USER GUIDE

2801/2802

Advanced

Single and

Dual-Channel

Power Analyzers

2 2801/2802 Power Analyzer User Guide

Warranty

Warranty 3

The Vitrek instrument is warranted against defects in material and workmanship

for a period of two years after the date of purchase. Vitrek agrees to repair or

replace any assembly or component (except batteries) found to be defective,

under normal use, during the warranty period. Vitrek’s obligation under this

warranty is limited solely to repairing any such instrument, which in Vitrek’s

sole opinion proves to be defective within the scope of the warranty, when

returned to the factory or to an authorized service center. Transportation to the

factory or service center is to be prepaid by the purchaser. Shipment should not

be made without prior authorization by Vitrek.

The warranty does not apply to any products repaired or altered by persons not

authorized by Vitrek, or not in accordance with instructions provided by Vitrek.

If the instrument is defective as a result of misuse, improper repair, or abnormal

conditions or operations, repairs will be billed at cost.

Vitrek assumes no responsibility for its product being used in a hazardous or

dangerous manner, either alone or in conjunction with other equipment. Special

disclaimers apply to this instrument. Vitrek assumes no liability for secondary

charges or consequential damages, and, in any event, Vitrek' liability for breach

of warranty under any contract or otherwise, shall not exceed the original

purchase price of the specific instrument shipped and against which a claim is

made.

Any recommendations made by Vitrek or its Representatives, for use of its

products are based upon tests believed to be reliable, but Vitrek makes no

warranties of the results to be obtained. This warranty is in lieu of all other

warranties, expressed or implied, and no representative or person is authorized

to represent or assume for Vitrek any liability in connection with the sale of

Vitrek products other than set forth herein.

Instrument Serial Number: __________________________________

4 2801/2802 Power Analyzer User Guide

Document Part Number: MO-2801/2802-M Revision A

Print date: June 28, 2007

Copyright

Copyright© 2007 Vitrek All rights reserved.

All rights reserved. No part of this publication may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form without prior written consent from Vitrek. This product

manual is copyrighted and contains proprietary information, which is subject

to change without notice. The product's displays and manual text may be

used or copied only in accordance with the terms of the license agreement.

XiTRON is a trademark of Vitrek. All other trademarks or registered

trademarks are acknowledged as the exclusive property of their respective

owners.

In the interest of continued product development, Vitrek reserves the right to

make changes in this guide and the product it describes at any time, without

notice or obligation.

Vitrek

Manufacturers of Engineering & Production Test Equipment

12169 Kirkham Road

Poway, California 9206 USA

Telephone: (858) 689-2755

Fax: (858) 689-2760

E-mail: info@vitrek.com

Contents

Contents 5

INTRODUCTION ____________________________________________________ 15

Scope _________________________________________________________ 15

Features _______________________________________________________ 16

FUNCTIONAL DESCRIPTION _________________________________________ 17

Theory of Operation ______________________________________________ 17

Analog Channel Board ________________________________________ 18

Interfaces ______________________________________________________ 23

Front Panel _________________________________________________ 23

IEEE488 ___________________________________________________ 23

USB Device_________________________________________________ 23

USB Host __________________________________________________ 24

RS-232 ____________________________________________________ 24

Digital I/O __________________________________________________ 24

Ethernet____________________________________________________ 24

USING THE POWER ANALYZER ______________________________________ 25

Setting Up______________________________________________________ 25

Using the Front Panel Interface _____________________________________ 26

Grounding of the Analyzer _________________________________________ 29

Rear Panel Connections - 2801 and 2802 _____________________________ 31

Power Requirements _________________________________________ 31

2801 Rear Panel Connections ______________________________________ 32

Single-Channel Measurements of a Power Source: Connection Method 1 34

Single-Channel Measurements of a Power Source: Connection Method 2 35

Single-Channel Measurements of a Load: Connection Method 1 _______ 36

Single-Channel Measurements of a Load: Connection Method 2 _______ 37

Measurements of a Power Source:Connection Method 1 – Ext CT ______ 38

6 2801/2802 Power Analyzer User Guide

2802 Rear Panel Connections ______________________________________ 39

Measurements of a Power Source: Connection Method 1 _____________ 39

Measurements of a Power Source: Connection Method 1 _____________ 40

Measurements of a Power Source: Connection Method 2 _____________ 41

Measurements of a Load: Connection Method 1 ____________________ 42

Measurements of a Load: Connection Method 2 ____________________ 43

Measurements of a Power Source and Load: Method 1, Two Ind. Chnls _44

Measurement: 3P-3W 2 Meter Connection, Method 1 ________________ 45

Measurements of a Power Source: Connection Method 1 – Ext CT _____ 47

Using an External Current Transducer________________________________ 48

Starting the Analyzer _____________________________________________ 50

Configuring the Power Analyzer 2801/2802____________________________ 51

Getting Started ______________________________________________ 52

Channel Configuration (2802 Only) ______________________________ 53

Configuring the Analyzer Measurement Results ________________________ 54

Setting Up the Measurement Configuration ________________________ 56

Setting Up the Ch2 Measurement Configuration (2802 Only) __________ 71

Setup System ___________________________________________________ 71

Configuration Storage ____________________________________________ 74

Perform DC Zero ________________________________________________ 75

Diagnostics_____________________________________________________ 75

About _________________________________________________________ 77

Default Settings _________________________________________________ 78

Using the Line Switch and Inrush Capabilities __________________________ 79

DISPLAY SCREENS _________________________________________________ 82

Viewing Measurement Results______________________________________ 82

Numeric Display Screens ______________________________________ 82

Chart Displays __________________________________________________ 88

Starting Startup and Inrush Charts___________________________________ 88

Line Switch Disabled and Inrush Detection Disabled _________________ 88

Line Switch Disabled and Inrush Detection Enabled _________________ 88

Line Switch Enabled and Inrush Detection Disabled _________________ 88

Line Switch Enabled and Inrush Detection Enabled __________________ 89

Chart Formats _______________________________________________ 89

Introduction 7

PRINTING RESULTS ________________________________________________ 99

Sample Printouts ________________________________________________ 99

SENDING COMMANDS AND INTERROGATIVES ________________________ 108

Operating using Multiple Interfaces _________________________________ 108

Interrogatives __________________________________________________ 108

USB______________________________________________________ 109

RS232 ____________________________________________________ 109

IEEE488 __________________________________________________ 109

Remote / Local Operation ________________________________________ 109

Resetting the Instrument _________________________________________ 110

Initializing an Interface ___________________________________________ 110

Identifying the Instrument _________________________________________ 110

Querying the Date or Time________________________________________ 110

Setting the Date or Time _________________________________________ 111

Setting the Interface & Front Panel Language _________________________ 111

Storing and Recalling Configurations ________________________________ 111

IEEE488 Status Byte Commands __________________________________ 112

Commands which affect the measurement process ____________________ 112

Commanding and Controlling a DC Zero _____________________________ 115

Controlling the Line Switch________________________________________ 115

Controlling the Display Backlight & Contrast __________________________ 115

Configuring Measurements _______________________________________ 116

APPLICATION – Application___________________________________ 116

RESULTAVG – Result Averaging Period _________________________ 117

MSRTYPE – Measurement Type _______________________________ 117

FILTERTYPE – HF Cutoff Filter ________________________________ 118

FILTERFREQ – HF Filter Cutoff Frequency _______________________ 118

CURRENTSYNC – Use current synchronization ___________________ 118

MINFUND – Minimum Fundamental Frequency____________________ 118

MAXFUND – Maximum Fundamental Frequency___________________ 119

MAXHARMS – Maximum Number of Measured Harmonics __________ 119

GENDNRANGEDLY – User Set Minimum Downrange Delay _________ 119

MSRDCRIPPLE – DC Ripple Measurement Method ________________ 119

RIPPLEFREQ – DC Ripple Base Frequency ______________________ 120

8 2801/2802 Power Analyzer User Guide

DCDNRANGEDLY – User Set Minimum Downrange Delay __________ 120

VRANGE – Select a Voltage Input Range ________________________ 120

AINPUT – Select the Current Input Mode_________________________ 120

ARANGE – Select a Current Input Range (Shunt Input Only) _________ 121

TRANGE – Select a Current Input Range (Transducer Input Only) _____ 121

STRICTRANGING – Forces the App. of the Requested Fixed Range___ 121

SHUNTRATIO1 and SHUNTRATIO2 – Sets A input CT Ratio ________ 122

TRANSRATIO1 and TRANSRATIO2 –sets T input CT Ratio__________ 122

MSRSOURCE – Sets Whether the Pwr Source / Load is to be Meas.___ 123

WIRINGCOMP – Enables Wiring Impedance Compensations_________ 123

WIRINGLOSS – Sets the Wiring Loss Impedance Value _____________ 123

WIRINGLOSSN – Neutral Wiring Loss (2802 only) _________________ 123

WIRINGLOSSG – Ground Wiring Loss (2802 only) _________________ 123

VBURDENCOMP – Enables Voltage Burden Compensation _________ 124

REVERSEV – Enables Reversal of Voltage Measurement Polarities ___ 124

REVERSEA – Enables Reversal of Current Measurement Polarities ___ 124

LINECONTROL – Configures the Line Switch _____________________ 124

LINEPHASE – Internal Line Switch Turn On Phase_________________ 124

INRUSHARNG – Sets the A input Inrush Range ___________________ 125

INRUSHTRNG – Sets the T input Inrush Range ___________________ 125

FILTEREDINRUSH –Filtered or Unfilt. Signal is Captured During Inrush 125

WAVETRIG – Sets the Method of Triggering Waveform Capture ______ 125

TRIGVOLTS – Sets the Voltage for Waveform Capture Triggering _____ 126

TRIGAMPS – Sets the Current for Waveform Capture Triggering ______ 126

READ and UPDATE commands ___________________________________ 127

Normal Results –____________________________________________ 129

Highest Measurement During an Inrush & Startup __________________ 138

Integrated Results (scaling in unit.Hours) _________________________ 139

Integrated Average Results ___________________________________ 139

Measurement Extents during Integration _________________________ 140

Charge & Discharge data (scaled in unit.Hours) ___________________ 143

Special Data _______________________________________________ 143

APPENDIX A - PHYSICAL SPECIFICATIONS____________________________ 146

General_______________________________________________________ 146

Environment _______________________________________________ 146

Introduction 9

Altitude Equivalent __________________________________________ 146

Warm Up __________________________________________________ 146

Accuracy __________________________________________________ 146

APPENDIX B - MEASUREMENT SPECIFICATIONS_______________________ 148

Autorange _________________________________________________ 148

Ranging___________________________________________________ 148

Input Filtering ______________________________________________ 148

Low Frequencies____________________________________________ 148

Measurement Rate Frequency _________________________________ 148

Non-Harmonics _____________________________________________ 149

Harmonics _________________________________________________ 149

DC Input Offset Compensation _________________________________ 149

Frequency Measurements ____________________________________ 149

Harmonic Analysis __________________________________________ 149

Result Averaging____________________________________________ 150

Input Sampling _____________________________________________ 150

Integration _________________________________________________ 150

History Charts ______________________________________________ 150

Startup Charts ______________________________________________ 151

Waveform Data _____________________________________________ 151

Captured Waveforms ________________________________________ 151

Inrush Waveforms___________________________________________ 151

Line Switch ________________________________________________ 151

APPENDIX C-INPUT & TARGET SPECIFICATIONS_______________________ 154

Voltage Input Specifications _______________________________________ 154

Transducer (15V) Input Specifications ___________________________ 157

Power Factor Specifications ___________________________________ 158

10 2801/2802 Power Analyzer User Guide

Introduction 11

Figures

Figure 1. Overall Block Diagram ____________________________________ 17

Figure 2. Voltage Input Attenuator Block Diagram_______________________ 19

Figure 3. Transducer Input Attenuator Block Diagram____________________ 20

Figure 4. Current and Line Switch Block Diagram _______________________ 21

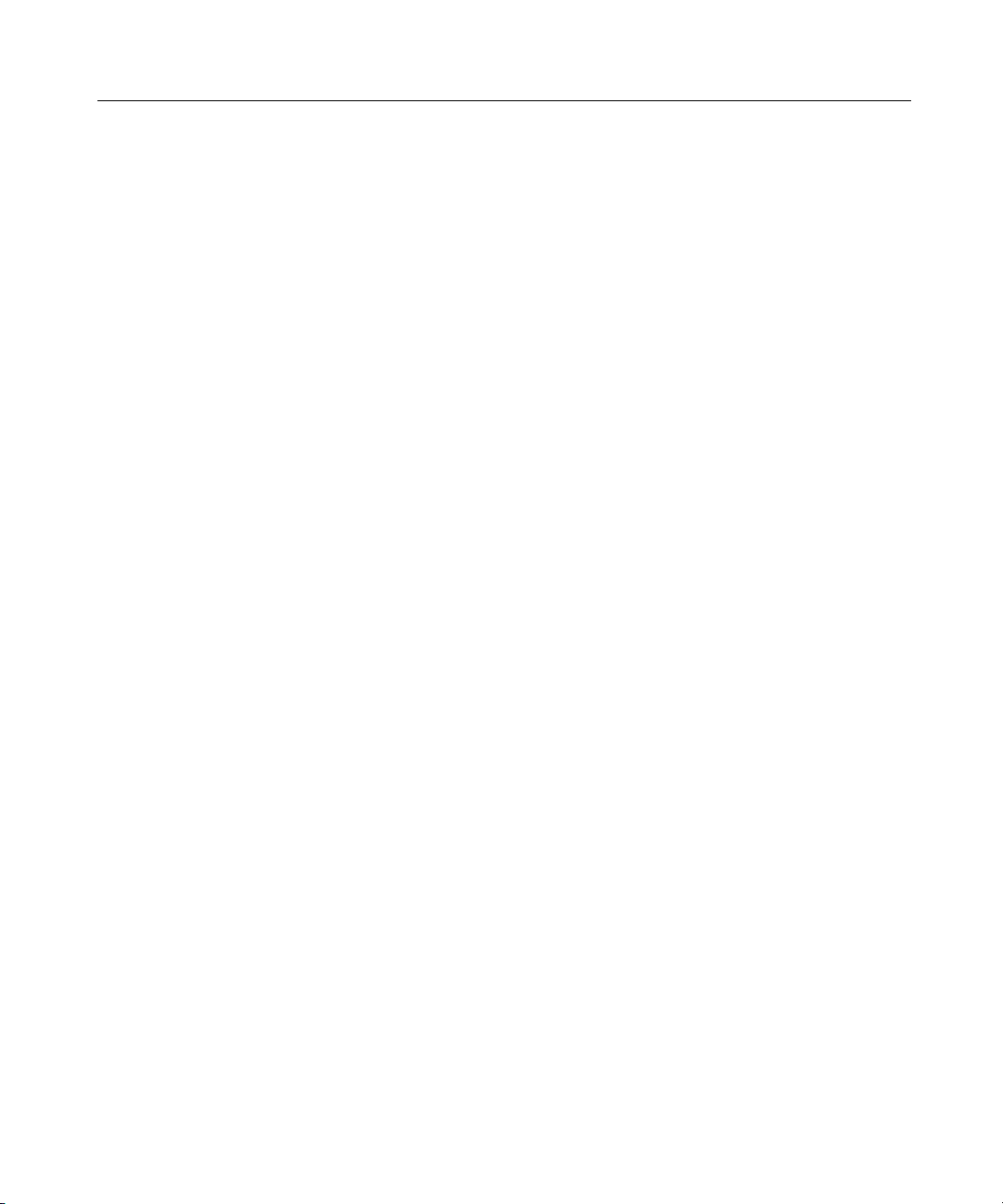

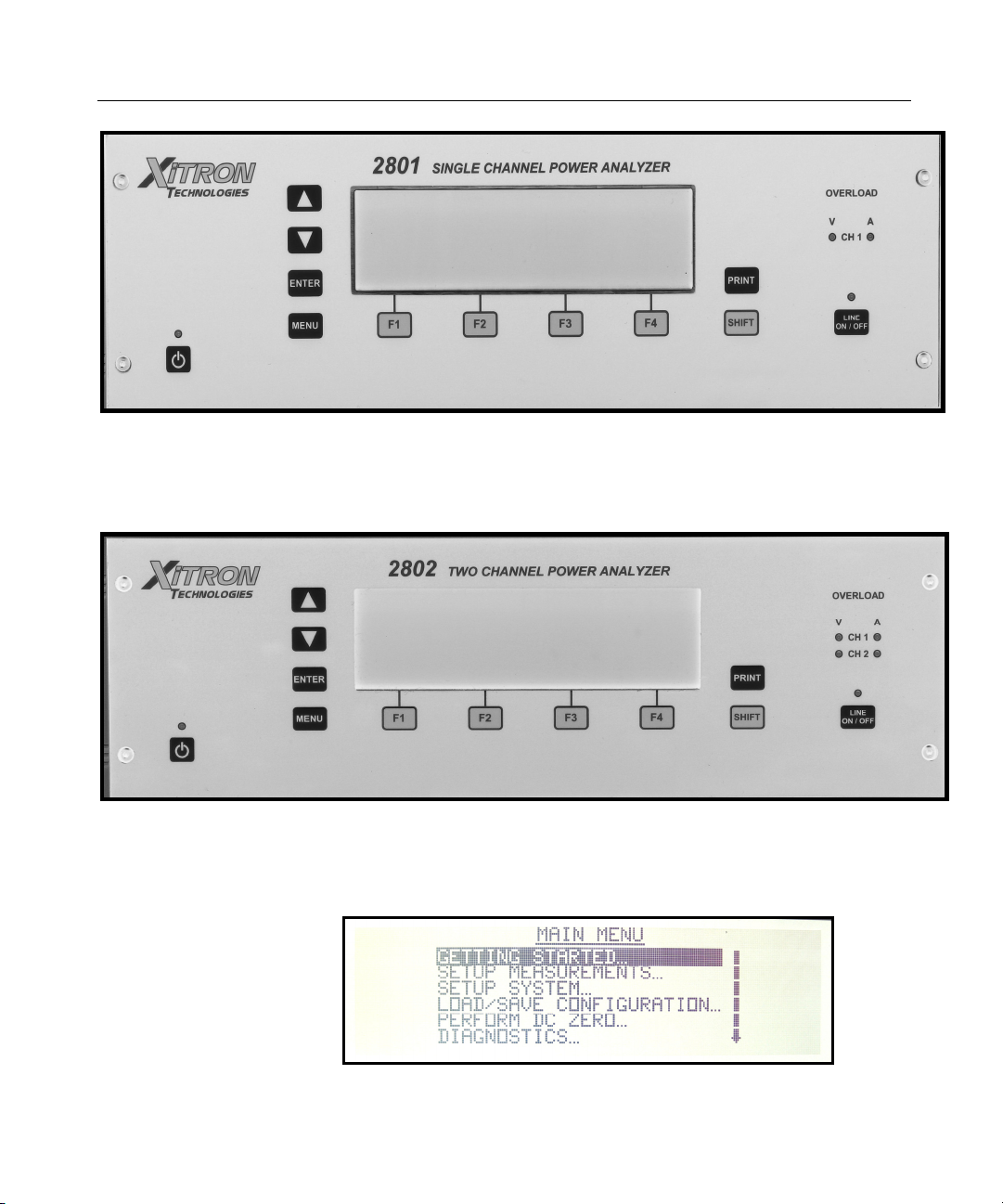

Figure 5. Benchtop Version of 2801 Power Analyzer ____________________ 25

Figure 6. Benchtop Version of 2802 Power Analyzer ____________________ 26

Figure 7. 2801 Front Panel Interface Detail ____________________________ 27

Figure 8. 2802 Front Panel Interface Detail ____________________________ 27

Figure 9. Sample Display __________________________________________ 27

Figure 10. Rear Connection Panel ___________________________________ 33

Figure 11. Measuring a Power Source, Method 1 _______________________ 34

Figure 12. Measuring a Power Source, Method 2 _______________________ 35

Figure 13. Measuring a Load, Method 1 ______________________________ 36

Figure 14. Measuring a Load, Method 2 ______________________________ 37

Figure 15. Measuring a Source Using a CT, Method 1 ___________________ 38

Figure 16. Rear Connection Panel ___________________________________ 39

Figure 17. Measuring a Power Source, Method 1 _______________________ 40

Figure 18. Measuring a Power Source, Method 2 _______________________ 41

Figure 19. Measuring a Load, Method 1 ______________________________ 42

Figure 20. Measuring a Load, Method 2 ______________________________ 43

Figure 21. Measuring a Power Source and Load, Method 1, Two Ind. Chnls __ 44

Figure 22. Measure 3P-3W 2 Meter Connection, Method 1 _______________ 45

Figure 23. Measuring a Source Using a CT, Method 1 ___________________ 47

Figure 24. External Transducer Test Connections ______________________ 48

Figure 25. Startup Screen 2801 and 2802 _____________________________ 50

12 2801/2802 Power Analyzer User Guide

Figure 26. Main Menu Screen ______________________________________ 51

Figure 27. Measurement Configuration Screen _________________________ 56

Figure 28. Measurement Configuration Screen _________________________ 56

Figure 29. Wiring Adjustments Menu Screen___________________________ 63

Figure 30. System Menu Screen ____________________________________ 72

Figure 31. LOAD/SAVE Main Menu Screen ___________________________ 74

Figure 32. Load Configuration Selection Screen ________________________ 74

Figure 33 Erase Configuration Selection Screen ________________________ 75

Figure 34. DC Zero Screen ________________________________________ 75

Figure 35. Diagnostic Menu Screen__________________________________ 76

Figure 36. Performance Screen _____________________________________ 77

Figure 37. About Screen __________________________________________ 77

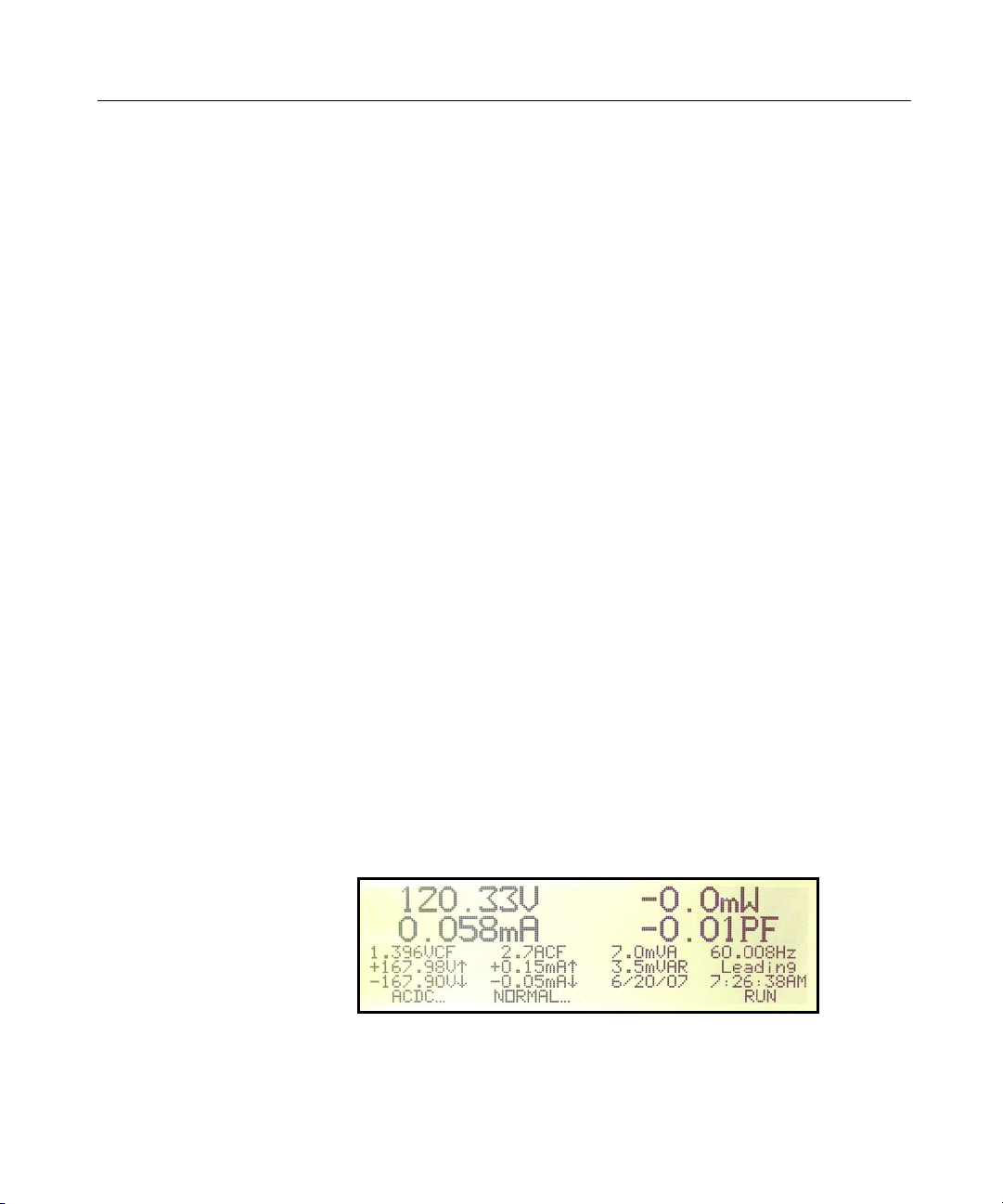

Figure 38. ACDC Normal __________________________________________ 82

Figure 39. ACDC Inrush___________________________________________ 83

Figure 40. ACDC Integrated________________________________________ 83

Figure 41. DC Normal ____________________________________________ 84

Figure 42. Rectified Normal ________________________________________ 84

Figure 43. Fundamental Normal ____________________________________ 85

Figure 44. ΣHarmonics Normal _____________________________________ 85

Figure 45. DC Charge & Discharge __________________________________ 85

Figure 46. DC Charge & Discharge __________________________________ 86

Figure 47. Harmonics % Log in Bar Chart _____________________________ 86

Figure 48. Harmonics Absolute in List Form ___________________________ 87

Figure 49. Real-time Waveform _____________________________________ 87

Figure 50. Distortion Waveform _____________________________________ 87

Figure 51. No Inrush Detected ______________________________________ 91

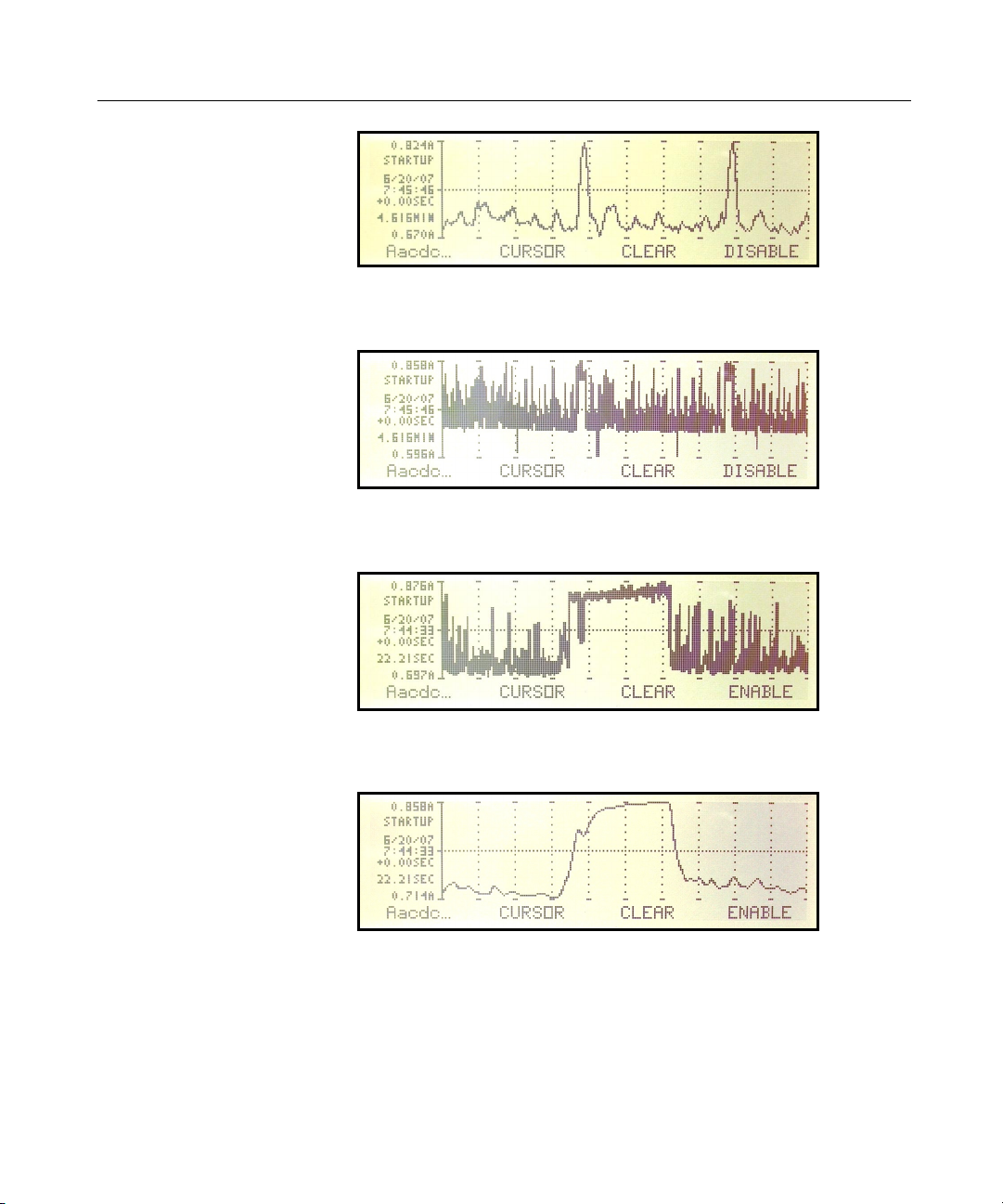

Figure 52. History of Amps ACDC, Trend in Full View____________________ 92

Figure 53. History of Amps ACDC, Extents in Full View __________________ 92

Figure 54. History of Amps ACDC, Trend in Zoom Mode _________________ 92

Figure 55. History of Amps ACDC, Trend; Scrolled ______________________ 92

Figure 56. History of Amps ACDC, Extents in Zoom Mode ________________ 93

Figure 57. Startup in Full View, Trend ________________________________ 95

Figure 58. Startup in Full View, Extents _______________________________ 95

Figure 59. Startup, Partial, Extents __________________________________ 95

Introduction 13

Figure 60. Startup, Partial, Extents __________________________________ 95

Figure 61. Startup in Zoom Mode ___________________________________ 96

Figure 62. Range Change _________________________________________ 97

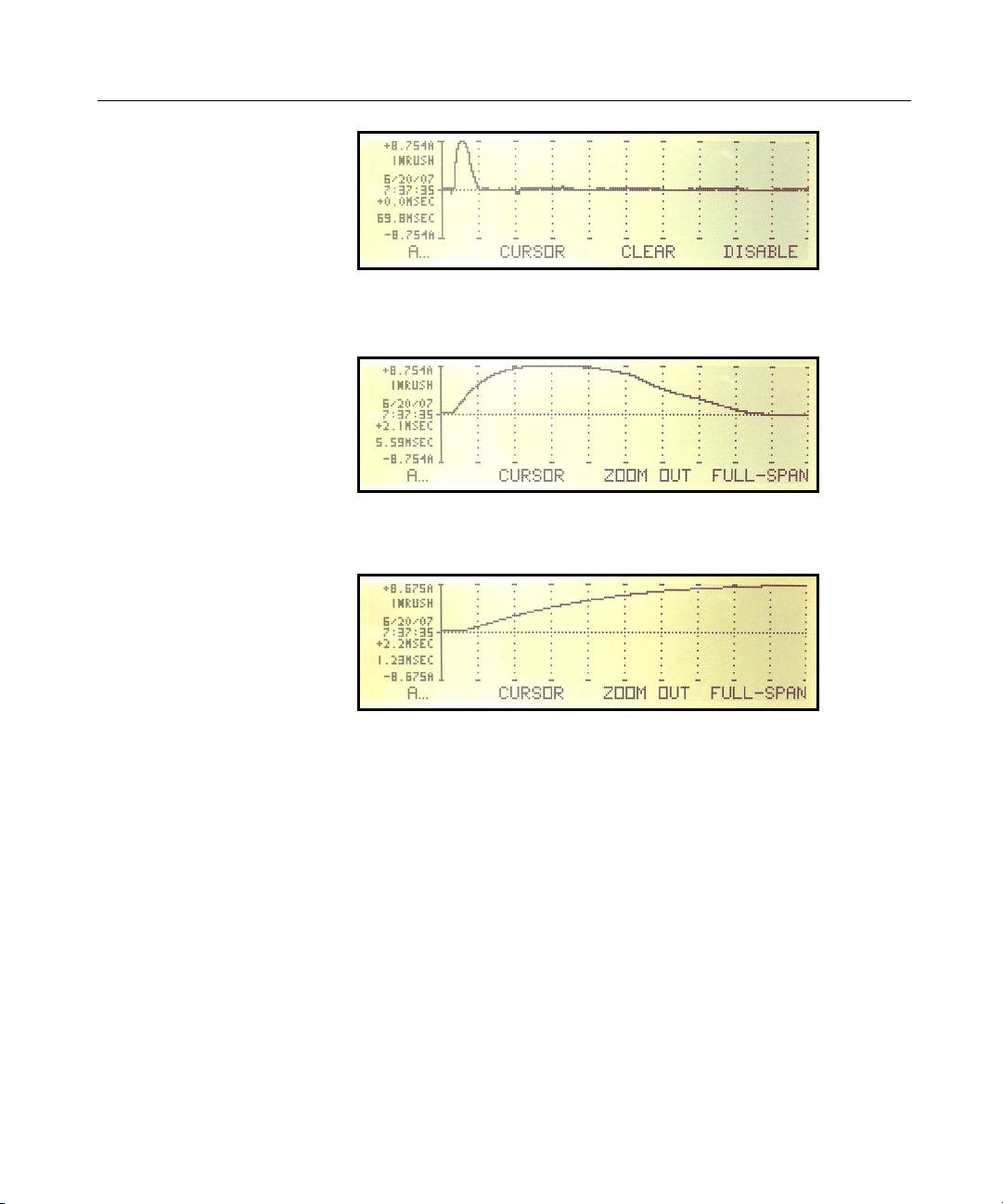

Figure 63. Amps Inrush in Normal Mode ______________________________ 98

Figure 64. Inrush in Zoom Mode ____________________________________ 98

Figure 65. Inrush in Zoom Mode, Additional Zoom Level _________________ 98

Figure 66. Configuration Printout ___________________________________ 101

Figure 67. Waveform Channel 1 Real-time ___________________________ 102

Figure 68. Waveform Channe1 Distortion ____________________________ 103

Figure 69. History Chart VOLTS ACDC, Trends View ___________________ 104

Figure 70. History Chart AMPS PERCENT THD Extents View ____________ 105

Figure 71. Harmonics Listing page 1 ________________________________ 106

Figure 72. Harmonics Listing page 2 ________________________________ 107

Figure 73. AC Voltage, Autorange __________________________________ 160

Figure 74. AC Voltage, Fixed Range, Low Frequency___________________ 161

Figure 75. AC Voltage, Autorange, High Frequency ____________________ 162

Figure 76. AC Voltage, Fixed Range, High Frequency __________________ 163

Figure 77. AC Current, Autorange, Low Frequency_____________________ 164

Figure 78. AC Current, Fixed Range, Low Frequency ___________________ 165

Figure 79. AC Current, Autorange, High Frequency ____________________ 166

Figure 80. AC Current, Fixed Range, High Frequency __________________ 167

Figure 81. DC Voltage, Autorange __________________________________ 168

Figure 82. DC Voltage, Fixed Range ________________________________ 169

Figure 83. DC Current, Autorange __________________________________ 170

Figure 84. DC Current, Fixed Range ________________________________ 171

Figure 85. AC Voltage (Transducer), Autorange, Line or LF Measurements _ 172

Figure 86. AC Voltage, (Transducer), Fixed Range, Line or LF Measurements173

Figure 87. AC Voltage, (Transducer), Autorange, HF Measurements_______ 174

Figure 88. AC Voltage, (Transducer), Fixed Range, HF Measurements _____ 175

Figure 89. DC Voltage, (Transducer), Autorange ______________________ 176

Figure 90. DC Voltage, (Transducer), Fixed Range_____________________ 177

Figure 91. Power, Autorange ______________________________________ 178

Figure 92. Power, Fixed Range ____________________________________ 179

14 2801/2802 Power Analyzer User Guide

Figure 93 VAR vs. Frequency _____________________________________ 180

Figure 94. Watts vs. Frequency ____________________________________ 181

Figure 95. Power Factor vs. Frequency ______________________________ 182

Introduction 15

Introduction

The purpose of this user guide is to describe the use and capabilities of the

2801/2802 Advanced Single and Dual-Channel Power Analyzers.

Scope

The 2801/2802 Advanced Single and Dual-Channel Power Analyzers

incorporate the ideal combination of precision, speed and ease-of-use in

instruments so economical they can be on every bench.

With an extended measurement range from micro-amps to hundreds of amps

and millivolts to kilovolts, the 2801/2802 is the ideal analyzer for efficiency,

standby power or ENERGY STAR testing. In addition to numerical results,

the 2801/2802 analyzer captures waveforms with true 512-point precision.

Results and waveforms can be displayed, read via the communication ports,

or sent directly at full resolution to a USB printer. Power and amplitude

measurements with an accuracy of <0.1% are automatically synchronized to

the fundamental frequency. Peak, RMS, rectified, and DC measurements of

voltage, current and power are provided including continuous, inrush, startup

and history modes, plus an integration mode for W-Hr, A-Hr, VA-Hr, as well

as integrated average power. The analyzer also provides waveform peak and

glitch capture modes.

16 2801/2802 Power Analyzer User Guide

Features

The 2801/2802 Power Analyzer’s features include the following—

• Highest Performance-to-Cost ratio in the industry

• Up to 2000V peak and 150A peak measurable internally (also external CT

capable)

• Base accuracy <0.08%. Current and voltage accuracies specified to less

than 1mArms and 1Vrms respectively (<0.2%)

• Measures and displays volts, current, power, frequency, harmonics, THD,

PF, CF, K-Factor, Triplens, inrush, distortion, glitches, and much more.

• Integrated line switch and inrush waveforms

• Source or load measurements with wiring loss and voltage burden

compensation

• DC charge and discharge measurements

• Frequency Range: DC and 20mHz – 200kHz

• Graphics display shows numerical results, waveforms, bar graphs, startup

& history plots

• 16-bit A/D converters at 235ksps

• 12 User-configurable digital I/O

• USB Flash drive support for data logging*

• Communications interfaces include GPIB (IEEE488), RS-232, and USB

(host and device) all standard.

* Planned feature

Functional Description 17

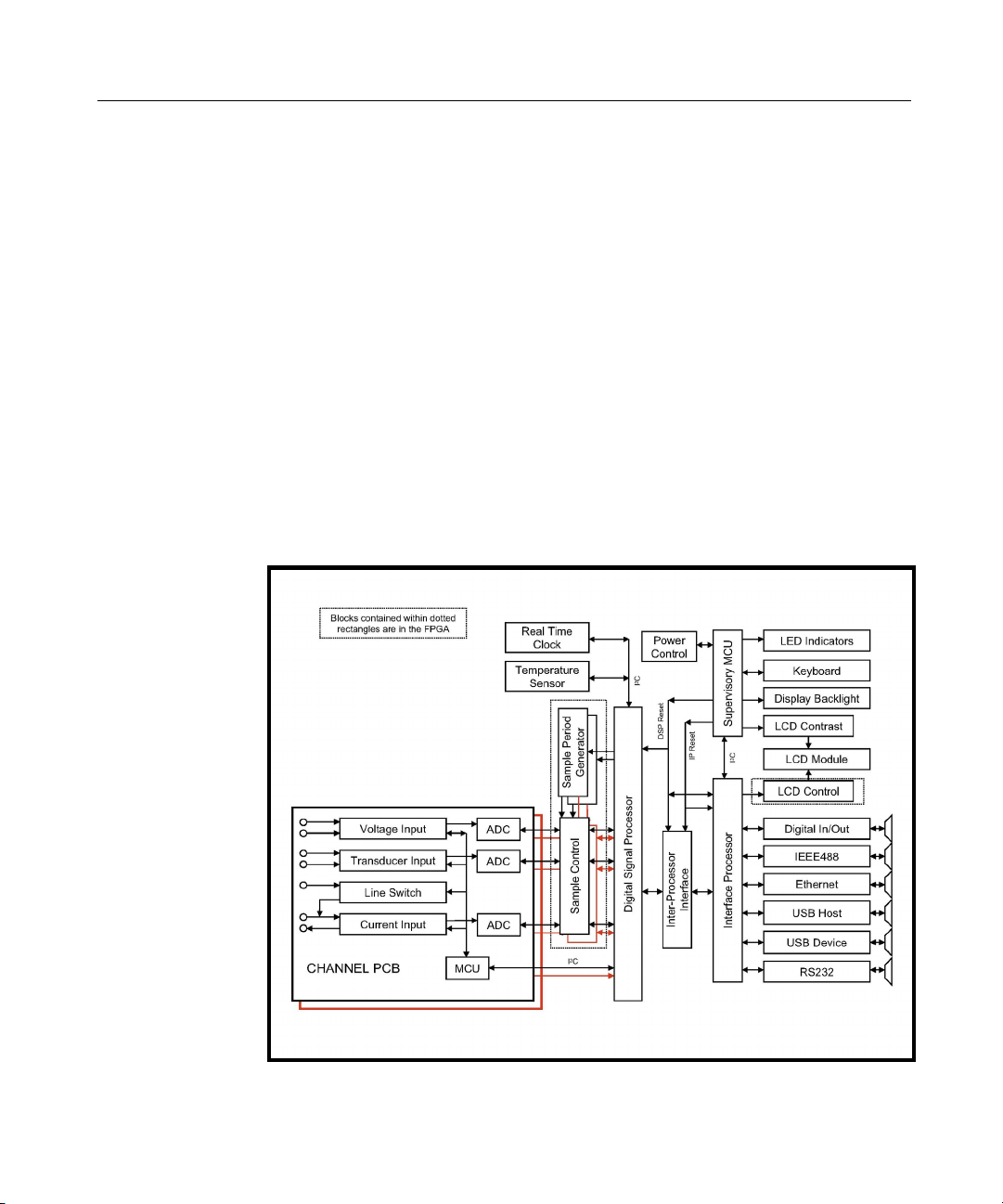

Functional Description

This chapter describes the circuitry and interfaces of the 2801/2802 Power

Analyzer.

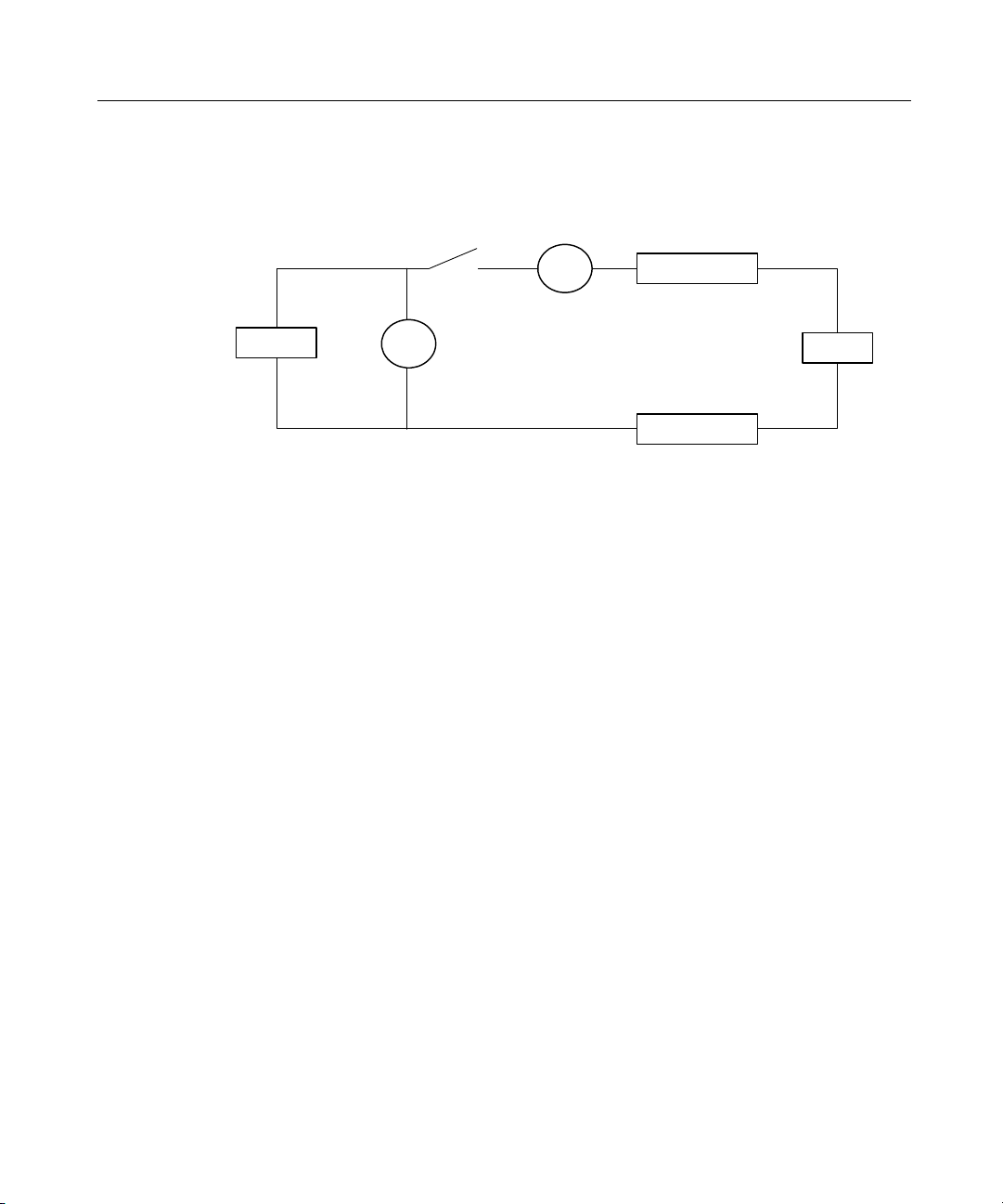

Theory of Operation

OVERALL BLOCK DIAGRAM

Figure 1. Overall Block Diagram

18 2801/2802 Power Analyzer User Guide

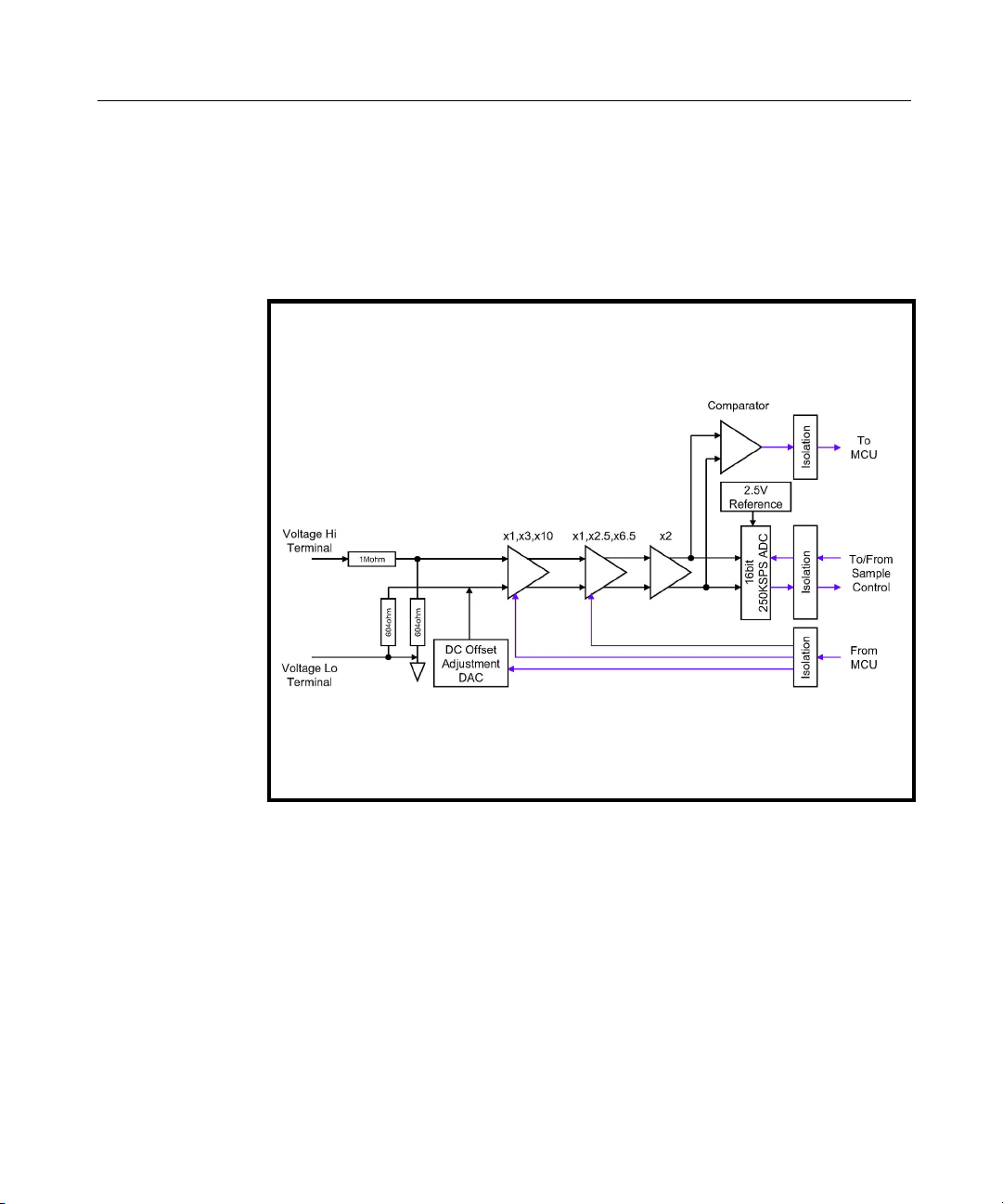

Analog Channel Board

The 2801 is built with one and the 2802 is built with two Analog Channel

Boards fitted. The block diagrams of this circuitry are shown below.

Voltage Input Attenuator Notes

The primary voltage-reducing element formed by the 1 Mohm portion of the

attenuator is comprised of several lesser value resistors in series:

a) To assure the input remains safe when a single resistor fails to a short

circuit;

b) To reduce the voltage coefficient of the attenuator caused by self heating

when high voltages are applied; and

c) To ensure that the input can withstand high voltages in excess of the

maximum specified to the user.

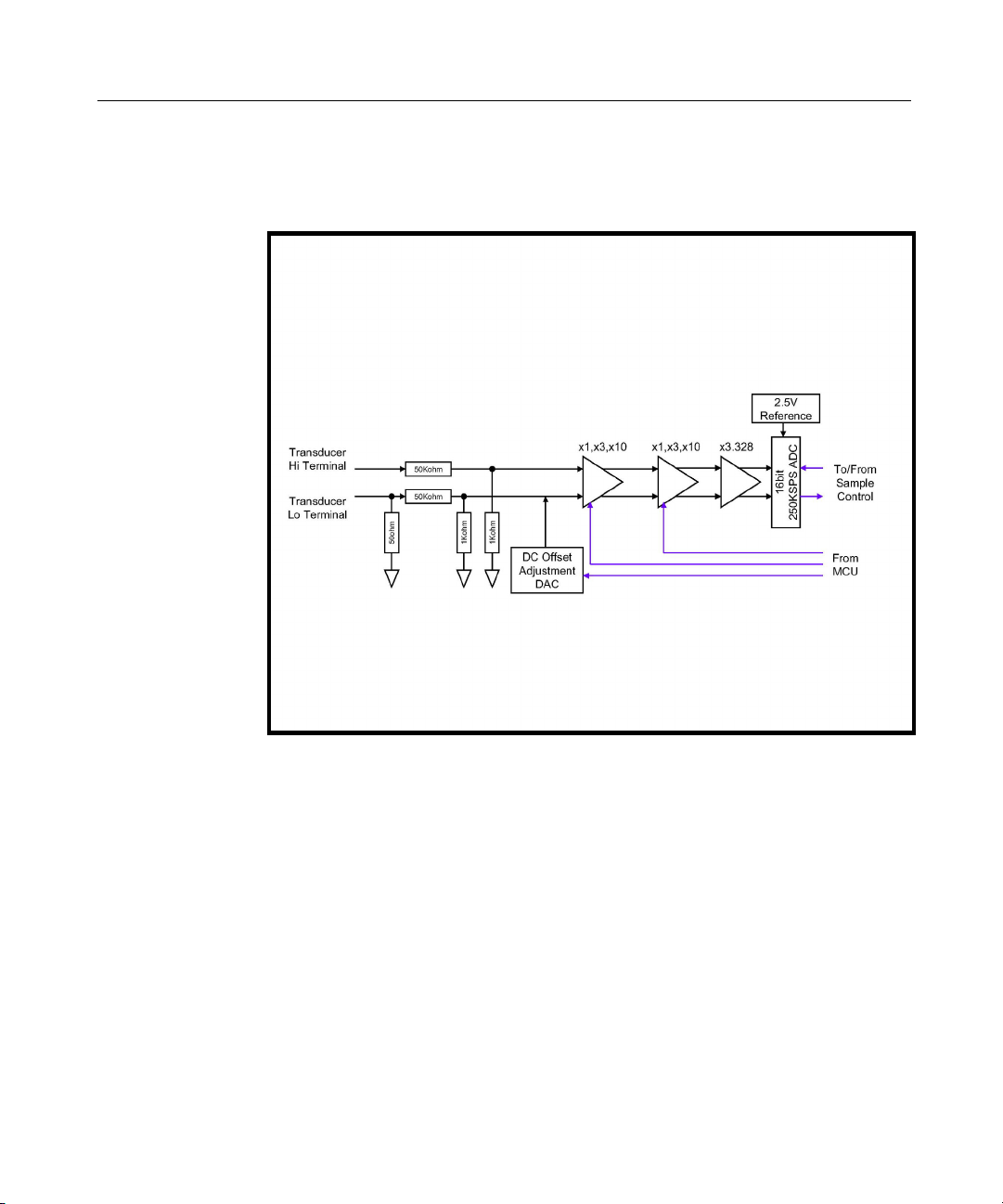

Transducer Input Attenuator Notes

The Transducer input attenuator is similar to the Voltage input attenuator but

with a much lower primary resistance value and a slightly higher output

impedance. Since the input voltages specified are low, only a single primary

attenuator resistor is used as there are no single fault safety issues with this

input.

Functional Description 19

Voltage Input Attenuator

Figure 2. Voltage Input Attenuator Block Diagram

20 2801/2802 Power Analyzer User Guide

Transducer Input Attenuator

Figure 3. Transducer Input Attenuator Block Diagram

Functional Description 21

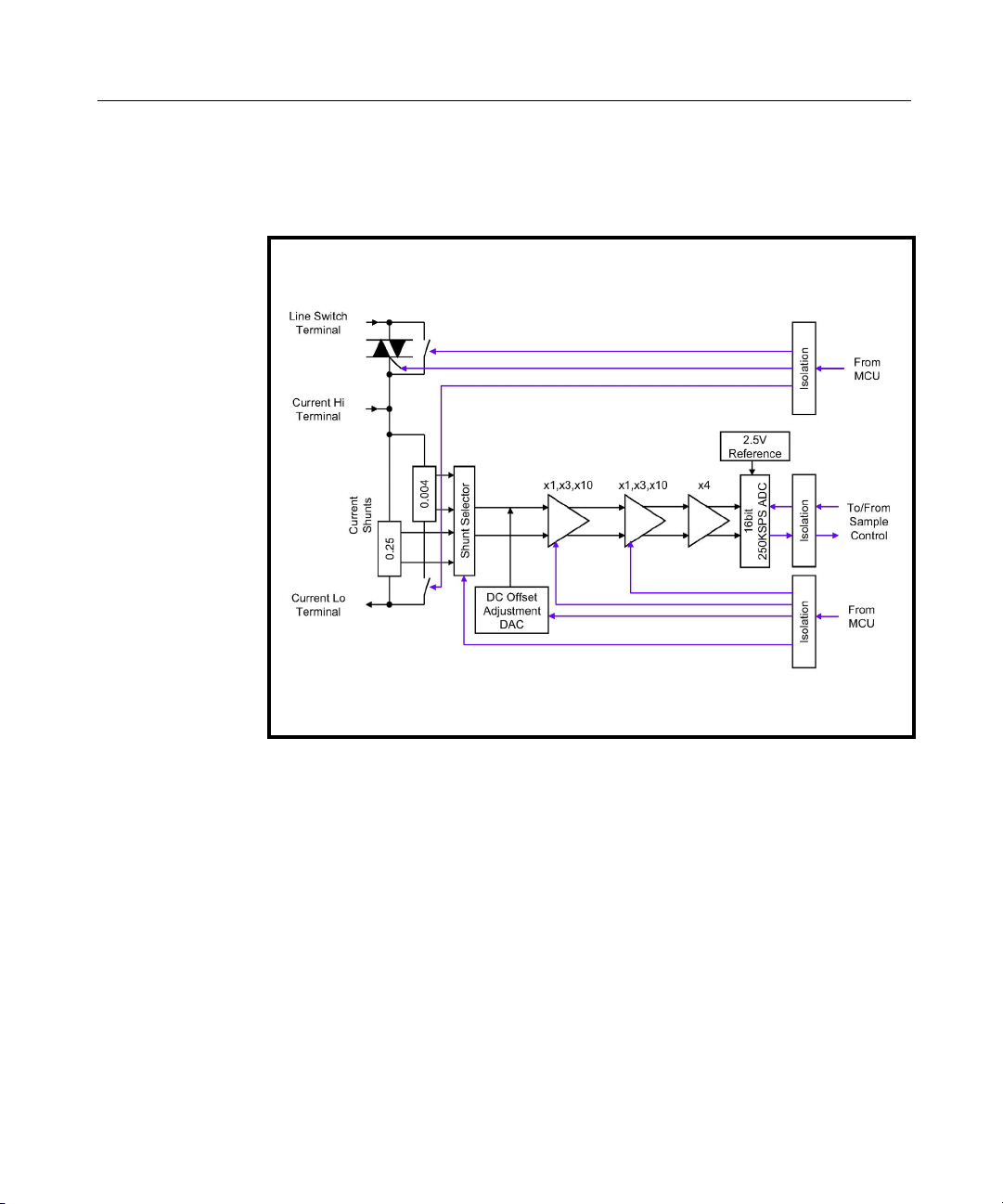

Current and Line Switch

Figure 4. Current and Line Switch Block Diagram

Line Switch Notes

The TRIAC and relay are controlled directly by the Channel MCU as

commanded by the DSP.

The timing of the turn on sequence when operating with AC voltages is

accomplished by the MCU delaying turning on the TRIAC (after being

commanded to do so by the DSP) by an amount commanded by the

DSP from the active edge of the “squared” signal from the comparator

in the Voltage Input circuitry. When set for DC voltage operation, the

TRIAC is turned on immediately after being commanded to do so

without reference to this signal.

22 2801/2802 Power Analyzer User Guide

Other than the delay noted above, the turn on sequence in either AC or DC

voltage modes is the same and is timed by the Channel MCU.

Nominally 50ms after the TRIAC is turned on, the parallel relay is

engaged, and then nominally 20ms after that the TRIAC has its control

signal removed. Since the relay has a low voltage drop, there is

insufficient current flowing through the TRIAC to hold it in the on

state, and thus only the relay conducts from this point onwards.

When configured for DC voltage operation, the turn off sequence

(controlled by the channel MCU) is simply to turn off the relay

immediately after being commanded to do so by the DSP.

When configured for AC voltage operation the timing sequence during turn

off is as follows. Immediately after being commanded to turn off the

switch, the MCU turns on the control signal to the TRIAC. After

nominally 20ms the relay is turned off, and after a further nominally

40ms the TRIAC control signal is removed. In this manner the actual

load turn off is controlled by the TRIAC rather than the relay.

If the switch is used in high dV/dT situations (e.g. inductive loads), then it

may be required that the user add an external snubber circuit. This

circuitry cannot be included internally, as it is dependent on the actual

load characteristics and its presence will directly affect the off

characteristics of the switch.

Since the relay is normally the current carrying device, the TRIAC does not

limit the continuous current capability of the switch as the thermal

issues with the TRIAC are not present. The TRIAC is only used to

withstand the turn on surge of the load, and to withstand any reverse

“kick” when an AC load is turned off. Similarly, the relay is not

required to withstand the surge current of the load during turn on, nor is

it required to withstand the turn off surge of an inductive AC load, so

the requirements on the relay are reduced.

DC Offset Adjustment DACs (all inputs)

The DC Offset adjustment DACs are adjusted by the DSP (via the Channel

MCUs) to produce a zero DC reading when commanded to do so by the user.

This is accomplished independently for each input, each range, and each

current shunt selection. The DAC settings required to produce each zero DC

reading is stored independently for each combination in the Channel MCU in

non-volatile memory.

Functional Description 23

Isolation (all inputs except the Transducer input)

The digital signals are all passed through digital isolation barriers. This

provides the required isolation between the measurement circuitry and

the chassis ground of the product.

A further area of isolation, not specifically shown on the block diagrams is

that of power to the analog circuitry in each input.

Interfaces

Note: Specifications are subject to change without notice.

Front Panel

Liquid Crystal Display—240 x 64 high-speed graphics LCD with CCFL

backlight (5" x 1.35" viewing area)

Keyboard—Seven fixed-purpose keys + four softkeys

IEEE488

Interface—

IEEE488.1 (Certain commands conform to IEEE488.2)

Addressing—

Single address, user selectable via front panel between 0 and 29 inclusive

Capabilities—

SH1 AH1 T6 L4 SR1 RL1 PP0 DC1 DT1 C0 E2 (350ns min. T1)

Max. Talk Data Rate—

>300,000 bytes per second

Max. Listen Data Rate—

>100,000 bytes per second

Command Set—

All front panel capabilities are provided via ASCII textual command

sequences.

Results—

Any results may be obtained at any time from the interface as ASCII textual

numerical data. Additionally, status and state interrogatives are provided for

on-the-fly determination of product status.

USB Device

USB 2.0 compliant, full-speed, multiple endpoint interface to a host.

24 2801/2802 Power Analyzer User Guide

Driver provided with instrument is for PC compatible computers running

Windows 2000 or later

USB Host

USB 2.0 compliant, low or full-speed (as selected by the device).

Compatible with all printers supporting either the PCL3 (or higher) language

or supporting unformatted text transfers.

Printer must be directly connected to the 2802 (hubs are not supported).

RS-232

RTS/CTS hardware handshaking. Also supports the DTR and DSR signals.

Baud rate user selectable as 9600, 19200, 38400, 57600, 115200 or

230400baud.

8 bits per character, no parity, 1 stop bit transmission format.

Digital I/O

The Digital I/O port can be used to control the internal line switch or to

control integration..

Ethernet

Not yet available.

Using the Power Analyzer 25

Using the Power Analyzer

The purpose of this chapter is to describe how to set up and use the 2802.

This chapter covers—

• Setting up the analyzer

• Using the front panel interface

• Rear panel connections

• Power testing

Setting Up

The power analyzer is made to sit on the bench. The viewing angle can be

optimized by adjusting the handle and the viewing brightness enhanced by

adjusting the DISPLAY CONTRAST. An optional rack adapter is available.

Figure 5. Benchtop Version of 2801 Power Analyzer

26 2801/2802 Power Analyzer User Guide

Figure 6. Benchtop Version of 2802 Power Analyzer

To adjust the handle—

Press and hold the buttons located on the rear side where the handle attaches

to the case sides. Rotate the hand

le until it clicks into place.

WARNING: IF THE POWER ANALYZER IS USED IN A MANNER NOT SPECIFIED

!

BY VITREK, THE PROTECTION PROVIDED BY THE EQUIPMENT MAY BE

IMPAIRED.

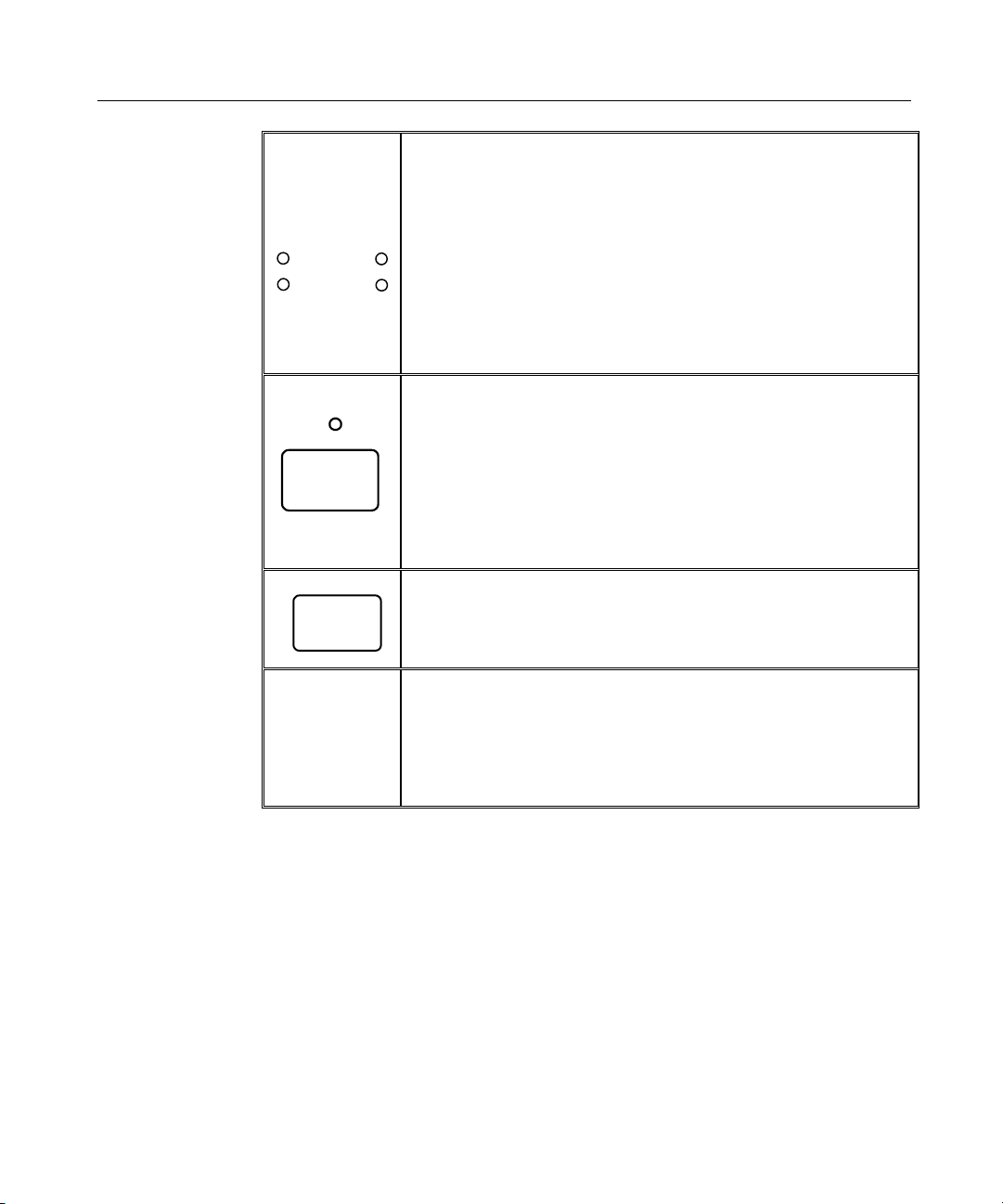

Using the Front Panel Interface

Use the 2801/2802 front panel interface to select and setup the desired tests

and to read the test results. The interface includes a power switch; LCD

display; two keys used for scrolling; a shift key to alter the softkey functions;

a line switch key; and separate keys used to pull up menus, to make

selections, and to print. Additionally, there are four softkeys. The four LEDs

function as indicators. Figure 7 shows the front panel interface display, keys

and LEDs.

Using the Power Analyzer 27

Figure 7. 2801 Front Panel Interface Detail

Figure 8. 2802 Front Panel Interface Detail

The highlighted menu item will be initiated by pressing the ENTER key.

Figure 9. Sample Display

28 2801/2802 Power Analyzer User Guide

The display is used to view and select the various menu options and to review

the power measurement results numerically and graphically, as shown in the

section on Viewing Results.

The display contains helpful navigational symbols, such as, the softkey labels;

and on the right there may be an arrow pointing either up or down, if

additional line items are available. The F1 through F4 softkey labels correlate

with each display and are used to modify setups and to expand on existing

numerical and graphical measurement results.

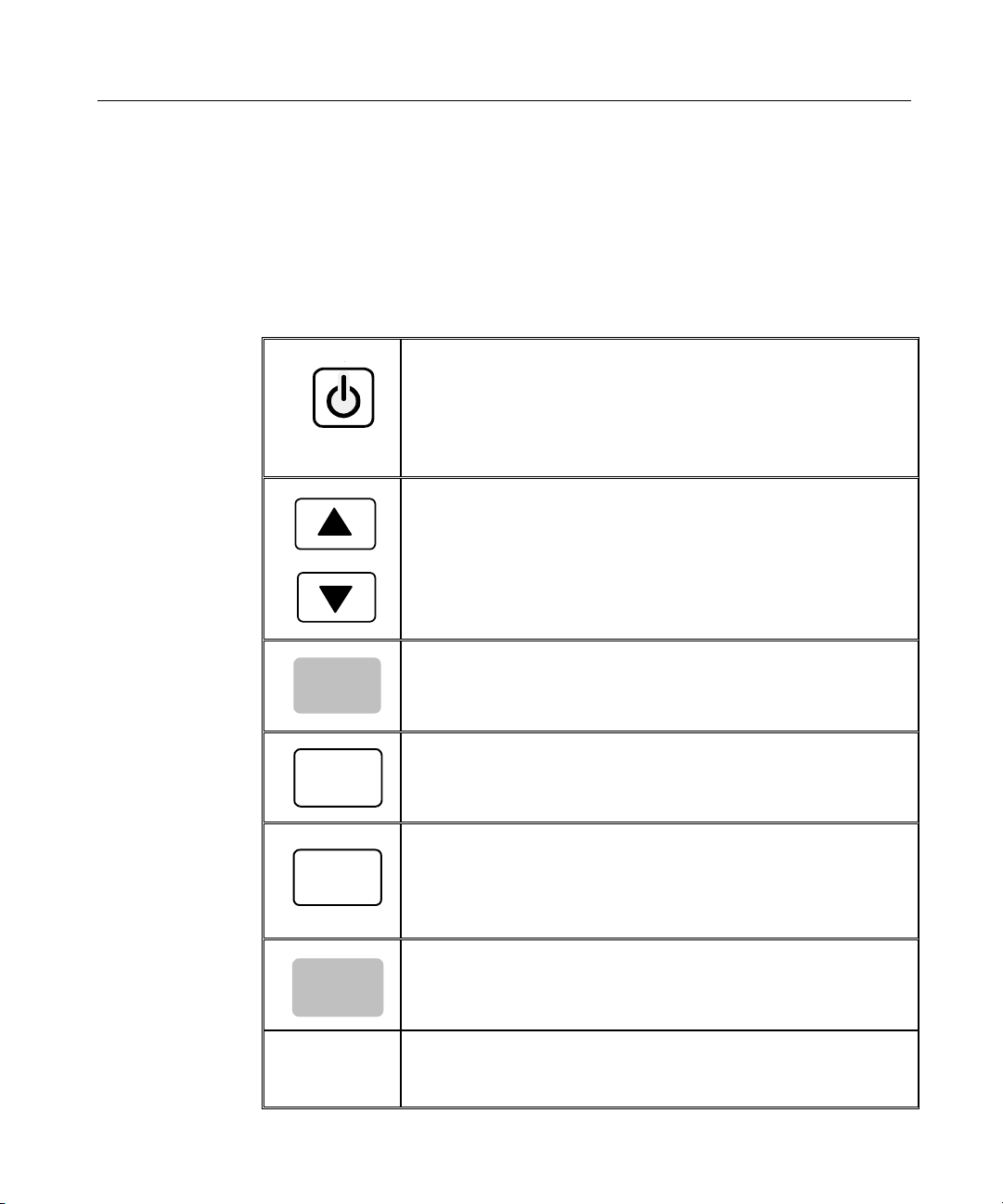

If the LED above the power key is yellow, it indicates power

has been connected. To power up the analyzer, hold the

power key until the LED turns green. It requires that the key

be pressed for 500 milliseconds. When turning it off the

LED turns from green to yellow.

Use the and (up and down arrow) keys to scroll a

highlight bar through options in a menu, to bring up the

various measurement results for viewing, and to view

additional measurement results. The up arrow key moves the

display to the previously viewed screen or item. The down

arrow key moves to the next viewable screen or item.

The SHIFT key provides additional options for softkeys F1

SHIFT

through F4 when applicable. This feature is most valuable

when viewing charts.

Use the ENTER key to make a selection. Press ENTER

ENTER

when the desired menu option or measurement selection is

highlighted.

Use the MENU key to access the MAIN MENU. The

MENU

MENU key is also used to move from submenus to higher

level menus and from the MAIN MENU to Measurement

Results.

The four softkeys, F1 through F4, change functionality

F1

within a display and correlate with that specific menu or

Measurement Results display.

Using the Power Analyzer 29

The LEDs designated OVERLOAD V and A indicate the

OVERLOAD

VA

CH 1

CH 2

selected current/voltage threshold has been exceeded, such

as, an input signal is greater than the selected range value,

above strict ranging or the selected maximum range. Note

that when either of these LEDs remains lighted, changes to

the test device’s signal input or values in the SETUP

MEASUREMENTS MENU are required.

2802 is shown, 2801 only has CH1 Overload LEDs

A lighted LED at LINE ON/OFF indicates that power has

been turned on to the device connected to the analyzer for

testing/measuring.

LINE

ON / OFF

Hold the LINE ON/OFF key for a few milliseconds to

power up or power down the test device. Note that this line

switch is ENABLED or DISABLED from within the

SETUP MEASUREMENTS MENU.

The PRINT key allows the user to print a full page of data

PRINT

reflecting the display results. The formatting of the printout

is either graphical or numerical tabulation.

The F1, F2, F3 and F4 keys are softkeys. They correlate

with labels given on the display. The softkey labels indicate

other options available or the status of the display. An

ellipsis (…) following the label indicates additional choices

available. See below.

Grounding of the Analyzer

There are two distinct grounded areas built into the 2801/2802 Power

Analyzer.

Chassis Ground

This comprises the entire external and internal chassis mechanical

components, the outside shells of all interface connectors, and the shield

connection in the IEEE488 interface connector. An external protective

ground terminal is directly connected to this ground.

Internal Electronic Ground

This comprises all grounded circuitry within the product and is the reference

30 2801/2802 Power Analyzer User Guide

for all interface signals within the interface connectors except for the Ethernet

connections (which are transformer isolated according to the applicable

Ethernet standards). This area is electrically connected to the negative side of

the DC power input via an RF pi filter network having a low DC resistance.

Notes on Grounding:

Between the two ground areas there is a 50ohm (1%) power resistor in

parallel with a 1000pF/50V ceramic capacitor for RF filtering.

The T input connections are isolated from the Internal Electronic Ground

via a nominally 50ohm (1%) power resistor. An isolating current

transducer having sufficient safety rating for the signals being measured

MUST be used when using this input.

The A and Line Switch connections are fully isolated from the Internal

Electronic Ground using transformer isolation to the requirements of

EN61010. This isolation is 100% tested to 4.5kV peak.

The V connections are fully isolated from the Internal Electronic Ground

using transformer isolation to the requirements of IEC61010. This

isolation is 100% tested to 4.5kV peak.

The V connections are resistively isolated from each other with nominally

1Mohm to the requirements of EN61010 in no fault, single fault and

dual fault conditions. This isolation is 100% tested to 2kV peak.

Mechanical isolation is provided between the V connections and the A and

Line Switch connections, which is well in excess of the class ratings of

either set of terminals, there are no electrical signals between these

connections.

Because of the use of transformer isolation, there is very little current

flowing between the UUT terminals and the ground of the product. The

isolation impedance is >10

9

ohms and the capacitance is typically a few

10s of pF.

The EN61010 ratings in each application category for each terminal are

stated on the rear panel of the product next to the terminals.

Using the Power Analyzer 31

Rear Panel Connections - 2801 and 2802

Power Requirements

In order to comply with the safety ratings stated on the rear panel of the

product according to the requirements contained in EN61010,these products

must be provided with an external ground connection in some manner (either

through the power source for the product or by connection to the protective

ground on the product).

These products must only b

isolation from the mains supply which meets the requirements of

EN61010.

WARNING: TO AVOID AN UNSAFE AND POTENTIALLY DAMAGING

CONDITION, NEVER USE AN EXTERNAL DC POWER SOURCE TO THIS

PRODUCT, WHICH IS NOT ISOLATED FROM THE MAINS SUPPLY.

When used with the external power supply provided with the product by

, the ground is supplied via the negative DC power input. If the

Vitrek

product is powered by any other equivalent grounded output DC

power supply, then the ground is supplied via that power supply. In

these cases the user need not provide any additional ground connection

to the product provided that the external DC Supply has a ground

connection to it.

In all other cases, e.g. powered from an external battery or any other

isolated DC supply, the instrument MUST be provided with a ground

connection to the protective ground terminal located on the rear panel of

the product (this is marked according to the requirements of EN61010.)

Never use an

from the mains supply – this is UNSAFE and may cause DAMAGE to

the product.

external DC power source to the product which is not isolated

e used with a power supply which contains

If at any time there is doubt regarding the continuity of the ground

connection to

rear panel protective ground terminal.

Operation of the product in the absence of any ground connection does not

intrinsically

the UUT terminals are significantly reduced in this situation. Safety

the product, then it is strongly recommended to use the

render the product unsafe; however the safety ratings for

32 2801/2802 Power Analyzer User Guide

ratings for the products have not been formally established when

operating without a ground connection.

!

!

WARNING: To avoid possible electrical shock, do not operate the product

without an external ground connection in a manner described herein.

CAUTION: The external DC power source for the product MUST be rated

to meet the voltage range and minimum current requirements stated on the

rear panel of the product.

2801 Rear Panel Connections

The 2801 Power Analyzer

to Figure 10. The connectors used for testing/measuring functions are along

the midline of the instrument. The connectors used for communications and

control are along the bottom. The ground terminal is at the lower left corner.

!

!

!

WARNING: IF THE POWER ANALYZER IS USED IN A MANNER NOT SPECIFIED

BY VITREK, THE PROTECTION PROVIDED BY THE EQUIPMENT MAY BE

IMPAIRED.

WARNING: IT IS RECOMMENDED THAT THE PROTECTIVE CONDUCTOR

TERMINAL IS CONNECTED TO EARTH GROUND WHEN THE SIGNALS

BEING MEASURED ARE REFERENCED TO EARTH GROUND.

CAUTION: THE USE OF THE T5 CHARGER FROM VITREK OR A VITREK

RECOMMENDED REPLACEMENT MUST BE USED TO ENSURE THAT THE UNIT

GROUND IS NOT COMPROMISED.

rear panel contains a variety of connectors. Refer

CAUTION: FOR ALL CONNECTIONS, KEEP INPUT AND OUTPUT WIRING

SEPARATED.

Using the Power Analyzer 33

Power Line Connection

Ground Terminal

Voltage Input

T- Connector

Optional

Line In

Figure 10. Rear Connection Panel

Current Input

34 2801/2802 Power Analyzer User Guide

Single-Channel Measurements of a Power Source:

Connection Method 1

Wiring Loss

W1 ohms

Source

Wiring Loss

ohms

W

2

Figure 11. Measuring a Power Source, Method 1

Configure the channel as follows -

• This connection method is suitable for most applications.

• At high frequencies, the wiring length between the source and the

current and voltage measurement points should be kept as short as

possible to avoid inductive and capacitive losses causing inaccuracies.

Optional

Line Switch

+

V

-

+

-

A

Load

• Optionally, set Wiring Impedance to (W1 + W2) ohms. Include all

wiring resistances between the source and the points at which the

voltage is measured in the entered value for wiring impedance.

• Set V Burden Compensation to YES.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

Using the Power Analyzer 35

Single-Channel Measurements of a Power Source:

Connection Method 2

Wiring Loss

ohms

W

1

Source

Wiring Loss

W2 ohms

Figure 12. Measuring a Power Source, Method 2

Configure the channel as follows -

• Method 2 may provide improved results for applications with very

low voltage and very high current, when using the internal shunt.

• At high frequencies, the wiring length between the source and the

current and voltage measurement points should be kept as short as

possible to avoid inductive and capacitive losses causing inaccuracies.

• Optionally, set Wiring Impedance to (W1 + W2) ohms. The

instrument will always automatically adjust for the internal shunt

burden resistance if the channel is set to use the internal shunt. Other

than the internal shunt burden, include all wiring resistances between

the source and the points at which the voltage is measured in the

entered value for wiring impedance.

+

-

A

+

V

Load

-

• Set V Burden Compensation to NO.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

36 2801/2802 Power Analyzer User Guide

Single-Channel Measurements of a Load: Connection Method 1

Optional

Line Switch

+

Source

Configure the channel as follows -

• This connection method is suitable for most applications.

• At high frequencies, the wiring length between the load and the

current and voltage measurement points should be kept as short as

possible to avoid inductive and capacitive losses causing inaccuracies.

V

-

Figure 13. Measuring a Load, Method 1

+

-

A

Wiring Loss

W

ohms

1

Load

Wiring Loss

W2 ohms

• Optionally, set Wiring Impedance to (W1 + W2) ohms. The

instrument will always automatically adjust for the internal shunt

burden resistance if the channel is set to use the internal shunt. Other

than the internal shunt burden, include all wiring resistances between

the load and the points at which the voltage is measured in the entered

value for wiring impedance.

• Set V Burden Compensation to NO.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

Using the Power Analyzer 37

Single-Channel Measurements of a Load: Connection Method 2

+

Source

-

A

+

V

Wiring Loss

ohms

W

1

Load

-

Wiring Loss

W2 ohms

Figure 14. Measuring a Load, Method 2

Configure the channel as follows -

• Method 2 may provide improved results for applications with very low

voltage and very high current, when using the internal shunt.

• At high frequencies, the wiring length between the load and the current

and voltage measurement points should be kept as short as possible to

avoid inductive and capacitive losses causing inaccuracies.

• Optionally, set Wiring Impedance to (W1 + W2) ohms. Include all wiring

resistances between the load and the points at which the voltage is

measured in the entered value for wiring impedance.

• Set V Burden Compensation to YES.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

38 2801/2802 Power Analyzer User Guide

Measurements of a Power Source:Connection Method 1 – Ext CT

Source

+

CT

-

Load

Optional

Wiring Loss

ohms

W

1

Wiring Loss

ohms

W

2

Figure 15. Measuring a Source Using a CT, Method 1

Configure the channel as follows –

• This connection method is suitable for most external transducer

applications.

• At high frequencies, the wiring length between the source and the current

and voltage measurement points should be kept as short as possible to

avoid inductive and capacitive losses causing inaccuracies.

• Optionally, set Wiring Impedance to (W1 + W2) ohms. Include all wiring

resistances between the source and the points at which the voltage is

measured in the entered value for wiring impedance.

+ +

V

-

A or T

-

• Set V Burden Compensation to YES.

• If the current measurement terminals of the 2801 or the wire through the

CT (but not both) are reversed then set Reverse Current to YES,

otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

• If using a current output CT then use the A terminals, otherwise use the T

connector, of the 2801. If using a current output CT and using the

internal line switch of the 2801, then take care to reduce the length of the

common wiring of the two signals to the A+ terminal of the 2801.

2802 Rear Panel Connections

The 2802 Power Analyzer rear panel contains a variety of connectors. Refer

to Figure 16. The connectors used for testing/measuring functions are along

the midline of the instrument. The connectors used for communications and

control are along the bottom. The ground terminal is at the lower left corner.

Using the Power Analyzer 39

!

BY VITREK, THE PROTECTION PROVIDED BY THE EQUIPMENT MAY BE

IMPAIRED.

WARNING: IT IS RECOMMENDED THAT THE PROTECTIVE CONDUCTOR

WARNING: IF THE POWER ANALYZER IS USED IN A MANNER NOT SPECIFIED

!

TERMINAL IS CONNECTED TO EARTH GROUND WHEN THE SIGNALS

BEING MEASURED ARE REFERENCED TO EARTH GROUND.

CAUTION: THE USE OF THE T5 CHARGER FROM VITREK OR A VITREK

!

RECOMMENDED REPLACEMENT MUST BE USED TO ENSURE THAT THE UNIT

GROUND IS NOT COMPROMISED.

CAUTION: FOR ALL CONNECTIONS, KEEP INPUT AND OUTPUT WIRING

SEPARATED.

Figure 16. Rear Connection Panel

Power Line Connection

Ground Terminal

Voltage Input

T- Connector

Optional

Line In

Current Input

40 2801/2802 Power Analyzer User Guide

Measurements of a Power Source: Connection

Method 1

Wiring Loss

W1 ohms

Source

Wiring Loss

ohms

W

2

Figure 17. Measuring a Power Source, Method 1

Configure the channel as follows -

• This connection method is suitable for most applications.

• At high frequencies, the wiring length between the source and the

current and voltage measurement points should be kept as short as

possible to avoid inductive and capacitive losses causing inaccuracies.

Optional

Line Switch

+

V

-

+

-

A

Load

• Optionally, set Wiring Impedance to (W1 + W2) ohms. Include all

wiring resistances between the source and the points at which the

voltage is measured in the entered value for wiring impedance.

• Set V Burden Compensation to YES.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

Using the Power Analyzer 41

Measurements of a Power Source: Connection Method 2

Wiring Loss

W

ohms

1

Source

Wiring Loss

W2 ohms

Figure 18. Measuring a Power Source, Method 2

Configure the channel as follows -

• Method 2 may provide improved results for applications with very

low voltage and very high current, when using the internal shunt.

• At high frequencies, the wiring length between the source and the

current and voltage measurement points should be kept as short as

possible to avoid inductive and capacitive losses causing inaccuracies.

• Optionally, set Wiring Impedance to (W1 + W2) ohms. The

instrument will always automatically adjust for the internal shunt

burden resistance if the channel is set to use the internal shunt. Other

than the internal shunt burden, include all wiring resistances between

the source and the points at which the voltage is measured in the

entered value for wiring impedance.

+

-

A

+

V

Load

-

• Set V Burden Compensation to NO.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

42 2801/2802 Power Analyzer User Guide

Measurements of a Load: Connection Method 1

Optional

Line Switch

+

Source

Configure the channel as follows -

• This connection method is suitable for most applications.

• At high frequencies, the wiring length between the load and the

current and voltage measurement points should be kept as short as

possible to avoid inductive and capacitive losses causing inaccuracies.

V

-

Figure 19. Measuring a Load, Method 1

+

-

A

Wiring Loss

W

ohms

1

Load

Wiring Loss

W2 ohms

• Optionally, set Wiring Impedance to (W1 + W2) ohms. The

instrument will always automatically adjust for the internal shunt

burden resistance if the channel is set to use the internal shunt. Other

than the internal shunt burden, include all wiring resistances between

the load and the points at which the voltage is measured in the entered

value for wiring impedance.

• Set V Burden Compensation to NO.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

Using the Power Analyzer 43

Measurements of a Load: Connection Method 2

+

Source

-

A

+

V

Wiring Loss

W1 ohms

Load

-

Wiring Loss

W2 ohms

Figure 20. Measuring a Load, Method 2

Configure the channel as follows -

• Method 2 may provide improved results for applications with very low

voltage and very high current, when using the internal shunt.

• At high frequencies, the wiring length between the load and the current

and voltage measurement points should be kept as short as possible to

avoid inductive and capacitive losses causing inaccuracies.

• Optionally, set Wiring Impedance to (W1 + W2) ohms. Include all wiring

resistances between the load and the points at which the voltage is

measured in the entered value for wiring impedance.

• Set V Burden Compensation to YES.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

44 2801/2802 Power Analyzer User Guide

Measurements of a Power Source and Load: Method

1, Two Ind. Chnls

Source

Source

Wiring Loss

W

ohms

1

Wiring Loss

W

ohms

2

V

V

+

-

+

-

+

A

Optional

Line Switch

-

Wiring Loss

W

ohms

1

Wiring Loss

W2ohms

+

Load

-

Channel 2

(Load Connection)

A

Load

Channel 1

(Source Connection)

Figure 21. Measuring a Power Source and Load, Method 1, Two Ind. Chnls

Configure the channels as follows -

• This connection method is suitable for most Independent or

Input/Output channel applications.

• At high frequencies, the wiring length between the source and the

current and voltage measurement points should be kept as short as

possible to avoid inductive and capacitive losses causing inaccuracies.

Using the Power Analyzer 45

• Optionally, set Wiring Impedance to (W1 + W2) ohms. Include all

wiring resistances between the source and the points at which the

voltage is measured in the entered value for wiring impedance.

• Set V Burden Compensation to YES.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

Measurement: 3P-3W 2 Meter Connection, Method 1

X

Source

Z

Source

Y

Source

+

A

+

V

-

-

V

+

+

A

Figure 22. Measure 3P-3W 2 Meter Connection, Method 1

-

Load

Load

Load

X

Channel 2

Z

Y

Channel 1

-

46 2801/2802 Power Analyzer User Guide

The above diagram is applicable when there are 3 wires connecting to the

Load. For ease, we have used X, Y and Z instead of A, B and C. The phase

rotation of the Channels must be opposite of each other and the current

measurement is made in the line phase connected to the corresponding voltage

HI terminal.

Configure the channels as follows -

• Select 3P-3W from the Getting Started Menu.

• The 2802 will provide the following results

Two of the actual measured voltages (X-Z and Y-Z)

The Voltage Difference (= Y-X)

Two of the actual measured currents (X and Y)

The Sum Current (=Z)

The individual and totals for VA, W, VAR, PF etc.

• If the current measurement terminals are reversed, then set Reverse

Current to YES, otherwise set to NO. (Only if both currents are

backwards)

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO. .(Only if both Voltages are

backwards)

Using the Power Analyzer 47

Measurements of a Power Source: Connection Method 1 – Ext CT

Source

+

CT

-

Load

Optional

Wiring Loss

ohms

W

1

Wiring Loss

ohms

W

2

Figure 23. Measuring a Source Using a CT, Method 1

Configure the channel as follows –

• This connection method is suitable for most external transducer

applications.

• At high frequencies, the wiring length between the source and the current

and voltage measurement points should be kept as short as possible to

avoid inductive and capacitive losses causing inaccuracies.

• Optionally, set Wiring Impedance to (W1 + W2) ohms. Include all wiring

resistances between the source and the points at which the voltage is

measured in the entered value for wiring impedance.

+ +

V

-

A or T

-

• Set V Burden Compensation to YES.

• If the current measurement terminals of the 2802 or the wire through the

CT (but not both) are reversed then set Reverse Current to YES,

otherwise set to NO.

• If the voltage measurement terminals are reversed, then set Reverse

Voltage to YES, otherwise set to NO.

• If using a current output CT then use the A terminals, otherwise use the T

connector, of the 2802. If using a current output CT and using the

internal line switch of the 2802, then take care to reduce the length of the

common wiring of the two signals to the A+ terminal of the 2802.

48 2801/2802 Power Analyzer User Guide

Using an External Current Transducer

When using the external current transducer, access the MAIN MENU by

pressing the MENU key. The analyzer can be configured for two types

transducers, the Current-to-Current or the Current-to-Voltage type. The

Current-to-Current type will be connected to the current input receptacles on

the rear panel. The Current-to-Voltage type will be connected to the T input

connection on the rear panel which is a BNC-Type connection.

The following diagram shows the recommended method for wiring up an

external current transducer to the 2801 or 2802.

of

Source

+

CT

-

Load

Optional

Wiring Loss

ohms

W

1

Wiring Loss

ohms

W

2

Figure 24. External Transducer Test Connections

To setup the unit for the type of current transducer being used, it is

recommended to use the GETTING STARTED routine under the MAIN

MENU. If not, then refer to the SETUP MEASUREMENTS/ SETUP

CHANNEL menu to configure the CURRENT INPUT and the CURRENT

SCALING for the type of current transducer used.

+ +

V

-

A or T

-

When the second choice SELECT CURRENT MEASUREMENT is

displayed, there are 3 choices from which to choose. Select choice 2 or 3

Using the Power Analyzer 49

depending on the type of current transducer being used. Use the ARROW

keys to highlight the choice and press ENTER to select

1 Internal Shunt (A terminals)

2 External CT (Current Out, A Terminals)

3 External CT (Voltage Out, T Connector)

The ENTER CURRENT RATIO 1 will now be displayed. Use the arrow

keys to change the highlighted item. Press the F1 or F2 keys to move the

highlight left or right. Use the DEL key to delete numbers and use the .X to

enter a decimal point. As an example, to set up a ratio of +1000 : 1.005 from

the default settings,

PERFORM THE FOLLOWING STEPS:

• Press the F2 key twice

• Press the DEL key once. The decimal point will disappear and the

screen will show +10 A.

• Press the F2 key once, the screen will show +100 A.

• Press the F2 key one more time, the screen will show +1000 A.

• Press the ENTER key.

The ENTER CURRENT RATIO 2 will now be displayed, set this for a

setting of 1.005 (as an example).

• Press the F2 key 4 times, the screen will show 1.000 V.

• Press the UP ARROW key 5 times, the screen will show 1.005 V.

• Press the ENTER key.

Complete any additional changes required to configure the analyzer for the

desired measurements.

Note the following-

1. If the power analyzer unexpectedly displays negative watts indications,

these indications mean that the current flow in the transducer is reversed.

Check for one of these conditions:

50 2801/2802 Power Analyzer User Guide

• the wire is reversed in the transducer;

• the neutral wire was inadvertently routed through the transducer

(instead of the live wire), or;

• the transducer output has the incorrect polarity.

The negative watts indication may be resolved by correcting the wiring, or by

setting the current input scale factor in the power analyzer to a negative

polarity, or by selecting REVERSE CURRENT INPUT from the WIRING

ADJUSTMENTS menu.

2. If a transducer is being used which has DC current capability then the

user should perform the DC ZERO procedure. This is performed after

making the connections and allowing the external transducer to settle after

application of its power.

3. Particularly when operating at low current levels, it may be important to

ensure that the voltage signals cannot capacitively couple into the current

transducer output. The use of flexible coaxial cable is recommended for

the current transducer output wiring.

Starting the Analyzer

The following startup display will show for a few seconds and then return to

the measurement display last used.

SERIAL N UMBER:

SERIAL N UMBER:

Figure 25. Startup Screen 2801 and 2802

Xitron 2801

MAIN v2.12/v1.01

ANALOG v2.11/v1.02/v1.02

FPGA v1.02

Xitron 2802

MAIN v2.12/v1.01

ANALOG v2.11/v1.02/v1.02

FPGA v1.02

Using the Power Analyzer 51

Configuring the Power Analyzer 2801/2802

The MAIN MENU screen gains access to the areas for setting up the

instrument. You will find the menus for the following routines –

2801

GETTING STARTED

SETUP MEASUREMENTS

SETUP SYSTEM

CONFIGURATION STORAGE

PERFORM DC ZERO

DIAGNOSTICS

ABOUT

2802

GETTING STARTED

CHANNEL CONFIGURATION

SETUP INPUT MEASUREMENTS

SETUP OUTPUT MEASUREMENTS

SETUP SYSTEM

CONFIGURATION STORAGE

PERFORM DC ZERO

DIAGNOSTICS

ABOUT

To gain access to the Main Menu, press the MENU key. This will bring up the

MAIN MENU screen display as shown below.

Figure 26. Main Menu Screen

52 2801/2802 Power Analyzer User Guide

Important Note: We recommend the GETTING STARTED setup

described below when setting up the 2801/2802 Power Analyzer for the

first-time.

Getting Started

The first item listed is GETTING STARTED. This is a listing of the preset

applications and predefined measurement settings that can be selected to

configure the 2801/2802. We recommend selecting the appropriate choice that

corresponds to your application when using the power analyzer for the first

time.

To initiate the Getting Started setup:

1. Press the up or down arrow key to highlight GETTING STARTED, press

the

ENTER key to view the application choices. The application in Bold

is the factory default setting

2801 APPLICATIONS

LINE (40Hz – 1kHz)

HF (40Hz-80kHz)

HF (10kHz-200kHz)

DC (40Hz-5kHz Ripple)

DC (nx50Hz Ripple)

DC (nx60Hz Ripple)

DC (nx400Hz Ripple)

LF (0.5Hz-20Hz)

LF (0.02Hz-5Hz)

Using the Power Analyzer 53

2802 APPLICATIONS

3Φ3w

2Φ3w

1Φ3w

DC:DC

DC:LINE

DC:HF

LINE:DC

LINE:LINE (SYNC)

LINE:LINE (ASYNC)

LINE:HF

DUAL:LINE (ASYNC)

DUAL HF (ASYNC)

2. Press the up or down arrow key to highlight the application that best fits

your intended use, press the

ENTER key to select your choice

Channel Configuration (2802 Only)

The second item listed is CHANNEL CONFIGURATION, this is used to set

how the channels will be used within the application. (Note. There is no need

to select one of these options if you had previously selected one of the

quick start choices)

This is a listing of the preset channel configuration settings that can be

selected to configure the 2802.

To initiate the CHANNEL CONFIGURATION setup:

1. Press the up or down arrow key to highlight CHANNEL

CONFIGURATION, press the

choices.

ENTER key to view the application

54 2801/2802 Power Analyzer User Guide

CHANNEL CONFIGURATION

3Φ3w

2Φ3w

1Φ3w

IN:OUT (ASYNC)

IN:OUT (SYNC)

INDEP CHANNELS

2. Press the up or down arrow key to highlight the application that fits your

intended use, press the

Configuring the Analyzer Measurement Results

This section gives a brief description of the menu selections from which to define the

desired measurements. The SETUP MEASUREMENT choices will vary depending

on which GETTING STARTED or CHANNEL CONFIGURATION has been

selected. Once in the setup menu the selections are listed in the order that they come

up on the analyzer display. Indentation is used to denote submenu position.

application in BOLD is the ship from factory default setting for the

2801/2802.

ENTER key to select your choice

The

For 2801 SETUP MEASUREMENTS is your only choice, for the 2802 and if the

application is set for

3Φ3w, 2Φ3w or 1Φ3w then the menu choice is

SETUP MEASUREMENTS

If the application is setup for DC:DC then the menu choice is

SETUP OVERALL MEASUREMENTS

SETUP INPUT MEASUREMENTS

SETUP OUTPUT MEASUREMENTS

Using the Power Analyzer 55

If the application is setup for DC:LINE, DC:HF, LINE:DC then the menu

choice is

SETUP INPUT MEASUREMENTS

SETUP OUTPUT MEASUREMENTS

If the application is setup for LINE:LINE (sync) then the menu choice is

SETUP OVERALL MEASUREMENTS

SETUP INPUT MEASUREMENTS

SETUP OUTPUT MEASUREMENTS

If the application is setup for LINE:LINE (async), LINE:HF then the menu

choice is

SETUP INPUT MEASUREMENTS

SETUP OUTPUT MEASUREMENTS

If the application is setup for DUAL:LINE (async), DUAL:HF then the

menu choice is (2802 Default setting)

SETUP Ch1 MEASUREMENTS

SETUP Ch2 MEASUREMENTS

To Select SETUP MEASUREMENTS 2801:

1. Press the

MENU key to bring up the MAIN MENU. The second

selection is SETUP MEASUREMENTS… Press the down arrow key

to highlight SETUP MEASUREMENTS.

2. Press the ENTER key to enter into the SETUP MEASUREMENTS,

as shown in Figure 26.

56 2801/2802 Power Analyzer User Guide

Figure 27. Measurement Configuration Screen

To Select SETUP MEASUREMENTS 2802:

3. Press the

MENU key to bring up the MAIN MENU. The third

selection is SETUP Ch1 MEASUREMENTS… from which Channel

One’s measurement settings are accessible.

4. Press the down arrow key to highlight SETUP Ch1

MEASUREMENTS.

5. Press the ENTER key to enter into the SETUP Ch1

MEASUREMENTS, as shown in Figure 27.

Figure 28. Measurement Configuration Screen

Setting Up the Measurement Configuration

There are six selections in the MEASUREMENT CONFIGURATION menu.

The following section defines each of the selections and the associated

submenu options available. Refer to the arrow on the side of this display and

scroll this menu down to access each one:

Using the Power Analyzer 57

RESULTS AVERAGING:

MEASUREMENT TYPE:

RANGING AND SCALING …

WIRING ADJUSTMENTS …

LINE SWITCH & INRUSH DETECTION …

WAVEFORM CAPTURE …

RESULTS AVERAGING

All displayed measurements can be averaged using a two-pole filter having a

user-selected time constant. This setting only affects the displayed

measurement results, it does not affect any charted measurement results.

• NONE; 10ms; 20ms; 50ms; 100ms; 200ms; 500ms; 1 Sec; 2 Sec; 5

Sec; 10 Sec; 20 Sec; 1 Min

MEASUREMENT TYPE

This menu item contains the following seven setup selections –

LINE FREQ (<1kHz)

Configures the analyzer to make optimal signal measurements at line

frequencies in the 40 to 1000Hz range. To accomplish this, the analyzer –

1) Synchronizes on the voltage waveform with frequencies in the range

of 40Hz to 1000Hz; and

2) Tracks the input signals using a low-pass filter where the filter corner

frequency automatically adjusts to maintain better than 5% accuracy at

200 times the fundamental frequency.

Note: When you enable autorange and a downrange is required, the

analyzer downranges at the rate of 20ms per range. LINE FREQ (401000Hz) is the recommended selection when making line measurements.

58 2801/2802 Power Analyzer User Guide

HIGH FREQ (>40Hz)

Configures the analyzer to make the optimal signal measurements at

frequencies higher than line frequency, in the range 40Hz to above

100kHz. The analyzer –

1) Synchronizes on the voltage waveform with frequencies in the range

of 40Hz to above 100kHz; and

2) Tracks input signals using no low-pass filtering.

Note: When you enable autoranging and a downrange is required, the

analyzer downranges at the rate of 20ms per range. HIGH FREQ (>40Hz)

is the recommended selection when making high frequency measurements

or for line measurements where a large amount of high frequency signal

content is present.

10kHz -200kHz

Configures the analyzer to make optimal signal measurements at

frequencies in the range 10kHz to 200kHz. To accomplish this, the

analyzer –

1) Synchronizes on the voltage waveform with frequencies in the range

of 10kHz to 200kHz; and

2) Tracks the input signals using a fixed low-pass filter where the filter

corner frequency is set to maintain better than 5% accuracy at 10kHz.

Note: When you enable autoranging and a downrange is required, the

analyzer downranges at the rate of 10ms per range. The 10kHz-200kHz

selection is recommended when making high frequency measurements.

The 10kHz -200kHz setting is not recommended for line measurements.

DC

Configures the analyzer to make optimal signal measurements at DC. To

accomplish this, the analyzer operates as follows.

1) When not configured for ripple measurements -

Measurements of DC and AC are made over 50ms periods. No harmonic

data is available. Frequency is not measured. Signals have a fixedcorner, 4kHz, low-pass filter applied.

2) When configured for ripple measurements –

All DC and non-harmonic AC measurements are made over the longer of

5ms (rounded upwards to the nearest integer number of cycles) or one

Using the Power Analyzer 59

cycle of the entered base ripple frequency. All harmonic data is measured

over the longer of 5ms (rounded upwards to the nearest integer number of

cycles) or four cycles of the entered base ripple frequency. Frequency is

not measured. Signals have a fixed-corner, low-pass filter applied with a

corner frequency equal to 200 times the entered base ripple frequency

Note: When you enable autorange and a downrange is required, the

analyzer downranges at the rate of 20ms per range. DC is the

recommended selection when making DC measurements.

USER SET

This selection brings up a menu choice in the Ch1 MEASUREMENT

CONFIGURATION that allows you to directly select USER SET

MEASUREMENT configuration parameters, which are automatically set

for the other selections. Refer to USER SET MEASUREMENT below.

Note: This USER SET selection is

not recommended for inexperienced

users.

LOW FREQ (0.5-20Hz)

Configures the analyzer to make optimal signal measurements at

frequencies less than line frequency, in the range 0.5 to 20Hz. To

accomplish this, the analyzer –

1) Synchronizes on the voltage waveform with frequencies in the range

of 0.5Hz to 20Hz; and

2) Tracks the input signals using a fixed low-pass filter where the filter

corner frequency is set to maintain better than 5% accuracy at 10kHz.

Note: When you enable autoranging and a downrange is required, the

analyzer downranges at the rate of 10s per range. The LOW FREQ (0.1100Hz) selection is recommended when making low frequency

measurements. LOW FREQ is not recommended for line measurements.

LOW FREQ (0.02-5Hz)

Configures the analyzer to make optimal signal measurements at

frequencies less than line frequency, in the range 0.02 to 5Hz. To

accomplish this, the analyzer –

1) Synchronizes on the voltage waveform with frequencies in the range

of 0.02Hz to 5Hz; and

60 2801/2802 Power Analyzer User Guide

2) Tracks the input signals using a fixed low-pass filter where the filter

corner frequency is set to maintain better than 5% accuracy at 10kHz.

Note: When you enable autoranging and a downrange is required, the

analyzer downranges at the rate of 10s per range. The LOW FREQ (0.02 5Hz) selection is recommended when making very low frequency

measurements. LOW FREQ is not recommended for line measurements.

USER SET MEASUREMENT…

The Following are the MENU choices for the

USER SET MEASUREMENT CONFIGURATION menu

HF FILTER TYPE:

SYNC SOURCE

MIN FUNDAMENTAL

MAX FUNDAMENTAL

MAX HARMONIC

DOWNRANGE DELAY

The following paragraphs define the above options.

• HF FILTER TYPE - NONE, ADAPTIVE CUTOFF OR FIXED

CUTOFF

• NONE: No HF Filter.

• Adaptive Cutoff HF Filter: This is a similar filter to that for the

Fixed Cutoff HF Filter, but the cutoff frequency is continuously

adjusted to maintain a specific ratio to the measured fundamental

frequency. Another name for this (and actually a better name) is a

Tracking Filter.

• Fixed Cutoff HF Filter: This provides a 4-pole Butterworth LP

filter which is 5% down at a defined, fixed, frequency.

• SYNC SOURCE

There are two selections for this entry –

FROM VOLTAGE

The analyzer measures the fundamental frequency from the

Using the Power Analyzer 61