Vitrek V4 Operating Manual

V4 Electrical Safety Analyzer

AC/DC/IR/GB

Operating Manual

Valid for all units S/N 14210 and up

99 Washington Street

Melrose, MA 02176

Fax 781-665-0780

TestEquipmentDepot.com

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Vitrek V4 – Electrical Safety Tester USER MANUAL

WA R N IN G

Vitrek Corporation, its representatives, vendors and distributors assume no liability for the operation of this

instrument in an unsafe manner. This instrument generates and delivers hazardous voltages (up to 5KVAC /

6KVDC). Always be extremely careful when using this instrument or any high voltage device. Read this

manual completely and observe operating precautions in section 3 before operating the instrument.

Limited Warranty

The standard warranty period for this instrument is one year from date of shipment. Please refer to your

invoice or shipping documents to determine appropriate warranty dates. Vitrek warrants to the original

purchaser that this product will be free from defects in material and workmanship under normal use

throughout the warranty period, provided that such defects are not determined by Vitrek to have been caused

by abuse, misuse, alteration, improper installation, neglect or adverse environmental conditions. Vitrek

Corporation's liability under this warranty is limited solely to the repair or replacement of this instrument

during the warranty period, provided it is returned to the factory freight prepaid with a return authorization

number.

No other warranty is expressed or implied. Vitrek Corporation is not liable for incidental, consequential,

direct or indirect damages nor for costs, losses or expenses of any kind. A return authorization number must

be obtained directly from the factory for warranty repairs. No liability will be accepted if returned without

factory authorization number.

Technical Support

After reading this manual, should you have any questions or need technical assistance – please contact Vitrek

customer support at:

Email: info@vitrek.com

Fax: (858)689-2760 9880A Via Pasar

Voice: (858)689-2755 San Diego, CA 92126 USA

Extended Three Year Warranty Program

To qualify your instrument for an extended three-year warranty period you must:

1. Register your unit within 30 days from receipt by faxing or emailing the following data

Vitrek Model no. & S/N

Contact Name

Company / Organization

Street Address

City, State, Zip Code

Contact Email Address

Contact Phone Number

2. Contact the factory for a reference number to return your unit to the factory for annual calibration and

re-certification prior to the expiration of the initial cal due date. Upon receipt of your PO for the

calibration fee, the warranty will be extended for an additional year (up to a maximum of three years

total warranty).

Vitrek Corporation

1

Vitrek V4 – Electrical Safety Tester USER MANUAL

TABLE OF CONTENTS PAGE

1. PRODUCT INTRODUCTION..........................…..

1-1. Description…………………………..………...

1-2. Feature………………………………….……...

2. SPECIFICATIONS………………………………... 7

5

5

6

3. PRECAUTIONS BEFORE OPERATION…….…

3-1. Unpacking the Instrument……..……………..

3-2. Safety Notice………………..………………….

3-3. Environment…………………………….…….

4. PANEL INTRODUCTION……………………..…

4-1. Front Panel…………………………………….

4-2. Rear Panel……………………………………..

10

10

10

11

11

11

12

5. OPERATING INSTRUCTIONS…..……………...

5-1. Main LCD Display..…………………………...

5-2. Preparing the EST for Use.…………………..

5-3. Structure of Stored Test Steps.……………….

5-4. Menu Parameter Setup & Operation………..

5-5. Remote Interface Operation.…………………

14

14

15

22

23

26

6. MAINTENANCE………..………………………… 27

7. PROGRAMMING…………………………………

7-1. Introduction…………………………………...

7-2. Connecting the V4 via the GPIB interface…..

7-3. Connecting the V4 via the RS232 interface….

7-4. Input and Output Queue……………………..

7-5. Commands and Syntax………………………..

7-6. Details of Command Reference………………

7-7. Status and Error Reporting…………………..

28

28

28

29

31

31

38

53

8. TROUBLE SHOOTING & MAINTENANCE..…

8-1. Fuse Rating and Type…………………………

8-2. Cleaning.………………………………...……..

8-3. Trouble Shooting.……..…………………...…..

8-4. V4 Calibration Procedure…………………….

58

58

58

58

59

2

Vitrek V4 – Electrical Safety Tester USER MANUAL

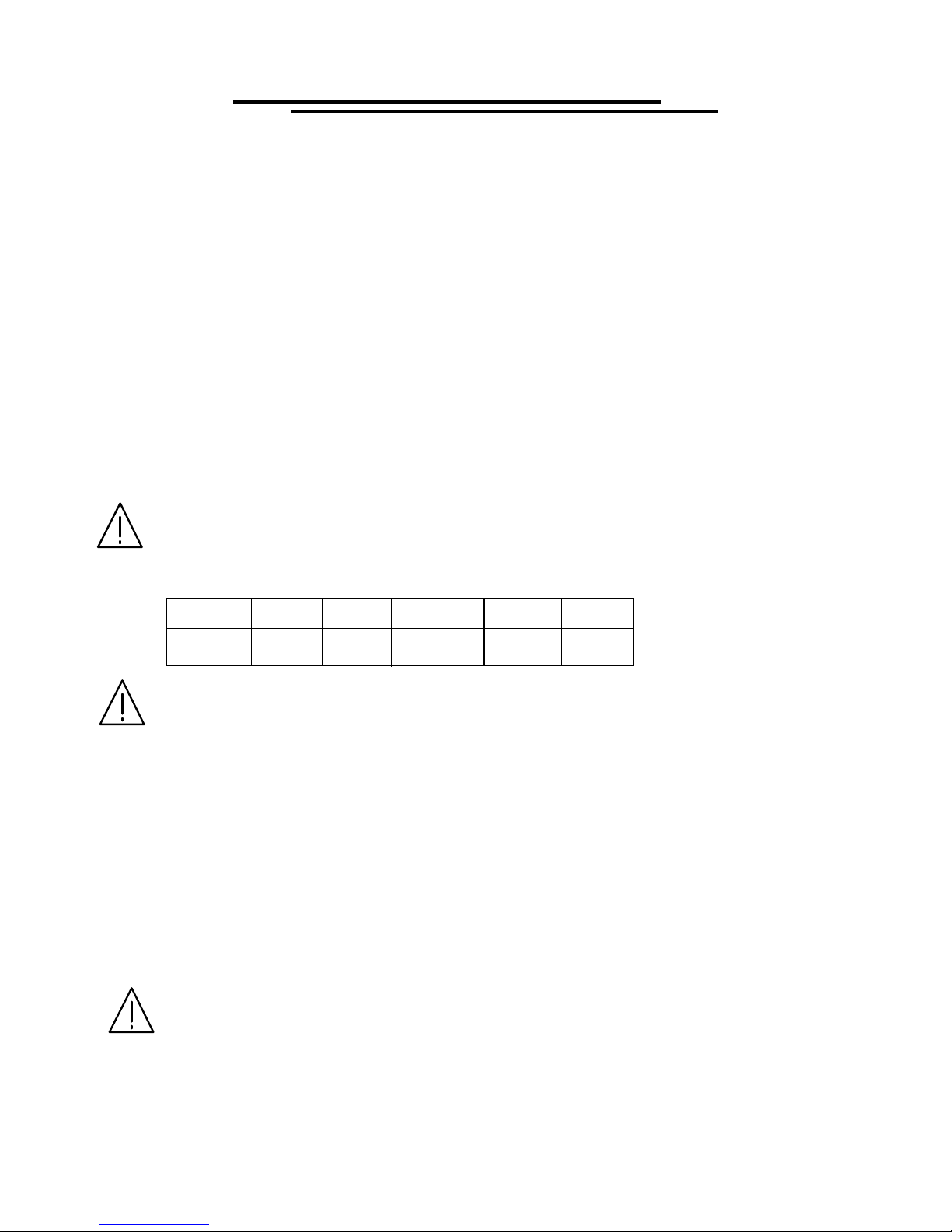

SAFETY TERMS AND SYMBOLS

These terms may appear in this manual or on the product:

WARNING. Warning statements identify conditions or practices that could result in injury or loss

of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

The following symbols may appear in this manual or on the product:

DANGER A TTENTION Protective Ground

High Voltage Refer to Manual Conductor Terminal

Terminal

1. V4 PRODUCT INTRODUCTION

Our goal at Vitrek is 100% customer satisfaction with both our products and our people. Please fill free to

contact us if we can be of help with application or technical assistance, repair or calibration services

accessories or spare parts. Vitrek Corporation

9880A Via Pasar

San Diego, CA 92126 USA

Phone: (858)689-2755 Fax: (858)689-2760 E-mail: info@vitrek.com

1-1. Description

The Vitrek V4 Electrical Safety Testers comply with the requirement for electrical equipment &

appliance control ordinances as defined by UL, CSA, JIS, BS and many other international standards.

The tester is ideal for AC & DC voltage withstand (Hipot), insulation resistance measurement and

ground bond testing on a wide variety of electrical equipment and components.

1-2. Features

The Vitrek V4 offers several features:

1) No load setup of trip current and output voltage

A safe way to setup trip current and output voltage without high voltage activated.

2) A large 24×2 character LCD with adjustable LED backlight

Provide a clear display about test parameters, which including group, step, mode, status, output

voltage, trip current and test time.

3

Vitrek V4 – Electrical Safety Tester USER MANUAL

3) Easily and quickly setup by front panel

A user-friendly interface provides user an easy and quick way to set all parameters.

4) Electronic ramping and testing

Digital controlled ramping time and testing time.

5) Line and load regulation

Linear amplifier and feedback-control maintain output voltage disregard of the variation of load.

6) Selectable output frequency

50/60 Hz is selectable by utility setup.

7) Adjustable ARC detect level

ARC detects the level selectable by setup by utility setup.

8) 10 groups of storage and each group has 16 steps

Total 10 storage groups provided for testing of different products, and each group has 16 steps.

9) Adjustable output voltage during test

A special test mode on the COM group allows the user to adjust the output voltage during testing

10) Flashing high voltage indicator

A flashing red LED indicates dangerous situation during high voltage output is activated.

11) Data lock function

Front panel could be locked or unlocked by utility setup.

12) PLC remote control

The 9-pin interface provides inputs (START, RESET) and outputs (TEST, PASS, FAIL).

13) Compact size with multi-capability

The compact size is geared with the Safety Test capabilities including AC Withstanding test, DC

Withstanding test, Insulation Resistance test and Ground Bond test.

14) R/P Output

The output terminal is located on the rear panel.

15) Scanner Interface

A pair of Scanner test with 96 channels.

16) RS-232 and GPIB Interface

The RS-232 and GPIB interface enables remote control operation and signal processing via a PC.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

4

Vitrek V4 – Electrical Safety Tester USER MANUAL

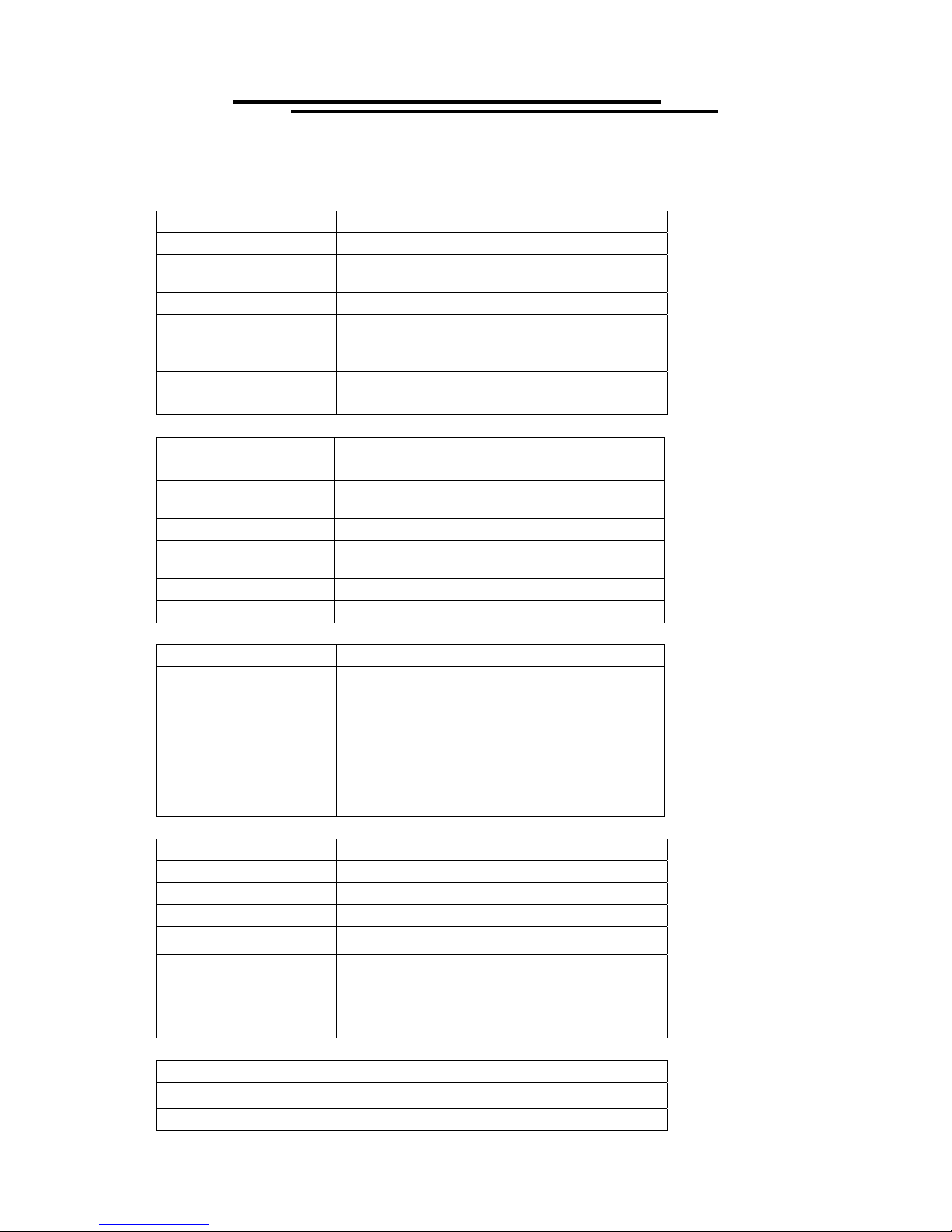

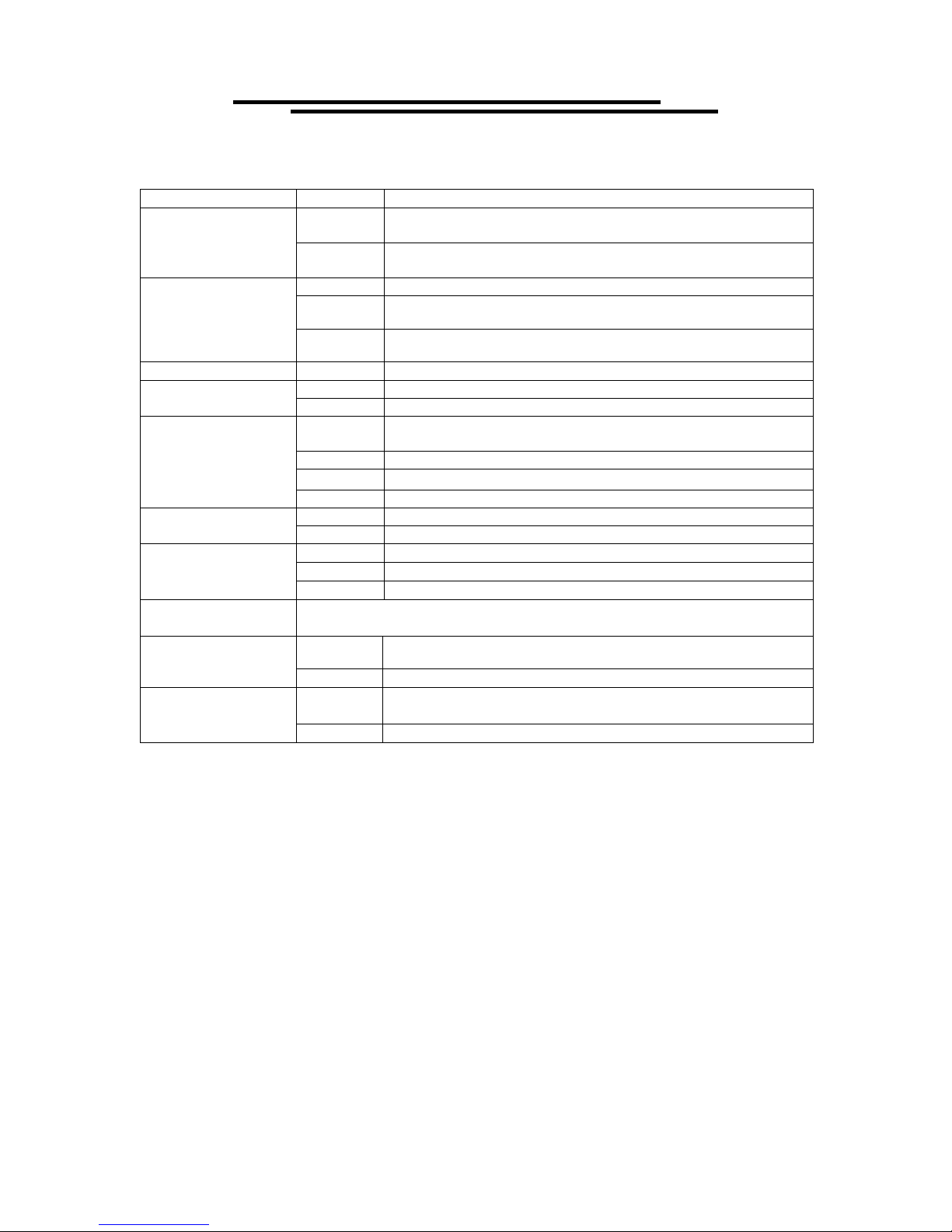

2. VITREK V4 FOUR IN ONE SAFETY TESTER SPECIFICATIONS

1) AC Hi-Pot Specifications:

Voltage Range 0.100~5.000kV

Voltage Step 5V/step

Voltage Regulation

(line & load)

Voltage Accuracy 1% of reading +10V

Current Sourcing* 30~40mA(above 500V, maximum test time: 180 sec)

Current Limit 0.10~40mA, 0.02mA/step

Current Accuracy 1% of reading + 50μ A

2) DC Hi-Pot Specifications:

Voltage Range 0.100~6.000kV

Voltage Step 5V/step

Voltage Regulation

(line & load)

Voltage Accuracy 1% of reading +10V

Current Sourcing* 0.10~10.00mA(above 500V, continuous test)

Current Limit 0.10~10mA, 0.01mA/step

Current Accuracy 1% of reading + 50μ A

3) Insulation Resistance Specifications:

DC Voltage

Resistance Accuracy

4) Ground Bond Specifications

Test Voltage Max. 8V(DC)

Current Range 3~42A

Current Resolution 0.02A

Current Accuracy 1% of reading + 50mA

Resistance Range

Resistance Resolution

Resistance Accuracy

Test Method Four Te r m i n a l s Test Mode

1% + 5V

0.10~29.99mA(above 500V, continuous test)

0.10~10mA(below 500V, continuous test)

1% + 5V

0.10~2mA(below 500V, continuous test)

50V/100V/500V/1000V

50V/100V:

1~50MΩ : 5% of reading

51~200MΩ : 10% of reading

201~1990MΩ : 20% of reading

500V/1000V:

1~500MΩ : 5% of reading

501~2000MΩ : 10% of reading

2001~9999MΩ : 20% of reading

0~600mΩ

0.1mΩ

1% of reading +2mΩ

5) Ramp Time and Test Time

AC Hi-Pot Ramp/Test time 000.0~999.9s

DC Hi-Pot Ramp/Test time 000.0~999.9s

Insulation Resistance Time 001.0~999.9s

5

Vitrek V4 – Electrical Safety Tester USER MANUAL

Ground Bond Test Time 000.0~999.9s

6) ARC Detect

Detect Current 40 level (1~40mA)

7) Storage

Groups

Steps

8) Interface

RS-232 Standard

GPIB Option

9) PLC Control

D-sub 9 pins female Standard

10) Scanner Interface

D-sub 9 pins female Standard

11) Real Plate Output

Hi-pot terminals and GB

terminals

12) General

Power Source

Operation

Environment

Storage temperature

& Humidity

Accessories

Dimension 446(L) × 330(W) × 149(H) (m/m)

Weigh

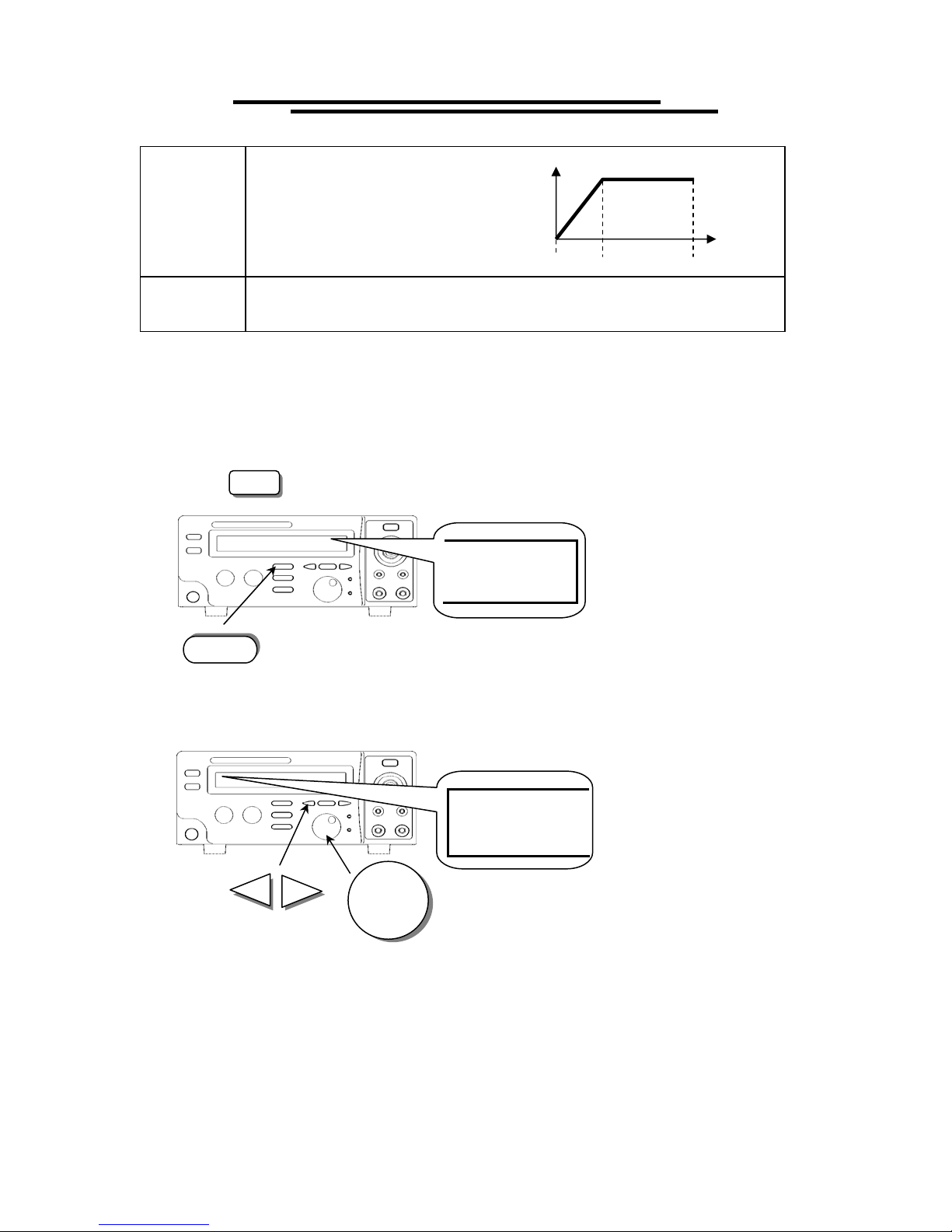

The main purpose provided by the series of instruments is for Puncture Testing. The specification is not for

continuous test. The temperature of heat sink is monitored. The test procedure will stop if the heat sink is too

hot. Please refer to Figure 2-1.

Stop the instrument for 10 minutes when continuously proceeding 30~40mA withstanding test for one hour.

GENERAL SPECIFICATIONS:

Test Database: 10 Test Sequences with up to 16 steps per test sequence

Front Panel Lockout: Prevents database edit while in lockout mode

Arc Detect: 10 level trip select

Remote Interface: Fully interactive RS232 standard, GPIB optional, standard 9-pin D-sub connector with

Outputs of Testing, Pass, Fail and inputs of Start, Reset. Output isolation is 400V with 130mA Continuous

load current.

Timer Accuracy: 0.10% ± 50mS

Power Source: AC100V, 120V, 220V, 230V (±10% 50/60Hz), 250W max

10

16

Standard interface for V4

AC100V, 120V, 220V, 230V±10% 50/60Hz

Indoor use, altitude up to 2000m.

Ambient Temperature 0℃ to 40℃.

Relative Humidity 80% (Maximum).

Installation category II

Pollution Degree 2

-10℃ to 70℃.

70% (Maximum).

TL-20-50 × 1, TL-463 × 1,

Instruction manual × 1,

Power Cord x 1

Approx. 14.9 kgs, 35lbs

6

Vitrek V4 – Electrical Safety Tester USER MANUAL

Operating Environment: Indoor use, Altitude up to 6500ft (2000m). Installation Category II. Pollution

Degree 2

Operating Temperature: 0°C to 40°C, 80% RH max.

Storage Temperature: -10°C to 70°C, 70% RH max

Dimension: 17.6”L x 13”W x 5.9”H, 446(L) x 330(W) x 149(H) mm

Weight: 30 lbs (14kg) net, 34 lbs (16 kg) ship

Accessories: NIST certification, TL-2050 Test Leads, Instruction Manual and power cord

Accuracy: Stated specifications apply for 1 year at 23 °C ± 5 °C

Calibration: Certificate of calibration, traceable to NIST provided

Compliance: CE mark certified to EN61010 and EMC directives EN50081-1 & EN50082-2

QuickTest™ Software Option QT-2: Bundled test automation software, with PC GPIB interface and cable.

It has an easy to load graphical test sequence development and operating environment. Provides time/date,

operator, test parameters, and test results for review, printout or export to database program.

mA

40

35

30

25

20

15

10

6

4

2

0

AC Hi-Pot

Spec 180sec

AC Hi-Pot Spec

Continuous

DC Hi-Pot Spec

Continuous

.1 .5 1kV 2 3 4 5 6 kV

Figure 2-1

7

Vitrek V4 – Electrical Safety Tester USER MANUAL

3. PRECAUTIONS BEFORE OPERATION

3-1. Unpacking the Instrument

The product has been fully inspected and tested before shipping from the factory. Upon receiving the

instrument, please unpack and inspect it for any damage that may have occurred during transportation. If

any sign of damage is found, notify the carrier and Vitrek or your distributor immediately.

3-2. Safety Notice

Work Place Safety

The work place must be isolated from routine traffic and when high voltage testing is in process, a

warning signal should be provided.

Checking the Line Voltage

The instrument can be connected to any kind of line voltage shown in the table below. Before connecting

the power plug to an AC line outlet, make sure the voltage selector on the rear panel is set to the correct

position corresponding to the line voltage. CAUTION: Damage to the instrument may occur if it is

connected to the wrong AC line voltage.

WARNING. To avoid electrical shock the power cord protective grounding conductor must be

connected to ground.

When line voltage is changed, install the required fuses shown as below:

Line voltage Range

100V

120V

WARNING. To avoid personal injury, disconnect the power cord before removing the fuse holder.

Operator’s Precaution

(1) Because of the extreme high output voltage and current of the breakdown tester, only a qualified person

should operate the tester in order to avoid fatal electric shock.

(2) On-the-job training is required for the operator to use the tester efficiently and safely.

(3) The operator should be prohibited from wearing metal jewelry, etc in order to avoid an electrical shock.

(4) A person with a heart condition or who wears a pacemaker must not operate the tester.

Safe, Secure Testing

The earth ground contact of the power cord must be properly connected in accordance with instructions.

The return lead must be connected to the tested object first before high voltage testing. Do not handle the

alligator test leads while high voltage is applied. Also, when using the optional HV probe do not touch the

exposed conductive tip of the test probe during testing. Provide full control the power supplied to the

tester by means of a carefully placed on/off switch or remote power control device.

WARNING: During testing, do not touch the test object or any other connected objects.

3-3.Environment

The normal ambient temperature range of this instrument is from 0° to 40°C (32° to 104°F). Operation of

the instrument above this specific temperature range may cause damage to the circuits.

90-110V

108-132V

Fuse Line voltage Range

T 7.0A

250V

220V

230V

198-242V

207-250V

Fuse

T 7.0A

250V

8

Vitrek V4 – Electrical Safety Tester USER MANUAL

Do not use the instrument in a place where a strong magnetic or electric field exists, as they may distort

the measurements.

4. PANEL INTRODUCTION

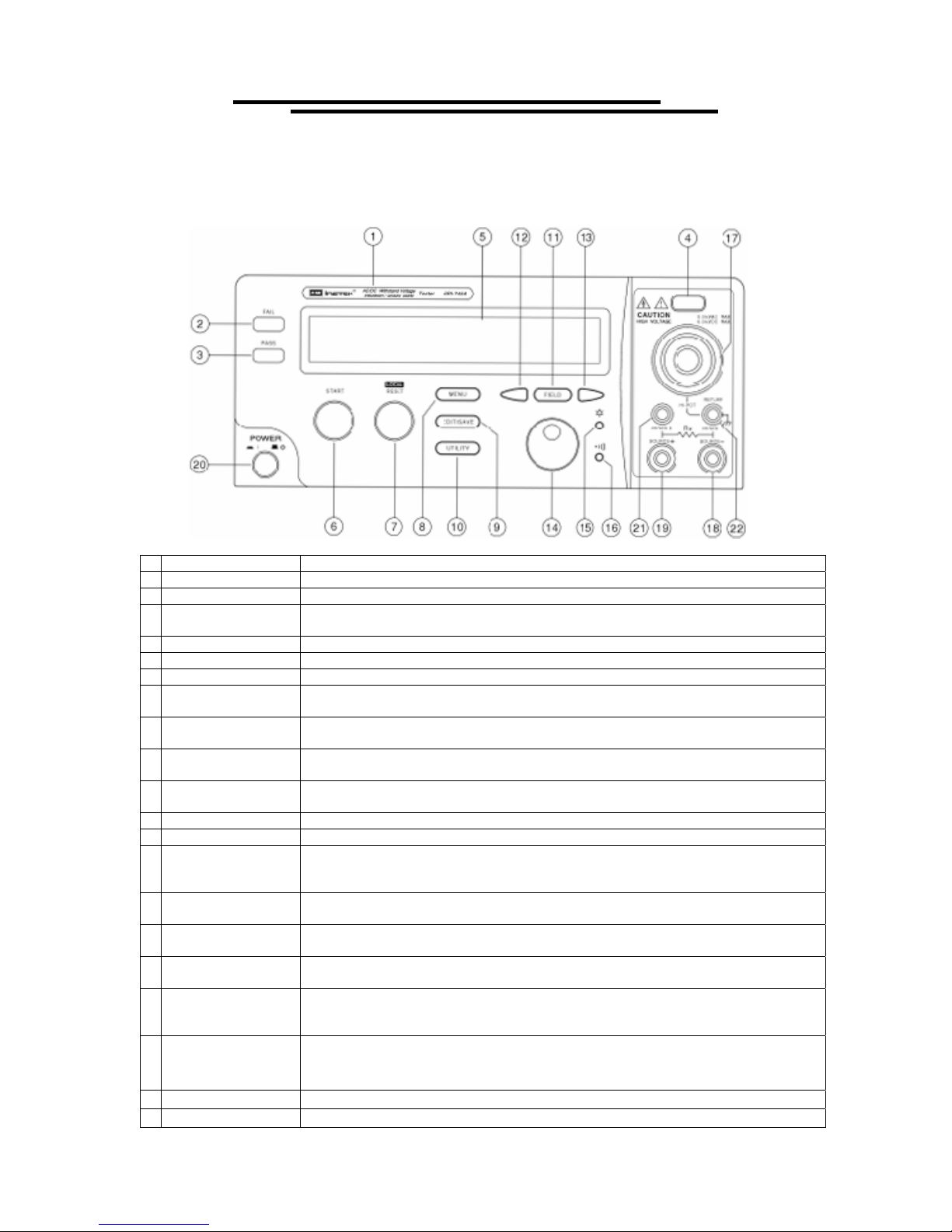

4-1. Front Panel

1 Model Number Model number and description

2 FAIL Indicator LED The red LED indicates failure of test procedure

3 PASS Indicator LED The green LED indicates pass of test procedure

4 CAUTION Indicator

LED

5 Main Display LCD The LCD displays all message about test procedure.

6 START Button Press the green button to start a test procedure.

7 RESET Button Press the red button to reset/stop a test procedure.

8 MENU Key

9 EDIT/SAVE Key

10 UTILITY Key

11 FIELD Key

12 Left Arrow Key Press the arrow key to adjust knob’s resolution.

13 Right Arrow Key Press the arrow key to adjust knob’s resolution.

14 Knob

15 LCD Backlight

Adjustment

16 Buzzer Volume

Adjustment

17 High Voltage Output

Seat

18 SOURCE-Terminal

(only for Ground

Bond Test)

19 SOURCE+ Terminal

(only for Ground

Bond Test)

20 Power Switch Press the power switch to turn on the tester.

21 SENSE+ Terminal Voltage Terminal for Ground Bond test.

During test the red LED will flash to indicate dangerous.

When you press the MENU key, the status becomes MENU and you can browse all

groups.

When you press the EDIT/SAVE key, the status EDIT is active and you can edit this

step or setup. Press the EDIT/SAVE key again will save this step or setup.

When you press the UTILITY key, the status UTILITY is active and you can view all

the utility setups.

When you edit the test step, press the FIELD key to change the active parameter of

stop.

If status EDIT is active, turn the knob to increase or decrease the value of active

parameter.

If status MENU is active, turn the knob to increase or decrease active Step.

Turn the VR to adjust the LED backlight of LCD.

Turn the VR to adjust the buzzer volume.

High voltage output terminal.

High current terminal for Ground Bond test.

High current terminal for Ground Bond test.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

9

22 SENSE- & Return

Terminal

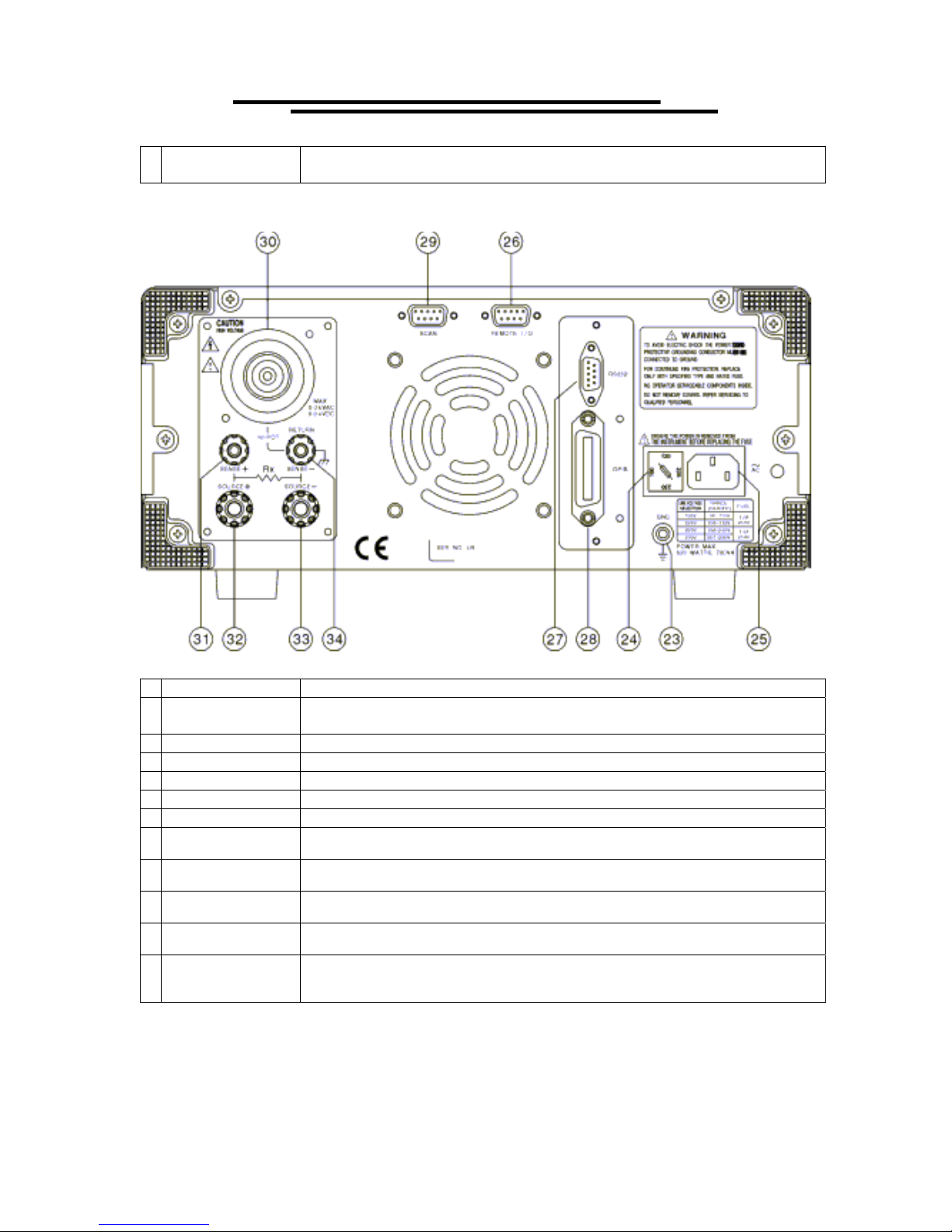

4-2. Rear Panel

Vitrek V4 – Electrical Safety Tester USER MANUAL

SENSE- Terminal is a voltage terminal for Ground Bond test, and Return Terminal is

for all test.

23 Ground Terminal Connect Ground terminal to the earth ground.

24 Fuse Holder with

Voltage Selector

25 AC Inlet Connect the AC power line to the inlet.

26 Remote Interface The remote interface performs all the functions of PLC control.

27 RS232 Terminal D-SUB 9 pin connector, Input/Output connector for RS232.

28 GPIB Terminal Blue 24 connector, Input/Output connector for IEE-488.

29 Scanner Interface D-sub 9 pins female connector for scanner box.

High Voltage Output

30

on rear panel

Sense + Terminal on

31

rear panel

Source + Terminal on

32

rear panel

Source - Terminal on

33

rear panel

Sense - Terminal &

34

Return Terminal on

rear panel

*The instrument can be used together with scanner box of SHB-001-1 & SHB-001-2.

To change AC source voltage, pull the fuse holder and rotate it to the proper value.

High voltage output terminal.

Voltage terminal for Ground Bond test.

High current terminal for Ground Bond test.

High current terminal for Ground Bond test.

Sense - terminal is a voltage terminal for Ground Bond test, Return terminal is for all

tests.

10

Vitrek V4 – Electrical Safety Tester USER MANUAL

5. OPERATION METHOD

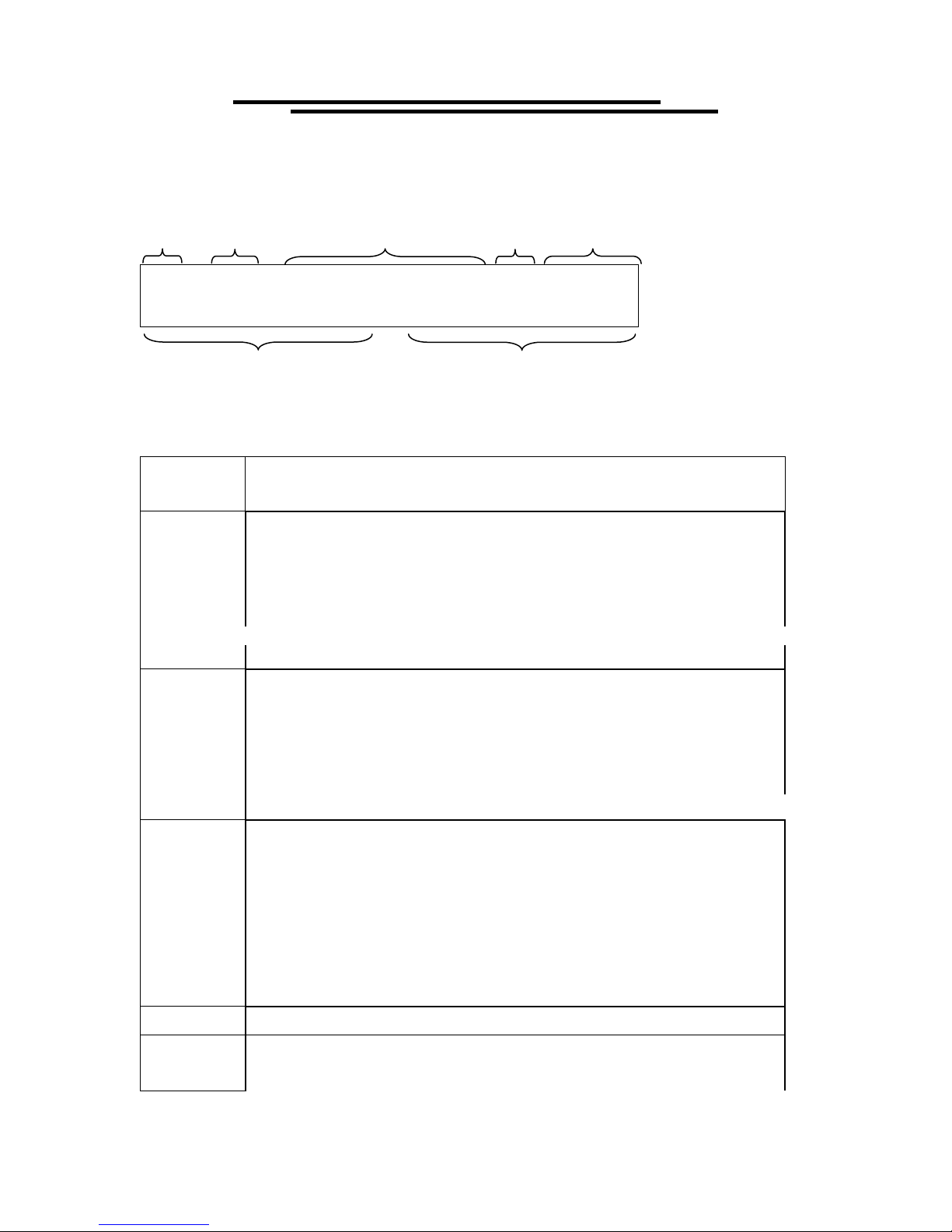

5-1. Main Display LCD

Storage Mode Output Voltage/Current ARC Status

1 ~ 0 1 A C

I ma x = 0

Measurement Limit Ramp/Test Time

W V = 5

1 . 0 0 m

Table of Parameters:

Group/ Step: There are total 10 groups, and each group has 16 steps. The first number

Storage

Ex. 3:1Æ 3 is for group number, 1 is for step number.

The test mode of tester includes:

ACW: AC Withstanding voltage test.

DCW: DC Withstanding voltage test.

Mode

GB: Ground Bond test.

The total types of mode will change for different model.

Output voltage or current for each step

AC: Output voltage (0.100~ 5.000 kV)

Output

Voltage/Current

DC: Output voltage (0.100~ 6.000 kV)

GB: Output current (3.00~42.00A)

. 0 0 0 k V *READY

A T E S T:0 0 0 . 0 s

represents group while the second number represents step.

IR: Insulation Resistance.

IR: Output voltage (50V/100V/500V/1000V)

The status of tester includes:

MENU: Browse and check steps of test.

EDIT: Edit parameters

SAVE: Save parameters

Status

ARC

Measurement

Limit

UTIL: Browse and check system utility.

READY: Ready for test

TEST: Testing

PASS: The result of test is pass

FAIL: The result of test is fail

STOP: Stop the test

If the ARC function is enabled, the sign “*” means that there is ARC during test.

Lower and upper limit of measurement

Imax/Imin: Current measurement limit (ACW & DCW)

Rmax/Rmin: Resistance measurement limit(IR&GB&CNT)

11

Vitrek V4 – Electrical Safety Tester USER MANUAL

Ramp/Test

Time

CHANNEL

Hi: 00

Lo: 00

When the measured load becomes capacitive, the test time must be extended.

5-2. Prepare the EST for Use

Ramp time and test time

AC: Ramp/Test (000.0~999.9 s)

DC: Ramp/Test (000.0~999.9 s)

IR: Test (001.0~999.9 s)

GB: Test (000.0~999.9 s)

CNT: Test (000.0~999.9 s)

Any of the channels can be selected from the Scanner Box for output. If the selection

are Hi=01 and Lo=02 means channel 1 is high voltage output, and channel 2 is at

Return or Source terminal.

voltage

ramp

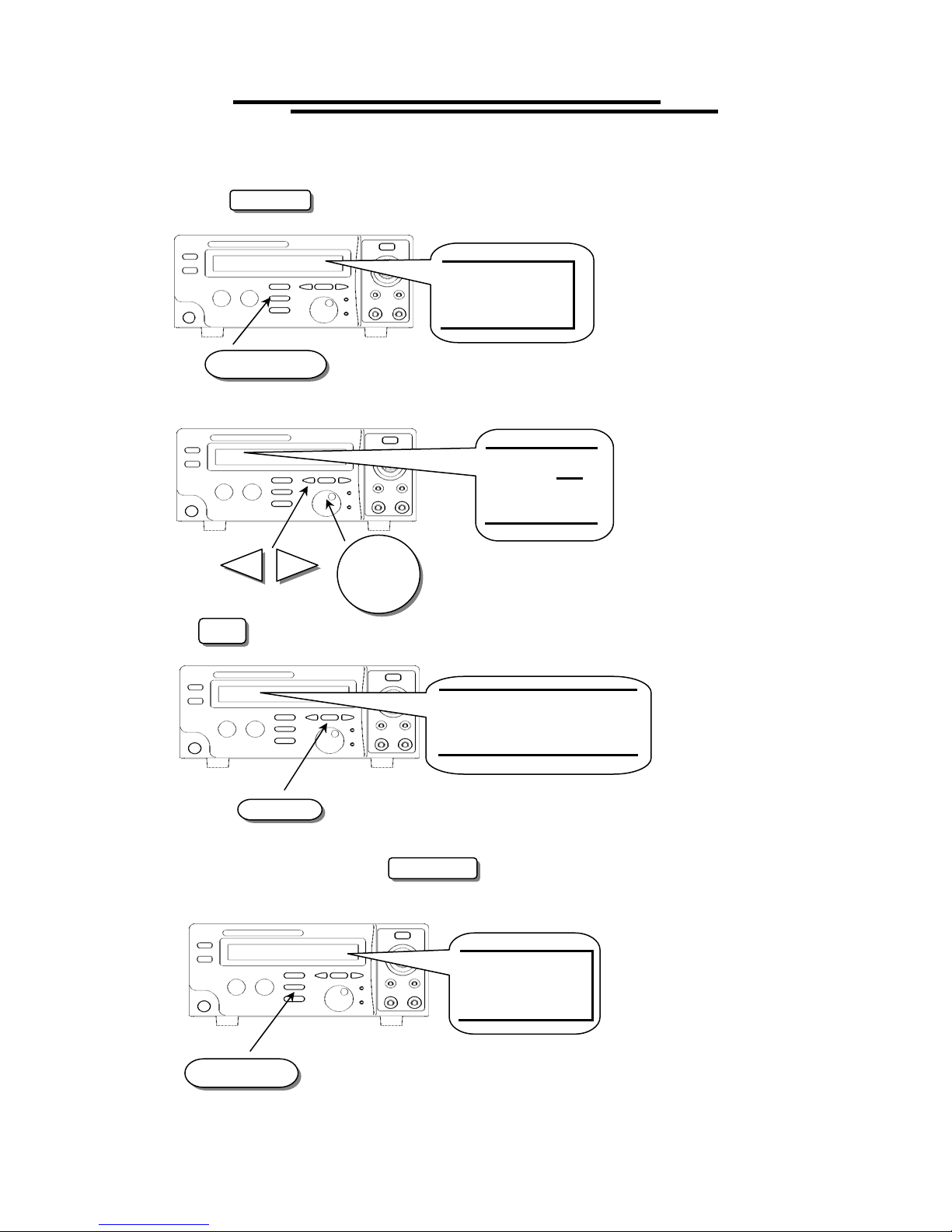

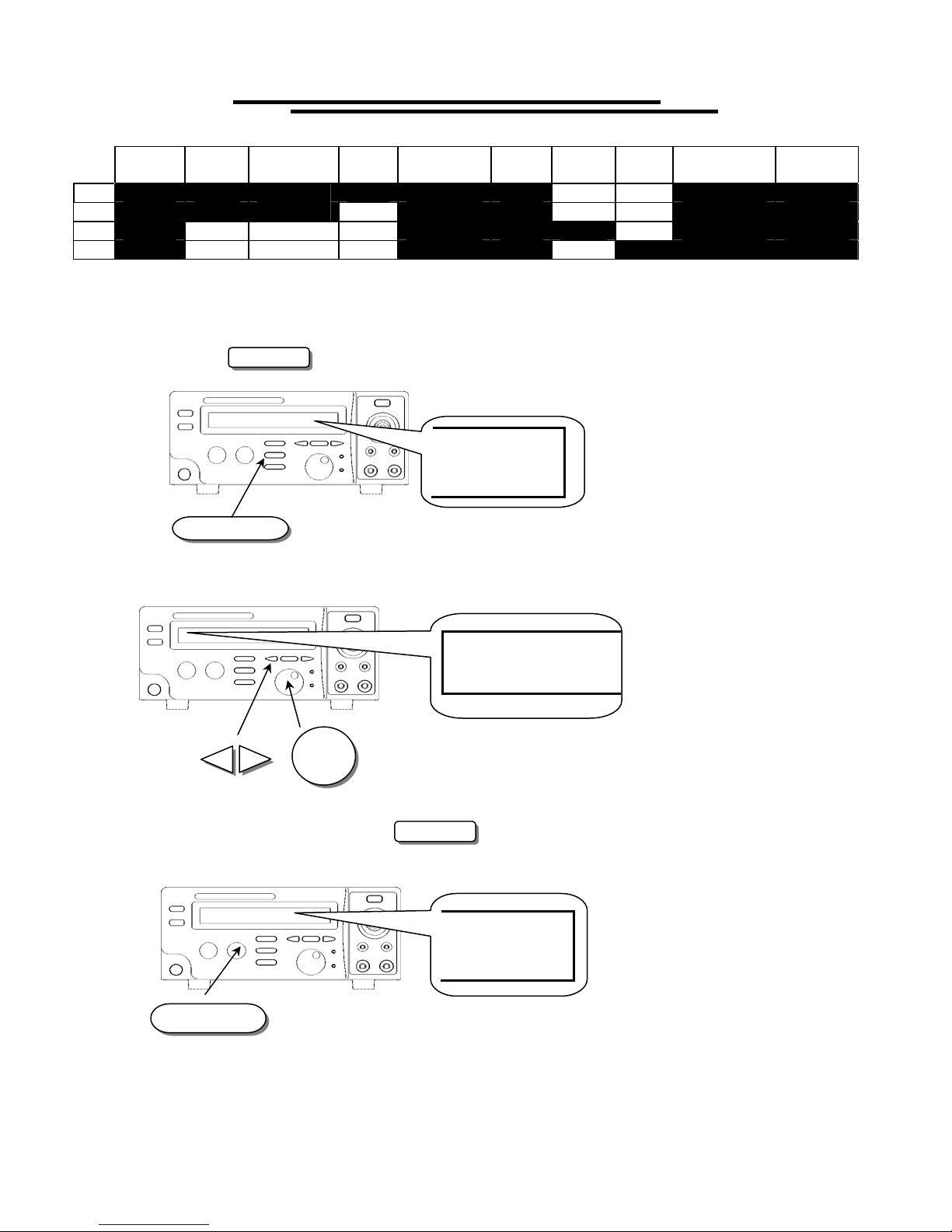

To view the Storage Steps

1. Press the MENU key to enter status MENU.

test

time

MENU

MENU

2. Use the left and right arrow keys to change knob’s resolution (group or step). Use the knob to change the

active step.

0-00 A C

12

Vitrek V4 – Electrical Safety Tester USER MANUAL

To Edit/Save the Storage Steps

1. Follow the above procedure “To View the Storage Steps “ to select a step.

2. Press the EDIT/SAVE key to enter status EDIT.

EDIT

EDIT/SAVE

3. Use knob to adjust parameter. Use arrow keys to change knob’s resolution.

AC W

4. Use FIELD key to change active parameter.

V=2

.00 0kV

5. Repeat step 3 and 4 to adjust parameter.

6. After setting all parameters, press EDIT/SAVE key to save the step. The status will become SAVE.

After the step is saved, the status will return to EDIT.

FIELD

SAVE

EDIT/SAVE

7. Repeat the procedure “To View the Storage Steps” to select another step.

13

Vitrek V4 – Electrical Safety Tester USER MANUAL

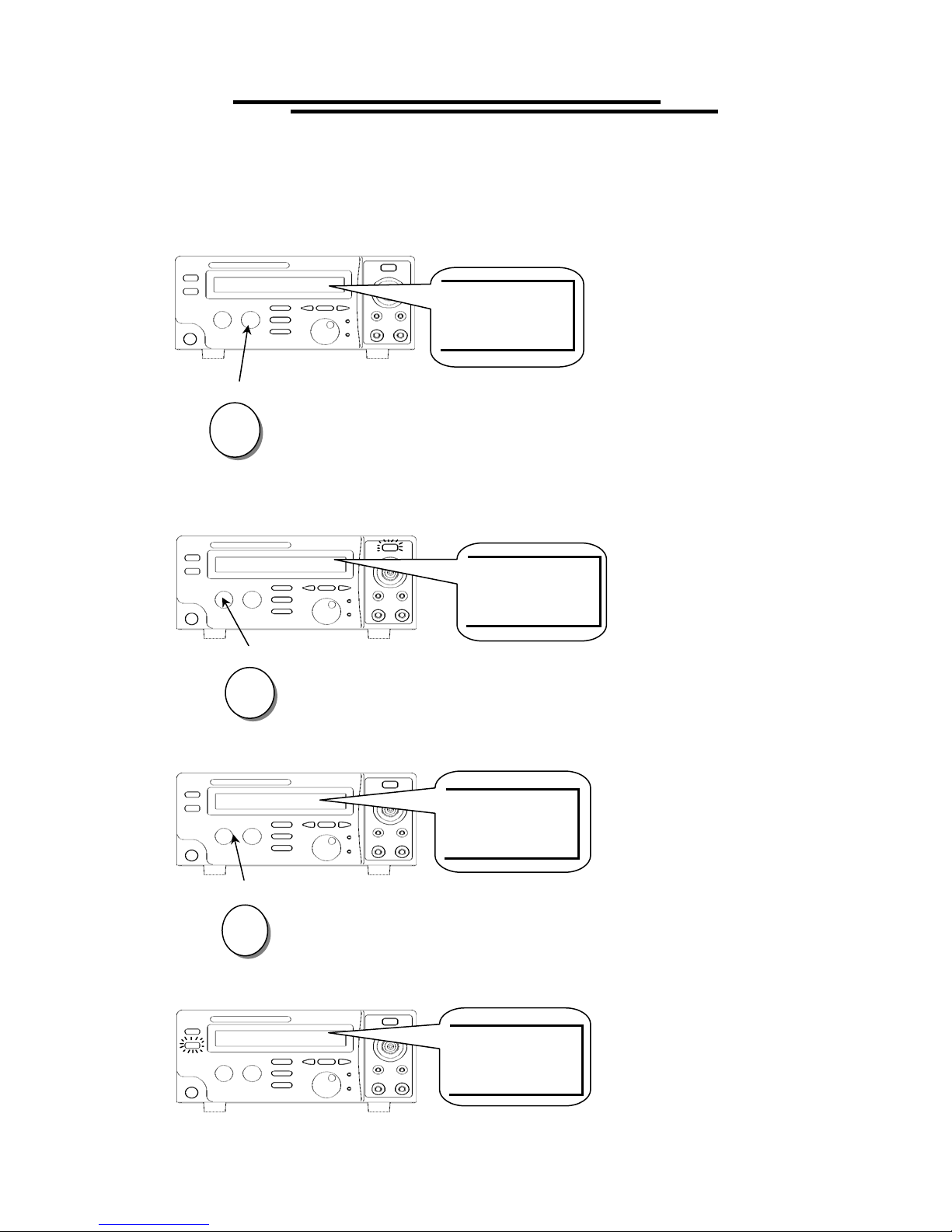

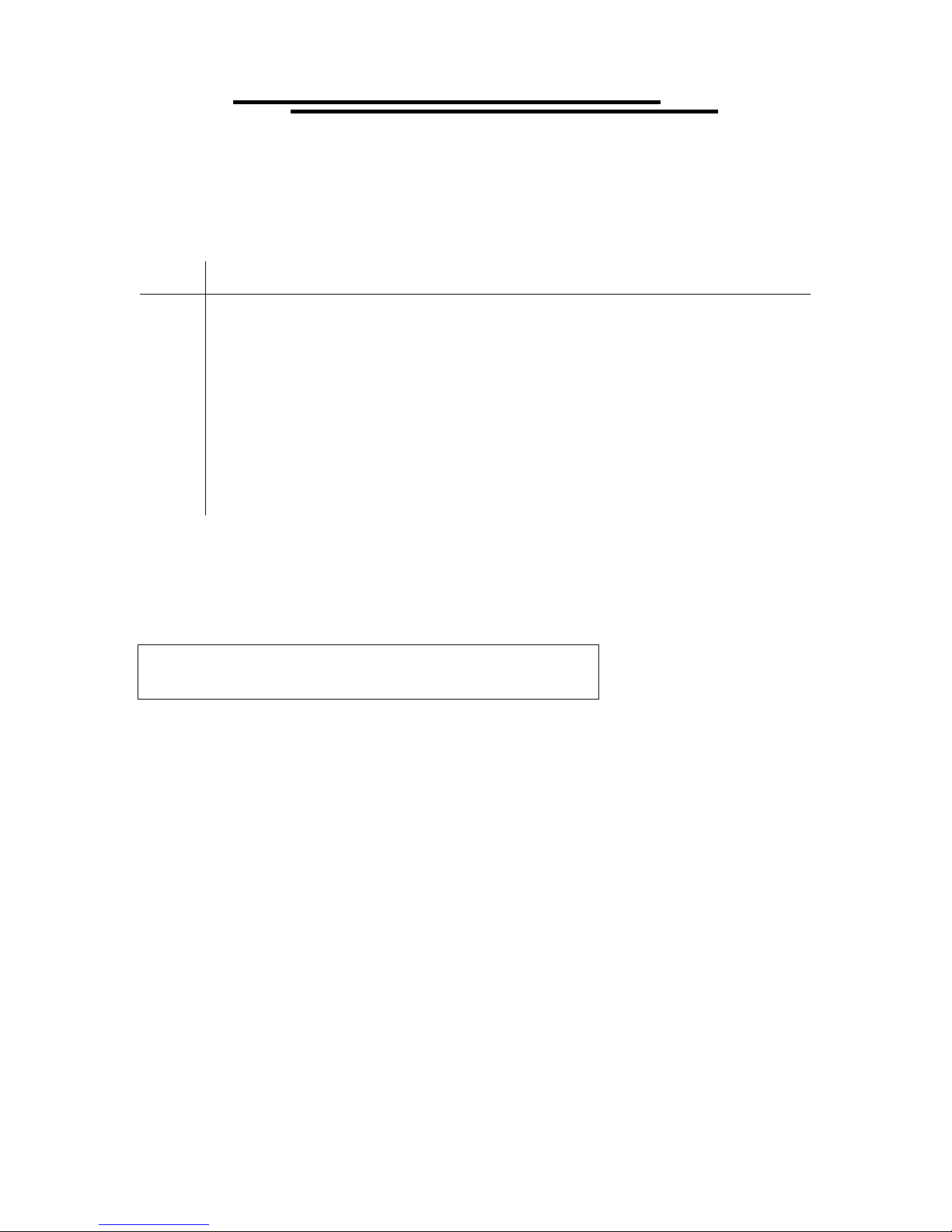

To Begin a Group Test

1. Repeat the procedure “To View the Storage Steps” to select a step.

2. Press RESET button to enter status READY.

READY

RESET

3. Make sure the test environment is safe.

4. Press START button to start the test while the status TEST is active and the CAUTION LED flashes.

5. If you press RESET button the test will stop immediately.

6. If the result is pass, the PASS LED will be active.

START

RESET

TEST

STOP

PASS

14

Vitrek V4 – Electrical Safety Tester USER MANUAL

7. If the result is fail, the FAIL LED will be active and the buzzer will alarm operator. To stop the alarm,

press RESET button again.

FAIL

RESET

8. Use knob to view the result of group step by step.

1-00

To View the System Utility

1. Press the UTILITY key to enter status UTIL.

UTIL

UTILITY

2. Use the knob or arrow keys to change the active parameter.

GRO UP TE ST

FRO M S TE P

15

1

Vitrek V4 – Electrical Safety Tester USER MANUAL

Table of System Utility:

Parameter Option Description

From STEP 1

GROUP TEST

ARC MODE*

From the

present step

DISABLE

ENABLE &

STOP

ENABLE &

CONTINUE

ARC CURRENT

AC FREQUENCY

TEST

CONTROL MODE

DATA LOCK

IR TEST MODE

ZERO CHECK

50 Hz

60 Hz

MODE 1

MODE 2

MODE 3

MODE 4

UNLOCKED

LOCKED

Stop on fail

Stop on pass

Timer

Zero check by shorting the resistance of test leads only for ground bond test.

(GB only)

RS-232 Baud

Interface

Rate

GPIB Address

Stop

FAIL Setting

Continue

*The arc detection circuit is tuned for high frequencies. It does not see any line frequency energy. Arcs are a

wide band phenomenon and are not required for electrical safety testing, so it is safe to disable this feature. It

is there primarily as a QC feature above and beyond the safety requirement. The safety spec is checking for

electrical breakdown of the primary insulation. Breakdown is defined by UL as a sudden and uncontrolled

flow of current. Since an arc tends to be a controlled flow of current it is not considered a breakdown.

Please note that the Utility menu is context sensitive—that is, the options available are contingent upon

which test is currently ready to be run. For example, if you have an ACW test ready, you will have the Arc

Mode and Current selections available to you, but not the IR Test Mode or GB Zero Check selections. To set

these, select either an IR or a GB test, respectively. The Group Test, Test Control Mode, Data Lock, Interface,

and Fail Setting options are available regardless of what test is selected. Refer to the following table for a

complete listing of options.

The group test procedure always begins from step 1 to end of group.

(e.g. 01~01)

The group test procedure always begins from the step selected to end

of group. (e.g. 01~03)

Disable the function arc detection.

Enable the arc detection and stop the test when arc is active.

Enable the arc detection and continue the test when arc is active.

Set the current level of arc detection.

Set the AC hi-pot output frequency to 50 Hz.

Set the AC hi-pot output frequency to 60 Hz.

Control mode of front panel.

Mode 1: Reset first (press reset button before test)

Mode 2: Press start button directly.

Mode 3: REMOTE I/O enable (the start button is disable)

Mode 4 : Reserved.

Accept and save all parameters of test step and utility.

Refuse to change any parameters of test step and utility.

Stop on fail at the DUT detection.

Stop on pass at the DUT detection.

Reach the time of determination for pass or fail.

1200, 2400, 4800, 9600.

00~31

The operation will stop upon the failure occurred at any step of group

test.

The operation will not stop until all 16 group steps have been tested.

16

Vitrek V4 – Electrical Safety Tester USER MANUAL

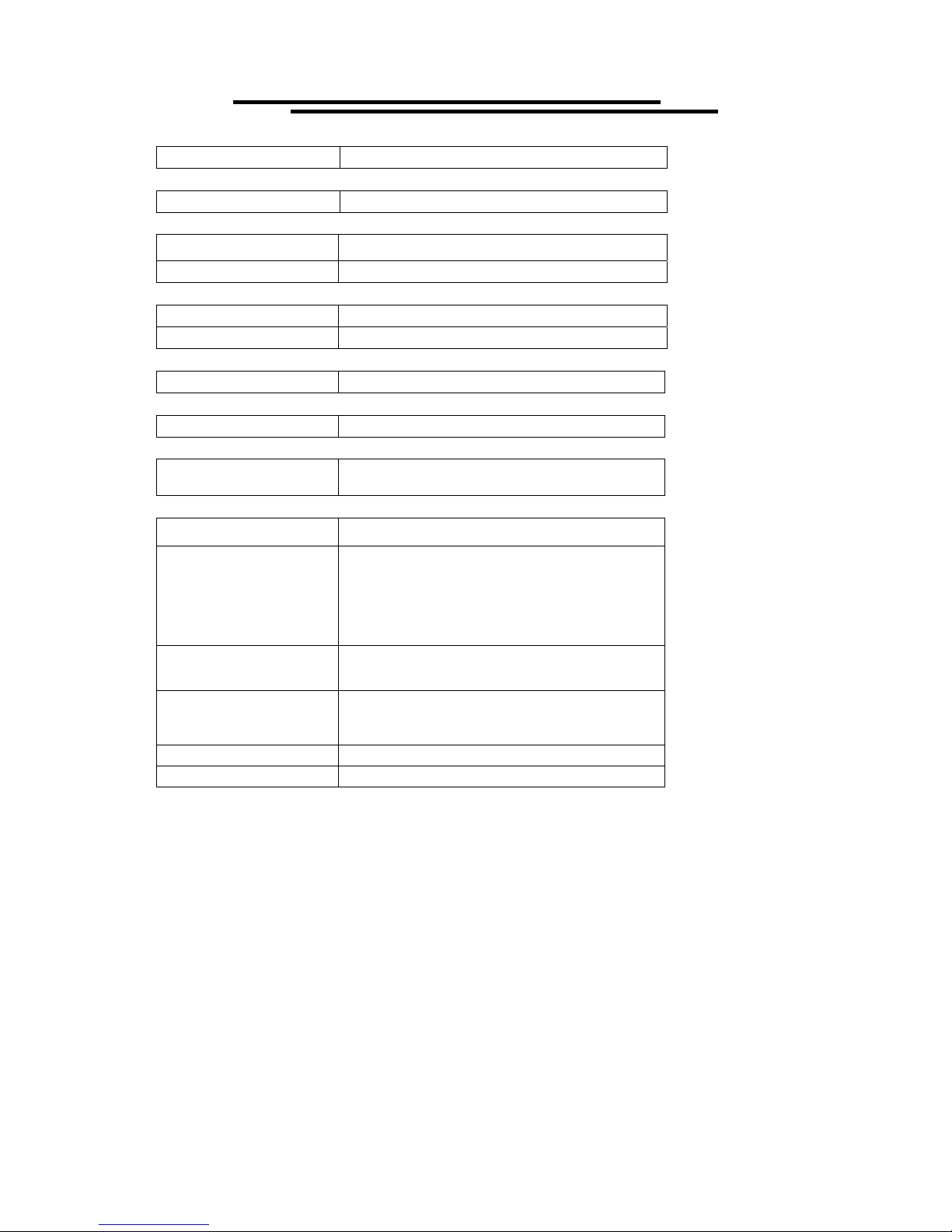

GROUP

TEST

AC

DC

IR

GB

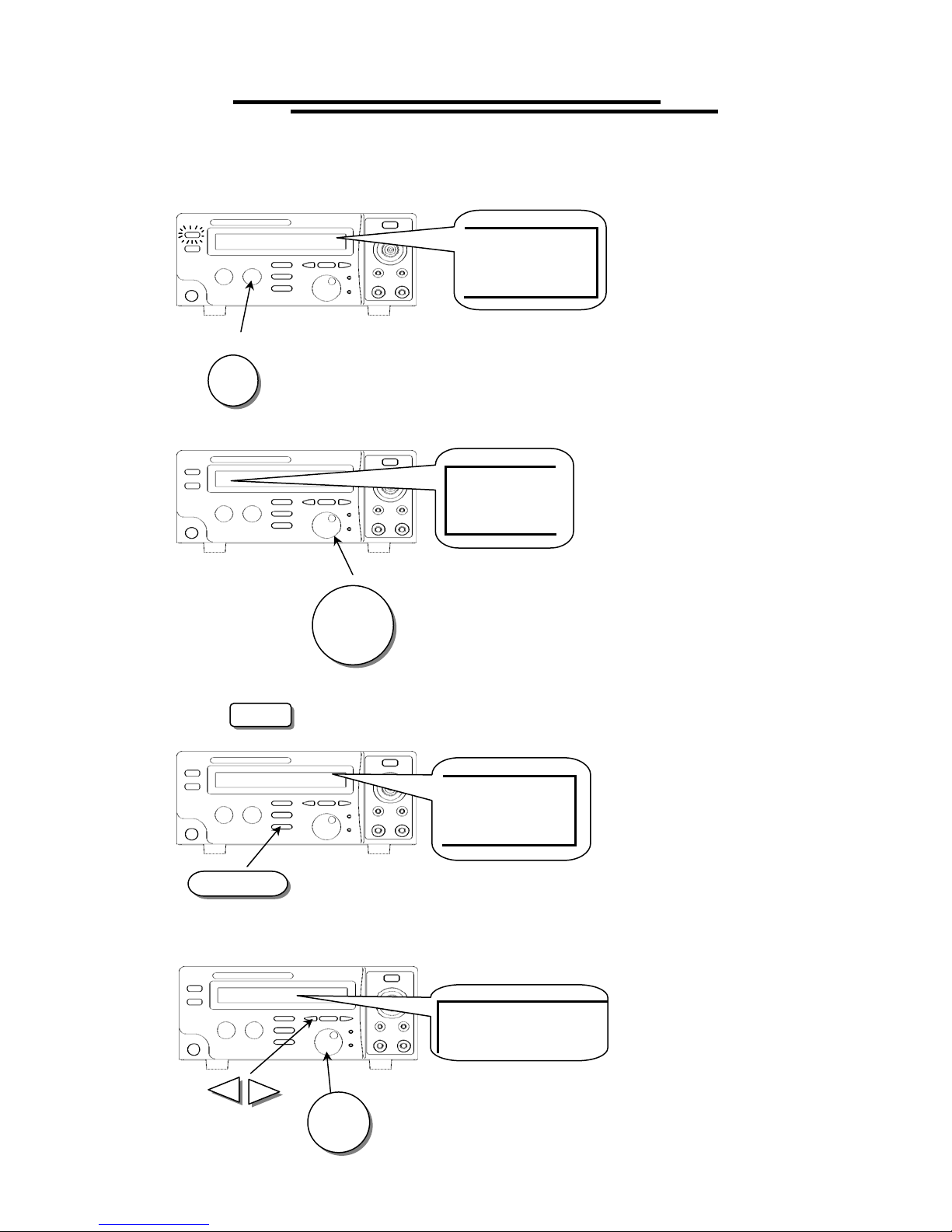

To Edit/Save the System Utility

ARC

MODE

1. Follow the above procedure “To View the System Utility” to select a parameter.

2. Press the EDIT/SAVE key to enter status EDIT.

ARC

CURRENT

AC

FREQ

TEST

CONTROL

DATA

LOCK

IR

MODE

GB

ZERO

INTERFACE FAIL

EDIT

EDIT/SAVE

3. Use knob to adjust parameter. Use arrow keys to change knob’s resolution.

SETTING

TE S T MO D

E

FR O M ST E P

4. After setting this parameter, press EDIT/SAVE key to save the parameter. The status will become

SAVE. After the parameter is saved, the status will return to EDIT.

SAVE

EDIT/SAVE

5. Repeat the procedure “To View the System Utility” to select another parameter.

17

Vitrek V4 – Electrical Safety Tester USER MANUAL

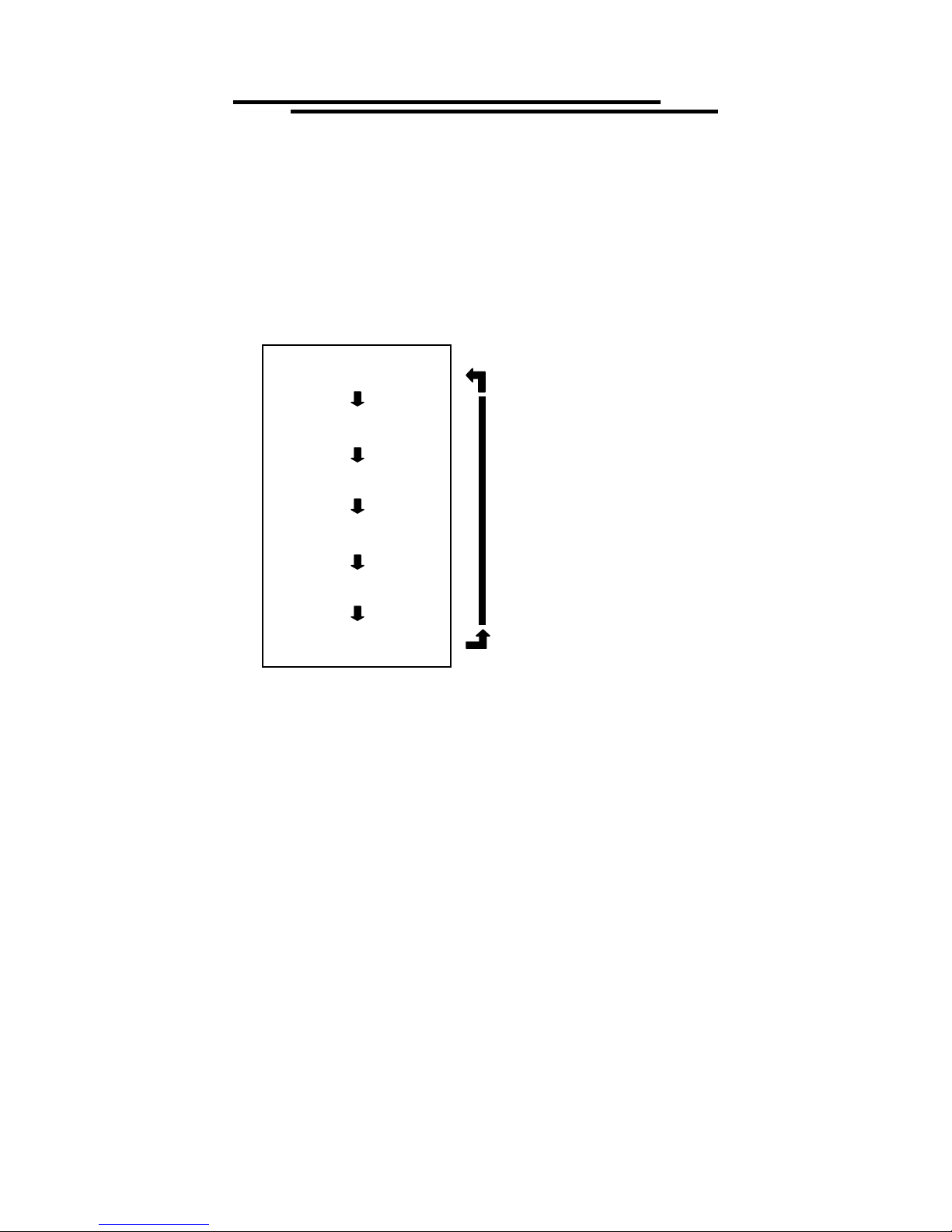

5-3. Structure of Storage Steps

The storage steps of EST are total 10 groups (group 0 ~ group 9), 16 steps (step 1 ~ step 16) for each group.

Except these steps, there is another step “COM” for special test. The presentation of storage steps is Group:

Step. The first number represents group while the second represents step.

Group 0 Group 1 Group 2 Group 3 Group 4 Group

5

Step 1 0:1 1:1 2:1 3:1 4:1 5:1 9:1

↓

Step 2 0:2 1:2 2:2 3:2 4:2 5:2 9:2

↓

Step 3 0:3 1:3 2:3 3:3 4:3 5:3 9:3

↓

Step 4 0:4 1:4 2:4 3:4 4:4 5:4 9:4

↓

Step 5

∣

Step 16

0:5

0:16

↓

↓

↓

↓

1:5

1:16

↓

↓

↓

↓

2:5

2:16

↓

↓

↓

↓

3:5

3:16

↓

↓

↓

↓

4:5

4:16

↓

↓

↓

↓

5:5

5:16

The special test step “COM” contains another two types of test: CAC and CDC. The function of CAC (CDC)

is as same as ACW (DCW), except user could adjust the output voltage during test.

After each step has been tested, the tested status will be shown on the screen:

Step 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6

Group

~

9:5

9:16

9

↓

↓

↓

↓

Test P P P P P P P P P P P P P P P P

N: Empty

P: Pass

F: Fail

Step 1: CH1

Step 2: CH2

Step 3: CH3

Step 4: CH4

Step 5: CH5

Step 6: CH6

Step 7: CH7

Step 8: CH8

Step 9: CH9

Step 0: CH10

Step 1: CH11

Step 2: CH12

Step 3: CH13

Step 4: CH15

Step 5: CH15

Step 6: CH16

18

Vitrek V4 – Electrical Safety Tester USER MANUAL

5-4. Menu Parameter Setup

z AC/DC Hipot – Voltage withstand test (ACW/DCW)

Press MENU key to enter MENU mode then use knob and arrow keys to select a step.

Press EDIT/SAVE key to enter EDIT mode. The cursor stays at the “test mode” field. Use knob to

select desired test ACW (DCW).

Functionality of FIELD key:

Measurement upper limit

Measurement lower limit

Press FIELD key to edit the next field “output voltage”. Use the knob to adjust the desired output

voltage while using the arrow keys to adjust the knob’s resolution (0.100~ 5.000 kV for ACW, 0.100~

6.000 kV for DCW).

Press FIELD key again to enter the next field “measurement upper limit”. Use the knob to adjust the

desired upper limit of leakage current while using the arrow keys to adjust the knob’s resolution

(0.10~15mA for ACW, 0.10~7.5mA for DCW).

Press FIELD key again to enter the next field “measurement lower limit”. Use the knob to adjust the

desired lower limit of leakage current while using the arrow keys to adjust the knob’s resolution

(0.10~15mA for ACW, 0.10~7.5mA for DCW).

Press FIELD key again to enter the next field “ramping time”. Use the knob to adjust the desired

ramping time while using the arrow keys to adjust the knob’s resolution (0~999.9s).

Press FIELD key again to enter the next field “testing time”. Use the knob to adjust the desired testing

time while using the arrow keys to adjust the knob’s resolution (0~999.9s).

Press FIELD key again to return to the first field “test mode” again.

Press EDIT/SAVE key to save all the parameters.

z Continuous AC/DC withstanding voltage test (CAC/CDC)

The CAC/CDC test is available only on “COM”. Like the traditional hipot tester, you can use the knob

and arrow keys to adjust output voltage during the test.

All the parameters of CAC/CDC are the same as ACW/DCW, except the testing time. The testing of

CAC/CDC is not limited.

Test mode

ACW (DCW)

Output voltage

V=X.XXXkV

Imax=XX.XxmA

Imin=XX.XxmA

Ramping time

RAMP=X.XXXs

Testing time

TEST=X.XXXs

19

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Loading...

Loading...