visible: _______31

ØTo adjust the time display:___________________________________________ 31

ØTo format the time display: __________________________________________ 32

ØTo set the date format: ______________________________________________ 32

ØTo set the date display: _____________________________________________32

10 6000-2 & -3 User Guide, Rev E

ØTo store a configuration in an already defined storage area:_________________33

ØTo store a new configuration (presently displaying): ______________________33

ØTo recall a configuration:____________________________________________ 34

ØTo rename an existing storage area:____________________________________34

ØTo delete a storage area: ____________________________________________34

ØTo manually prompt the repacking of storage areas:_______________________ 35

ØSetting fundamental frequency mode and range for input connectors: _________39

ØSetting the input mode for each input connector: _________________________41

ØTo change the (input) scale factor: ____________________________________42

ØSetting the Guard connection for each input connector: ____________________42

ØTo configure the Nullmeter parameter display:___________________________42

ØTo complete a configuration setup: ____________________________________ 43

ØTo measure signal content of harmonics, amplitude, phase, and sync:_________60

ØTo measure harmonic content, or wideband amplitudes synchronously: _______61

ØTo perform spectral analysis of the input signal.__________________________62

ØTo measure wideband amplitudes over a known period of time: _____________ 62

ØTo perform an external calibration: ____________________________________ 91

ØTo perform a calibration check:_______________________________________ 93

Introduction

Congratulations on purchasing one of the high technology signal analysis

instruments available from Vitrek. The 6000 family of Phase Angle Voltmeters

offers the utmost in accuracy and flexibility.

These instruments contain an automatic switching power supply, thus no changes are

required for local AC supply voltage or frequency variations, simply select the power

cord extension that connects to your supplied power.

Features

The Phase Angle Voltmeter instruments are available as a two input, the 6000-2, and

as a three input, the 6000-3. Both have full accuracies available on all inputs fitted.

The following lists some of their significant features.

Introduction 11

• Fully digital signal processor (DSP) based operation, no analog phase-locked

loops, phase detectors or other delicate, inaccurate circuitry. These instruments

have a 0.0005Hz to 200kHz range of frequencies.

• True 18-bit resolution on each input, which yields exceptional phase, amplitude

and harmonic resolution.

• 500kHz sampling frequency on each input simultaneously, which yields

excellent high frequency accuracies, even with heavily distorted waveforms, and

the widest range of harmonics measurement (up to the 2047th harmonic).

• DSP based fundamental frequency component detection, which yields the widest

range of fundamental “reference” input, even when buried in noise and

distortion.

• Two 40mHz 24-bit Digital Signal Processors for each pair of inputs, and one

68020 32-bit Central Processor, which yields the highest measurement speeds

available.

• Full Range of measurement capabilities, not just amplitude, frequency and

phase. THD, inter-harmonic phase, spectrum analysis, cross-correlation are just

a few of the additional measurements available at the touch of a button.

12 6000-2 & -3 User Guide, Rev E

• Fully customizable display window. Shows 4 lines at a time and is scrollable to

50 lines.

• High resolution bargraph contains 101 elements and two supporting interface

keys.

• Both voltage and current input capabilities on each input, which allows for high

accuracy power measurements from a few nanowatts to hundreds of watts.

• The interface package adds control capabilites with the IEEE488 and RS232

connections; printing capacity with the Parallel printer connectors; and analog

output ability with 12 analog connections, when AIO option is fitted.

Principles of Operation

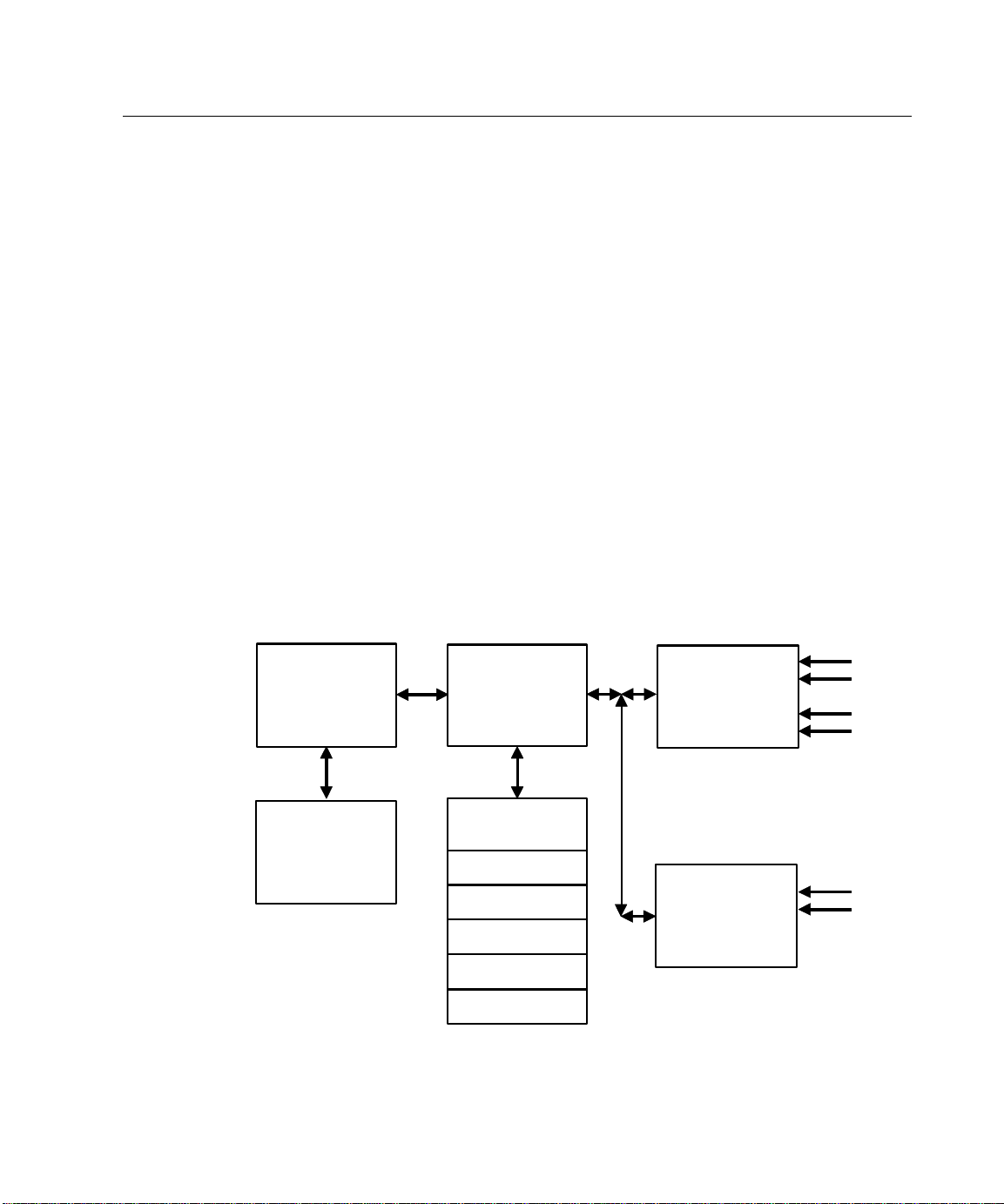

For basic details regarding the circuitry and methods used in the 6000 instruments,

Figure 1 shows the overall block description of their internal system’s circuitry.

Central Processor

The central processor consists of circuitry surrounding a Motorola 32-bit

MC68EC020 processor and a MC68882 math co-processor, both of which run at

25mHz. These processors perform all interfacing and inter-digital signal processing

and coordination required in the instrument.

Equation

Coprocessor

(MC68882)

Flash

Memory

(up to 4 Mbyte)

Central

Processor

(MC68020)

Interfaces

Front Panel

IEEE488

2 x RS232

Parallel Printer

Option AIO

Figure 1. System Block Diagram

Conditioning

and DSPs

(2xDSP56001)

Conditioning

and DSPs

(2xDSP56001)

Signal

Signal

A

B

Sync

Introduction 13

High Speed

High Speed

High Speed

Optical Isolation Barrier

Digital Peak

Digital Peak

Range/Mode

V

A

High Speed

The software run by this processor is stored in flash memory, allowing the

instrument’s software to be field upgradeable without requiring removal of the

covers or any circuitry. The interface of this processor to the interface components:

IEEE488, (2) RS232 and Parallel Printer is via the processor’s native bus interface.

This bus interface uses standard commercial integrated circuits for hardware. All of

these interfaces use interrupt driven software to perform their input/output duties,

yielding a high-speed interface.

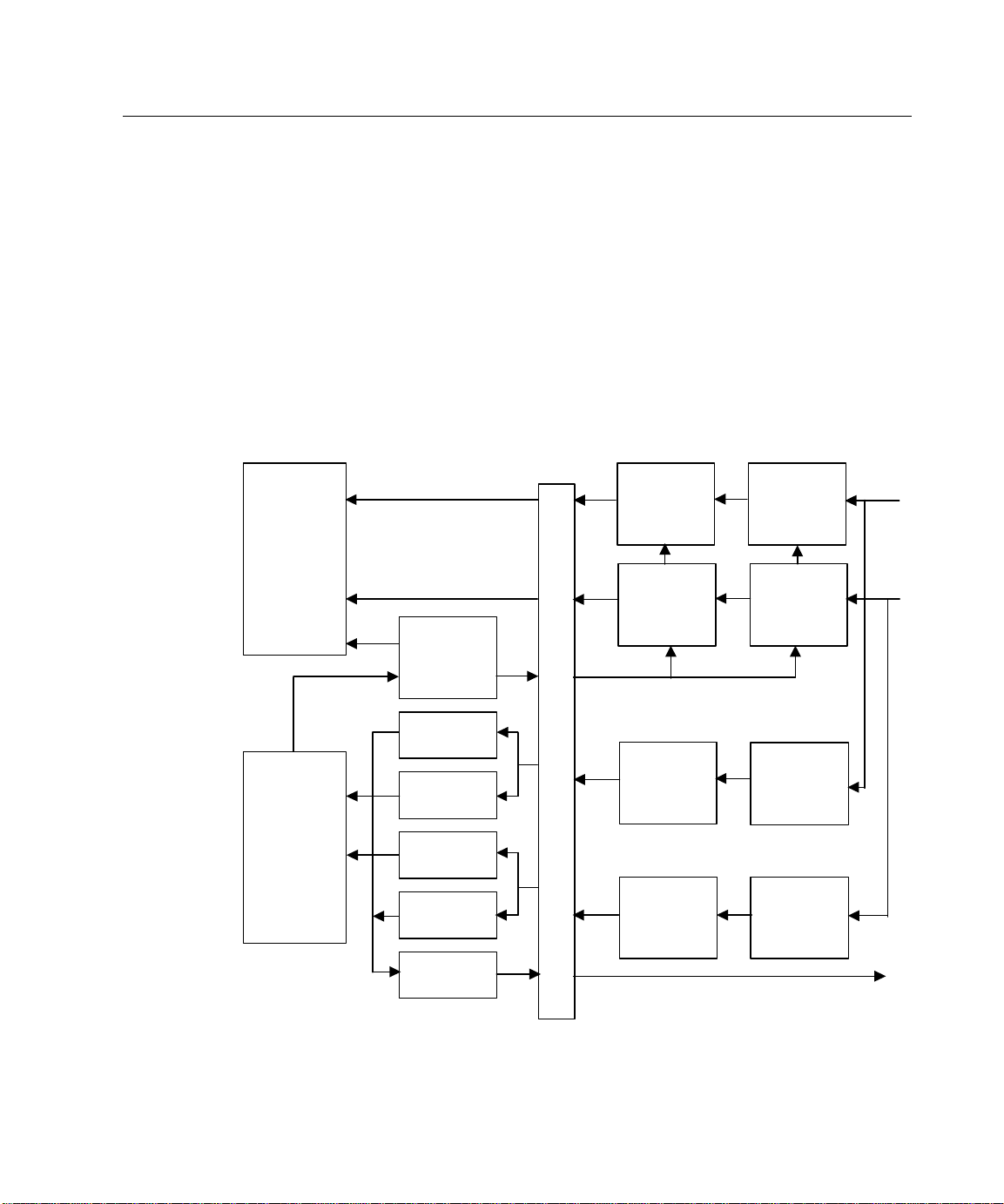

Signal Conditioning and DSP Sections

For each pair of the instrument’s inputs, there is a set of circuitry that contains two

Motorola DSP56001 24-bit processors interfaced to the central processor. The

interface is made via a high speed RS485 data link. Refer to Figures 1 and 2.

56-bit

Digital

Signal

Processor

(DSP56001)

56-bit

Digital

Signal

Processor

(DSP56001)

AMPLITUDE

MEASUREMENT

Digital

Noisy

Sample

Generator

Detector

Digital HI-Q

BP Filter

Digital HI-Q

BP Filter

Detector

500KHz

18-bit

Digitizer

500KHz

18-bit

Digitizer

SYNCHRONOUS SAMPLE CONTROL

2MHz

8-bit

Digitizer

FREQUENCY MEASUREMENT

RANGE/MODE CONTROL

2MHz

8-bit

Digitizer

Digital

LP filter

(Variable)

Digital

LP filter

(Variable)

Analog

LP filter

(1 MHz)

Analog

LP filter

(1 MHz)

control

Range & Mode

Figure 2. Digital Signal Processing Block Diagram

14 6000-2 & -3 User Guide, Rev E

These sections also provide the primary isolation between the grounded digital

circuitry of the instrument and the floating input circuitry via an optical isolation

barrier, which passes digital signals only.

Each of these sections is capable of operating independently, or can be “joined” to

one or both of the other sections to perform simultaneous sampling, as required, by

the central processor.

Input Scaling

Each input has identical systems that perform the required scaling of the input

signals to the levels required by the amplitude and supervisory systems. Each

input’s scaling is fully differential throughout, and is powered by isolated power

supplies having its common driven by the respective GUARD terminal. In this

manner, excellent common-mode performance is achieved, and the signal quality

delivered to the respective amplitude and supervisory sections is maintained, even in

a digital “backplane” environment. Each input’s scaling and mode is controlled by

parallel digital codes provided by the relevant supervisory DSP. The form of

amplification chosen maintains excellent phase shift, even at high frequencies, using

many gain stages for amplification. Each gain stage is configured to produce the

same nominal phase shift independent of gain setting. Each input system also

presents the GUARD terminal connection to its amplitude and supervisory DSPs to

act as the common for their isolated power supply requirements.

Amplitude Measurement Circuitry and DSP

Each input, after scaling, is filtered by a high speed digital low-pass filter having its

corner frequency (filter clock frequency) controlled by one of three filter clocks

common to all amplitude systems. After filtering, each input signal is then converted

to 18-bit digital form by an 18-bit. analog-to-digital converter system, whose sample

clock is taken from one of three sample clocks common to all amplitude systems.

Each converter consists of a pair of time interleaved 250kHz converters, allowing for

sampling up to 500kHz. Refer to Figure 2, the Digital Signaling Processing Block

diagram.

The output of all four converters (two per input) is read by Motorola’s digital

converter, DSP56001, at a rate controlled by the same sample clock used by the

converters.

This processor performs all amplitude and harmonic analysis required by the system,

and maintains a database of the results of the latest such measurements for its

channel. The central processor gains access to these results via a high speed RS485

data link. This same link is used to pass to the DSP the selections to use for its

sample and filter clock signals, and details regarding the measurements to be made.

Introduction 15

The channel’s circuit board with this harmonic analysis DSP is internally named the

"Amplitude DSP".

Frequency Measurement

Each scaled input passes to a second sub-system for additional analysis. This second

sub-system is internally named the “Supervisor DSP” board and consists of the

following portions:

Filter and High Speed ADC—Each input passes through an analog 1mHz low

pass filter, and sampled at 2mHz by a pair of 8-bit analog-to-digital converters.

Supervisory Processor—The outputs of the pair of 8-bit converters is read by a

Motorola DSP56001, which performs several asynchronous tasks using this data.

This processor is linked to the central processor using the high speed RS485 data

link.

Range/Mode Control

Overload and Underload Detection—Each sample is checked for overload

status. If an overload is detected then the DSP changes the range presented to the

input scaling circuitry (if able) and informs the central processor that a range change

has occurred.

If an underload condition remains for longer than a period provided by the central

processor (actually set by the minimum fundamental frequency expected) then the

DSP changes the range presented to the input scaling circuitry (if able), and informs

the central processor that a range change has occurred. This process is continuous,

independent between the inputs, and completely independent of any other activities

in progress in the instrument. You can also set a fixed range, rather than the above

autorange process.

Bandpass Filtering and Frequency Measurement—Input samples are

passed through a proprietary system. The system performs a tracking bandpass filter

function, maintaining track of the fundamental frequency reading within set range.

This tracked frequency reading is then used to measure the frequency of the

remaining signal component. This process is continuous and independent between

the inputs, and completely independent of any other instrument or supervisory

processor activities in progress.

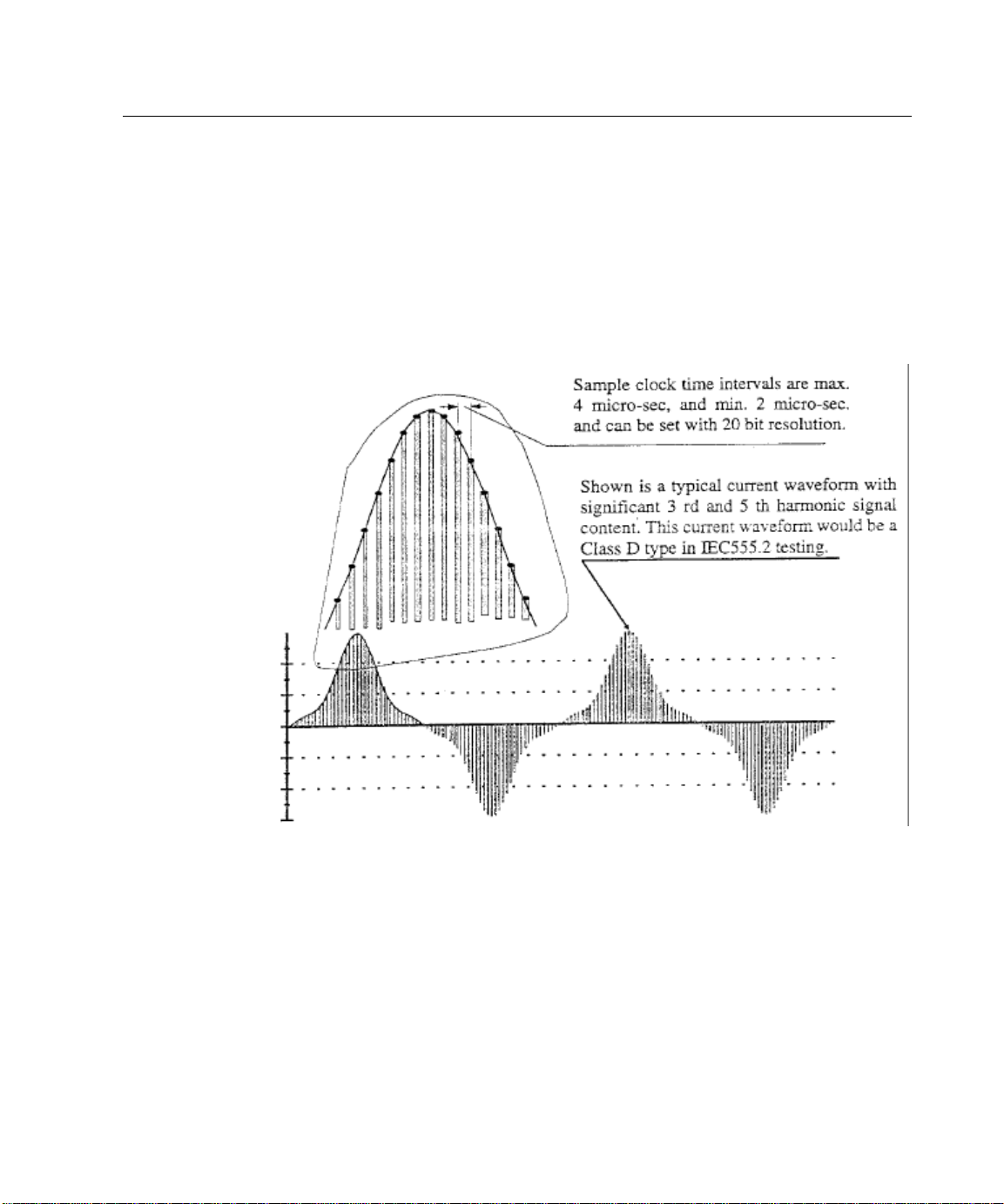

Sample Clock Generation

Under the direction of the central processor, the supervisory DSP controls circuitry

contained in an ASIC, which generates a digital clock signal whose average

16 6000-2 & -3 User Guide, Rev E

frequency is settable with 20-bit resolution over a 2:1 range of frequencies. This

clock signal is available to all amplitude DSP systems on one of three such signal

lines. If desired by the central processor, the supervisory processor can “link” this

frequency to that of either of its measured input frequencies. The form of the sample

clock is such that the individual sample-to-sample clock period can vary by up to

1%, however, the average over any 256 sample period is always within 1ppm of the

set value. This “jittered” sampling ensures that no input signal component can be

synchronous to the amplitude system’s sample rate, removing the anomalous effects

that occur when this happens.

Figure 3. Sample Clock

Filter Clock Generation

Under the direction of the central processor, the supervisory DSP controls circuitry

contained in an ASIC which generates a digital clock signal whose frequency is

selectable in 1.2:1 steps over 4.5 decades of frequencies. This clock signal is

available to all amplitude DSP systems on one of three such signal lines.

Front Panel Operation 17

Not installed on the 6000-2

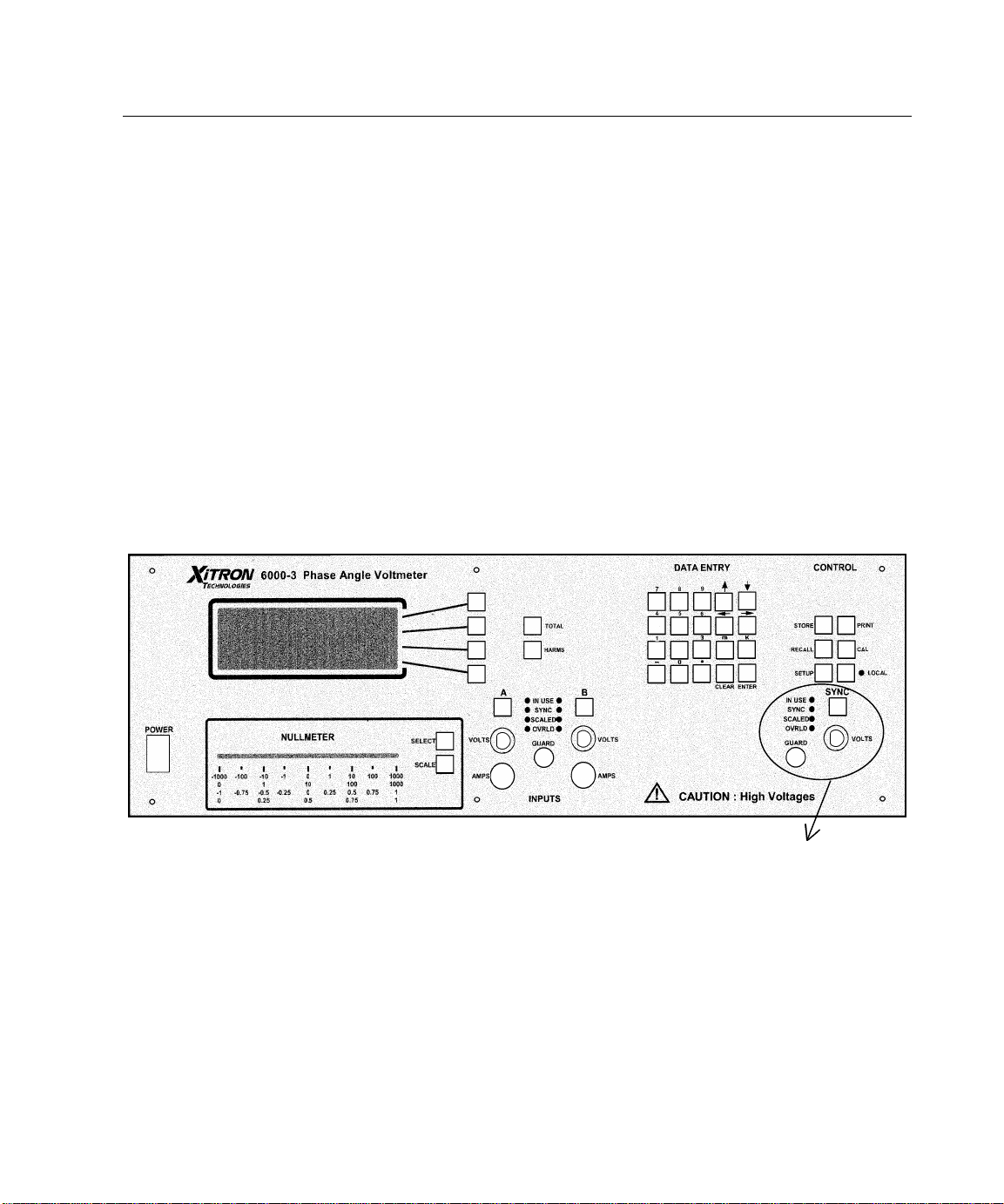

Front Panel Operation

This section includes a description of the front panel interface features of the Phase

Angle Voltmeter instruments and their basic operation. Refer to Configuration

Control for an explanation of the menus.

Front Panel Operational Features

The 6000-2 and -3 Phase Angle Voltmeter instruments have a number of controls

and indicators available. See Figure 4.

Figure 4. The 6000-3 Voltmeter Front Panel

Power Switch

Turns the unit ON and OFF.

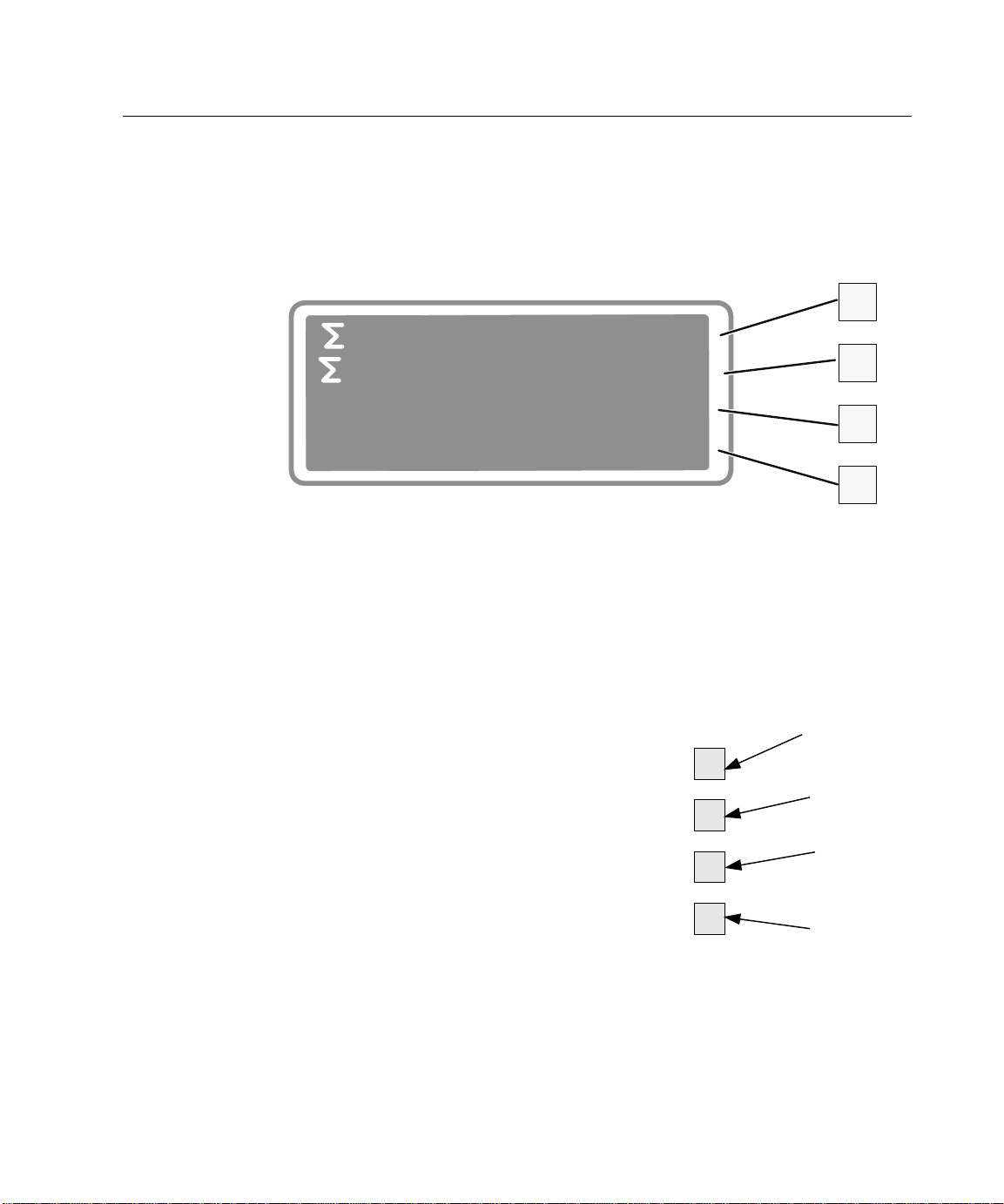

The Display

The front panel display is a “window” that provides a visual interface to the alphanumeric measurement Results Data and the changeable configuration menu. Refer to

18 6000-2 & -3 User Guide, Rev E

Figure 5. The instrument’s display can show (up to) four lines of information at one

time and maintains up to fifty lines of displayable measurement results, which are

accessible by scrolling. You can add or delete lines, as necessary. The display is the

interface focus, as it responds to all front panel key presses, showing the options

available for that key.

rms 118.7 Vrms B

rms 3.410 Arms B

true 350.2 W A

true 404.8 VA A

The display responds to all front panel keys described below. To place a cursor in a

display line, use a DISPLAY SELECT key, which are the corresponding unmarked keys

on the right. Press the ENTER key once to remove the cursor. Press it twice to action

the configuration.

Figure 5. Display Showing Results Data

Display Select Keys

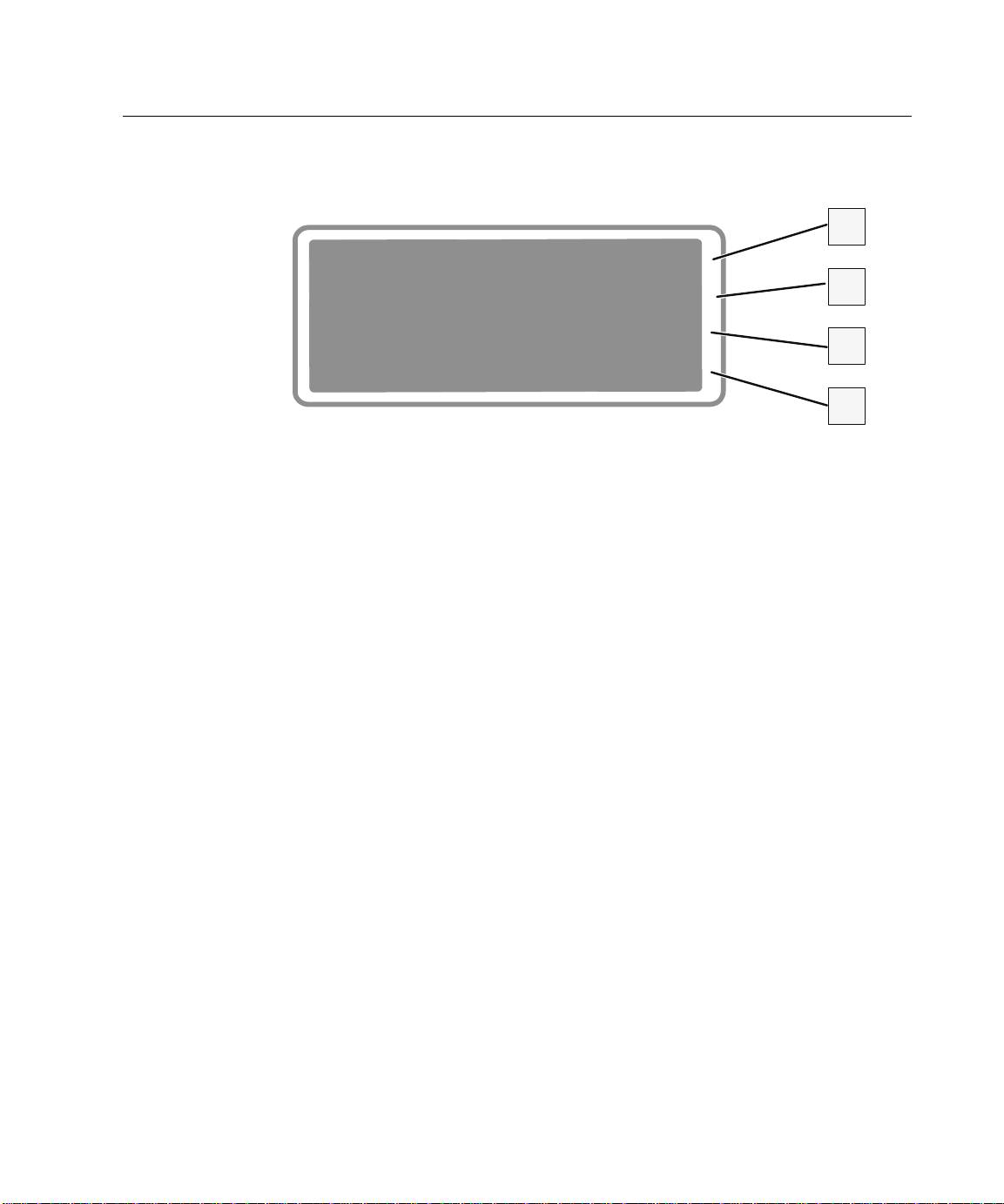

The unmarked keys located to the right of the

display are called the DISPLAY SELECT keys.

The topmost key is 1, second is 2, third is 3, and

forth is 4:

• Use to bring up the configuration for each

line of Results Data, including blank lines.

• Use to place the cursor in the menu display.

• Use to page through the various parameter

screens using the topmost key identified

here as the DISPLAY SELECT 1 key; and

• Use in combination with arrow keys, to

scroll through options to edit a

configuration menu item.

1

2

4

3

Front Panel Operation 19

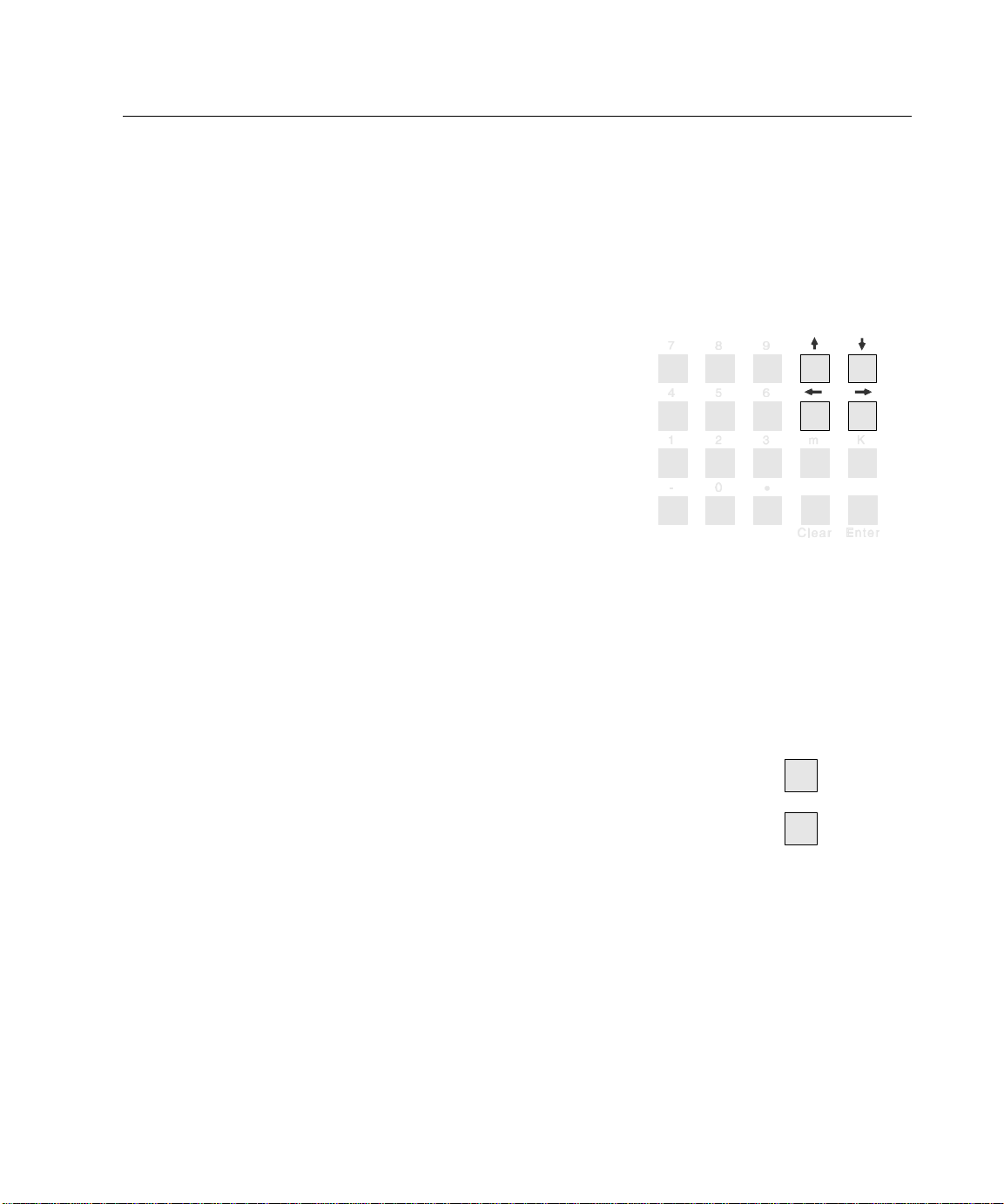

The Up and Down Arrow Keys

The é and ê keys (up and down arrows) are

part of the DATA ENTRY keypad. Use these keys:

• For scrolling the display Results Data lines,

one line at a time;

• To scroll through selectable options at a

DATA ENTRY

cursor position;

• When no cursor displays, use the é and ê

keys to scroll through various parameter

menu details given in the last three

configuration menu lines.

The Left and Right Arrow Keys

The ç and è keys (left and right arrows) are

part of the DATA ENTRY keypad.

Use these keys:

• To move the cursor to a new selectable

option within a menu line.

• When no cursor displays, use the ç and è

keys to scroll through various parameter

menu details given in the last three

configuration menu lines.

Total & Harms Keys

The TOTAL key requests a total value of the

selected parameter item.

The HARMS key toggles the “bandwidth”

selection between AC+DC and a harmonic

range.

TOTAL

HARMS

20 6000-2 & -3 User Guide, Rev E

Numeric Entry Keys

These keys are part of the DATA ENTRY keypad:

• Use the numbered keys to enter numerical

data into the display.

• Use the – (minus sign) to enter negative

integers and to change negative integers to

positive, as required.

• Use the . (decimal point) to enter decimal

values.

• Use the m and K keys to designate “micro”

and “kilo”. Note that these keys become

disabled automatically when not applicable.

Clear & Enter Keys

The CLEAR key is part of the DATA ENTRY

keypad and is used to:

• Discard changes made in either a menu line

or a menu.

• Abandon any change made, restarting the

selection from the beginning.

The ENTER key is part of the DATA ENTRY

keypad and is used to:

• Implement the action per the changes made

in either a menu line or a menu.

• Enter updated data into the menu settings.

DATA ENTRY

.

0

-

CLEAR

DATA ENTRY

ENTER

CLEAR ENTER

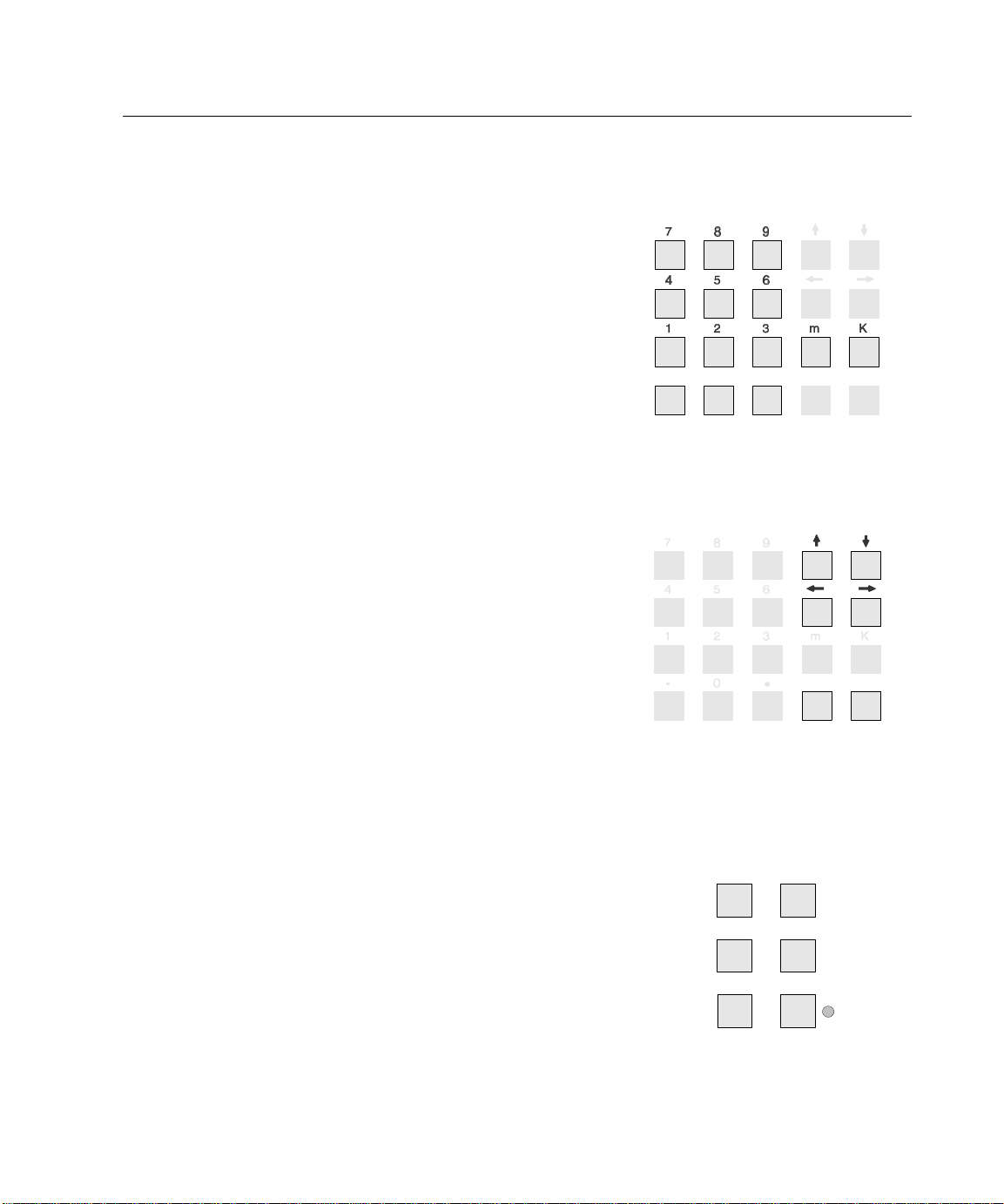

Store & Recall Keys

The STORE and RECALL keys are part of the

CONTROL keypad. These keys are used within

the Configuration Setup menus to:

• Store configurations in the internal non-

volatile “library” (65535 configurations).

• Recall any of the stored configurations.

• Overwrite and remove a configuration,

select or enter the number of an already

defined stored configuration.

Refer to Storing and Retrieving Configurations

on page 32.

STORE

RECALL

SETUP

CONTROL

PRINT

CAL

LOCAL

Setup Key

The SETUP key brings up a menu list so you can

reset the instrument to its default configuration.

Note that the Measurement Configuration

default is set to measure signals in the 40Hz to

500Hz frequency range.

• Use to set Analog inputs and outputs. Note

that the AIO option provides additional

outputs, if fitted.

• Use to set the IEEE488, RS232 interfaces

and Parallel printer. For more details refer

to Interface Operation on page 63.

• Use to set the display format of time and

date information. Refer to Setting/Format-

ting Time & Date on page 31, for details.

• Use to set the internal real time clock.

• Use to enable the ê key to scroll the

display to the lowermost menu lines.

• Use to perform “covers-on” software

upgrades.

Note: Contact Vitrek for specific details to

perform software upgrades.

Front Panel Operation 21

CONTROL

STORE

RECALL

SETUP

PRINT

CAL

LOCAL

Local Key & Indicator

The LOCAL key is part of the CONTROL keypad.

• Use to return control to the front panel

when using the IEEE488 interface to

another controller. For more details refer to

Interface Operation on page 63.

• The indicator light illuminates when front

panel operation is active.

22 6000-2 & -3 User Guide, Rev E

Calibration Key

The CAL key, is used to perform the following

tasks:

• Display the present status of the instrument:

Model

Options fitted

Software version

# of days since last calibration

Status of the internal multiprocessor

communications and memory checks.

• Test of the internal digital and analog

circuitry.

• Perform an Internal, Input, and External

Calibration of the instrument.

Print Key

Use the PRINT key to print the display menu or

data results.

STORE

RECALL

SETUP

CONTROL

PRINT

CAL

LOCAL

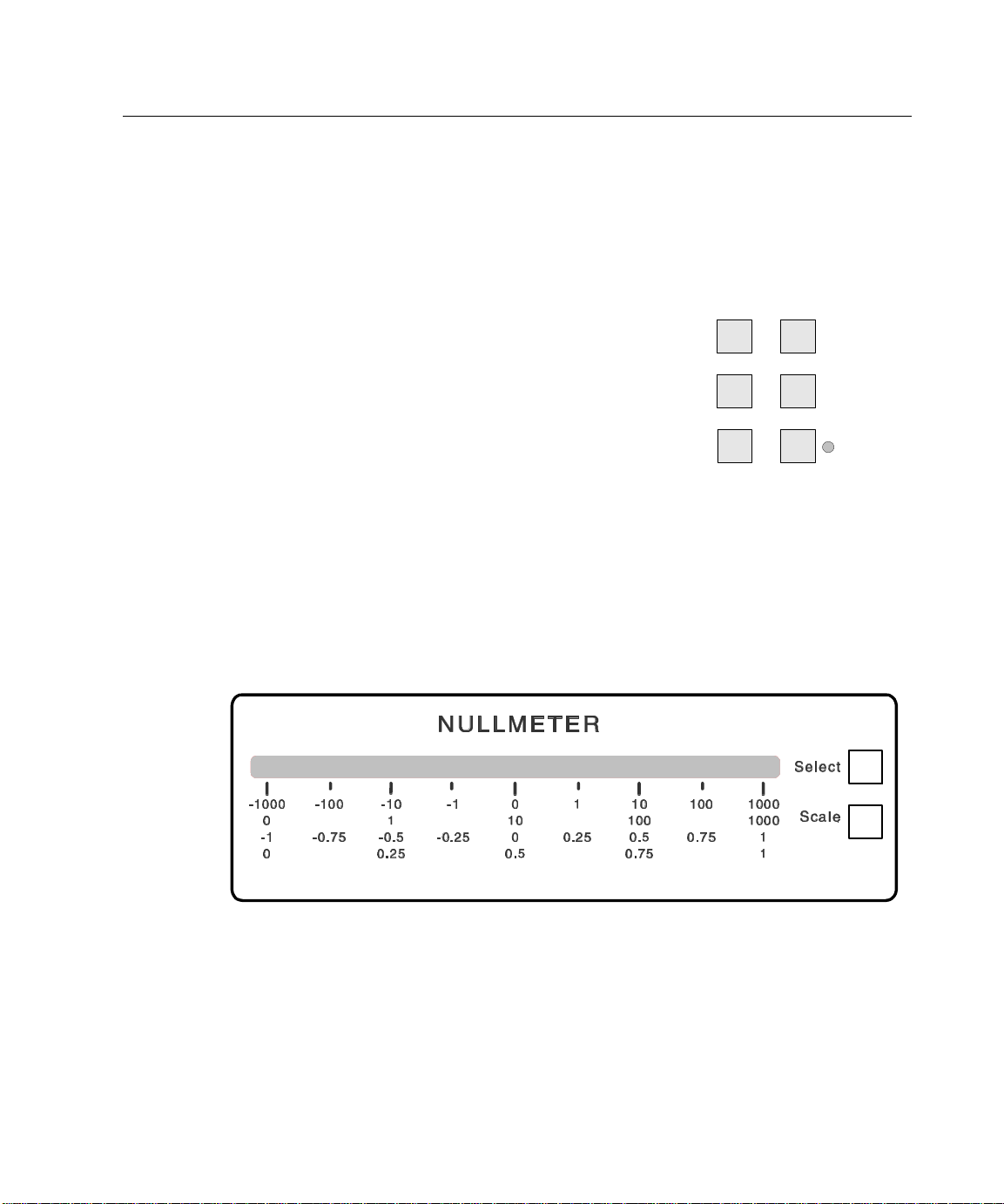

The Nullmeter

The nullmeter is a lighted bargraph. You can customize the graph by pressing its

SELECT and SCALE keys.

Figure 6. The Nullmeter

The NULLMETER SELECT key allows you to select the parameter to be displayed on

the nullmeter in the same manner as defining a display line parameter.

Note: If the zero position of the nullmeter is defined as other than zero, then a

deviation parameter must be selected to perform the required offset. Refer to the

Nullmeter Display Menu on page 49, for details on displaying Nullmeter results.

Front Panel Operation 23

The NULLMETER SCALE key allows you to select the:

• Scaling type: dot or bar;

• Linearity: linear or logarithmic;

• Zero position: left, centered, or mirrored around the center.

Note: The center zero position, log-scaled format provides a useful adjustment

capability of “coarse/medium/fine”. Refer to Nullmeter Scale Menu on page 58,

for more details.

Input Connector Keys & Indicators

Use either the voltage (V) or the current (A) input connection, but not both. The

6000-2 voltmeter has inputs A and B, and the 6000-3 voltmeter has A, B and SYNC.

If you select an externally driven guard, then connect a convenient source of a low

impedance-guarding signal to the GUARD terminal.

Volts

Amps Amps

Volts

Figure 7. Input Terminals

Warning: Ensure that all voltages are removed before coming in contact with any

of the input signal wiring to your voltmeter. This caution particularly applies to the

outer cover of the input BNC connectors.

Use the respective input (A, B, or SYNC) key:

• To select the individual input range (or autorange) and mode desired.

• To set a desired amplitude scaling for each individual input.

• To select whether the GUARD terminal is to be internally or externally driven.

Refer to Configuration Setup on page 39.

!

CAUTION : High Voltages

Volts

24 6000-2 & -3 User Guide, Rev E

View the respective connector’s indicator lights to determine, which input is being:

• Measured (IN USE);

• Used for fundamental frequency determination (SYNC);

• Scaled (SCALED);

• Overloaded (OVERLOAD). The instrument automatically protects itself against

serious overload, even when held on the most sensitive input range

Notes:

1) The maximum voltage between the GUARD terminal and an Input Low is 10V for

all voltage ranges of 2.5V and below, and for all current ranges. On the higher

voltage ranges, up to 1000V may be present between the terminal and input.

2) Noisy and inaccurate readings may result if the GUARD terminal is left

disconnected when external guard has been selected.

Making Input Connections

When deciding which inputs to use, attempt to follow the same pattern for all

applications. Use the following guidelines:

• If measuring amplitudes and/or distortion of a single signal, use input A.

• If measuring phase (or phase related amplitudes) between a pair of signals,

connect the ‘reference’ signal to input A and the “unknown” signal to input B.

• If making a power measurement, use input A for voltage and B for current.

• If using a third signal purely for synchronization purposes, use the SYNC input

for this purpose.

Guard Connections

The input capacitance of each input to ground is very low (a few hundred picofarads)

thus the use of an external connection for guard is rarely needed. We recommend

using external guarding under the following circumstances:

• If low level (less than 1V or 10mA) signals are being measured in the presence

of significant common mode voltages or interference.

• The input connections are extremely long (greater than 10ft).

• When using the current input, current low MUST be externally connected to the

GUARD terminal. And the input pair configured to use External guard

• When using internally connected Guard, choose the input having the largest

signal.

Front Panel Operation 25

Input Cables

Signal input connections are made to the front panel BNC connectors, using the V or

A connector for each input as desired. Each input is configured, such that the outer

shell of the connector is the input LO (negative) connection, and the central pin is the

input HI (positive) connection.

• Reconfigure each input while no signals are present.

• Check the configuration of each input prior to making connections, particularly

the GUARD connections.

Warning: NEVER TOUCH the outer shell of any of the BNC connectors

(including unused ones) when signals are applied to the instrument.

Notes:

1) Particularly when high frequency phase sensitive measurements are being made, it

is highly recommended that all cables be similar in both construction and length.

The phase shift caused by dissimilar cable lengths is of the order of 0.03° per foot at

100kHz.

2) When measuring voltages, reduce potential interference and crosstalk between

inputs by the use of shielded cables (e.g., coaxial cable). If input capacitance is of

concern, then use tightly wound wires of small gage, twisted pairs.

3) When measuring currents, particularly at the lower levels (10mA and less), use

tightly twisted pairs of wires of sufficient gage for the current being carried. In the

presence of severe interference, or where the current signal has significant common

mode voltage, keep the input connections as short as possible.

4) The GUARD connections (if any) may be made with any suitable form of

connection.

Using the Operational Keys

Whether viewing a display showing parameters, measurement results, or

configuration menu items, the method of front panel operation is the same. Refer

also to Configuration Setup on page 39.

Changing Displayed Information or Settings

To enter changes to a configuration, press a DISPLAY SELECT key to place the cursor

on the line of data you are modifying. If you press the ENTER key once, the cursor

disappears, although the displayed menu accommodates the new data. Press a

26 6000-2 & -3 User Guide, Rev E

DISPLAY SELECT key again to place the cursor in the display. If you press the ENTER

key twice the new data is applied and the display shows the Results Data.

Line #03 Parameter

p= Phs Bh01--Ah01

Display as +/-180

Filter = 30.000s

Figure 8. Display Line Configuration Data

Ø To change a display line of Results Data:

1. While the display shows the Results Data screen, press the DISPLAY SELECT key

that corresponds to the display line requiring change. A display showing

parameter values will come up.

o

2. Press a corresponding DISPLAY SELECT key a second time. A cursor will flash in

the display line to allow you to:

• Directly change the displayed information at the cursor.

• Change the displayed selection to the next one available.

3. Use the ç and è keys to move the cursor to the data or option you wish to

change.

4. Use the DATA ENTRY keys to enter a value.

5. Press the é and ê keys to scroll the options, as required.

6. Press the ENTER key twice to apply the change.

Ø To select an option:

1. From the Results Data display, press a DISPLAY SELECT key that correlates with

the line of Results Data you wish to modify. Refer to the Display Select Keys on

page 18.

2. From the Parameter display, press the DISPLAY SELECT key that correlates with

the line containing the option you wish to select, until the cursor flashes at the

option.

3. Use the é, ê, ç and è keys to select a new option. Press ENTER twice.

Front Panel Operation 27

Setting Defaults

Ø To set defaults:

Important Note: This action applies to all configured Results Data display lines.

Store any preferred setups before performing this step.

1. Press the SETUP key.

2. Press the DISPLAY SELECT key correlating to Set Defaults. The defaults will

automatically apply.

3. Press the ENTER key. The Results Data display will show the first four

configured lines, which are based on the preset Parameter and Setup

Measurement defaults.

For line #00 the Results Data is: Fund xx.xu Vrms A

The default Parameter setup is: p = True RMSAh 1 - 1

Display as volts rms

Filter = 0.000S

For line #01 the Results Data is: Fund xx.xu Vrms B

The default Parameter setup is: p = True RMSBh 1 - 1

Display as volts rms

Filter = 0.000S

For line #02 the Results Data is: Greal + x.xx B

The default Parameter setup is: p = Gre Bh01/Ah01

Display as Ratio

Filter = 0.000S

For line #03 the Results Data is: Fund - xxx.xxx B

The default Parameter setup is: p = Phs Bh01/Ah01

Display as +/- 180

Filter = 0.000S

If you press the Nullmeter’s SELECT key, the default Nullmeter Parameter screen

displays. Press ENTER to show Nullmeter Results Data and the Nullmeter light will

reflect the reading.

The default Nullmtr: Parameter setup is: p = Phs Bh01/Ah01

Display as +/- 180

Filter = 0.000S

28 6000-2 & -3 User Guide, Rev E

The default Nullmeter Scaling screen is: NULLMETER SCALING

0 to 1 = + 180.000

Bar Lin Centered

The default Setup Measurements are as follows:

Fundamental Frequency Fund: Measured

Fundamental Frequency Range Fund: 40.0 – 500 Hz

Fundamental Source From: AB

Nom Amplitude Measurement Period Min Period 0.250S

Filter frequency Filter 50.0kHz

Maximum Harmonics Max Harmonics: 200

Fundamental Bandwidth Fundamental÷BW: 2

Analysis FFT Type: Normal

Fundamental Frequency Averaging Sync Averaging: med

Fundamental Frequency Measured Period Sync Period: 0.250S

Ø To abort a displayed menu and discard any changes:

• Press the CLEAR key to abandon any change made and restart the selection from

the beginning. Note that the cursor remains in the item being changed.

—Or—

• Select an all-uppercase “heading line” and press the DISPLAY SELECT 1 key.

Press a new DISPLAY SELECT key.

Ø To change a display line:

1. Within the Results Data display, press the DISPLAY SELECT key next to the line

to be changed. Use the é and ê keys to scroll up and down to the various lines.

Note that the topmost line is #00.

2. The display will show the present measurement details/configuration for that

Results Data line. Press the DISPLAY SELECT 1 key repetitively, to change the

Parameter Type for the display data.

• With this menu line, you may select: a single parameter; a deviation between

two parameters, such as a parameter and constant; or various “special” data.

• The menu line corresponding to DISPLAY SELECT 2 key, indicates the

primary (p) parameter for that Results Data display line and it may give the

bandwidth, harmonic, or harmonic range that applies to the primary

parameter.

Front Panel Operation 29

Note: These parameters: gain (ratio), real (in phase), imaginary (quad), and

phase have a primary input, a reference input and a harmonic specification.

Since the 6000 instrument family has no dedicated reference input or

harmonic specification, it offers greater flexibility in usage.

• You may select a reference parameter (r) similarly to the primary parameter

from a difference (p-r), a ratio (p/r) or a ratio difference (p/r: 1).

• You can choose to display the Results Data measurement in units other than

the instrument’s default units for that parameter. Note that the instrument

automatically applies any conversions necessary.

• Filter the final measurement result using a single pole filter having any time

constant between 10mS and 1000S. Note that the filtering applies to each

Results Data line. Note that the same parameter or Results Data can be

displayed in a separate display line using either no filtering or completely

different filtering.

3. Press the ENTER once to set the change. This action removes the cursor, but

rather than implementing the change allows you to make another edit.

4. When the displayed menu has been changed to suit your requirements, press the

ENTER key, once if no cursor is flashing and twice if one is, to action any

changes made. The Results Data will display with readings based on the changes

you made.

Ø To adjust a “noisy” measurement (to a given value):

1. Press the DISPLAY SELECT key next to the line to be changed. The display will

show details of the presently selected parameter for this measurement result.

2. Press the DISPLAY SELECT key corresponding to FILTER =.

3. Enter a numeric value using the DATA ENTRY keys to apply a single pole filter

having any time constant between 10mS and 1000S.

4. Press ENTER twice.

Ø To provide a “fast/medium/slow” style of adjustment capability:

1. Press the DISPLAY SELECT key next to the line to be changed. The display will

show details of the presently selected parameter for the measurement result for

this line.

2. Apply a single pole filter having any time constant between 10mS and 1000S.

3. Select the same parameter for three or more Results Data display lines and apply

decreasing degrees of filtering, the smaller the filter the less the adjustment

capacity.

30 6000-2 & -3 User Guide, Rev E

Ø To add display lines (up to 50 lines possible):

1. Scroll the Results Data display until a blank line shows.

2. Press the DISPLAY SELECT key next to the blank line. As a starting condition, the

display will show the next line number with the same parameter/configuration

menu as the previous line.

3. Redefine the display line, as required.

Ø To delete a display line:

1. Press the DISPLAY SELECT key next to the Results Data display line to be

deleted. The display will show the line number and the parameter details for the

selected line.

2. Press the DISPLAY SELECT 1 key repetitively, to move the parameter format

through several format options. Note that the line number does not change.

Continue pressing until the command, Delete shows in the display.

3. Press the ENTER key. Note that if the deleted line was between other display

lines the other lines automatically close up around the deleted line.

Ø To add dashes in a display line as a separator:

1. Press the DISPLAY SELECT key next to the Results Data display line to have

separation dashes below it. The display will show details of the presently

selected parameter for the Results Data for this line.

2. Press the DISPLAY SELECT 1 key repetitively, to move the parameter format

through several format options. Note that the line number does not change.

Continue pressing until the command, Blank shows in the display.

Entering New or Changed Information

Ø To “enter” data and changes into the menu—when the cursor is flashing:

1. Move the cursor to the display line’s data or menu item you wish to change.

Press the ç or è keys to move the cursor along the line to the previous or next

(respectively) data or menu item to be changed.

2. Display the desired option: Press the é or ê keys when the cursor is in a

multiple-choice type of selection,

—Or—

Use DATA ENTRY keys to enter a numeric value.

3. Press the ENTER key. Note that the remaining contents of the menu may also

change because of a significant change in menu selections.

4. Press the ENTER key a second time to view the Results Data for your change.

Front Panel Operation 31

Ø To “enter” data and changes into the menu—when no cursor is visible:

• Press the ENTER key to “enter” the selections contained in a menu display. The

instrument will replace the menu display with the selected measurement Results

Data, based on the menu entered.

• Press a DISPLAY SELECT key and the cursor will reappear on the corresponding

display line, then press the ENTER key twice.

Setting/Formatting Time & Date

Use the Set Time and Date menu to set and adjust the present time and date

maintained by the instrument. Using this menu, you can select a display format for

the time and date for use as a “time & date stamp” for printing with your Results

Data.

Note: The selected display changes apply when printing, if the option INT is fitted.

Ø To adjust the time display:

1. Initiate this menu by pressing the SETUP key.

2. Use the ê key to scroll to Set Time and Date in the display and press the

DISPLAY SELECT key next to this line.

3. Select the TIME display line by pressing the corresponding DISPLAY SELECT

key.

4. With the cursor flashing at the displayed time, use the DATA ENTRY keys to enter

two digits each for the hours, minutes and seconds based on 24-hour time. Note

that you cannot enter PM, however, the instrument translates 24-hour time to 12hour time, if the 12 Hour time format is selected.

For example: Enter “05” for the hour of 5am and “17” for the hour of 5pm.

5. Press the ENTER key to set the internal real time clock to your adjusted hours,

minutes and seconds.

6. Press the CLEAR key to abort and start again.

32 6000-2 & -3 User Guide, Rev E

Ø To format the time display:

1. From the Set Time and Date menu, press the DISPLAY SELECT key next to the

Time Format line.

2. Repeated presses of the corresponding DISPLAY SELECT key will toggle the

display between the two choices of: 12 Hour and 24 Hour.

• 12 hour format is displayed as between:

12:00:00am and 12:59:59am—Or—01:00:00am and 11:59:59am

—Or—

12:00:00pm and 12:59:59pm—Or—01:00:00pm and 11:59:59pm.

• 24 hour format is displayed as between: 00:00:00 and 23:59:59.

3. When the displayed menu has been altered to suit your requirements and even

though no cursor character is displayed, press the ENTER key to action any

changes made.

Ø To set the date format:

1. From the Set Time and Date menu, press the DISPLAY SELECT key next to the

Date Format: display line.

2. Use the ê key to toggle between the three choices of: dd/mm/yy, yy/mm/dd,

and mm/dd/yy. Note that the displayed date is based on format.

3. To select a format, press the ENTER key, while the format shows in the display.

Ø To set the date display:

1. From the Set Time and Date menu, press the DISPLAY SELECT key next to the

DATE line.

2. Using the DATA ENTRY keys, enter all six digits of the present date. Follow the

format as defined in the Date Format: line.

3. Press the ENTER key to set the internal real time clock to the entered day, month,

and year.

Storing & Retrieving Configurations

This section describes, in detail, the Configuration menus that allow you to store and

retrieve configurations of the instrument. Maintenance of these storage areas is also

covered in this section. These menus are initiated using the STORE and RECALL keys

found in the CONTROL keypad.

Front Panel Operation 33

Store & Recall Memory Menus

The lowermost two lines of the STORE MEMORY menu and the RECALL MEMORY

menu show the presently defined storage areas. The storage area number that has an

* (asterisk) character adjacent to it, is the area that was last accessed. You can use é

or ê keys to scroll the storage lines up and down. (Shown with an asterisk)

Power Up Conditions—

When power is applied, the instrument automatically recalls and uses the contents of

the storage area you last accessed, before removal of power.

Storage Areas—

Each “stored” configuration is internally kept in an area of memory, identified by a

set of numbers and a character string, which you have defined. The numeric portion

can be up to 5 digits and the alpha characters up to 12. These storage areas are nonvolatile, that is they are maintained even when the instrument is not powered up for

10 years.

Ø To store a configuration in an already defined storage area:

1. Press the STORE key.

2. Use the é or ê keys to scroll through the numerically ordered list of defined

storage areas,

—Or—

Use the numeric keys to type the number of the desired storage area and press

the ENTER key.

3. When the desired storage area number displays, press the corresponding

DISPLAY SELECT key. You will get the message: Settings Recalled from

Memory and the instrument will go to the Results Data display reflecting the

recalled settings.

Ø To store a new configuration (presently displaying):

1. Press the STORE key.

2. Press the é or ê keys to scroll the cursor to the lower most lines.

3. Choose a number to represent the new storage area, use up to 5 digits,

—And—

Review the already defined storage areas, to ensure your new storage area

number does not already exist. Use the é or ê keys to scroll.

4. Use the numeric DATA ENTRY keys, to type the number of the new storage area.

5. Press the ENTER key.

34 6000-2 & -3 User Guide, Rev E

Ø To recall a configuration:

1. Press the RECALL key.

2. Use the é or ê keys to scroll through the numerically ordered list of defined

storage areas.

3. When the desired storage area number displays, press the corresponding

DISPLAY SELECT key.

—Or—

Use the numeric keys to type the number of the desired storage area, then press

the ENTER key to bring up the stored configuration on your instrument.

Storage Area Maintenance

Maintenance includes renaming and deleting previously created storage areas for

organizational purposes. An existing storage area may be renamed or deleted. Note

that a presently active storage area (that last accessed) cannot be modified. If you

wish to rename or delete an area, then first store the present configuration, or recall

another storage area.

Ø To rename an existing storage area:

1. Press either the STORE or RECALL key.

2. Press the DISPLAY SELECT key next to the Edit Directory menu line.

3. Scroll using the é or ê keys to display the Storage number you wish to rename.

4. Press the DISPLAY SELECT 2 key, which corresponds to the Name: menu line.

5. Enter the new name using the numeric keys in the DATA ENTRY. Use the CLEAR

key to correct a mistake.

6. When the required numeric characters have been entered, press the ENTER key.

Your previous storage area number and your new one will show in the display.

7. Press ENTER a second time to display your Results Data.

Ø To delete a storage area:

1. Press either the STORE or RECALL key.

2. Press the DISPLAY SELECT key next to the Edit Directory menu line. Review the

contents of these display lines to find the correct storage area you will delete.

3. Use the é or ê keys to show the storage area number, then press the

corresponding DISPLAY SELECT key.

Front Panel Operation 35

4. Press the DISPLAY SELECT 3 key, which corresponds to the Delete menu line. A

message saying Deleted Memory will show and your display return to Results

Data. Note that if you have chosen a storage number that reflects your active

settings, the number will not delete.

Repacking of the Storage Areas

The media used for these storage areas is known as “Flash Memory”. This nonvolatile memory is both readable and writable, but only previously erased areas of

memory may be written to. The internal system of the instrument ensures that this

memory is correctly written to, while maintaining its efficient usage.

This storing process will slowly fill the memory with each written storage area until

the memory becomes full. When full, the system automatically retrieves all storage

areas into internal volatile memory, erases the entire non-volatile memory, and then

rewrites all the storage areas back into non-volatile memory. Thus, rarely, will you

need to manually prompt the execution of this procedure, except when a software

upgrade has been performed, or in the unlikely event that a storage area has become

corrupted.

Ø To manually prompt the repacking of storage areas:

Caution: Power must not be removed while this procedure is being performed,

complete data loss (including calibration data) may result if this occurs.

1. Press the SETUP key.

2. Scroll to NV Data Control menu line.

3. Press the corresponding DISPLAY SELECT key to edit.

4. Press the DISPLAY SELECT key corresponding to Pack Data in Memory menu

line. You will get a message saying Erasing Flash Memory.

36 6000-2 & -3 User Guide, Rev E

Rear Panel 37

Rear Panel

Connectors & Controls

The rear panel contains the power cord connection; Configuration Control switch

and four connectors: Analog output, Digital I/O, Parallel printer, IEEE-488, and two

RS232. Refer to Figure 9.

DIGITAL I/O

ANALOG OUTPUT

RS232 #1

PARALLEL PRINTER

!

IEEE488

RS232 #2

Figure 9. Rear Panel Partial View

CONFIGURATION

LOCKED

UNLOCKED

!

38 6000-2 & -3 User Guide, Rev E

Power Connection

The 6000 instrument is designed to operate with a three-conductor power cord. The

third conductor is securely connected to ground to ensure the external chassis of the

instrument remains at ground potential.

Warning: Operation with a two-conductor power cord, or without a secure ground

connection may render the Phase Angle Voltmeter instrument unsafe for use.

Configuration Control Switch

The Configuration Control switch allows you to disable reconfiguration of the

instrument by unauthorized users. This switch is located in the upper right-hand

corner of the rear panel. When in the LOCKED (upper) position the instrument’s

configuration is locked against changes, other than any caused by recalling

predefined memory locations.

The following changes are made to the menus when in the Configuration Control

switch is in the LOCKED position:

• Display lines cannot be altered.

• The SETUP and STORE keys are disabled.

• The Nullmeter’s SELECT and SCALE keys are disabled.

• The CALIBRATION menu is reduced to System Status and Internal

Calibration selections.

• The phase A, B, SYNC and GUARD input keys are disabled.

Parallel Printer Interface

Use standard Centronics parallel cable compatible with IBM-PCs. This interface

option supports serial stand-alone types or PCL and compatible printers only.

RS232 Connectors

Use this connection for control or for printer output. Baud rates can be set from

1,200 to 38,400 baud. Flow control via RTS/CTS handshake. See Interface

Operation on page 63, for information on using this feature.

IEEE488 Connector

This connection enables full talk/listen capabilities. See Interface Operation on

page 63, for information on using this feature.

Configuration Setup 39

Configuration Setup

The various menu selections available allow you to define the data configuration

appropriate for testing your products. The menus that facilitate setup include: Setup

Measurements, Input Configure, the Parameter displays and if you wish to use the

Nullmeter, the Nullmeter displays. For basic use of the keys and the display

interface, refer to Using the Operational Keys on page 25.

Important Note: Before using your instrument, be aware of the rear panel mounted

“Configuration Disable” switch. This slide switch must be in the UNLOCKED ,

specifically in the down position, to enable any reconfiguration activities.

Setup Guidelines

As a standard setup, configure each input independently for input mode, fundamental

frequency, ranging, and scale factor. Setup the input pair’s GUARD terminal for

internal or external connection. Refer to the following “setting” instructions as

guidelines for standard setups. Initial steps to configuring inputs include:

• Removal of all connections to the BNC and GUARD terminals; and

• Resetting the configuration using the Set Defaults menu, unless the present

configuration has been set for your needs. Please refer to Using the Operational

Keys on page 25.

Ø Setting fundamental frequency mode and range for input connectors:

1. Press the SETUP key while

viewing Results Data to bring

up the SETUP

CONFIGURATION menu.

See Figure 10.

2. Press the DISPLAY SELECT

key corresponding to Setup

Measurements.

SETUP CONFIGURATION

Set Defaults

Setup Measurements

Interface

Figure 10. Initial Setup Display

40 6000-2 & -3 User Guide, Rev E

3. The first four display lines of the SETUP MEASUREMENTS menu show the

fundamental frequency measurement type, range, and input source menu. See

Figure 11.

4. On the second line, select

the type of Fundamental

Frequency. See Funda-

mental Frequency on

page 44.

5. When fundamental frequency is not Fixed, you

have the option of setting

its range.

The default range and menu line reads: Fund: 40.0 – 500 Hz. For details, see

Fundamental Frequency Range on page 45.

6. The fourth line reads From: and shows the input connector signal source, or to

which inputs your fundamental frequency applies. You can change this selection

by pressing one or more of the INPUTS keys: A, B, AB, or SYNC (-3 only). Those

located above the BNC connectors. Note that if the display reads an input, such

as A, and you press A, the display will read none.

SETUP MEASUREMENTS

Fund: Meas x .000000

Fund: 40.0 - 500 Hz

From: AB

Figure 11. Setup Measurements Display

You may get two different message displays here:

Action at Input Source menu line Message Display

Use INPUT Keys

If you attempt to use the DISPLAY SELECT keys to

change inputs:

Use Fundamental

If you press ENTER when none shows in the

display:

Use Fundamental

7. When complete with the Setup Measurement display, press ENTER twice to

action the changes.

Note: To access all the display lines of the SETUP MEASUREMENTS menu,

scroll down using the é and ê keys when no cursor is flashing. To remove the

cursor, press ENTER once. This menu’s additional display lines include:

minimum period, filter, maximum harmonics, fundamental bandwidth, FFT type,

and synchronize averaging and period. Refer to Measurement Configuration

Menu on page 44, for details.

To

Select/Deselect

Sorry

Must Select

An input To

Configuration Setup 41

Ø Setting the input mode for each input connector:

These settings select which signal, voltage or current, is going to be measured on

which input. Additional settings in the display affect the range for voltage and

current, Scaling and the Guard connection being internal or external. Note that when

making these input settings you must call up the INPUT CONFIGURE display

uniquely for each input connector used. See Figure 12.

1. Press the A, B, AB, or S

(-3 only) key located at the

INPUT connectors while

viewing the Results Data.

The display now shows the

INPUT A CONFIGURE menu

corresponding to the A input

key, or the one you pressed.

2. Correlate the display’s input mode (power measurement) with the actual input.

Note that the display shows the input configured for voltage measurements, using

DC coupling. Update the display by pressing the DISPLAY SELECT 2 key twice

and using the é or ê keys to alter the option. The input mode choices are:

V (dc); V (ac); V (50) and A (dc).

Note: Use the respective VOLTS BNC connector for all voltage input V. Use

AMPS input connector for the current input A.

Important Note: Take care, when measuring low frequency signals, particularly phase measurements. After applying a signal containing a significant DC

level, the input may take an extended period (time) to settle as the input time

constant is 300mS ± 2%.

3. The default for voltage/current input range is auto. To set a fixed range value,

scroll through the given selections. Choose a range of 6Vrms, or higher, which

effectively creates an input impedance of 600kΩ. The selectable options are: 2.5;

6; 20; 65; 200; 700; 6m; 20m; 70m; 200m; and 750m. Note that the range

currently being used shows in brackets to the right when the selected input mode

and the in-use input mode are the same.

INPUT A CONFIGURE

auto ( 6m) V(dc)

Scaling x +1.0000

Guard : Lo Input A

Figure 12. Input Configure Display

4. Press ENTER once to move onto the next display line, press ENTER twice to

action changes for the separate input connections.

42 6000-2 & -3 User Guide, Rev E

Ø To change the (input) scale factor:

1. While viewing the INPUT CONFIGURE display for the respective input you are

configuring, press the DISPLAY SELECT 3 key.

2. Enter the desired scale factor using the DATA ENTRY keypad. For details, see

Input Scaling on page 43.

3. Press ENTER once to move onto the next display line, press ENTER twice to

action changes for the separate input connections.

Ø Setting the Guard connection for each input connector:

1. While viewing the INPUT CONFIGURE display for the respective input you are

configuring, press the DISPLAY SELECT 4 key.

2. Repetitively press the DISPLAY SELECT 4 key to toggle the options for external

and internal connections. Choose External, or one of the internal connections:

Lo Input A, Lo Input B, or Lo Input Sync (-3 only).

3. When complete with your input connector selections, press ENTER to action the

changes.

Ø To configure the Nullmeter parameter display:

The Nullmeter does not light until valid measurements for Results Data are

configured. For details on the options, refer to Nullmeter Display Menu on page 49.

1. Press the NULLMETER

SELECT key. One of five

Nullmeter parameter displays will come up.

See Figure 13.

2. Continue pressing the

DISPLAY SELECT 1 key to

view the four possible parameter displays for the

Nullmeter.

Refer to Nullmeter Parameter Types on page 49.

4. Press the NULLMETER SCALE key. Refer back to The Nullmeter on page 22.

If you do not choose to use the Nullmeter, then configure a Parameter (p) display to

match your measurement requirements. Refer to Parameter Display Menus on

page 50.

Nullmtr:- Parameter

p = Phs Bh01--Ah01

Display as +/-180

o

Filter = 0.000s

Figure 13. Nullmeter Sample Display

Configuration Setup 43

Ø To complete a configuration setup:

1. Connect the signal(s) to the respective BNC and GUARD terminals.

2. Apply signals.

3. Make any adjustments required to SETUP MEASUREMENT configuration.

4. Make adjustments, as needed to the parameter displays or the Nullmeter

parameter displays.

5. When complete with this setup store the configuration using the Control

keypad’s STORE key. See Storing & Retrieving Configurations on page 32.

Input Configuration Menu

Each selectable option of the Input Configuration menu is described in the following

subsections. When the displayed menu has been altered to suit your requirements,

press the ENTER key twice to action any changes made.

Input Scaling

This indicates the present amplitude scale factor (if any) applied to measurements of

this input. If the default scale factor of +1.0 shows in the display, then no input

scaling is performed. You may enter any desired scale factor (including negative

factors) for application to each input. Negative scale factors are correctly applied,

such as, the corresponding positive scale factor is applied, in concert with a 180°

phase shift.

Guard

This indicates the presently selected GUARD terminal connection.

• External—Indicates that the GUARD terminal is to be externally driven.

• Lo Input A, B or S (-3)—Indicates that the GUARD terminal is internally

connected to the respective input’s BNC outer shell.

Caution: If you are measuring current, or if the voltage range is less than 6vrms,

ensure that less than 10Vpk exists between each BNC outer shell of the pair of inputs

and outer shell and the guard terminal.

Notes:

1) When making external connections only connect to the GUARD terminals.

2) When using the current input, current low MUST be externally connected to the

GUARD terminal and the input pair configured to use external guard.

44 6000-2 & -3 User Guide, Rev E

Measurement Configuration Menu

The Setup Measurements line of the SETUP key menu allows you to fully configure

your instrument’s measuring characteristics according to each particular situation.

The discussions below deal with each menu line in the same order as shown in the

display menu. For this display, scroll using the ê key, to access the lower lines.

When the displayed menu matches your requirements, press the ENTER key once or

twice, as required, to action any changes made.

Fundamental Frequency

The Fund: menu line allows you to select from three types of fundamental frequency

measurements, which you can use to synchronize your instrument’s amplitude

measurements.

The fundamental frequency types are:

Measured—

The default is MEASURED. A selected input measured frequency is indicated for the

instrument’s fundamental frequency.

Measured (multiplied by a factor)—

The option Meas x .000000 allows you to select an input measured frequency

multiplied by a defined factor, as its fundamental frequency. Enter a value with this

selection. You can also use this menu item to measure sub-harmonic content of a

signal, for example, at 1/2 the fundamental frequency.

Fixed—

The FIXED type directly sets the fundamental frequency to be any frequency you

have entered within the range of 0.0005HZ to 100kHZ:

Select the FIXED type when:

• There is no signal present, which has sufficient amplitude at the fundamental

frequency.

• The fundamental frequency is not stable.

• The input signal is first applied and the input fundamental frequency is well

known (within a few percent), rather than allowing the instrument time to

establish the fundamental frequency.

• The fundamental frequency is very low (e.g., 0.0005Hz), forcing the instrument

to wait at least 4 cycles of the input waveform before starting harmonic analysis.

Configuration Setup 45

• You want to perform a spectral analysis of the input signal(s), rather than

harmonic analysis.

Note: When performing a spectral analysis, set the fundamental frequency to

the desired frequency step between available spectral points, set the RBW ratio

to 1, and set the maximum harmonic to the number of spectral points, desired.

Fundamental Frequency Range

When the fundamental is not fixed, the Fundamental Frequency Range menu is

active. The menu line Fund: 40.0 – 500 Hz allows you to set a frequency range for a

measured fundamental frequency.

• The default frequency range shows on the display as 40Hz to 500Hz. You may

set any range of frequencies within the 0.0005Hz to 100kHz range, with a limit

of a 128:1 range.

• When in-phase precision is required, or where harmonic distortion is present, it

is beneficial to reduce this to a 2:1 range around the nominal fundamental

frequency. An example of this is 40 to 80Hz.

• When specifying a fundamental frequency range, consider that the instrument

will take the lowest frequency component having a signal of greater than 5% of

range, as its fundamental. If there is signal having a sub-fundamental frequency

component of any significance, then the exclusion of that frequency from the

selected range will substantially eliminate its effect on the measurement.

• If your instrument requires signal measurements having fundamental frequencies

beyond the 40Hz to 500Hz range, or other requirements to accommodate

abnormal measurement situations;

—Then—

Use the SETUP key to enter a configuration reflecting your instrument’s needs.

Note that previous configurations may be stored and recalled using the STORE

and RECALL keys.

Fundamental Source

When the fundamental frequency is not fixed, the From: menu line becomes active.

The Fundamental Source menu sets an input, or a set of inputs. The fundamental is

based on the measured frequency of the input(s) set by this menu line.

The source applies when:

• An input is added to or removed from the list by pressing the respective INPUT

key.

• The default is set to AUTO-SELECT between all inputs.

46 6000-2 & -3 User Guide, Rev E

• When selecting this input, or set of inputs, consider which input has the least

noise content, the least amplitude variability, and the least cycle-to-cycle phase

noise.

—An example of a signal that should NOT be allowed to act as the fundamental

frequency source is a RVD or LVD transformer’s output, which has its

frequency shifted during the time it is moved—

• If more than one input is selected, the instrument will continuously monitor all

selected inputs, selecting the one having the most stable frequency measurement.

The front panel SYNC lights indicate, which input is actually being used at any

given moment.

Nominal Amplitude Measurement Period

The Nominal Amplitude Measurement Period menu, shows on the display as Min

Period: It is always active and allows you to define the period of time amplitude

measurements are made. For all, but the shortest of periods, this effectively sets the

results update rate of the instrument. Note that the default measurement period is

250S.

The update rate of the display is limited to 250mS and the Nullmeter is limited to

100ms. Selecting a measurement period, less than these figures is ineffective when

using front panel operation.