ViTREK

951 to 957i, and 959i

OPERATING & MAINTENANCE MANUAL

95x Series Operating Manual - June 27, 2016

About this Manual ......................................................................................................................................................... 9

Warranty Information ................................................................................................................................................. 10

SECTION 1 – PRODUCT INFORMATION........................................................................................................................ 11

Features ................................................................................................................................................................... 11

Available Models and Options ................................................................................................................................. 12

Interfacing Option................................................................................................................................................ 12

DC Voltage Options .............................................................................................................................................. 12

Internal AC Voltage Options ................................................................................................................................ 12

Internal GROUND BOND Option .......................................................................................................................... 13

External AC Voltage Option ................................................................................................................................. 13

Pulse Testing Option ............................................................................................................................................ 13

DUT Isolation Option ........................................................................................................................................... 13

Terminal Option ................................................................................................................................................... 13

Power Input Option ............................................................................................................................................. 13

Rack Mounting Option ......................................................................................................................................... 13

Output Voltage/Current Limiting Options ........................................................................................................... 13

SECTION 2 – SAFETY..................................................................................................................................................... 15

Power and Grounding .............................................................................................................................................. 15

Terminals and Wiring ............................................................................................................................................... 15

User Activated Safety Abort .................................................................................................................................... 16

Automatic Safety Abort ........................................................................................................................................... 16

SECTION 3 –INSTALLATION .......................................................................................................................................... 18

General Specifications ............................................................................................................................................. 18

Initial Inspection ...................................................................................................................................................... 18

Cooling ..................................................................................................................................................................... 18

Mounting Position and Orientation ......................................................................................................................... 19

Installing in a 19” Rack Enclosure ............................................................................................................................ 19

Line Power ............................................................................................................................................................... 19

Connecting Option AC-30 to the 95x ....................................................................................................................... 19

SECTION 4 – GENERAL FRONT PANEL OPERATION ...................................................................................................... 21

Front Panel .............................................................................................................................................................. 21

Menu Operation and Data Entry ............................................................................................................................. 23

Base Menu State .................................................................................................................................................. 23

Navigating Menus ................................................................................................................................................ 24

Page 2 of 154

95x Series Operating Manual - June 27, 2016

Modifying Menu Entries ...................................................................................................................................... 24

Adjusting the Display Contrast ................................................................................................................................ 26

Locking and Unlocking Menus ................................................................................................................................. 26

Unlocking Menus ................................................................................................................................................. 26

Setting, Changing or Clearing a Menu Lock Password ......................................................................................... 27

Relocking Menus.................................................................................................................................................. 27

Unknown Menu Lock Password........................................................................................................................... 28

Displaying Build Information ................................................................................................................................... 28

System Configuration Settings ................................................................................................................................. 29

Returning All Configuration Settings to Factory Defaults ........................................................................................ 30

SECTION 5 – TEST SEQUENCES .................................................................................................................................... 31

Test Sequence Configuration ................................................................................................................................... 32

Creating a New Test Sequence ................................................................................................................................ 33

Editing an Existing Test Sequence............................................................................................................................ 34

Deleting an Existing Test Sequence ......................................................................................................................... 35

Selecting and Running an Existing Test Sequence ................................................................................................... 35

Displayed Measurement Results ............................................................................................................................. 36

Reviewing Test Results after Running a Test Sequence .......................................................................................... 37

Printing a Test Results Report.................................................................................................................................. 39

Configuring the Test Results Report .................................................................................................................... 39

Manually Commanding a Test Results Report ..................................................................................................... 41

Compensating for External Lead Leakage and Impedance ...................................................................................... 41

SECTION 6 – TEST STEPS .............................................................................................................................................. 42

Choosing Within the Voltage Withstand and Leakage Testing Group ..................................................................... 42

Choosing AC, DC or PULSE Testing ....................................................................................................................... 43

Choosing the Limits ............................................................................................................................................. 43

AC Voltage Withstand and Leakage Testing (ACez, ACW and ACCAP) .................................................................... 46

Actions While Running ......................................................................................................................................... 47

Configuring .......................................................................................................................................................... 47

Connecting to the DUT ........................................................................................................................................ 50

Lead Compensation ............................................................................................................................................. 52

Examples .............................................................................................................................................................. 52

Specifications ....................................................................................................................................................... 53

DC Voltage Withstand and Leakage Testing (DCez, DCW and DCIR) ....................................................................... 56

Page 3 of 154

95x Series Operating Manual - June 27, 2016

Actions While Running ......................................................................................................................................... 57

Configuring .......................................................................................................................................................... 58

Connecting to the DUT ........................................................................................................................................ 62

Lead Compensation ............................................................................................................................................. 63

Examples .............................................................................................................................................................. 64

Specifications ....................................................................................................................................................... 66

Pulsed Voltage Withstand Testing (PULSE).............................................................................................................. 70

Actions While Running ......................................................................................................................................... 71

Configuring .......................................................................................................................................................... 71

Connecting to the DUT ........................................................................................................................................ 72

Lead Compensation ............................................................................................................................................. 72

Examples .............................................................................................................................................................. 73

Specifications ....................................................................................................................................................... 73

DC Breakdown Voltage Device Testing (BRKDN) ..................................................................................................... 74

Actions while Running ......................................................................................................................................... 74

Configuring .......................................................................................................................................................... 75

Connecting to the DUT ........................................................................................................................................ 75

Lead Compensation ............................................................................................................................................. 76

Examples .............................................................................................................................................................. 76

Specifications ....................................................................................................................................................... 77

Choosing Within the Resistance Testing Group ....................................................................................................... 77

DC Low Resistance Testing (LowΩ) .......................................................................................................................... 77

Actions while Running ......................................................................................................................................... 77

Configuring .......................................................................................................................................................... 78

Connecting to the DUT ........................................................................................................................................ 78

Lead Compensation (2-Wire) ............................................................................................................................... 79

Lead Compensation (4-Wire) ............................................................................................................................... 80

Examples .............................................................................................................................................................. 80

Specifications ....................................................................................................................................................... 80

AC Ground Bond Testing (GBez and GB) .................................................................................................................. 81

Actions While Running ......................................................................................................................................... 82

Configuring .......................................................................................................................................................... 82

Connecting to the DUT ........................................................................................................................................ 83

Lead Compensation ............................................................................................................................................. 85

Page 4 of 154

95x Series Operating Manual - June 27, 2016

Examples .............................................................................................................................................................. 85

Specifications ....................................................................................................................................................... 87

Ground Leakage Testing (DCI and ACI) .................................................................................................................... 88

Actions While Running ......................................................................................................................................... 88

Configuring .......................................................................................................................................................... 88

Connecting to the DUT ........................................................................................................................................ 89

Lead Compensation ............................................................................................................................................. 89

Examples .............................................................................................................................................................. 90

Specifications ....................................................................................................................................................... 91

Switch Unit Control (SWITCH) ................................................................................................................................. 92

Actions While Running ......................................................................................................................................... 92

Configuring .......................................................................................................................................................... 92

Examples .............................................................................................................................................................. 93

Specifications ....................................................................................................................................................... 93

Test Sequence Timing Control (PAUSE and HOLD) .................................................................................................. 93

Configuring .......................................................................................................................................................... 93

Examples .............................................................................................................................................................. 94

Specifications ....................................................................................................................................................... 94

SECTION 7 – CONNECTING AND CONFIGURING INTERFACES ..................................................................................... 95

LOCAL and REMOTE Operation ............................................................................................................................... 95

Controlling External Switch Matrix Units ................................................................................................................. 95

Configuration ....................................................................................................................................................... 95

Connections ......................................................................................................................................................... 97

Controlling the 95x by the RS232 Interface ............................................................................................................. 97

Specifications ....................................................................................................................................................... 97

Configuration ....................................................................................................................................................... 97

Connections ......................................................................................................................................................... 98

Controlling the 95x by the GPIB Interface ............................................................................................................... 98

Configuration ....................................................................................................................................................... 98

Connections ......................................................................................................................................................... 99

Controlling the 95x by the Ethernet Interface ......................................................................................................... 99

Specifications ....................................................................................................................................................... 99

Configuration ....................................................................................................................................................... 99

Connections ....................................................................................................................................................... 101

Page 5 of 154

95x Series Operating Manual - June 27, 2016

Printing from the 95x using the USB Interface ...................................................................................................... 101

Specifications ..................................................................................................................................................... 101

Connecting ......................................................................................................................................................... 101

Printing .............................................................................................................................................................. 102

SECTION 8 – DIO INTERFACE...................................................................................................................................... 103

Connector and Pinout ............................................................................................................................................ 103

Configuring ............................................................................................................................................................ 104

Signal Levels ........................................................................................................................................................... 105

Signal Isolation ....................................................................................................................................................... 106

Signal Timing .......................................................................................................................................................... 107

Starting with the START signal ........................................................................................................................... 107

Aborting with the ABORT or INTERLOCK signals................................................................................................ 107

PASS, FAIL and TESTING signals at the end of a Test Sequence ........................................................................ 107

HV PRESENT and DWELL Output Signals ........................................................................................................... 107

Examples ................................................................................................................................................................ 108

SECTION 9 – PERIODIC MAINTENANCE ..................................................................................................................... 110

Cleaning and Inspection ........................................................................................................................................ 110

Cable Inspection ................................................................................................................................................ 110

Fan Filter Cleaning ............................................................................................................................................. 110

Display Filter Cleaning ....................................................................................................................................... 110

Terminal Inspection ........................................................................................................................................... 111

Self Test ................................................................................................................................................................. 111

SECTION 10 – PERFORMANCE VERIFICATION AND ADJUSTMENT ............................................................................ 112

Adjustment Calibration .......................................................................................................................................... 112

Equipment Required .......................................................................................................................................... 113

Procedure .......................................................................................................................................................... 114

Verifying Calibration .............................................................................................................................................. 116

Equipment Required .......................................................................................................................................... 117

Starting Verification ........................................................................................................................................... 117

DC Voltage Verification ...................................................................................................................................... 118

DC Current Scaling Verification .......................................................................................................................... 118

DC Current Zero Verification ............................................................................................................................. 119

AC Voltage Verification ...................................................................................................................................... 119

AC Current Zero Verification .............................................................................................................................. 119

Page 6 of 154

95x Series Operating Manual - June 27, 2016

Low Ohms Resistance Verification..................................................................................................................... 120

Ground Bond Verification .................................................................................................................................. 120

Option HSS Current Verification ........................................................................................................................ 121

SECTION 11 – PROGRAMMING VIA AN INTERFACE ................................................................................................... 123

General Command Syntax ..................................................................................................................................... 123

Field Syntax ........................................................................................................................................................ 124

Field Separator................................................................................................................................................... 125

Command Separator .......................................................................................................................................... 125

Command Terminator ....................................................................................................................................... 125

General Response Syntax ...................................................................................................................................... 125

Delays and Timeouts.............................................................................................................................................. 126

Multiple Interface Operation ................................................................................................................................. 126

Front Panel Operation While Using Interfaces ...................................................................................................... 126

GPIB Bus Commands.............................................................................................................................................. 127

Device Clear (SDC and DCL) ............................................................................................................................... 127

Interface Clear (IFC) ........................................................................................................................................... 127

Group Execute Trigger (GET) ............................................................................................................................. 127

Ethernet Sessions .................................................................................................................................................. 127

Status Registers ..................................................................................................................................................... 128

STB and SRE Registers ........................................................................................................................................ 128

OPC Register ...................................................................................................................................................... 128

ESR Register ....................................................................................................................................................... 129

ERR Register ....................................................................................................................................................... 129

Commands ............................................................................................................................................................. 130

*IDN? Response Fields ....................................................................................................................................... 134

ACez Configuration Fields .................................................................................................................................. 134

ACW Configuration Fields .................................................................................................................................. 135

DCez Configuration Fields .................................................................................................................................. 136

DCW Configuration Fields .................................................................................................................................. 137

DCIR Configuration Fields .................................................................................................................................. 138

GBez Configuration Fields .................................................................................................................................. 139

GB Configuration Fields ..................................................................................................................................... 139

LowΩ Configuration Fields ................................................................................................................................. 140

ACCAP Configuration Fields ............................................................................................................................... 141

Page 7 of 154

95x Series Operating Manual - June 27, 2016

ACI Configuration Fields .................................................................................................................................... 142

DCI Configuration Fields .................................................................................................................................... 142

PULSE Configuration Fields ................................................................................................................................ 143

BRKDN Configuration Fields .............................................................................................................................. 144

PAUSE Configuration Fields ............................................................................................................................... 144

HOLD Configuration Fields ................................................................................................................................. 145

SWITCH (948i configuration) Configuration Fields ............................................................................................ 145

SWITCH (964i configuration) Configuration Fields ............................................................................................ 145

Test Step Status Flags ........................................................................................................................................ 146

STEPRSLT? Response Fields ............................................................................................................................... 147

Programming Example........................................................................................................................................... 148

Programming Guidelines ....................................................................................................................................... 148

Migrating from Earlier Firmware Versions ................................................................................................................ 152

Page 8 of 154

95x Series Operating Manual - June 27, 2016

ABOUT THIS MAN UAL

Throughout this document the instrument is referred to as the 95x, this applies to all instruments in the 95x series

having a main firmware revision of 2.30, there may be differences if the 95x being operated has a different main

firmware version. At the end of this manual is a section detailing the differences between v2.30 and earlier

versions of the firmware (see Migrating from Earlier Firmware Versions).

Due to continuing product refinement and possible manufacturer changes to components used in this product,

ViTREK reserves the right to change any or all specifications without notice.

This manual has been created with “clickable” links. Where a reference is made to another section of the manual,

the user may click on the section name reference and the document will automatically go to that section.

The table of contents is “clickable”. The user may click on any of the entries to go to that section.

The table of contents is also made available as Bookmarks for Adobe Reader or Acrobat, allowing the user to

permanently display the table of contents alongside the document and navigate by clicking on each section as

needed.

Page 9 of 154

95x Series Operating Manual - June 27, 2016

WA RRAN TY I NFORMAT ION

This ViTREK instrument is warranted against defects in material and workmanship for a period of 1 year after the

date of purchase (extended up to a total of 3 years with registration and annual calibrations at ViTREK). ViTREK

agrees to repair or replace any assembly or component (except batteries) found to be defective, under normal use,

during the warranty period. ViTREKs obligation under this warranty is limited solely to repairing any such

instrument, which in ViTREKs sole opinion proves to be defective within the scope of the warranty, when returned

to the factory or to an authorized service center. Transportation to the factory or service center is to be prepaid by

the purchaser. Shipment should not be made without prior authorization by ViTREK.

This warranty does not apply to any products repaired or altered by persons not authorized by ViTREK or not in

accordance with instructions provided by ViTREK. If the instrument is defective as a result of misuse, improper

repair, improper shipment, or abnormal conditions or operations, repairs will be billed at cost.

ViTREK assumes no responsibility for its products being used in a hazardous or dangerous manner, either alone or

in conjunction with other equipment. Special disclaimers apply to this instrument. ViTREK assumes no liability for

secondary charges or consequential damages, and, in any event, ViTREKs liability for breach of warranty under any

contract or otherwise, shall not exceed the original purchase price of the specific instrument shipped and against

which a claim is made.

Any recommendations made by ViTREK or its representatives, for uses of its products are based on tests believed

to be reliable, but ViTREK makes no warranties of the results to be obtained. This warranty is in lieu of all other

warranties, expressed or implied and no representative or person is authorized to represent or assume for ViTREK

any liability in connection with the sale of our products other than set forth herein.

Document number MO-95x-GOM revision H, 26 June 2016.

Copyright© 2009-2015 ViTREK.

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language in any form without prior written consent from ViTREK. This document is

copyrighted and contains proprietary information, which is subject to change without notice. The product displays

and instructional text may be used or copied only in accordance with the terms of the license agreement.

In the interest of continued product development, ViTREK reserves the right to make changes in this document

and the product it describes at any time, without notice or obligation.

ViTREK

12169 Kirkham Road,

Poway, CA 92064 USA

Telephone: 858-689-2755

Fax : 858-689-2760

Web : www.vitrek.com

Email : info@vitrek.com

Page 10 of 154

95x Series Operating Manual - June 27, 2016

SECTION 1 – PRODUCT INFORMATION

FEATUR ES

The 95x is an advanced Electrical Safety Analyzer with many standard features which make it unique in this field.

Multiple Capabilities. The 95x is capable of a very wide range of safety tests and is also capable of making

specialty measurements on components – all in the same instrument.

Multiple Safety features. The 95x has many built-in safety features, such as ground current detection,

DUT safety ground disconnection detection, and more. The standard digital interface allows the user to

use safety interlocks and remote safety indicators with ease.

No regrets. With all of the features shown here, the 95x is capable of so much more than the typical

users’ present requirements, the user will not regret choosing the 95x when new more stringent

requirements come up in the future.

Wide range of voltages and currents generated. The 95x has a test voltage range from a few 10’s of volts

to several 10’s of kilovolts (for withstand testing) and a test current range from a few microamps to 10’s

of amps (for chassis ground bond testing) at DC or over a frequency range from 20 to 500Hz. The 95x is

not limited to just a few voltages, currents or frequencies, the user can specify the actual level and

frequency they desire. The 95x is not weak either – loads up to 500VA can be accommodated.

Wide range of voltages and currents measured. The 95x does not just have a wide range of generated

voltages and currents – it can measure them too. From microvolts to 10’s of kilovolts, and from 100’s of

picoamps to 100’s of milliamps are all measured by the 95x. Using its’ DSP based technology the 95x

knows the difference between breakdown currents, leakage currents and arcing currents and gives you all

of the results.

Advanced measurements. When it comes to AC measurements the 95x does not just measure the basics -

the 95x measures total, in phase and quadrature components all of the time and makes available more

advanced results such as in phase resistance, quadrature reactance, capacitance and dissipation factors.

Result Analysis. The 95x does not just measure, it analyses the measurements – after a test has been run

the minimum, maximum, average and final measurements are available, a running total of the passes and

failures for each test step are also maintained across multiple runs.

Not just “does not breakdown” but “does breakdown” too. The 95x is not only capable of testing that a

DUT does not breakdown, but it is also capable of testing that a surge suppressor type device does

breakdown at the correct voltage. Ever worried if that surge suppressor you disconnected while safety

testing was correctly reconnected, does it work, is it in specification? Not a problem for the 95x – it can

be tested after safety testing.

The 95x adapts itself to the load automatically. The 95x does not have the load restrictions so often found

(and so often hidden in the small print) in other safety analyzers – load capacitances up to a farad during

DC withstand testing, highly inductive loads when low resistance testing, and more, are automatically

accommodated by the 95x adapting itself to the actual load during each test. Measurements on DUTs like

solar panels and computer system line filters are made by the 95x with ease.

Stand alone operation. The 95x can be programmed by the user to perform up to 254 test steps in a

sequence. Each step is automatically performed by the 95x either with or without user intervention as

the user desires. Up to 100 such sequences can be defined and maintained in the instrument, no

Page 11 of 154

95x Series Operating Manual - June 27, 2016

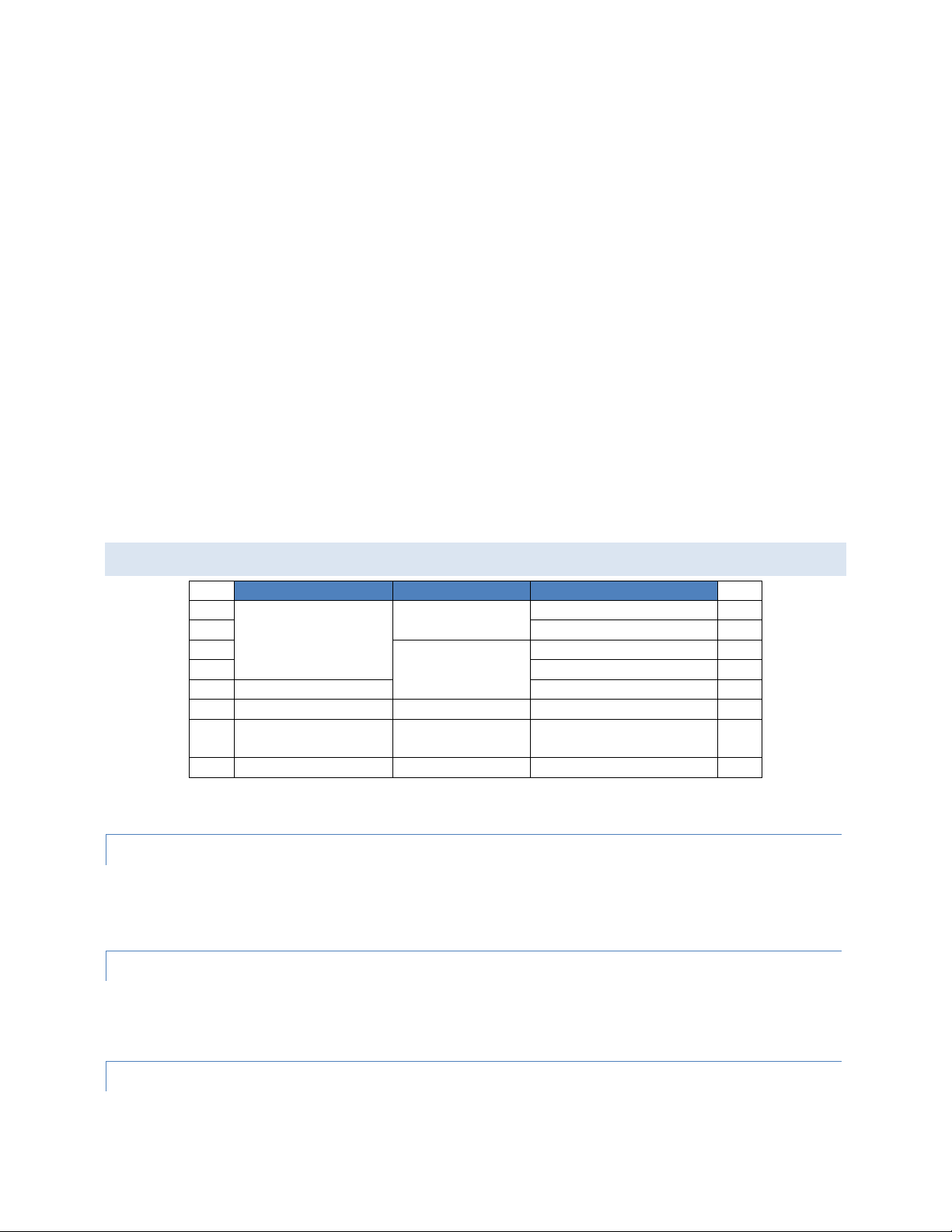

AC Voltage Testing

DC Voltage Testing

AC Low Resistance Testing

951i

20-6000V

20-6500V

No

951i

952i

0.1-40A @ 8V

952i

953i

40-11000V

No

953i

954i

0.1-40A @ 8V

954i

955i

40-10000V

No

955i

956i

No

20-6500V

No

956i

957i

20-6000V

(40-10000V Opt AC10)

75-15000V

No

(0.1-40A Opt GB40)

957i

959i

No

No

0.1-40A @ 8V

959i

computer is required. The 95x is capable of controlling switch matrix units (also available from ViTREK) –

up to 256 channels can be controlled without needing a computer or software. The 95x can even print a

test report on a printer for you when a test sequence has completed.

System operation - Wide range of interfaces available. If the user wishes to use the 95x with a computer,

then RS232, GPIB or Ethernet interfacing can be chosen as the interfacing medium between them. Giving

the user the flexibility to use the 95x in almost any computing environment. Software (QuickTest Pro) is

available from ViTREK to provide all the control needed for any system from the simple (just the 95x) to

the most complex with the 95x terminals being multiplexed between DUTs and/or points within DUTs by

up to 1024 channels in switch matrix units (also available from ViTREK).

High Speed. The 95x is capable of performing very quickly, up to 100 tests per second can be performed

with the test results being made available both during each test and after the entire sequence has been

run. The 95x is also capable of chaining similar tests without needing to reduce the applied voltage or

current to zero between test steps, this considerably speeds up testing when multiple test levels are

required.

All of the measurements, all of the time. The 95x does not just measure what the user has set limits for,

all measurement results for the specific type of test being performed are made available to the user.

Energy Efficient. The 95x uses direct line switching power supplies to provide a very energy efficient

instrument, the 95x only draws significant power from the line when needed to power the load.

AVAILABLE MODELS AND O PTIONS

In addition to the above, all models have 2- and 4-wire DC Low Resistance and Ground Leakage Testing capabilities,

a RS232 interface, a Digital I/O interface and a VICL proprietary interface.

INT ERFA C ING OPTI ON

This option may be fitted in any 95x.

Option GPIB-9 adds a GPIB interface.

The 95x has Digital I/O, RS232, Ethernet and USB Printer interfaces as standard.

DC VOLT A GE O PTIO N S

This option may be fitted in any 95x except the 959i.

Option DCNEG changes the polarity of the DC Voltage capability to negative, but limits the minimum DC output

voltage to 200V.

INT ERNA L AC VOLTA GE O PTIO NS

One or none of these options may be fitted in a 951i, 952i, 953i, 954i or 957i.

Page 12 of 154

95x Series Operating Manual - June 27, 2016

Option AC-2 changes the AC Voltage capability to 10-2000V, and has increased drive capability at all voltage output

levels.

Option 500VA (not available for the 952i or 954i) extends the AC voltage drive capability to 100mArms.

Option AC-10 (only available for the 957i) extends the AC voltage drive capability to 10KVrms (same as standard in

a 955i).

INT ERNA L GR O UND BOND OPTION

This option may be fitted in a 957i and cannot be fitted if Opt. AC-10 is fitted.

Option GB-40 adds ground bond testing capability to the 957i (same as standard in a 952i, 954i and 959i).

EXT ERNA L AC VOLT AGE OPTI O N

This option may be fitted in a 951i, 952i, 953i, 954i, 955i or 957i.

Option AC-30 extends the maximum AC Voltage capability to 30KV by means of an external unit.

PUL SE T ESTI N G OP TION

This option may be fitted in a 951i, 952i, 953i or 954i (not available with Option 500VA) or a 957i (not available

with Opt. AC-10).

Option PMT-1 adds pulsed voltage testing.

DUT ISO L ATI O N OPT ION

One of these options may be fitted in a 951i, 952i or 956i.

Option HSS adds the ability to measure AC or DC breakdown and/or leakage into a grounded DUT with down to

10nA resolution.

Option HSS-2 adds the ability to measure DC breakdown and/or leakage into a grounded DUT with down to 1nA

resolution.

TE R MINA L OPT ION

One or none of these options may be fitted in any 95x.

Option RPO-95 adds rear panel terminals in parallel with the front panel terminals.

Option RPOO-95 replaces the front panel terminals with rear panel terminals.

POW ER I NPUT OPTI ON

Any of these options may be fitted in any 95x.

Option LOLINE changes the standard 105-245Vrms line voltage range to 80-125Vrms.

Option INRUSH reduces the power-on inrush current at 230V line from over 100Apk to nominally 40Apk but limits

the line voltage range to 200-245Vrms.

RAC K MO UNTI N G OP TION

This option may be fitted in any 95x.

Option RM-1 allows for standard 19” rack mounting of the 95x.

OUT PUT V OLTA GE/CURR E NT L IMITING OPTI O NS

The user may, at the time of order, specify that the DC and/or AC Voltage generated by the 95x may be limited to a

user specified voltage less than that normally available from the specific unit model (but must be greater than

Page 13 of 154

95x Series Operating Manual - June 27, 2016

100V). Similarly, the user may specify that the Ground Bond current generated by a 952i, 954i or 959i is limited to

a user specified current between 1 and 40Arms. The remainder of this manual assumes that these optional limits

are at the maximum for the specific model.

SOF TWAR E

QT Pro II – 950. A 45 day free trial included with each unit. This software provides-

The user does not need to write software to use the 95x with a computer.

Can control testing using very complex switching systems when used with ViTREK 964 Switch Matrix units.

Easy to use fully graphical interface on a Windows based computer.

Multi-level user login, enabling the configuration of tests to be locked except for certain users.

Company wide use of test sequences using the company network.

Test sequences can be downloaded into the 95x and run without the computer.

Test results recorded on a computer or on the company network.

Computer generated multi-level test reports.

Compatibility with a wide range of Windows versions (Windows XP through Windows 8 as a Desktop

Application).

ACC ESSO RIES

TL-115-95. 115V Receptacle Hipot Test Adaptor

TL-115-GBR. 115V Receptacle Ground Bond Test Adaptor

TL-115-95GBR. 115V Receptacle Hipot and Ground Bond Test Adaptor

TL-IEC-95. IEC320 Power Socket Lead set for HiPot

TL-IEC-GBR. IEC320 Power Socket Lead set for Ground Bond

TL-IEC-95GBR. IEC320 Power Socket Lead set for HiPot and Ground Bond

TL-209. Standard HV/CONT Alligator Clip Test Lead Set (one supplied with each unit).

K-1R. 4-Wire Kelvin Low Resistance Measurement Lead Set

K-2R. 4-Wire 40A GB Test Lead Set (one supplied with each 952i, 954i, 959i, and 957i with Opt GB40).

RS-2. 6ft RS232 null-modem cable (95x to Computer).

RSS-9. Remote Start Switch.

RSF-9. Remote Start Footswitch.

HVW-9. High Voltage Warning Light.

RM-1. Rack Mount Kit for the 95x series.

DIO-IS9. DIO Isolator for the 95x series. Available in models for 3V, 5V, 12V, or 24V logic.

Page 14 of 154

95x Series Operating Manual - June 27, 2016

SECTION 2 – SAFETY

The user should be aware of these safety warnings at all times while using the 95x.

WARNING - THE 95x PRODUCES VOLTAGES AND CURRENTS WHICH MAY BE LETHAL, UNSAFE

OPERATION MAY RESULT IN SEVERE INJURY OR DEATH.

WARNING - IF THE 95x IS USED IN A MANNER NOT SPECIFIED BY VITREK, THE PROTECTION PROVIDED BY

THE EQUIPMENT MAY BE IMPAIRED AND SAFETY MAY BE COMPROMISED.

POWER AND GROUNDING

WARNING - THE 95x IS INTENDED TO BE POWERED FROM A POWER CORD HAVING A PROTECTIVE

GROUND WIRE WHICH MUST BE INSERTED INTO A POWER OUTLET HAVING A PROTECTIVE GROUND

TERMINAL. IF THE 95x IS NOT POWERED FROM A SUITABLE POWER SOURCE THEN THE CHASSIS

GROUND TERMINAL LOCATED NEAR THE POWER ENTRY CONNECTOR ON THE REAR PANEL MUST BE

PROTECTIVE GROUNDED.

WARNING - TURNING OFF OR OTHERWISE REMOVING POWER TO THE 95x WHILE IT IS GENERATING

HIGH VOLTAGES WILL NOT ENABLE THE 95x TO DISCHARGE THE DUT AND MAY DAMAGE THE 95x. THE

DUT MAY HAVE DANGEROUS VOLTAGES PRESENT FOR LONG PERIODS OF TIME AFTER THIS OCCURS.

WARNING - DO NOT REMOVE THE POWER CORD FROM THE 95x OR FROM THE SOURCE OF POWER

WHILE IT IS OPERATING AT HIGH VOLTAGES. THIS WILL REMOVE THE PROTECTIVE GROUND FROM THE

CHASSIS OF THE 95x AND THE DUT WHICH MAY RESULT IN HAZARDOUS VOLTAGES BEING ACCESSIBLE

TO THE USER.

TERMINALS AND WIRING

WARNING - THE 95x PRODUCES VOLTAGES AND CURRENTS WHICH MAY BE LETHAL, ENSURE NO

VOLTAGE OR CURRENT IS PRESENT WHEN CONNECTING TO OR DISCONNECTING FROM THE TERMINALS

OR DUT.

The HIGH VOLTAGE OR HIGH CURRENT PRESENT warning symbol on the front panel of the 95x is illuminated

whenever an unsafe voltage is present on the HV terminal or a high current is present between the SOURCE

terminals.

WARNING - THE 95x PRODUCES VOLTAGES OF UP TO 10kVrms ON THE HV TERMINAL(S). THE USER

MUST ENSURE THAT CONNECTIONS TO THESE TERMINALS HAVE SUFFICIENT INSULATION FOR THESE

VOLTAGES. EVEN WHEN SUFFICIENT INSULATION IS PRESENT, THE USER SHOULD NOT PUT ANY PART OF

THEIR BODY IN CLOSE PROXIMITY TO THE CONNECTIONS WHILE HIGH VOLTAGES ARE PRESENT.

The insulation of the wiring to the HV terminal of the 95x must be rated for at least the highest voltage expected

during the test sequence.

The user should ensure that all personnel remain at a safe distance from the HV wiring during testing.

Page 15 of 154

95x Series Operating Manual - June 27, 2016

When using high voltages, even if there is sufficient insulation, there may be significant capacitive coupling which

can cause an unsafe current to flow to nearby objects and corona can occur even outside of the insulation. This is

made worse by sharp corners on objects or the wiring. In severe cases corona can cause interference with the

measurements of the 95x and will reduce the capabilities of the wiring insulation over time, eventually resulting in

insulation failure.

When using extremely high voltages, especially when using Opt. AC-30, there may be significant mechanical force

between the HV wiring and nearby objects. Loose wiring can move several inches, and nearby loose objects (e.g.

screws or papers) can be attracted to the high voltage wire.

All terminals of the 95x other than the HV terminal are always protected to be within a safe voltage of the 95x

chassis ground, so high voltage wire is generally unnecessary for connections to them.

Should the DUT exhibit significant breakdown or arcing while being tested, there may be very high energy HF

interference generated. Although this only lasts for a small period of time before the 95x shuts down, in severe

cases this can damage nearby equipment, such as computers. The wiring between the 95x terminals and the DUT

should be routed as far as possible away from other equipment and from all cabling connected to other

equipment.

When charging high capacitance loads to high DC voltages the capacitor may be unsafe if it or the wiring to it

exhibits breakdown while being tested. The energy in the breakdown is generated by the capacitor itself, so there

can be no limit on this energy imposed by the 95x.

WARNING - SOME 95x MODELS PRODUCES CURRENTS OF UP TO 40Arms ON THE SOURCE + AND TERMINALS. THE USER MUST ENSURE THAT CONNECTIONS TO THESE TERMINALS HAVE A SUFFICIENT

CURRENT CARRYING RATING.

The current rating of all wiring must be sufficient for at least the highest current expected from that terminal

during the test sequence.

Generally all wiring should be rated for at least 100mA, but the SOURCE+ and SOURCE- terminal wiring for a 952i,

954i or 959i performing Ground Bond testing should be rated for the highest set test current (this may be up to

40A).

USER A CTIV ATED SAFETY ABOR T

The user may depress the STOP button on the 95x front panel at any time while a test sequence is being

run to remove the voltage or current as quickly as possible and abort the test sequence.

The user can configure for a digital INTERLOCK signal to be input to the DIO Interface which will abort a

high voltage or current test step if the interlock is opened. See SECTION 8 – DIO INTERFACE.

The user can configure for a digital ABORT signal to be input to the DIO Interface which will abort any type

of test step if asserted. See

Page 16 of 154

95x Series Operating Manual - June 27, 2016

SECTION 8 – DIO INTERFACE.

There are several interface commands which can be used to abort a running test sequence. See SECTION

11 – PROGRAMMING VIA AN INTERFACE.

AUTOMA TIC SAFETY ABORT

For AC or DC voltage test steps, if the breakdown current level is set to <7mApk and the HI SAFETY setting

in the CNFG - TEST menu is enabled, the 95x will fail the test if excessive HV terminal current is detected.

This effectively reduces the drive capability of the 95x to a safer level of current (nominally 7.5mA peak)

during these test steps. See Test Sequence Configuration.

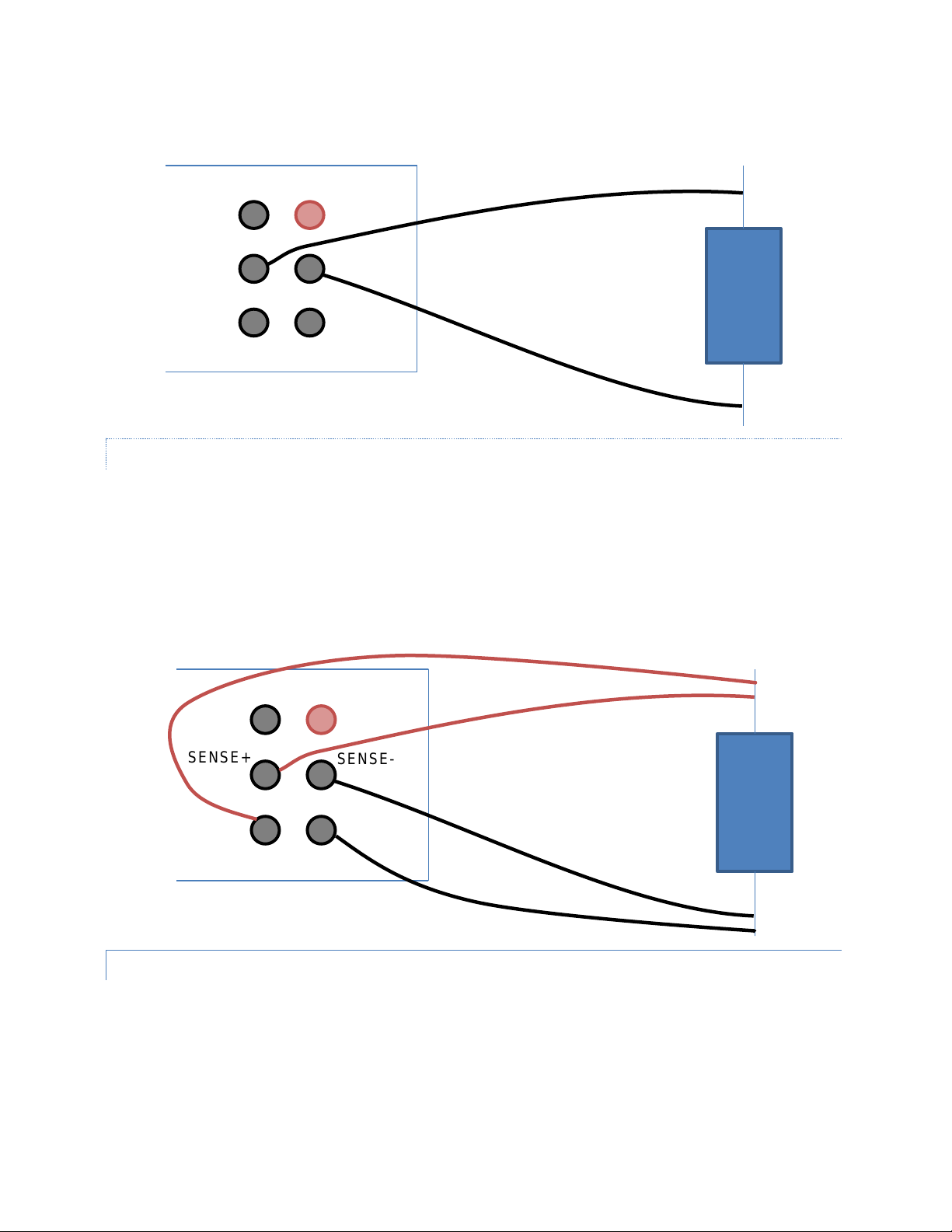

For AC or DC voltage test steps, the RETURN terminal of the 95x provides a protective ground to the DUT.

The user may wish to take precautions to ensure its’ connection to the DUT. If the CONTINUITY SENSE

setting in the CNFG - TEST menu is enabled, and the user connects a separate wire between the SENSE+

terminal of the 95x and the portion of the DUT to which the RETURN terminal wire is connected, then if

the RETURN terminal wire becomes disconnected from the DUT the test step will be immediately aborted

and the high voltage removed, preventing a potentially unsafe condition. See Test Sequence

Configuration.

If option HSS-2 is not fitted then for AC or DC voltage test steps, if the voltage present on the HV terminal

is detected as being significantly different from that expected during the execution of a test step, then the

test sequence is immediately aborted and any high voltage removed, preventing a potentially unsafe

condition. This requires no specific configuration by the user.

All processors in the 95x which participate in monitoring the output of the 95x and the condition of the

load check each other nominally every 5ms, if any mis-operation is detected which lasts more than 10ms

then the test sequence is immediately aborted and any high voltage removed, preventing a potentially

unsafe condition. This requires no specific configuration by the user.

All processors in the 95x have an associated hardware “watchdog” which recovers a mis-operating

processor within typically 100msec. If this occurs during a test then the test sequence is immediately

aborted and any high voltage removed, preventing a potentially unsafe condition. This requires no

specific configuration by the user.

Page 17 of 154

95x Series Operating Manual - June 27, 2016

SECTION 3 –INSTALLATION

GENERAL SP ECIF ICATIONS

Nominal Dimensions 89mmH x 432mmW x 457mmD (3.5” x 17” x 18”)

Nominal Weight 951i,953i,957i,959i : 9kg (18lb) net, 12kg (25lb) shipping

956i : 5kg (11lb) net, 8kg (18lb) shipping

951i,953i Opt. 500VA : 13kg (27lb) net, 16kg (35lb) shipping

952i, 954i, 955i : 13kg (27lb) net, 16kg (35lb) shipping

957i Opt AC10 or GB40 : 13kg (27lb) net, 16kg (35lb) shipping

Opt. AC-30 : additional 17kg (36lb) net, 21kg (46lb) shipping

Storage Environment -20 to 75C (non-condensing)

Operating Environment 0 to 50C, <85% RH (non-condensing), Pollution Degree 2

Operating Altitude 0 to 7000ft ASL (10000ft with reduced output drive capability)

Line Power Installation Category II

Standard: 105-265Vrms (45 to 450Hz) or 160-300Vdc, having at least 500VA (750VA for

Opt. 500VA) capability

Opt. LOLINE: 85 to 130Vrms (45 to 450Hz)

Opt. INRUSH : 200-265Vrms (45 to 450Hz) having at least 500VA (750VA for Opt. 500VA)

capability

Measurement Measurement Category I

THE 95x MUST NOT BE USED IN AN ENVIRONMENT WHERE CONDUCTIVE POLLUTION CAN OCCUR, E.G. IN AN

OUTDOOR ENVIRONMENT.

IF FLUIDS OR OTHER CONDUCTIVE MATERIALS ARE ALLOWED TO ENTER THE UNIT ENCLOSURE, EVEN IF NOT

POWERED, THEN THE UNIT SHOULD BE IMMEDIATELY TAKEN OUT OF OPERATION AND SERVICED AS SAFETY MAY

HAVE BEEN COMPROMISED.

IF THE UNIT IS TRANSPORTED BETWEEN DIFFERING ENVIRONMENTS AND CONDENSATION IS SUSPECTED, THE

UNIT SHOULD REMAIN UNPOWERED FOR SUFFICIENT TIME FOR CONDENSATION TO HAVE DISSIPATED.

INI TIAL IN SPECTION

After the 95x has been shipped or otherwise handled in an unknown manner, the user should visually inspect the

95x for damage before attempting to operate it. Particular attention should be taken to ensure that there are no

significant dents or cracks in any outer surfaces and that all terminals are securely mounted to the unit. If any

significant dents or cracks, or any loosely mounted terminals, are noted then it is recommended that the 95x be

serviced prior to being placed into use, as safety may have been compromised.

COOLIN G

The 95x is cooled by means of a rear panel mounted fan and cooling vents in the top cover. Sufficient free air must

be allowed behind the rear panel and above the top cover to allow sufficient airflow for cooling purposes. At least

2” of well ventilated unrestricted space is recommended around the fan intake and above the vents.

The cooling fan has variable speed to save energy while the 95x is not in use or is not heavily loaded. The user may

notice that the fan activates shortly after initial application of line power. This is normal; the fan should stop or

Page 18 of 154

95x Series Operating Manual - June 27, 2016

slow to low speed within 1 minute of application of power. If the fan maintains high speed operation for a long

time then the airflow may be overly restricted, or the fan filter may be blocked, the user should take corrective

action.

The cooling fan has a removable filter. This is easily removed for cleaning or replacement without disassembling

the 95x, see SECTION 9 – PERIODIC MAINTENANCE

The 95x is fully specified for operation in ambient temperatures between 0 and 50C, however best accuracy and

full loading capability is obtained if the ambient temperature is maintained below 30C. For best results the user

may wish to operate the 95x in a conditioned environment.

MO UNTI NG P OSIT ION AND ORIE NTATION

The 95x may be installed as either a bench top instrument or installed into a standard 19” rack.

The 95x is primarily intended to be used in a horizontal, or close to horizontal position, oriented with the top cover

(with the vent holes) uppermost. There are no known issues with mounting the 95x at any angle or orientation, as

long as it is mounted in a secure and stable fashion taking into consideration its’ weight and weight distribution.

INSTALLING IN A 19 ” RA CK E NCLOSUR E

Often when installing the 95x into a rack enclosure it is desired to remove the feet from the bottom of the 95x.

This is easily achieved by simply removing the screws mounting the feet to the bottom of the unit. The user should

place the removed feet and mounting hardware into a bag for safe keeping should they be needed at a later date

for bench top usage. DO NOT INSERT THE MOUNTING HARDWARE BACK INTO THE BOTTOM OF THE 95x WITHOUT

THE FEET INSTALLED, THIS MAY DAMAGE THE UNIT.

Option RM-1 provides the rack mount ears required for mounting in a standard 19” rack enclosure.

When installing the 95x into a rack enclosure it is recommended that the unit be supported through its’ depth.

The use of a tray or angle brackets supporting the bottom edges of the unit is recommended.

LINE POWER

WARNING - THE 95x IS INTENDED TO BE POWERED FROM A POWER CORD HAVING A PROTECTIVE GROUND WIRE

WHICH MUST BE INSERTED INTO A POWER OUTLET HAVING A PROTECTIVE GROUND TERMINAL. IF THE 95x IS NOT

POWERED FROM A SUITABLE POWER SOURCE THEN THE CHASSIS GROUND TERMINAL LOCATED NEAR THE POWER

ENTRY CONNECTOR ON THE REAR PANEL MUST BE PROTECTIVE GROUNDED.

The user may connect the 95x to any source of line power within the allowable range of voltages and frequencies

(see above) without requiring any adjustment to the 95x.

The 95x line power input is fused with a 5mm x 20mm TT3.15A fuse mounted in the rear panel next to the line

power entry. If the user needs to replace this fuse it must be replaced with an exact equivalent fuse, noting the

time and current ratings. Although the 95x is fused at 3.15Arms, the unit can draw surges of up to 10Apk during

normal operation and up to 100Apk during initial application of power. The user should ensure that the power

cord is rated for at least 5Arms continuous operation.

CONNECTING OPTION AC-30 TO T HE 95X

If the 95x has option AC-30 installed, the user must connect the external transformer unit to the 95x in order to be

able to use it.

Page 19 of 154

95x Series Operating Manual - June 27, 2016

The user may use the 95x without the external transformer unit if the capabilities of option AC-30 are neither

programmed nor required.

CAUTION – ENSURE THAT ALL CONNECTIONS ARE PROPERLY MADE BETWEEN THE OPTION AC-30 EXTERNAL

TRANSFORMER UNIT AND THE 95x BEFORE ATTEMPTING TO PERFORM ANY TEST USING OPTION AC-30.

EXTREMELY HIGH VOLTAGES CAN BE PRESENT WITHOUT WARNING IF MIS-WIRED.

There are two cables from the option AC-30 external transformer unit which must be correctly connected to the

95x before attempting to perform any test using option AC-30.

A shielded coaxial cable terminated in a BNC connector. This must be connected to the BNC connector

marked EXT FB on the rear panel of the 95x. Ensure this connector is securely fastened to the rear panel

connector on the 95x, if this should become disconnected while performing a test, extremely high

voltages can exist on the output of the external transformer unit.

A power line cord type cable terminated in three separate connections –

o A spade lug. This must be securely connected to the Ground terminal located above the power

connector on the rear panel of the 95x.

o A pair of shrouded banana plugs. These must be connected to the safety banana sockets marked

EXT DRIVE on the rear panel of the 95x. There is no polarity requirement regarding these

connections.

Page 20 of 154

95x Series Operating Manual - June 27, 2016

SECTION 4 – GENERAL FRONT PANEL OPERATION

This section gives general information regarding using the front panel and its’ menus.

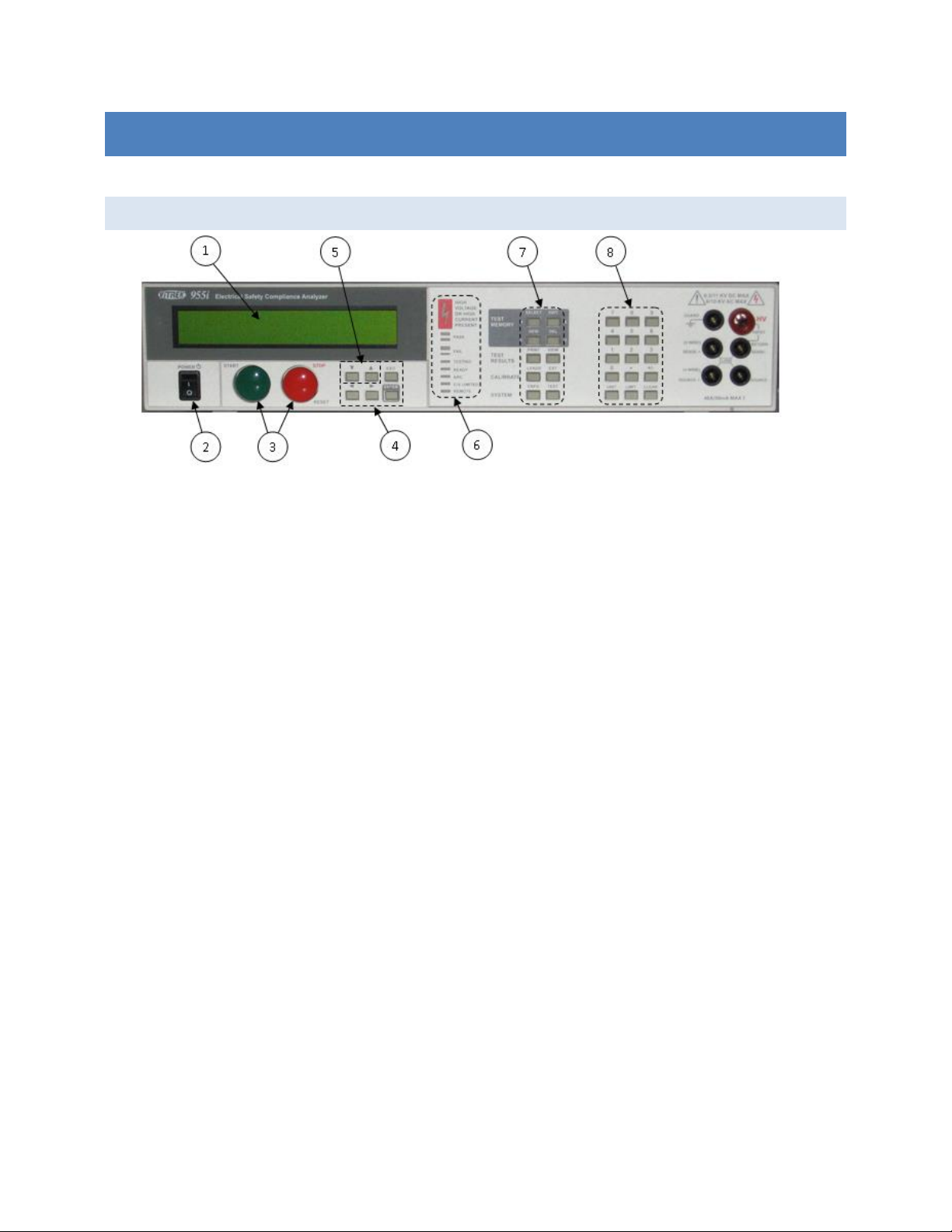

FRONT PANE L

1. The display. This shows all menus during interactive data entries, all measurements during a test, and the

present date/time when not performing any other duties.

2. The POWER switch. This turns on/off the power to the 95x.

3. The START and STOP buttons.

a. The START button allows the user to start performing a previous selected test sequence, or

(while running a test sequence) select to continue a test step when it is waiting for the user to do

so.

b. The STOP button aborts any test sequence in progress (while running a test sequence), aborts

the menu activity in progress discarding any changes made (while performing a menu), or makes

no test sequence selected (otherwise).

4. The menu selection keys. During all menus, the selected element of the menu is highlighted by flashing

between the data and blocks. These keys allow the user to move the selection point within a menu.

a. The Left and Right Arrow keys are used to move the selection point within a menu.

b. The ENTER key is used to finish entry of a menu data and automatically move to the next menu

item.

c. The EXIT key (labeled EXIT/SAVE on later units) is used to save all changes made within a menu

and return to the previous menu (if any) or to the inactive display.

5. The edit keys. These allow the user to decrement or increment a selected menu items’ value. During

numeric entry these initiate “edit” mode of data entry, rather than “direct” mode of data entry (i.e. allow

the user to adjust the existing entry using the Up/Down Arrow keys, rather than overwriting the existing

value with a new value using the numeric keys). For convenience, these keys auto-repeat if the user

maintains pressure on them.

6. The indicators.

a. HIGH VOLTAGE OR HIGH CURRENT PRESENT. This is illuminated whenever the 95x has a high

voltage (>30V) or a high current (>5A) present on its’ terminals.

Page 21 of 154

95x Series Operating Manual - June 27, 2016

b. PASS. This is illuminated whenever a test sequence is passing (while running a test sequence) or

it has passed all test steps (following completion of the test sequence).

c. FAIL. This is illuminated whenever a test sequence is failing (while running a test sequence) or

the previously run test sequence has failed any test steps (following completion of the test

sequence).

d. TESTING. This is illuminated when the 95x is running a test sequence.

e. READY. This is illuminated after the user has selected a test sequence to run and the 95x is ready

to perform that test sequence.

f. ARC. This is illuminated whenever the 95x is detecting an arc current while running a test

sequence and the specific test step is enabled to detect arc current.

g. C/V LIMITED. This is illuminated when the 95x output is either current or voltage limited by the

load while running a test sequence. This is only used in certain types of test steps.

h. REMOTE. This is illuminated when the 95x is under the control of an interface (i.e. RS232,

Ethernet or GPIB). If the user wishes to return to front panel control of the 95x the CNFG key

should be pressed to achieve this.

7. The menu keys. These initiate a menu allowing the user to perform certain activities via the front panel of

the 95x. Many of these can be disabled by the user by requiring a password in order to utilize them.

a. SELECT. Initiates a menu allowing the user to select a test sequence which has already been

defined in the 95x. This never requires a password.

b. EDIT. Initiates a menu allowing the user to select an existing test sequence and then edit it.

After editing it is automatically made ready to run. This optionally requires a password.

c. NEW. Initiates a menu allowing the user to select a presently undefined test sequence number

and name, and then to create the sequence of tests to be performed. This optionally requires a

password. While editing or creating a test sequence, this key is also used to insert a new test

step into the test sequence.

d. DEL. Initiates a menu allowing the user to select an existing test sequence and delete it from the

95x. This optionally requires a password. While editing or creating a test sequence, this key is

also used to delete a test step from the test sequence.

e. PRINT. If option UL-2 or GUL-3 is fitted and a suitable printer is attached, this key causes a

printout to be generated. This never requires a password. The printout generated is dependent

on the menu (if any) which is active when the key is pressed –

i. If pressed while no menu is active, or the configuration menu is active, a configuration

printout is generated.

ii. If pressed while selecting an existing test sequence, a test sequence printout is

generated.

iii. If pressed while reviewing the results of a completed test sequence, a test results report

printout is generated. The 95x can also be configured to automatically produce this

printout if desired.

f. VIEW. Initiates a menu allowing the user to either –

Page 22 of 154

95x Series Operating Manual - June 27, 2016

i. If no test sequence is ready to run. View the pass and fail counts for any defined test

sequence, and optionally to clear them. This never requires a password except

(optionally) to clear the counts.

ii. If a test sequence has been run and is still selected. View the test results of each step

within the previously run test sequence. This is automatically performed after a test

sequence has been run. This never requires a password.

g. LEADS. Allows the user to run the presently selected test sequence in Lead Compensation mode.

This allows the 95x to store any load offsets for each step in the test sequence and to correct all

future tests using that test sequence for these load offsets. This optionally requires a password.

h. EXT. Allows the user to perform either an adjustment or verification calibration of the 95x

against external standards. This optionally requires a password (this is separate to the other

menu activity password).

i. CNFG. Initiates a menu allowing the user to configure the 95x. This uses a series of sub-menus.

This optionally requires a password.

j. TEST. Shows the present operational status of the 95x and allows the user to perform internal

operation verification (this optionally requires a password).

8. The data entry keys.

a. The numeric keys (0 through 9), decimal point and change sign keys. These are used during

numeric or character data entry. NOTE – during hexadecimal or character data entry, certain of

the menu keys can be used for entry of the A through F characters.

b. The UNIT key. This is used to change the units during numeric data entry, and is also used while

running a test, or while reviewing test results, to change the displayed test result measurement.

c. The LIMIT key. This is used during numeric data entry to set a value to the largest possible.

When setting test dwell times this sets that the dwell should be user terminated rather than

automatically terminated after the entered time. When setting a resistance type upper limit, this

allows the user to set that there is no upper limit.

d. CLEAR key. This is used to clear an entry during numeric or character data entry.

ME NU O PERATION AND DAT A ENTRY

Most user activities using the front panel controls are performed using menus. All menus use the same general

operating methods described in this section. The user should read this section before attempting to operate the

95x.

BAS E ME N U S T ATE

When the 95x is not performing a menu and is not performing a test sequence, the display shows the model # in

the uppermost display line and the date and time in the lower most display line, this is called the base menu state

in this document. Most menus require the 95x to be in the base menu state to be initiated, an example of the

base menu state display is -

ViTREK 951i

9-Feb-10 9:08:51am

If the 95x is not in this state and the user is unsure how to return to this state, then pressing the STOP button will

accomplish this (in some circumstances the STOP button may need to be pressed more than once).

Page 23 of 154

95x Series Operating Manual - June 27, 2016

NAV IGAT ING M ENUS

The present selection point in a menu is denoted by the displayed information flashing between the

information and solid blocks.

The user can move the selection point in a menu by using the Left and/or Right Arrow keys.

o The Right Arrow key moves the selection point further down the menu. Moving the selection

point past the last selectable item in a menu selects the first selectable item in the menu (a

double beep sound is made when this occurs).

o The Left Arrow key moves the selection point further up the menu. Moving the selection point

before the first selectable item in a menu selects the last selectable item in the menu (a double

beep sound is made when this occurs).

Although the 95x display is limited to two lines, most menus have more lines than this. The display is

automatically scrolled up and down the menu to display the menu line containing the present selection

point.

Not all menus or menu lines may be available.

o Generally items which are not pertinent to the specific model or option content of the 95x are

not shown.

o All menus in the 95x utilize a “top down” priority. Selections or entries made may affect

subsequent entries in the menu. Entries may be limited in allowable values, or may not be

shown.

If a menu line is an entry into a sub-menu, then the left side of the line shows descriptive text followed by

an ellipsis character (…). The descriptive text is selectable. If the user presses the ENTER key while a sub-

menu entry line is selected then the sub-menu is opened.

o When a sub-menu is terminated by pressing the EXIT key then the user is returned to the